relay MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1069 of 1500

BODY42-2

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-23

GENERAL DESCRIPTION . . . . . .

42-23

CENTRAL DOOR LOCKING SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

POWER WINDOW DIAGNOSIS . . . . . . 42-23

DOOR DIAGNOSIS . . . . . . . . . . . . . . . . 42-23

INTRODUCTION TO GLASS AND DOOR

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

GLASS AND DOOR DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . 42-23

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-24

SYMPTOM PROCEDURES . . . . . . . . . 42-24

HOW TO LOCATE WIND NOISE . . . . . 42-27

SPECIAL TOOLS. . . . . . . . . . . . . .42-28

ON-VEHICLE SERVICE. . . . . . . . .42-30

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-30

DOOR WINDOW GLASS ADJUSTMENT42-31

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-32

POWER WINDOW TIMER FUNCTION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-32

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-33

POWER WINDOW RELAY CHECK . . . 42-33

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

POWER WINDOW CHECK . . . . . . . . . . 42-34

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR OUTSIDE HANDLE PLAY CHECK42-35

DOOR INSIDE HANDLE PLAY CHECK 42-35

DOOR ASSEMBLY . . . . . . . . . . . .42-37

REMOVAL AND INSTALLATION . . . . . 42-37

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-38

DOOR GLASS AND REGULATOR42-39

REMOVAL AND INSTALLATION . . . . . 42-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-43

DOOR HANDLE AND LATCH . . . .42-46

REMOVAL AND INSTALLATION . . . . . 42-46

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-49

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-52

REMOVAL AND INSTALLATION . . . . . . 42-52

TRUNK LID. . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSIS . . . . . . . .

42-60

INTRODUCTION TO TRUNK LID

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-60

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-60

SYMPTOM PROCEDURES . . . . . . . . . . 42-60

ON-VEHICLE SERVICE . . . . . . . . .42-61

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-61

TRUNK LID LATCH ADJUSTMENT. . . . 42-61

TRUNK LID HEIGHT ADJUSTMENT . . . 42-62

TRUNK LID . . . . . . . . . . . . . . . . . . .42-63

REMOVAL AND INSTALLATION . . . . . . 42-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-65

KEYLESS ENTRY SYSTEM 42-67

GENERAL DESCRIPTION . . . . . . .

42-67

KEYLESS ENTRY SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . .

42-68

SPECIAL TOOL . . . . . . . . . . . . . . .42-68

ON-VEHICLE SERVICE . . . . . . . . .42-69

TRANSMITTER BATTERY CHECK . . . . 42-69

HOW TO REPLACE THE TRANSMITTER

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . 42-70

KEYLESS ENTRY SYSTEM INSPECTION42-71

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION . . . . . . . . . . . 42-71

