wiring diagram MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 749 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-48

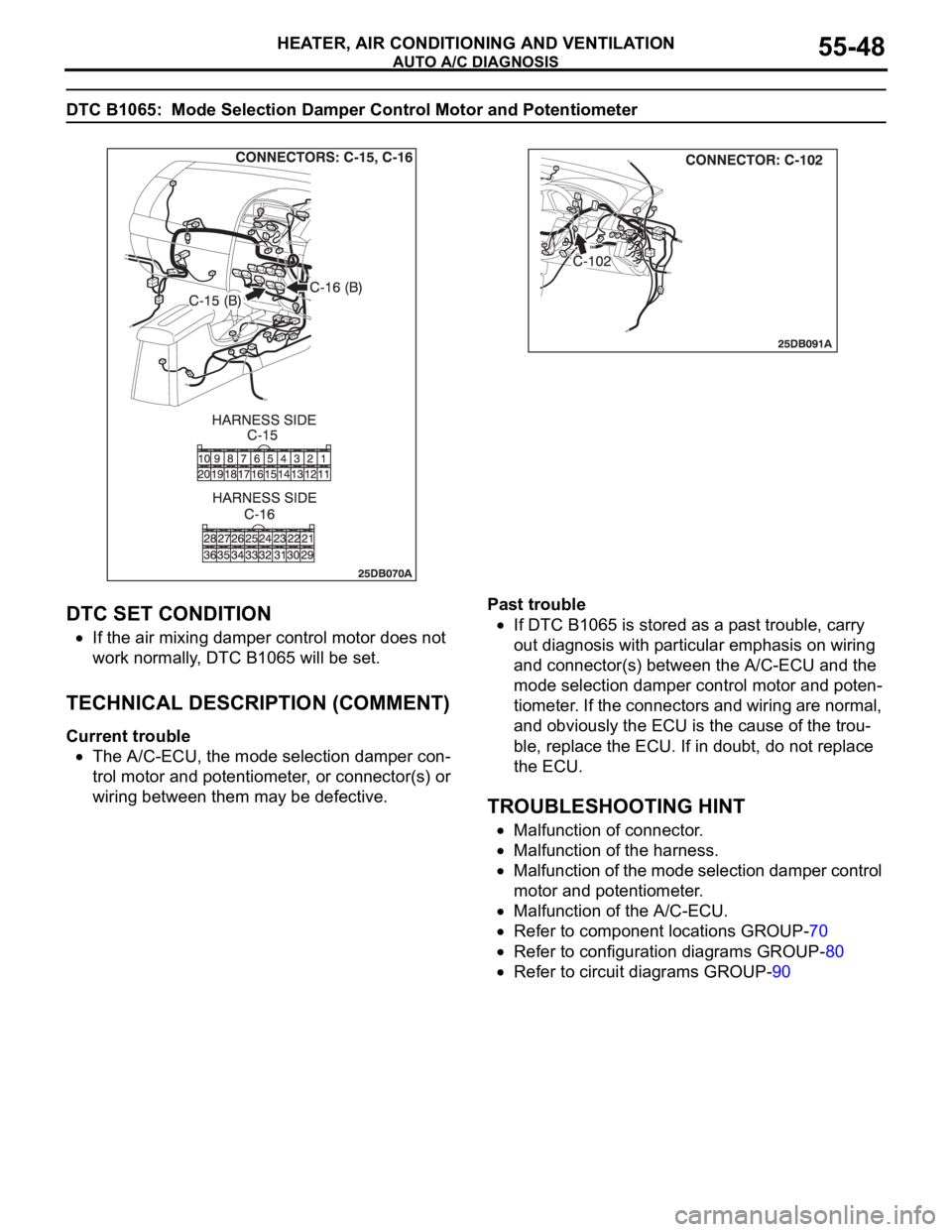

DTC B1065: Mode Selection Damper Control Motor and Potentiometer

.

DTC SET CONDITION

If the air mixing damper control motor does not

work normally, DTC B1065 will be set.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

The A/C-ECU, the mode selection damper con-

trol motor and potentiometer, or connector(s) or

wiring between them may be defective.Past trouble

If DTC B1065 is stored as a past trouble, carry

out diagnosis with particular emphasis on wiring

and connector(s) between the A/C-ECU and the

mode selection damper control motor and poten-

tiometer. If the connectors and wiring are normal,

and obviously the ECU is the cause of the trou-

ble, replace the ECU. If in doubt, do not replace

the ECU.

