sensor MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1398 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-67

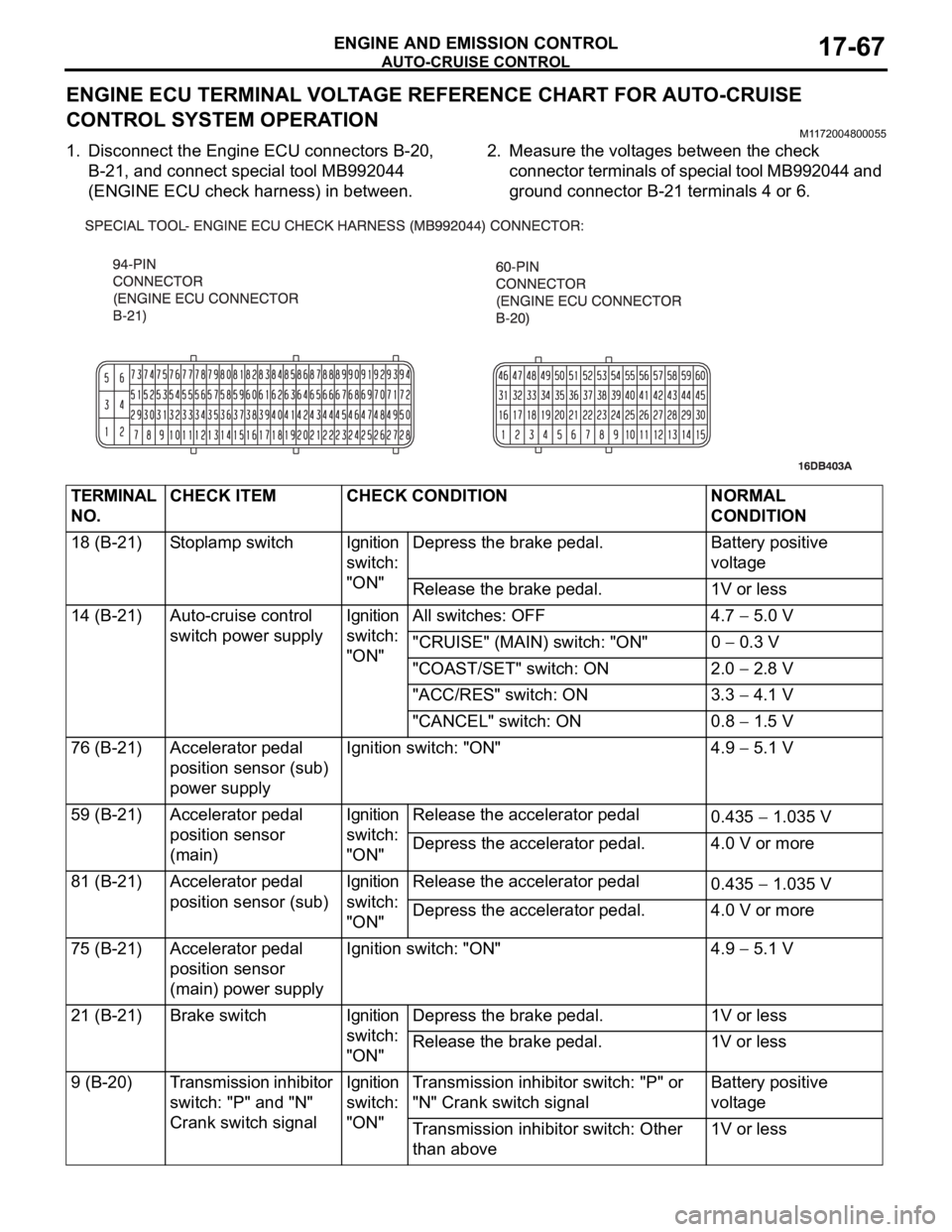

ENGINE ECU TERMINAL VOLTAGE REFERENCE CHART FOR AUTO-CRUISE

CONTROL SYSTEM OPERATION

M1172004800055

1. Disconnect the Engine ECU connectors B-20,

B-21, and connect special tool MB992044

(ENGINE ECU check harness) in between.2. Measure the voltages between the check

connector terminals of special tool MB992044 and

ground connector B-21 terminals 4 or 6.

