relay MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 794 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-93

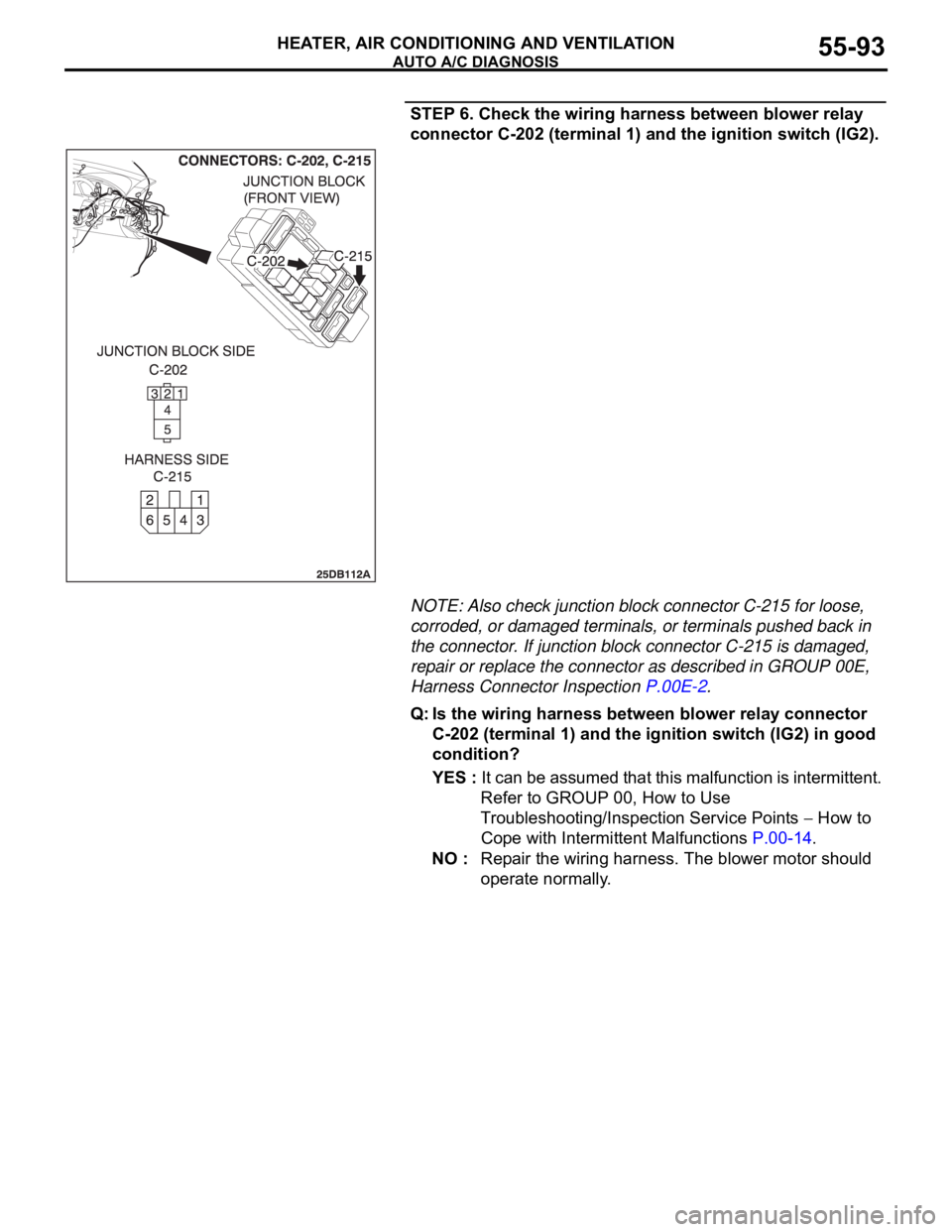

STEP 6. Check the wiring harness between blower relay

connector C-202 (terminal 1) and the ignition switch (IG2).

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 1) and the ignition switch (IG2) in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

