service indicator MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 108 of 1146

13-2

Boost Meter

Components Location........................................................36

Crank Angle Sensor

............................................................72Detonation Sensor................................................................84EGR Control Solenoid Valve

EGR Temperature Sensor

Fuel Pump Operation Check................................................137Fuel Pump Relay No. 2........................................................53Fuel Pump Resistor............................................................53

Idle Position Switch............................................................68Idle Speed Control Servo (Stepper Motor Type)............1 IOIgnition Coil and Power Transistor....................................115Ignition Switch-ST and Inhibitor Switch ................76Ignition Switch-ST

Injectors

94

Oxygen Sensor

Power Steering Oil Pressure Switch................................80Power Supply and Ignition Switch-IG................................41

Purge Control Solenord Valve............................................1 19Release of Residual Pressure from High

Pressure Fuel Hose............................................................137Throttle Position Sensor....................................................65Top Dead Center Sensor....................................................70Variable Induction Control Servo (DC Motor)

SERVICE ADJUSTMENT PROCEDURES............................31

Adjustment of Fixed SAS....................................................35Adjustment of Idle Position Switch and

Throttle Position Sensor (TPS)............................................33Basic Idle Speed Adjustment............................................31Throttle Body (Throttle Valve Area) Cleaning....................33

SPECIAL TOOLS........................................................................8

SPECIFICATIONS

....................................................................6

General Specifications........................................................6Sealant....................................................................................7Service Specifications........................................................7

THROlTLE BODY....................................................................143

TROUBLESHOOTING............................................................9

Check Chart Classified by Problem Symptoms................16Circuit Diagram....................................................................18Engine Warning Light (Malfunction Indicator Light)........11Explanation and Cautions about Harness Check............10Explanation of Troubleshooting Procedures....................9Fuel Tank and Fuel Line........................................................30

Problem Symptoms Table (For Your Information)............17Self-diagnosis........................................................................12)

I

Page 285 of 1146

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

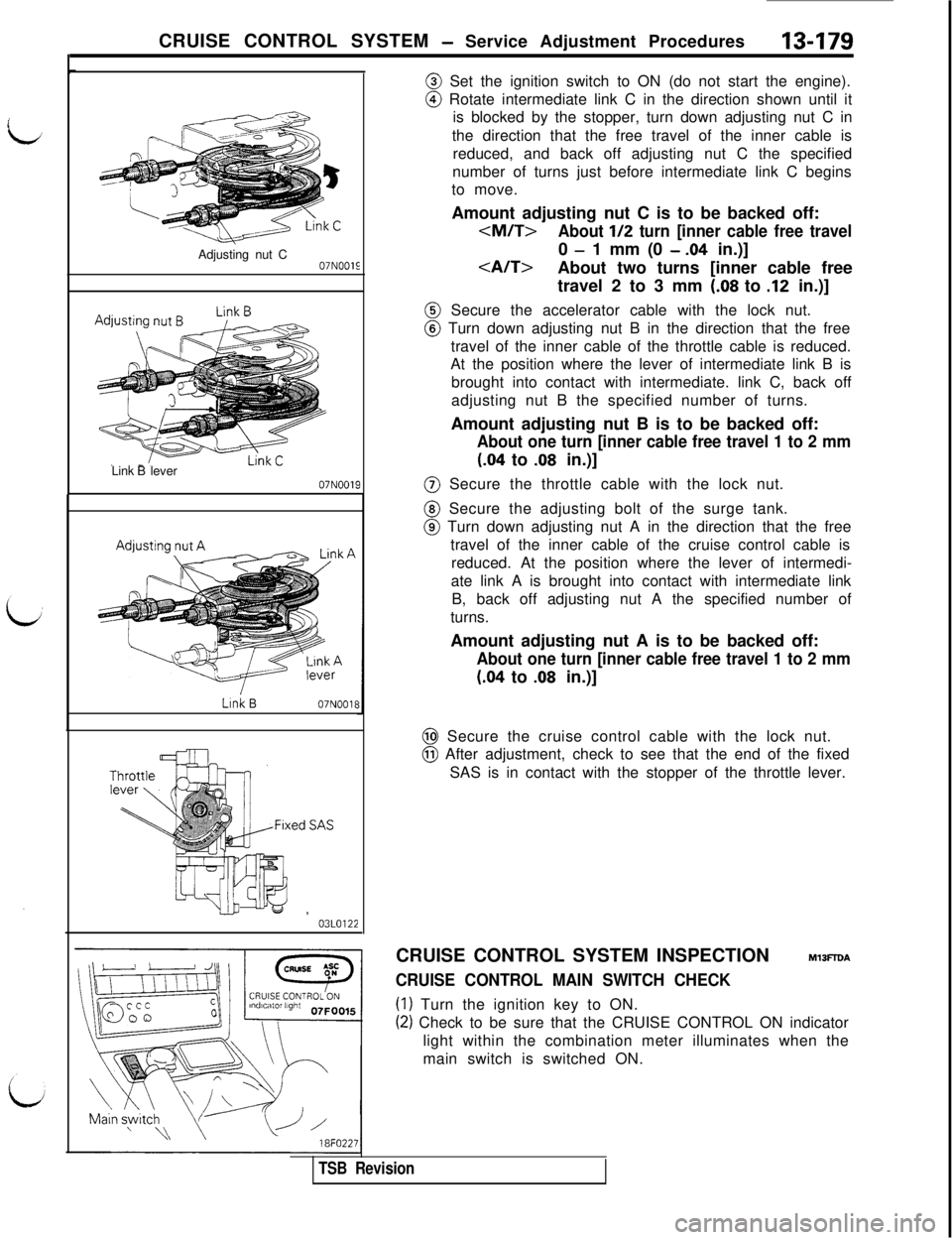

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 286 of 1146

13-180CRUISE CONTROL SYSTEM - Service Adjustment Procedures.

