light MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1303 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-24

.

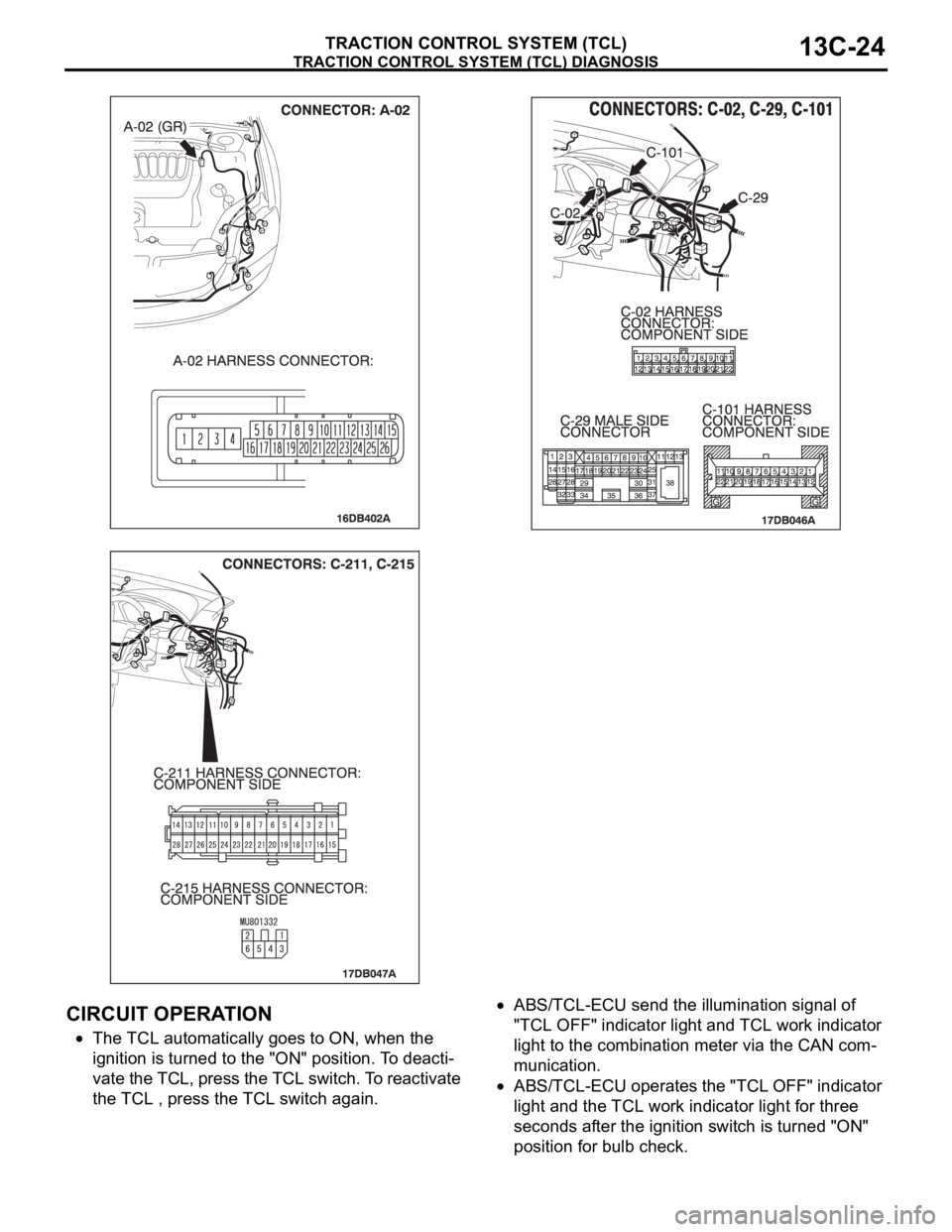

CIRCUIT OPERATION

The TCL automatically goes to ON, when the

ignition is turned to the "ON" position. To deacti-

vate the TCL, press the TCL switch. To reactivate

the TCL , press the TCL switch again.

ABS/TCL-ECU send the illumination signal of

"TCL OFF" indicator light and TCL work indicator

light to the combination meter via the CAN com-

munication.

ABS/TCL-ECU operates the "TCL OFF" indicator

light and the TCL work indicator light for three

seconds after the ignition switch is turned "ON"

position for bulb check.

Page 1307 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-28

STEP 4. Retest the system

Q: Turn the ignition switch to the "ON" position. Do the

"TCL OFF" indicator light and the TCL work indicator

light illuminate for three seconds, and then go out after

the engine starts?

YES : The procedure is complete.

NO : . Return to Step 1.

