Assembly MITSUBISHI 3000GT 1995 2.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1995, Model line: 3000GT, Model: MITSUBISHI 3000GT 1995 2.GPages: 738, PDF Size: 35.06 MB

Page 463 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-17

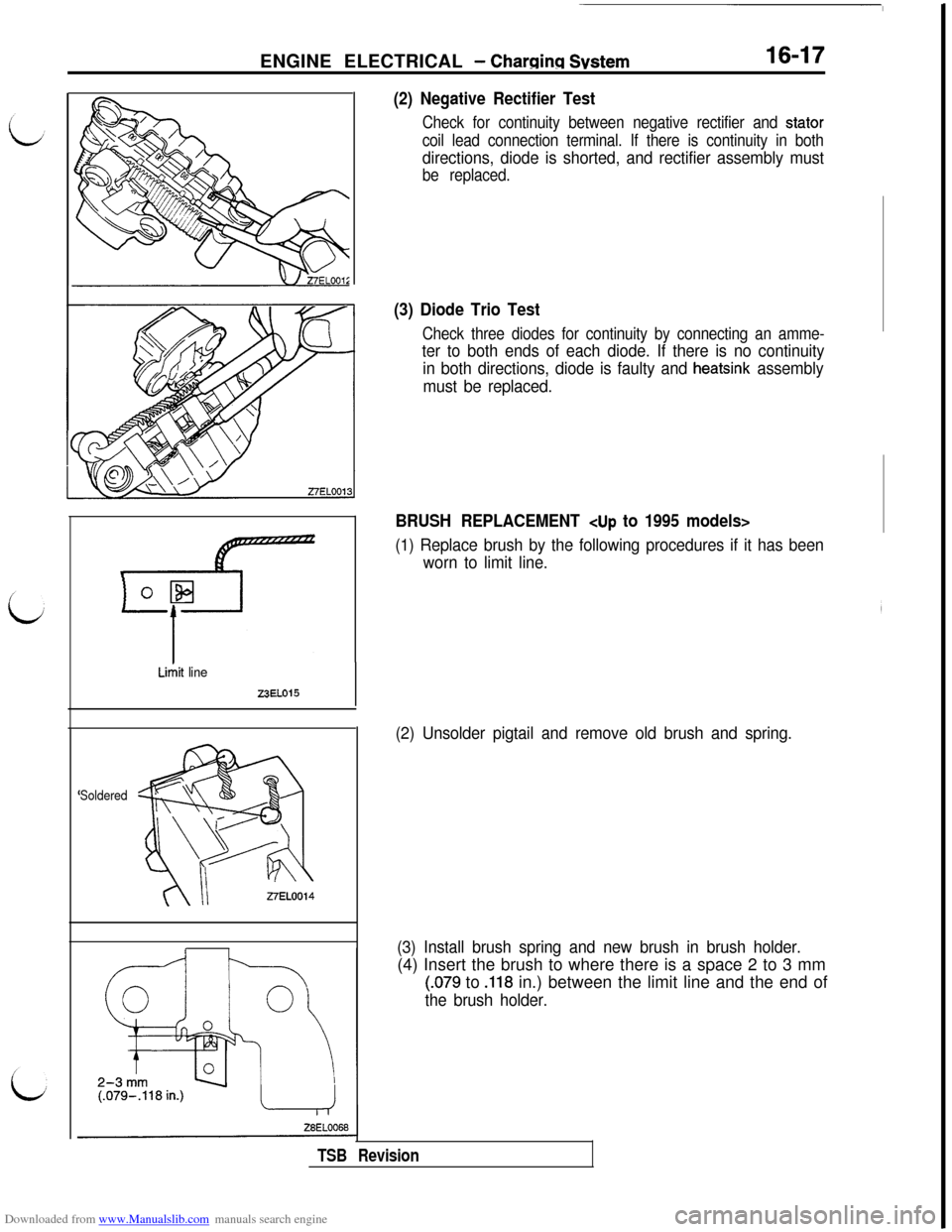

Limit line

WELO

,Soldered

27EL0014

(2) Negative Rectifier Test

Check for continuity between negative rectifier and stator

coil lead connection terminal. If there is continuity in both

directions, diode is shorted, and rectifier assembly must

be replaced.

(3) Diode Trio Test

Check three diodes for continuity by connecting an amme-

ter to both ends of each diode. If there is no continuity

in both directions, diode is faulty and

heatsink assembly

must be replaced.

BRUSH REPLACEMENT

(1) Replace brush by the following procedures if it has been

worn to limit line.

(2) Unsolder pigtail and remove old brush and spring.

(3) Install brush spring and new brush in brush holder.(4) Insert the brush to where there is a space 2 to 3 mm

(.079 to .118 in.) between the limit line and the end of

the brush holder.

