lock MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 155 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-155

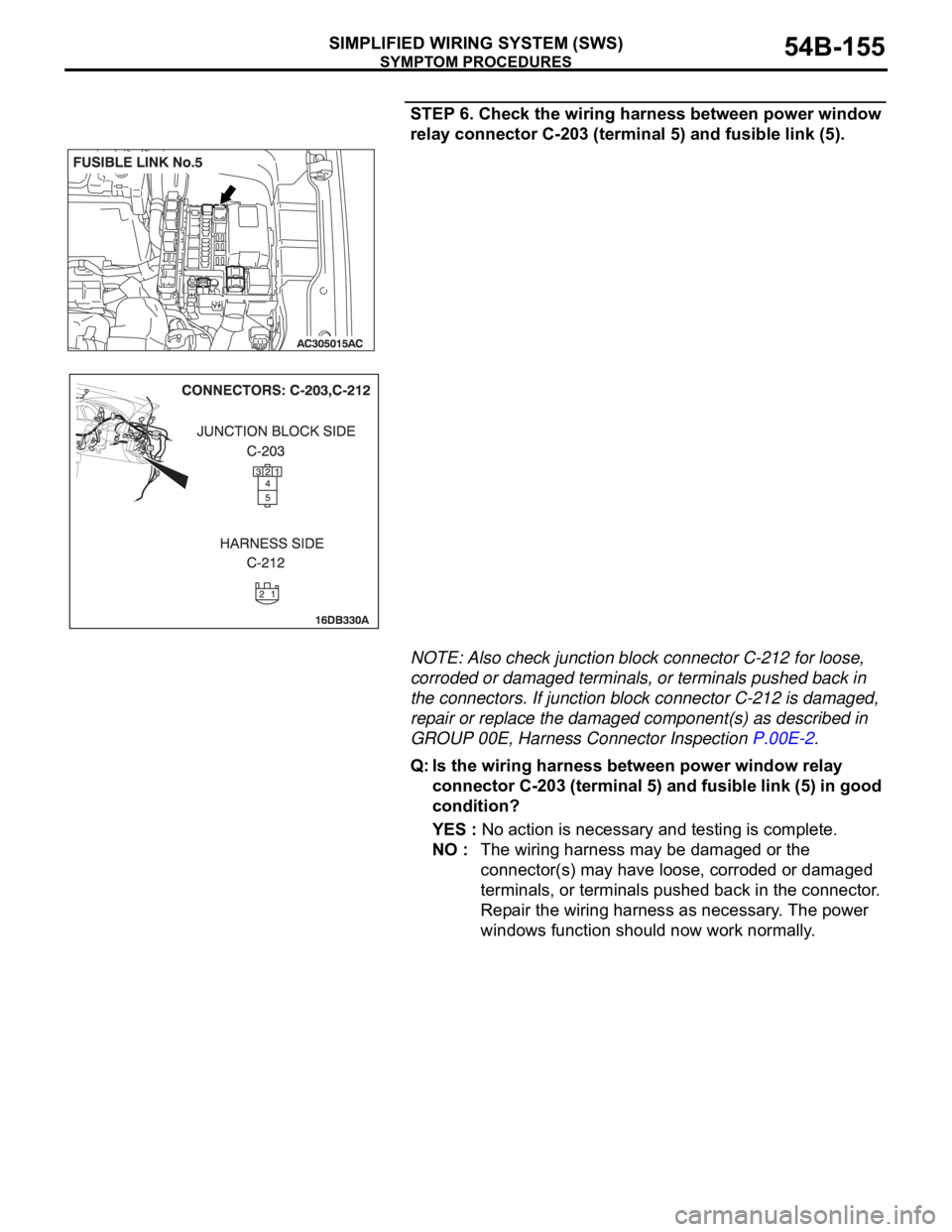

STEP 6. Check the wiring harness between power window

relay connector C-203 (terminal 5) and fusible link (5).

NOTE: Also check junction block connector C-212 for loose,

corroded or damaged terminals, or terminals pushed back in

the connectors. If junction block connector C-212 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 5) and fusible link (5) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 156 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-156