Page 795 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-94

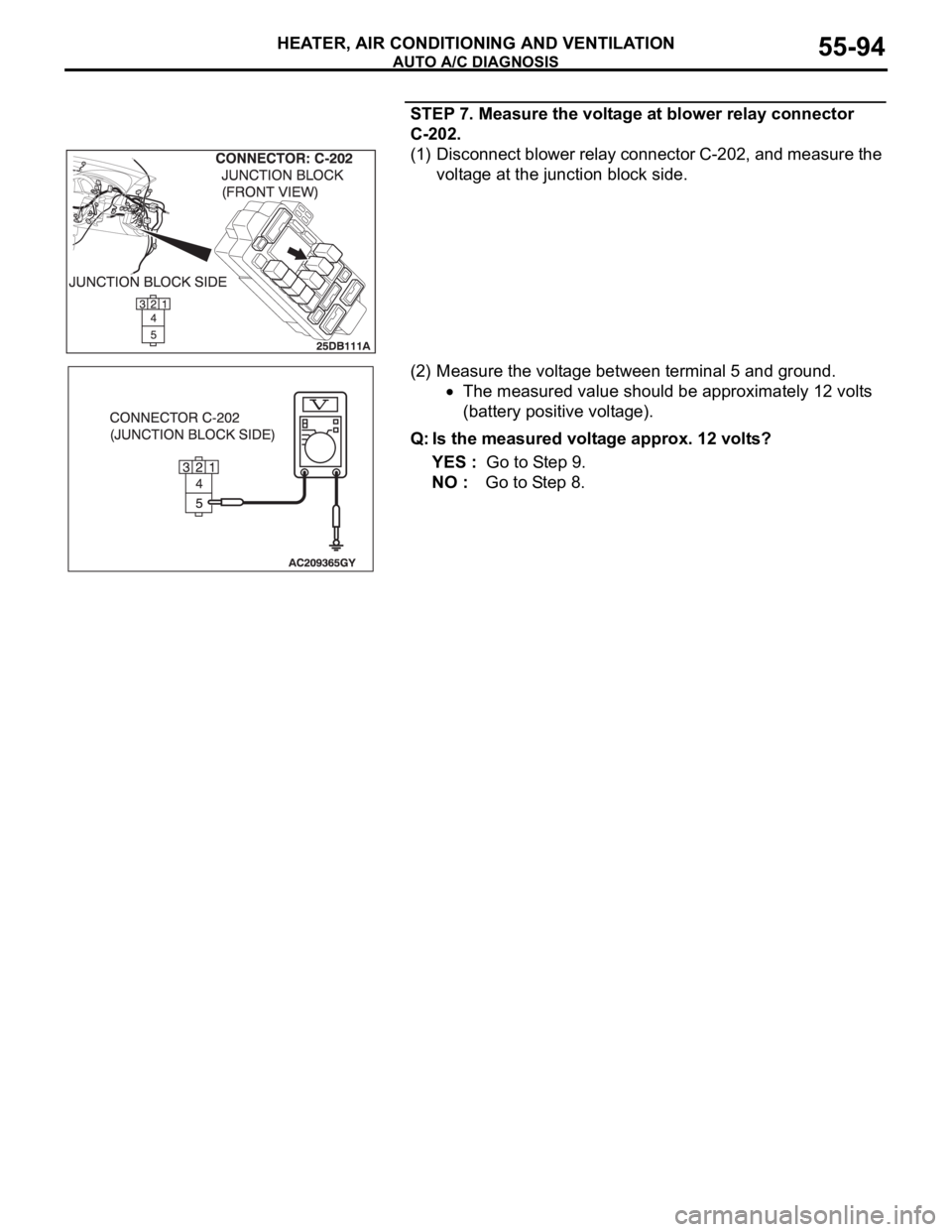

STEP 7. Measure the voltage at blower relay connector

C-202.

(1) Disconnect blower relay connector C-202, and measure the

voltage at the junction block side.

(2) Measure the voltage between terminal 5 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 9.

NO : Go to Step 8.

