sensor MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1307 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-28

STEP 4. Retest the system

Q: Turn the ignition switch to the "ON" position. Do the

"TCL OFF" indicator light and the TCL work indicator

light illuminate for three seconds, and then go out after

the engine starts?

YES : The procedure is complete.

NO : . Return to Step 1.

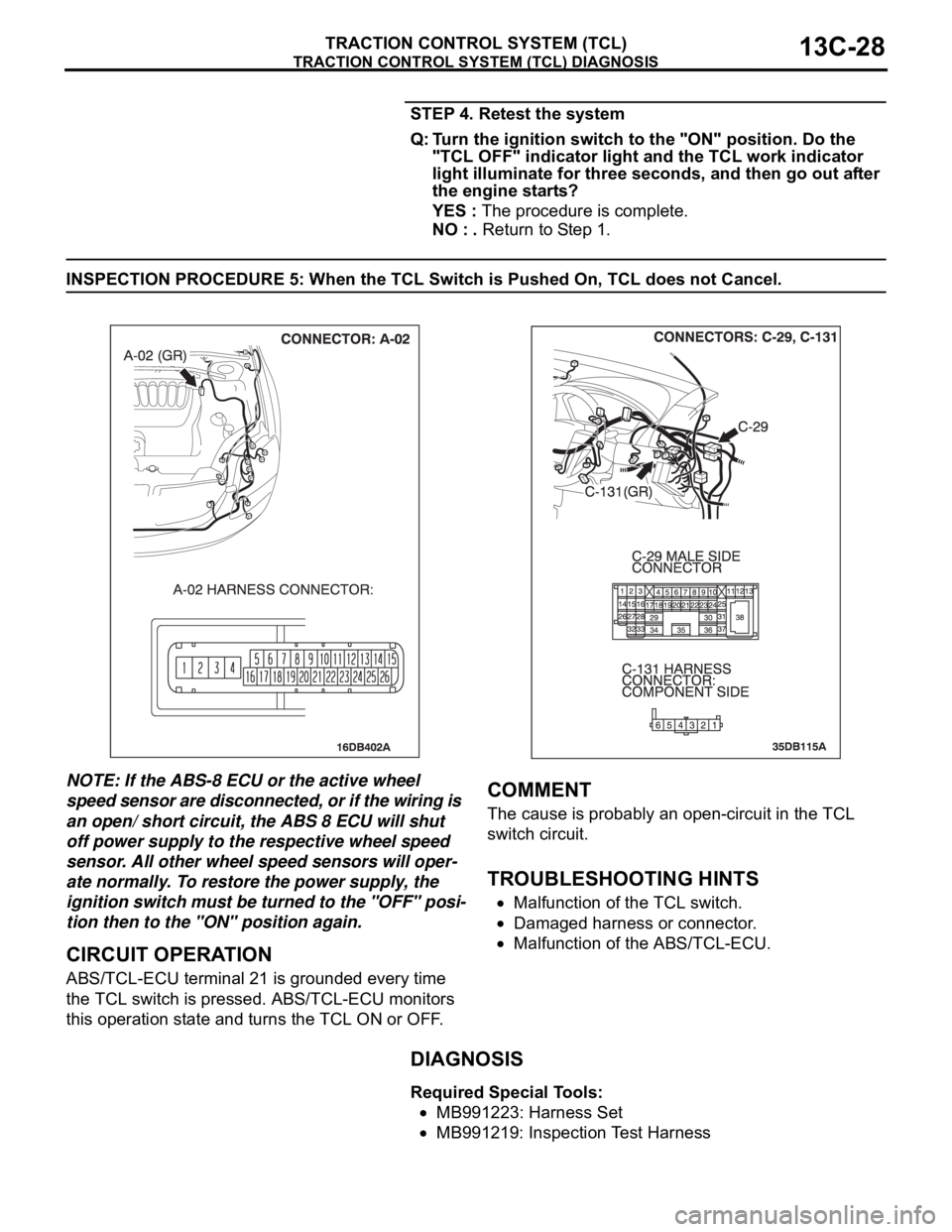

INSPECTION PROCEDURE 5: When the TCL Switch is Pushed On, TCL does not Cancel.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

CIRCUIT OPERATION

ABS/TCL-ECU terminal 21 is grounded every time

the TCL switch is pressed. ABS/TCL-ECU monitors

this operation state and turns the TCL ON or OFF.

