Assembly MITSUBISHI 3000GT 1995 2.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1995, Model line: 3000GT, Model: MITSUBISHI 3000GT 1995 2.GPages: 738, PDF Size: 35.06 MB

Page 375 of 738

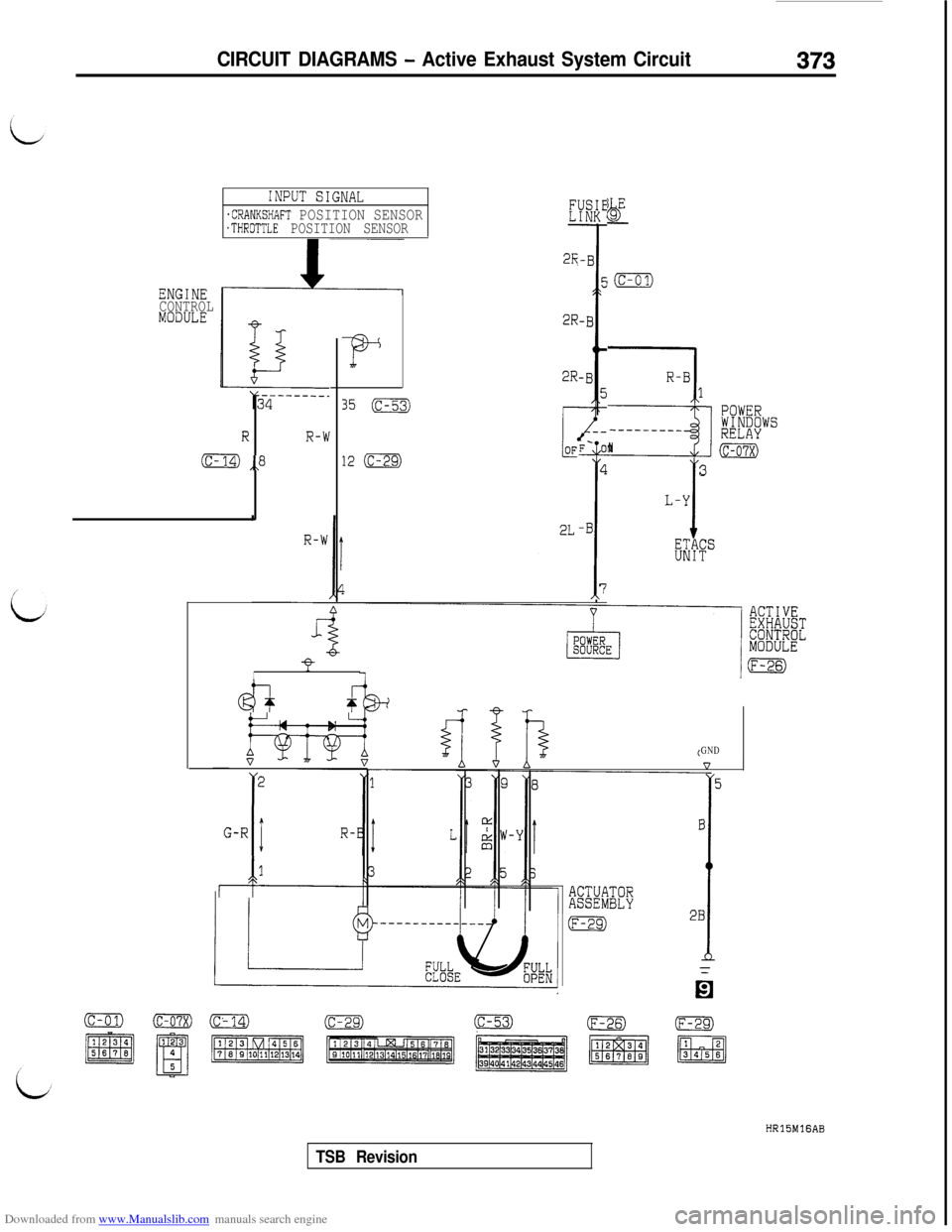

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Active Exhaust System Circuit373

ENGINE

CONTROL

MODULE

INPUT SIGNAL

.CRANKSHAFT POSITION SENSOR.THROTTLE POSITION SENSOR

RR-W

(c- ,,8

F

35 (c-53)

12 (c-29)

2R

2R

2R

I

@I-+ f

2

G-R

IIR-B

r-k-

F- 01

4

T

-B

7

bjgE-

‘(c-01)

R-B1

3

POWERWINDOWS-____---_RELAYN(c-07x)

3

L-Y

KkF"