4

ET: ON

07FOOl;Control switch

\E: ON

t

07FOOliControl switch

\

SET: ON

07FOOlControl switch

\

07FOOl

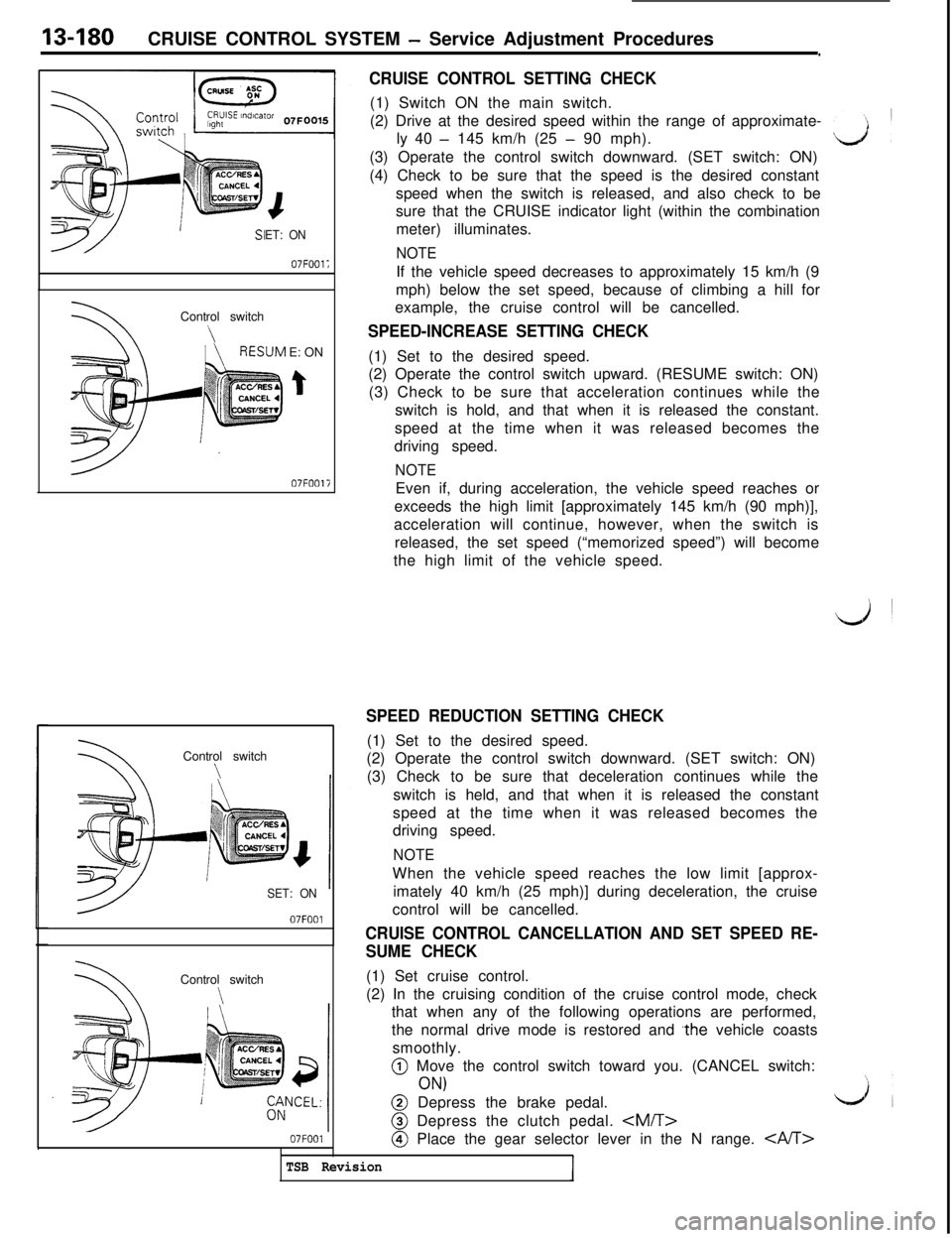

CRUISE CONTROL SETTING CHECK(1) Switch ON the main switch.

(2) Drive at the desired speed within the range of approximate-

ly 40

- 145 km/h (25 - 90 mph).

(3) Operate the control switch downward. (SET switch: ON)

(4) Check to be sure that the speed is the desired constant

speed when the switch is released, and also check to be

sure that the CRUISE indicator light (within the combination

meter) illuminates.

NOTEIf the vehicle speed decreases to approximately 15 km/h (9

mph) below the set speed, because of climbing a hill for

example, the cruise control will be cancelled.

SPEED-INCREASE SETTING CHECK(1) Set to the desired speed.

(2) Operate the control switch upward. (RESUME switch: ON)

(3) Check to be sure that acceleration continues while the

switch is hold, and that when it is released the constant.

speed at the time when it was released becomes the

driving speed.

NOTEEven if, during acceleration, the vehicle speed reaches or

exceeds the high limit [approximately 145 km/h (90 mph)],

acceleration will continue, however, when the switch is

released, the set speed (“memorized speed”) will become

the high limit of the vehicle speed.

SPEED REDUCTION SETTING CHECK(1) Set to the desired speed.

(2) Operate the control switch downward. (SET switch: ON)

(3) Check to be sure that deceleration continues while the

switch is held, and that when it is released the constant

speed at the time when it was released becomes the

driving speed.

NOTEWhen the vehicle speed reaches the low limit [approx-

imately 40 km/h (25 mph)] during deceleration, the cruise

control will be cancelled.

CRUISE CONTROL CANCELLATION AND SET SPEED RE-

SUME CHECK(1) Set cruise control.

(2) In the cruising condition of the cruise control mode, check

that when any of the following operations are performed,

the normal drive mode is restored and

,the vehicle coasts

smoothly.@ Move the control switch toward you. (CANCEL switch:@ Depress the brake pedal.@ Depress the clutch pedal.