TSB Revision

Page 472 of 738

Downloaded from www.Manualslib.com manuals search engine 16-26ENGINE ELECTRICAL - Starting System

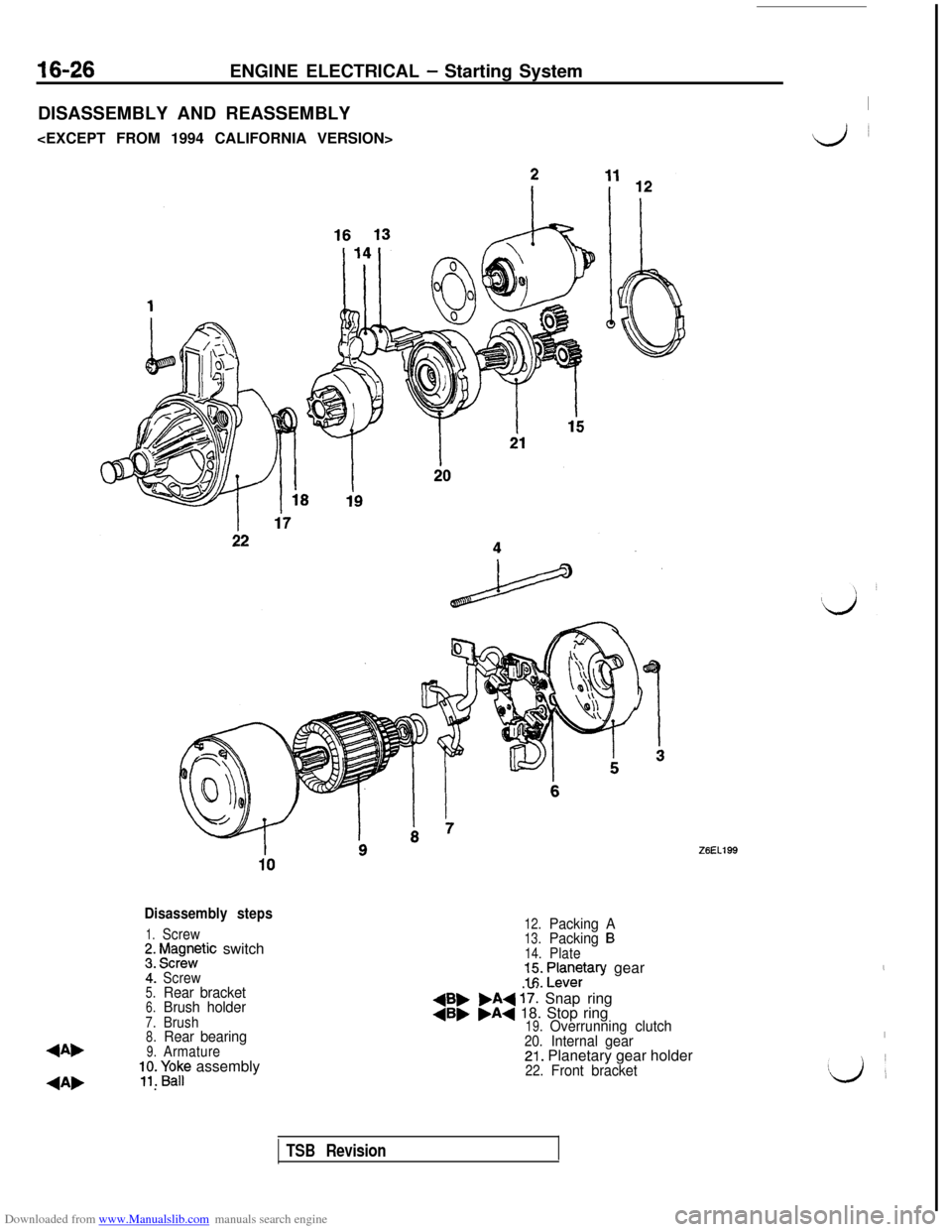

DISASSEMBLY AND REASSEMBLY

I

Lj~

Disassembly steps

1.Screw;. f$gnntic switch

4:Screw5.Rear bracket6.Brush holder7.Brush8.Rear bearing

4Ab9.Armature;;. paF assembly

4A, .

12.Packing A13.Packing B14.Plate=I:. ;an$ary gear

+B, .A+ 17: Snap ring4B, .A+ 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracket

,

I!Lj

’