TROUBLESHOOTING HINT

Malfunction of connector.

Malfunction of the harness.

Malfunction of the mode selection damper control

motor and potentiometer.

Malfunction of the A/C-ECU.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

Page 755 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-54

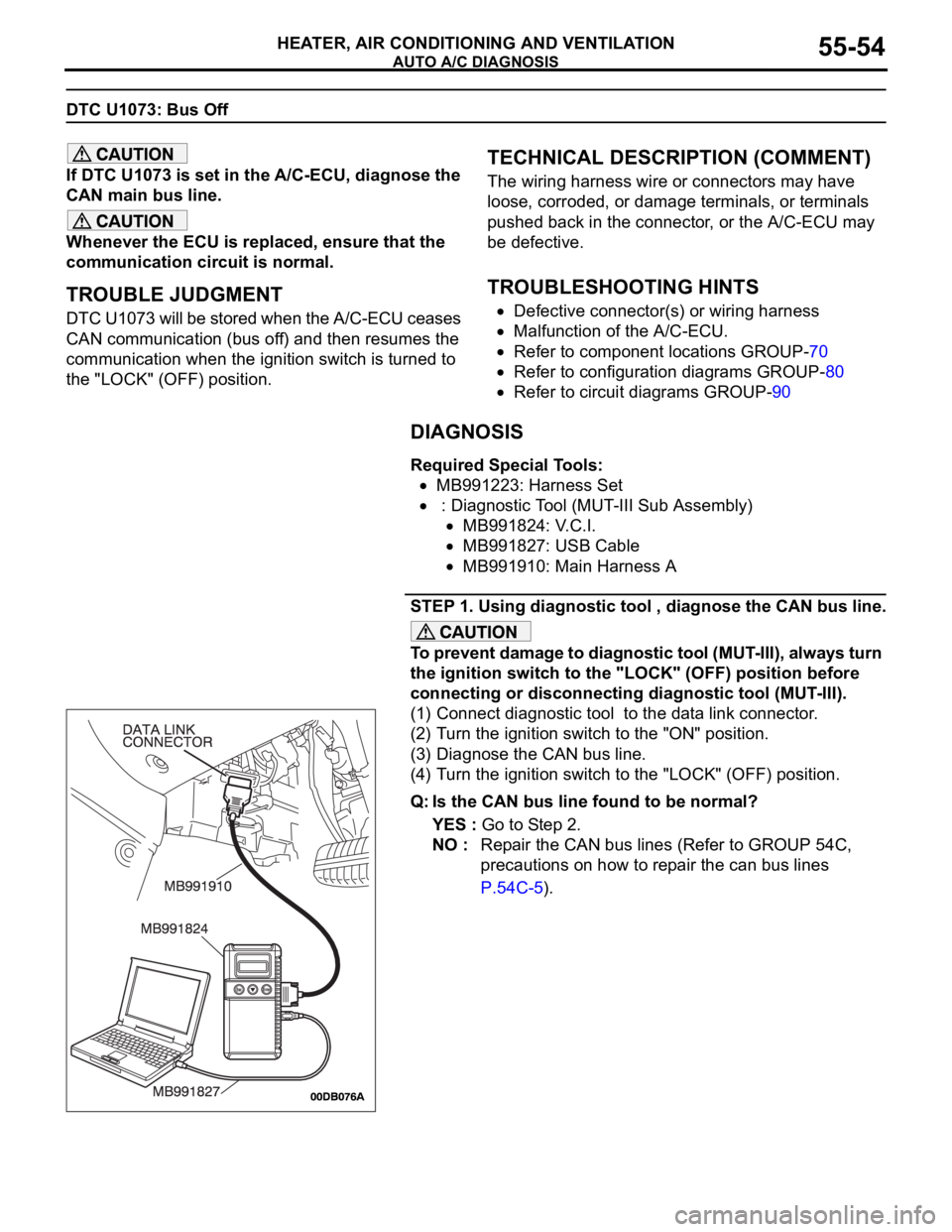

DTC U1073: Bus Off

If DTC U1073 is set in the A/C-ECU, diagnose the

CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

.