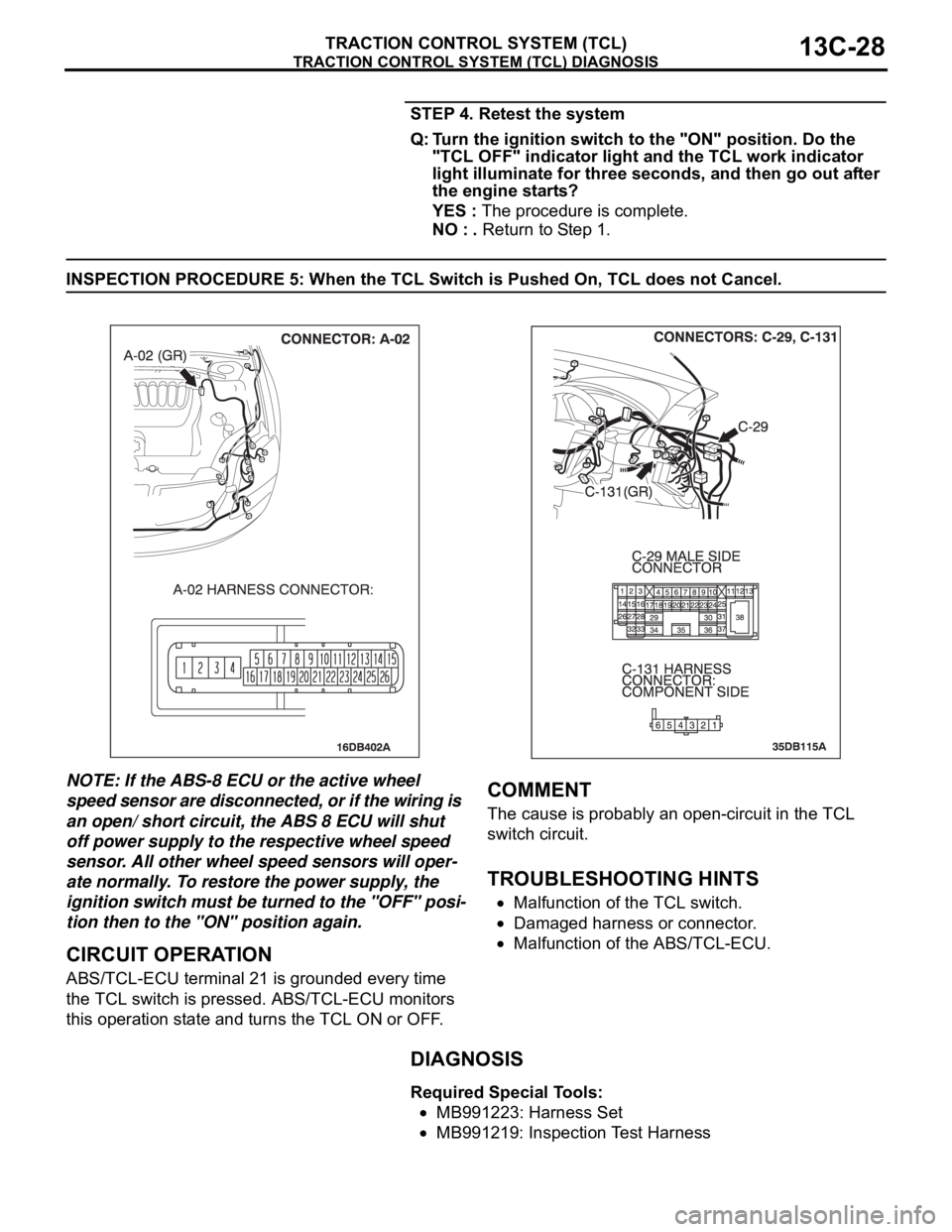

INSPECTION PROCEDURE 5: When the TCL Switch is Pushed On, TCL does not Cancel.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

CIRCUIT OPERATION

ABS/TCL-ECU terminal 21 is grounded every time

the TCL switch is pressed. ABS/TCL-ECU monitors

this operation state and turns the TCL ON or OFF.

.

COMMENT

The cause is probably an open-circuit in the TCL

switch circuit.

.

TROUBLESHOOTING HINTS

Malfunction of the TCL switch.

Damaged harness or connector.

Malfunction of the ABS/TCL-ECU.

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991219: Inspection Test Harness

Page 1315 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-36

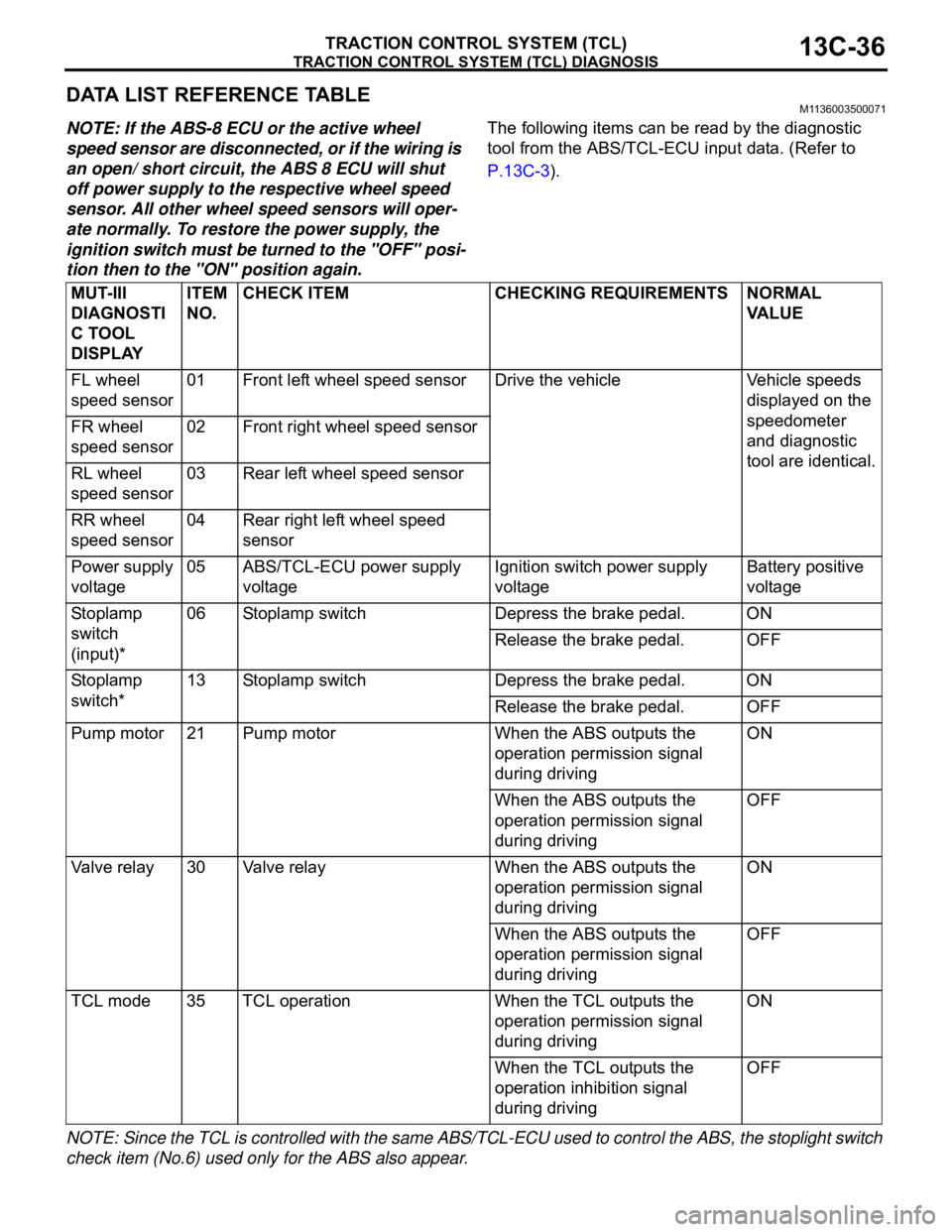

DATA LIST REFERENCE TABLEM1136003500071

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.The following items can be read by the diagnostic

