power steering fluid MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 31 of 1146

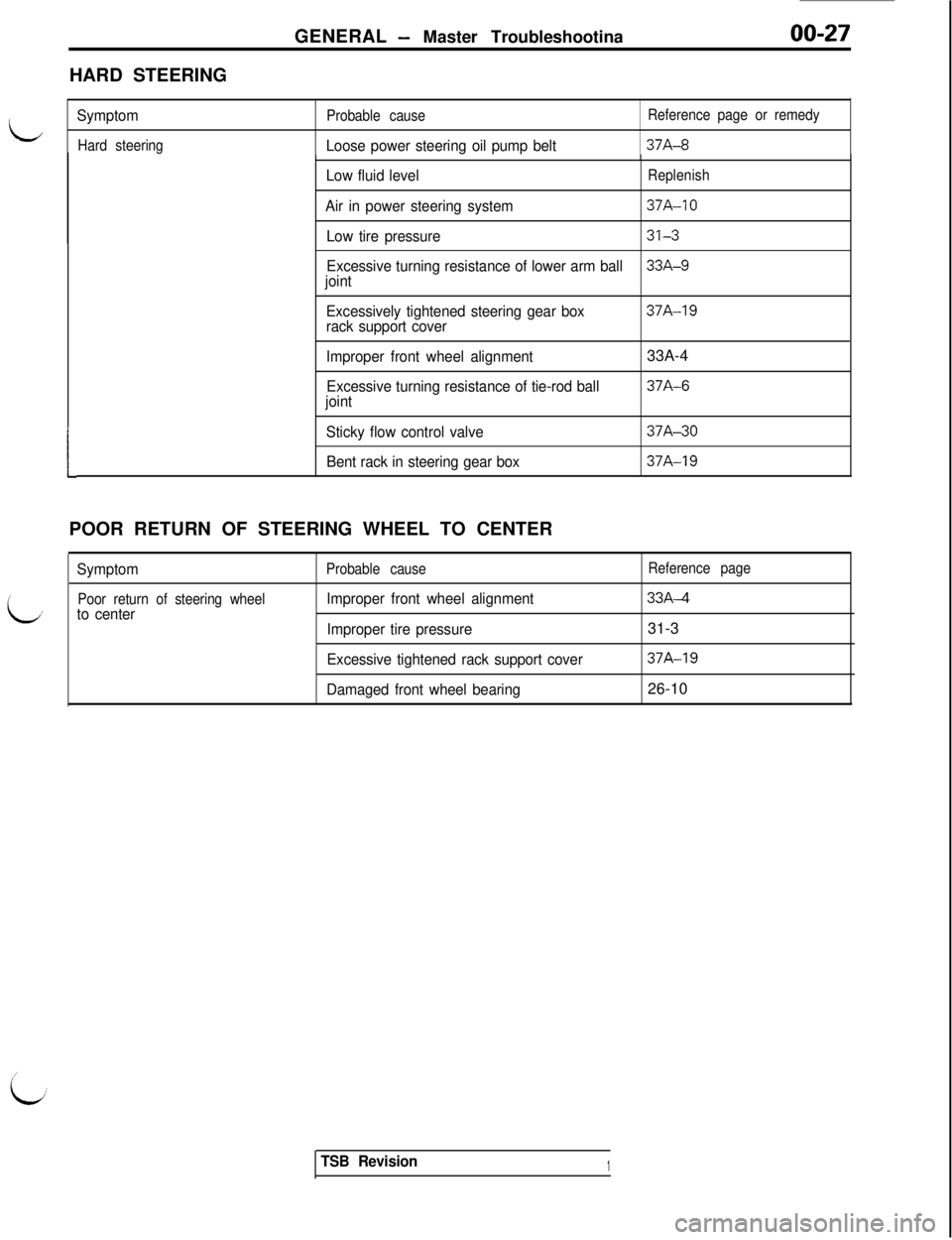

GENERAL - Master Troubleshootina00-27HARD STEERING

L

L

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Reference page or remedy37A-8