GND

5

ACTUATORASSEMBLY

lEgI

B

i

2B

(c-01)o(c’14)m(c-53)(F-26)HRlSMlGAB

TSB Revision

Page 418 of 738

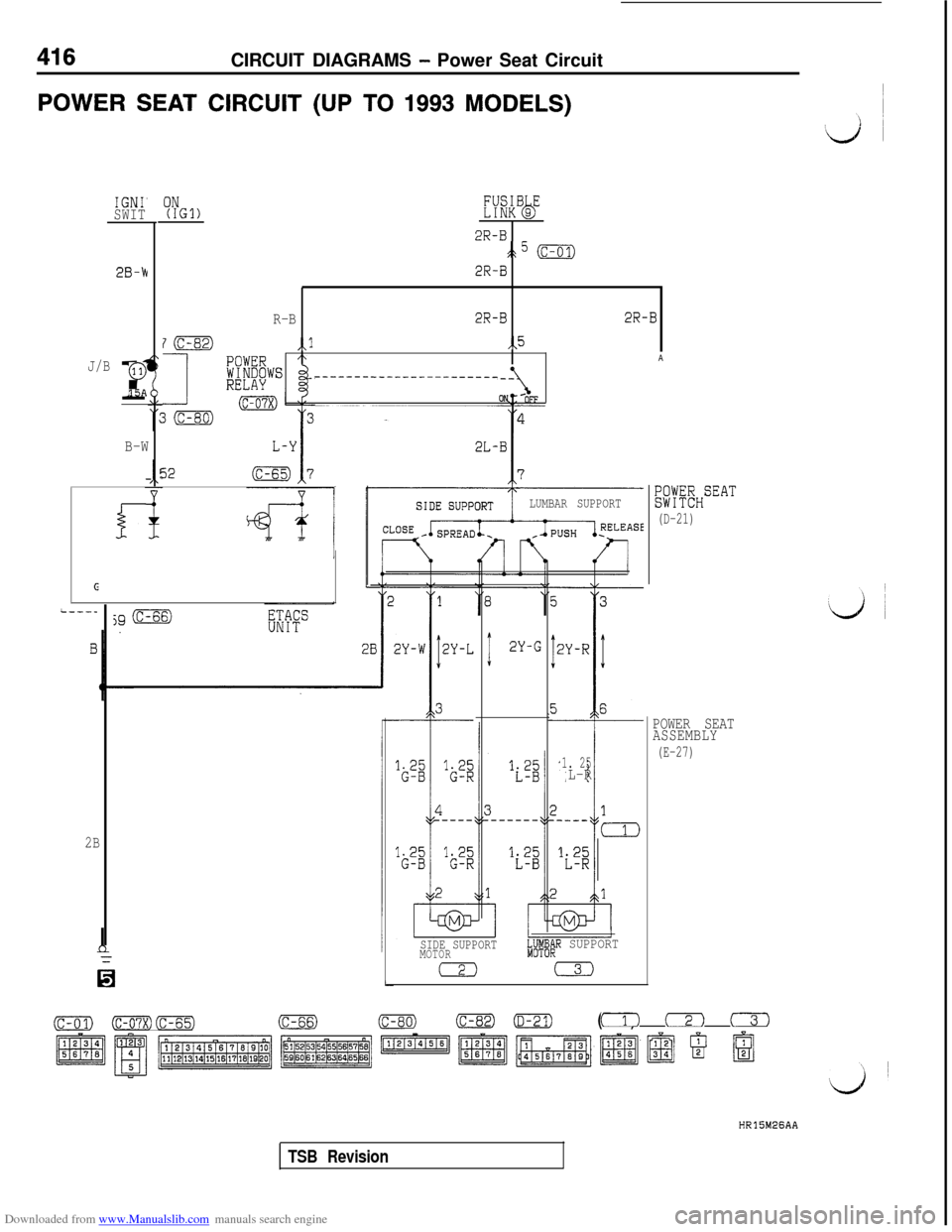

Downloaded from www.Manualslib.com manuals search engine 416CIRCUIT DIAGRAMS - Power Seat Circuit

POWER SEAT CIRCUIT (UP TO 1993 MODELS)

IGNI'SWIT

2B-k

J/Br

0

15A

B-W

i-

G

2B

ON(IGl)E%B9Eb

2R-B

:k5 (c-01)

2R-B

R-B2R-B2R-B

7m,,l,,5

IA

-------__-___----------

32

LUMBAR SUPPORT

jg (c-66)

0

I2Y-G

1. 25L-R

SIDE SUPPORTMOTOR"MJJyi;R SUPPORT

aCD#;$HSEAT

(D-21)

POWER SEAT

ASSEMBLY

(E-27)