.

COMMENT

The cause is probably an open-circuit in the TCL

switch circuit.

.

TROUBLESHOOTING HINTS

Malfunction of the TCL switch.

Damaged harness or connector.

Malfunction of the ABS/TCL-ECU.

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991219: Inspection Test Harness

Page 1313 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-34

INSPECTION PROCEDURE 6: TCL does not Operate.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

COMMENT

The fail-safe function is probably cancelling TCL. In

this case, diagnostic tool MB991958 can be used to

retest each system by checking the diagnostic trou-

ble codes.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the CAN bus line.

Malfunction of the MPI system.

Malfunction of the A/T system.

Malfunction of the ABS/TCL-ECU.

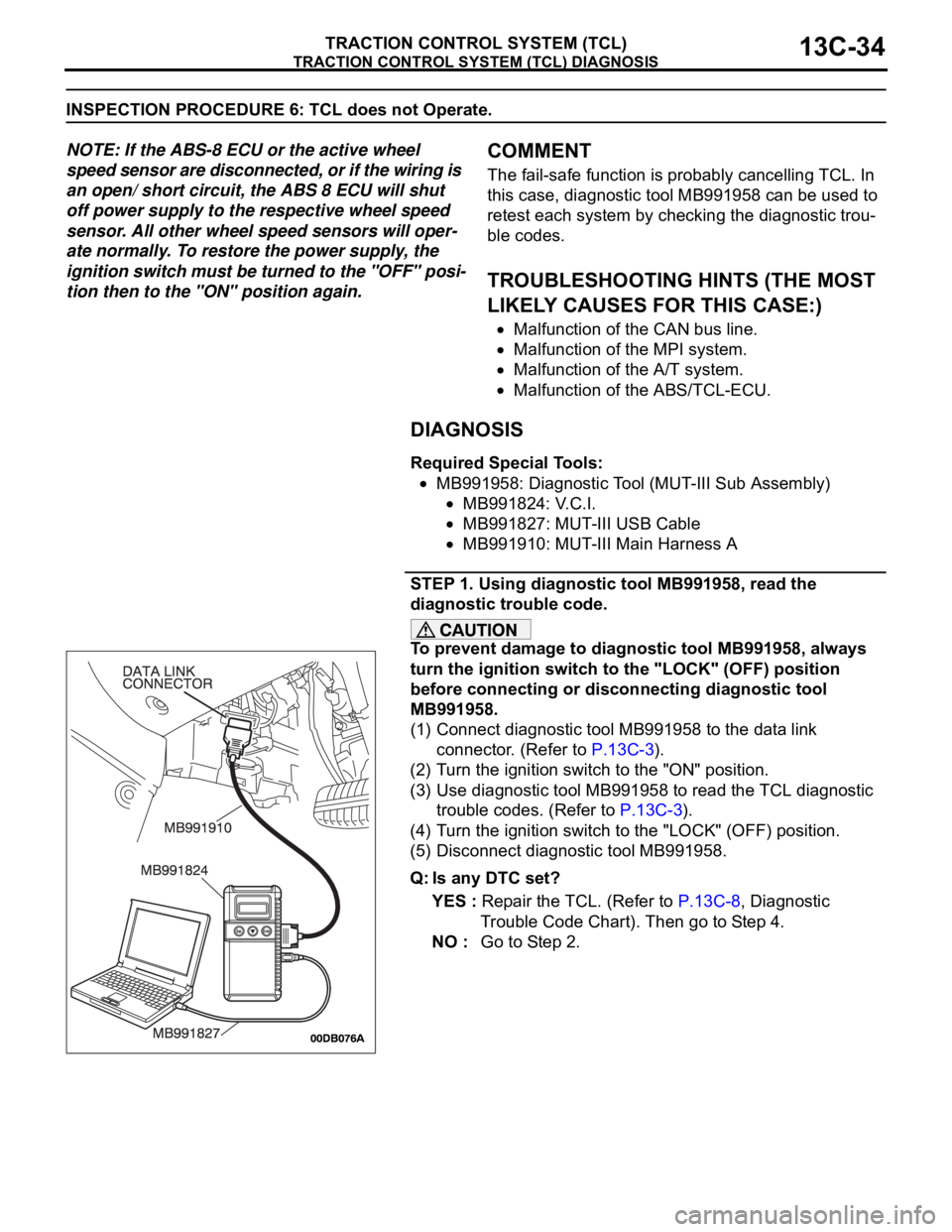

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is any DTC set?

YES : Repair the TCL. (Refer to P.13C-8, Diagnostic

Trouble Code Chart). Then go to Step 4.

NO : Go to Step 2.

