service reset MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 77 of 1146

ENGINE - Timinn Belt11-27

r bol

I01 NO07

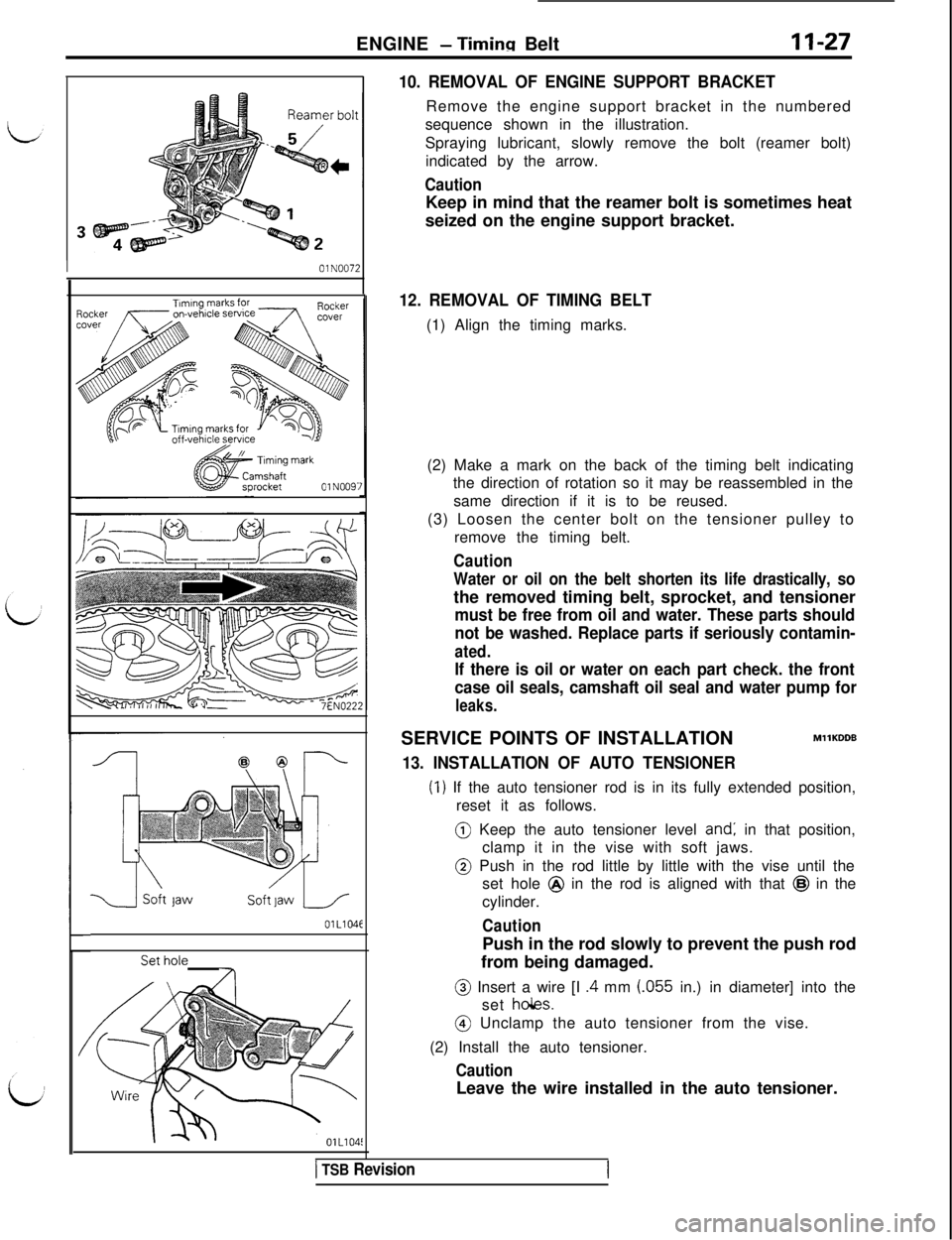

10. REMOVAL OF ENGINE SUPPORT BRACKETRemove the engine support bracket in the numbered

sequence shown in the illustration.