Page 796 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-95

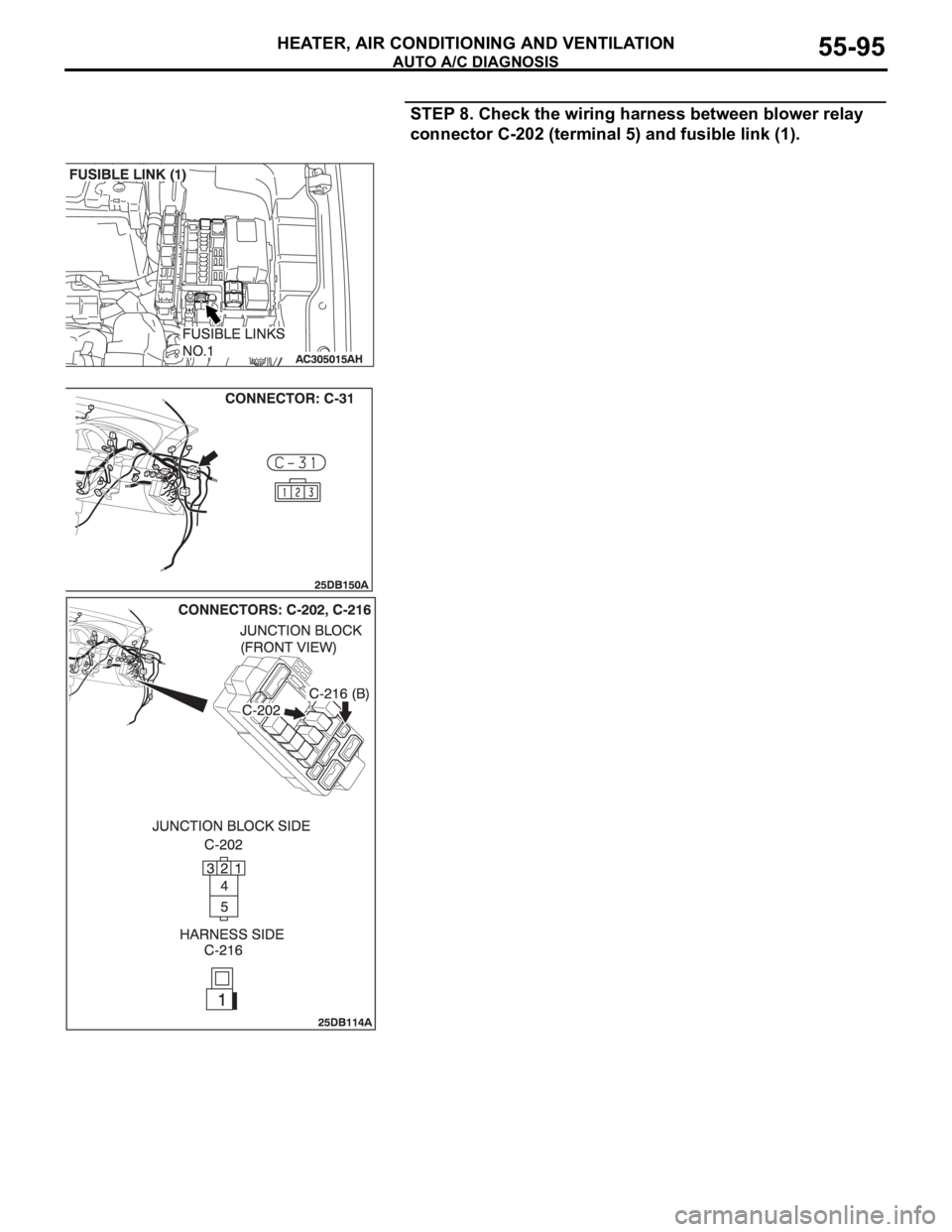

STEP 8. Check the wiring harness between blower relay

connector C-202 (terminal 5) and fusible link (1).

Page 797 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-96

NOTE: Also check intermediate connector C-31 and junction

block connector C-216 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If intermediate

connector C-31, junction block connector C-216 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 5) and fusible link (1) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

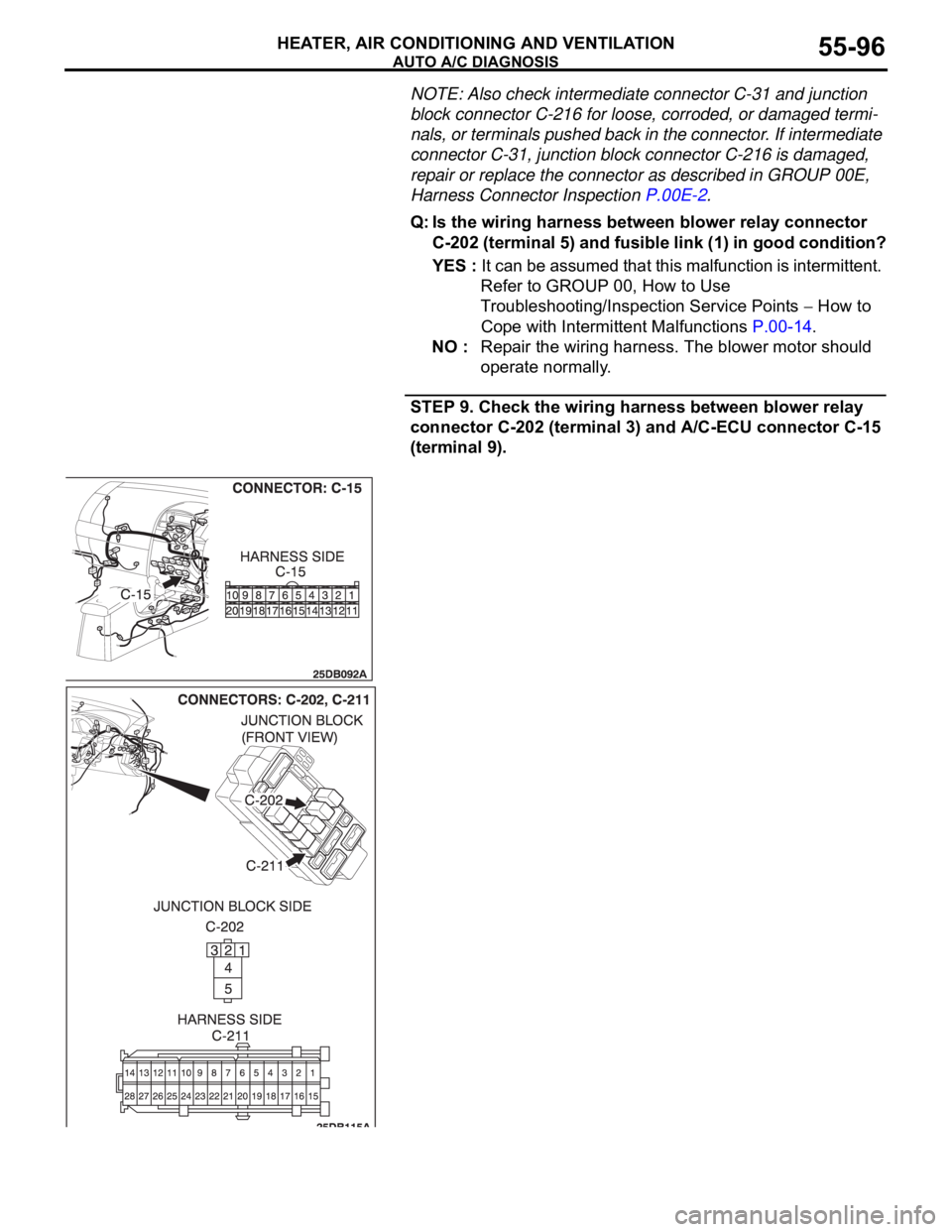

STEP 9. Check the wiring harness between blower relay

connector C-202 (terminal 3) and A/C-ECU connector C-15

(terminal 9).

