hood release MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 494 of 1500

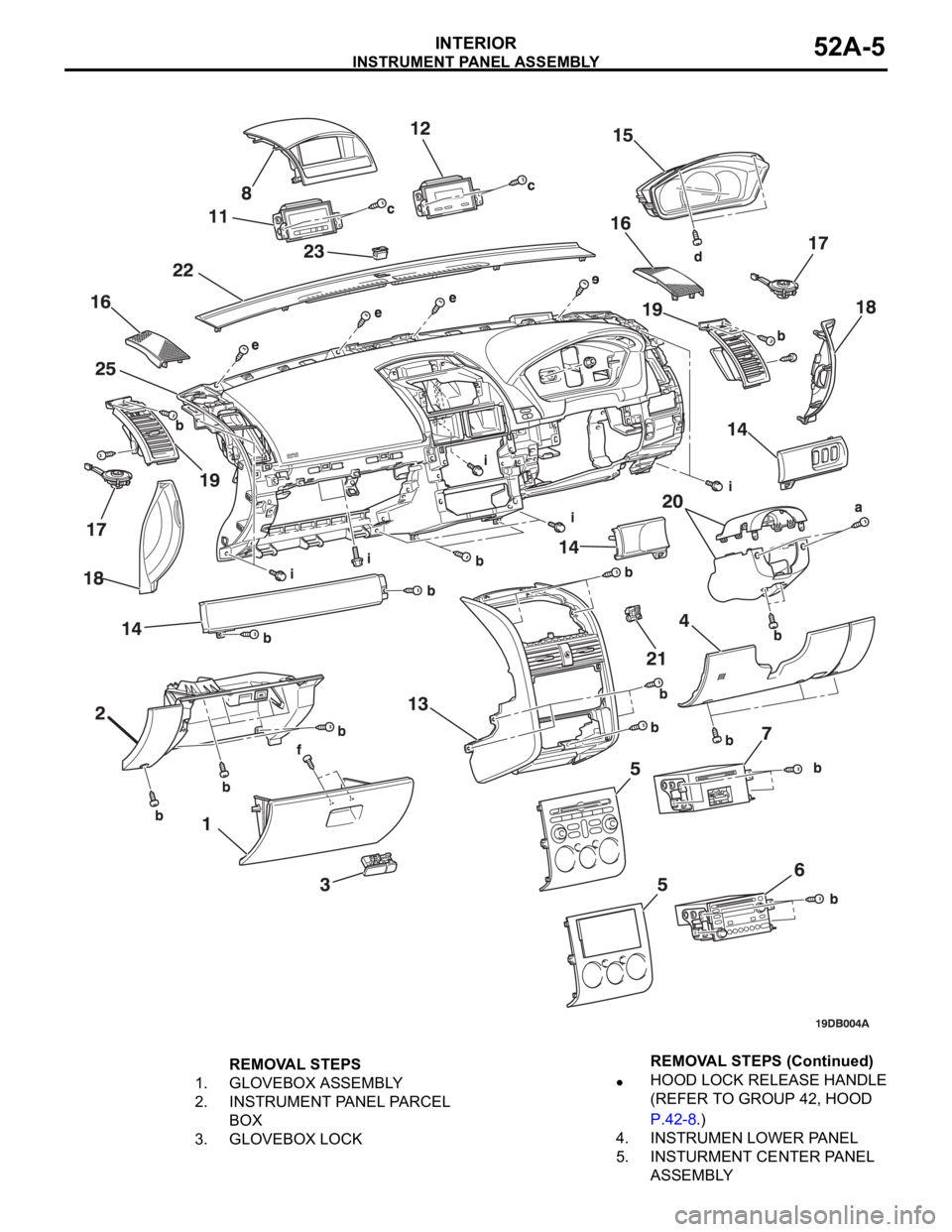

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-5

REMOVAL STEPS

1. GLOVEBOX ASSEMBLY

2. INSTRUMENT PANEL PARCEL

BOX

3. GLOVEBOX LOCKHOOD LOCK RELEASE HANDLE

(REFER TO GROUP 42, HOOD

P.42-8.)

