weight MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 14 of 1146

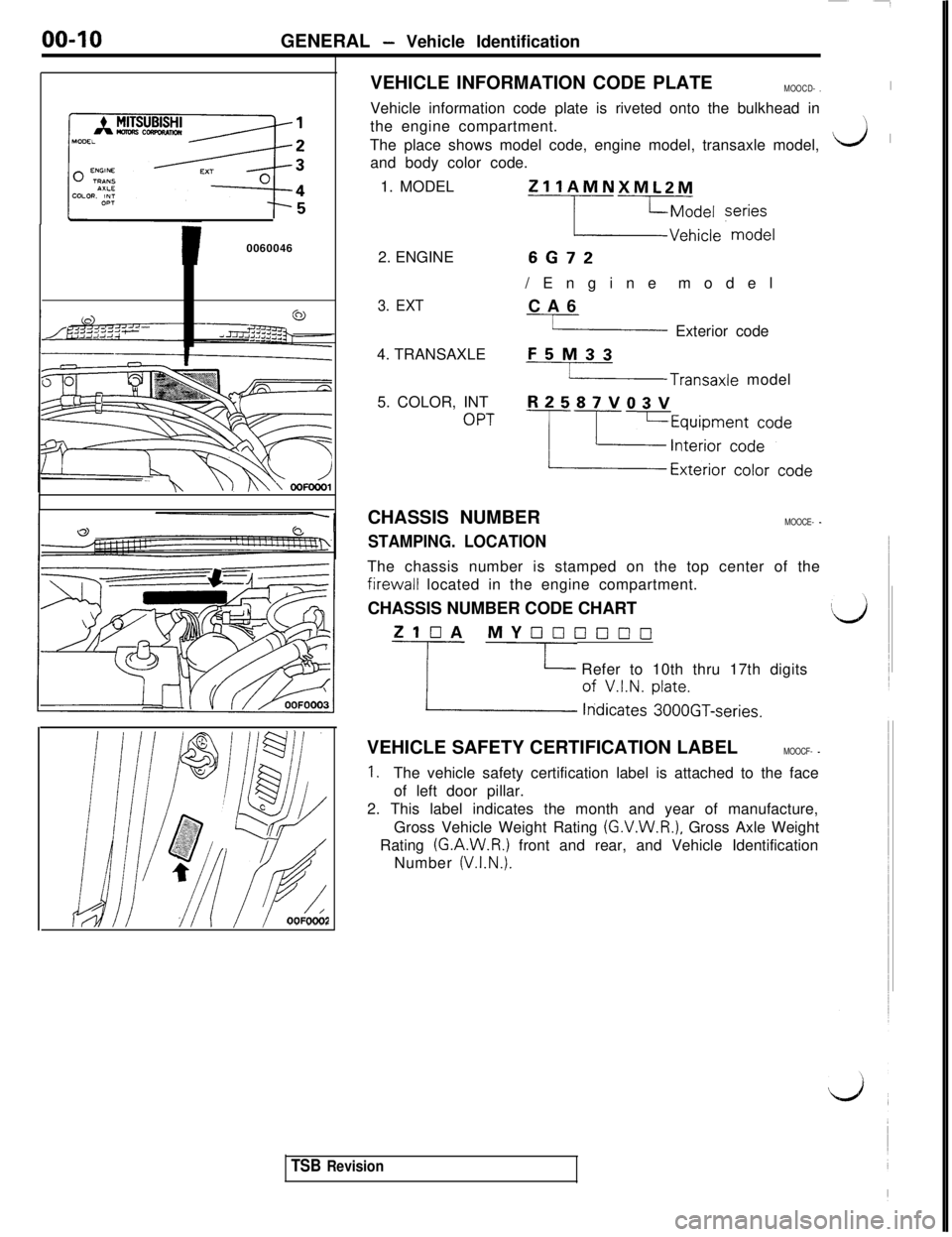

00-10GENERAL - Vehicle Identification

0060046

.:@I*

@+!jg.., ,”

0

<1

~~~ k

,.‘.r, SS?b‘,,.‘$ .’‘S,‘,,:’

t

I

nf/OOFDO&VEHICLE INFORMATION CODE PLATE

MOOCD- .IVehicle information code plate is riveted onto the bulkhead in

the engine compartment.

:

i3' 'The place shows model code, engine model, transaxle model,

and body color code.