Page 798 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-97

NOTE: Also check junction block connector C-211 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-211 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 3) and A/C-ECU connector C-15

(terminal 9) in good condition?

YES : Go to Step 10.

NO : Repair the wiring harness. The blower motor should

operate normally.

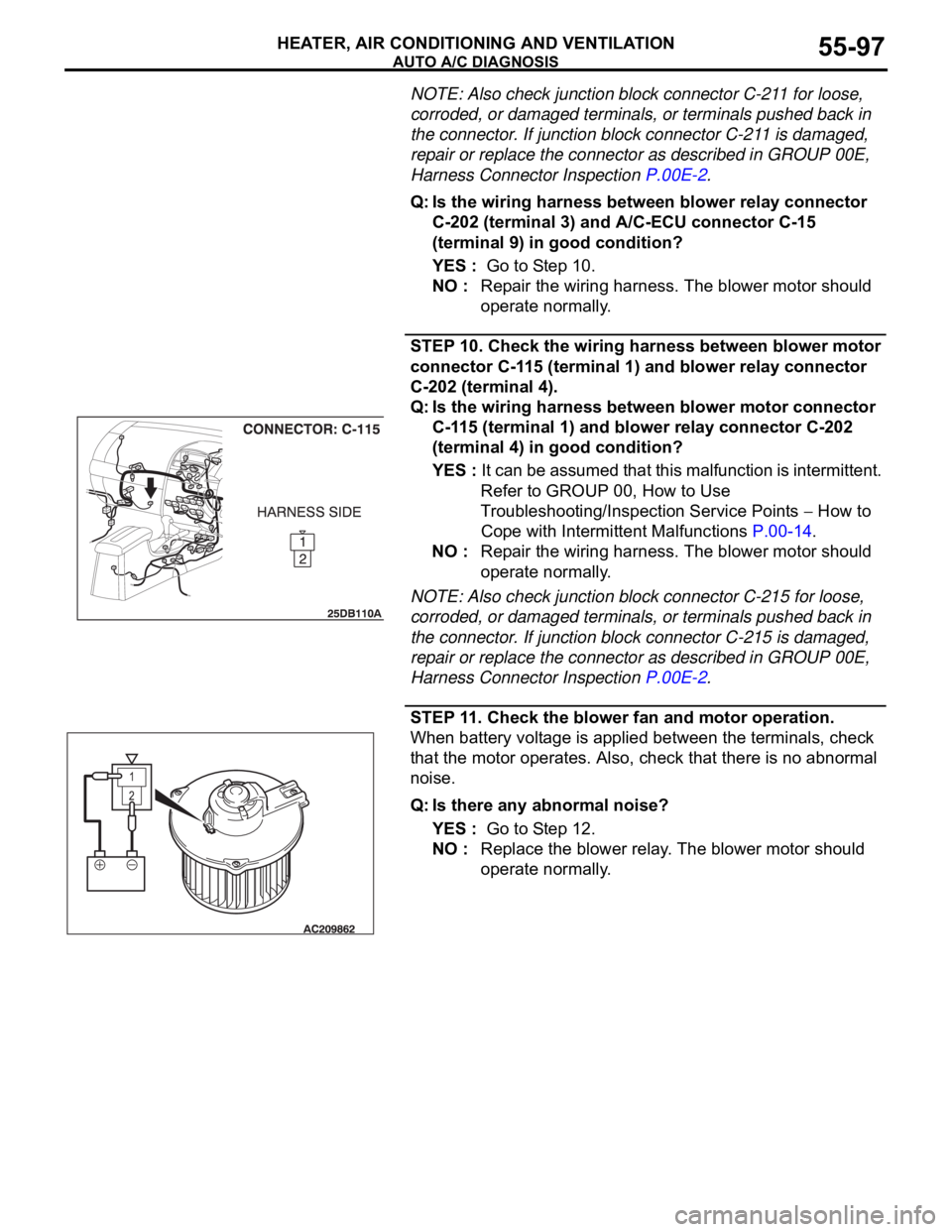

STEP 10. Check the wiring harness between blower motor

connector C-115 (terminal 1) and blower relay connector

C-202 (terminal 4).

Q: Is the wiring harness between blower motor connector

C-115 (terminal 1) and blower relay connector C-202

(terminal 4) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

STEP 11. Check the blower fan and motor operation.

When battery voltage is applied between the terminals, check

that the motor operates. Also, check that there is no abnormal

noise.

Q: Is there any abnormal noise?

YES : Go to Step 12.

NO : Replace the blower relay. The blower motor should

operate normally.