tool from the ABS/TCL-ECU input data. (Refer to

P.13C-3).

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the stoplight switch

check item (No.6) used only for the ABS also appear.MUT-III

DIAGNOSTI

C TOOL

DISPLAYITEM

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL

VA L U E

FL wheel

speed sensor01 Front left wheel speed sensor Drive the vehicle Vehicle speeds

displayed on the

speedometer

and diagnostic

tool are identical. FR wheel

speed sensor02 Front right wheel speed sensor

RL wheel

speed sensor03 Rear left wheel speed sensor

RR wheel

speed sensor04 Rear right left wheel speed

sensor

Power supply

voltage05 ABS/TCL-ECU power supply

voltageIgnition switch power supply

voltageBattery positive

voltage

Stoplamp

switch

(input)*06 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Stoplamp

switch*13 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Pump motor 21 Pump motor When the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

Valve relay 30 Valve relayWhen the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

TCL mode 35 TCL operation When the TCL outputs the

operation permission signal

during drivingON

When the TCL outputs the

operation inhibition signal

during drivingOFF

Page 1326 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-47

ON-VEHICLE SERVICE

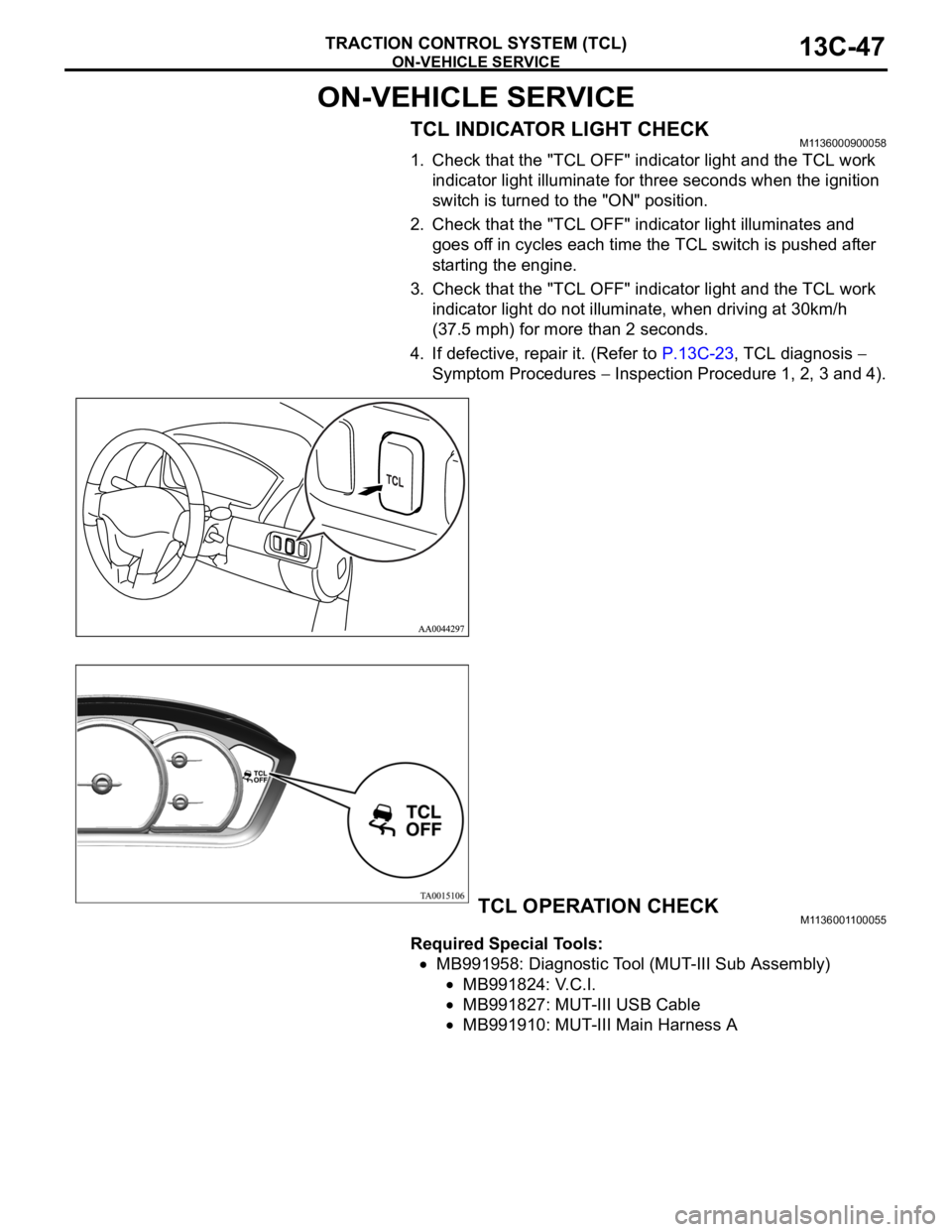

TCL INDICATOR LIGHT CHECKM1136000900058

1. Check that the "TCL OFF" indicator light and the TCL work

indicator light illuminate for three seconds when the ignition

switch is turned to the "ON" position.

2. Check that the "TCL OFF" indicator light illuminates and

goes off in cycles each time the TCL switch is pushed after

starting the engine.