TSB Revision

Page 301 of 1146

COOLING - Service Adiustment Procedures.14-7

SERVICE ADJUSTMENT PROCEDURES

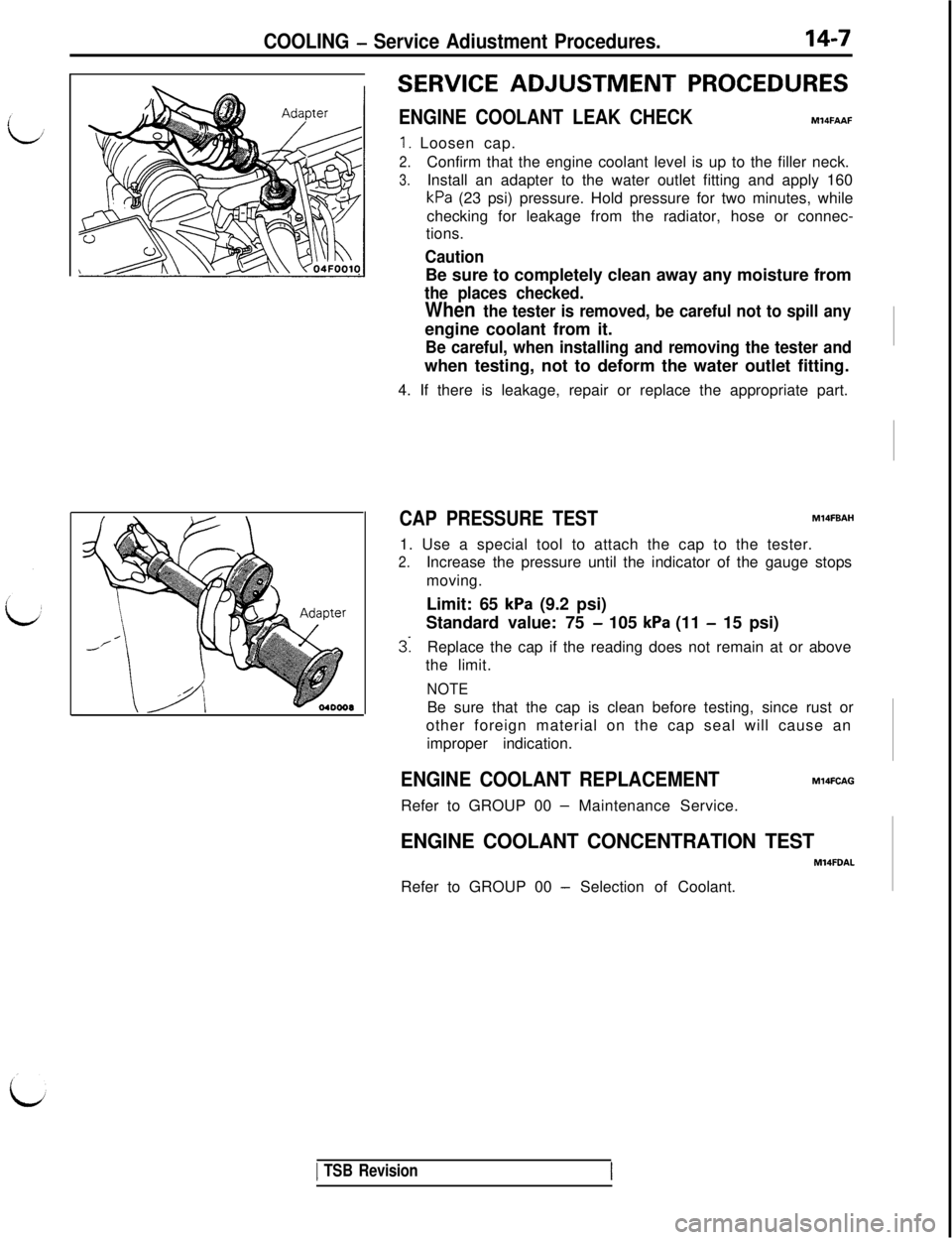

ENGINE COOLANT LEAK CHECKMl4FAAF

1. Loosen cap.

2.Confirm that the engine coolant level is up to the filler neck.

3.Install an adapter to the water outlet fitting and apply 160

kPa (23 psi) pressure. Hold pressure for two minutes, while

checking for leakage from the radiator, hose or connec-

tions.

CautionBe sure to completely clean away any moisture from

the places checked.

When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester andwhen testing, not to deform the water outlet fitting.

4. If there is leakage, repair or replace the appropriate part.

CAP PRESSURE TESTM14FBAH1. Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gauge stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value: 75

- 105 kPa (11 - 15 psi)

3:Replace the cap if the reading does not remain at or above

the limit.

NOTEBe sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENTM14FCAGRefer to GROUP 00

- Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST

M14FDALRefer to GROUP 00

- Selection of Coolant.

1 TSB Revision

Page 358 of 1146

17-14 EMISSION CONTROL -Exhaust Gas Recirculation (EGR) System / Catalytic Converter