(c-01)(rn(c-65)(c-66)(c-80)(C-82)0(E-27)(1) cz-) c-T-1

~1~~~1~~~~~9 @

HR15M26AA

TSB Revision

Page 420 of 738

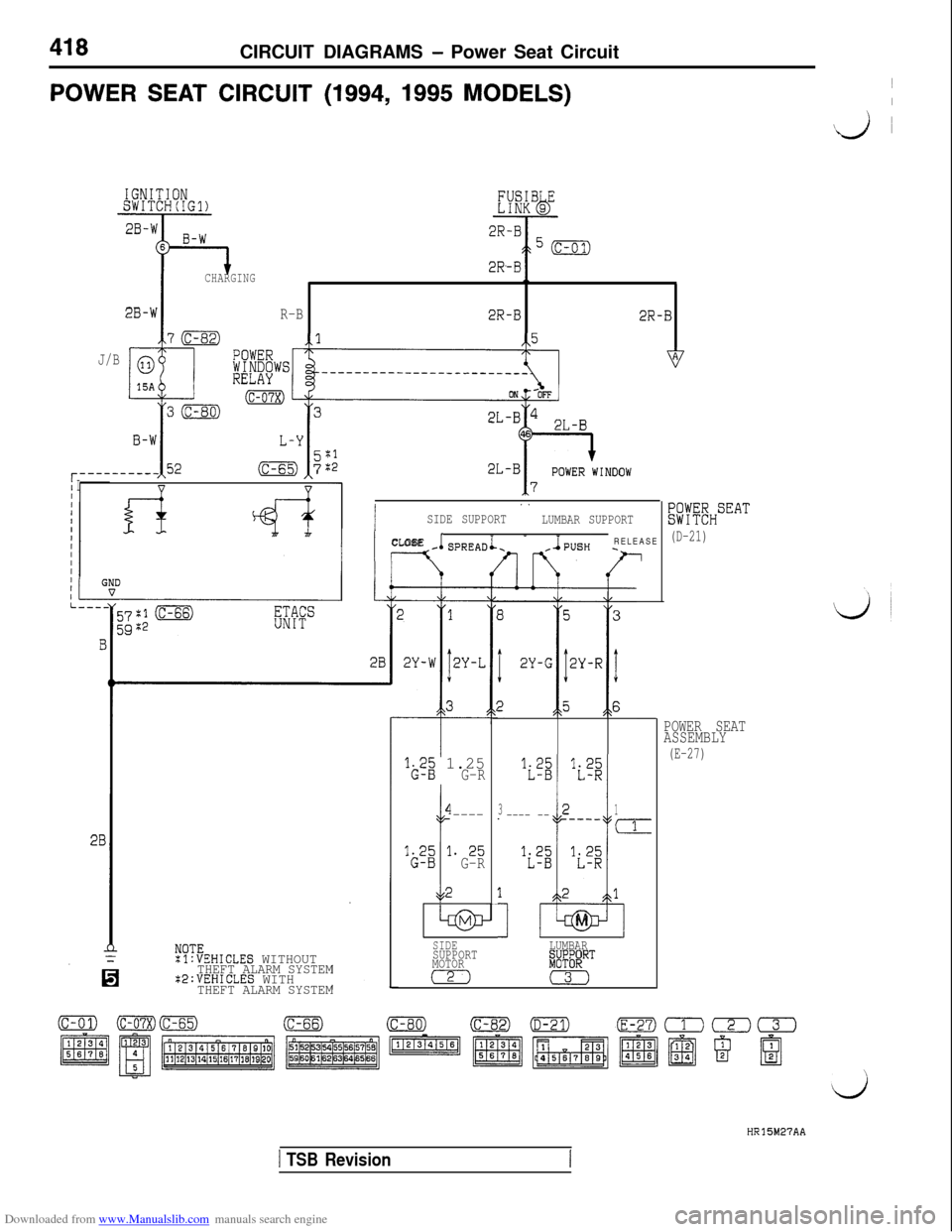

Downloaded from www.Manualslib.com manuals search engine 418CIRCUIT DIAGRAMS - Power Seat Circuit

POWER SEAT CIRCUIT (1994, 1995 MODELS)1I

\j i

CHARGING1.

2B-WR-B2R-B2R-B

70,l-5

J/B

r----/ Ivv

B

28

NOTE

0

:l:VEHICLES WITHOUTTHEFT ALARM SYSTEM:2:VEHICLES WITHTHEFT ALARM SYSTEM

I

. .

SIDE SUPPORT

LUMBAR SUPPORT

I IL’CLOSE- SPREADiRELEASE--h

‘G.2; 1.25G-R

I

4----

‘22 l. 25G-R

li’Z ‘i’g

32

I-i

1_ ---- ---___m

‘i’s ‘is;

121

u!z!lM

SIDELUMBAR

SUPPORT

MOTOR$JF@RT

m0

Kl:fEHSEAT

(D-21)

POWER SEAT

ASSEMBLY

(E-27)