3. Check that the "TCL OFF" indicator light and the TCL work

indicator light do not illuminate, when driving at 30km/h

(37.5 mph) for more than 2 seconds.

4. If defective, repair it. (Refer to P.13C-23, TCL diagnosis

Symptom Procedures

Inspection Procedure 1, 2, 3 and 4).

TCL OPERATION CHECKM1136001100055

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1393 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-62

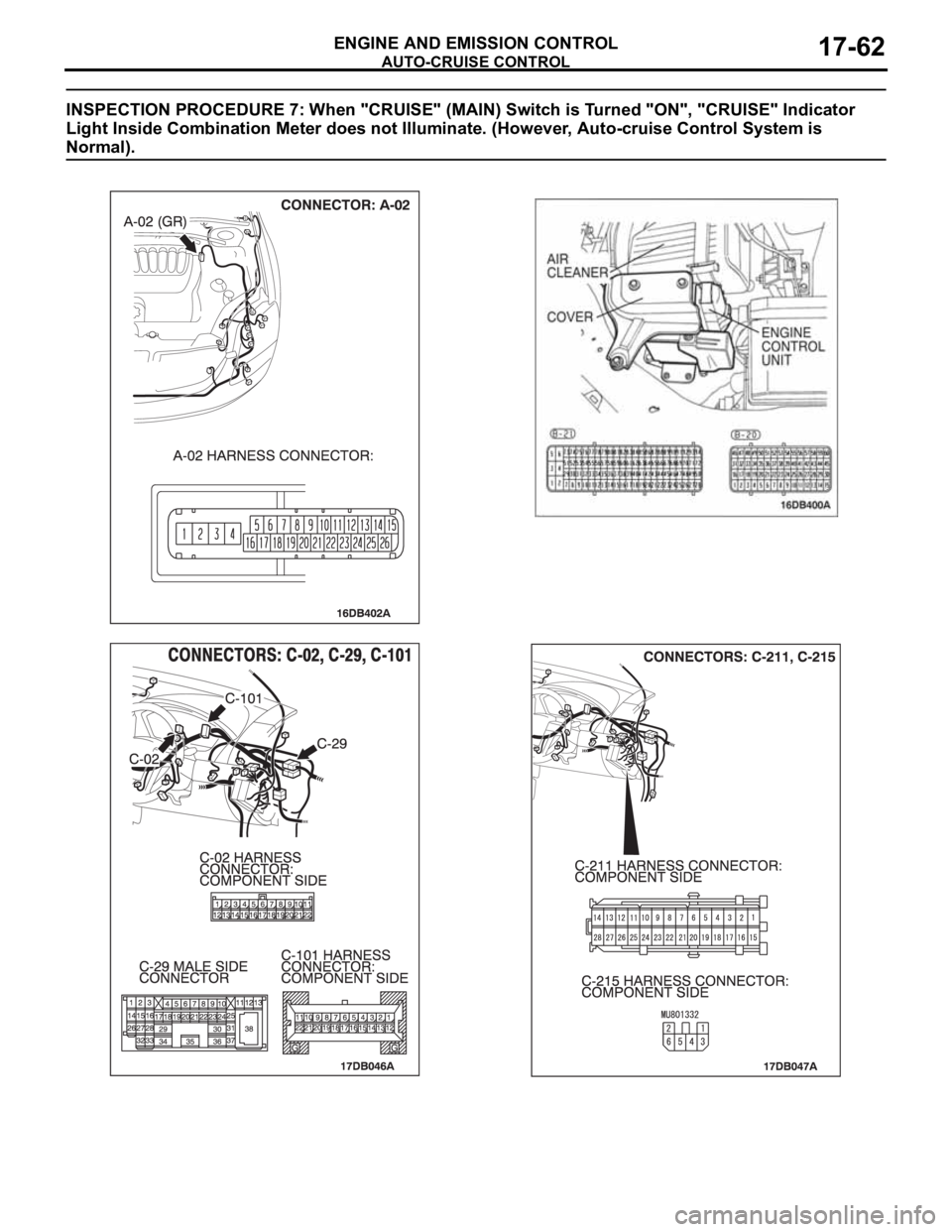

INSPECTION PROCEDURE 7: When "CRUISE" (MAIN) Switch is Turned "ON", "CRUISE" Indicator

Light Inside Combination Meter does not Illuminate. (However, Auto-cruise Control System is

Normal).

.