TERMINAL

NO.CHECK ITEM CHECK CONDITION NORMAL

CONDITION

18 (B-21) Stoplamp switch Ignition

switch:

"ON"Depress the brake pedal. Battery positive

voltage

Release the brake pedal. 1V or less

14 (B-21) Auto-cruise control

switch power supplyIgnition

switch:

"ON"All switches: OFF 4.7

5.0 V

"CRUISE" (MAIN) switch: "ON" 0

0.3 V

"COAST/SET" switch: ON 2.0

2.8 V

"ACC/RES" switch: ON 3.3

4.1 V

"CANCEL" switch: ON 0.8

1.5 V

76 (B-21) Accelerator pedal

position sensor (sub)

power supplyIgnition switch: "ON" 4.9

5.1 V

59 (B-21) Accelerator pedal

position sensor

(main)Ignition

switch:

"ON"Release the accelerator pedal

0.435

1.035 V

Depress the accelerator pedal. 4.0 V or more

81 (B-21) Accelerator pedal

position sensor (sub)Ignition

switch:

"ON"Release the accelerator pedal

0.435

1.035 V

Depress the accelerator pedal. 4.0 V or more

75 (B-21) Accelerator pedal

position sensor

(main) power supplyIgnition switch: "ON" 4.9

5.1 V

21 (B-21) Brake switch Ignition

switch:

"ON"Depress the brake pedal. 1V or less

Release the brake pedal. 1V or less

9 (B-20) Transmission inhibitor

switch: "P" and "N"

Crank switch signalIgnition

switch:

"ON"Transmission inhibitor switch: "P" or

"N" Crank switch signalBattery positive

voltage

Transmission inhibitor switch: Other

than above1V or less

Page 1399 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-68

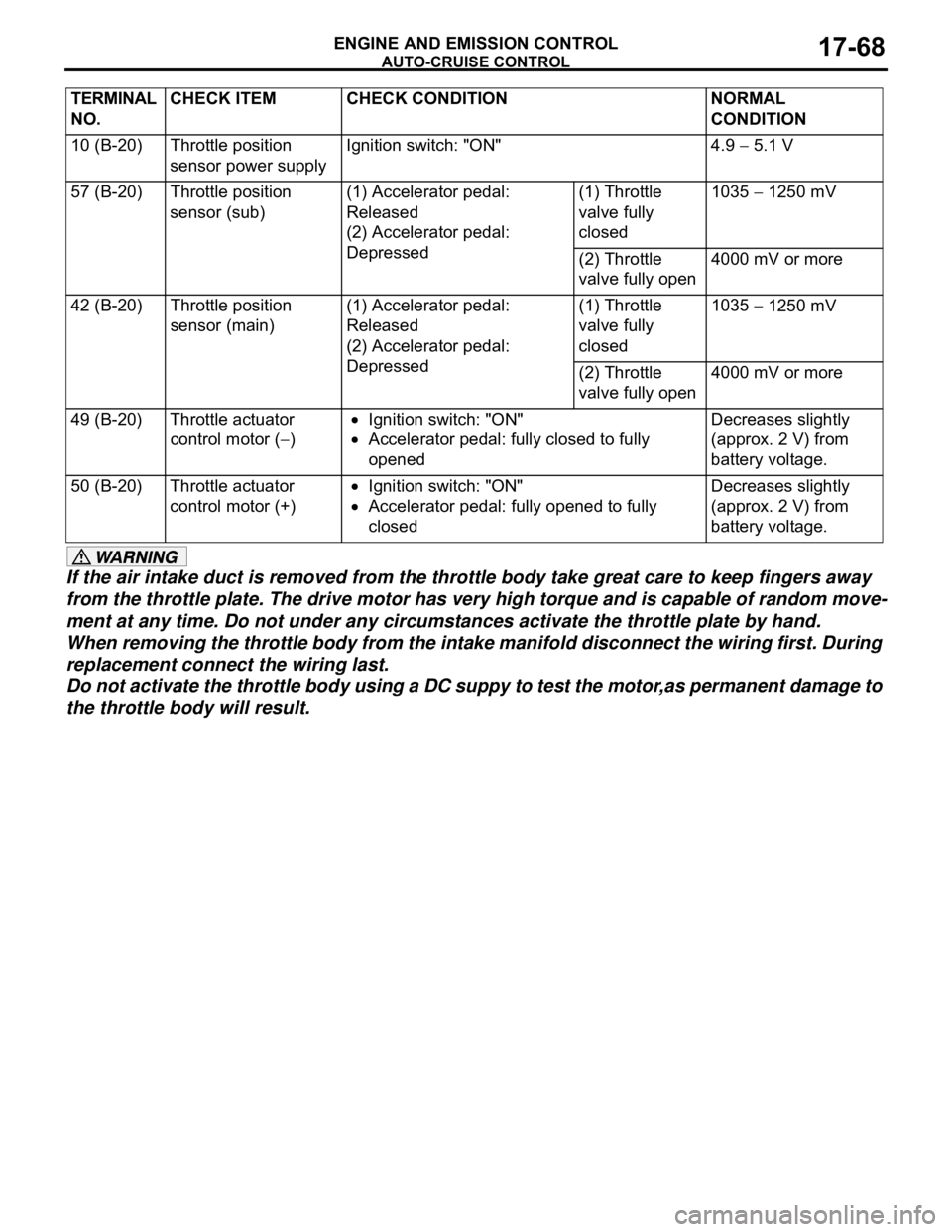

If the air intake duct is removed from the throttle body take great care to keep fingers away

from the throttle plate. The drive motor has very high torque and is capable of random move-

ment at any time. Do not under any circumstances activate the throttle plate by hand.