HR15M27AA

1 TSB Revision

Page 422 of 738

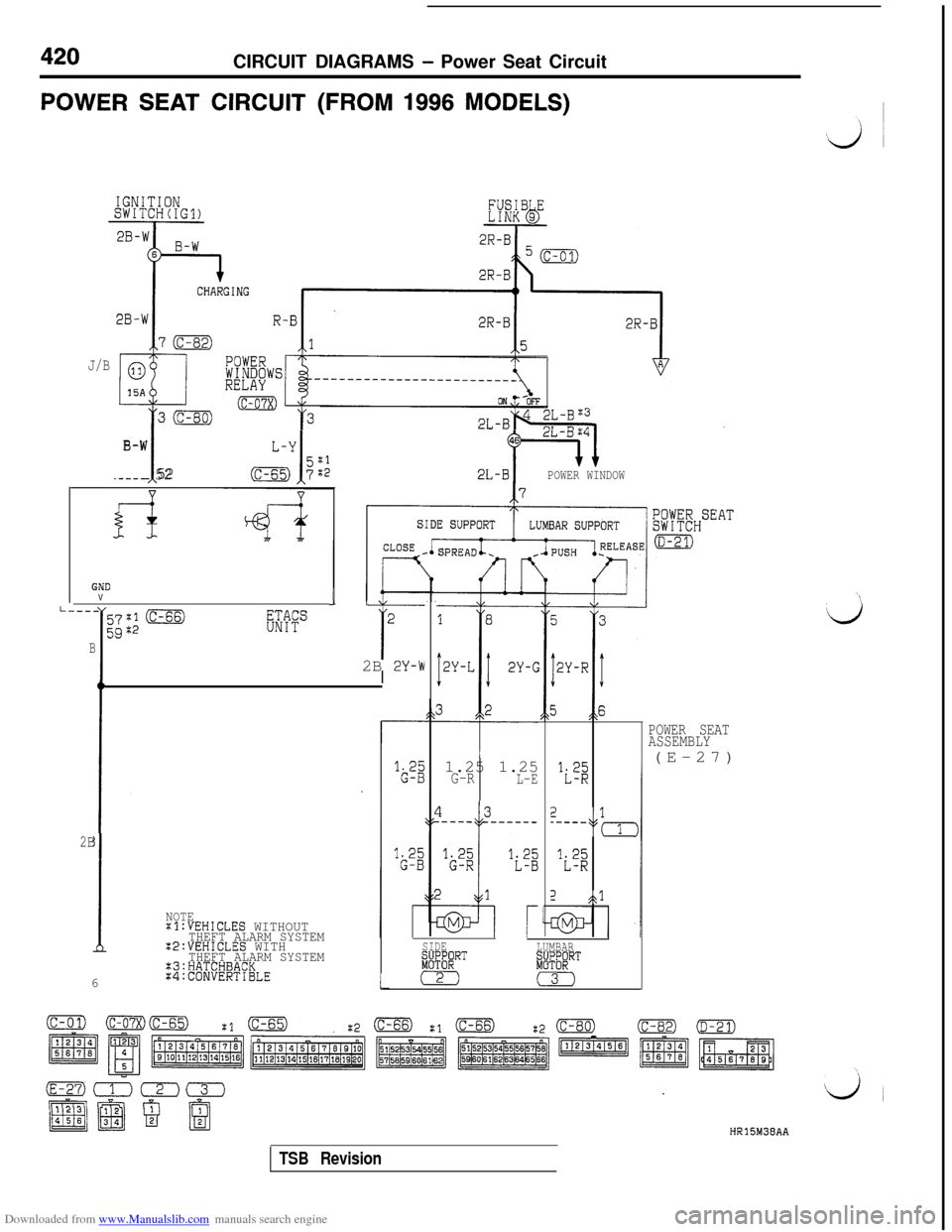

Downloaded from www.Manualslib.com manuals search engine 420

CIRCUIT DIAGRAMS - Power Seat Circuit

POWER SEAT CIRCUIT (FROM 1996 MODELS)

70

015A

t

30

B-W

__--- 52

J/B

- T32L-Bw

I

TV2L-BPOWER WINDOW

GNDV

.,I-----

l

57:10

5Qx2RF"

B

iL

2

t2B 2Y-\NI

'i'$

2--,,1,

'i'2

2$$l

POWER SEAT

ASSEMBLY(E-27)

1.25 1.25

G-RL-E

2B

!

NOTEXl:VEHICLES WITHOUTTHEFT ALARM SYSTEMZ2:VEHICLES WITH6THEFT ALARM SYSTEM:3:HATCHBACKX4:CONVERTIBLE

SIDE

LUMBAR

aRiRT&J;'RT

1'2)0L

HR15M38AA

TSB Revision

Page 429 of 738

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Tension-reducer Type Seat Belt Circuit427OPERATION

L0If the driver fastens the seat belt with the ignition switch placed in the “ON” position, the seat belt

switch in the seat belt buckle is turned “ON” to operate the seat belt solenoid in the retractor.

0This will reduce the seat belt rewinding torqe to minimize a sense of oppression given by the belt.

lOwing to the timer function of the ETACS unit, the seat belt solenoid is kept in operation for 30 seconds

after turning off the ignition switch, with due consideration to elimination of the sudden rise in a senseof oppression caused by the belt immediately after the ignition switch is turned off.

TROUBLESHOOTING HINTS

PhenomenonInspection method

Some of the tension-reducers do not operates.0Check dedicated fuse No. 1 and 19.