1POOR RETURN OF STEERING WHEEL TO CENTER

Symptom

Poor return of steering wheelto center

Probable cause

Improper front wheel alignment

Improper tire pressure

Excessive tightened rack support cover

Damaged front wheel bearing

Reference page33A-4

31-3

37A-1926-10

Low fluid levelReplenish

Air in power steering system37A-10

Low tire pressure

313

Excessive turning resistance of lower arm ball33A-9joint

Excessively tightened steering gear box

rack support cover

37A-19

Improper front wheel alignment

Excessive turning resistance of tie-rod ball

joint

Sticky flow control valve

Bent rack in steering gear box33A-437A-6

37A-30

37A-19

TSB Revision1

Page 76 of 1146

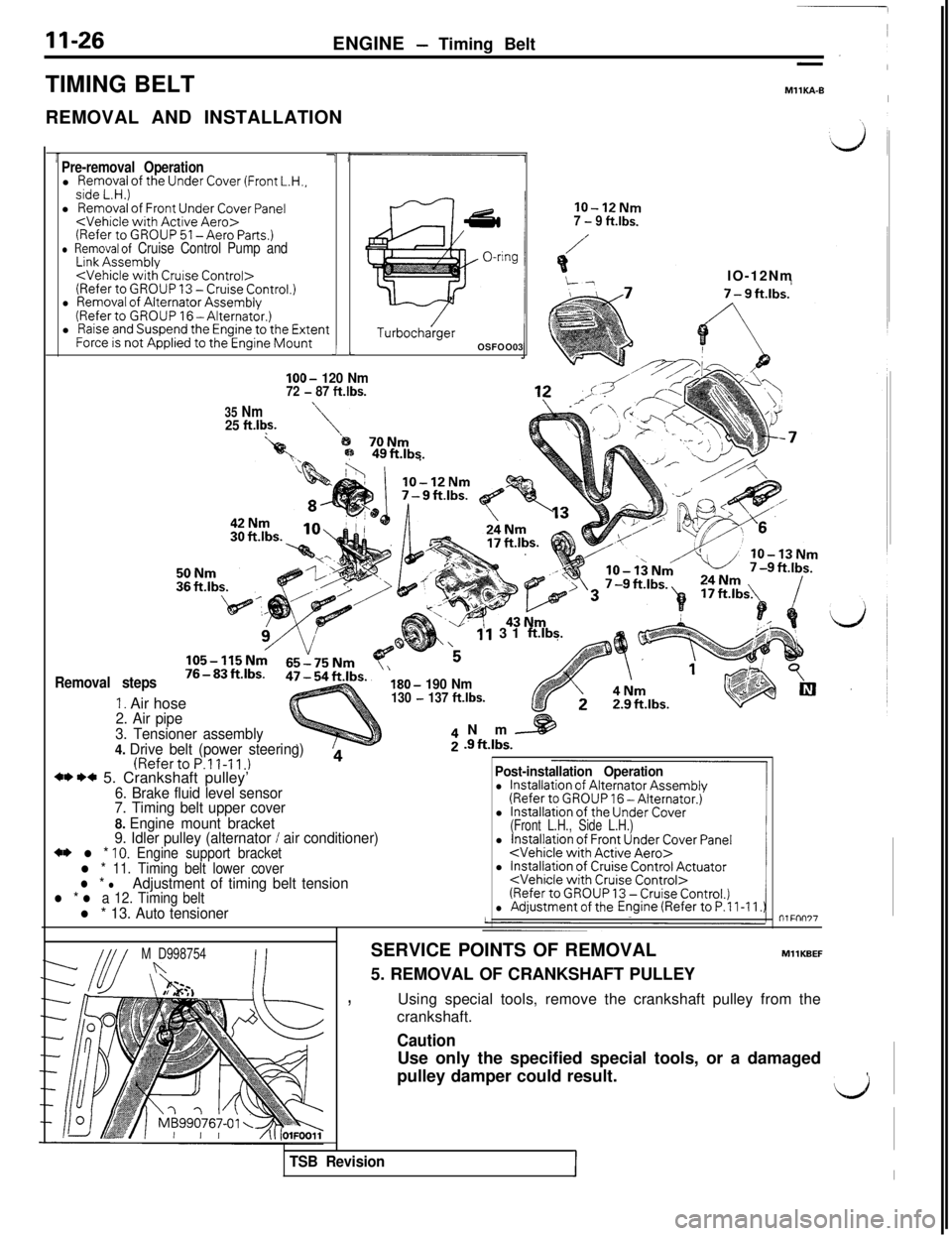

11-26ENGINE - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

MllKA-BI

Pre-removal Operationl Removal of the Under Cover (Front L.H.,side L.H.)l Removal of Front Under Cover Panel

l Raise and Suspend the Engine to the ExtentForce is not Applied to the Engine Mounti LIOO-

120 Nm72 - 87 ft.lbs.

35 Nm25 ft.l$.

TurbochargerOSFOO03

lo-12Nm7 - 9 ft.lbs.

Removal steps

1. Air hose

11 31 ftlbs.

‘5IO-12Nm

B;p 49ftJbs.

\

180- 190 Nm130 - 137 ft.lbs.

2. Air pipe

3. Tensioner assembly

4. Drive belt (power steering)

(RefertoP.ll-11.)4** I)* 5. Crankshaft pulley’6. Brake fluid level sensor

7. Timing belt upper cover

8. Engine mount bracket

9. Idler pulley (alternator

/ air conditioner)+* l * 10. Engine support bracketl * 11. Timing belt lower coverl * lAdjustment of timing belt tensionl * l a 12. Timing beltl * 13. Auto tensionerNm

[email protected].

Post-installation Operation

l Installation of Alternator Assembly(Refer to GROUP 16 -Alternator.)

l Installation of the Under Cover(Front L.H., Side L.H.)l Installation of Front Under Cover Panel

l Installation of Cruise Control Actuator

M D998754nSERVICE POINTS OF REMOVAL

5. REMOVAL OF CRANKSHAFT PULLEYMllKBEF

,Using special tools, remove the crankshaft pulley from the

crankshaft.

TSB RevisionII

CautionUse only the specified special tools, or a damaged

pulley damper could result.