Page 811 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-110

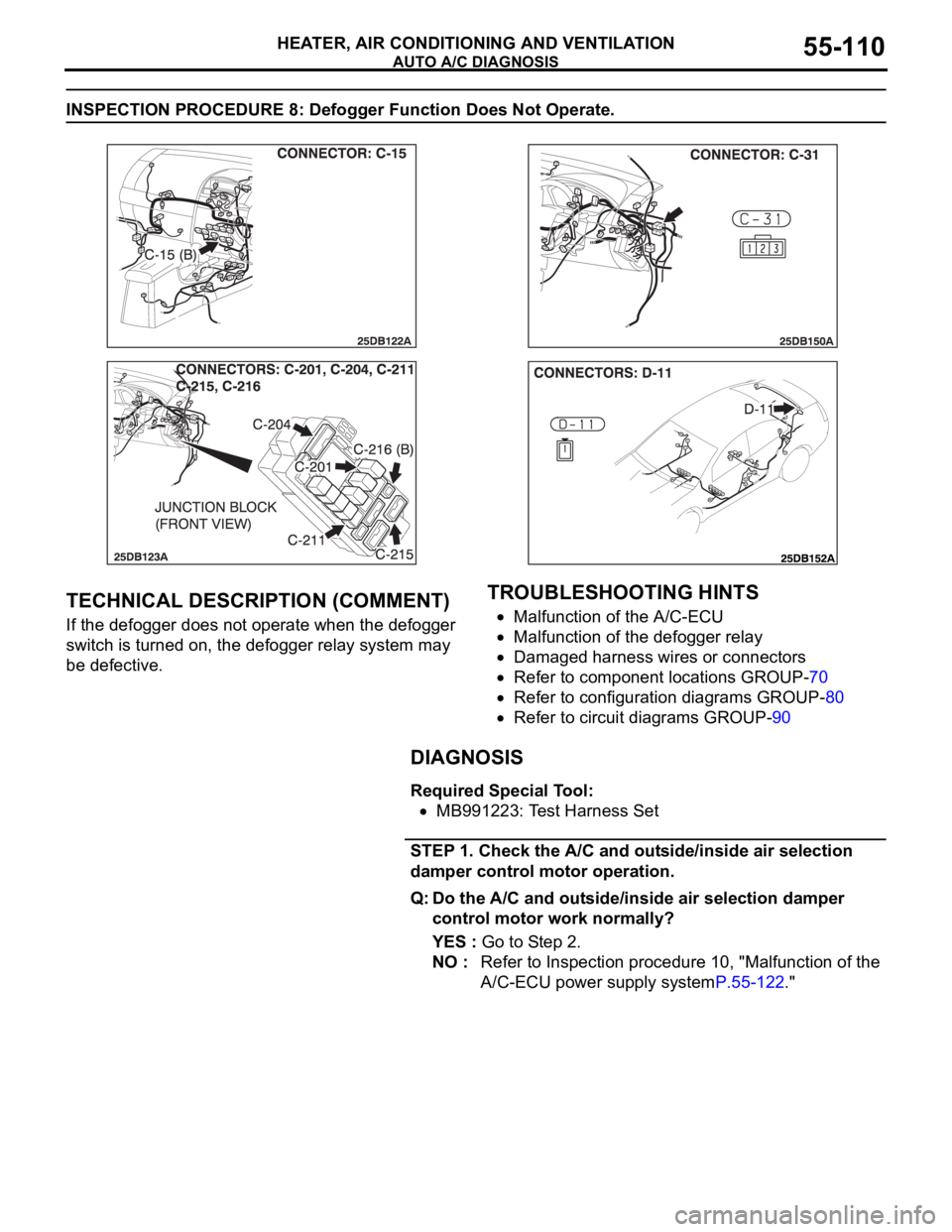

INSPECTION PROCEDURE 8: Defogger Function Does Not Operate.

.

TECHNICAL DESCRIPTION (COMMENT)

If the defogger does not operate when the defogger

switch is turned on, the defogger relay system may

be defective.

.

TROUBLESHOOTING HINTS

Malfunction of the A/C-ECU

Malfunction of the defogger relay

Damaged harness wires or connectors

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tool:

MB991223: Test Harness Set

STEP 1. Check the A/C and outside/inside air selection

damper control motor operation.

Q: Do the A/C and outside/inside air selection damper

control motor work normally?

YES : Go to Step 2.

NO : Refer to Inspection procedure 10, "Malfunction of the

A/C-ECU power supply systemP.55-122."