4. INSTRUMEN LOWER PANEL

5. INSTURMENT CENTER PANEL

ASSEMBLY REMOVAL STEPS (Continued)

Page 1040 of 1500

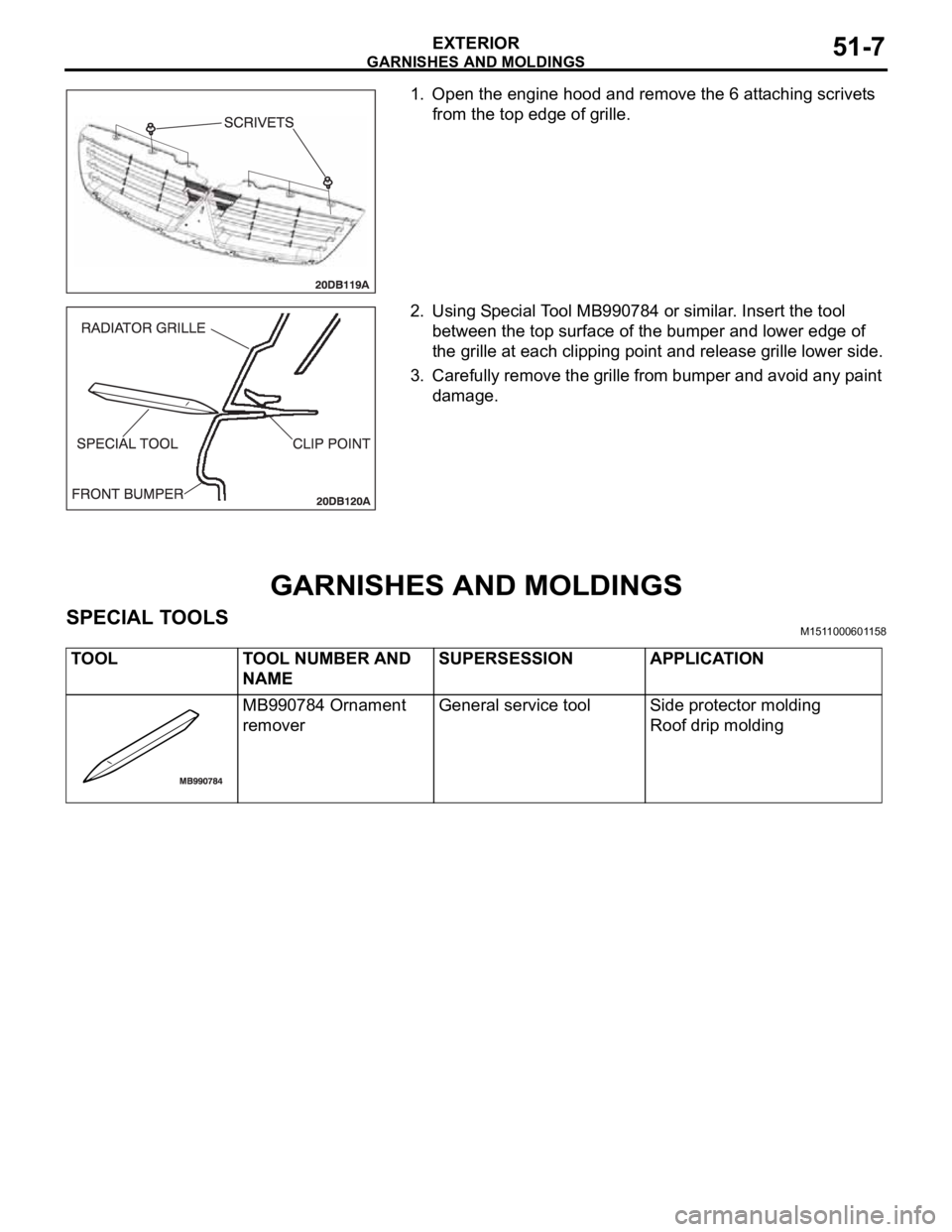

GARNISHES AND MOLDINGS

EXTERIOR51-7

1. Open the engine hood and remove the 6 attaching scrivets

from the top edge of grille.

2. Using Special Tool MB990784 or similar. Insert the tool

between the top surface of the bumper and lower edge of

the grille at each clipping point and release grille lower side.

3. Carefully remove the grille from bumper and avoid any paint

damage.