Page 1396 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-65

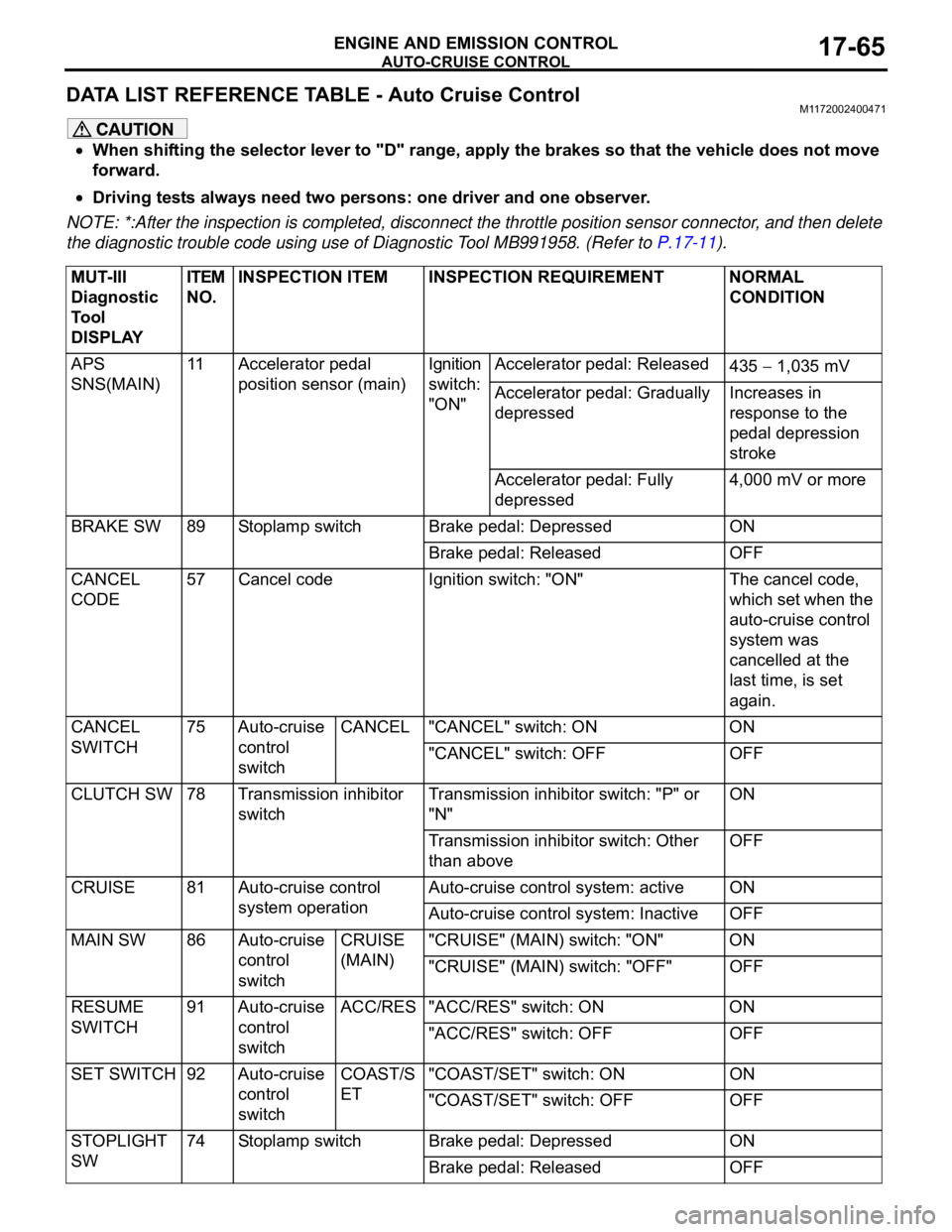

DATA LIST REFERENCE TABLE - Auto Cruise ControlM1172002400471

When shifting the selector lever to "D" range, apply the brakes so that the vehicle does not move

forward.

Driving tests always need two persons: one driver and one observer.

NOTE: *:After the inspection is completed, disconnect the throttle position sensor connector, and then delete

the diagnostic trouble code using use of Diagnostic Tool MB991958. (Refer to P.17-11).

MUT-III

Diagnostic

To o l

DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL

CONDITION

APS

SNS(MAIN)11 A c c e l e r a t o r p e d a l

position sensor (main)Ignition

switch:

"ON"Accelerator pedal: Released

435

1,035 mV

Accelerator pedal: Gradually

depressedIncreases in

response to the

pedal depression

stroke

Accelerator pedal: Fully

depressed4,000 mV or more

BRAKE SW 89 Stoplamp switch Brake pedal: Depressed ON

Brake pedal: Released OFF

CANCEL

CODE57 Cancel code Ignition switch: "ON" The cancel code,

which set when the

auto-cruise control

system was

cancelled at the

last time, is set

again.