6EM01871

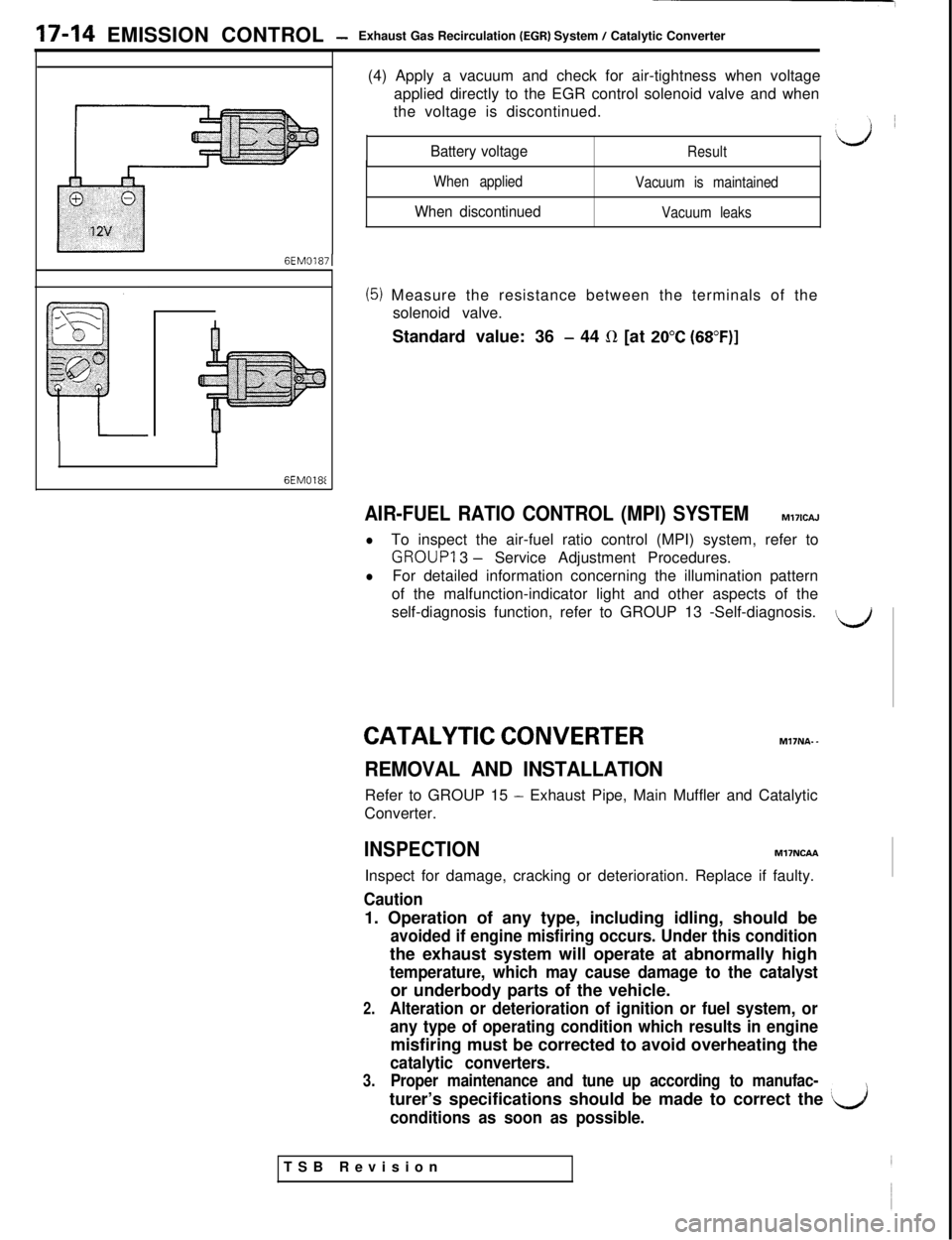

6EM0181(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and when

the voltage is discontinued.

Battery voltageResult

When applied

When discontinued

Vacuum is maintained

Vacuum leaks

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36

- 44 R [at 20°C (68”F)]

AIR-FUEL RATIO CONTROL (MPI) SYSTEMM17ICAJ

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP1 3 - Service Adjustment Procedures.

lFor detailed information concerning the illumination pattern

of the malfunction-indicator light and other aspects of the

self-diagnosis function, refer to GROUP 13 -Self-diagnosis.

\.J

CATALYTIC CONVERTERMl7N& -

REMOVAL AND INSTALLATIONRefer to GROUP 15

- Exhaust Pipe, Main Muffler and Catalytic

Converter.

INSPECTIONMl7NCAA

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally high

temperature, which may cause damage to the catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enginemisfiring must be corrected to avoid overheating the

catalytic converters.

3.Proper maintenance and tune up according to manufac-turer’s specifications should be made to correct the

‘bi

conditions as soon as possible.TSB Revision

Page 502 of 1146

23-50AUTOMATIC TRANSAXLE - service AdiustmentProcedures

09FO117

m09FOO19

L Pushbuttonv09FOO61

@ Button pressed (while brakepedal is depressed)c Button not pressed@ Button pressed