GARNISHES AND MOLDINGS

SPECIAL TOOLSM1511000601158

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990784 Ornament

removerGeneral service tool Side protector molding

Roof drip molding

Page 1071 of 1500

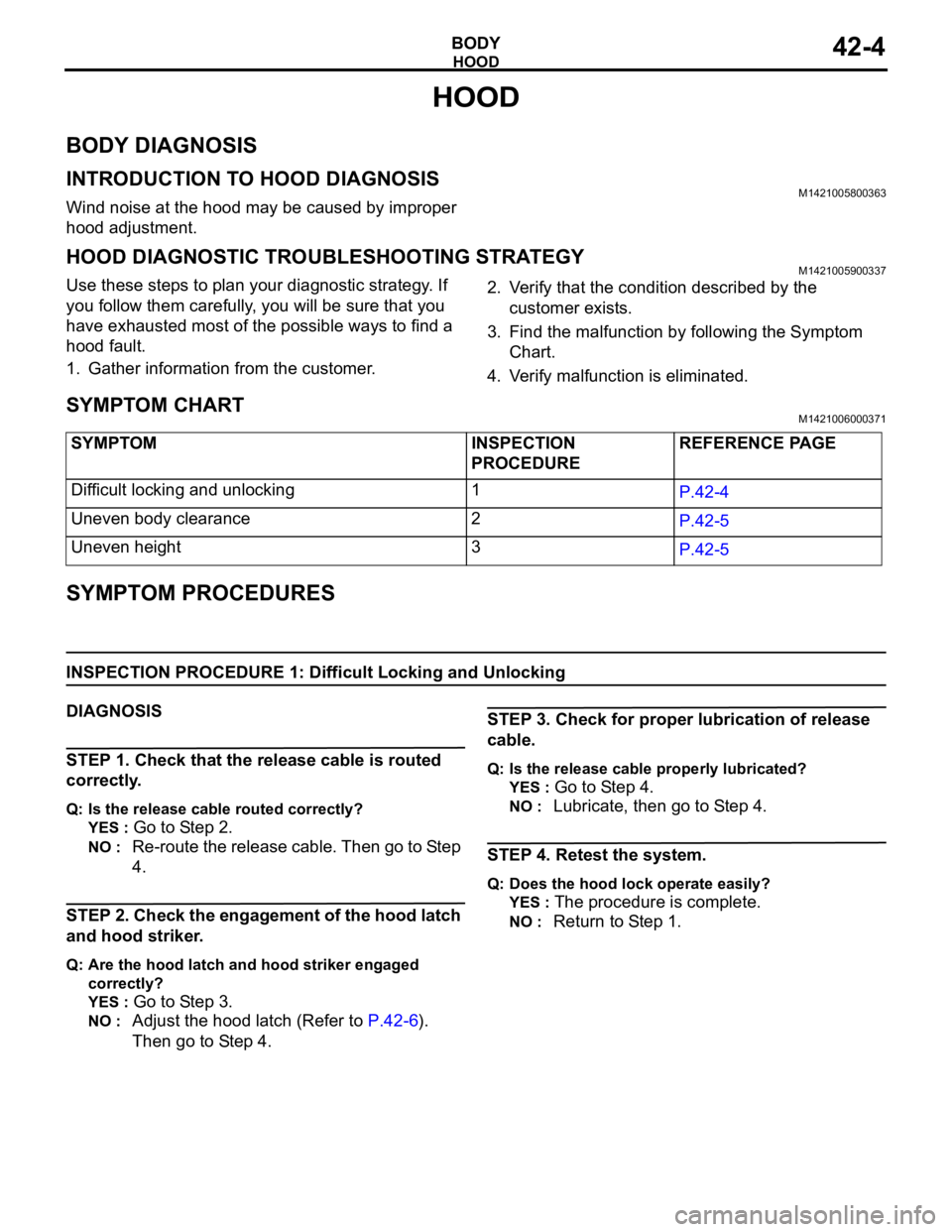

HOOD

BODY42-4

HOOD

BODY DIAGNOSIS

INTRODUCTION TO HOOD DIAGNOSISM1421005800363

Wind noise at the hood may be caused by improper

hood adjustment.

HOOD DIAGNOSTIC TROUBLESHOOTING STRATEGYM1421005900337

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

hood fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1421006000371

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Difficult Locking and Unlocking

DIAGNOSIS

STEP 1. Check that the release cable is routed

correctly.

Q: Is the release cable routed correctly?

YES :

Go to Step 2.

NO : Re-route the release cable. Then go to Step

4.