Page 812 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-111

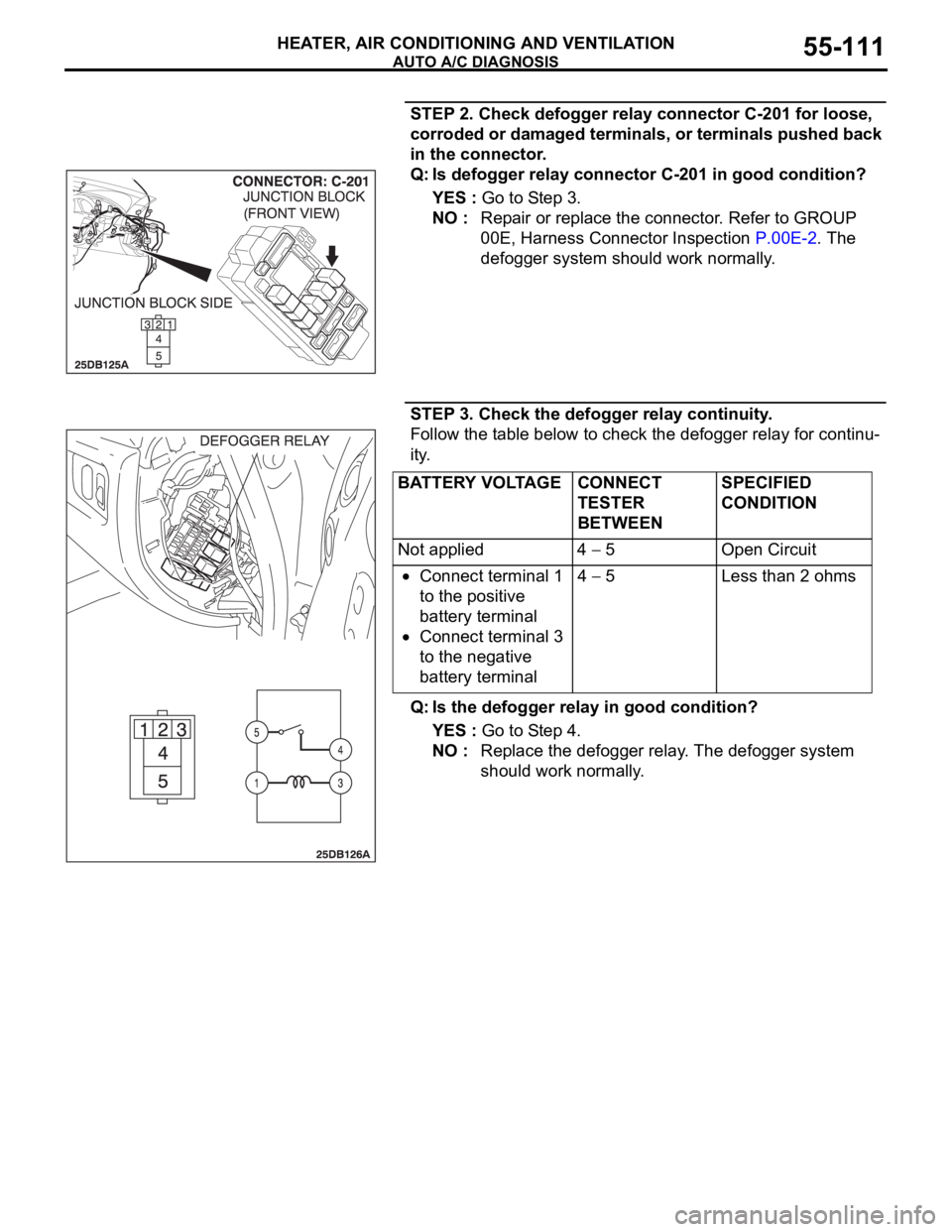

STEP 2. Check defogger relay connector C-201 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is defogger relay connector C-201 in good condition?

YES : Go to Step 3.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. The

defogger system should work normally.

STEP 3. Check the defogger relay continuity.

Follow the table below to check the defogger relay for continu-

ity.

Q: Is the defogger relay in good condition?

YES : Go to Step 4.

NO : Replace the defogger relay. The defogger system

should work normally.