TROUBLE JUDGMENT

DTC U1073 will be stored when the A/C-ECU ceases

CAN communication (bus off) and then resumes the

communication when the ignition switch is turned to

the "LOCK" (OFF) position.

.

TECHNICAL DESCRIPTION (COMMENT)

The wiring harness wire or connectors may have

loose, corroded, or damage terminals, or terminals

pushed back in the connector, or the A/C-ECU may

be defective.

.

TROUBLESHOOTING HINTS

Defective connector(s) or wiring harness

Malfunction of the A/C-ECU.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: USB Cable

MB991910: Main Harness A

STEP 1. Using diagnostic tool , diagnose the CAN bus line.

To prevent damage to diagnostic tool (MUT-III), always turn

the ignition switch to the "LOCK" (OFF) position before

connecting or disconnecting diagnostic tool (MUT-III).

(1) Connect diagnostic tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP 54C,

precautions on how to repair the can bus lines

P.54C-5).

Page 757 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-56

DTC U1100: Electronic control unit Time-out (Related to Engine)

If DTC U1100 is set in the A/C-ECU, diagnose the

CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

.

TROUBLE JUDGMENT

The A/C-ECU receives engine control sys-

tem-related signal from the Electronic control unit. If

the ECU cannot receive the signal, DTC U1100 will

be set.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

Connector(s) or wiring harness in the CAN bus

lines between the Electronic control unit and the

A/C-ECU, the power supply system to the

Electronic control unit, the Electronic control unit

itself, or the A/C-ECU may be defective.Past trouble

If DTC U1100 is stored as a past trouble, carry

out diagnosis with particular emphasis on wiring

and connector(s) in the CAN bus line between

the A/C-ECU and the Electronic control unit, and

the power supply system to the Electronic control

unit. If the connectors and wiring are normal, and

obviously the ECU is the cause of the trouble,

replace the ECU. If in doubt, do not replace the

ECU.

NOTE: For a past trouble, you cannot find it by

the diagnostic tool CAN bus diagnostics even if

there is a failure in CAN bus lines. In this case,

refer to GROUP 00, How to Use Troubleshoot-

ing/Inspection Service Points

How to Cope with

Intermittent Malfunctions P.00-14) and check the

CAN bus lines. You can narrow down the possi-

ble cause of the trouble by referring to the DTC,

which is set regarding the CAN communica-

tion-linked ECUs (Refer to GROUP 54C, Expla-

nation about the scan too CAN bus diagnostics

P.54C-6).

.

TROUBLESHOOTING HINTS

Electronic control unit failed

Malfunction of the A/C-ECU

Damaged harness wires and connectors

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

Page 761 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-60

DTC U1111: Multi-Center Display Unit Time-out

If DTC U1111 is set in the A/C-ECU, diagnose the

CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

.

TROUBLE JUDGMENT

The A/C-ECU receives signals from the multi-center

display unit. If the ECU cannot receive the signal

r e l a t e d t o t h e m u l t i - c e n t e r d i s p l a y u n i t , D T C U 1111

will be set.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

Connector(s) or wiring harness in the CAN bus

lines between the A/C-ECU and the multi-center

display unit, the power supply system to the dis-

play unit, the display unit itself, or the A/C-ECU

may be defective.

Past trouble

W h e n D T C U 1111 i s s e t a s a p a s t t r o u b l e , c a r r y

out diagnosis with particular emphasis on con-

nector(s) or wiring harness in the CAN bus lines

between the A/C-ECU and the multi-center dis-

play unit, the power supply system to the display unit. If the connectors and wiring are normal, and

obviously the ECU or the multi-center display is

the cause of the trouble, replace the ECU or the

multi-center display. If in doubt, do not replace

the ECU or the display unit.

NOTE: For a past trouble, you cannot find it by

the diagnostic tool CAN bus diagnostics even if

there is a failure in the CAN bus lines. In this

case, refer to GROUP 00, How to Use Trouble-

shooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.)

and check the CAN bus lines. You can narrow

down the possible cause of the trouble by refer-

ring to the DTC, which is set regarding the CAN

communication-linked ECUs (Refer to GROUP

54C

Explanation about the diagnostic tool CAN

bus diagnostics P.54C-6).