,

LJ

Page 648 of 1146

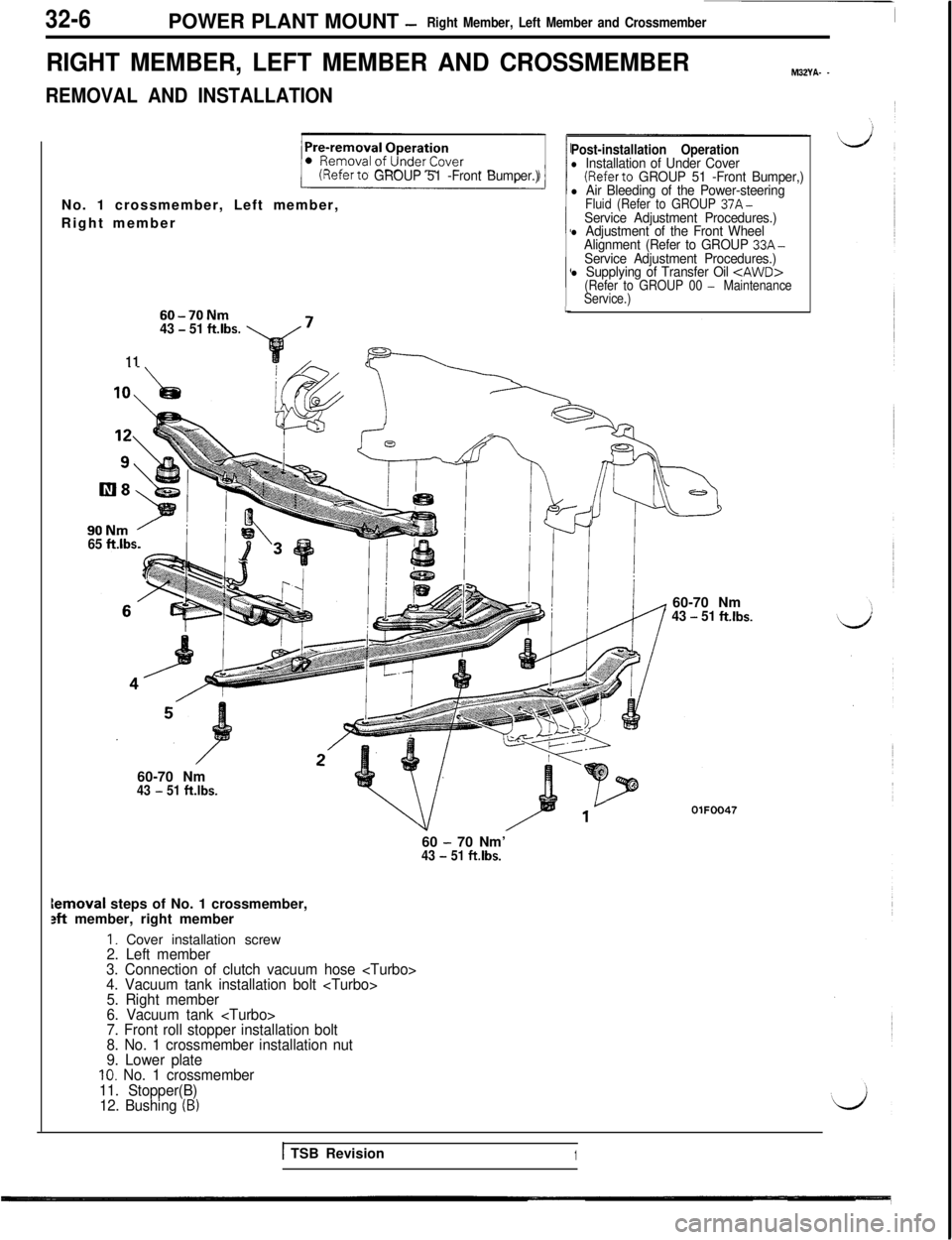

32-6POWER PLANT MOUNT -Right Member, Left Member and Crossmember

RIGHT MEMBER, LEFT MEMBER AND CROSSMEMBER

I

M32YA- _

REMOVAL AND INSTALLATION

(Referto GROUP 51 -Front Bumper.)No. 1 crossmember, Left member,

Right member

60-70Nm43 - 51 ft.lbs.

11

F=----lL90Nm

’65 ft.lbs.

/I

Post-installation Operationl Installation of Under Cover(Referto GROUP 51 -Front Bumper,)l Air Bleeding of the Power-steeringFluid (Refer to GROUP 37A-Service Adjustment Procedures.)l Adjustment of the Front Wheel

Alignment (Refer to GROUP 33A-Service Adjustment Procedures.)l Supplying of Transfer Oil

Service.)60-70 Nm

43 - 51 ft.lbs.60-70 Nm

43 - 51 ftlbs.

/aa lVOiFOO4760

- 70 Nm’43 - 51 ft.lbs.lemoval steps of No. 1 crossmember,

M member, right member

I. Cover installation screw2. Left member

3. Connection of clutch vacuum hose

4. Vacuum tank installation bolt

5. Right member

6. Vacuum tank

7. Front roll stopper installation bolt

8. No. 1 crossmember installation nut

9. Lower plate

10. No. 1 crossmember

11. Stopper(B)

12. Bushing

(B)

1 TSB Revision1

Page 829 of 1146

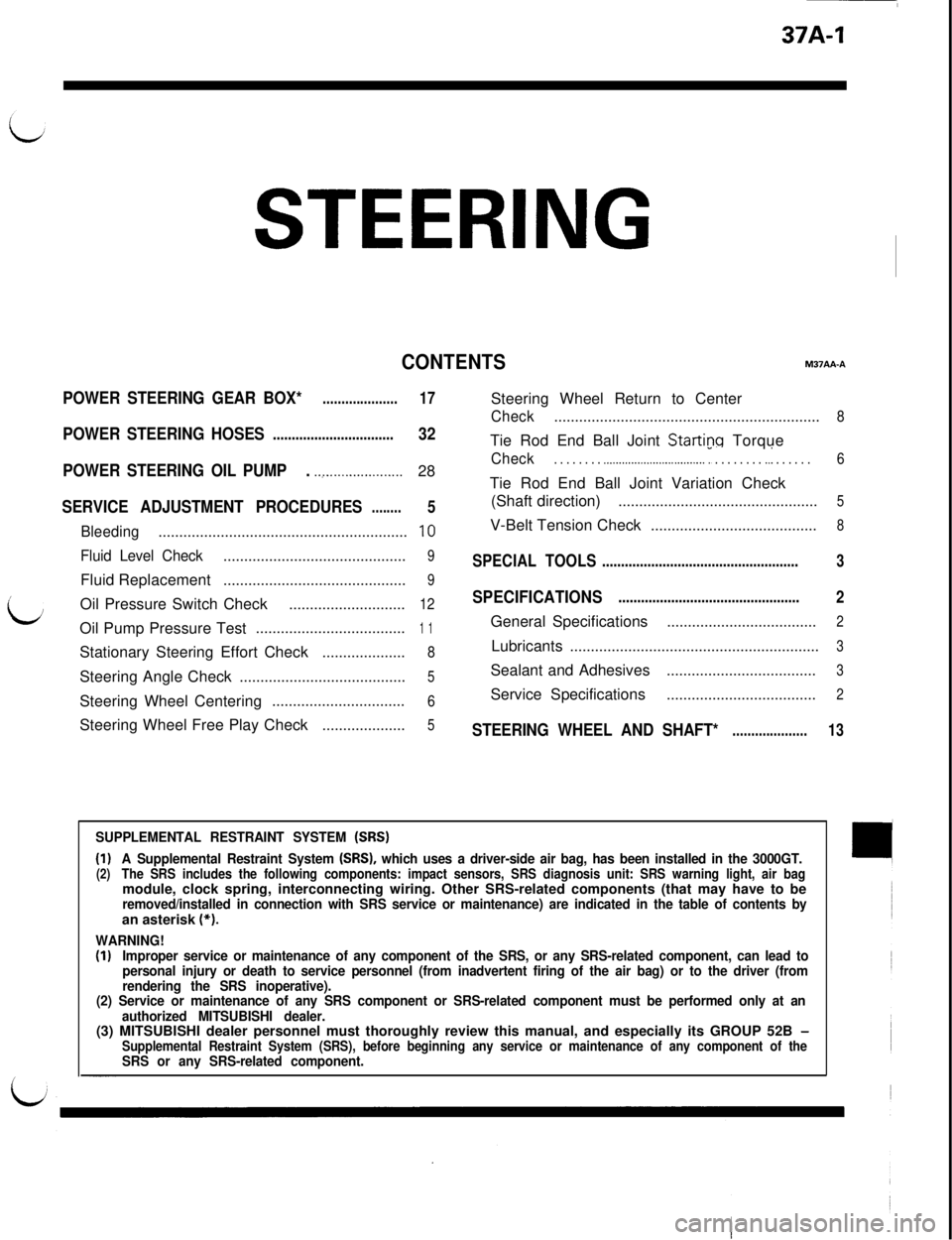

37A-1

STEERING

CONTENTSM37AA-A

POWER STEERING GEAR BOX*....................17Steering Wheel Return to Center

Check................................................................8

POWER STEERING HOSES................................32Tie Rod End Ball Joint Startinq Torque

POWER STEERING OIL PUMP. .._....................28Check. . . . . . . . .._.............................. r . . . . . . . . ..I . . . . . .6Tie Rod End Ball Joint Variation Check

SERVICE ADJUSTMENT PROCEDURES5(Shaft direction)................................................5........