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-72

HOW TO REGISTER SECRET CODE . 42-73

Continued on next page

Page 1100 of 1500

DOOR

BODY42-33

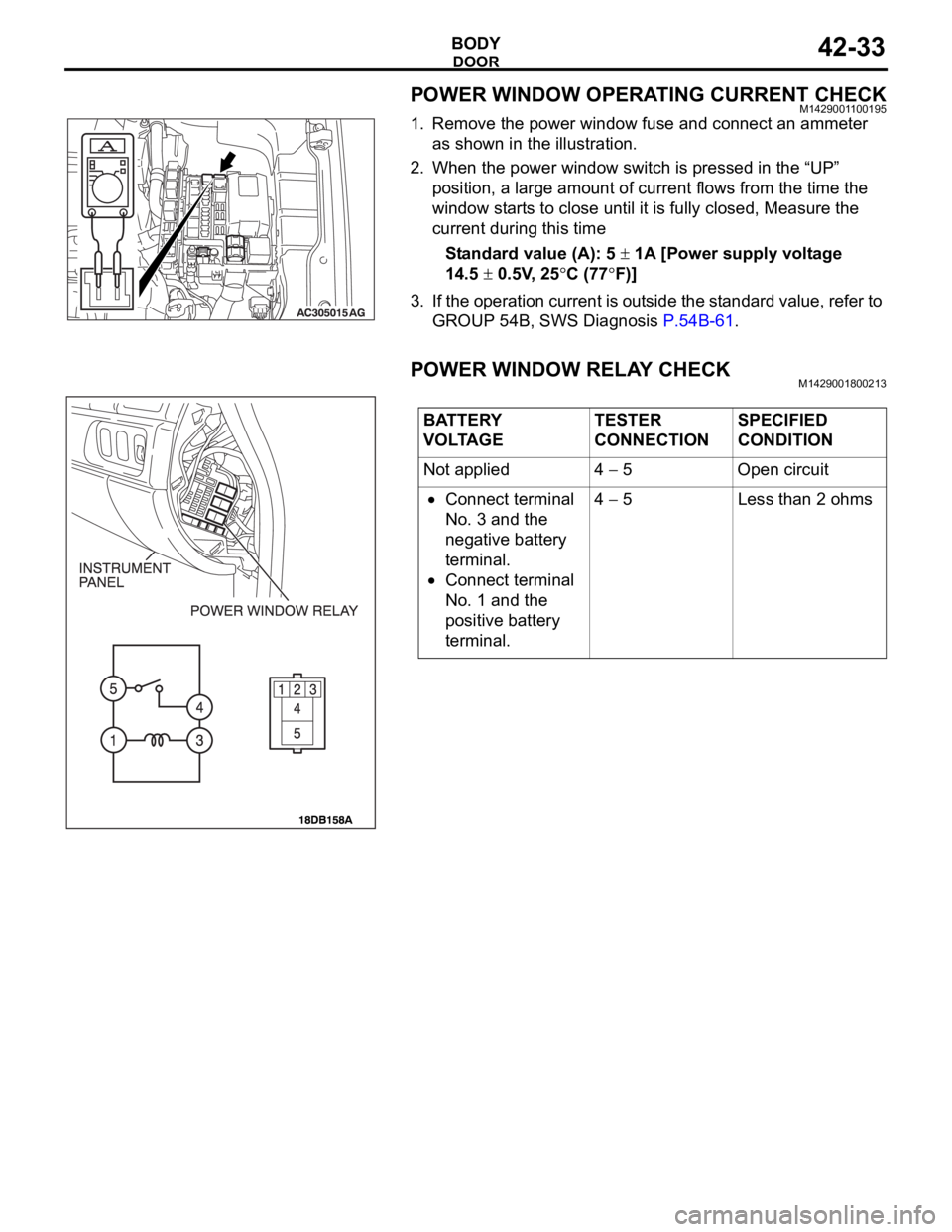

POWER WINDOW OPERATING CURRENT CHECKM1429001100195

1. Remove the power window fuse and connect an ammeter

as shown in the illustration.

2. When the power window switch is pressed in the “UP”

position, a large amount of current flows from the time the

window starts to close until it is fully closed, Measure the

current during this time

Standard value (A): 5

1A [Power supply voltage

14.5

0.5V, 25C (77F)]

3. If the operation current is outside the standard value, refer to

GROUP 54B, SWS Diagnosis P.54B-61.

POWER WINDOW RELAY CHECKM1429001800213

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal

No. 3 and the

negative battery

terminal.

Connect terminal

No. 1 and the

positive battery

terminal.4

5 Less than 2 ohms

Page 1288 of 1500

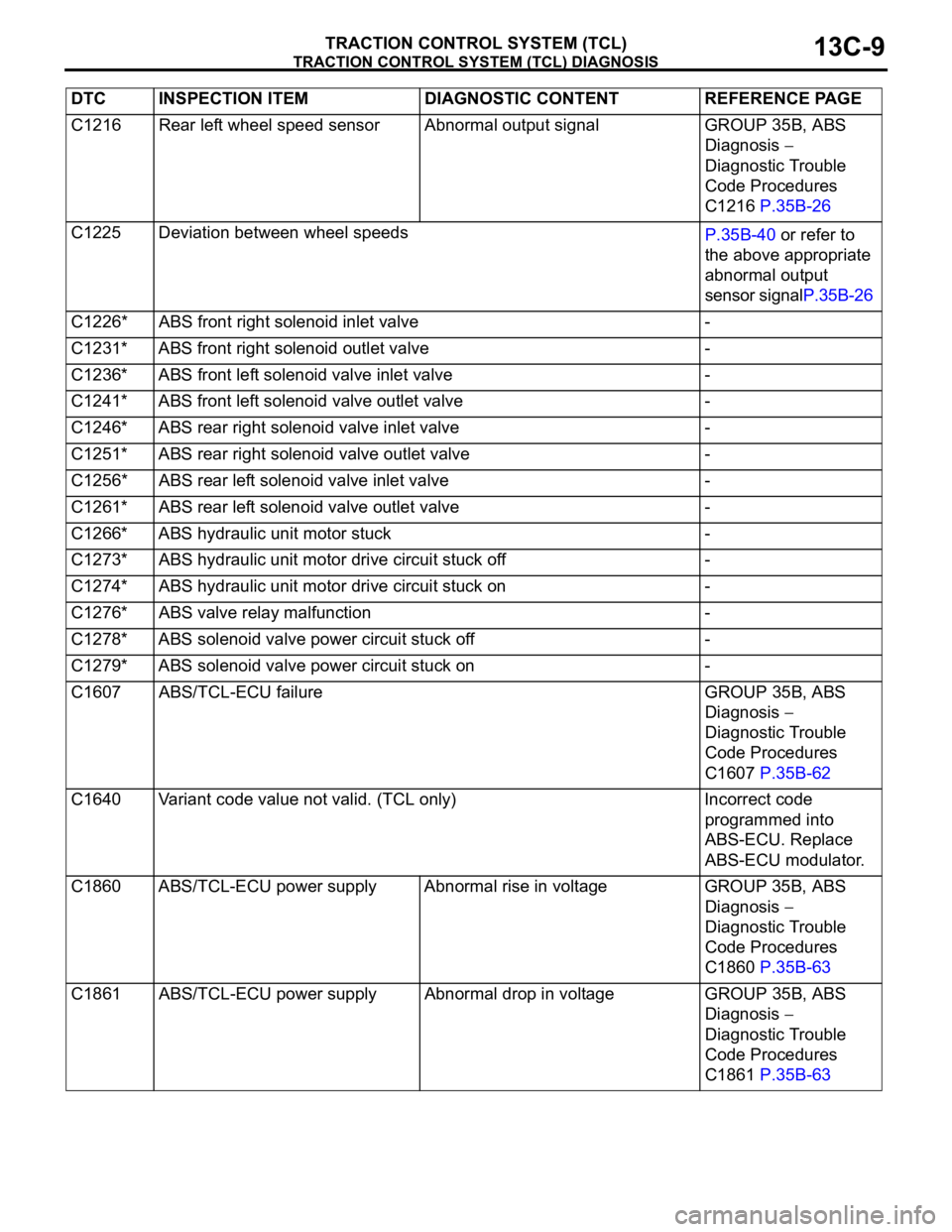

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-9

C1216 Rear left wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1216 P.35B-26

C1225 Deviation between wheel speeds

P.35B-40 or refer to

the above appropriate

abnormal output

sensor signalP.35B-26

C1226* ABS front right solenoid inlet valve -

C1231* ABS front right solenoid outlet valve -

C1236* ABS front left solenoid valve inlet valve -

C1241* ABS front left solenoid valve outlet valve -

C1246* ABS rear right solenoid valve inlet valve -

C1251* ABS rear right solenoid valve outlet valve -

C1256* ABS rear left solenoid valve inlet valve -

C1261* ABS rear left solenoid valve outlet valve -

C1266* ABS hydraulic unit motor stuck -

C1273* ABS hydraulic unit motor drive circuit stuck off -

C1274* ABS hydraulic unit motor drive circuit stuck on -

C1276* ABS valve relay malfunction -

C1278* ABS solenoid valve power circuit stuck off -

C1279* ABS solenoid valve power circuit stuck on -

C1607 ABS/TCL-ECU failure GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1607 P.35B-62

C1640 Variant code value not valid. (TCL only) Incorrect code

programmed into

ABS-ECU. Replace

ABS-ECU modulator.