TSB Revision

Page 473 of 738

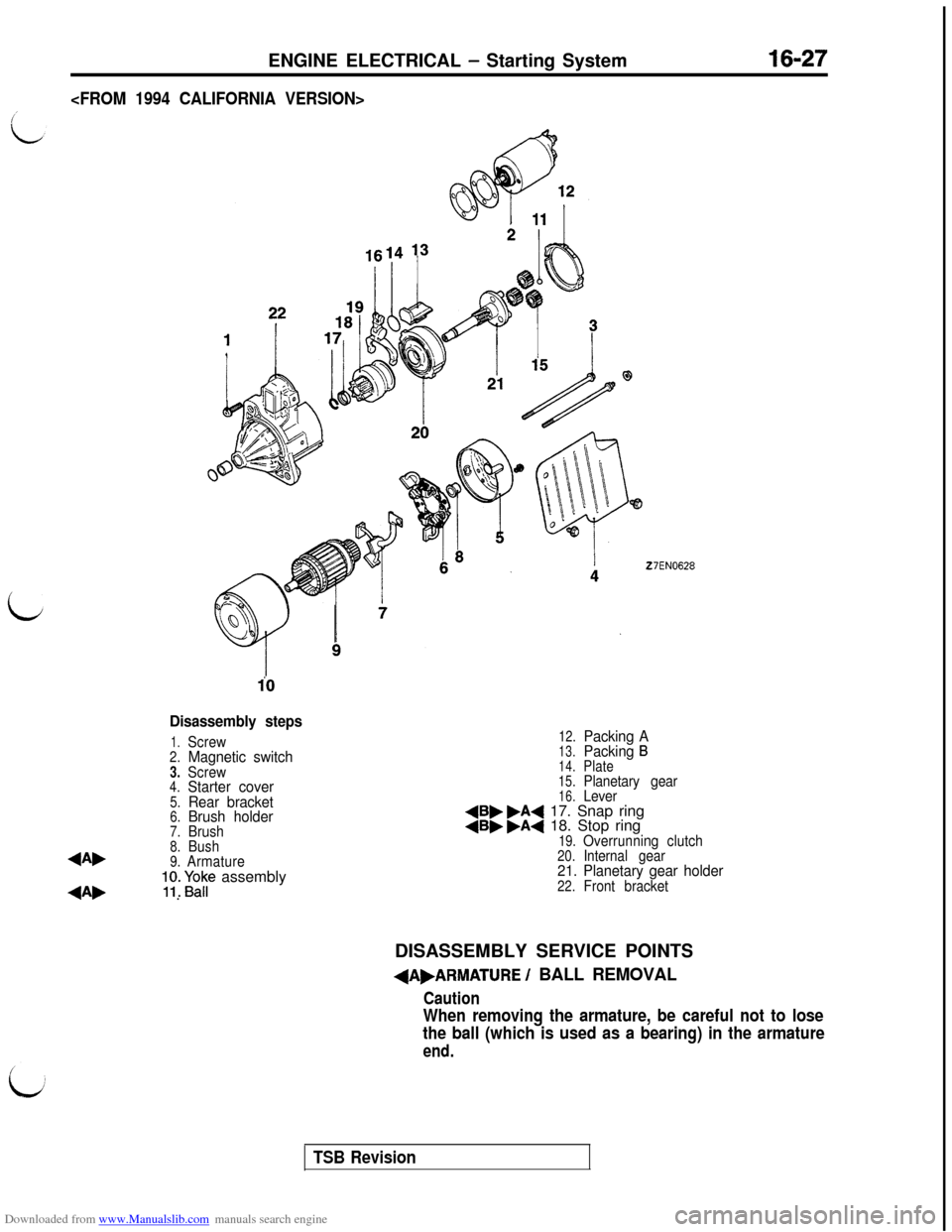

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-27

27EN0628

1'0

Disassembly steps

1.Screw2.Magnetic switch3.Screw4.Starter cover5.Rear bracket6.Brush holder7.Brush8.Bush4A,9.Armature;y. Fap assembly

4A, .

12.Packing A13.Packing B

14.Plate

15.Planetary gear16.Lever4B, .A4 17. Snap ring4B, .A4 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracketDISASSEMBLY SERVICE POINTS

+A,ARMATURE / BALL REMOVAL

Caution

When removing the armature, be careful not to lose

the ball (which is used as a bearing) in the armature

end.

TSB Revision

Page 474 of 738

Downloaded from www.Manualslib.com manuals search engine 16-28ENGINE ELECTRICAL - Starting System