When removing the throttle body from the intake manifold disconnect the wiring first. During

replacement connect the wiring last.

Do not activate the throttle body using a DC suppy to test the motor,as permanent damage to

the throttle body will result.

10 (B-20) Throttle position

sensor power supplyIgnition switch: "ON" 4.9 5.1 V

57 (B-20) Throttle position

sensor (sub)(1) Accelerator pedal:

Released

(2) Accelerator pedal:

Depressed(1) Throttle

valve fully

closed1035

1250 mV

(2) Throttle

valve fully open4000 mV or more

42 (B-20) Throttle position

sensor (main)(1) Accelerator pedal:

Released

(2) Accelerator pedal:

Depressed(1) Throttle

valve fully

closed1035

1250 mV

(2) Throttle

valve fully open4000 mV or more

49 (B-20) Throttle actuator

control motor (

)

Ignition switch: "ON"

Accelerator pedal: fully closed to fully

openedDecreases slightly

(approx. 2 V) from

battery voltage.

50 (B-20) Throttle actuator

control motor (+)

Ignition switch: "ON"

Accelerator pedal: fully opened to fully

closedDecreases slightly

(approx. 2 V) from

battery voltage. TERMINAL

NO.CHECK ITEM CHECK CONDITION NORMAL

CONDITION

Page 1405 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-74

THROTTLE POSITION SENSOR

Refer to GROUP 13A, On-vehicle Service Throttle Actuator

Control Motor Check 13A-671 (3.8L engine).

If the air intake duct is removed from the throttle

body take great care to keep fingers away from the

throttle plate. The drive motor has very high torque

and is capable of random movement at any time. Do

not under any circumstance activate the throttle plate

by hand.

When removing the throttle body from the intake

manifold disconnect the wiring first.During replace-

ment connect the wiring last.

Do not activate the throttle body using a DC supply to

test the motor, as permanent damage to the throttle

body will result.

TRANSMISSION INHIBITOR SWITCH ("N"

POSITION)

Refer to GROUP 23A, On-vehicle Service Essential Service

P.23A-294.