.

TROUBLESHOOTING HINTS

Malfunction of multi-center display unit

Malfunction of the A/C-ECU

Damaged harness wires and connectors

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

Page 765 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-64

DTC U1120: Failure Information on Electronic control unit (Related to Engine)

If DTC U1120 is set in the A/C-ECU, diagnose the

CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

The engine control system- related DTC may be

set when DTC U1120 is set. (For details refer to

GROUP 00, Intersystem Affiliated DTC Reference

Ta b l e P.00-17.) Diagnose the engine control sys-

tem first when the engine control system- related

DTC is set.

.

TROUBLE JUDGMENT

The A/C-ECU receives engine control sys-

tem-related signal from the Electronic control unit by

the CAN bus lines. If a fail-safe related data is con-

tained in the signal from the Electronic control unit,

DTC U1120 will be stored.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

The wiring harness wire or connectors may have

loose, corroded, or damage terminals, or termi-

nals pushed back in the connector, the Electronic

control unit, or the A/C-ECU may be defective.Past trouble

If DTC U1120 is stored as a past trouble, carry

out diagnosis with particular emphasis on wiring

and connector(s) in the CAN bus line between

the A/C-ECU and the Electronic control unit, and

the power supply system to the Electronic control

unit. If the connectors and wiring are normal, and

obviously the ECU is the cause of the trouble,

replace the ECU. If in doubt, do not replace the

ECU.

NOTE: For a past trouble, you cannot find it by

the diagnostic tool CAN bus diagnostics even if

there is a failure in CAN bus lines. In this case,

refer to GROUP 00, How to Use Troubleshoot-

ing/Inspection Service Points

How to Cope with

Intermittent Malfunctions P.00-14.) and check the

CAN bus lines. You can narrow down the possi-

ble cause of the trouble by referring to the DTC,

which is set regarding the CAN communica-

tion-linked ECUs (Refer to GROUP 54C

Expla-

nation about the diagnostic tool CAN bus

diagnostics P.54C-6).

.

TROUBLESHOOTING HINTS

Malfunction of the A/C-ECU.

Malfunction of the Electronic control unit.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tool:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