Stop ringZ6EL0097

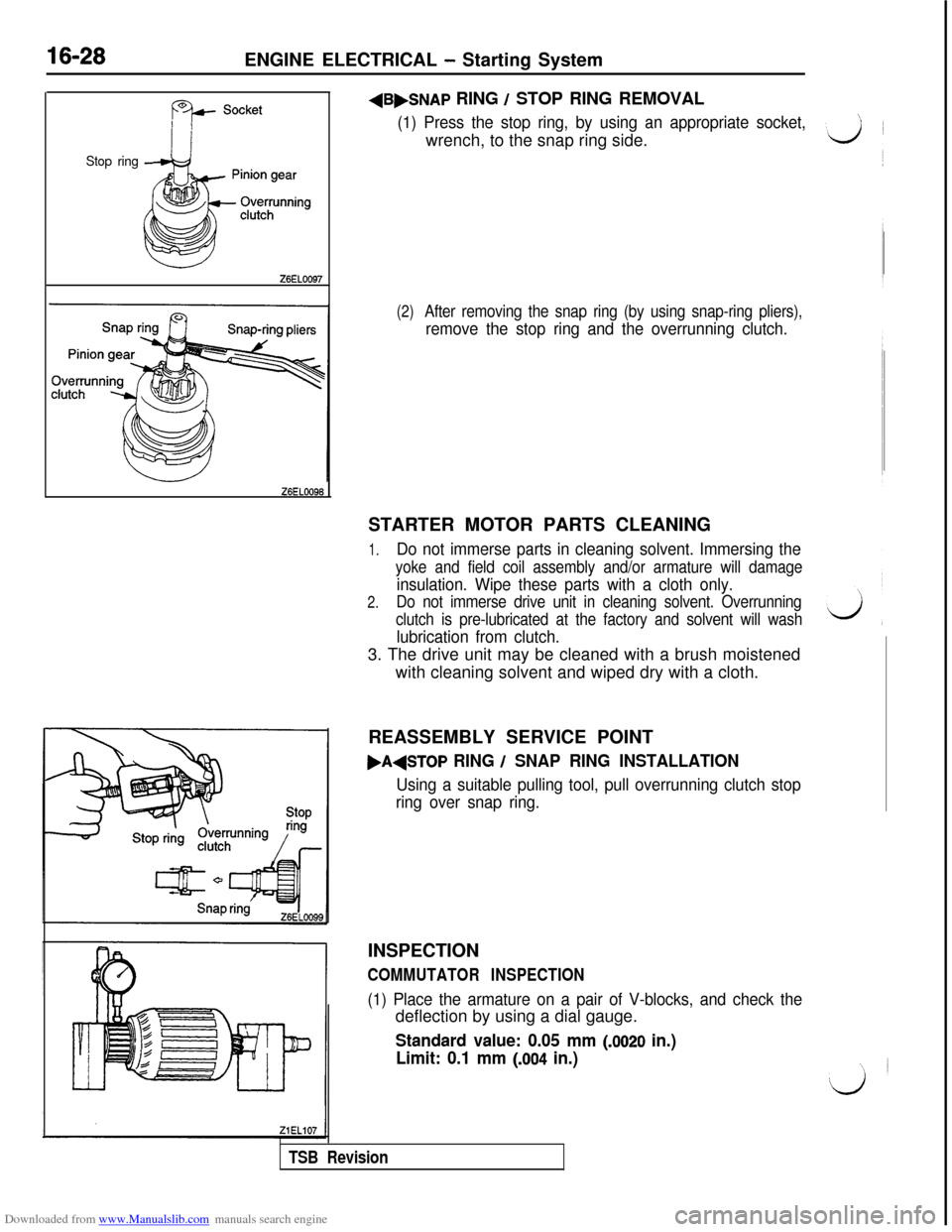

Z6ELOO96+B,SNAP

RING / STOP RING REMOVAL

(1) Press the stop ring, by using an appropriate socket,wrench, to the snap ring side.

(2)After removing the snap ring (by using snap-ring pliers),

remove the stop ring and the overrunning clutch.STARTER MOTOR PARTS CLEANING

1.Do not immerse parts in cleaning solvent. Immersing the

yoke and field coil assembly and/or armature will damage

insulation. Wipe these parts with a cloth only.

2.Do not immerse drive unit in cleaning solvent. Overrunning

clutch is pre-lubricated at the factory and solvent will wash

lubrication from clutch.3. The drive unit may be cleaned with a brush moistened

with cleaning solvent and wiped dry with a cloth.

REASSEMBLY SERVICE POINT

,A+TOP RING / SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop

ring over snap ring.INSPECTION

COMMUTATOR INSPECTION

(1) Place the armature on a pair of V-blocks, and check thedeflection by using a dial gauge.

Standard value: 0.05 mm (JO20 in.)

Limit: 0.1 mm

(.004 in.)

TSB Revision

Page 475 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-29

ZiELllS

UndercutI

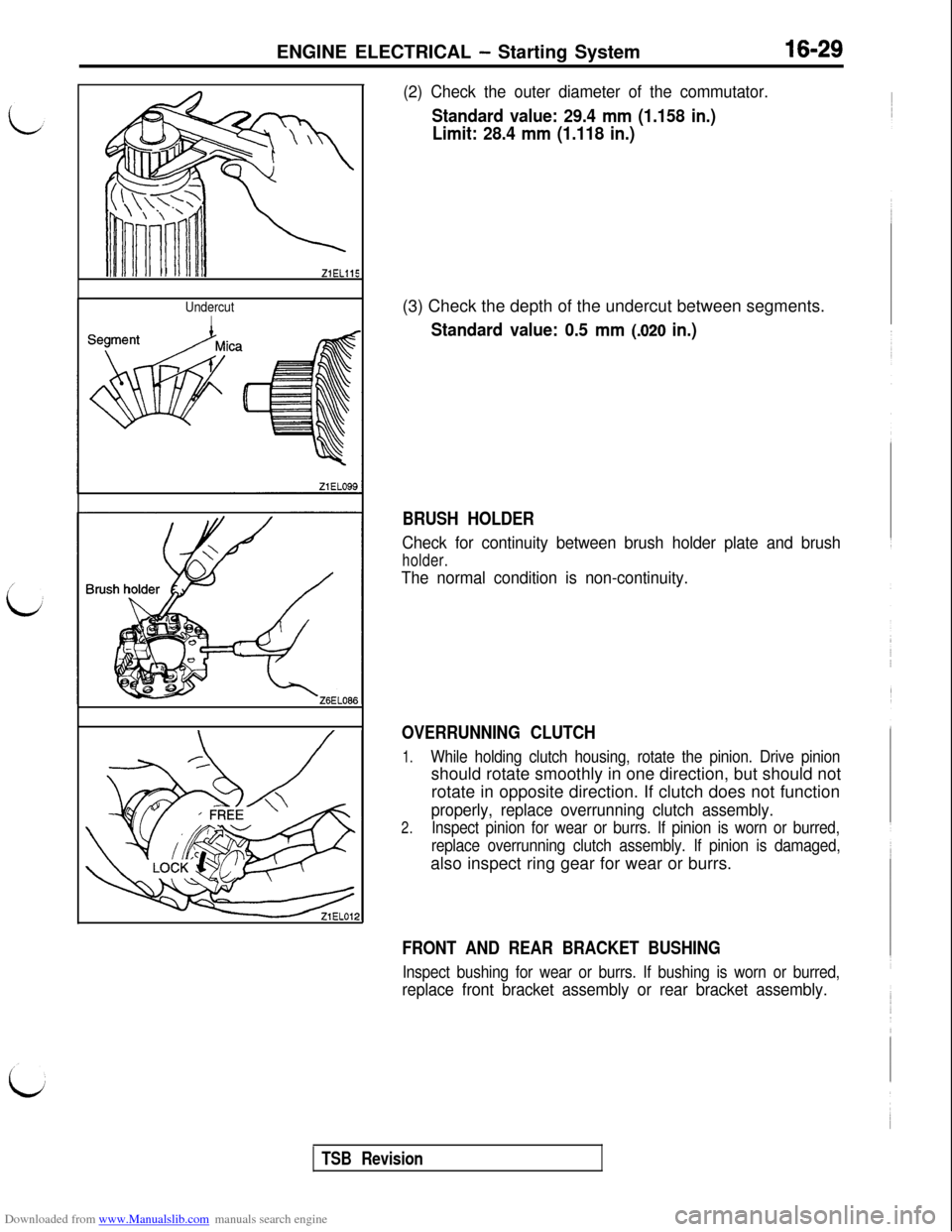

(2) Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.158 in.)