Page 1406 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

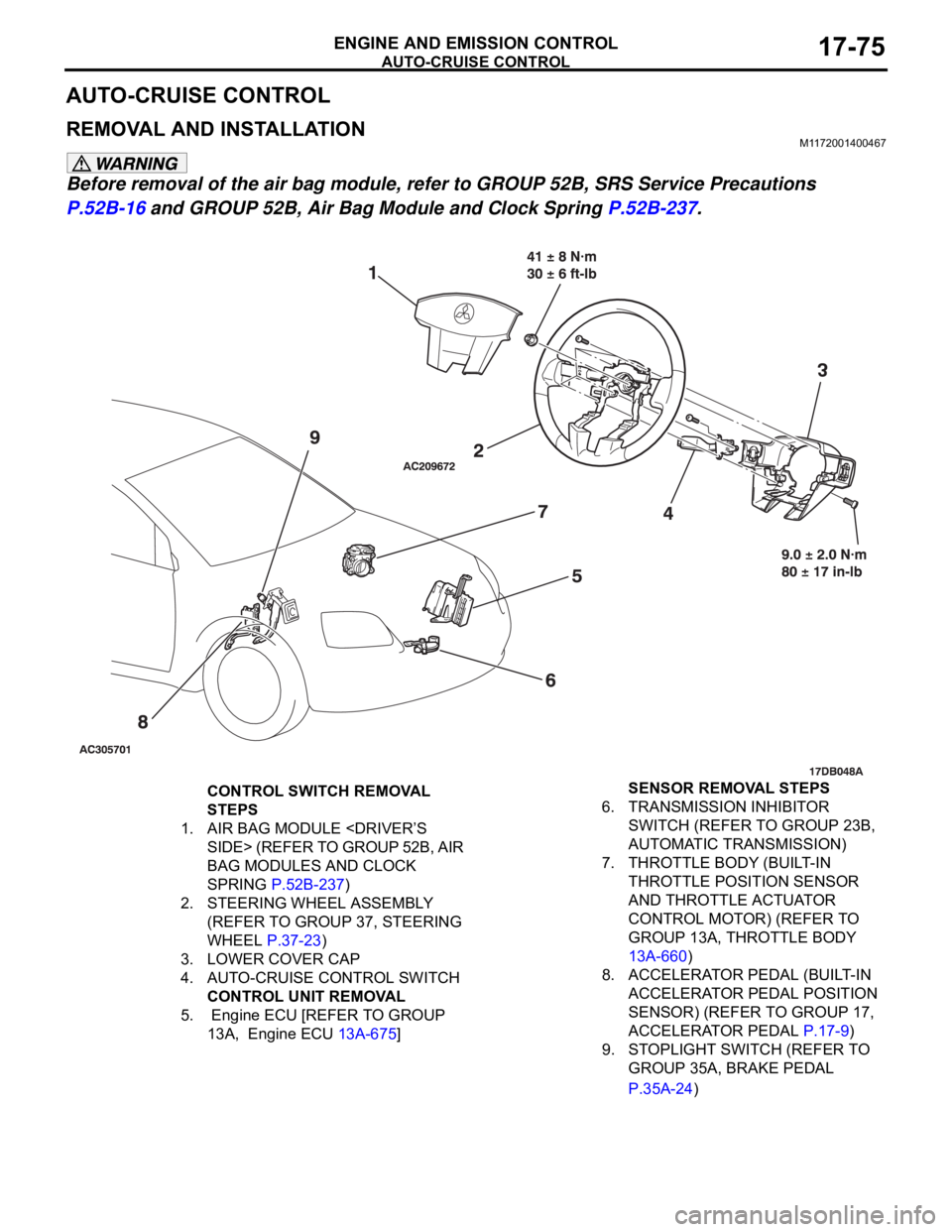

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

Page 1407 of 1500

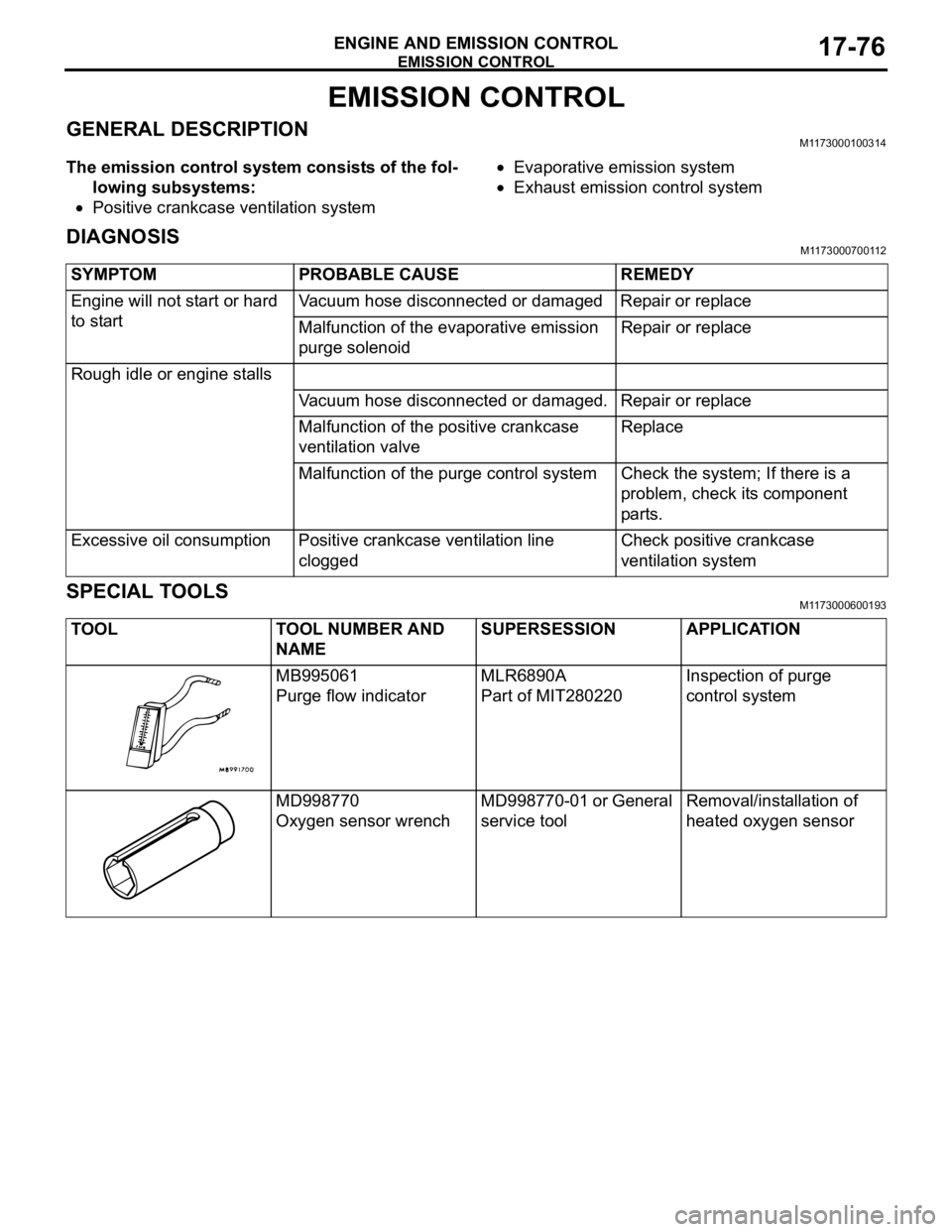

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-76

EMISSION CONTROL

GENERAL DESCRIPTIONM1173000100314

The emission control system consists of the fol-

lowing subsystems:

Positive crankcase ventilation system

Evaporative emission system

Exhaust emission control system

DIAGNOSISM1173000700112

SPECIAL TOOLSM1173000600193

SYMPTOM PROBABLE CAUSE REMEDY

Engine will not start or hard

to startVacuum hose disconnected or damaged Repair or replace

Malfunction of the evaporative emission

purge solenoidRepair or replace

Rough idle or engine stalls

Vacuum hose disconnected or damaged. Repair or replace

Malfunction of the positive crankcase

ventilation valveReplace

Malfunction of the purge control system Check the system; If there is a

problem, check its component

parts.

Excessive oil consumption Positive crankcase ventilation line

cloggedCheck positive crankcase

ventilation system

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB995061

Purge flow indicatorMLR6890A

Part of MIT280220Inspection of purge

control system

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval/installation of

heated oxygen sensor

Page 1415 of 1500

![MITSUBISHI 380 2005 Workshop Manual EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is MITSUBISHI 380 2005 Workshop Manual EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is](/img/19/57086/w960_57086-1414.png)

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is out of specification.

MASS AIRFLOW SENSOR CHECKM1173050400053

To inspect these parts, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

ENGINE COOLANT TEMPERATURE SENSOR

CHECK

M1173008100523

To inspect the sensor, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

INTAKE AIR TEMPERATURE SENSOR CHECKM1173008200263

To inspect the sensor, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

CATALYTIC CONVERTER

GENERAL DESCRIPTION (CATALYTIC CONVERTER)M1173005300131

The three way catalytic converter, together with the

closed loop air-fuel ratio control based on the oxygen

sensor signal, oxidizes carbon monoxides (CO) and

hydrocarbons (HC), also reduces nitrogen oxides

(NOx). When the mixture is controlled at stoichiometric

air-fuel ratio, the three way catalytic converter pro-

vides the highest purification against the three con-

stituents, namely, CO, HC and NOx.