STEP 2. Check the engagement of the hood latch

and hood striker.

Q: Are the hood latch and hood striker engaged

correctly?

YES :

Go to Step 3.

NO : Adjust the hood latch (Refer to P.42-6).

Then go to Step 4.

STEP 3. Check for proper lubrication of release

cable.

Q: Is the release cable properly lubricated?

YES :

Go to Step 4.

NO : Lubricate, then go to Step 4.

STEP 4. Retest the system.

Q: Does the hood lock operate easily?

YES :

The procedure is complete.

NO : Return to Step 1. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Difficult locking and unlocking 1

P.42-4

Uneven body clearance 2

P.42-5

Uneven height 3

P.42-5

Page 1073 of 1500

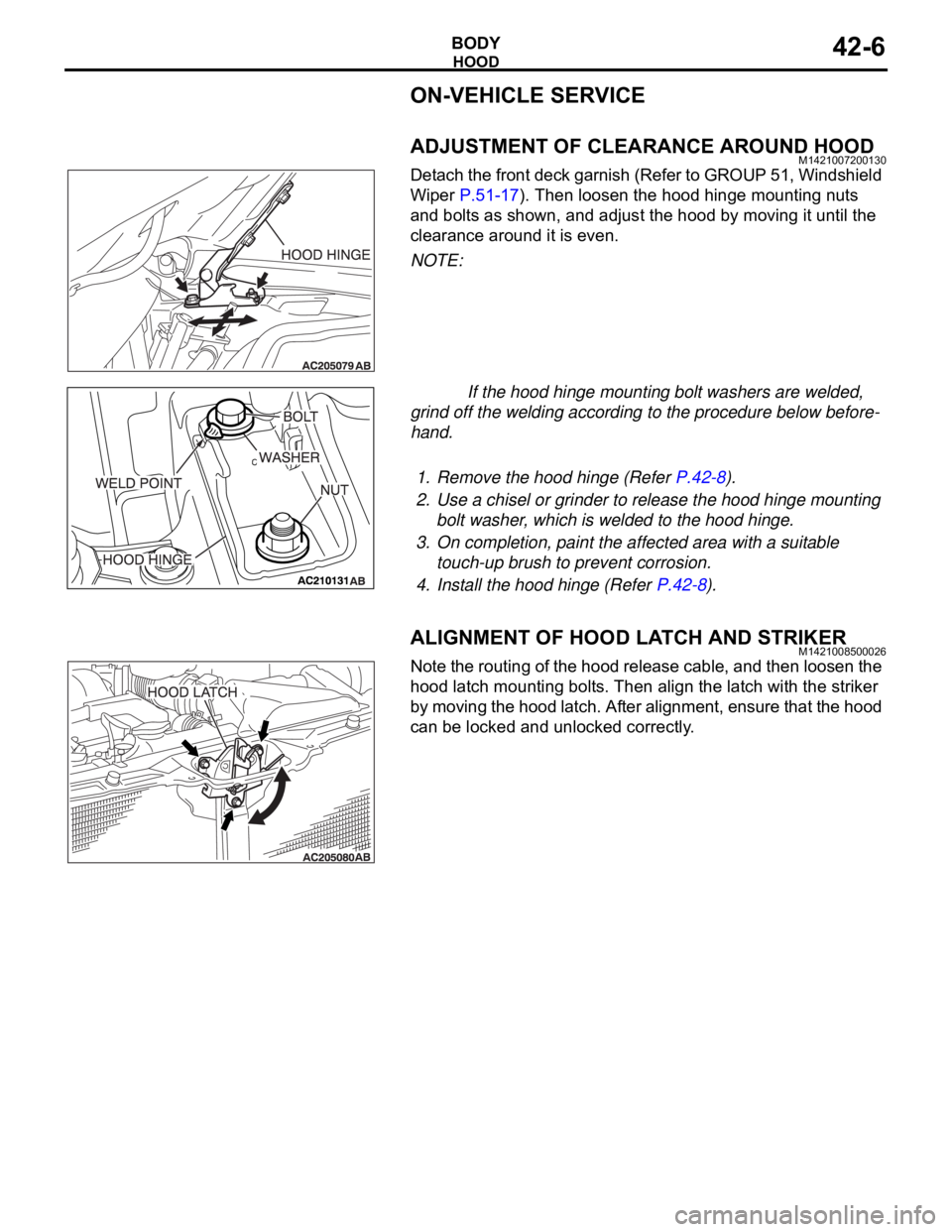

HOOD

BODY42-6

ON-VEHICLE SERVICE

ADJUSTMENT OF CLEARANCE AROUND HOODM1421007200130

Detach the front deck garnish (Refer to GROUP 51, Windshield

Wiper P.51-17). Then loosen the hood hinge mounting nuts

and bolts as shown, and adjust the hood by moving it until the

clearance around it is even.