Limit: 28.4 mm (1.118 in.)(3) Check the depth of the undercut between segments.

Standard value: 0.5 mm (.020 in.)

BRUSH HOLDER

Check for continuity between brush holder plate and brush

holder.

The normal condition is non-continuity.

OVERRUNNING CLUTCH

1.While holding clutch housing, rotate the pinion. Drive pinionshould rotate smoothly in one direction, but should not

rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2.Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

TSB Revision

Page 502 of 738

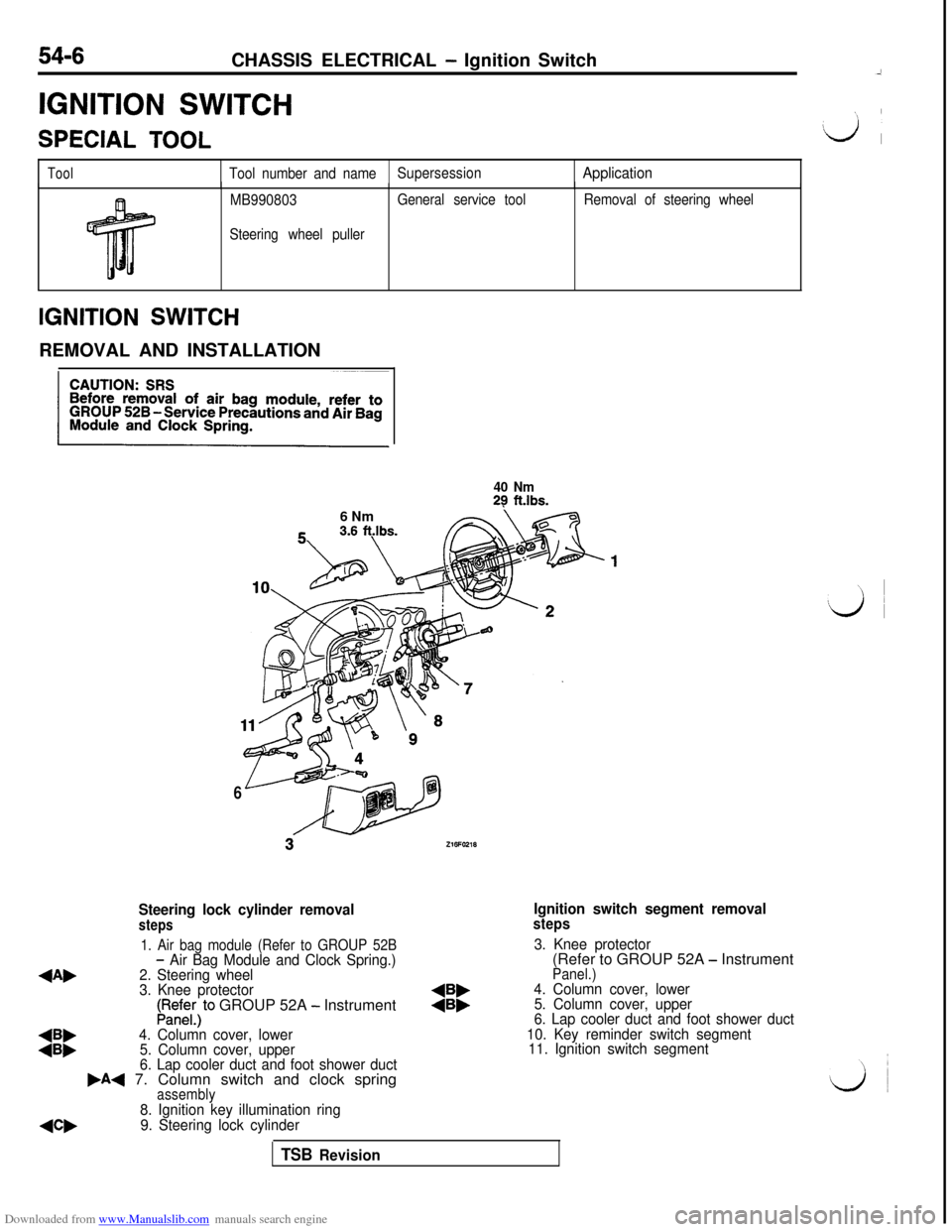

Downloaded from www.Manualslib.com manuals search engine 54-6CHASSIS ELECTRICAL - Ignition Switch

IGNITION SWITCHSPECIAL

TOOL

ToolTool number and nameSupersessionApplication

MB990803

Steering wheel pullerGeneral service toolRemoval of steering wheel

IGNITION SWITCHREMOVAL AND INSTALLATION

40 Nm29 ft.lbs.6 Nm

6

Steering lock cylinder removalsteps

Ignition switch segment removalsteps

1. Air bag module (Refer to GROUP 52B

4Ab

- Air Bag Module and Clock Spring.)3. Knee protector

2. Steering wheel(Refer to GROUP 52A - Instrument

3. Knee protector

Panel.)