Page 1315 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-36

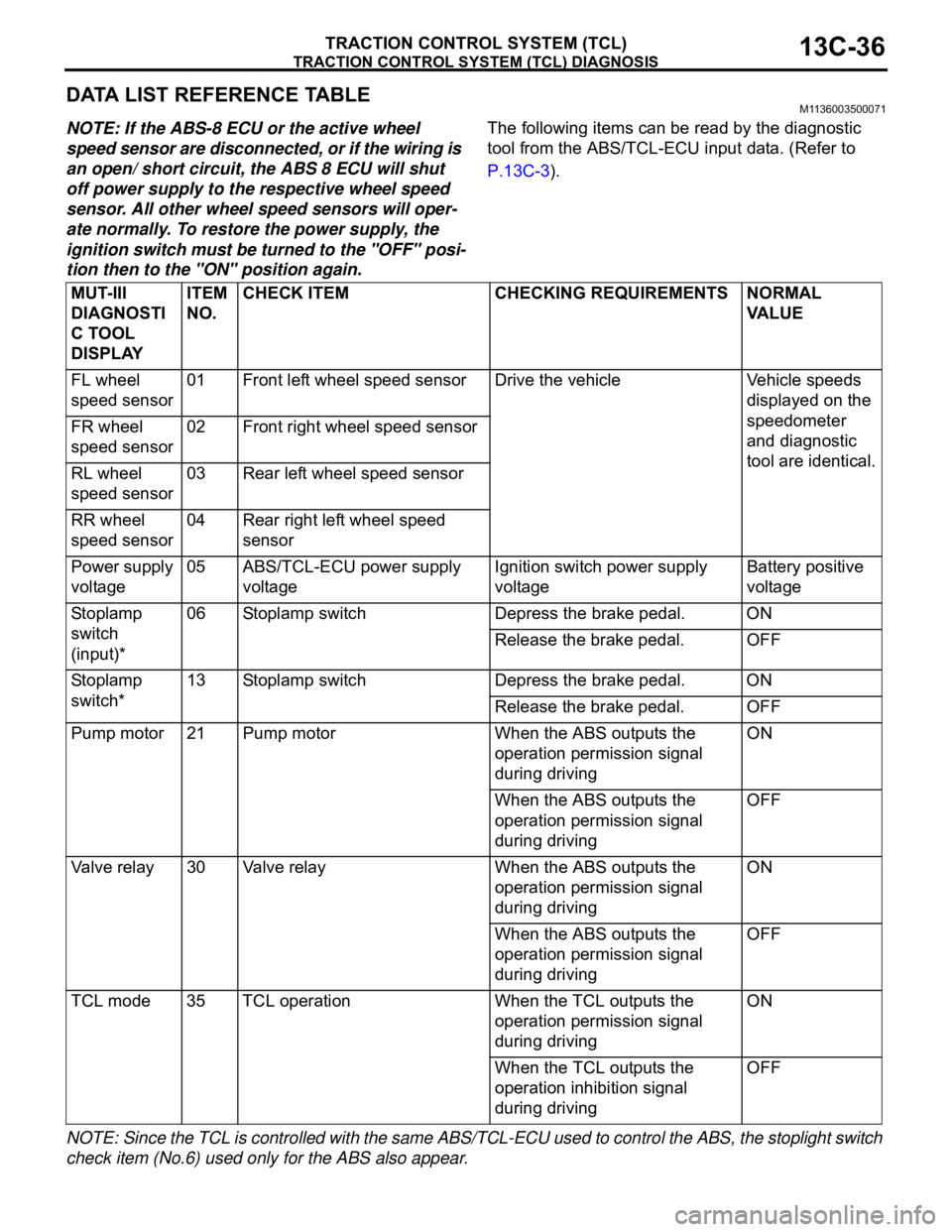

DATA LIST REFERENCE TABLEM1136003500071

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.The following items can be read by the diagnostic

tool from the ABS/TCL-ECU input data. (Refer to

P.13C-3).

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the stoplight switch

check item (No.6) used only for the ABS also appear.MUT-III

DIAGNOSTI

C TOOL

DISPLAYITEM

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL

VA L U E

FL wheel

speed sensor01 Front left wheel speed sensor Drive the vehicle Vehicle speeds

displayed on the

speedometer

and diagnostic

tool are identical. FR wheel

speed sensor02 Front right wheel speed sensor

RL wheel

speed sensor03 Rear left wheel speed sensor

RR wheel

speed sensor04 Rear right left wheel speed

sensor

Power supply

voltage05 ABS/TCL-ECU power supply

voltageIgnition switch power supply

voltageBattery positive

voltage

Stoplamp

switch

(input)*06 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Stoplamp

switch*13 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Pump motor 21 Pump motor When the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

Valve relay 30 Valve relayWhen the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