BATTERY VOLTAGE CONNECT

TESTER

BETWEENSPECIFIED

CONDITION

Not applied 4

5 Open Circuit

Connect terminal 1

to the positive

battery terminal

Connect terminal 3

to the negative

battery terminal4

5 Less than 2 ohms

Page 815 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-114

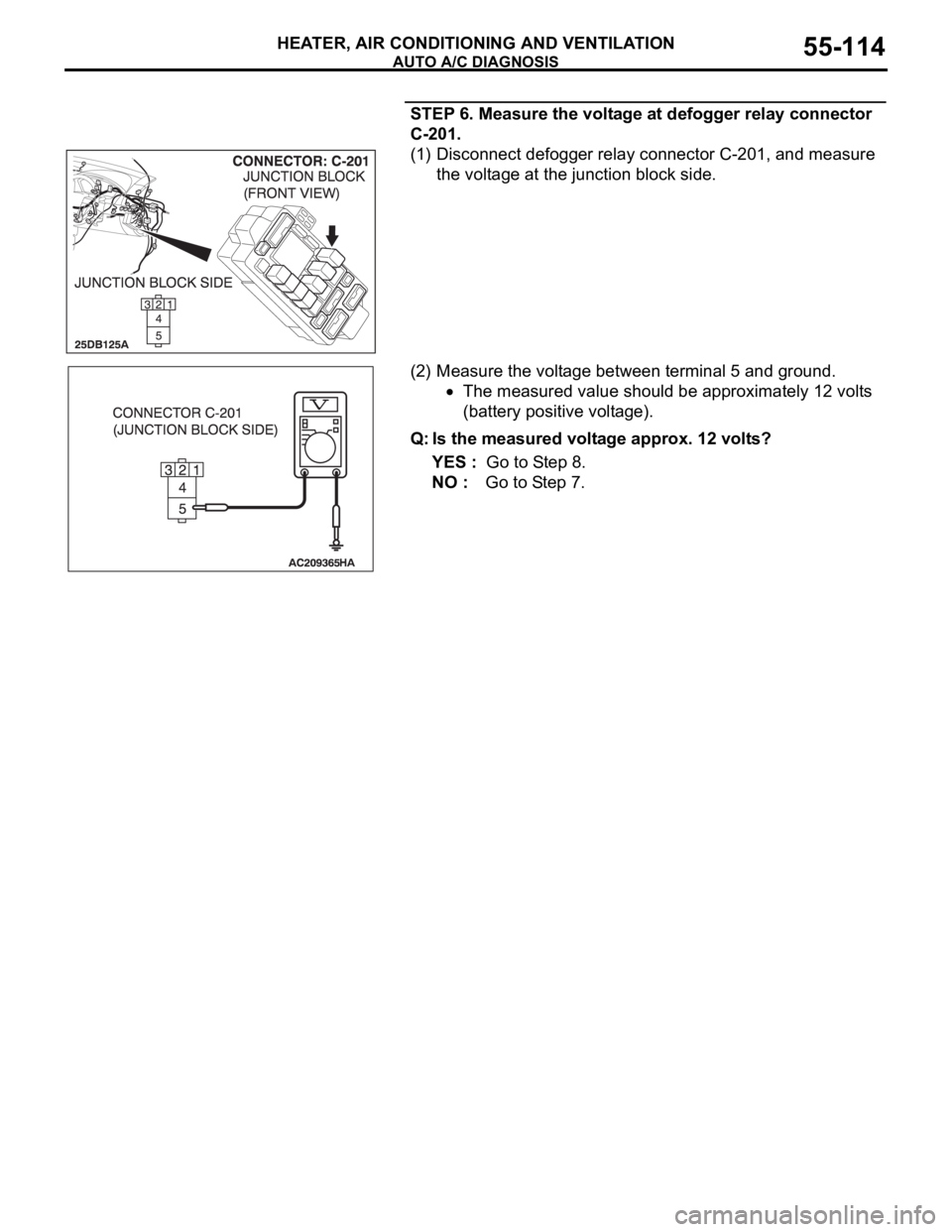

STEP 6. Measure the voltage at defogger relay connector

C-201.

(1) Disconnect defogger relay connector C-201, and measure

the voltage at the junction block side.

(2) Measure the voltage between terminal 5 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 8.

NO : Go to Step 7.