Spraying lubricant, slowly remove the bolt (reamer bolt)

indicated by the arrow.

CautionKeep in mind that the reamer bolt is sometimes heat

seized on the engine support bracket.

Timing mark

mshaftrocket01 N009:

d Soft jawSoft jaw

OlL104E

Set hole

n

12. REMOVAL OF TIMING BELT(1) Align the timing marks.

(2) Make a mark on the back of the timing belt indicating

the direction of rotation so it may be reassembled in the

same direction if it is to be reused.

(3) Loosen the center bolt on the tensioner pulley to

remove the timing belt.

Caution

Water or oil on the belt shorten its life drastically, sothe removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contamin-

ated.

If there is oil or water on each part check. the front

case oil seals, camshaft oil seal and water pump for

leaks.SERVICE POINTS OF INSTALLATION

MllKDDB

13. INSTALLATION OF AUTO TENSIONER

(‘I) If the auto tensioner rod is in its fully extended position,

reset it as follows.@ Keep the auto tensioner level

and: in that position,

clamp it in the vise with soft jaws.@ Push in the rod little by little with the vise until the

set hole @ in the rod is aligned with that @ in the

cylinder.

CautionPush in the rod slowly to prevent the push rod

from being damaged.@ Insert a wire [I

.4 mm (.055 in.) in diameter] into the

set

ho&.@ Unclamp the auto tensioner from the vise.

(2) Install the auto tensioner.

CautionLeave the wire installed in the auto tensioner.