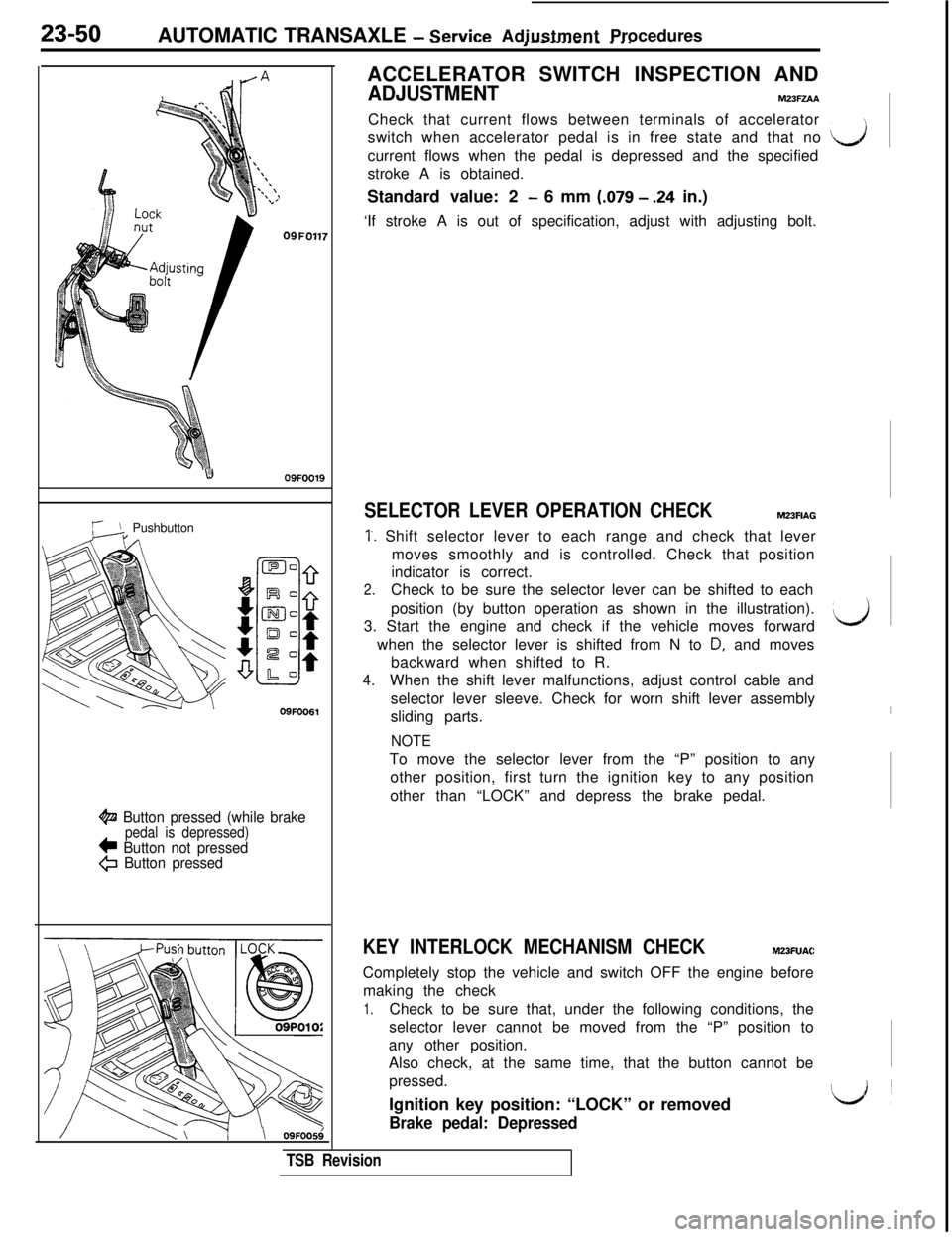

/\ \\ OSFODdACCELERATOR SWITCH INSPECTION AND

ADJUSTMENTM23FZAACheck that current flows between terminals of accelerator

switch when accelerator pedal is in free state and that no

dcurrent flows when the pedal is depressed and the specified

stroke A is obtained.

Standard value: 2

- 6 mm (.079 - .24 in.)

‘If stroke A is out of specification, adjust with adjusting bolt.

SELECTOR LEVER OPERATION CHECKM23FIAG

1.. Shift selector lever to each range and check that lever

moves smoothly and is controlled. Check that position

indicator is correct.

2.Check to be sure the selector lever can be shifted to each

position (by button operation as shown in the illustration).

3. Start the engine and check if the vehicle moves forward

dwhen the selector lever is shifted from N to

D, and moves

backward when shifted to R.

4.When the shift lever malfunctions, adjust control cable and

selector lever sleeve. Check for worn shift lever assembly

sliding parts.

I

NOTETo move the selector lever from the “P” position to any

other position, first turn the ignition key to any position

other than “LOCK” and depress the brake pedal.

KEY INTERLOCK MECHANISM CHECKM23FlJACCompletely stop the vehicle and switch OFF the engine before

making the check

1.Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P” position to

any other position.

Also check, at the same time, that the button cannot be

pressed.

Ignition key position: “LOCK” or removed

Brake pedal: Depressed

TSB Revision

Page 566 of 1146

25-2PROPELLER SHAFT - Specifications

SPECIFICATIONSM25CA- -

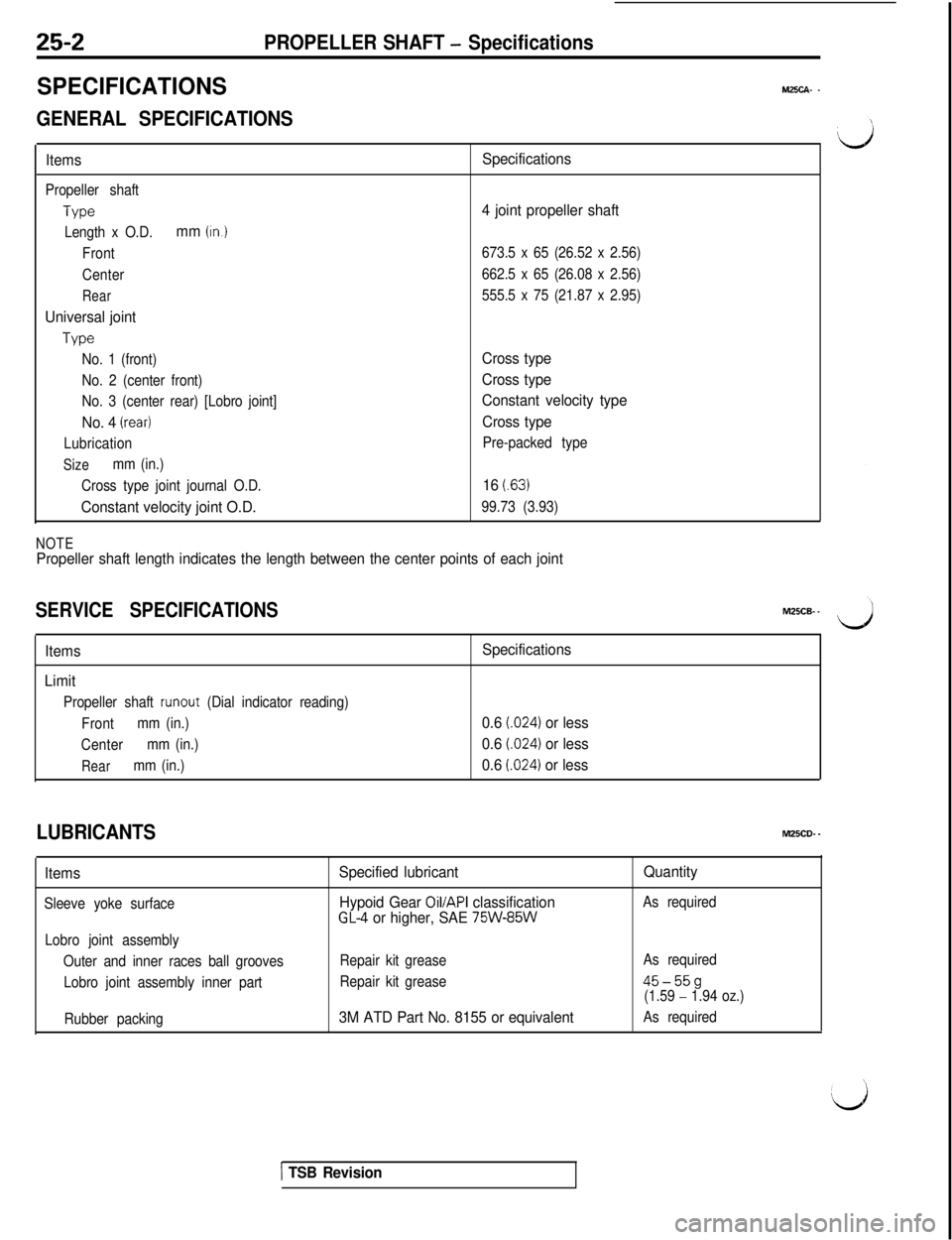

GENERAL SPECIFICATIONS

Items

Propeller shaft

Type

Length x O.D.