Page 816 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-115

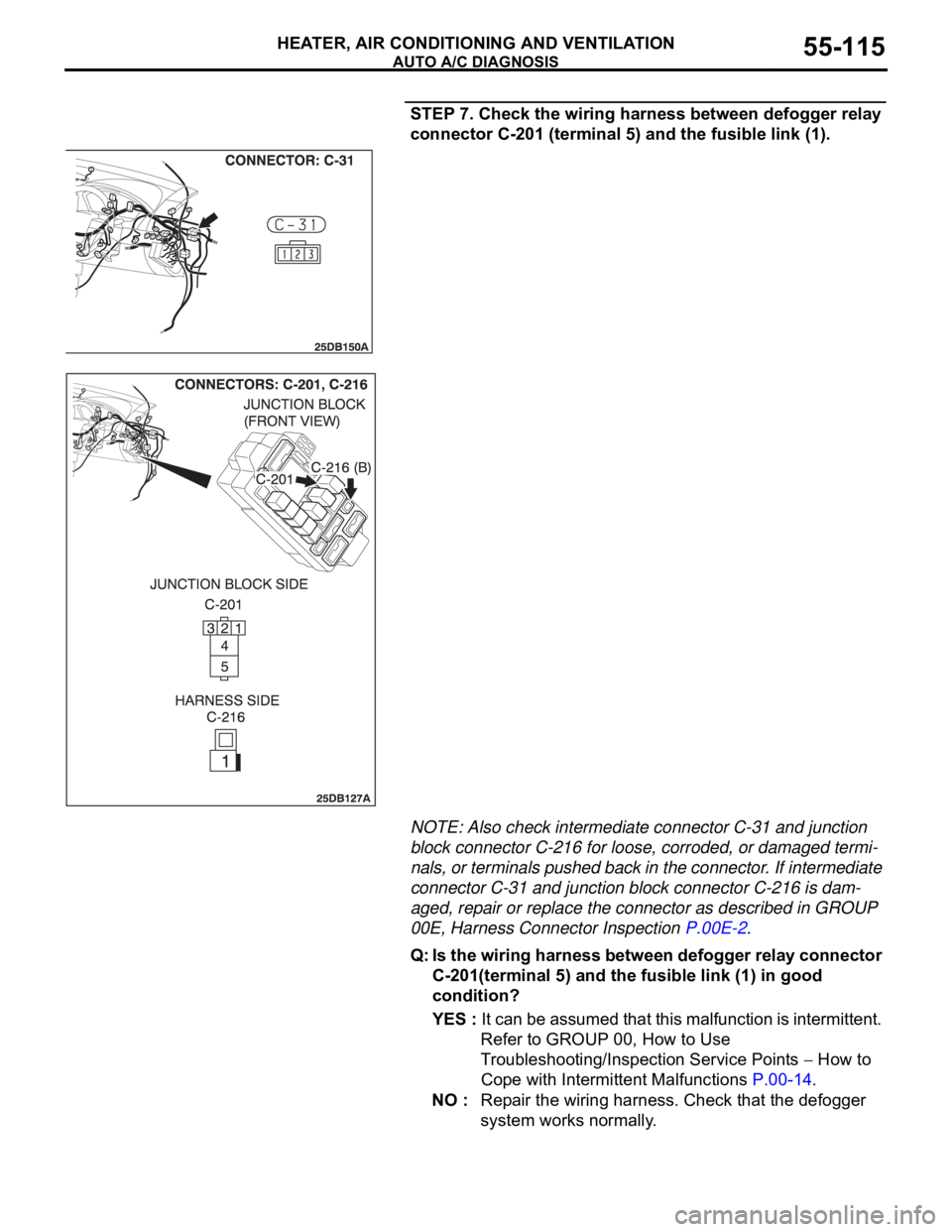

STEP 7. Check the wiring harness between defogger relay

connector C-201 (terminal 5) and the fusible link (1).

NOTE: Also check intermediate connector C-31 and junction

block connector C-216 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If intermediate

connector C-31 and junction block connector C-216 is dam-

aged, repair or replace the connector as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between defogger relay connector

C-201(terminal 5) and the fusible link (1) in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the defogger

system works normally.

Page 817 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-116

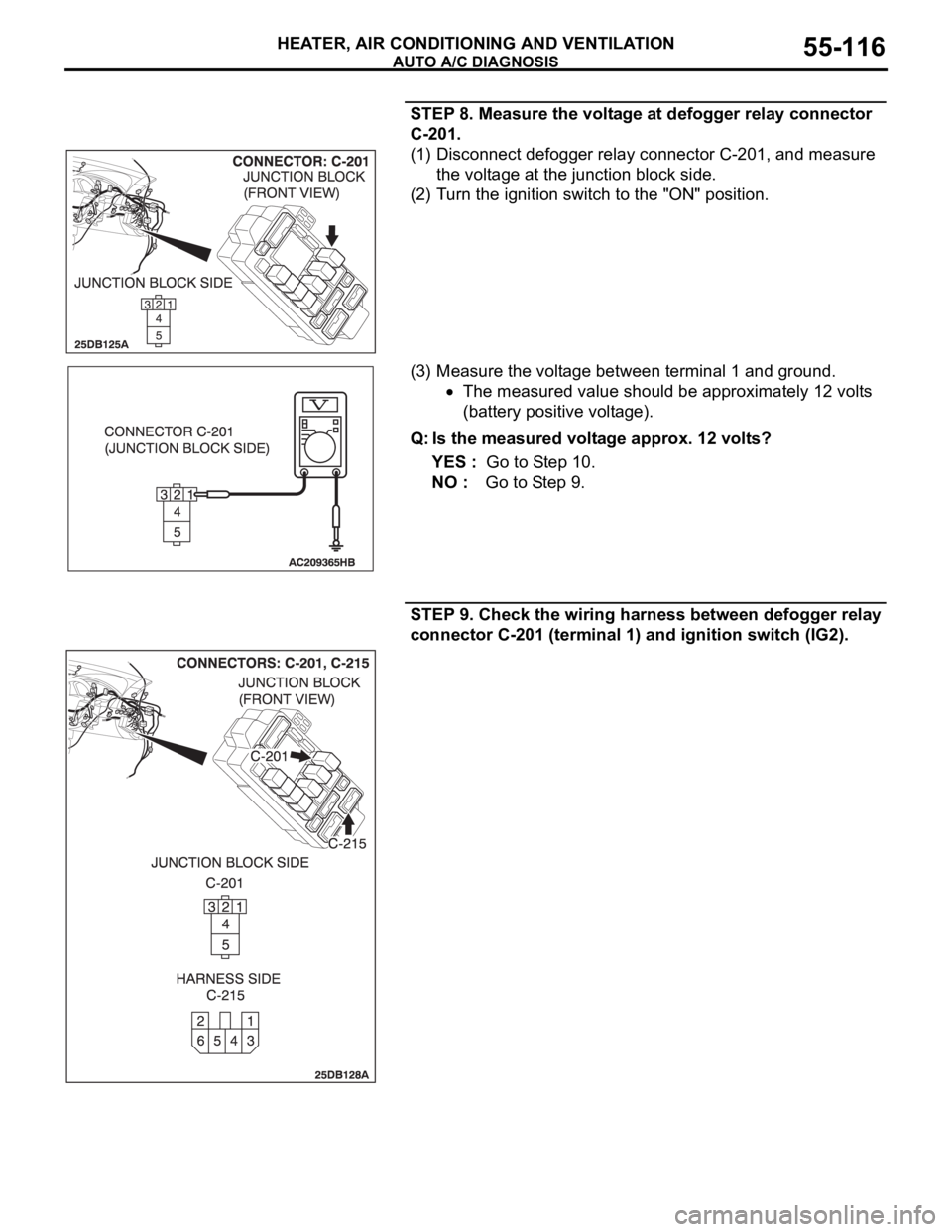

STEP 8. Measure the voltage at defogger relay connector

C-201.

(1) Disconnect defogger relay connector C-201, and measure

the voltage at the junction block side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 10.

NO : Go to Step 9.

STEP 9. Check the wiring harness between defogger relay

connector C-201 (terminal 1) and ignition switch (IG2).