C1860 ABS/TCL-ECU power supply Abnormal rise in voltage GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1860 P.35B-63

C1861 ABS/TCL-ECU power supply Abnormal drop in voltage GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1861 P.35B-63 DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE

Page 1315 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-36

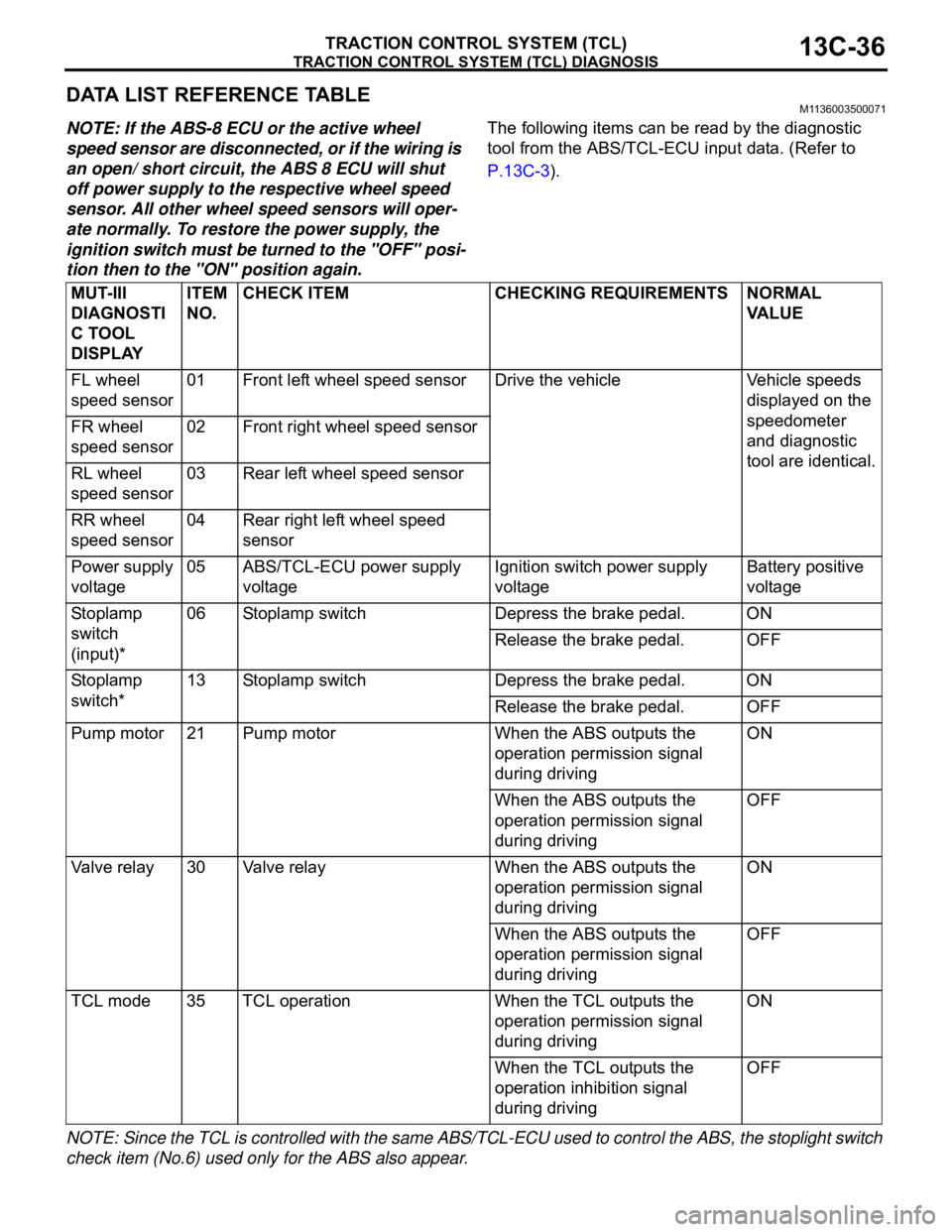

DATA LIST REFERENCE TABLEM1136003500071

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.The following items can be read by the diagnostic

tool from the ABS/TCL-ECU input data. (Refer to

P.13C-3).