Bleeding............................................................10V-Belt Tension Check........................................8

Fluid Level Check............................................9SPECIAL TOOLS....................................................3Fluid Replacement

............................................9

/

bOil Pressure Switch Check

SPECIFICATIONS2............................12................................................Oil Pump Pressure Test

....................................1 1General Specifications....................................2Stationary Steering Effort Check

....................8Lubricants............................................................3Steering Angle Check

5Sealant and Adhesives....................................3........................................Steering Wheel Centering

6Service Specifications....................................2................................Steering Wheel Free Play Check

....................5STEERING WHEEL AND SHAFT*....................13

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 831 of 1146

STEERING -Specifications / Special Tools37A-3

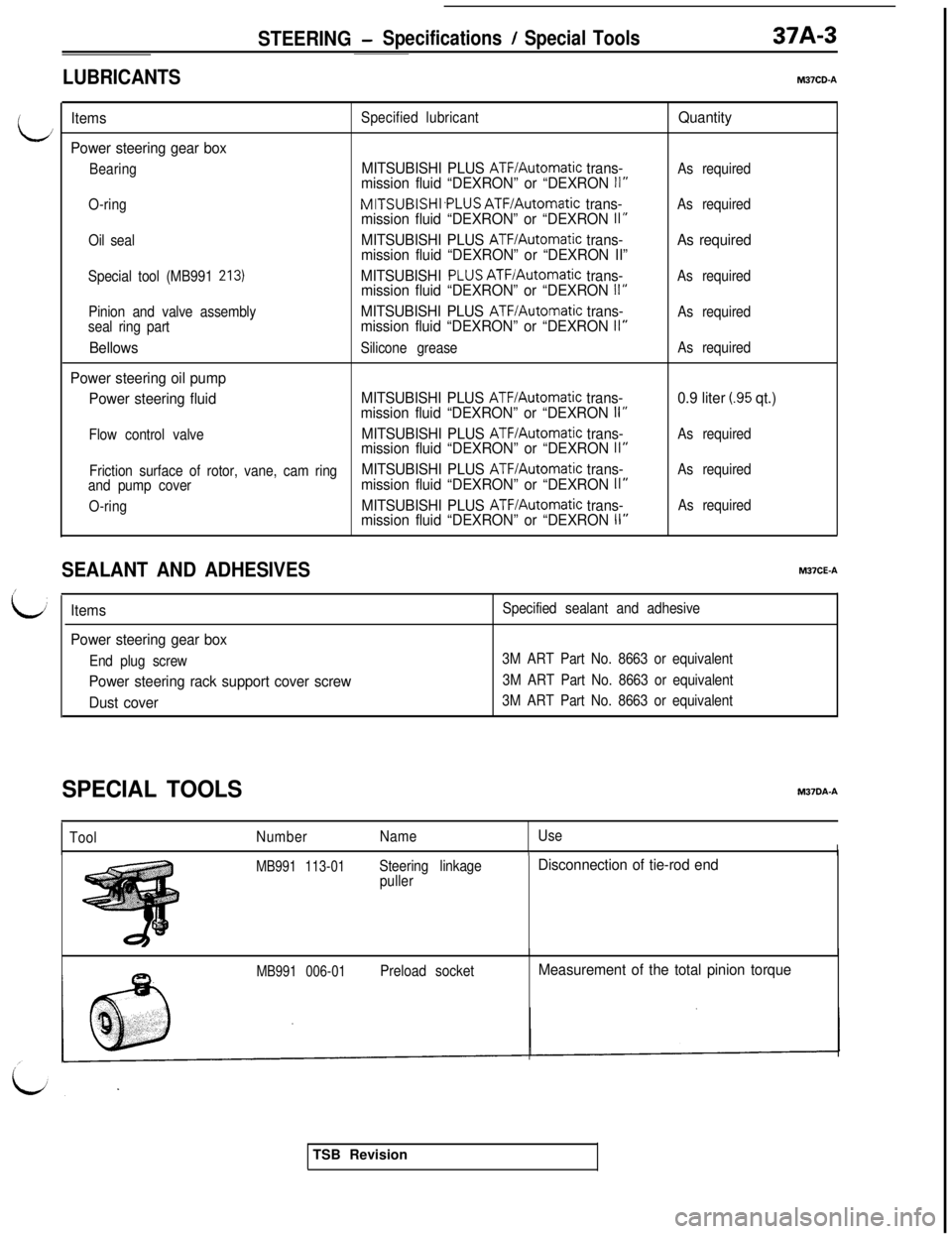

LUBRICANTSM37CD-A

L

/

b

ItemsSpecified lubricantQuantity

Power steering gear box

BearingMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

O-ringMlTSUBlSHl.PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Oil sealMITSUBISHI PLUS ATF/Automatic trans-As required

mission fluid “DEXRON” or “DEXRON II”

Special tool (MB991 213)MITSUBISHI PLUSATFIAutomatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Pinion and valve assemblyMITSUBISHI PLUS ATF/Automatic trans-As required

seal ring partmission fluid “DEXRON” or “DEXRON II”

BellowsSilicone greaseAs required

Power steering oil pump

Power steering fluidMITSUBISHI PLUS

ATF/Automatic trans-0.9 liter (.95 qt.)

mission fluid “DEXRON” or “DEXRON II”

Flow control valveMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Friction surface of rotor, vane, cam ringMITSUBISHI PLUS ATF/Automatic trans-As required

and pump covermission fluid “DEXRON” or “DEXRON II”