Page 829 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-128

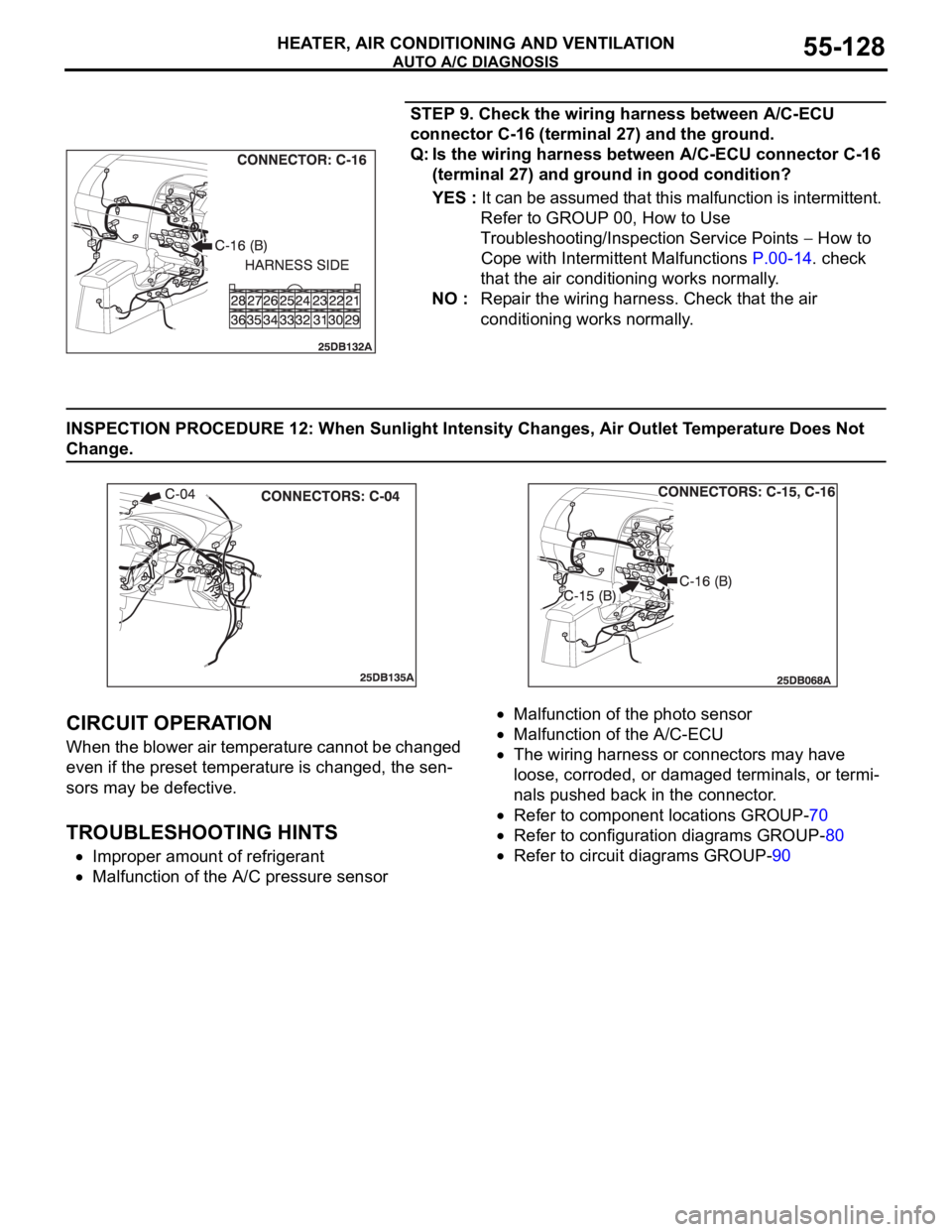

STEP 9. Check the wiring harness between A/C-ECU

connector C-16 (terminal 27) and the ground.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 27) and ground in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14. check

that the air conditioning works normally.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

INSPECTION PROCEDURE 12: When Sunlight Intensity Changes, Air Outlet Temperature Does Not

Change.

.

CIRCUIT OPERATION

When the blower air temperature cannot be changed

even if the preset temperature is changed, the sen-

sors may be defective.

.

TROUBLESHOOTING HINTS

Improper amount of refrigerant

Malfunction of the A/C pressure sensor

Malfunction of the photo sensor

Malfunction of the A/C-ECU

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

Page 920 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-5

INSPECTION PROCEDURE 3: Radiator Fan and Condenser Fan do not Operate

.

CIRCUIT OPERATION

The fan controller is powered from fusible link

No.2.

The engine-ECU uses input signals from the A/C

switch, the water temperature sensor unit and the

vehicle speed sensor

speed sensor to control the speed of the

radiator fan motor and the condenser fan motor.

The engine-ECU controls the fan controller to

activate the radiator fan motor and the condenser

fan motor.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor and fan control-

ler

Malfunction of engine-ECU.

Damaged wiring harness or connector

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 940 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-25

STEP 7. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5)

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-5)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ) Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 5: Radiator Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the radiator fan

motor or an open circuit between the fan controller

and the radiator fan motor.

.

TROUBLESHOOTING HINTS

Malfunction of radiator fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

DIAGNOSIS

Replace the radiator fan motor and fan controller assembly.

Q: Does the radiator fan operate correctly?

YES : There is no action to be taken?

NO : Repair the wiring harness between the fan controller

and the radiator fan motor.

INSPECTION PROCEDURE 6: Condenser Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the condenser

fan motor or fan controller.

.

TROUBLESHOOTING HINTS

Malfunction of condenser fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 1394 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-63

CIRCUIT OPERATION

The Engine ECU detects "CRUISE" (MAIN) switch

"ON" signal to illuminate the "CRUISE" indicator

lamp on the combination meter.

.

COMMENT

Connector(s), wiring harness in the CAN bus line

between the Engine ECU and the combination

meter, power supply to the Engine ECU, the combi-

nation meter, the Engine ECU may be defective.

.

TROUBLESHOOTING HINTS

Malfunction of the combination meter.