0Check the inoperative seat belt switch.

lCheck the inoperative seat belt solenoid.

The tension-reducer does not operate with the ignition

0Check the ignition switch input signal.

switch placed in the ON position.

0 Check the ignition switch. (Refer to GROUP

M-Ignition switch.)

The tension-reducer is in operation immediately after the0Check the door switch input signal.

ignition switch is turned off, but it does not stop operationlCheck the door switch. (Refer to GROUP 42-Door

even if the door is opened within 30 seconds from theAssembly.)

turning-off the ignition switch.

TSB Revision

I

Page 458 of 738

Downloaded from www.Manualslib.com manuals search engine 16-12ENGINE ELECTRICAL - Charging System

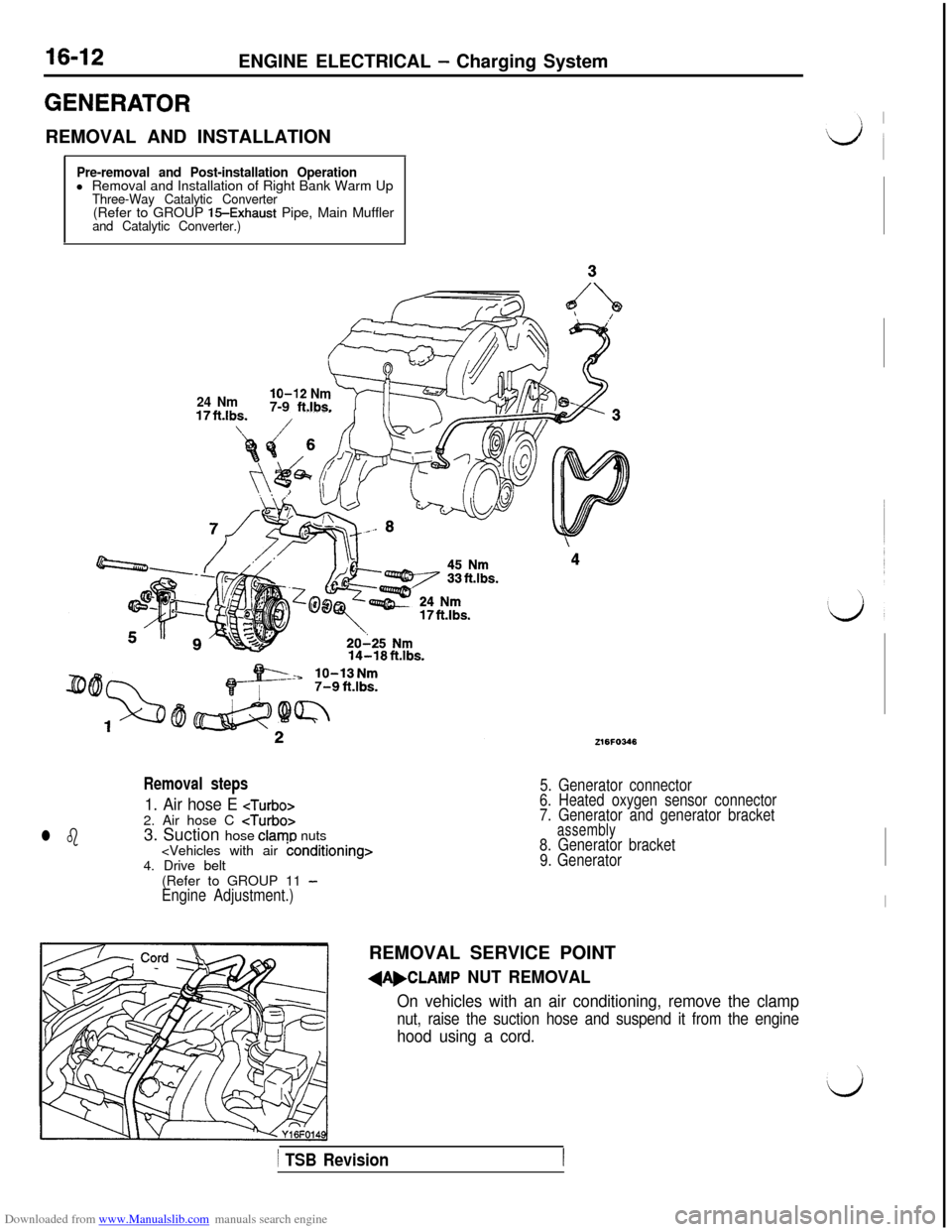

GENERATORREMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Removal and Installation of Right Bank Warm Up

Three-Way Catalytic Converter(Refer to GROUP 15-Exhaust Pipe, Main Mufflerand Catalytic Converter.)14-18ft.lbs.

l b

Removal steps

1. Air hose E

3. Suction hose clamo nuts

(Refer to GROUP 11

-Engine Adjustment.)