O-ringMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

SEALANT AND ADHESIVESM37CE-A

Items

Power steering gear box

End plug screw

Power steering rack support cover screw

Dust cover

Specified sealant and adhesive

3M ART Part No. 8663 or equivalent

3M ART Part No. 8663 or equivalent

3M ART Part No. 8663 or equivalent

SPECIAL TOOLSM37DA.A

ToolNumberNameUseII

MB991 113-01Steering linkage

pullerDisconnection of tie-rod end

MB991 006-01Preload socketMeasurement of the total pinion torqueTSB Revision

Page 845 of 1146

STEERING- Power Steering Gear Box

POWER STEERING GEAR BOX

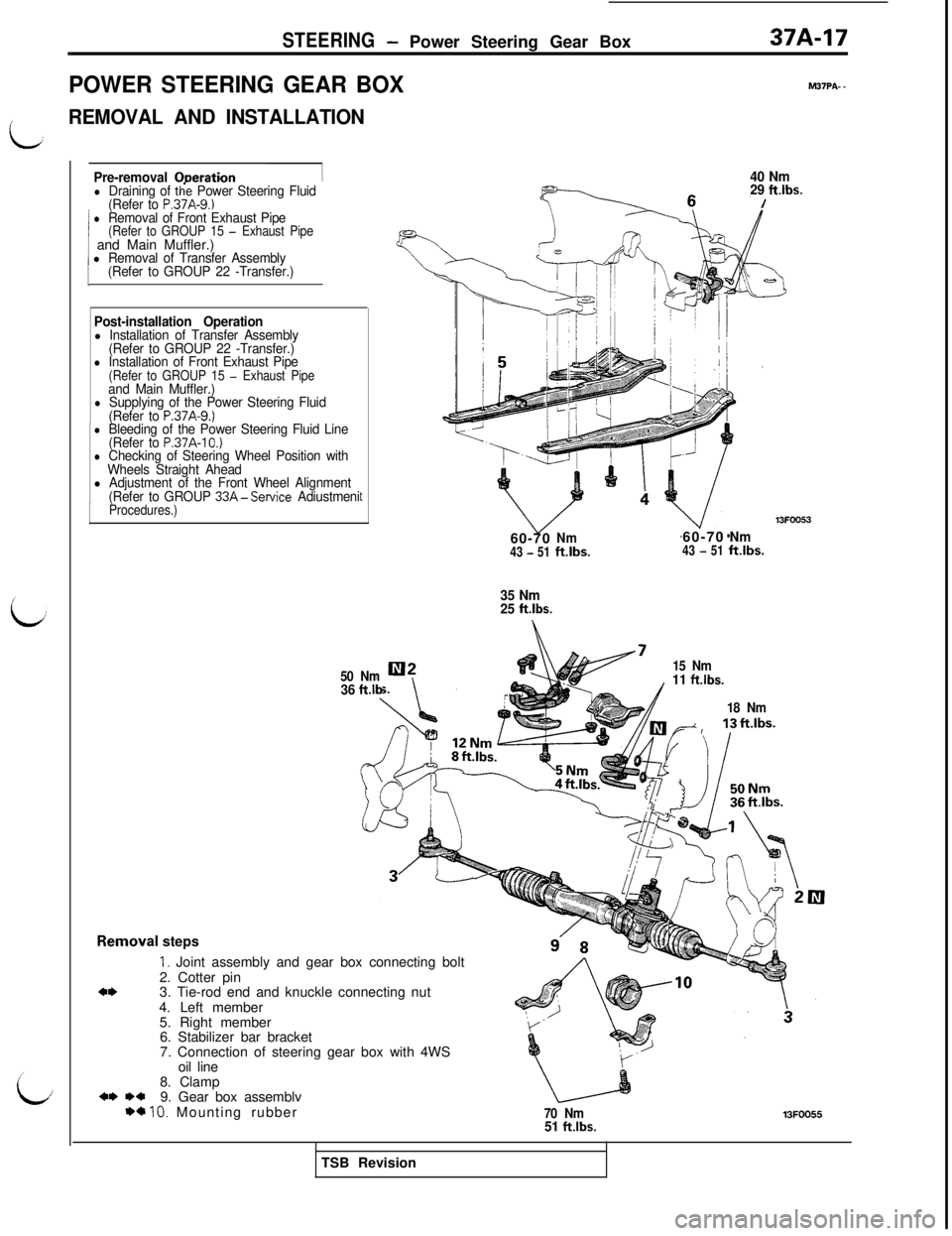

/REMOVAL AND INSTALLATION37A-17

M37PA- -

i

i/

Pre-removal ODerationl Draining of the Power Steering Fluid

(Refer to P.37A-9.)l Removal of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipe1 and Main Muffler.)1l Removal of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

Post-installation Operationl Installation of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

l Installation of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipeand Main Muffler.)l Supplying of the Power Steering Fluid

(Refer to P.37A-9.)l Bleeding of the Power Steering Fluid Line

(Refer to P.37A-IO.)l Checking of Steering Wheel Position with

Wheels Straight Ahead

l Adjustment of the Front Wheel Alignment

(Refer to GROUP 33A-Service AdiustmeniProcedures.)Removt

50 Nm

c40 Nm

29 ftlbs.

/60-70

Nm43 - 51ft.lbs.60-70Nm43 - 51ft.lbs.

36

ft.lb

35 Nm

25 ft.lbs.

15 Nm

11 ftlbs.