LRedE;)to GROUP 52A - Instrument:i:4. Column cover, lower

5. Column cover, upper

:::4. Column cover, lower6. Lap cooler duct and foot shower duct

5. Column cover, upper10. Key reminder switch segment

6. Lap cooler duct and foot shower duct11. Ignition switch segment

,A+ 7. Column switch and clock springassembly

NW

8. Ignition key illumination ring

9. Steering lock cylinder

TSB Revision

Page 503 of 738

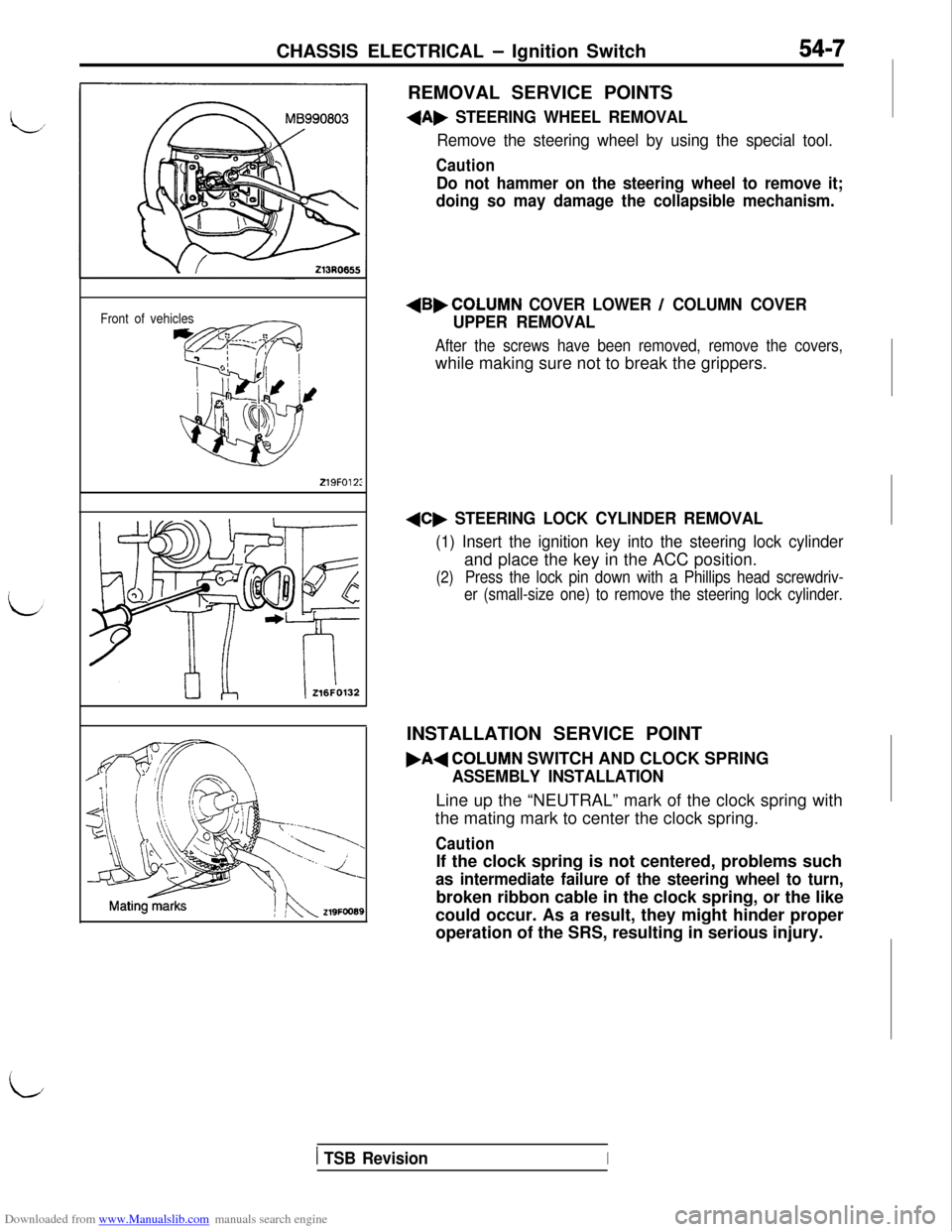

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Ignition Switch54-7REMOVAL SERVICE POINTS

+A, STEERING WHEEL REMOVAL

Remove the steering wheel by using the special tool.

Caution

Do not hammer on the steering wheel to remove it;

doing so may damage the collapsible mechanism.

Front of vehicles

219FO12:

+B,COLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

+C, STEERING LOCK CYLINDER REMOVAL

(1) Insert the ignition key into the steering lock cylinderand place the key in the ACC position.

(2)Press the lock pin down with a Phillips head screwdriv-

er (small-size one) to remove the steering lock cylinder.INSTALLATION SERVICE POINT

.A+COLUMN SWITCH AND CLOCK SPRING

ASSEMBLY INSTALLATIONLine up the “NEUTRAL” mark of the clock spring with

the mating mark to center the clock spring.

CautionIf the clock spring is not centered, problems such

as intermediate failure of the steering wheel to turn,broken ribbon cable in the clock spring, or the like

could occur. As a result, they might hinder proper

operation of the SRS, resulting in serious injury.

iI

1 TSB RevisionI

Page 514 of 738

Downloaded from www.Manualslib.com manuals search engine 54-18CHASSIS ELECTRICAL - Meters and Gauges

OPERATION

When the ignition key is at the “ON” position,the fuel gauge is activated.

l

When there is much fuel, the unit’s resistanceis small and the current flowing in the circuit

is great, so the gauge’s indicator indicates inthe “F” area.

l When there is little fuel, the unit’s resistance

is high and the current flowing in the circuit

is small, so the gauge’s indicator indicates inthe

“E” area.

lWhen the ignition key is at the “ON” position,

the engine coolant temperature gauge is acti-

vated.l

When the engine coolant temperature is high,

the unit’s resistance is low and there is a greatflow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l

When the engine coolant temperature is low,

the unit’s resistance is high and there is a smallflow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

vehicle speed, and vehicle-speed signals areinput to systems (the MFI system, etc.) that

regulate according to the vehicle speed.