1. MODEL

ZllAMNXMLZM

L2iie ‘zze[2. ENGINE

6672/Engine model

3. EXTCA6

Y Exterior code

4. TRANSAXLE

F5M33

-Transaxle model

5. COLOR, INT

R2587VQ3V

OPT-p=~izgTj+Ly~deCHASSIS NUMBER

MOOCE- -

STAMPING. LOCATIONThe chassis number is stamped on the top center of thefirewall located in the engine compartment.

CHASSIS NUMBER CODE CHART

ZlOA MY[7000~10

Y cd:at!s t:beOGT-series. Refer to 10th thru 17th digits

VEHICLE SAFETY CERTIFICATION LABEL

MOOCF- -

1.The vehicle safety certification label is attached to the face

of left door pillar.

2. This label indicates the month and year of manufacture,

Gross Vehicle Weight Rating

(G.V.W.R.), Gross Axle Weight

Rating

(G.A.W.R.) front and rear, and Vehicle Identification

Number

(V.I.N.).

TSB Revision

Page 22 of 1146

00-18

GENERAL - Towing and Hoisting

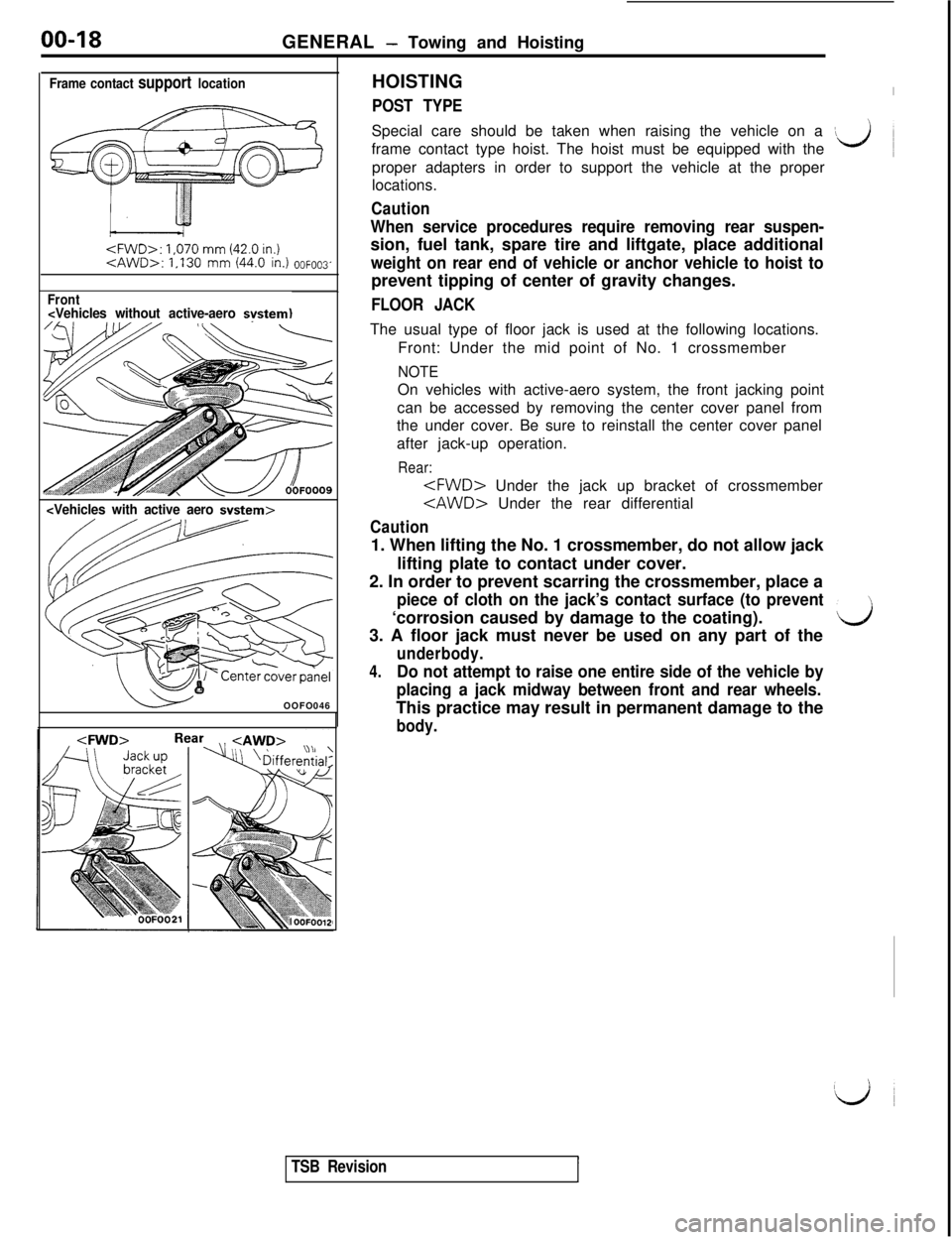

Frame contact support location

1,070 mm (42.0 in.)