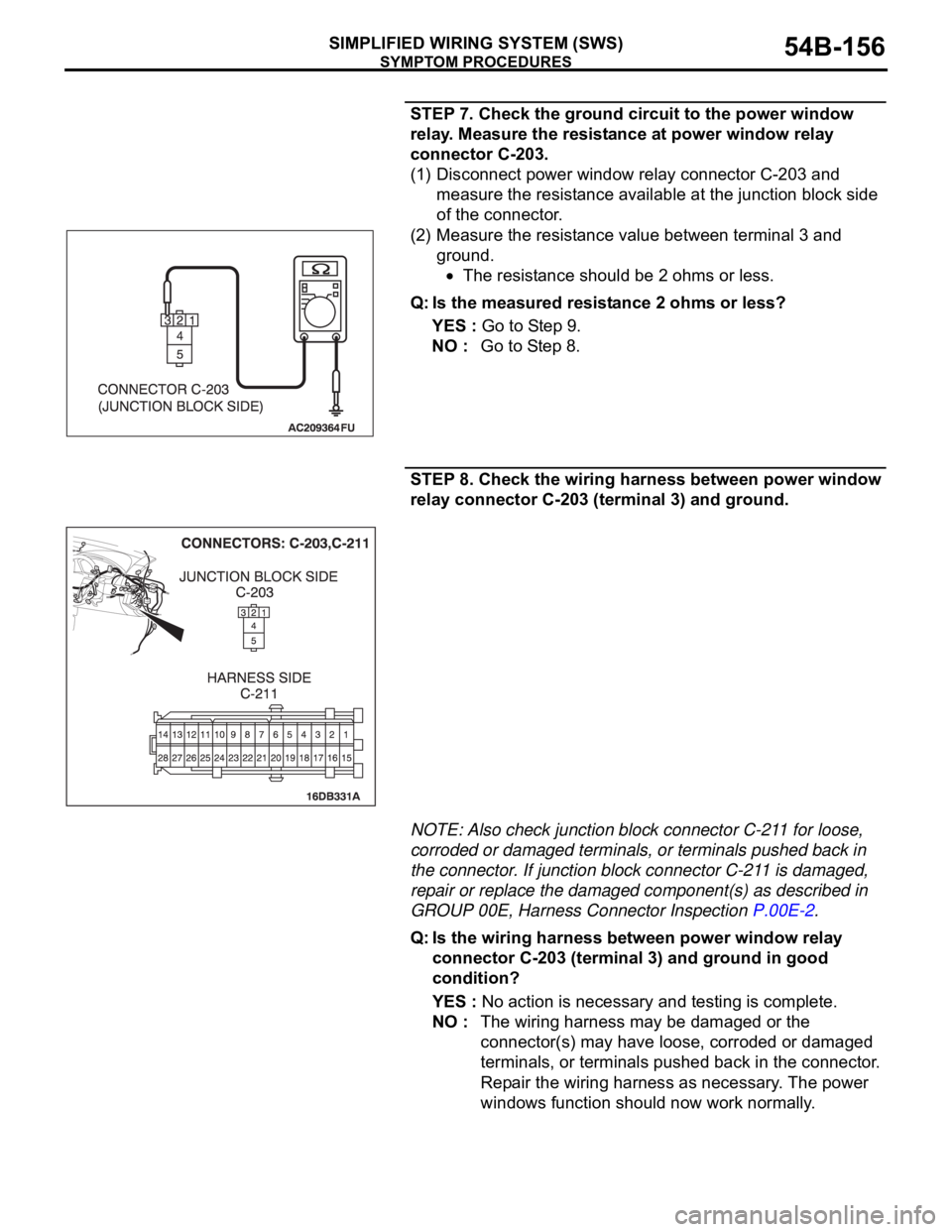

STEP 7. Check the ground circuit to the power window

relay. Measure the resistance at power window relay

connector C-203.

(1) Disconnect power window relay connector C-203 and

measure the resistance available at the junction block side

of the connector.

(2) Measure the resistance value between terminal 3 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 9.

NO : Go to Step 8.

STEP 8. Check the wiring harness between power window

relay connector C-203 (terminal 3) and ground.

NOTE: Also check junction block connector C-211 for loose,

corroded or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-211 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 3) and ground in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 160 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-160

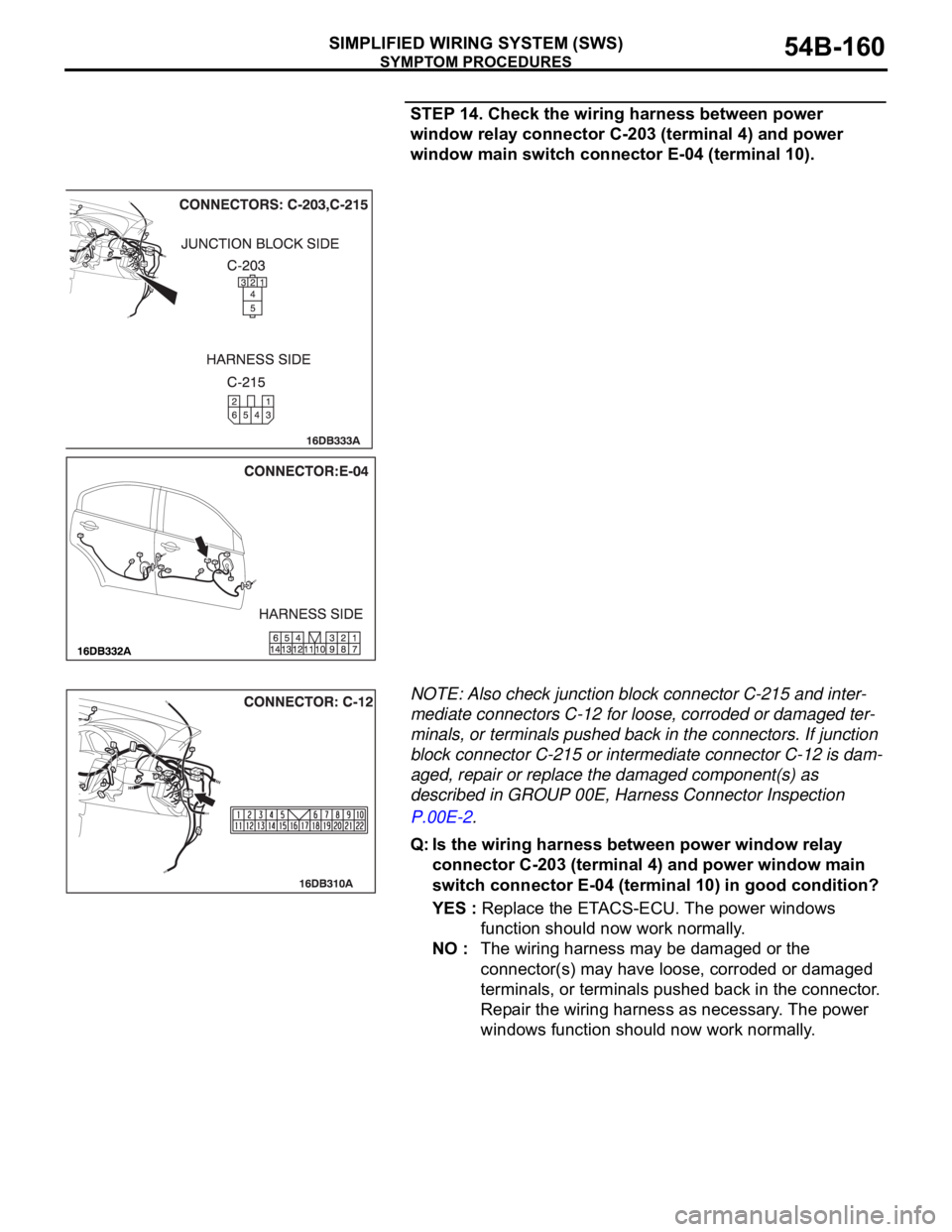

STEP 14. Check the wiring harness between power

window relay connector C-203 (terminal 4) and power

window main switch connector E-04 (terminal 10).