NOTE:

If the hood hinge mounting bolt washers are welded,

grind off the welding according to the procedure below before-

hand.

.

1. Remove the hood hinge (Refer P.42-8).

2. Use a chisel or grinder to release the hood hinge mounting

bolt washer, which is welded to the hood hinge.

3. On completion, paint the affected area with a suitable

touch-up brush to prevent corrosion.

4. Install the hood hinge (Refer P.42-8).

ALIGNMENT OF HOOD LATCH AND STRIKERM1421008500026

Note the routing of the hood release cable, and then loosen the

hood latch mounting bolts. Then align the latch with the striker

by moving the hood latch. After alignment, ensure that the hood

can be locked and unlocked correctly.

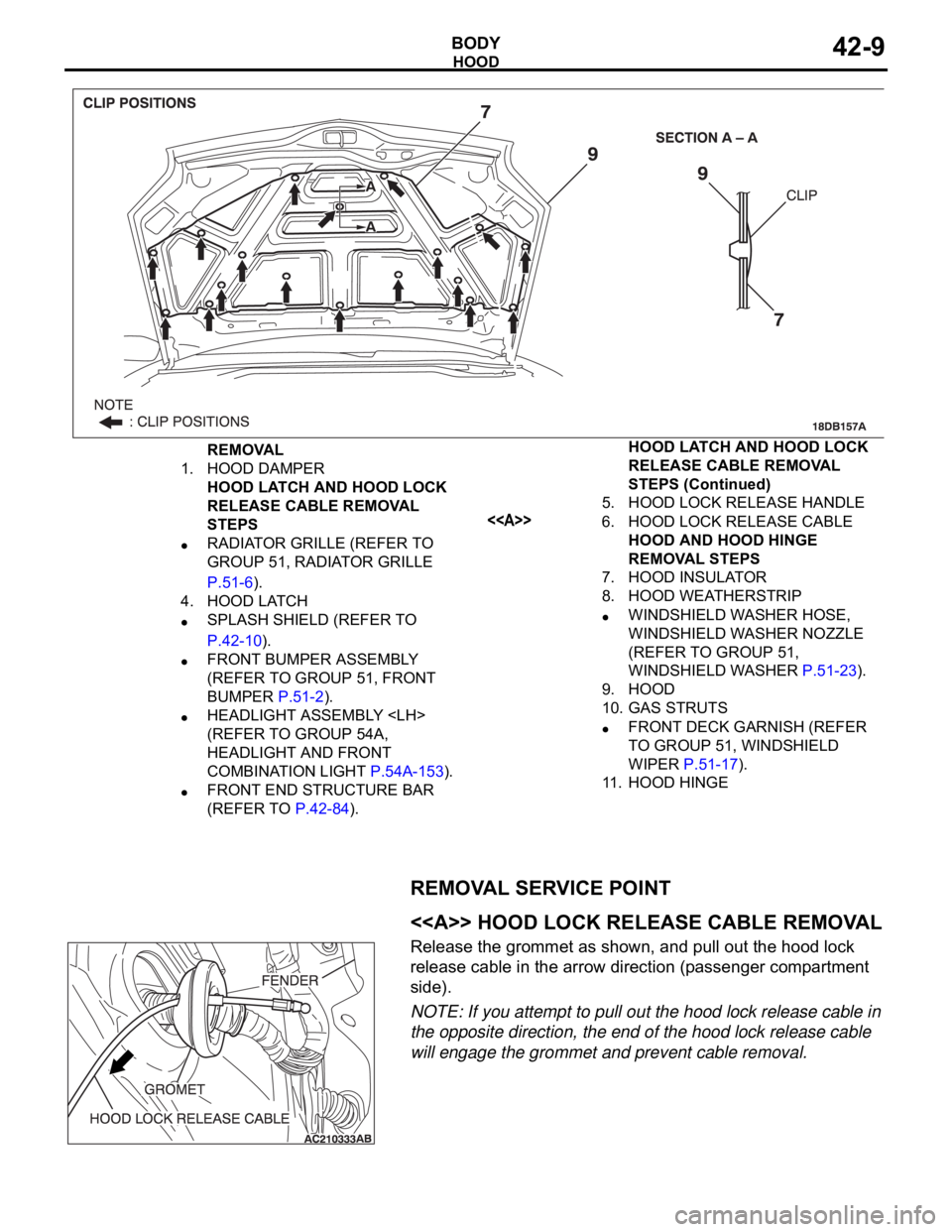

Page 1076 of 1500

HOOD

BODY42-9

REMOVAL SERVICE POINT

.

<> HOOD LOCK RELEASE CABLE REMOVAL

Release the grommet as shown, and pull out the hood lock

release cable in the arrow direction (passenger compartment

side).

NOTE: If you attempt to pull out the hood lock release cable in

the opposite direction, the end of the hood lock release cable

will engage the grommet and prevent cable removal.

REMOVAL

1. HOOD DAMPER

HOOD LATCH AND HOOD LOCK

RELEASE CABLE REMOVAL

STEPS

RADIATOR GRILLE (REFER TO

GROUP 51, RADIATOR GRILLE

P.51-6).

4. HOOD LATCH

SPLASH SHIELD (REFER TO

P.42-10).

FRONT BUMPER ASSEMBLY

(REFER TO GROUP 51, FRONT

BUMPER P.51-2).

HEADLIGHT ASSEMBLY

(REFER TO GROUP 54A,

HEADLIGHT AND FRONT

COMBINATION LIGHT P.54A-153).

FRONT END STRUCTURE BAR

(REFER TO P.42-84).5. HOOD LOCK RELEASE HANDLE

<>6. HOOD LOCK RELEASE CABLE

HOOD AND HOOD HINGE