Front

POST TYPESpecial care should be taken when raising the vehicle on a

\frame contact type hoist. The hoist must be equipped with theL)proper adapters in order to support the vehicle at the proper

locations.

Caution

When service procedures require removing rear suspen-sion, fuel tank, spare tire and liftgate, place additional

weight on rear end of vehicle or anchor vehicle to hoist toprevent tipping of center of gravity changes.

FLOOR JACKThe usual type of floor jack is used at the following locations.

Front: Under the mid point of No. 1 crossmember

NOTEOn vehicles with active-aero system, the front jacking point

can be accessed by removing the center cover panel from

the under cover. Be sure to reinstall the center cover panel

after jack-up operation.

Rear:

Caution1. When lifting the No. 1 crossmember, do not allow jack

lifting plate to contact under cover.

2. In order to prevent scarring the crossmember, place a

piece of cloth on the jack’s contact surface (to prevent‘corrosion caused by damage to the coating).

d3. A floor jack must never be used on any part of the

underbody.

4.Do not attempt to raise one entire side of the vehicle by

placing a jack midway between front and rear wheels.This practice may result in permanent damage to the

body.

TSB Revision

Page 25 of 1146

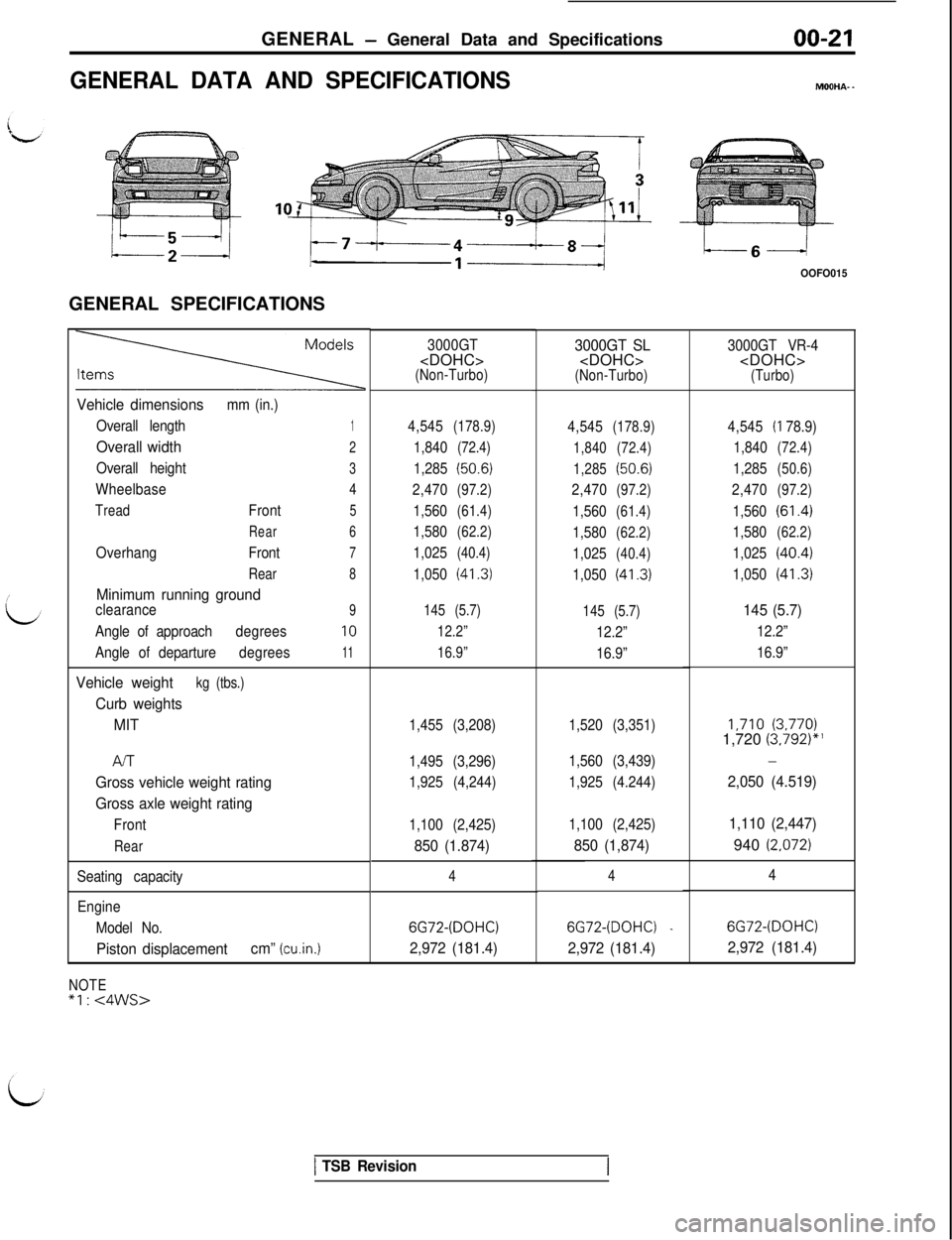

GENERAL - General Data and Specifications

GENERAL DATA AND SPECIFICATIONS

00-21

MOOHA- -

c-i----J---i!--8GENERALSPECIFICATIONS

Vehicle dimensionsmm (in.)