CANCEL

SWITCH75 Auto-cruise

control

switchCANCEL "CANCEL" switch: ON ON

"CANCEL" switch: OFF OFF

CLUTCH SW 78 Transmission inhibitor

switchTransmission inhibitor switch: "P" or

"N"ON

Transmission inhibitor switch: Other

than aboveOFF

CRUISE 81 Auto-cruise control

system operationAuto-cruise control system: active ON

Auto-cruise control system: Inactive OFF

MAIN SW 86 Auto-cruise

control

switchCRUISE

(MAIN)"CRUISE" (MAIN) switch: "ON" ON

"CRUISE" (MAIN) switch: "OFF" OFF

RESUME

SWITCH91 Auto-cruise

control

switchACC/RES "ACC/RES" switch: ON ON

"ACC/RES" switch: OFF OFF

SET SWITCH 92 Auto-cruise

control

switchCOAST/S

ET"COAST/SET" switch: ON ON

"COAST/SET" switch: OFF OFF

STOPLIGHT

SW74 Stoplamp switch Brake pedal: Depressed ON

Brake pedal: Released OFF

Page 1399 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-68

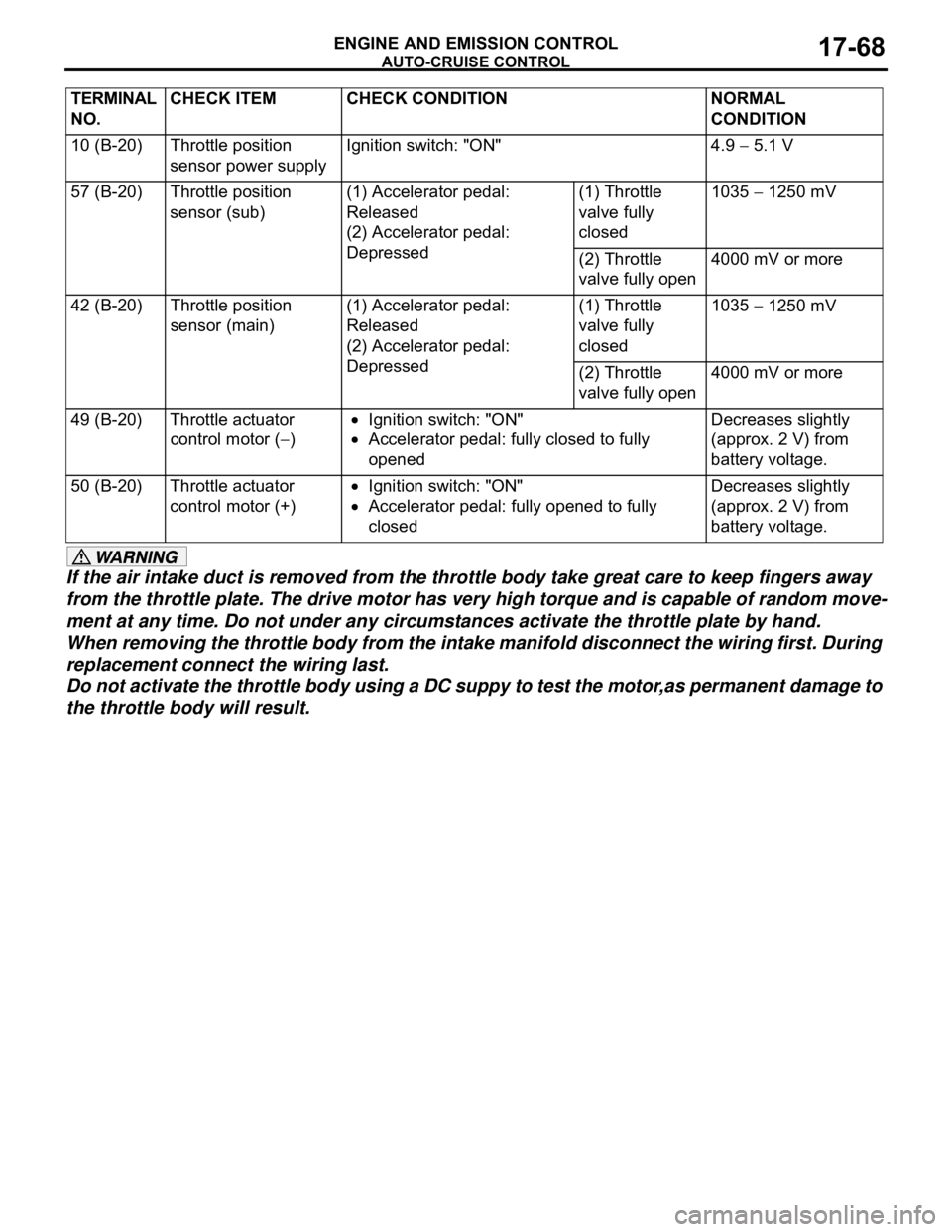

If the air intake duct is removed from the throttle body take great care to keep fingers away

from the throttle plate. The drive motor has very high torque and is capable of random move-

ment at any time. Do not under any circumstances activate the throttle plate by hand.

When removing the throttle body from the intake manifold disconnect the wiring first. During

replacement connect the wiring last.

Do not activate the throttle body using a DC suppy to test the motor,as permanent damage to

the throttle body will result.

10 (B-20) Throttle position

sensor power supplyIgnition switch: "ON" 4.9 5.1 V

57 (B-20) Throttle position

sensor (sub)(1) Accelerator pedal:

Released

(2) Accelerator pedal:

Depressed(1) Throttle

valve fully

closed1035

1250 mV

(2) Throttle

valve fully open4000 mV or more

42 (B-20) Throttle position

sensor (main)(1) Accelerator pedal:

Released

(2) Accelerator pedal:

Depressed(1) Throttle

valve fully

closed1035

1250 mV

(2) Throttle

valve fully open4000 mV or more

49 (B-20) Throttle actuator

control motor (

)

Ignition switch: "ON"

Accelerator pedal: fully closed to fully

openedDecreases slightly

(approx. 2 V) from

battery voltage.

50 (B-20) Throttle actuator

control motor (+)

Ignition switch: "ON"