216FO346

5. Generator connector

6. Heated oxygen sensor connector

7. Generator and generator bracket

assembly8. Generator bracket

9. Generator

lo-12 Nm7-9 ft.lbs.24 NmREMOVAL SERVICE POINT

dAbCLAMP NUT REMOVAL

On vehicles with an air conditioning, remove the clamp

nut, raise the suction hose and suspend it from the engine

hood using a cord.

1 TSB Revision

Page 459 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-13DISASSEMBLY AND REASSEMBLY

i(Up to 1995 models)23I

LDisassembly steps

4A,1. Generator pulley.A+ 2. Rotor assembly3.Rear bearing4.Bearing retainer5.Front bearing6.Front bracket4B,7.Stator8. Insulator

9. Plate

10. Reaulator and brush holder

11.

Slinlger12. Rectifier13. Brush14. Brush spring

15. Rear bracket

4B,27EL0104

1 TSB Revision

Page 460 of 738

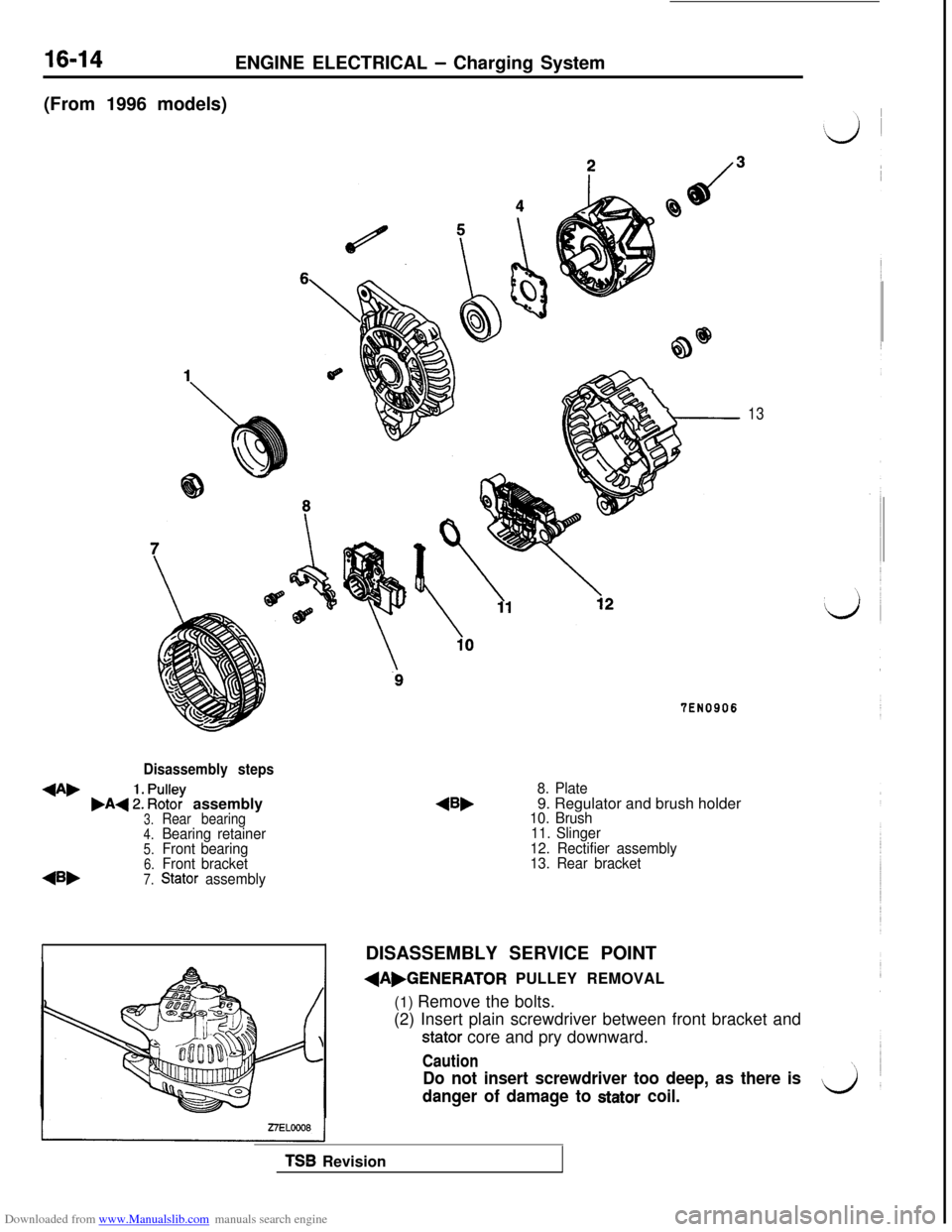

Downloaded from www.Manualslib.com manuals search engine 16-14ENGINE ELECTRICAL - Charging System

(From 1996 models)

Disassembly steps

+A,,A+ :: ~%? assembly3.Rear bearing4.Bearing retainer5.Front bearing6.Front bracket

45,7.Stator assembly

13

TEN0906

8. Plate9. Regulator and brush holder

10. Brush

11. Slinger

12. Rectifier assembly

13. Rear bracket

IDISASSEMBLY SERVICE POINT

dAbGENERATOR PULLEY REMOVAL

(1) Remove the bolts.