Overall length

1

Overall width2

Overall height3

Wheelbase4

Tread

Front5

Rear6

OverhangFront7

Rear8

Minimum running groundclearance9

Angle of approachdegrees10

Angle of departuredegrees11

Vehicle weightkg (tbs.)

Curb weights

MIT

AI-T

Gross vehicle weight rating

Gross axle weight rating

Front

Rear

Seating capacity

Engine

Model No.

Piston displacementcm” (cu.in.)

3000GT

(Non-Turbo)

4,545(178.9)

1,840(72.4)

1,285(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145(5.7)

12.2”

16.9”

1,455 (3,208)

1,495 (3,296)

1,925 (4,244)

1,100 (2,425)

850 (1.874)

4

6G72-(DOHC)

2,972 (181.4)3000GT SL

(Non-Turbo)

4,545(178.9)

1,840(72.4)

1,285

(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145(5.7)

12.2”

16.9”

1,520 (3,351)

1,560 (3,439)

1,925 (4.244)

1,100 (2,425)

850 (1,874)

4

6G72-(DOHC) -

2,972 (181.4)

+64

OOFO015

3000GT VR-4

(Turbo)

4,545(I 78.9)

1,840

(72.4)

1,285(50.6)

2,470(97.2)

1,560(61.4)

1,580(62.2)

1,025(40.4)

1,050(41.3)

145 (5.7)

12.2”

16.9”

1,710 (3.770)1,720 (3,792)“’

-

2,050 (4.519)

1,110 (2,447)940

(2,072)

4

6G72-(DOHC)

2,972 (181.4)

NOTE“I : <4ws>

1 TSB Revision

Page 396 of 1146

22-16MANUAL TRANSAXLE