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the stoplight switch

check item (No.6) used only for the ABS also appear.MUT-III

DIAGNOSTI

C TOOL

DISPLAYITEM

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL

VA L U E

FL wheel

speed sensor01 Front left wheel speed sensor Drive the vehicle Vehicle speeds

displayed on the

speedometer

and diagnostic

tool are identical. FR wheel

speed sensor02 Front right wheel speed sensor

RL wheel

speed sensor03 Rear left wheel speed sensor

RR wheel

speed sensor04 Rear right left wheel speed

sensor

Power supply

voltage05 ABS/TCL-ECU power supply

voltageIgnition switch power supply

voltageBattery positive

voltage

Stoplamp

switch

(input)*06 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Stoplamp

switch*13 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Pump motor 21 Pump motor When the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

Valve relay 30 Valve relayWhen the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

TCL mode 35 TCL operation When the TCL outputs the

operation permission signal

during drivingON

When the TCL outputs the

operation inhibition signal

during drivingOFF

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

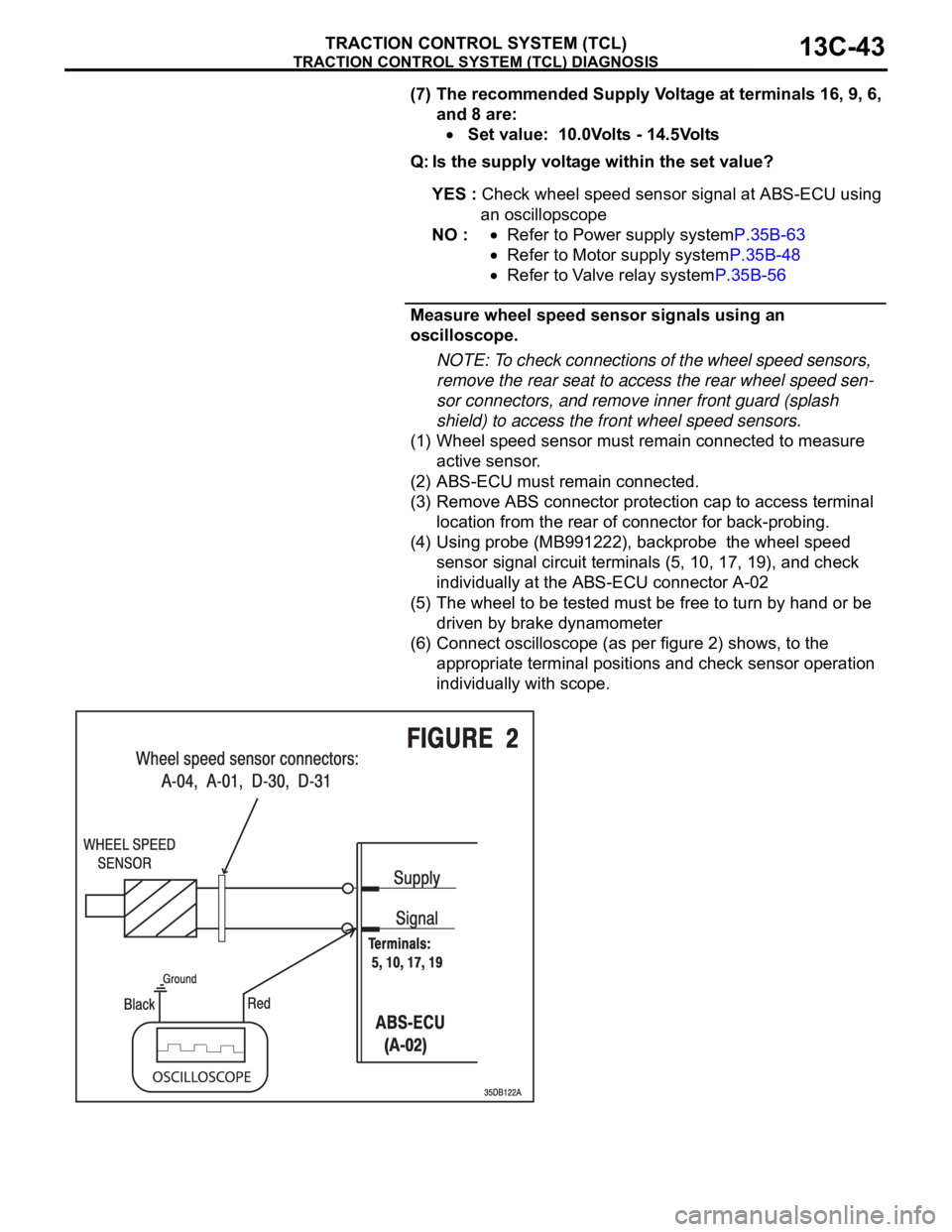

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1372 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-41