mm (In.)

Front

Center

Rear

Universal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Lobro joint]

No. 4 (rear)

Lubrication

Sizemm (in.)

Cross type joint journal O.D.

Constant velocity joint O.D.Specifications

4 joint propeller shaft

673.5 x 65 (26.52 x 2.56)

662.5 x 65 (26.08 x 2.56)

555.5 x 75 (21.87 x 2.95)

Cross type

Cross type

Constant velocity type

Cross type

Pre-packed type

16 t.63)

99.73 (3.93)

NOTEPropeller shaft length indicates the length between the center points of each joint

SERVICE SPECIFICATIONSM25CE -d

Items

Limit

Propeller shaft runout (Dial indicator reading)

Frontmm (in.)

Centermm (in.)

Rearmm (in.)

Specifications

0.6

l.024) or less

0.6

i.024) or less

0.6

t.024) or less

LUBRICANTSM25CD..

Items

Sleeve yoke surface

Lobro joint assembly

Outer and inner races ball grooves

Lobro joint assembly inner part

Rubber packing

Specified lubricant

Hypoid Gear

Oil/API classificationGL-4 or higher, SAE 75W-85W

Repair kit grease

Repair kit grease

3M ATD Part No. 8155 or equivalentQuantity

As required

As required

45-55g(1.59 - 1.94 oz.)

As required

1 TSB Revision

Page 568 of 1146

25-4PROPELLER SHAFT - ProDeller ShaftPropeller

LGbro joint

shaftL6bro Jointbootassembly

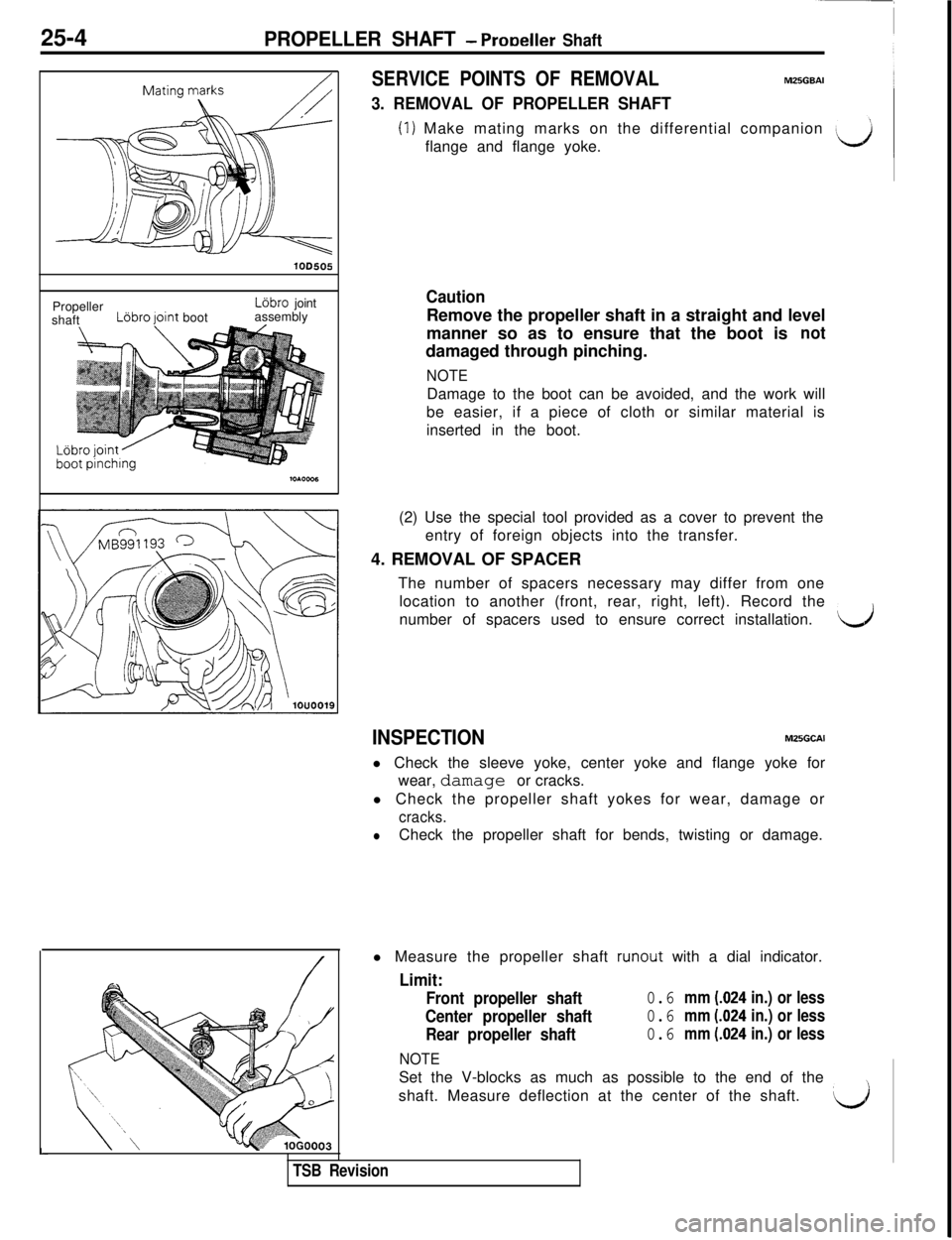

SERVICE POINTS OF REMOVALM25GEAI

3. REMOVAL OF PROPELLER SHAFT

(1) Make mating marks on the differential companion

flange and flange yoke.