1 TSB Revision

Page 961 of 1146

EXTERIOR - Aero Parts

18FO257

RearFrontView

A_ View B

Adhesive

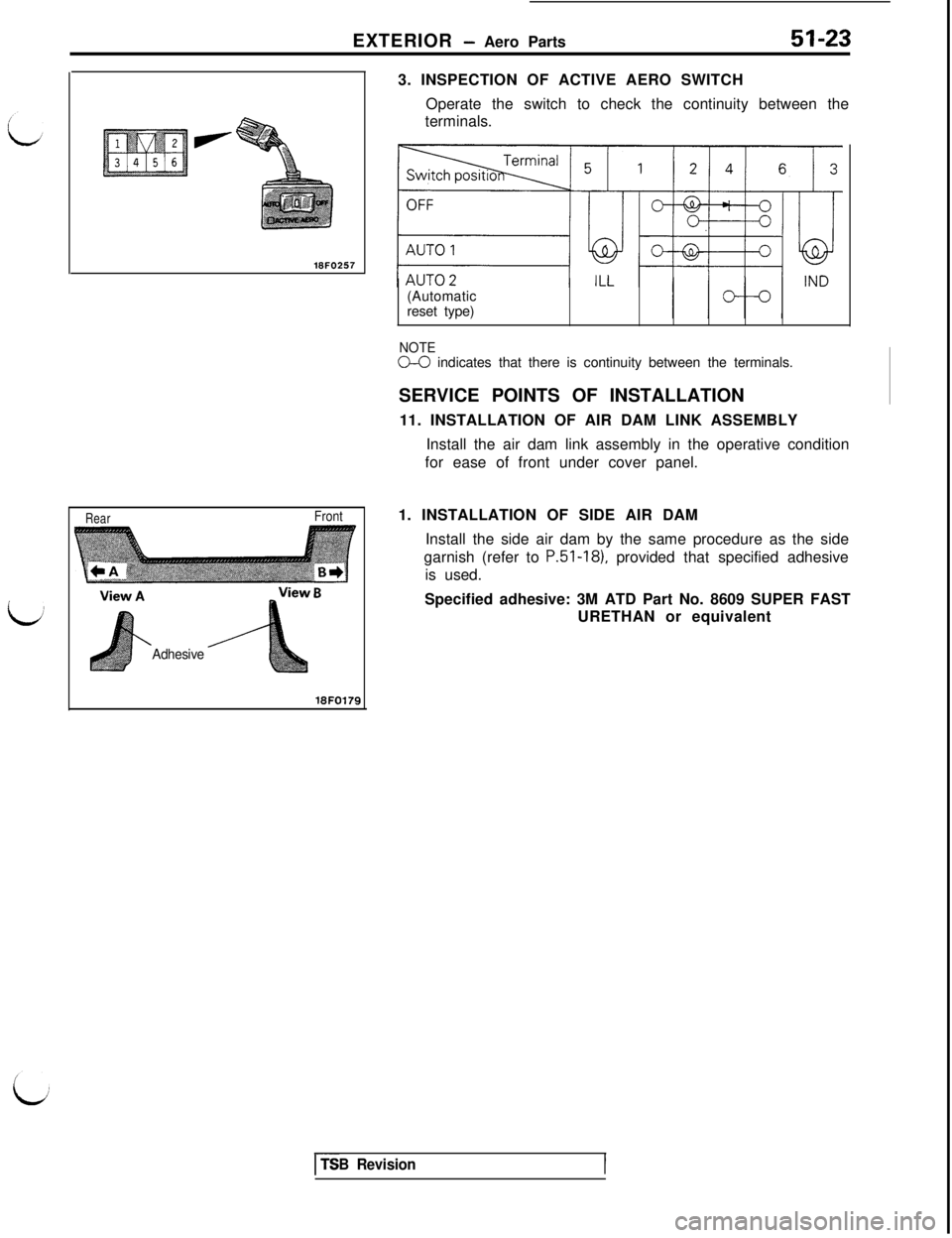

18FO17533. INSPECTION OF ACTIVE AERO SWITCH

Operate the switch to check the continuity between the

terminals.

(Automatic

reset type)

NOTEO-0 indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF AIR DAM LINK ASSEMBLY

Install the air dam link assembly in the operative condition

for ease of front under cover panel.

1. INSTALLATION OF SIDE AIR DAM

Install the side air dam by the same procedure as the side

garnish (refer to

P.51-181, provided that specified adhesive

is used.