Damaged harness or connector.

Malfunction of the Engine ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

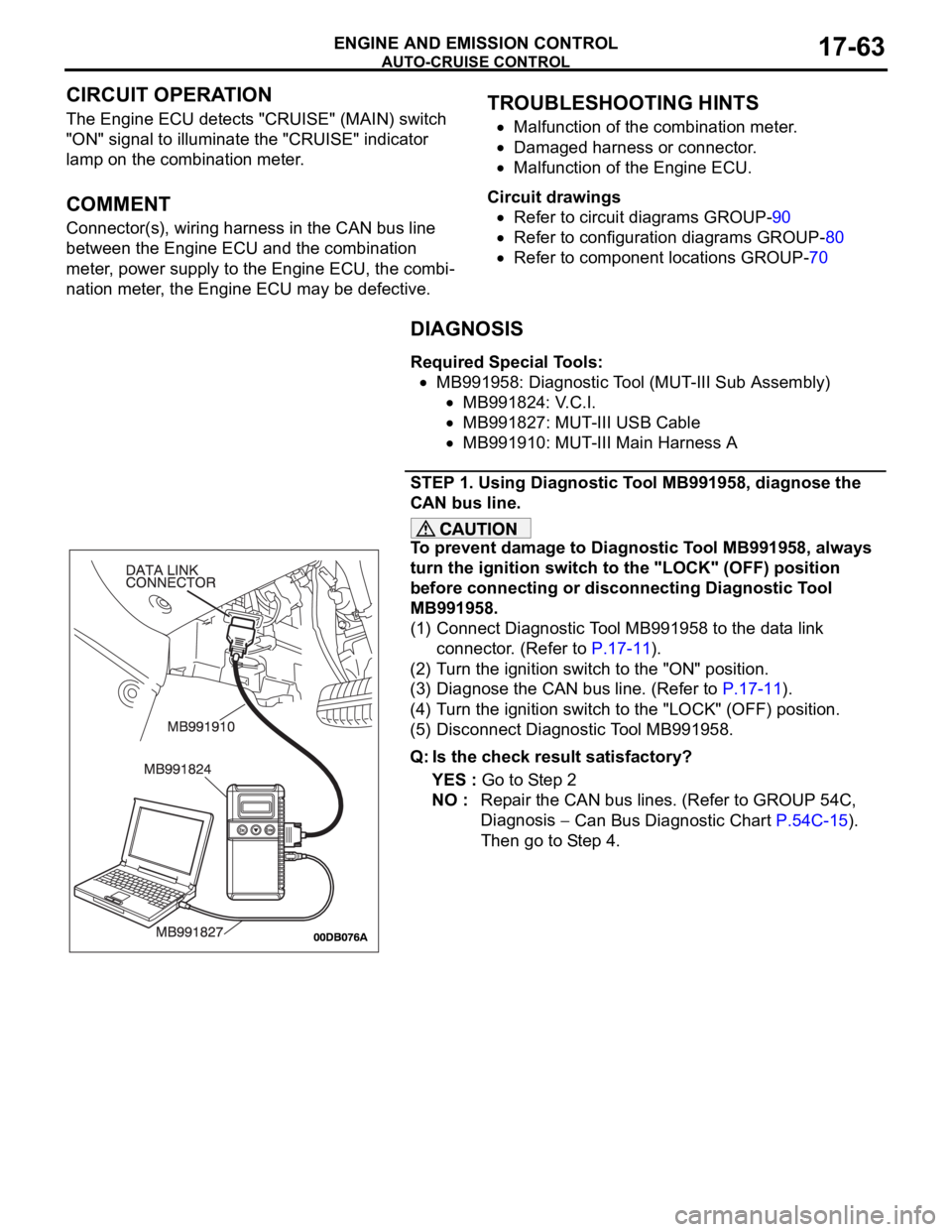

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Using Diagnostic Tool MB991958, diagnose the

CAN bus line.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line. (Refer to P.17-11).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the check result satisfactory?

YES : Go to Step 2

NO : Repair the CAN bus lines. (Refer to GROUP 54C,

Diagnosis

Can Bus Diagnostic Chart P.54C-15).

Then go to Step 4.