REMOVAL STEPS

7. HOOD INSULATOR

8. HOOD WEATHERSTRIP

WINDSHIELD WASHER HOSE,

WINDSHIELD WASHER NOZZLE

(REFER TO GROUP 51,

WINDSHIELD WASHER P.51-23).

9. HOOD

10. GAS STRUTS

FRONT DECK GARNISH (REFER

TO GROUP 51, WINDSHIELD

WIPER P.51-17).

11. HOOD HINGEHOOD LATCH AND HOOD LOCK

RELEASE CABLE REMOVAL

STEPS (Continued)

Page 1248 of 1500

TOWING AND HOISTING

GENERAL00-27

TOWING WITH REAR WHEELS OFF THE

GROUND (TYPE B)

Place the gearshift lever in the "Neutral" position (M/T) or the

selector lever in the "N" (NEUTRAL) position (A/T). Turn the

ignition key to the "ACC" position and secure the steering

wheel in a straight-ahead position with a rope or tie-down strap.

Never place the ignition key in the "LOCK" position when tow-

ing.

Never tow an A/T vehicle with the rear wheels up (and

the front wheels on the ground) when the automatic

transmission fluid level is low. this may cause serious

and expensive damage to the transmission.

Do not use the steering column lock to secure the front

wheels for towing.

Make sure the transaxle is in Neutral if vehicle will have

drive wheels on the ground.

If these requirements cannot be met, the front wheels

must be placed on a tow dolly.

.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not avail-

able, the vehicle may be lifted and towed from the front, pro-

vided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle:

1. DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING

TO OR WRAPPING AROUND THE BUMPER.

2. Any loose, protruding, or damaged parts such as hoods,

doors, fenders, trim, etc. should be secured or removed

prior to moving the vehicle.