Specified adhesive: 3M ATD Part No. 8609 SUPER FAST

URETHAN or equivalent

I---TSB Revision

Page 971 of 1146

EXTERIOR - Windshield Wiper and Washer51-33

L

lj

Inspection of Operation

Low-speed High-speedoperationoperation1610026

Inspection of Stop Posltion

n

16NOO25

16FO200

ITSB ISERVICE POINT OF REMOVAL

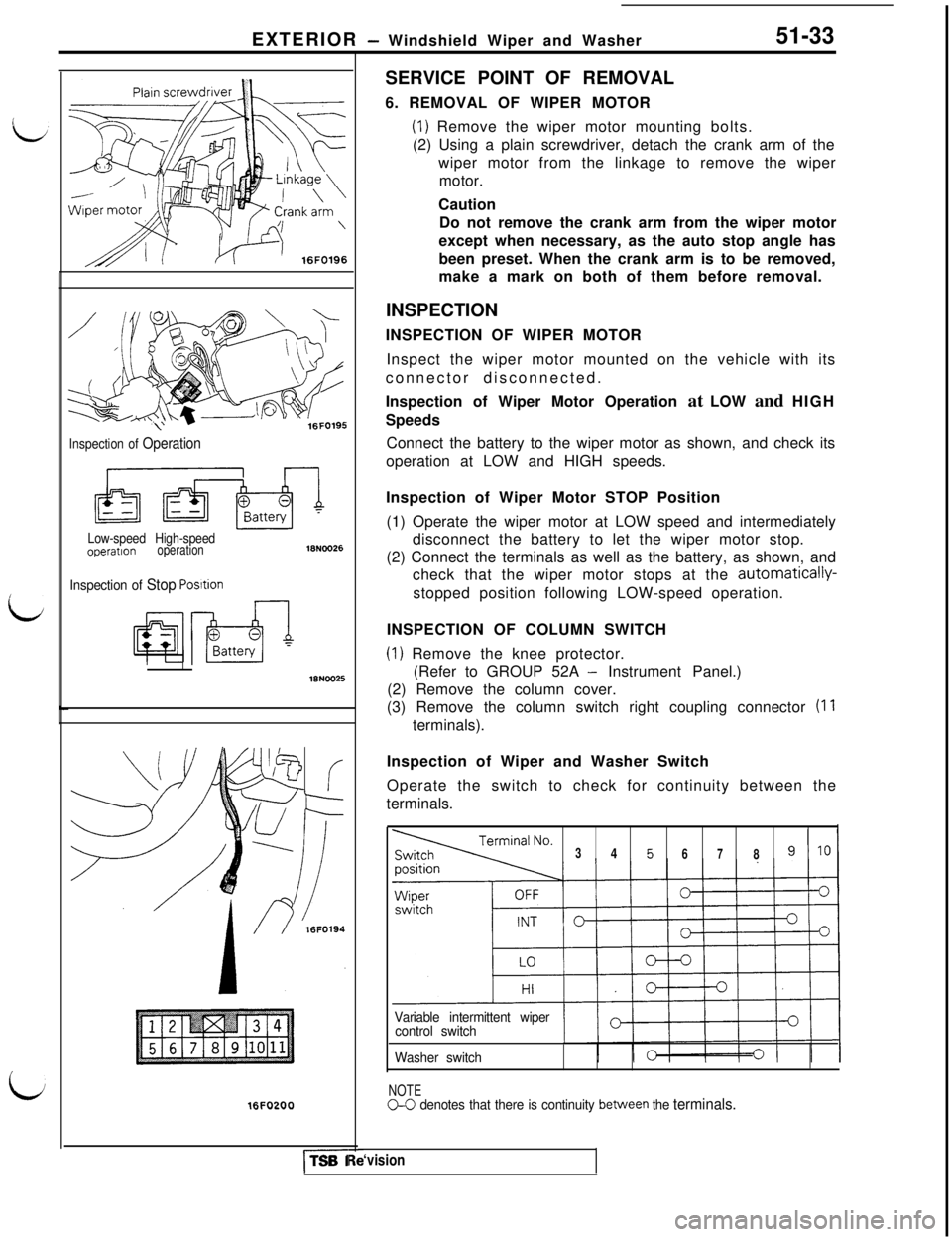

6. REMOVAL OF WIPER MOTOR

(1) Remove the wiper motor mounting bolts.

(2) Using a plain screwdriver, detach the crank arm of the

wiper motor from the linkage to remove the wiper

motor.

Caution

Do not remove the crank arm from the wiper motor

except when necessary, as the auto stop angle has

been preset. When the crank arm is to be removed,

make a mark on both of them before removal.

INSPECTION

INSPECTION OF WIPER MOTOR

Inspect the wiper motor mounted on the vehicle with its

connector disconnected.

Inspection of Wiper Motor Operation at LOW and HIGH

Speeds

Connect the battery to the wiper motor as shown, and check its

operation at LOW and HIGH speeds.

Inspection of Wiper Motor STOP Position

(1) Operate the wiper motor at LOW speed and intermediately

disconnect the battery to let the wiper motor stop.

(2) Connect the terminals as well as the battery, as shown, and

check that the wiper motor stops at the automatically-

stopped position following LOW-speed operation.

INSPECTION OF COLUMN SWITCH

(1) Remove the knee protector.

(Refer to GROUP 52A

- Instrument Panel.)

(2) Remove the column cover.

(3) Remove the column switch right coupling connector

(11terminals).

Inspection of Wiper and Washer Switch

Operate the switch to check for continuity between the

terminals.

345678

Variable intermittent wiper

control switch

Washer switch

NOTEC-0 denotes that there is continuity between the terminals.

‘vision