CautionRemove the propeller shaft in a straight and level

manner so as to ensure that the boot is

notdamaged through pinching.

NOTEDamage to the boot can be avoided, and the work will

be easier, if a piece of cloth or similar material is

inserted in the boot.

(2) Use the special tool provided as a cover to prevent the

entry of foreign objects into the transfer.

4. REMOVAL OF SPACER

The number of spacers necessary may differ from one

location to another (front, rear, right, left). Record the

number of spacers used to ensure correct installation.

INSPECTIONM25GCAIl Check the sleeve yoke, center yoke and flange yoke for

wear, damage or cracks.

l Check the propeller shaft yokes for wear, damage or

cracks.

lCheck the propeller shaft for bends, twisting or damage.

l Measure the propeller shaft runout with a dial indicator.

Limit:

Front propeller shaft0.6 mm (.024 in.) or less

Center propeller shaft0.6 mm (.024 in.) or less

Rear propeller shaft0.6 mm (.024 in.) or less

NOTESet the V-blocks as much as possible to the end of the

shaft. Measure deflection at the center of the shaft.

d

Lj

TSB Revision

Page 581 of 1146

FRONT AXLE - Troubleshooting / Service Adjustment Procedures

TROUBLESHOOTING

26-5

MPBEBAA

i.

Symptom

Vehicle pulls to one

side

Vibration

Shimmy

Excessive noiseProbable cause

Seizure of drive shaft ball joint

Abnormal wear, play or seizure of wheel bearing

Malfunction of front suspension or steering

Bend, damage or abnormal wear of drive shaft

Play in drive shaft and hub serration

Abnormal wear, play or seizure of wheel bearing

Improper wheel alignment

Malfunction of front suspension or steering

Broken boot, grease leakage

Bend, damage or abnormal wear of drive shaft

Play of drive shaft and hub serration

Abnormal wear, play or seizure of center bearing

Abnormal wear, play or seizure of wheel bearing

Loose wheel nut

Malfunction of front suspension and steering

Remedy

Replace

Replace

Adjust or replace

Replace

Replace

Replace

Adjust or replace

Adjust or replace

Replace, repack grease

Replace

Replace

Replace

Replace

Retighten

Adjust or replace

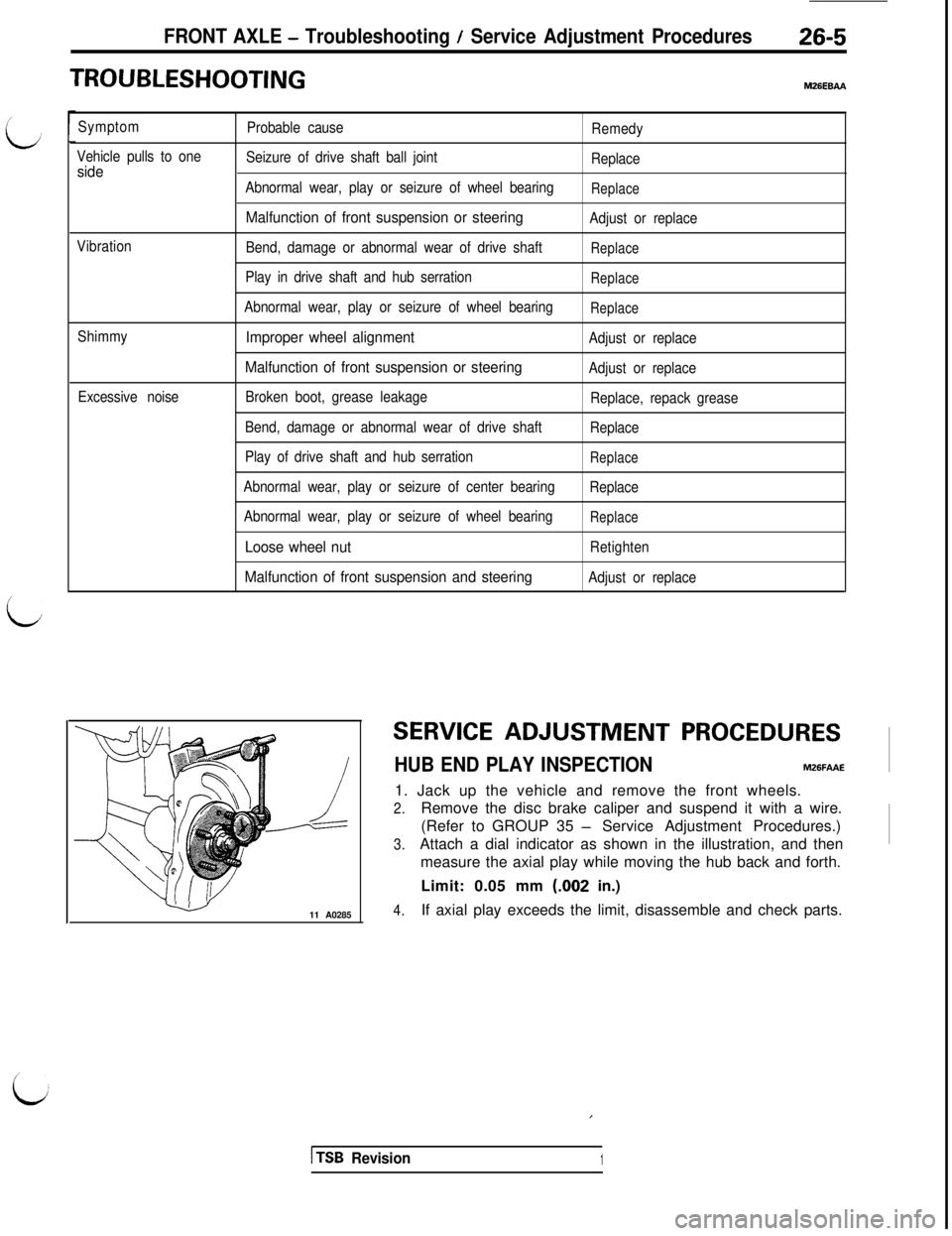

u11 A0285

SERVICE ADJUSTMENT PROCEDURES

HUB END PLAY INSPECTIONM26FAAE1. Jack up the vehicle and remove the front wheels.