NOTE: Also check junction block connector C-215 and inter-

mediate connectors C-12 for loose, corroded or damaged ter-

minals, or terminals pushed back in the connectors. If junction

block connector C-215 or intermediate connector C-12 is dam-

aged, repair or replace the damaged component(s) as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and power window main

switch connector E-04 (terminal 10) in good condition?

YES : Replace the ETACS-ECU. The power windows

function should now work normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 162 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-162

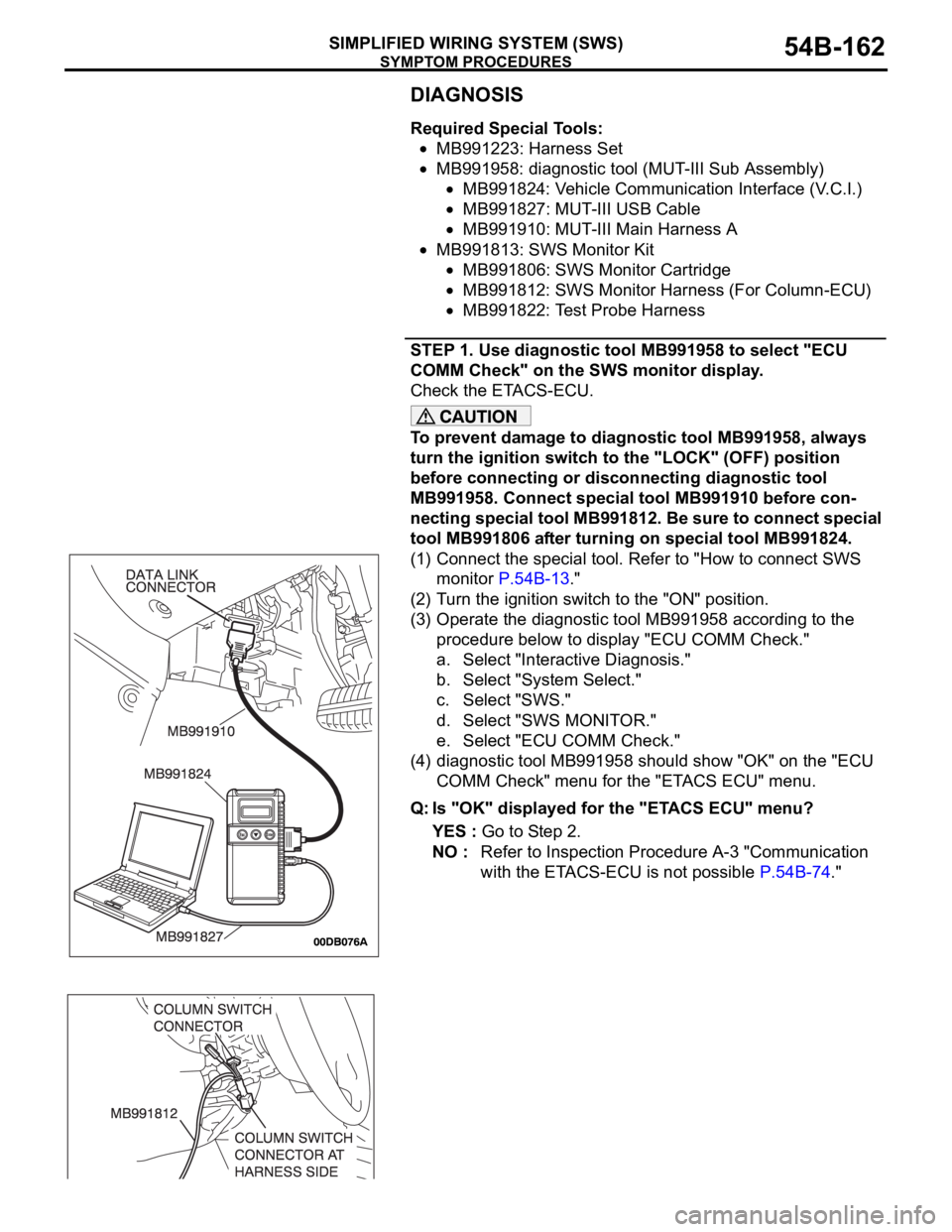

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: diagnostic tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

STEP 1. Use diagnostic tool MB991958 to select "ECU

COMM Check" on the SWS monitor display.

Check the ETACS-ECU.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958. Connect special tool MB991910 before con-

necting special tool MB991812. Be sure to connect special

tool MB991806 after turning on special tool MB991824.

(1) Connect the special tool. Refer to "How to connect SWS

monitor P.54B-13."

(2) Turn the ignition switch to the "ON" position.

(3) Operate the diagnostic tool MB991958 according to the

procedure below to display "ECU COMM Check."

a. Select "Interactive Diagnosis."

b. Select "System Select."

c. Select "SWS."

d. Select "SWS MONITOR."

e. Select "ECU COMM Check."

(4) diagnostic tool MB991958 should show "OK" on the "ECU

COMM Check" menu for the "ETACS ECU" menu.

Q: Is "OK" displayed for the "ETACS ECU" menu?

YES : Go to Step 2.