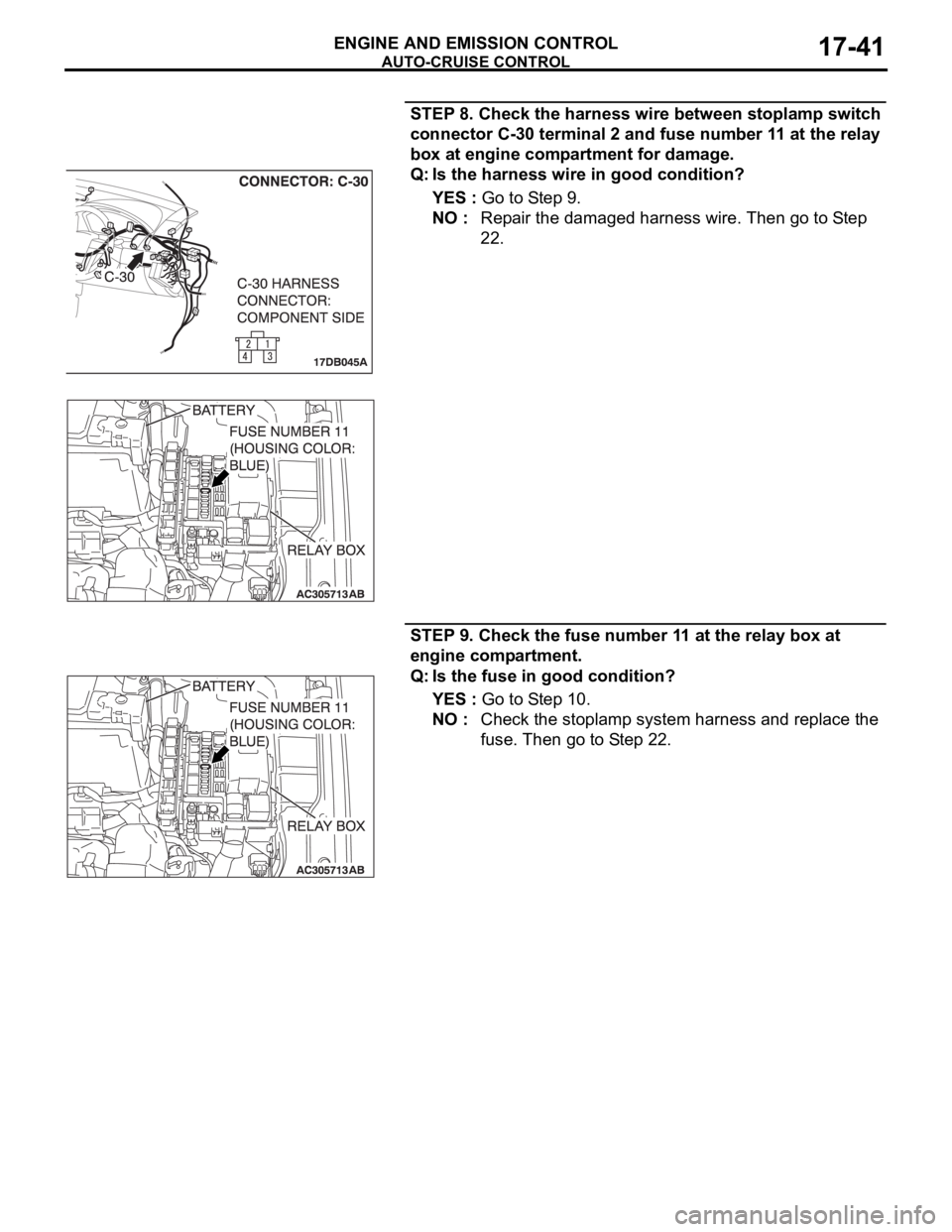

STEP 8. Check the harness wire between stoplamp switch

connector C-30 terminal 2 and fuse number 11 at the relay

box at engine compartment for damage.

Q: Is the harness wire in good condition?

YES : Go to Step 9.

NO : Repair the damaged harness wire. Then go to Step

22.

STEP 9. Check the fuse number 11 at the relay box at

engine compartment.

Q: Is the fuse in good condition?

YES : Go to Step 10.

NO : Check the stoplamp system harness and replace the

fuse. Then go to Step 22.

Page 1461 of 1500

AUTOMATIC TRANSMISSION23A-2

SPECIAL TOOLS . . . . . . . . . . . . . . . .23A-286

ON-VEHICLE SERVICE. . . . . . . . . . .23A-289

A/T CONTROL COMPONENT LAYOUT . . 23A-289

ESSENTIAL SERVICE . . . . . . . . . . . . . . . . 23A-291

TRANSMISSION FLUID CHECK . . . . . . . . 23A-291

TRANSMISSION FLUID CHANGE . . . . . . . 23A-292

OIL COOLER FLOW CHECK . . . . . . . . . . . 23A-294

TRANSMISSION RANGE SWITCH

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-294

TRANSMISSION RANGE SWITCH AND

CONTROL CABLE ADJUSTMENT. . . . . . . 23A-294

AUTOMATIC TRANSMISSION CONTROL

COMPONENT CHECK . . . . . . . . . . . . . . . . 23A-295

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-295

TRANSMISSION FLUID TEMPERATURE

SENSOR CHECK . . . . . . . . . . . . . . . . . . . . 23A-296

TRANSMISSION RANGE SWITCH

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-296

STOPLIGHT SWITCH CHECK . . . . . . . . . . 23A-296

A/T CONTROL RELAY CHECK . . . . . . . . . 23A-296

SOLENOID VALVE CHECK . . . . . . . . . . . . 23A-298SELECTOR LEVER OPERATION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-299

TRANSMISSION CONTROL CABLE

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 23A-299

TRANSMISSION CONTROL* . . . . . . .23A-300

REMOVAL AND INSTALLATION . . . . . . . . 23A-300

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 23A-301

DISASSEMBLY AND ASSEMBLY . . . . . . . 23A-302

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 23A-303

TRANSMISSION ASSEMBLY . . . . . .23A-304

REMOVAL AND INSTALLATION . . . . . . . . 23A-304

TRANSMISSION FLUID COOLER,

HOSE AND PIPE . . . . . . . . . . . . . . . .23A-312

REMOVAL AND INSTALLATION . . . . . . . . 23A-312

SPECIFICATIONS . . . . . . . . . . . . . . .23A-313

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 23A-313

SERVICE SPECIFICATIONS . . . . . . . . . . . 23A-313

LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . 23A-314

Page 1472 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-13

A/T DIAGNOSTIC TROUBLESHOOTING STRATEGYM1231007600339

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will find most A/T mal-

functions.

1. Gather as much information as possible about the

complaint from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any A/T Diagnostic Trouble

Codes (DTCs).

4. If you can not verify the condition and there are no

DTCs, the malfunction is intermittent. For

information on how to cope with intermittent

malfunctions, refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunction P.00-14.

5. If you can verify the condition but there are no

DTCs, or the system can not communicate with

diagnostic tool, refer to the Symptom Chart

P.23A-35.6. If there is a DTC, record the number of the code,

then erase the code from memory using

diagnostic tool.

7. Reconfirm the symptom with a Road Test.

8. If a DTC is set again, go to the Inspection Chart

for Diagnostic Trouble Codes.