TCL mode 35 TCL operation When the TCL outputs the

operation permission signal

during drivingON

When the TCL outputs the

operation inhibition signal

during drivingOFF

Page 1316 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-37

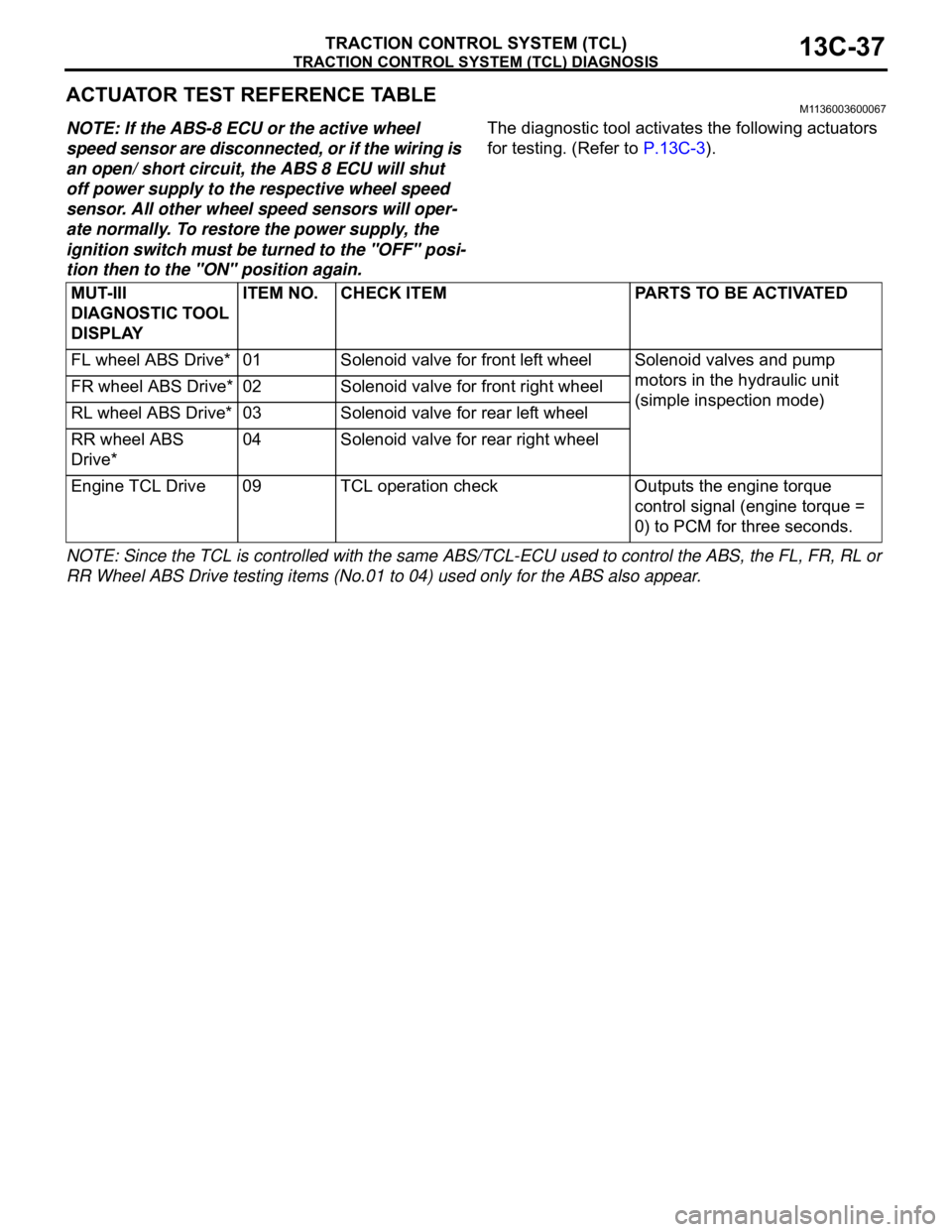

ACTUATOR TEST REFERENCE TABLEM1136003600067

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.The diagnostic tool activates the following actuators

for testing. (Refer to P.13C-3).

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the FL, FR, RL or

RR Wheel ABS Drive testing items (No.01 to 04) used only for the ABS also appear. MUT-III

DIAGNOSTIC TOOL

DISPLAYITEM NO. CHECK ITEM PARTS TO BE ACTIVATED

FL wheel ABS Drive* 01 Solenoid valve for front left wheel Solenoid valves and pump

motors in the hydraulic unit

(simple inspection mode) FR wheel ABS Drive* 02 Solenoid valve for front right wheel

RL wheel ABS Drive* 03 Solenoid valve for rear left wheel

RR wheel ABS

Drive*04 Solenoid valve for rear right wheel

Engine TCL Drive 09 TCL operation check Outputs the engine torque

control signal (engine torque =

0) to PCM for three seconds.