NO : Refer to Inspection Procedure A-3 "Communication

with the ETACS-ECU is not possible P.54B-74."

Page 168 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-168

CIRCUIT OPERATION

power window regulator motors raise and lower the

door windows when the front passenger's or rear

passenger's sub switch is moved to "UP" or "DOWN"

position.

.

TECHNICAL DESCRIPTION (COMMENT)

A power window sub switch or power window regula-

tor motor may be defective. Or, the power window

lock switch (incorporated in the power window main

switch in the driver’s door) may remain pressed in

the "LOCK" position.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The power window main switch may be defective

The front power window sub switch may be

defective

The rear power window sub switches may be

defective

The front power window regulator motor (RH)

may be defective

The rear power window regulator motors may be

defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

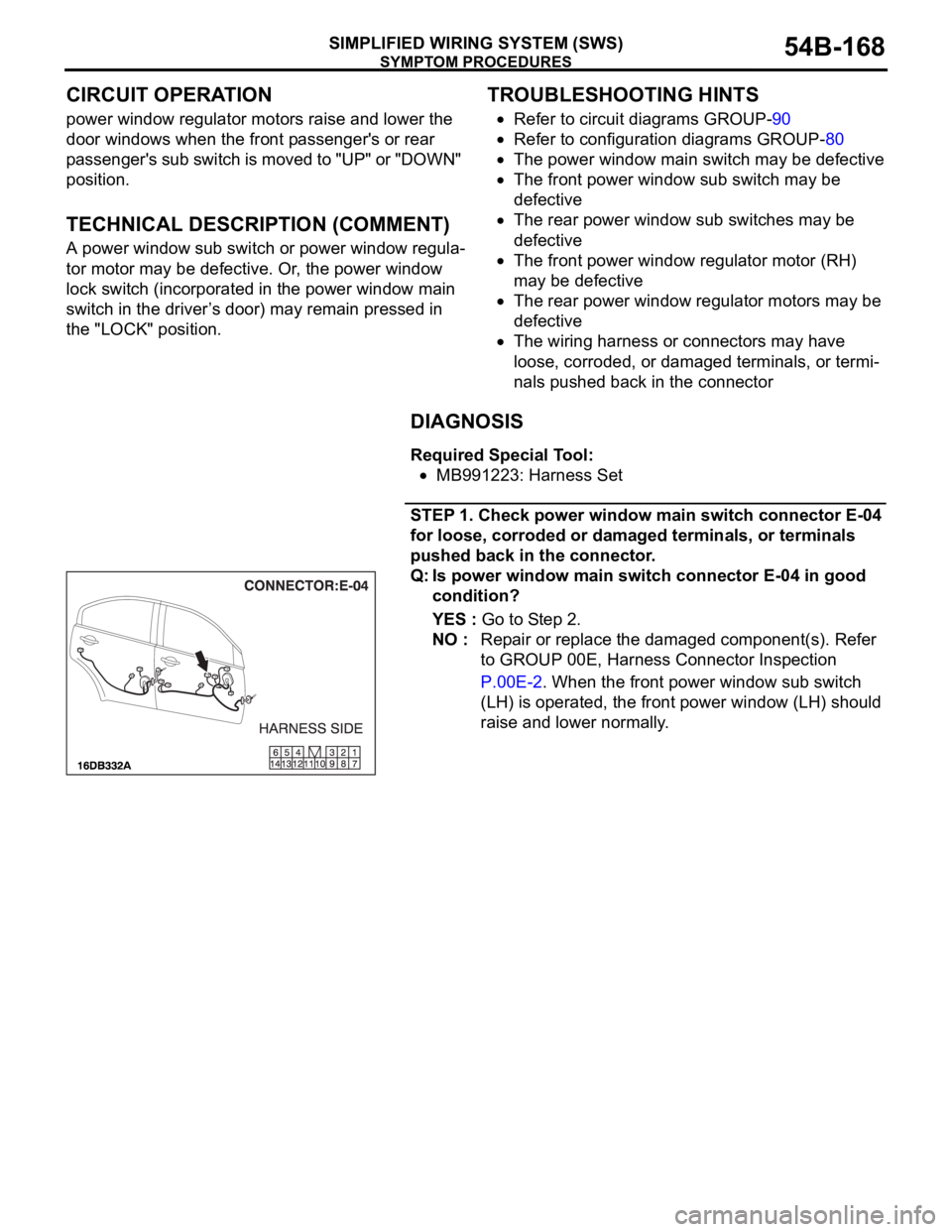

STEP 1. Check power window main switch connector E-04

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window main switch connector E-04 in good

condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. When the front power window sub switch

(LH) is operated, the front power window (LH) should

raise and lower normally.