9. If a DTC is not set again, the malfunction is

intermittent. For information on how to cope with

intermittent malfunctions, refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

How to Cope with Intermittent

Malfunction P.00-14.

10.After repairs are completed, conduct a Road Test

duplicating the complaint conditions to confirm the

malfunction has been eliminated.

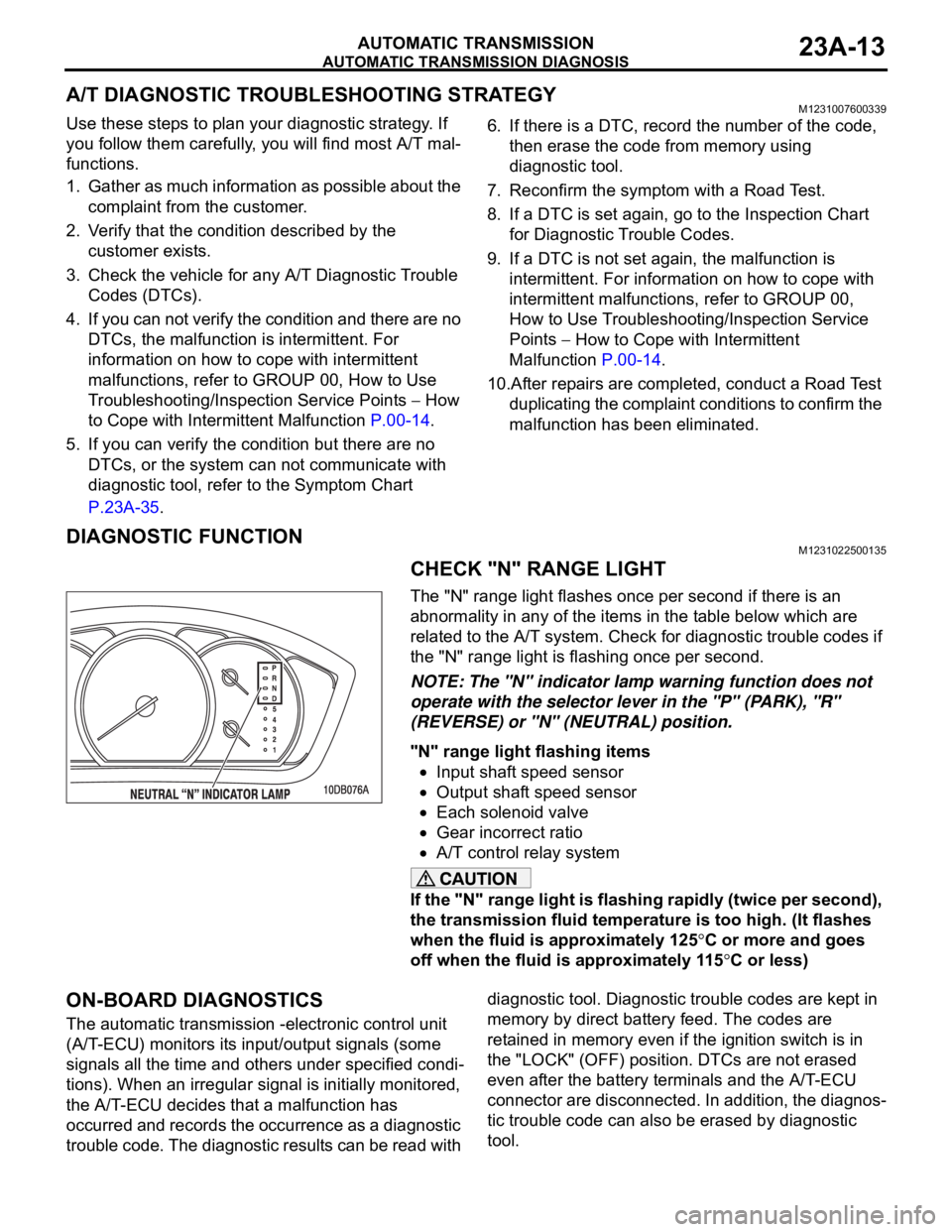

DIAGNOSTIC FUNCTIONM1231022500135

CHECK "N" RANGE LIGHT

The "N" range light flashes once per second if there is an

abnormality in any of the items in the table below which are

related to the A/T system. Check for diagnostic trouble codes if

the "N" range light is flashing once per second.

NOTE: The "N" indicator lamp warning function does not

operate with the selector lever in the "P" (PARK), "R"

(REVERSE) or "N" (NEUTRAL) position.

"N" range light flashing items

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Gear incorrect ratio

A/T control relay system

If the "N" range light is flashing rapidly (twice per second),

the transmission fluid temperature is too high. (It flashes

when the fluid is approximately 125

C or more and goes

off when the fluid is approximately 115

C or less)

ON-BOARD DIAGNOSTICS

The automatic transmission -electronic control unit

(A/T-ECU) monitors its input/output signals (some

signals all the time and others under specified condi-

tions). When an irregular signal is initially monitored,

the A/T-ECU decides that a malfunction has

occurred and records the occurrence as a diagnostic

trouble code. The diagnostic results can be read with diagnostic tool. Diagnostic trouble codes are kept in

memory by direct battery feed. The codes are

retained in memory even if the ignition switch is in

the "LOCK" (OFF) position. DTCs are not erased

even after the battery terminals and the A/T-ECU

connector are disconnected. In addition, the diagnos-

tic trouble code can also be erased by diagnostic

tool.