18 Nm

lal steps

1. Joint assembly and gear box connecting bolt

2. Cotter pin

3. Tie-rod end and knuckle connecting nut

4. Left member

5. Right member

6. Stabilizer bar bracket

7. Connection of steering gear box with 4WS

oil line

8. Clamp

9. Gear box assemblv

*a 10. Mounting rubber70 Nm51 ftlbs.13FOOE.5TSB Revision

Page 848 of 1146

37A-20

STEERING - Power Steering Gear Box

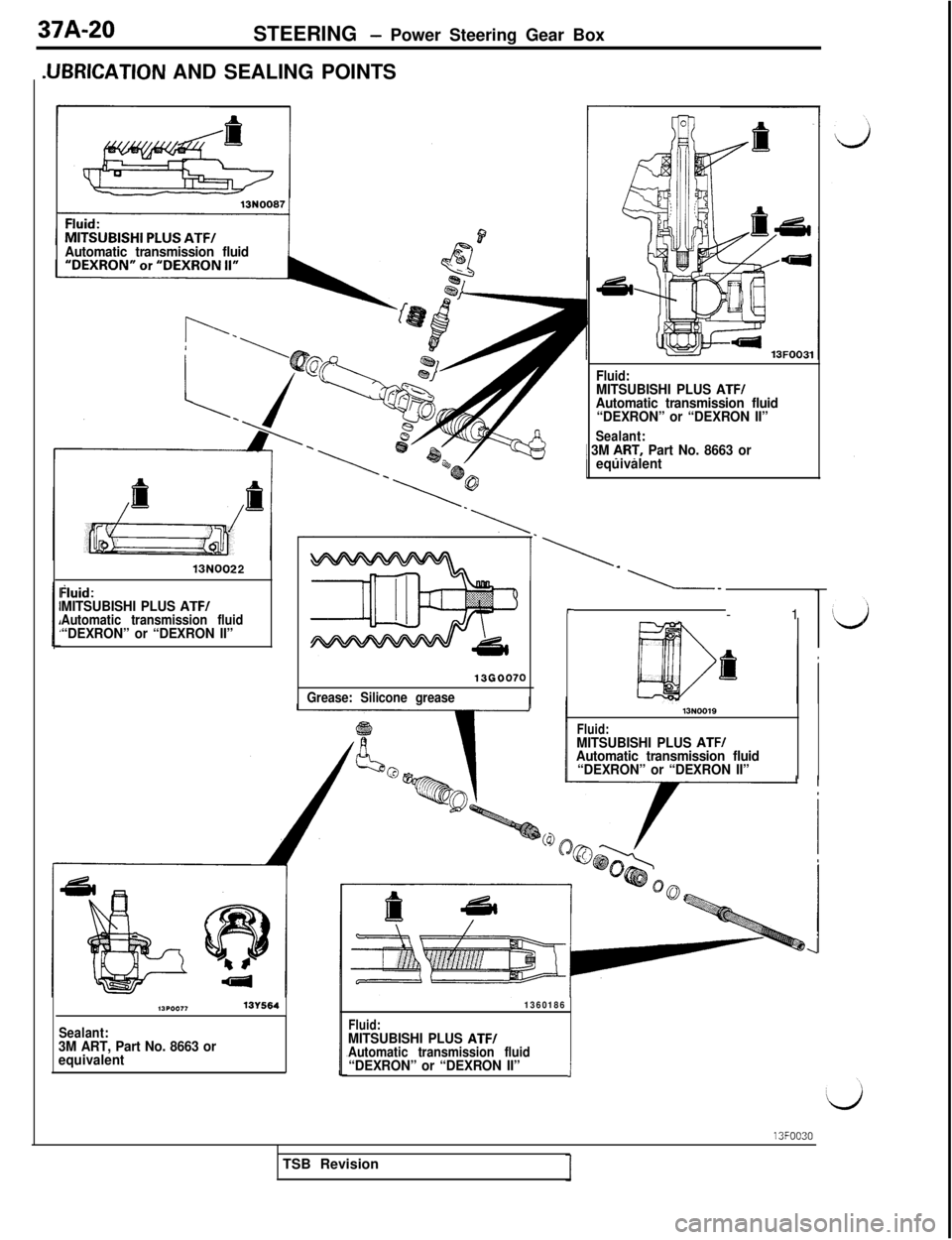

.UBRICATION AND SEALING POINTS

Automatic transmission fluid

13N0022

hid:MITSUBISHI PLUS ATF/Automatic transmission fluid“DEXRON” or “DEXRON II”

13G0070

Grease: Silicone greaseFluid:

MITSUBISHI PLUS ATF/Automatic transmission fluid

“DEXRON” or “DEXRON II”

Sealant:1 3M ART, Part No. 8663 or

equivalent.

L--1

I-

13N0019

Fluid:MITSUBISHI PLUS ATF/Automatic transmission fluid

“DEXRON” or “DEXRON II”