Page 169 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-169

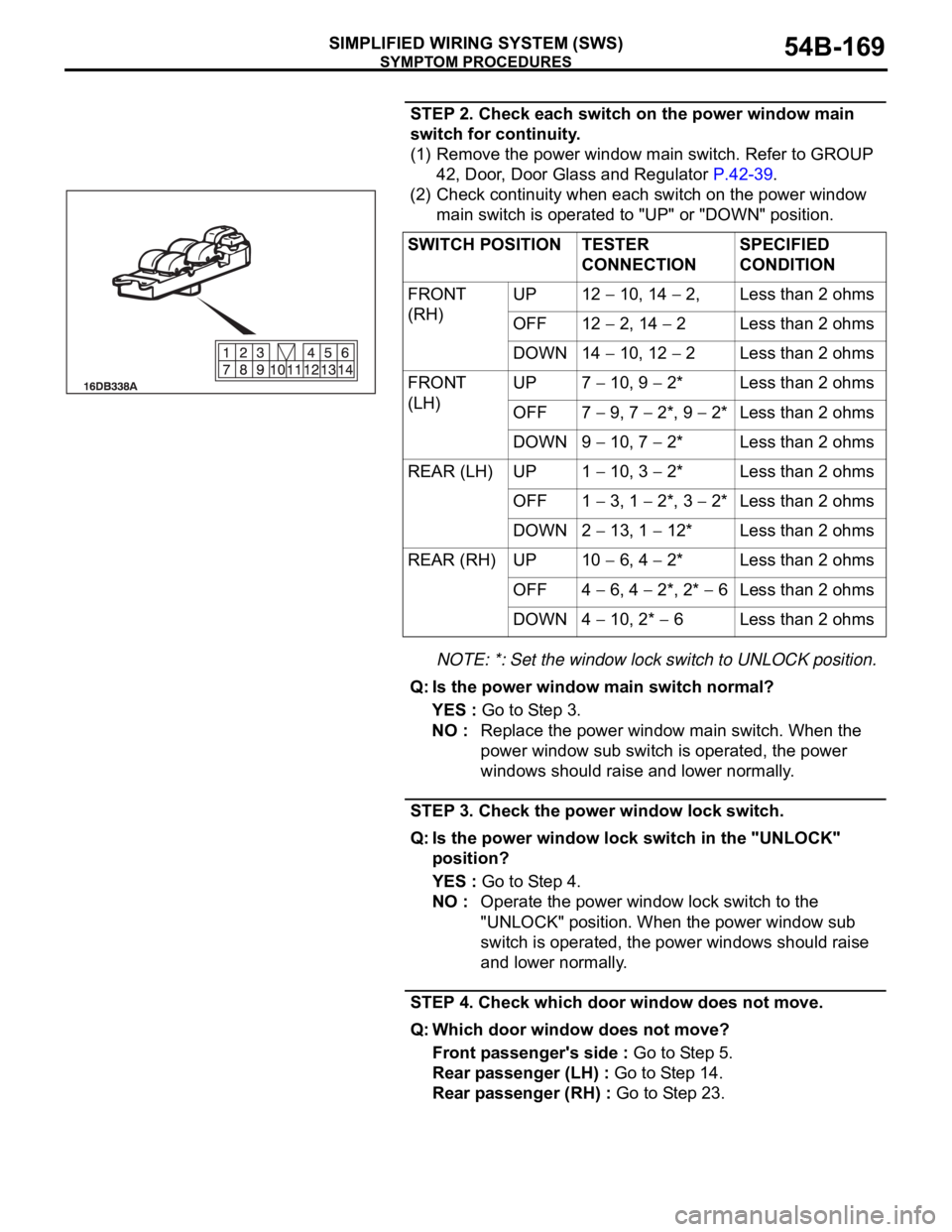

STEP 2. Check each switch on the power window main

switch for continuity.

(1) Remove the power window main switch. Refer to GROUP

42, Door, Door Glass and Regulator P.42-39.

(2) Check continuity when each switch on the power window

main switch is operated to "UP" or "DOWN" position.

NOTE: *: Set the window lock switch to UNLOCK position.

Q: Is the power window main switch normal?

YES : Go to Step 3.

NO : Replace the power window main switch. When the

power window sub switch is operated, the power

windows should raise and lower normally.

STEP 3. Check the power window lock switch.

Q: Is the power window lock switch in the "UNLOCK"

position?

YES : Go to Step 4.

NO : Operate the power window lock switch to the

"UNLOCK" position. When the power window sub

switch is operated, the power windows should raise

and lower normally.

STEP 4. Check which door window does not move.

Q: Which door window does not move?

Front passenger's side : Go to Step 5.

Rear passenger (LH) : Go to Step 14.

Rear passenger (RH) : Go to Step 23. SWITCH POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