Page 1477 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-18

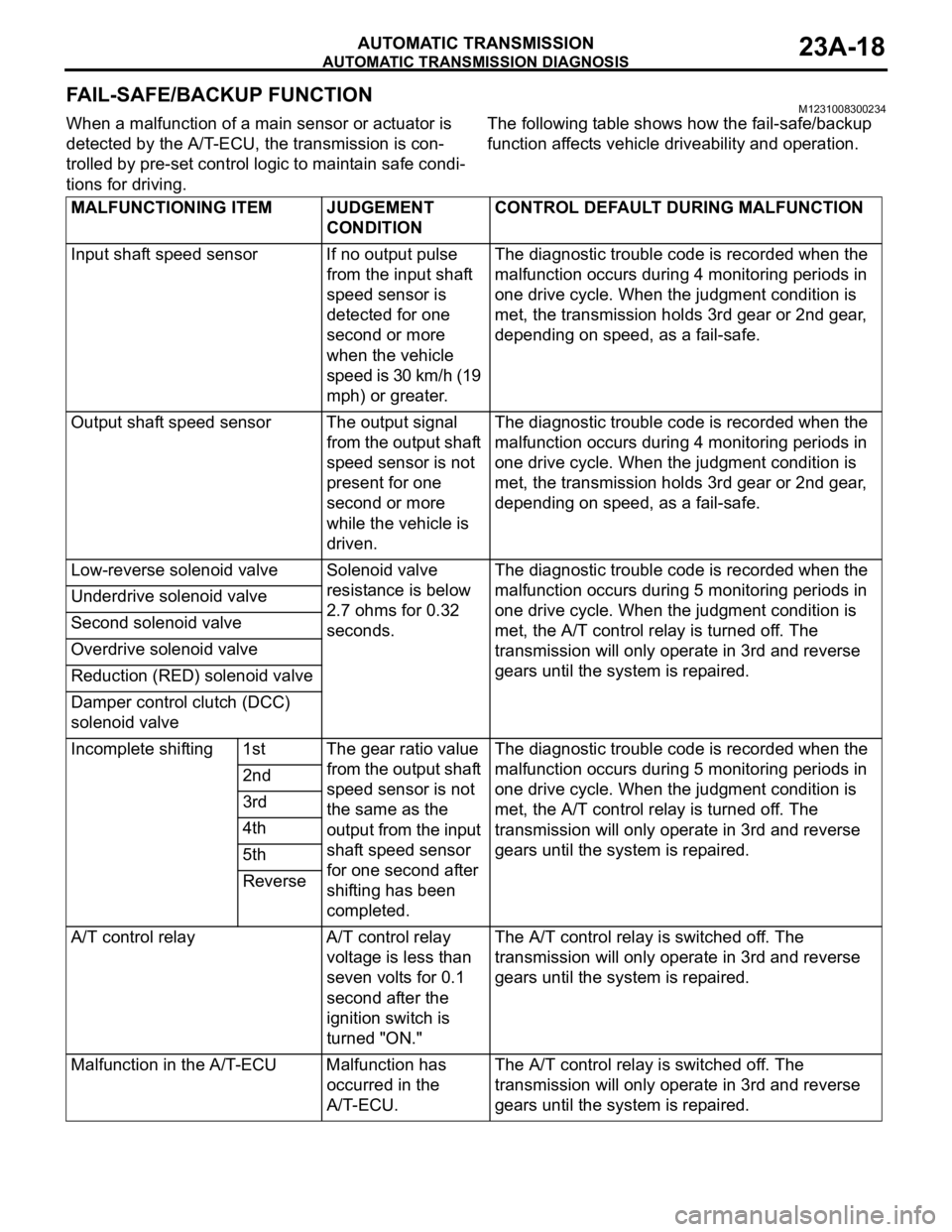

FAIL-SAFE/BACKUP FUNCTIONM1231008300234

When a malfunction of a main sensor or actuator is

detected by the A/T-ECU, the transmission is con-

trolled by pre-set control logic to maintain safe condi-

tions for driving.The following table shows how the fail-safe/backup

function affects vehicle driveability and operation.

MALFUNCTIONING ITEM JUDGEMENT

CONDITIONCONTROL DEFAULT DURING MALFUNCTION

Input shaft speed sensor If no output pulse

from the input shaft

speed sensor is

detected for one

second or more

when the vehicle

speed is 30 km/h (19

mph) or greater.The diagnostic trouble code is recorded when the

malfunction occurs during 4 monitoring periods in

one drive cycle. When the judgment condition is

met, the transmission holds 3rd gear or 2nd gear,

depending on speed, as a fail-safe.

Output shaft speed sensor The output signal

from the output shaft

speed sensor is not

present for one

second or more

while the vehicle is

driven.The diagnostic trouble code is recorded when the

malfunction occurs during 4 monitoring periods in

one drive cycle. When the judgment condition is

met, the transmission holds 3rd gear or 2nd gear,

depending on speed, as a fail-safe.

Low-reverse solenoid valve Solenoid valve

resistance is below

2.7 ohms for 0.32

seconds.The diagnostic trouble code is recorded when the

malfunction occurs during 5 monitoring periods in

one drive cycle. When the judgment condition is

met, the A/T control relay is turned off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired. Underdrive solenoid valve

Second solenoid valve

Overdrive solenoid valve

Reduction (RED) solenoid valve

Damper control clutch (DCC)

solenoid valve

Incomplete shifting 1st The gear ratio value

from the output shaft

speed sensor is not

the same as the

output from the input

shaft speed sensor

for one second after

shifting has been

completed.The diagnostic trouble code is recorded when the

malfunction occurs during 5 monitoring periods in

one drive cycle. When the judgment condition is

met, the A/T control relay is turned off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired. 2nd

3rd

4th

5th

Reverse

A/T control relay A/T control relay

voltage is less than

seven volts for 0.1

second after the

ignition switch is

turned "ON."The A/T control relay is switched off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired.

Malfunction in the A/T-ECU Malfunction has

occurred in the

A/T-ECU.The A/T control relay is switched off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired.