Page 1426 of 1500

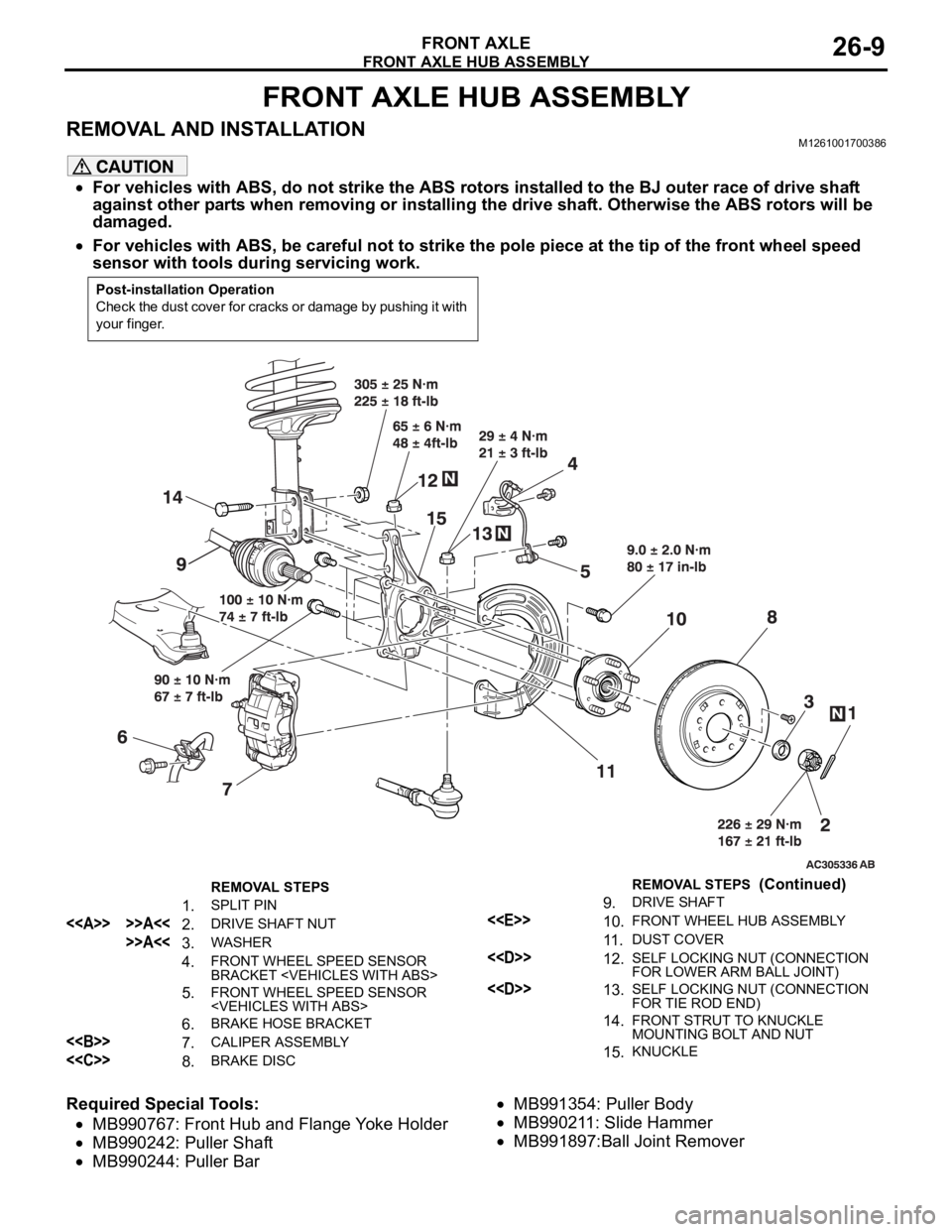

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-9

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1261001700386

For vehicles with ABS, do not strike the ABS rotors installed to the BJ outer race of drive shaft

against other parts when removing or installing the drive shaft. Otherwise the ABS rotors will be

damaged.

For vehicles with ABS, be careful not to strike the pole piece at the tip of the front wheel speed

sensor with tools during servicing work.

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB990242: Puller Shaft

MB990244: Puller Bar

MB991354: Puller Body

MB990211: Slide Hammer

MB991897:Ball Joint Remover

Post-installation Operation

Check the dust cover for cracks or damage by pushing it with

your finger.

REMOVAL STEPS

1. SPLIT PIN

<> >>A<<2. DRIVE SHAFT NUT

>>A<<3. WASHER

4. FRONT WHEEL SPEED SENSOR

BRACKET

5. FRONT WHEEL SPEED SENSOR

6. BRAKE HOSE BRACKET

<> 7. CALIPER ASSEMBLY

<

9. DRIVE SHAFT

<

11 .DUST COVER

<

FOR LOWER ARM BALL JOINT)

<

FOR TIE ROD END)

14.FRONT STRUT TO KNUCKLE

MOUNTING BOLT AND NUT

15.KNUCKLE

REMOVAL STEPS (Continued)