2.Remove the disc brake caliper and suspend it with a wire.

(Refer to GROUP 35

- Service Adjustment Procedures.)

3.Attach a dial indicator as shown in the illustration, and then

measure the axial play while moving the hub back and forth.

Limit: 0.05 mm (.002 in.)

4.If axial play exceeds the limit, disassemble and check parts.

,

1 TSB Revision1

i

Page 622 of 1146

27-26

REAR AXLE

SERVICE POINTS OF INSTALLATION

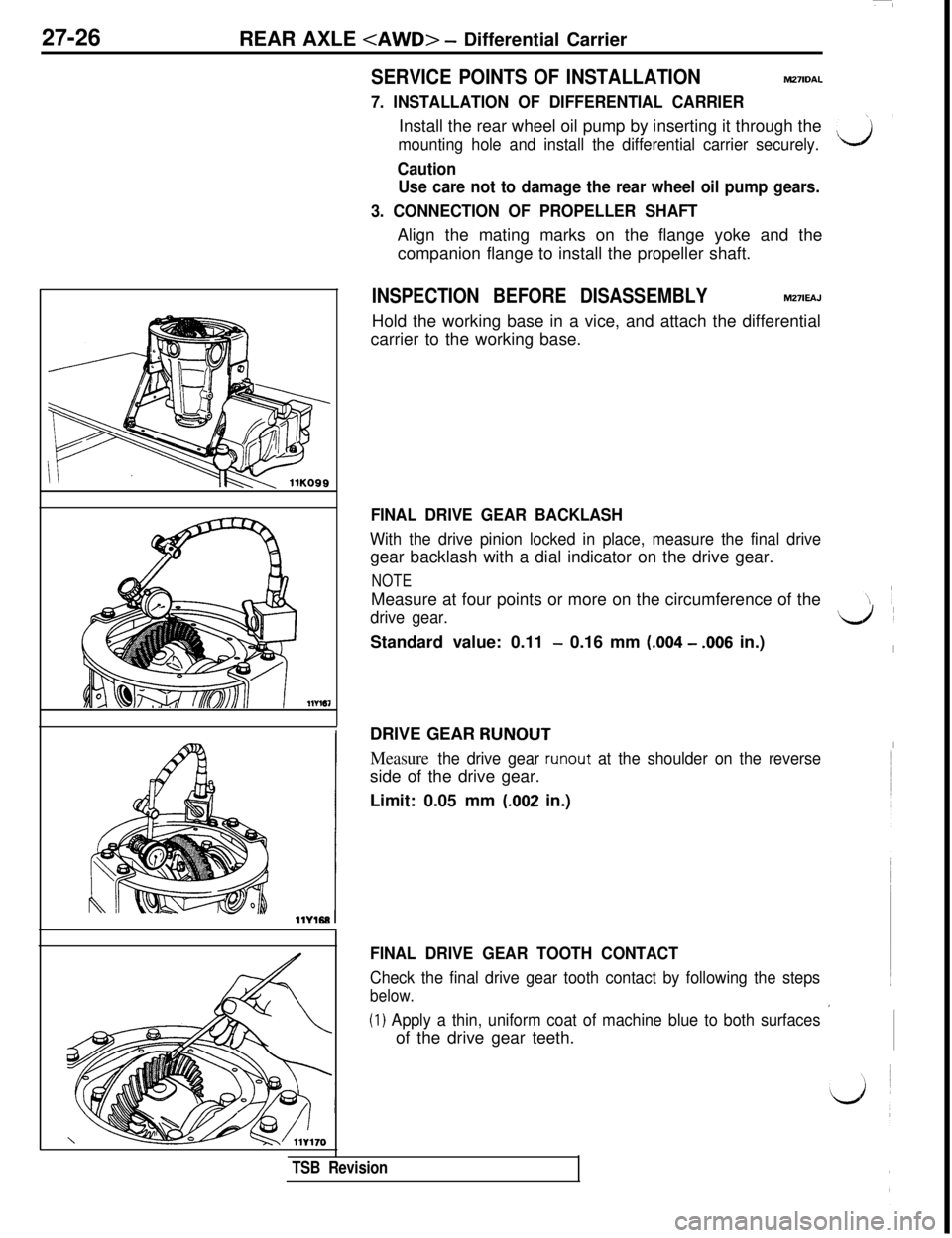

7. INSTALLATION OF DIFFERENTIAL CARRIERm27lDAL

Install the rear wheel oil pump by inserting it through the

mounting hole and install the differential carrier securely.\yiIlYl61

Caution

Use care not to damage the rear wheel oil pump gears.

3. CONNECTION OF PROPELLER SHAFTAlign the mating marks on the flange yoke and the

companion flange to install the propeller shaft.

INSPECTION BEFORE DISASSEMBLYM27lEAJHold the working base in a vice, and attach the differential

carrier to the working base.

FINAL DRIVE GEAR BACKLASH

With the drive pinion locked in place, measure the final drivegear backlash with a dial indicator on the drive gear.

NOTEMeasure at four points or more on the circumference of the

drive gear.d’Standard value: 0.11

- 0.16 mm (.004 - .006 in.)IDRIVE GEAR

RUNOUTI

Measure the drive gear runout at the shoulder on the reverseside of the drive gear.

Limit: 0.05 mm

(.002 in.)

FINAL DRIVE GEAR TOOTH CONTACT

Check the final drive gear tooth contact by following the steps

below.

(1) Apply a thin, uniform coat of machine blue to both surfaces ’of the drive gear teeth.

TSB Revision