Accelerator pedal: fully opened to fully

closedDecreases slightly

(approx. 2 V) from

battery voltage. TERMINAL

NO.CHECK ITEM CHECK CONDITION NORMAL

CONDITION

Page 1404 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-73

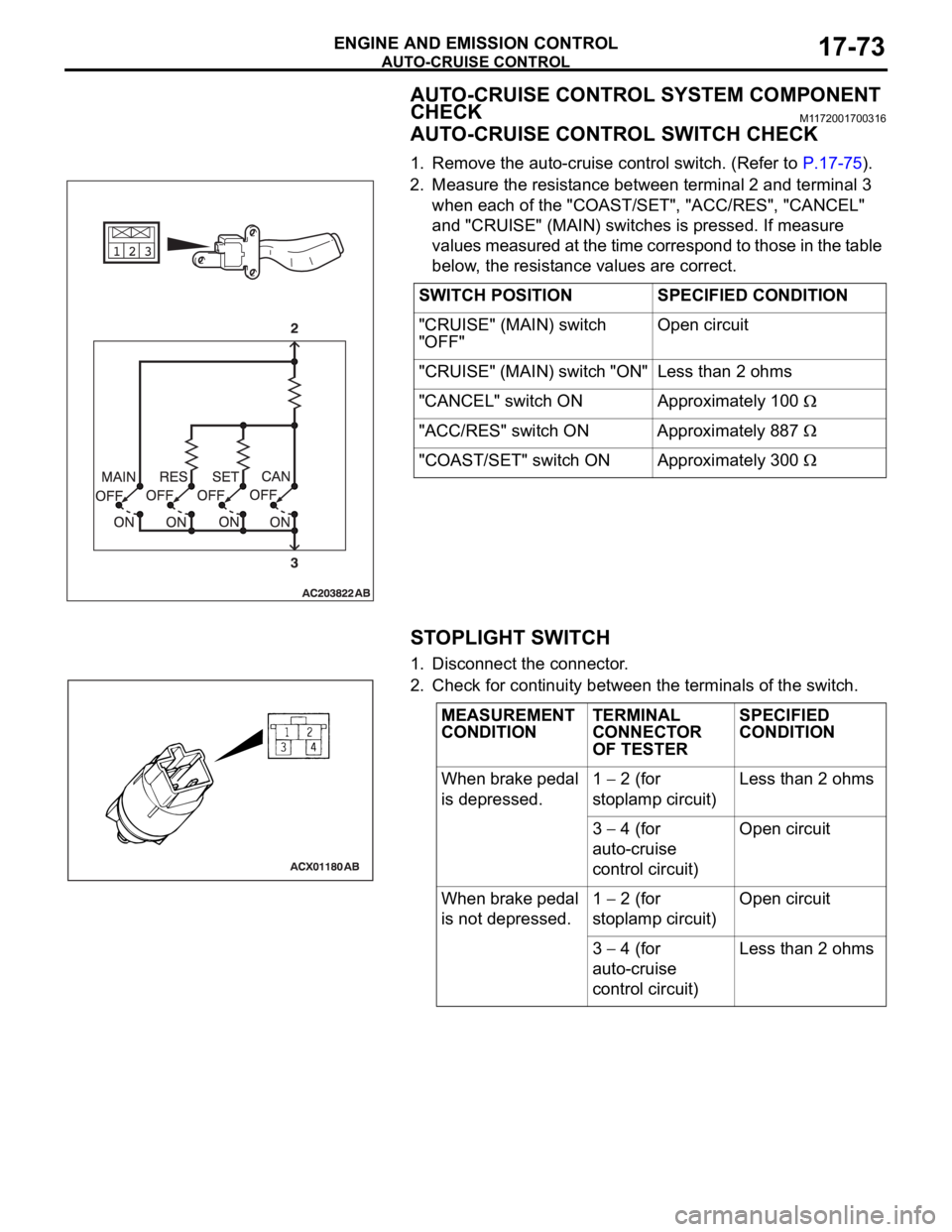

AUTO-CRUISE CONTROL SYSTEM COMPONENT

CHECK

M1172001700316

AUTO-CRUISE CONTROL SWITCH CHECK

1. Remove the auto-cruise control switch. (Refer to P.17-75).

2. Measure the resistance between terminal 2 and terminal 3

when each of the "COAST/SET", "ACC/RES", "CANCEL"

and "CRUISE" (MAIN) switches is pressed. If measure

values measured at the time correspond to those in the table

below, the resistance values are correct.

STOPLIGHT SWITCH

1. Disconnect the connector.

2. Check for continuity between the terminals of the switch.SWITCH POSITION SPECIFIED CONDITION

"CRUISE" (MAIN) switch

"OFF"Open circuit

"CRUISE" (MAIN) switch "ON" Less than 2 ohms

"CANCEL" switch ON Approximately 100

"ACC/RES" switch ON Approximately 887

"COAST/SET" switch ON Approximately 300

MEASUREMENT

CONDITIONTERMINAL

CONNECTOR

OF TESTERSPECIFIED

CONDITION

When brake pedal

is depressed.1

2 (for

stoplamp circuit)Less than 2 ohms

3

4 (for

auto-cruise

control circuit)Open circuit

When brake pedal

is not depressed.1

2 (for

stoplamp circuit)Open circuit

3

4 (for

auto-cruise

control circuit)Less than 2 ohms

Page 1406 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

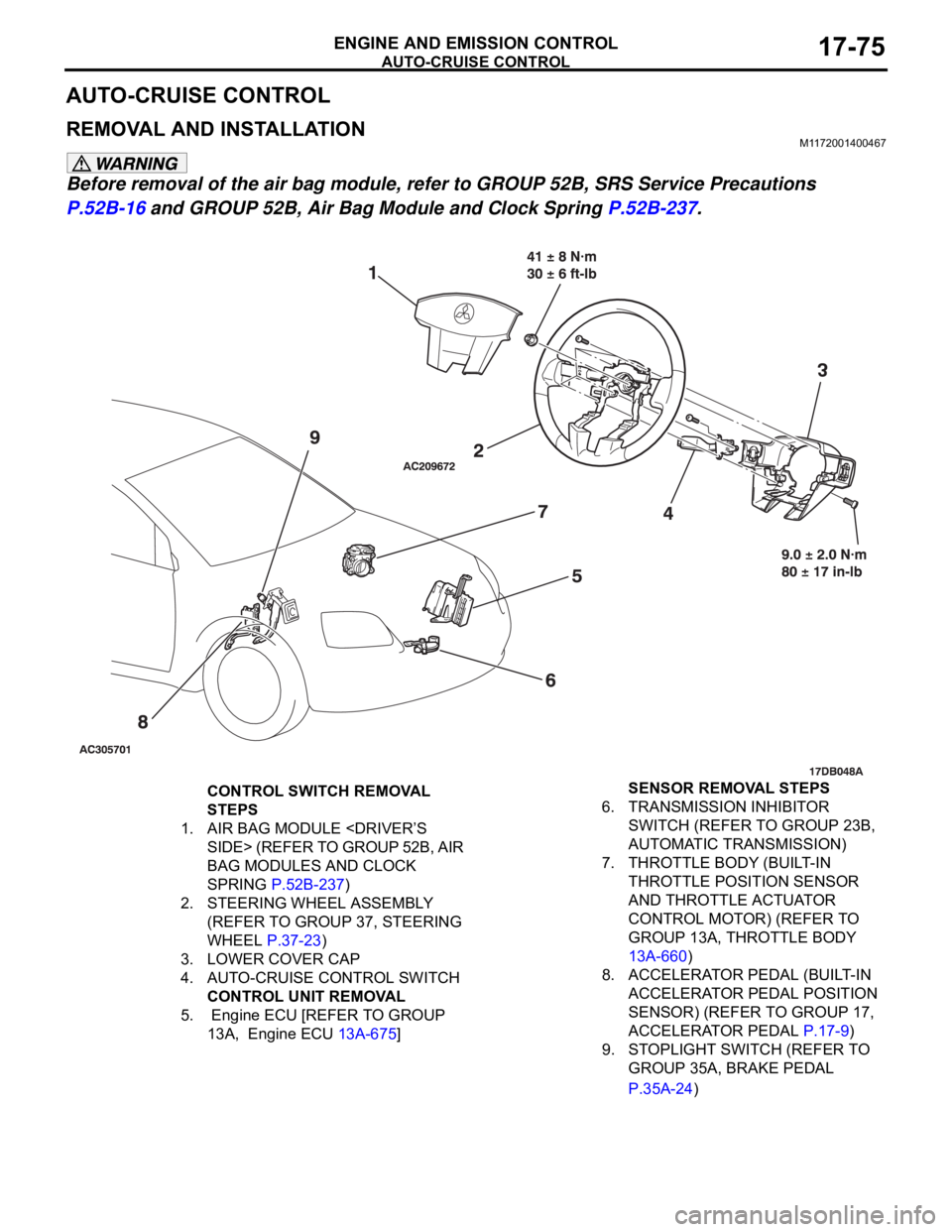

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

Page 1414 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-83

Required Special Tool:

MB995061: Purge Flow Indicator

1. Disconnect the purge hose from the evaporative emission

(EVAP) purge solenoid, and connect special tool MB995061

between the EVAP purge solenoid and the purge hose.