Page 1430 of 1500

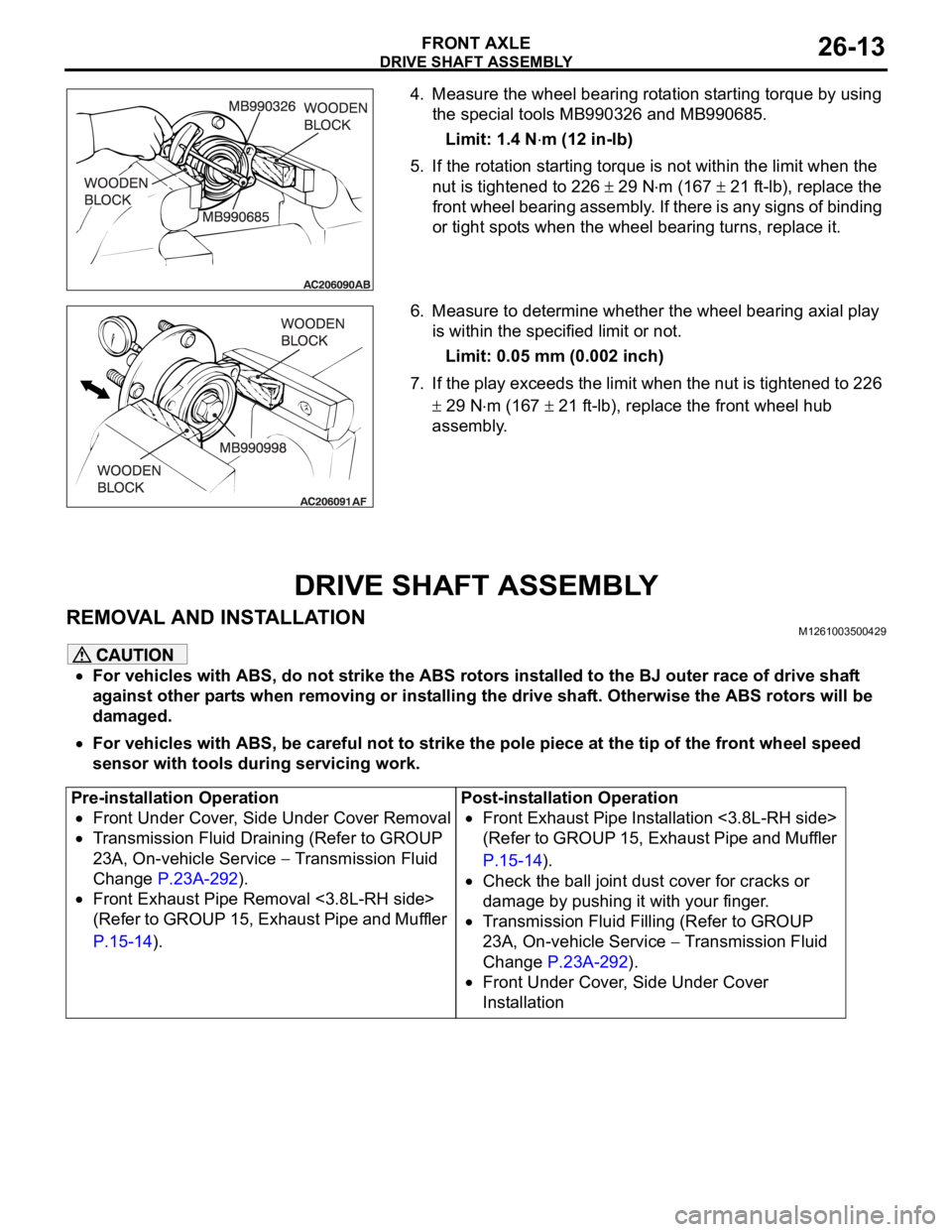

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-13

4. Measure the wheel bearing rotation starting torque by using

the special tools MB990326 and MB990685.

Limit: 1.4 N

m (12 in-lb)

5. If the rotation starting torque is not within the limit when the

nut is tightened to 226

29 Nm (167 21 ft-lb), replace the

front wheel bearing assembly. If there is any signs of binding

or tight spots when the wheel bearing turns, replace it.

6. Measure to determine whether the wheel bearing axial play

is within the specified limit or not.

Limit: 0.05 mm (0.002 inch)

7. If the play exceeds the limit when the nut is tightened to 226

29 Nm (167 21 ft-lb), replace the front wheel hub

assembly.

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500429

For vehicles with ABS, do not strike the ABS rotors installed to the BJ outer race of drive shaft

against other parts when removing or installing the drive shaft. Otherwise the ABS rotors will be

damaged.

For vehicles with ABS, be careful not to strike the pole piece at the tip of the front wheel speed

sensor with tools during servicing work.

Pre-installation Operation

Front Under Cover, Side Under Cover Removal

Transmission Fluid Draining (Refer to GROUP

23A, On-vehicle Service

Transmission Fluid

Change P.23A-292).

Front Exhaust Pipe Removal <3.8L-RH side>

(Refer to GROUP 15, Exhaust Pipe and Muffler

P.15-14).Post-installation Operation

Front Exhaust Pipe Installation <3.8L-RH side>

(Refer to GROUP 15, Exhaust Pipe and Muffler

P.15-14).

Check the ball joint dust cover for cracks or

damage by pushing it with your finger.

Transmission Fluid Filling (Refer to GROUP

23A, On-vehicle Service

Transmission Fluid

Change P.23A-292).

Front Under Cover, Side Under Cover

Installation

Page 1431 of 1500

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB991897: Ball Joint Remover

MB990242: Puller Shaft Puller

MB990244: Puller Bar

MB991354: Puller Body

MB990998: Front Hub Remover and Installer

MB991000: Spacer

REMOVAL STEPS

1. SPLIT PIN

<> >>B<<2. DRIVE SHAFT NUT

3. WASHER

4. FRONT WHEEL SPEED SENSOR

BRACKET

5. FRONT WHEEL SPEED SENSOR

6. BRAKE HOSE BRACKET

<>7. SELF LOCKING NUT (LOWER

ARM BALL JOINT CONNECTION)

<>8. SELF LOCKING NUT (TIE ROD

END CONNECTION)