Page 1328 of 1500

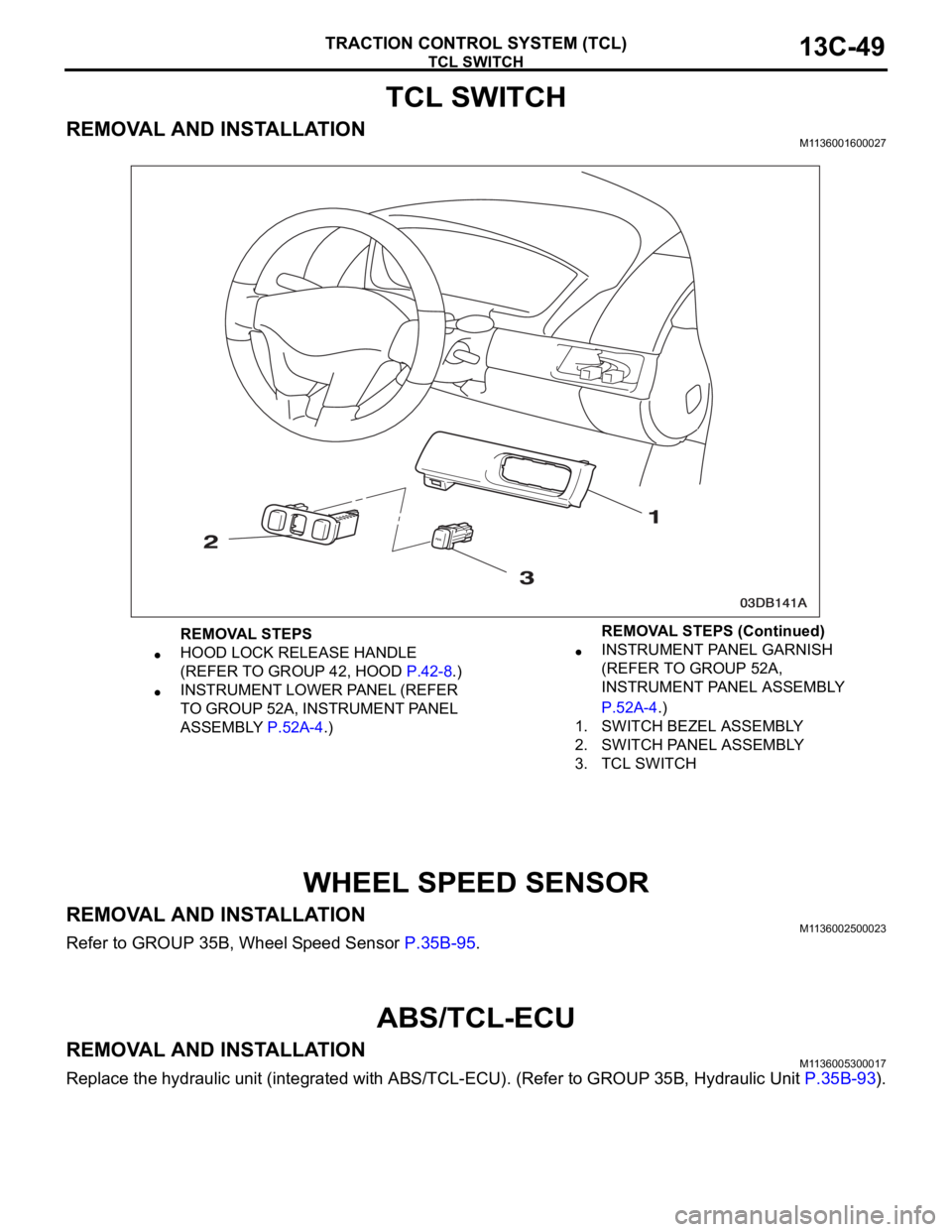

TCL SWITCH

TRACTION CONTROL SYSTEM (TCL)13C-49

TCL SWITCH

REMOVAL AND INSTALLATIONM1136001600027

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATIONM1136002500023

Refer to GROUP 35B, Wheel Speed Sensor P.35B-95.

ABS/TCL-ECU

REMOVAL AND INSTALLATIONM1136005300017

Replace the hydraulic unit (integrated with ABS/TCL-ECU). (Refer to GROUP 35B, Hydraulic Unit P.35B-93).

REMOVAL STEPS

HOOD LOCK RELEASE HANDLE

(REFER TO GROUP 42, HOOD P.42-8.)

INSTRUMENT LOWER PANEL (REFER

TO GROUP 52A, INSTRUMENT PANEL

ASSEMBLY P.52A-4.)

INSTRUMENT PANEL GARNISH

(REFER TO GROUP 52A,

INSTRUMENT PANEL ASSEMBLY

P.52A-4.)

1. SWITCH BEZEL ASSEMBLY

2. SWITCH PANEL ASSEMBLY

3. TCL SWITCH REMOVAL STEPS (Continued)