l.?POO,,13Y564

Sealant:3M ART, Part No. 8663 or

equivalent

1360186

Fluid:MITSUBISHI PLUS ATF/

Automatic transmission fluid

“DEXRON” or “DEXRON II”i13FOO30

TSB Revision

Page 852 of 1146

37A-24

STEERING - Power Steering Gear Box

/Oil seal

Back-up washer13A0181L

GuideNeedle roller

bearmg13R0547

MB990927-01

&

13R0378

Vent hole

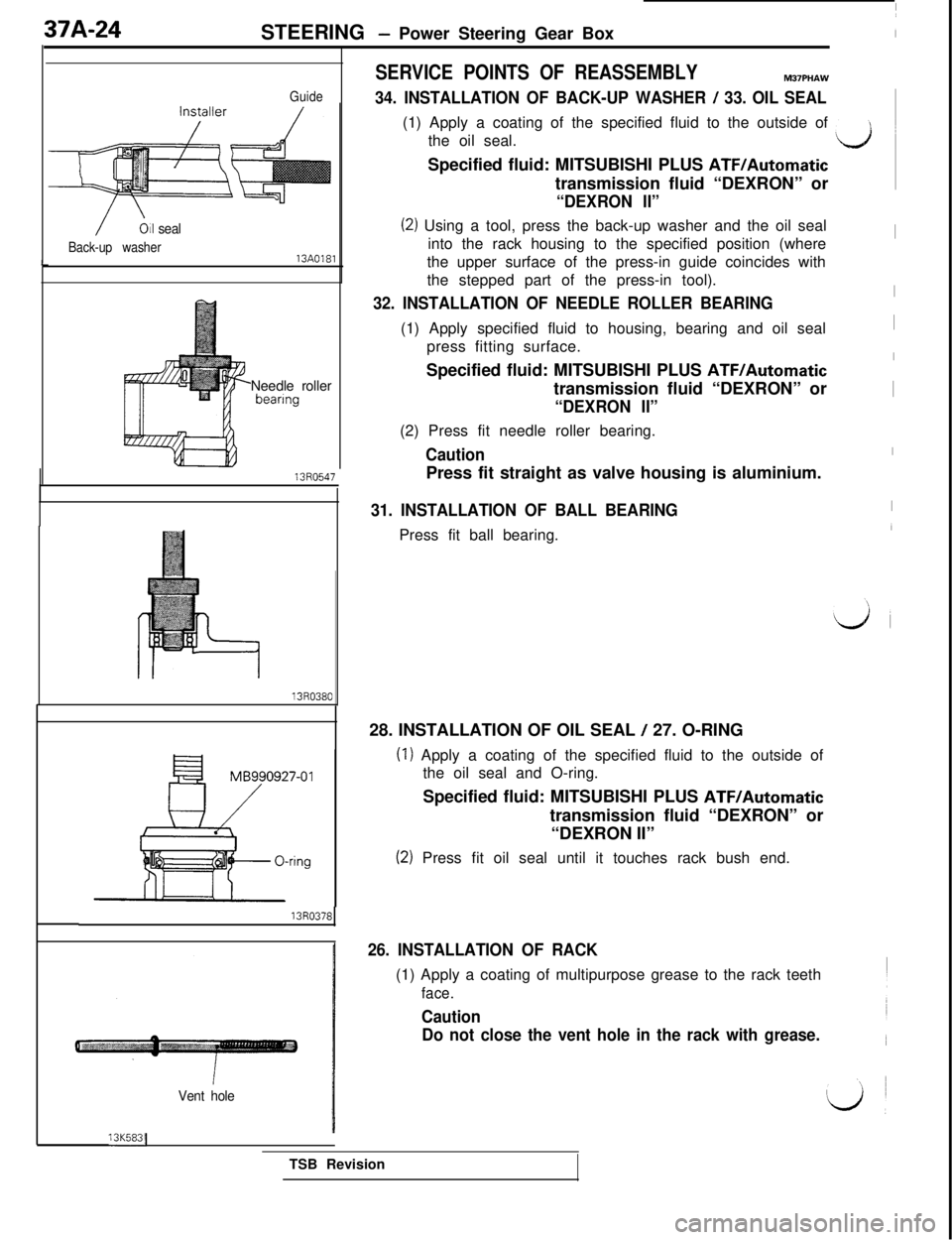

SERVICE POINTS OF REASSEMBLYM37PHAW

34. INSTALLATION OF BACK-UP WASHER / 33. OIL SEAL(1) Apply a coating of the specified fluid to the outside of

the oil seal.

LJSpecified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

(2) Using a tool, press the back-up washer and the oil seal

into the rack housing to the specified position (whereIthe upper surface of the press-in guide coincides with

the stepped part of the press-in tool).

32. INSTALLATION OF NEEDLE ROLLER BEARINGI(1) Apply specified fluid to housing, bearing and oil seal

Ipress fitting surface.

ISpecified fluid: MITSUBISHI PLUS ATF/Automatictransmission fluid “DEXRON” or

I“DEXRON II”(2) Press fit needle roller bearing.

CautionIPress fit straight as valve housing is aluminium.

31. INSTALLATION OF BALL BEARINGPress fit ball bearing.

28. INSTALLATION OF OIL SEAL

/ 27. O-RING

(1) Apply a coating of the specified fluid to the outside of

the oil seal and O-ring.

Specified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

(2) Press fit oil seal until it touches rack bush end.

26. INSTALLATION OF RACK(1) Apply a coating of multipurpose grease to the rack teeth

face.

Caution

Do not close the vent hole in the rack with grease.13K583(

TSB Revision

Page 853 of 1146

STEERING - Power Steering Gear Box37A-25

Back-up washer1360147

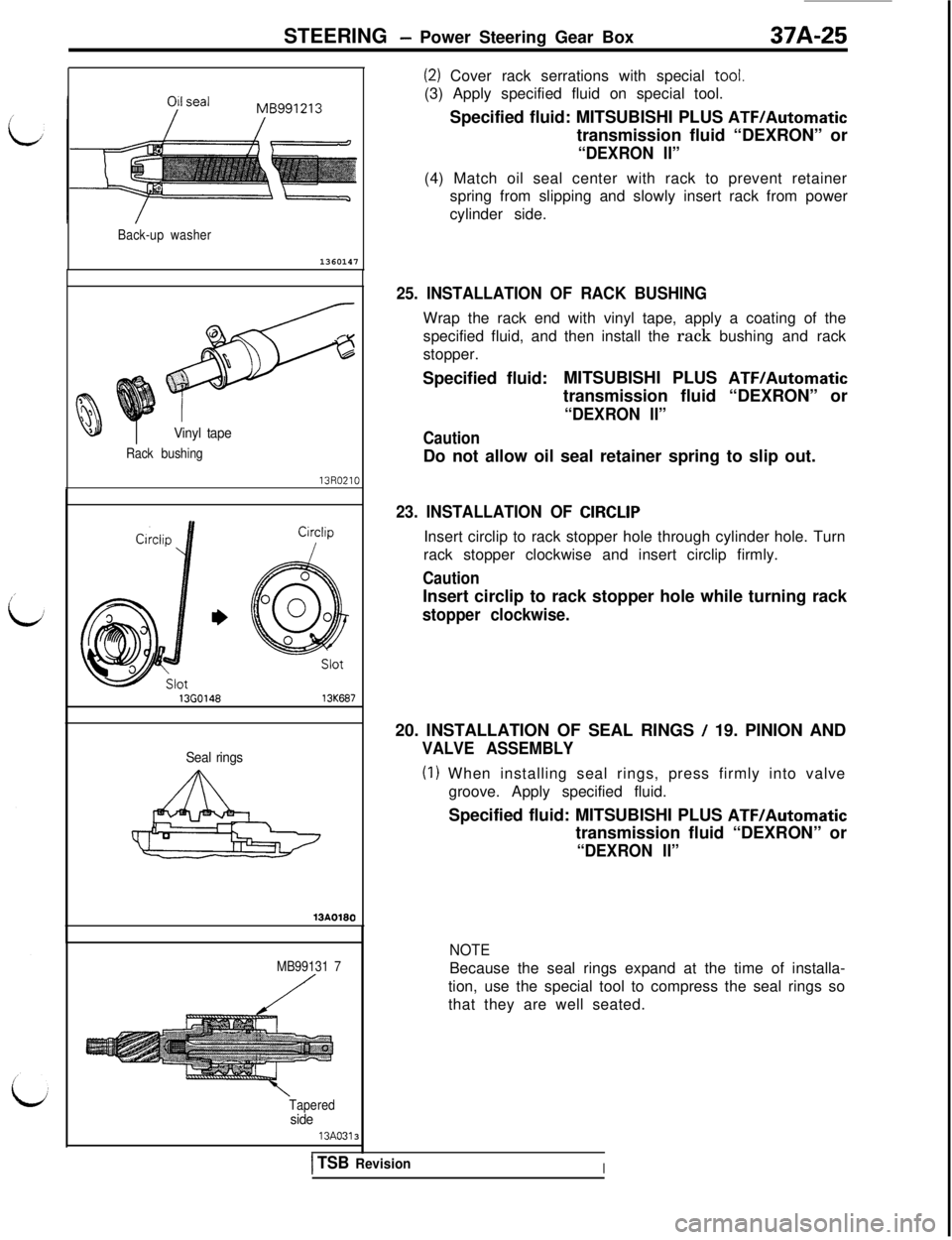

(2) Cover rack serrations with special tool.