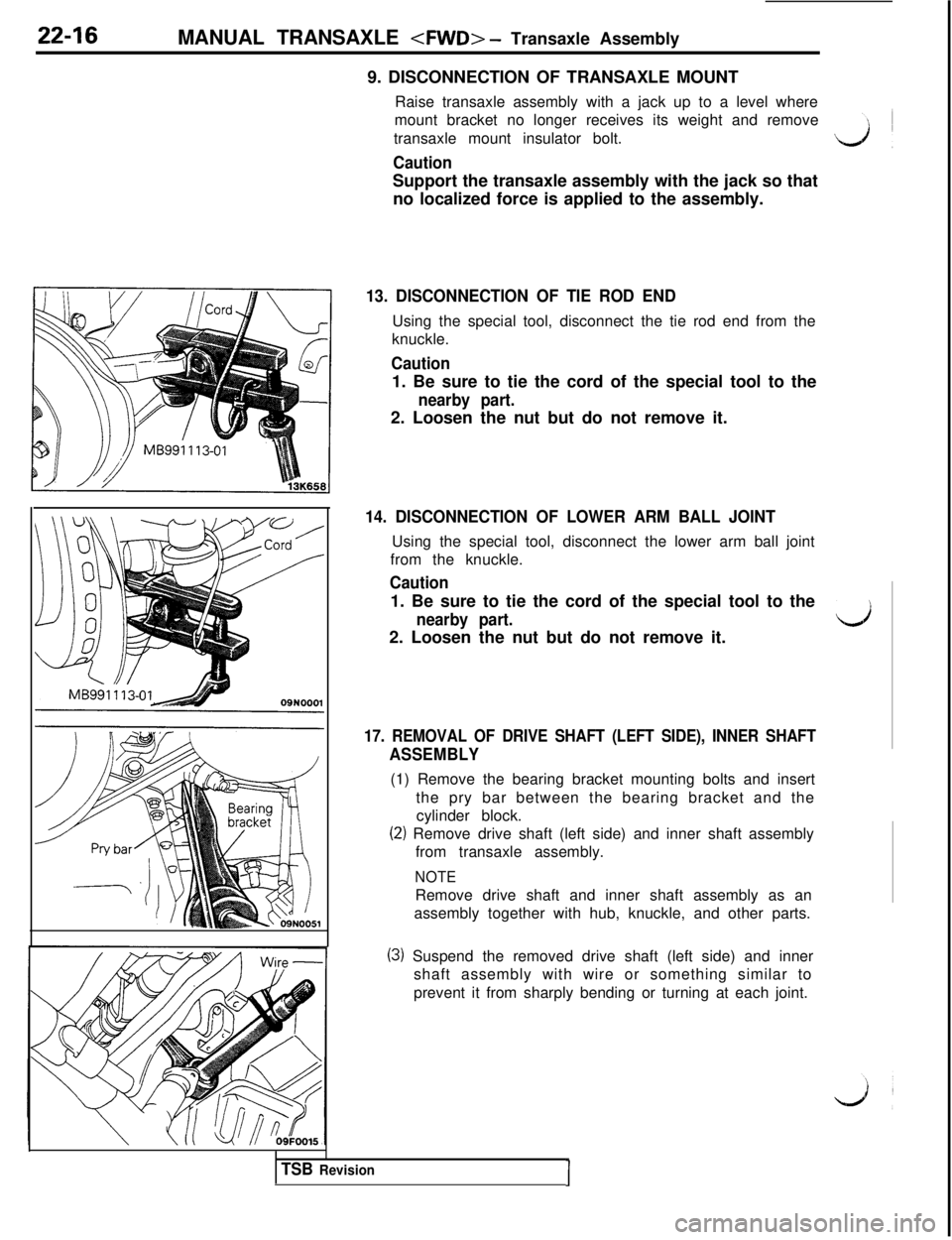

9. DISCONNECTION OF TRANSAXLE MOUNT

Raise transaxle assembly with a jack up to a level where

mount bracket no longer receives its weight and remove

transaxle mount insulator bolt.

CautionSupport the transaxle assembly with the jack so that

no localized force is applied to the assembly.

13. DISCONNECTION OF TIE ROD ENDUsing the special tool, disconnect the tie rod end from the

knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.2. Loosen the nut but do not remove it.

14. DISCONNECTION OF LOWER ARM BALL JOINTUsing the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.2. Loosen the nut but do not remove it.

17. REMOVAL OF DRIVE SHAFT (LEFT SIDE), INNER SHAFT

ASSEMBLY(1) Remove the bearing bracket mounting bolts and insert

the pry bar between the bearing bracket and the

cylinder block.

(2) Remove drive shaft (left side) and inner shaft assembly

from transaxle assembly.

NOTERemove drive shaft and inner shaft assembly as an

assembly together with hub, knuckle, and other parts.

(3) Suspend the removed drive shaft (left side) and inner

shaft assembly with wire or something similar to

prevent it from sharply bending or turning at each joint.