FRONT

(RH)UP 12

10, 14 2, Less than 2 ohms

OFF 12

2, 14 2 Less than 2 ohms

DOWN 14

10, 12 2 Less than 2 ohms

FRONT

(LH)UP 7

10, 9 2* Less than 2 ohms

OFF 7

9, 7 2*, 9 2* Less than 2 ohms

DOWN 9

10, 7 2* Less than 2 ohms

REAR (LH) UP 1

10, 3 2* Less than 2 ohms

OFF 1

3, 1 2*, 3 2* Less than 2 ohms

DOWN 2

13, 1 12* Less than 2 ohms

REAR (RH) UP 10

6, 4 2* Less than 2 ohms

OFF 4

6, 4 2*, 2* 6 Less than 2 ohms

DOWN 4

10, 2* 6 Less than 2 ohms

Page 173 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-173

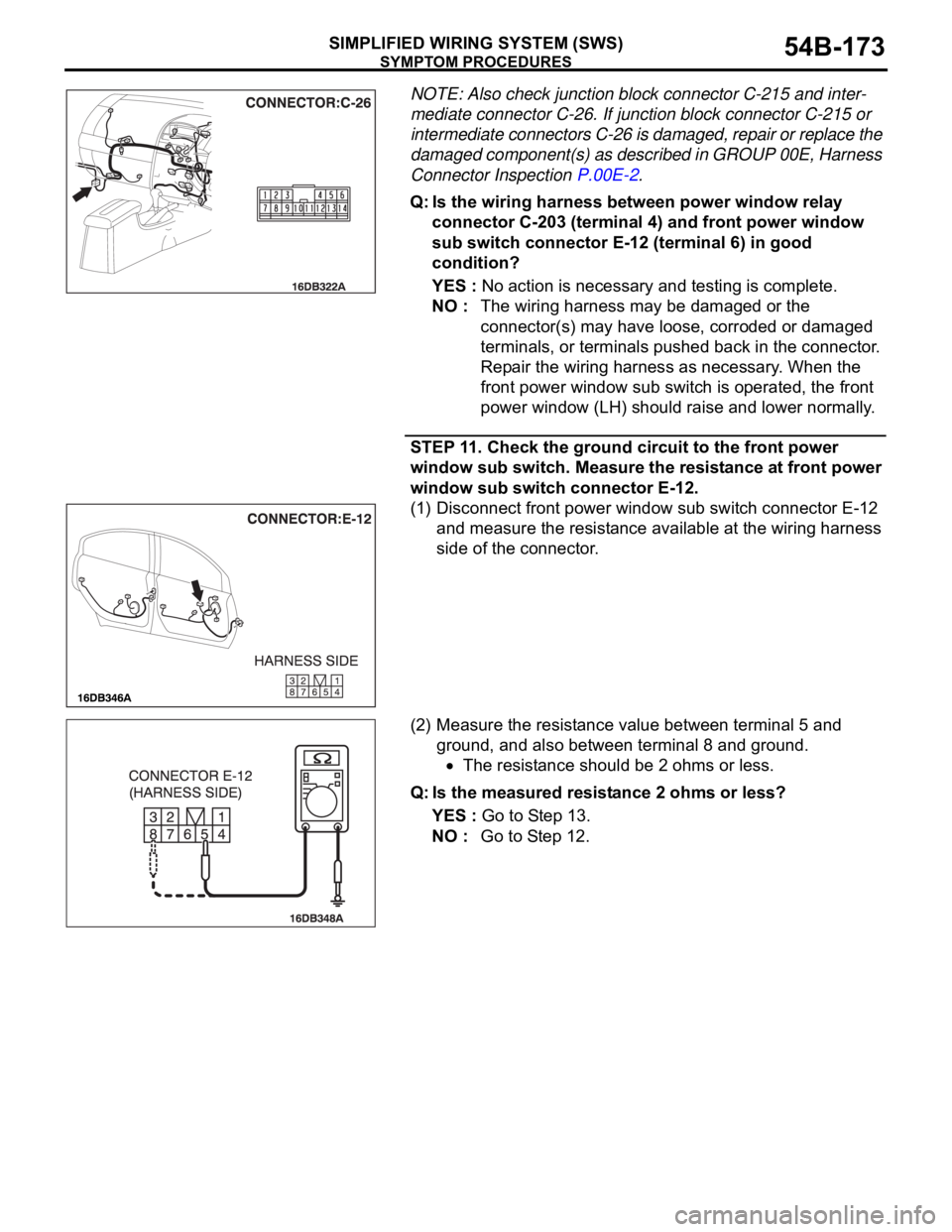

NOTE: Also check junction block connector C-215 and inter-

mediate connector C-26. If junction block connector C-215 or

intermediate connectors C-26 is damaged, repair or replace the

damaged component(s) as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and front power window

sub switch connector E-12 (terminal 6) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

front power window sub switch is operated, the front

power window (LH) should raise and lower normally.

STEP 11. Check the ground circuit to the front power

window sub switch. Measure the resistance at front power

window sub switch connector E-12.

(1) Disconnect front power window sub switch connector E-12

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminal 5 and

ground, and also between terminal 8 and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 13.

NO : Go to Step 12.