(2) Insert plain screwdriver between front bracket and

stator core and pry downward.

Caution

Do not insert screwdriver too deep, as there is

danger of damage to

stator coil.

TSB Revision

Page 461 of 738

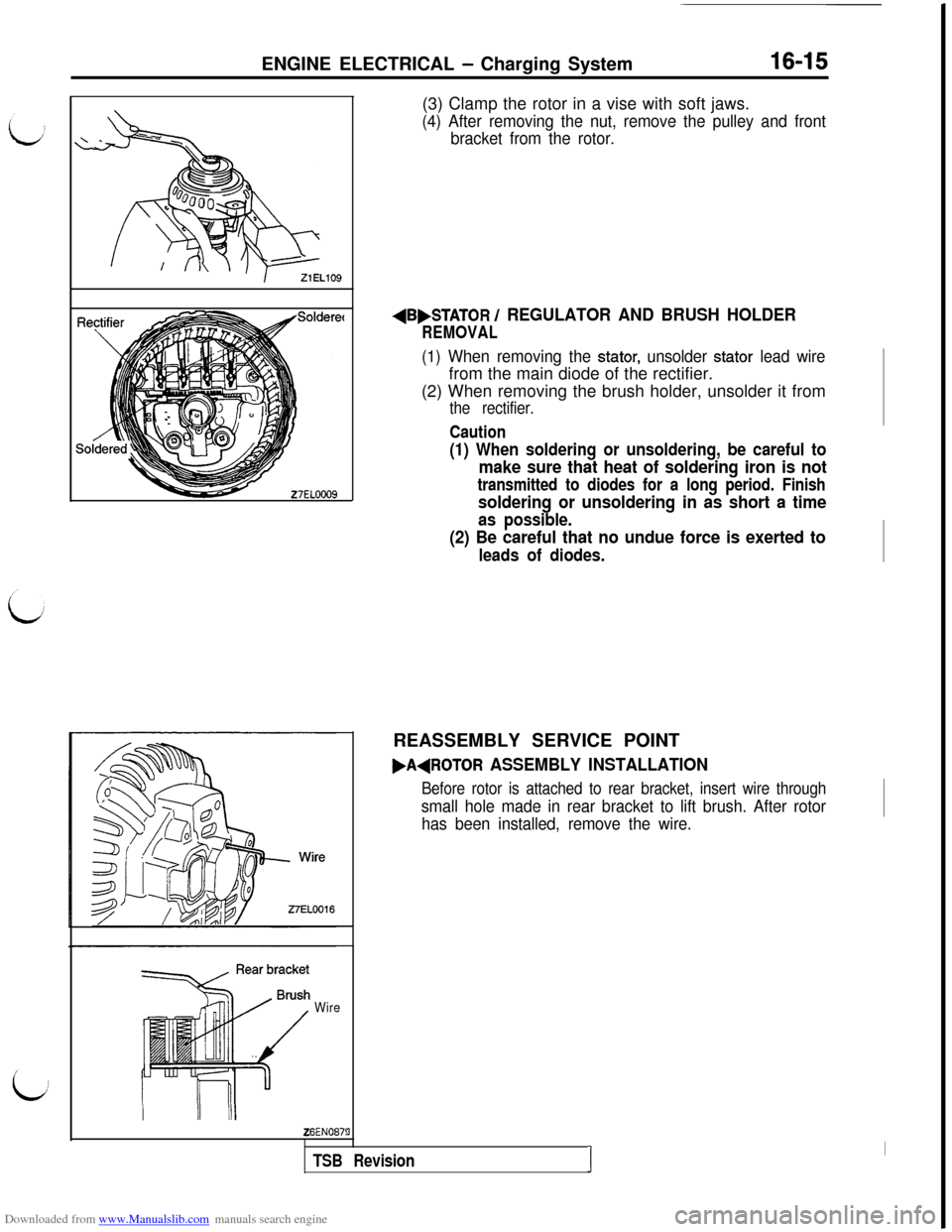

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-15

WireZ6EN087!(3) Clamp the rotor in a vise with soft jaws.

(4) After removing the nut, remove the pulley and front

bracket from the rotor.

AB,STATOR / REGULATOR AND BRUSH HOLDER

REMOVAL

(1) When removing the stator, unsolder stator lead wirefrom the main diode of the rectifier.

(2) When removing the brush holder, unsolder it from

the rectifier.

Caution

(1) When soldering or unsoldering, be careful to

make sure that heat of soldering iron is not

transmitted to diodes for a long period. Finish

soldering or unsoldering in as short a time

as possible.