Page 1478 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-19

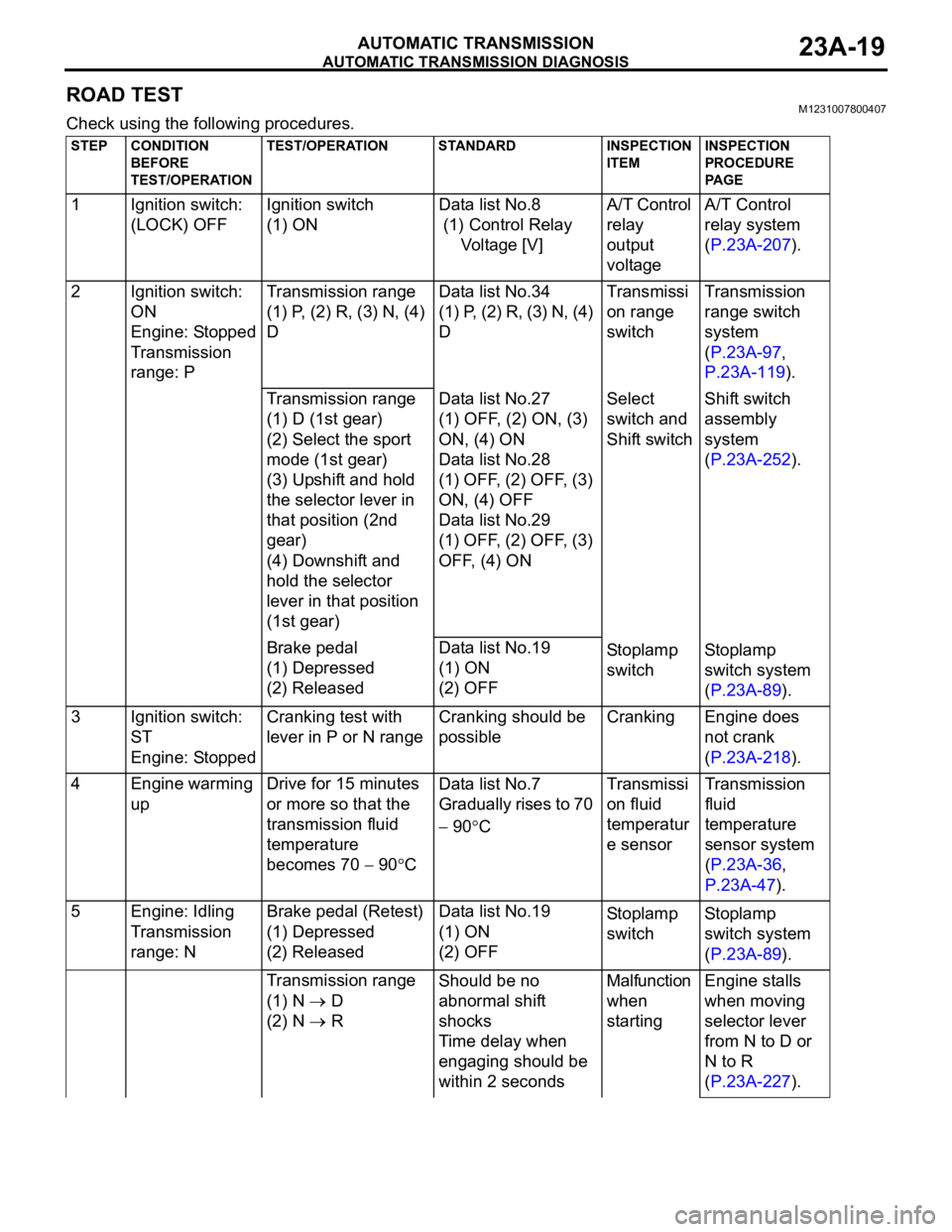

ROAD TESTM1231007800407

Check using the following procedures.

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

1 Ignition switch:

(LOCK) OFFIgnition switch

(1) ONData list No.8

(1) Control Relay

Voltage [V]A/T Control

relay

output

voltageA/T Control

relay system

(P.23A-207).

2 Ignition switch:

ON

Engine: Stopped

Transmission

range: PTransmission range

(1) P, (2) R, (3) N, (4)

DData list No.34

(1) P, (2) R, (3) N, (4)

DTransmissi

on range

switchTransmission

range switch

system

(P.23A-97,

P.23A-119).

Transmission range

(1) D (1st gear)

(2) Select the sport

mode (1st gear)

(3) Upshift and hold

the selector lever in

that position (2nd

gear)

(4) Downshift and

hold the selector

lever in that position

(1st gear)Data list No.27

(1) OFF, (2) ON, (3)

ON, (4) ON

Data list No.28

(1) OFF, (2) OFF, (3)

ON, (4) OFF

Data list No.29

(1) OFF, (2) OFF, (3)

OFF, (4) ONSelect

switch and

Shift switchShift switch

assembly

system

(P.23A-252).

Brake pedal

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

3 Ignition switch:

ST

Engine: StoppedCranking test with

lever in P or N rangeCranking should be

possibleCranking Engine does

not crank

(P.23A-218).

4 Engine warming

upDrive for 15 minutes

or more so that the

transmission fluid

temperature

becomes 70

90CData list No.7

Gradually rises to 70

90CTransmissi

on fluid

temperatur

e sensorTransmission

fluid

temperature

sensor system

(P.23A-36,

P.23A-47).

5 Engine: Idling

Transmission

range: NBrake pedal (Retest)

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

Transmission range

(1) N

D

(2) N

RShould be no

abnormal shift

shocks

Time delay when

engaging should be

within 2 secondsMalfunction

when

startingEngine stalls

when moving

selector lever

from N to D or

N to R

(P.23A-227).