Page 178 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-178

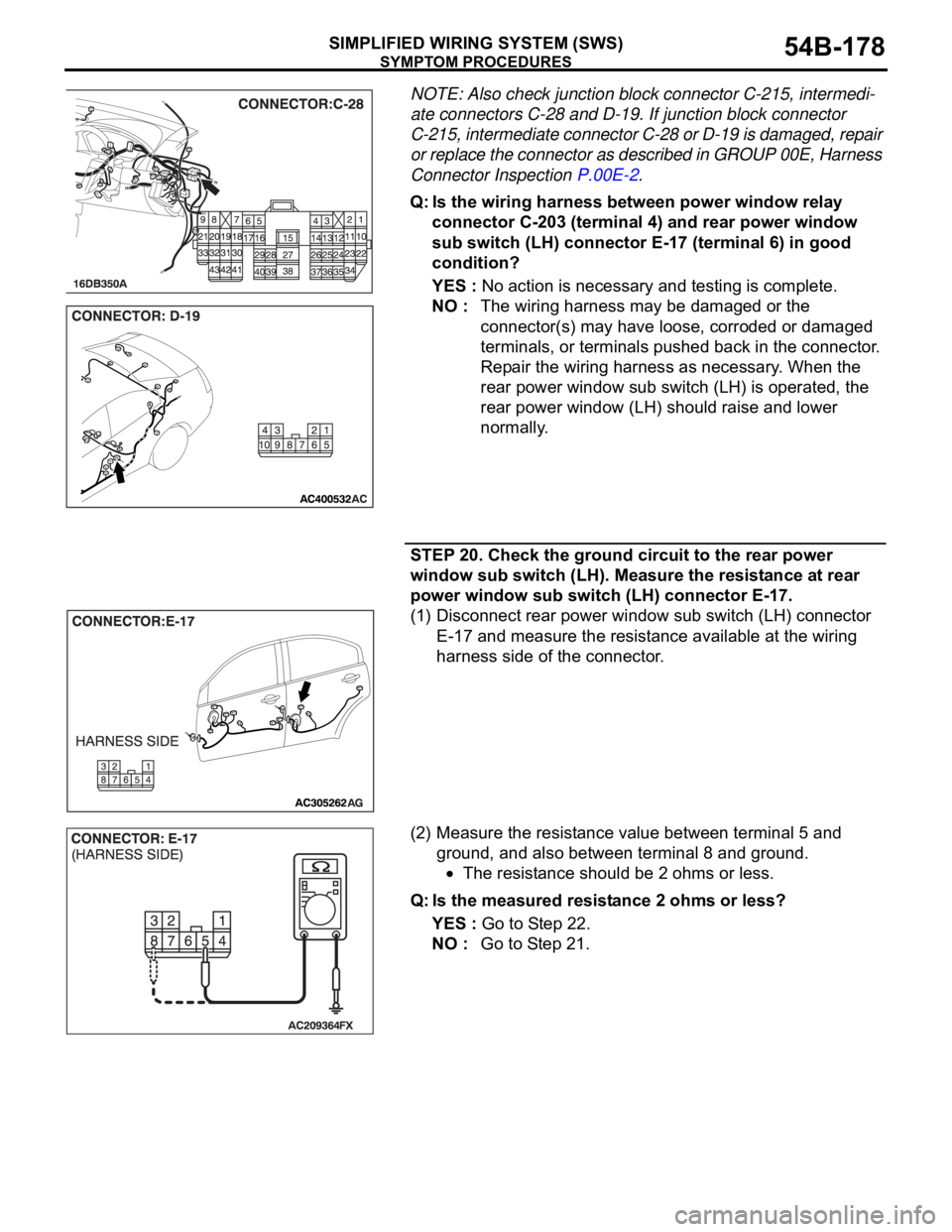

NOTE: Also check junction block connector C-215, intermedi-

ate connectors C-28 and D-19. If junction block connector

C-215, intermediate connector C-28 or D-19 is damaged, repair

or replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and rear power window

sub switch (LH) connector E-17 (terminal 6) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

rear power window sub switch (LH) is operated, the

rear power window (LH) should raise and lower

normally.

STEP 20. Check the ground circuit to the rear power

window sub switch (LH). Measure the resistance at rear

power window sub switch (LH) connector E-17.

(1) Disconnect rear power window sub switch (LH) connector

E-17 and measure the resistance available at the wiring

harness side of the connector.

(2) Measure the resistance value between terminal 5 and

ground, and also between terminal 8 and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 22.

NO : Go to Step 21.

Page 184 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-184

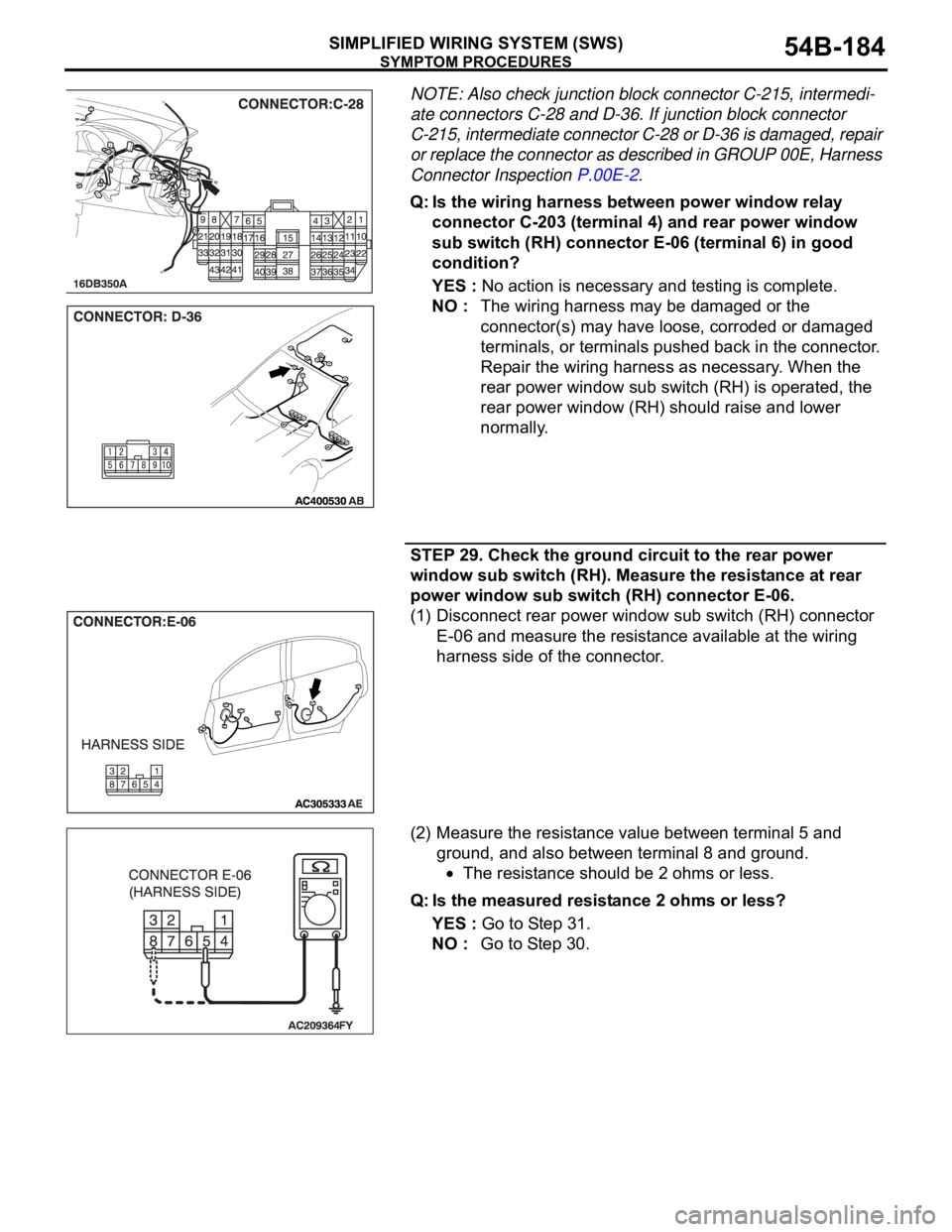

NOTE: Also check junction block connector C-215, intermedi-

ate connectors C-28 and D-36. If junction block connector

C-215, intermediate connector C-28 or D-36 is damaged, repair

or replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and rear power window

sub switch (RH) connector E-06 (terminal 6) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

rear power window sub switch (RH) is operated, the

rear power window (RH) should raise and lower

normally.