TROUBLESHOOTING HINTS

1.The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel pumpand gauge unit assembly; the ‘F” side is

indicated when terminal (5) is then

grounded.l Check the fuel gauge.

2.The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1)The “l-l” side is indicated when the connector

of the engine coolant temperature gauge

unit is disconnected and then grounded.l

Check the engine coolant temperature

gauge unit.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.l Check the reed switch (mechanical

speedometer type)l Check the speed sensor (electrical

speedometer type)

coil pressure gauge>l

When the ignition key is at the “ON” position,

the oil pressure gauge is activated.

lWhen oil pressure is high, the internal contacts

of the gauge unit are kept closed for a longerperiod of time. This causes more current to

flow in the circuit, and the gauge pointer swings

to the high pressure side.

lWhen oil pressure is low, the internal contactsof the gauge unit open in a shorter period of

time. Therefore, there is less current flowing

in the circuit and the gauge pointer swings to

the low pressure side.

lWhen the ignition key is set to the “ON” position,the gauge indicator will be at

“0”.l

When the engine is started, the indicator will

move from

“0” to the minus (-) side, and then,as the boost level increases, it will move to

the plus

(+) side.

position, the voltage gauge operates and indi-

cates a battery voltage of approximately 12 V.l

When the engine is started, the voltage gauge

indicates a battery voltage of 12 to 16 V, indicat-ing that the battery is on charge.

4. The oil pressure gauge doesn’t function, or

shows the incorrect indication.

(1)The “H” side is indicated when the connectorof the oil pressure gauge unit is discon-

nected and then grounded.l Check the oil pressure gauge unit.

5.The meter illumination light does not illuminate.

(1) The tail lights illuminate.l Check the rheostat.

6. The voltage gauge doesn’t function, or shows

the incorrect indication.l Check the voltage gauge.

TSB Revision

Page 528 of 738

Downloaded from www.Manualslib.com manuals search engine 54-32CHASSIS ELECTRICAL - Meters and Gauges

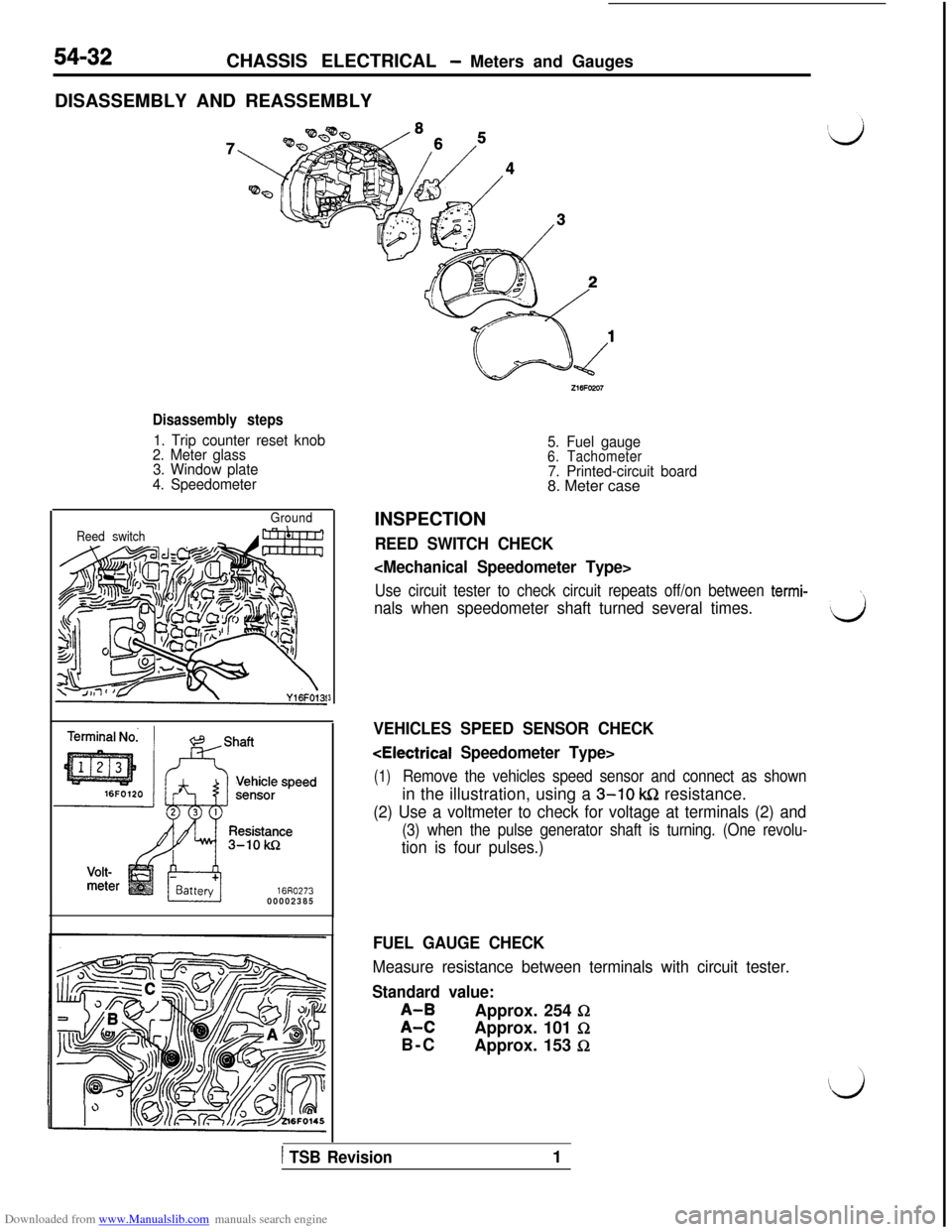

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Trip counter reset knob

2. Meter glass

3. Window plate

4. Speedometer

Ground

Reed switch

16R027300002385

3

5. Fuel gauge6. Tachometer7. Printed-circuit board8. Meter case

INSPECTION

REED SWITCH CHECK

Use circuit tester to check circuit repeats off/on between termi-\

nals when speedometer shaft turned several times.d

VEHICLES SPEED SENSOR CHECK

(1)Remove the vehicles speed sensor and connect as shownin the illustration, using a

3-10 k&2 resistance.