2. Before inspection, set the vehicle in the following conditions:

Engine coolant temperature: 80 95C (176 203F)

Lights, electric cooling fan and accessories: OFF

Transaxle: P range

3. Run the engine at idle for more than four minutes.

4. Check the purge flow volume when engine is revved

suddenly several times.

Standard value: Momentarily 20 cm

3/s (2.5 SCFH) or

more.

5. If the purge flow volume is less than the standard value,

check it again with the vacuum hose disconnected from the

EVAP canister. If the purge flow volume is less than the

standard value, check the vacuum port and the vacuum

hose for clogging. Also check the EVAP purge solenoid. If

the purge flow volume is at the standard value, replace the

EVAP canister.

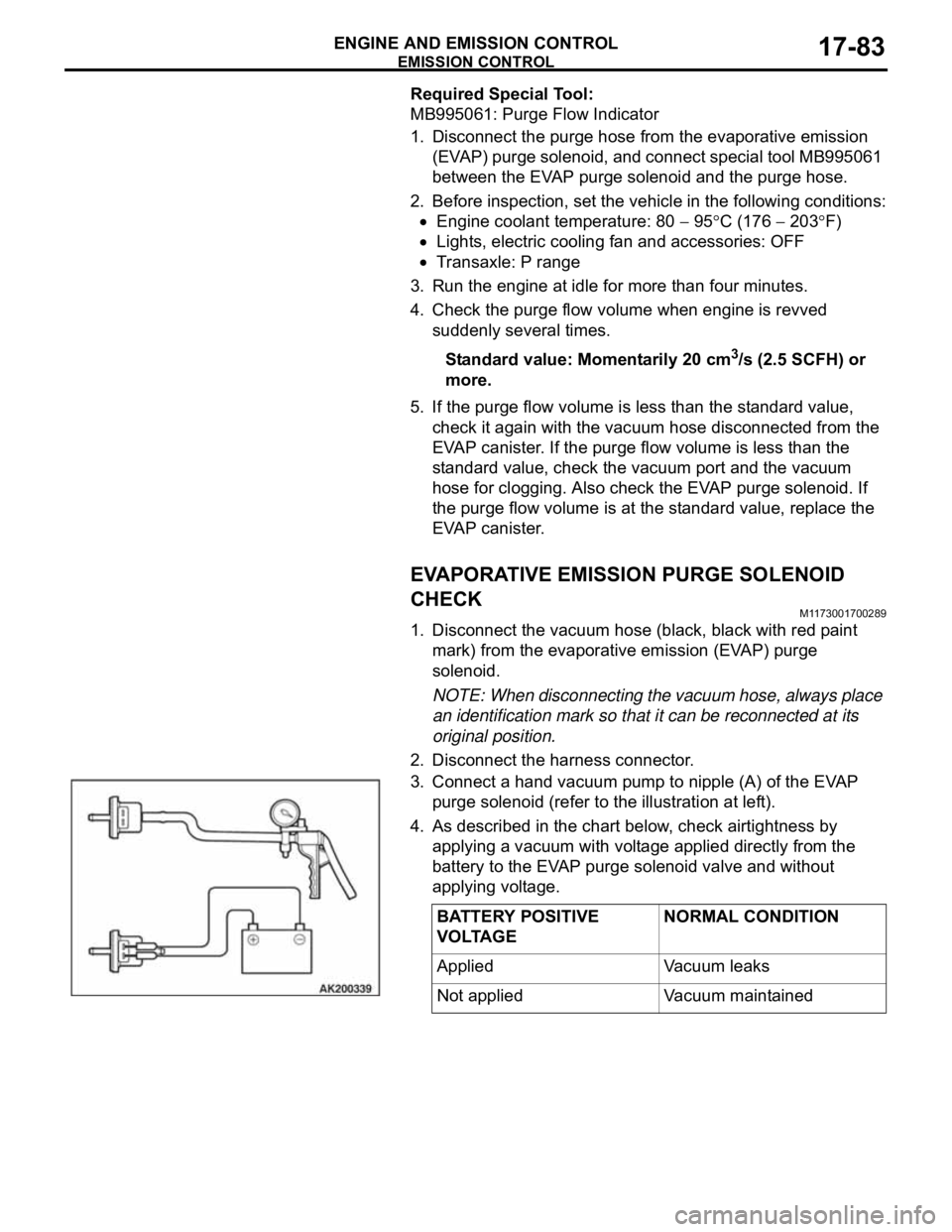

EVAPORATIVE EMISSION PURGE SOLENOID

CHECK

M1173001700289

1. Disconnect the vacuum hose (black, black with red paint

mark) from the evaporative emission (EVAP) purge

solenoid.

NOTE: When disconnecting the vacuum hose, always place

an identification mark so that it can be reconnected at its

original position.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the EVAP

purge solenoid (refer to the illustration at left).

4. As described in the chart below, check airtightness by

applying a vacuum with voltage applied directly from the

battery to the EVAP purge solenoid valve and without

applying voltage.

BATTERY POSITIVE

VOLTAGENORMAL CONDITION

Applied Vacuum leaks

Not applied Vacuum maintained