(2) Be careful that no undue force is exerted to

leads of diodes.REASSEMBLY SERVICE POINT

FAdROTOR ASSEMBLY INSTALLATION

Before rotor is attached to rear bracket, insert wire through

small hole made in rear bracket to lift brush. After rotor

has been installed, remove the wire.

3

TSB RevisionI

I

Page 462 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System

h\Z3ELOlO

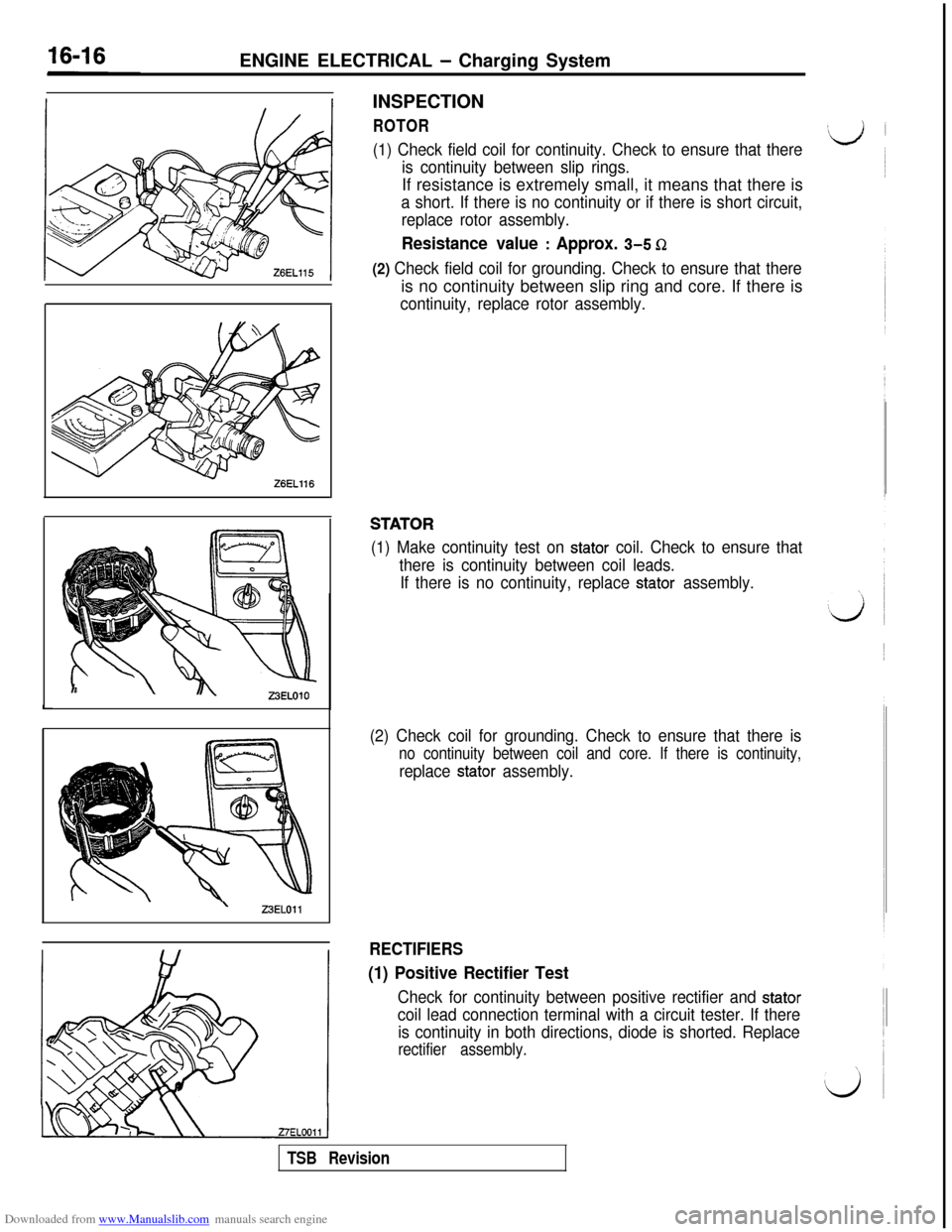

\23ELOllINSPECTION

ROTOR

(1) Check field coil for continuity. Check to ensure that there

is continuity between slip rings.If resistance is extremely small, it means that there is

a short. If there is no continuity or if there is short circuit,

replace rotor assembly.

Resistance value : Approx. 3-5 Q

(2) Check field coil for grounding. Check to ensure that thereis no continuity between slip ring and core. If there is

continuity, replace rotor assembly.

STATOR

(1) Make continuity test on stator coil. Check to ensure that

there is continuity between coil leads.

If there is no continuity, replace

stator assembly.

(2) Check coil for grounding. Check to ensure that there is

no continuity between coil and core. If there is continuity,

replace stator assembly.

RECTIFIERS

(1) Positive Rectifier Test

Check for continuity between positive rectifier and stator

coil lead connection terminal with a circuit tester. If there

is continuity in both directions, diode is shorted. Replace

rectifier assembly.

TSB Revision