STEP 29. Check the ground circuit to the rear power

window sub switch (RH). Measure the resistance at rear

power window sub switch (RH) connector E-06.

(1) Disconnect rear power window sub switch (RH) connector

E-06 and measure the resistance available at the wiring

harness side of the connector.

(2) Measure the resistance value between terminal 5 and

ground, and also between terminal 8 and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 31.

NO : Go to Step 30.

Page 187 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-187

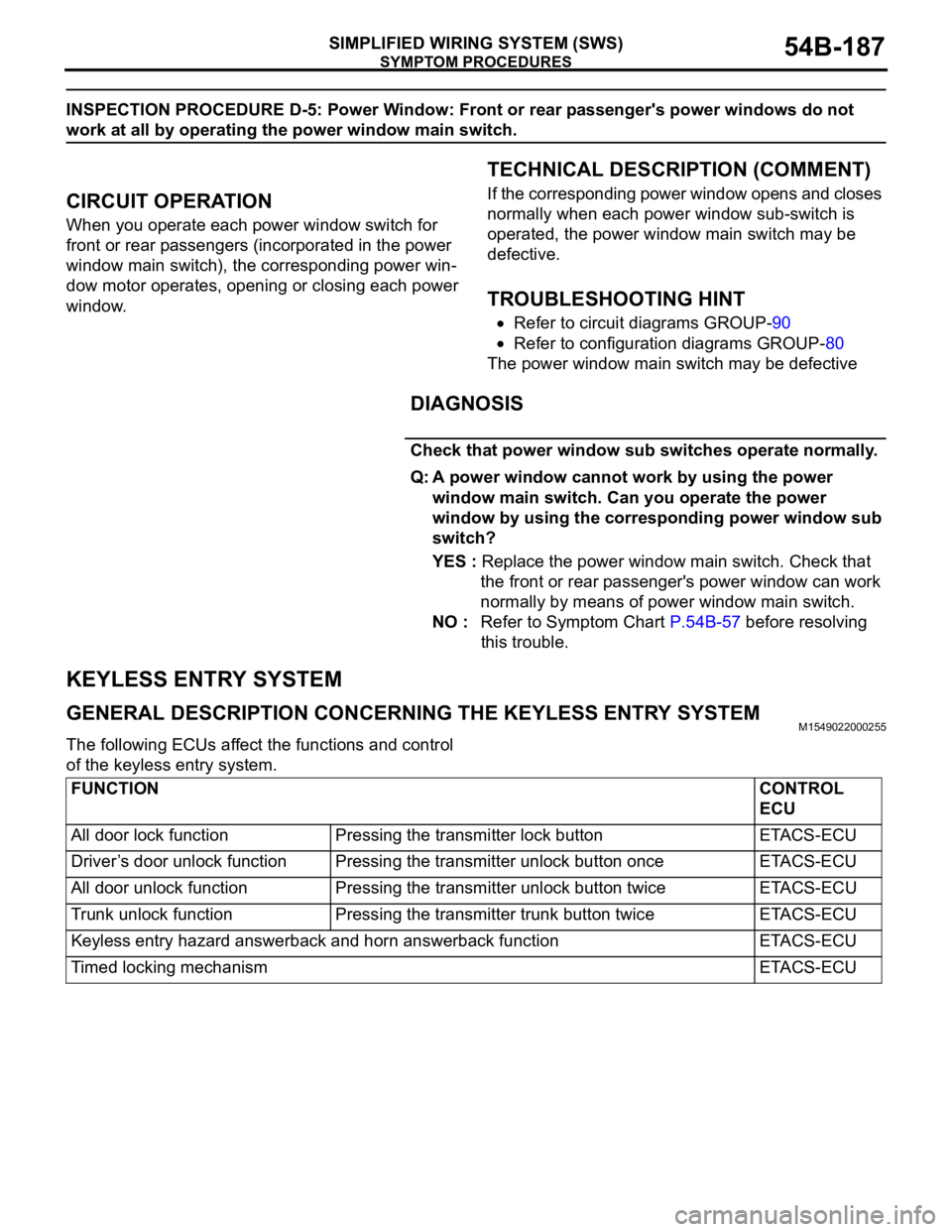

INSPECTION PROCEDURE D-5: Power Window: Front or rear passenger's power windows do not

work at all by operating the power window main switch.

.

CIRCUIT OPERATION

When you operate each power window switch for

front or rear passengers (incorporated in the power

window main switch), the corresponding power win-

dow motor operates, opening or closing each power

window.

.

TECHNICAL DESCRIPTION (COMMENT)

If the corresponding power window opens and closes

normally when each power window sub-switch is

operated, the power window main switch may be

defective.

.

TROUBLESHOOTING HINT

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The power window main switch may be defective

DIAGNOSIS

Check that power window sub switches operate normally.

Q: A power window cannot work by using the power

window main switch. Can you operate the power

window by using the corresponding power window sub

switch?

YES : Replace the power window main switch. Check that

the front or rear passenger's power window can work

normally by means of power window main switch.

NO : Refer to Symptom Chart P.54B-57 before resolving

this trouble.

KEYLESS ENTRY SYSTEM

GENERAL DESCRIPTION CONCERNING THE KEYLESS ENTRY SYSTEMM1549022000255

The following ECUs affect the functions and control

of the keyless entry system.

FUNCTIONCONTROL

ECU

All door lock function Pressing the transmitter lock button ETACS-ECU

Driver’s door unlock function Pressing the transmitter unlock button once ETACS-ECU

All door unlock function Pressing the transmitter unlock button twice ETACS-ECU

Trunk unlock function Pressing the transmitter trunk button twice ETACS-ECU

Keyless entry hazard answerback and horn answerback function ETACS-ECU

Timed locking mechanism ETACS-ECU