<

<

SHAFT ASSEMBLY RH

11. CIRCLIPREMOVAL STEPS (Continued)

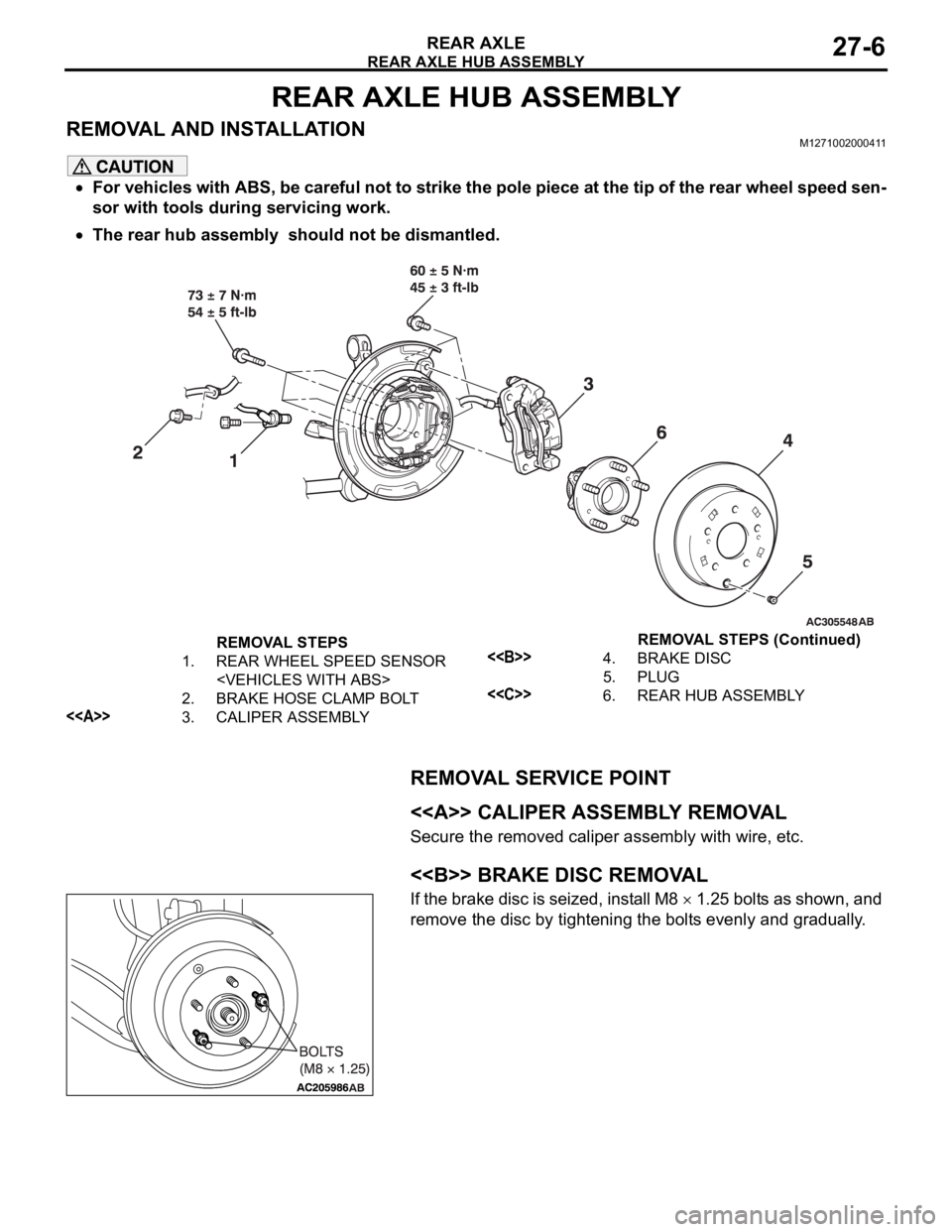

Page 1453 of 1500

REAR AXLE HUB ASSEMBLY

REAR AXLE27-6

REAR AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1271002000411

For vehicles with ABS, be careful not to strike the pole piece at the tip of the rear wheel speed sen-

sor with tools during servicing work.

The rear hub assembly should not be dismantled.

REMOVAL SERVICE POINT

.

<> CALIPER ASSEMBLY REMOVAL

Secure the removed caliper assembly with wire, etc.

.

<> BRAKE DISC REMOVAL

If the brake disc is seized, install M8 1.25 bolts as shown, and

remove the disc by tightening the bolts evenly and gradually.

.

REMOVAL STEPS

1. REAR WHEEL SPEED SENSOR

2. BRAKE HOSE CLAMP BOLT

<>3. CALIPER ASSEMBLY

<>4. BRAKE DISC

5. PLUG

<