(2) Use a voltmeter to check for voltage at terminals (2) and

(3) when the pulse generator shaft is turning. (One revolu-

tion is four pulses.)

FUEL GAUGE CHECK

Measure resistance between terminals with circuit tester.

Standard value:

;I;Approx. 254 0Approx. 101

I2B-C

Approx. 153

fi

1 TSB Revision1

Page 529 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges

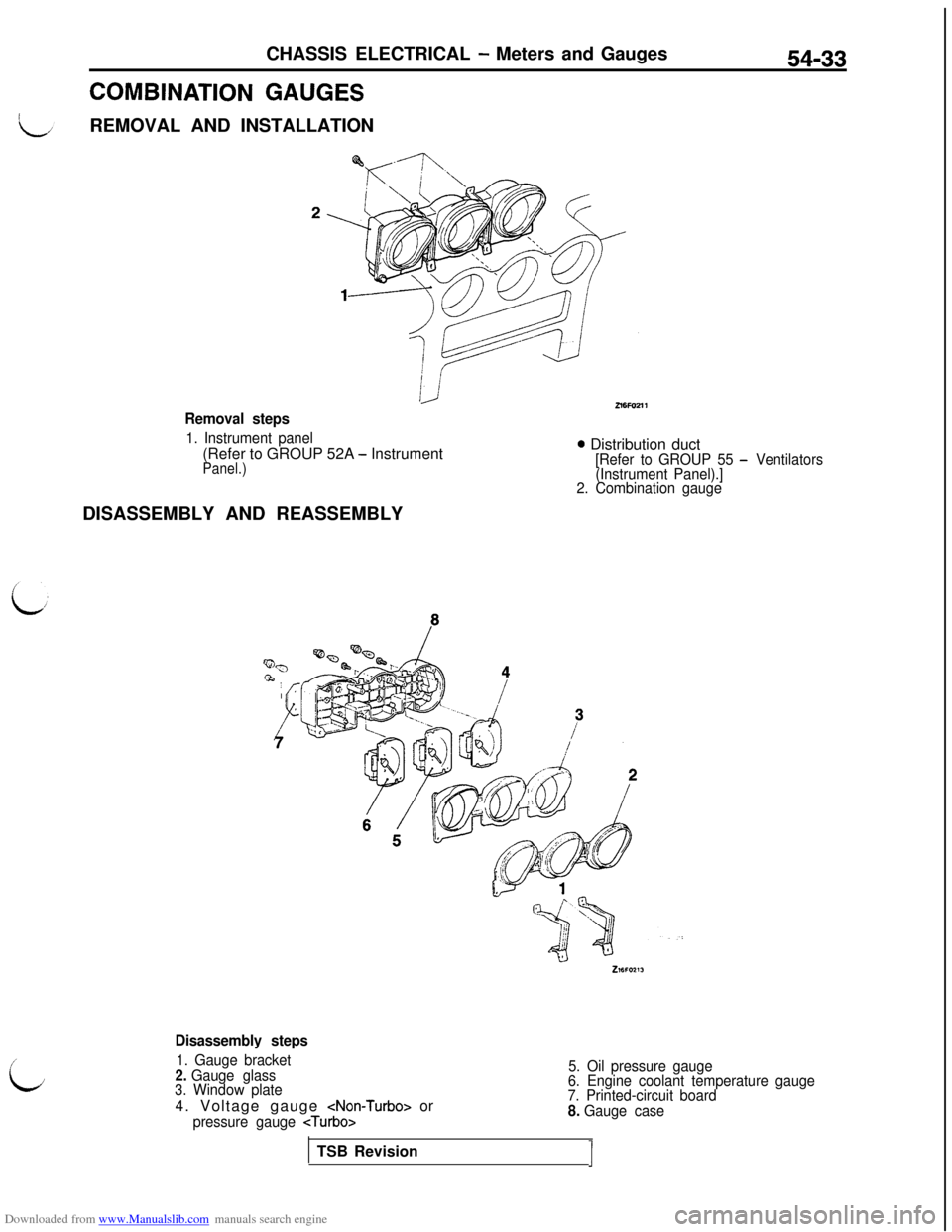

COMBINATION GAUGESREMOVAL AND INSTALLATION

54-33

Removal steps

1. Instrument panel(Refer to GROUP 52A

- InstrumentPanel.)

0 Distribution duct[Refer to GROUP 55 - Ventilators

(Instrument Panel).]

2. Combination gaugeDISASSEMBLY AND REASSEMBLY

i;

Disassembly steps

1. Gauge bracket2. Gauge glass

3. Window plate4. Voltage gauge

pressure gauge

5. Oil pressure gauge

6. Engine coolant temperature gauge

7. Printed-circuit board

8. Gauge caseTSB Revision

J