TSB RevisionI

Page 515 of 1146

LJ

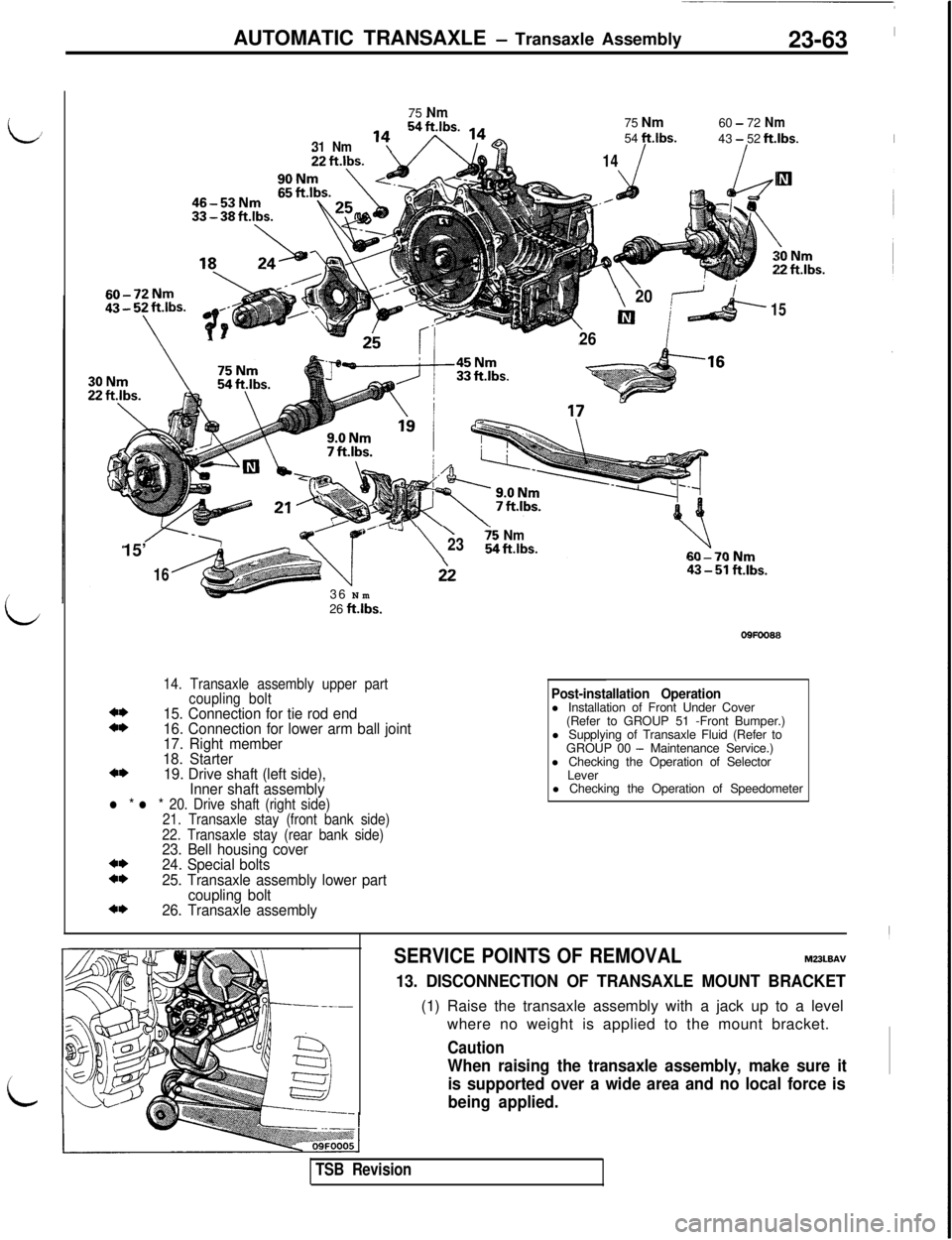

LAUTOMATIC TRANSAXLE

- Transaxle Assembly

23-63 ’

31 Nm‘?“.75

Nm75 Nm60- 72Nm54 ftlbs.

43

- 52ft.lbs.I

14II

60-72Nm\20

Ia15

26

). C-J\

\23j5 Nm64ft.lbs.15’

1636 Nm43-G,“.%S.26

ft.lbs.

OSFOOBH

14. Transaxle assembly upper part

coupling bolt

4*15. Connection for tie rod end4*16. Connection for lower arm ball joint

17. Right member

18. Starter

4*19. Drive shaft (left side),

Inner shaft assembly

l * l * 20. Drive shaft (right side)

21. Transaxle stay (front bank side)

22. Transaxle stay (rear bank side)

23. Bell housing cover4*24. Special bolts4*25. Transaxle assembly lower part

coupling bolt

4*26. Transaxle assemblyPost-installation Operationl Installation of Front Under Cover

(Refer to GROUP 51 -Front Bumper.)

l Supplying of Transaxle Fluid (Refer to

GROUP 00

- Maintenance Service.)

l Checking the Operation of Selector

Lever

l Checking the Operation of Speedometer

SERVICE POINTS OF REMOVALM22kBAV

13. DISCONNECTION OF TRANSAXLE MOUNT BRACKET(1) Raise the transaxle assembly with a jack up to a level

where no weight is applied to the mount bracket.

Caution

When raising the transaxle assembly, make sure it

is supported over a wide area and no local force is

being applied.

TSB Revision