(3) Apply specified fluid on special tool.

Specified fluid: MITSUBISHI PLUS

ATFIAutomatictransmission fluid “DEXRON” or

“DEXRON II”(4) Match oil seal center with rack to prevent retainer

spring from slipping and slowly insert rack from power

cylinder side.

Vinyl tape

Rack bushing

136014613K687

Seal rings

MB99131 7

Tapered

side13A0313

25. INSTALLATION OF RACK BUSHINGWrap the rack end with vinyl tape, apply a coating of the

specified fluid, and then install the rack bushing and rack

stopper.

Specified fluid:MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

CautionDo not allow oil seal retainer spring to slip out.

23. INSTALLATION OF CIRCLIPInsert circlip to rack stopper hole through cylinder hole. Turn

rack stopper clockwise and insert circlip firmly.

CautionInsert circlip to rack stopper hole while turning rack

stopper clockwise.20. INSTALLATION OF SEAL RINGS

/ 19. PINION AND

VALVE ASSEMBLY

(I) When installing seal rings, press firmly into valve

groove. Apply specified fluid.

Specified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

NOTEBecause the seal rings expand at the time of installa-

tion, use the special tool to compress the seal rings so

that they are well seated.

ITSB RevisionI

Page 856 of 1146

37A-28

STEERING - Power Steering Oil Pump

POWER STEERING OIL PUMP

REMOVAL AND INSTALLATION

I

M37RA-.

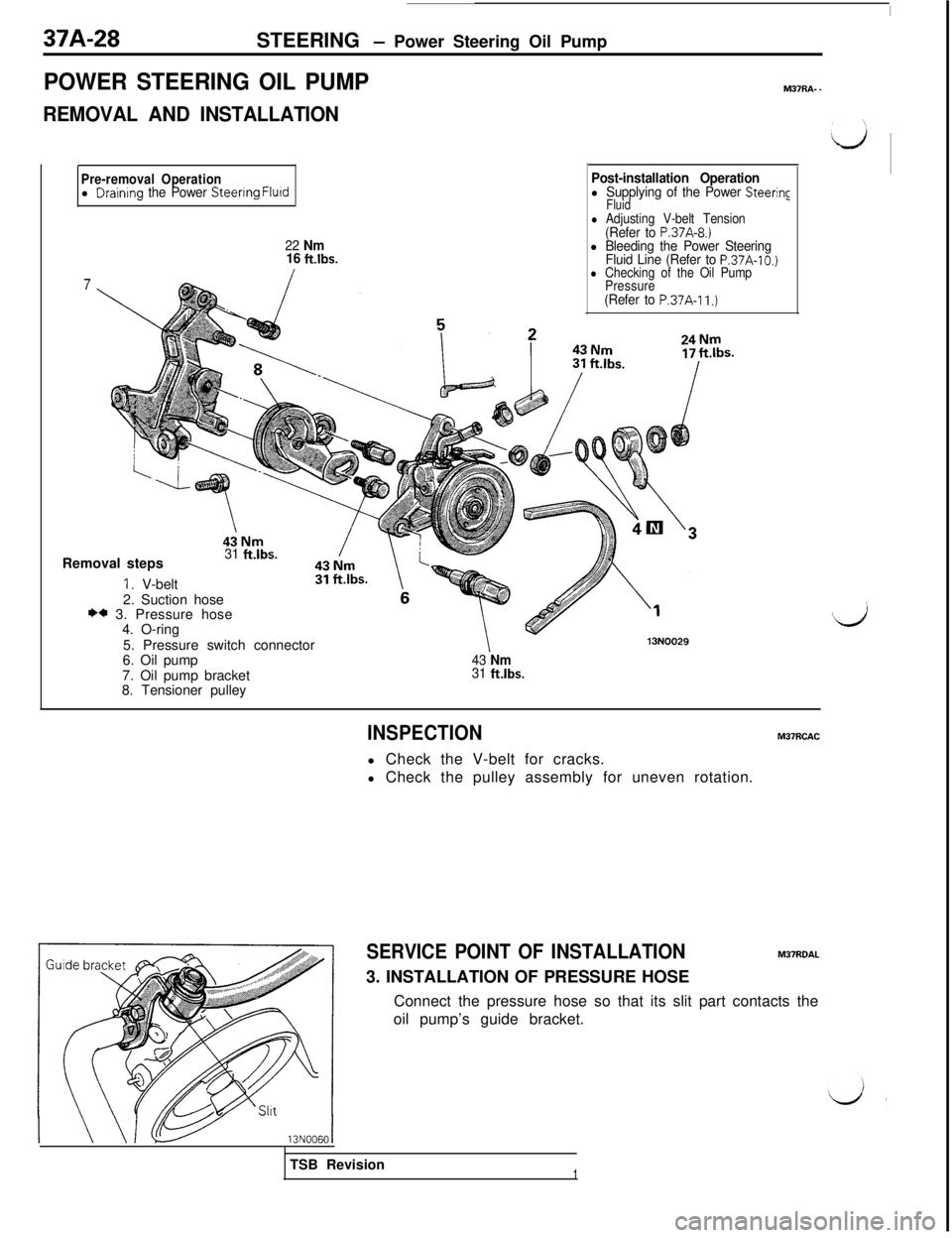

Pre-removal Operationl Draintng the Power Steenng Flurd

22 Nm

16 ft.lbs.

7

Post-installation Operationl Supplying of the Power Steering

Fluid

l Adjusting V-belt Tension(Refer to P.37A-8.)l Bleeding the Power Steering

Fluid Line (Refer to P.37A-10.)l Checking of the Oil Pump

Pressure

(Refer to P.37A-11.)Removal steps

31 ft.lbs.

1. V-belt

2. Suction hose

** 3. Pressure hose

4. O-ring

5. Pressure switch connector

6. Oil pump

7. Oil pump bracket

8. Tensioner pulley

43 Nm31 fklbs.

13N0029

Ij

INSPECTIONM37RCACl Check the V-belt for cracks.

l Check the pulley assembly for uneven rotation.

SERVICE POINT OF INSTALLATIONM37ROAL3. INSTALLATION OF PRESSURE HOSE

Connect the pressure hose so that its slit part contacts the

oil pump’s guide bracket.

TSB Revision

1