Page 1318 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-39

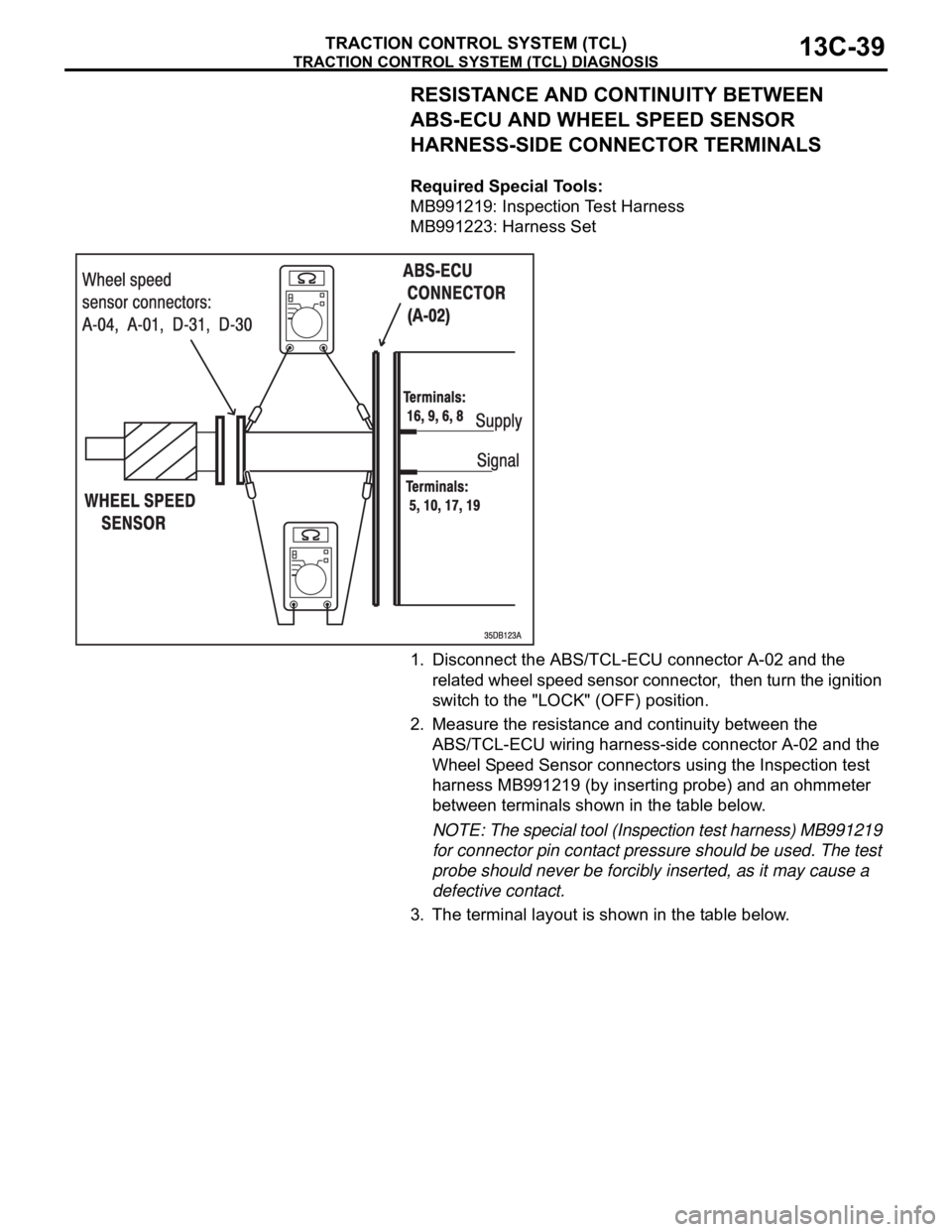

RESISTANCE AND CONTINUITY BETWEEN

ABS-ECU AND WHEEL SPEED SENSOR

HARNESS-SIDE CONNECTOR TERMINALS

.

Required Special Tools:

MB991219: Inspection Test Harness

MB991223: Harness Set

1. Disconnect the ABS/TCL-ECU connector A-02 and the

related wheel speed sensor connector, then turn the ignition

switch to the "LOCK" (OFF) position.

2. Measure the resistance and continuity between the

ABS/TCL-ECU wiring harness-side connector A-02 and the

Wheel Speed Sensor connectors using the Inspection test

harness MB991219 (by inserting probe) and an ohmmeter

between terminals shown in the table below.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

3. The terminal layout is shown in the table below.

Page 1319 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-40

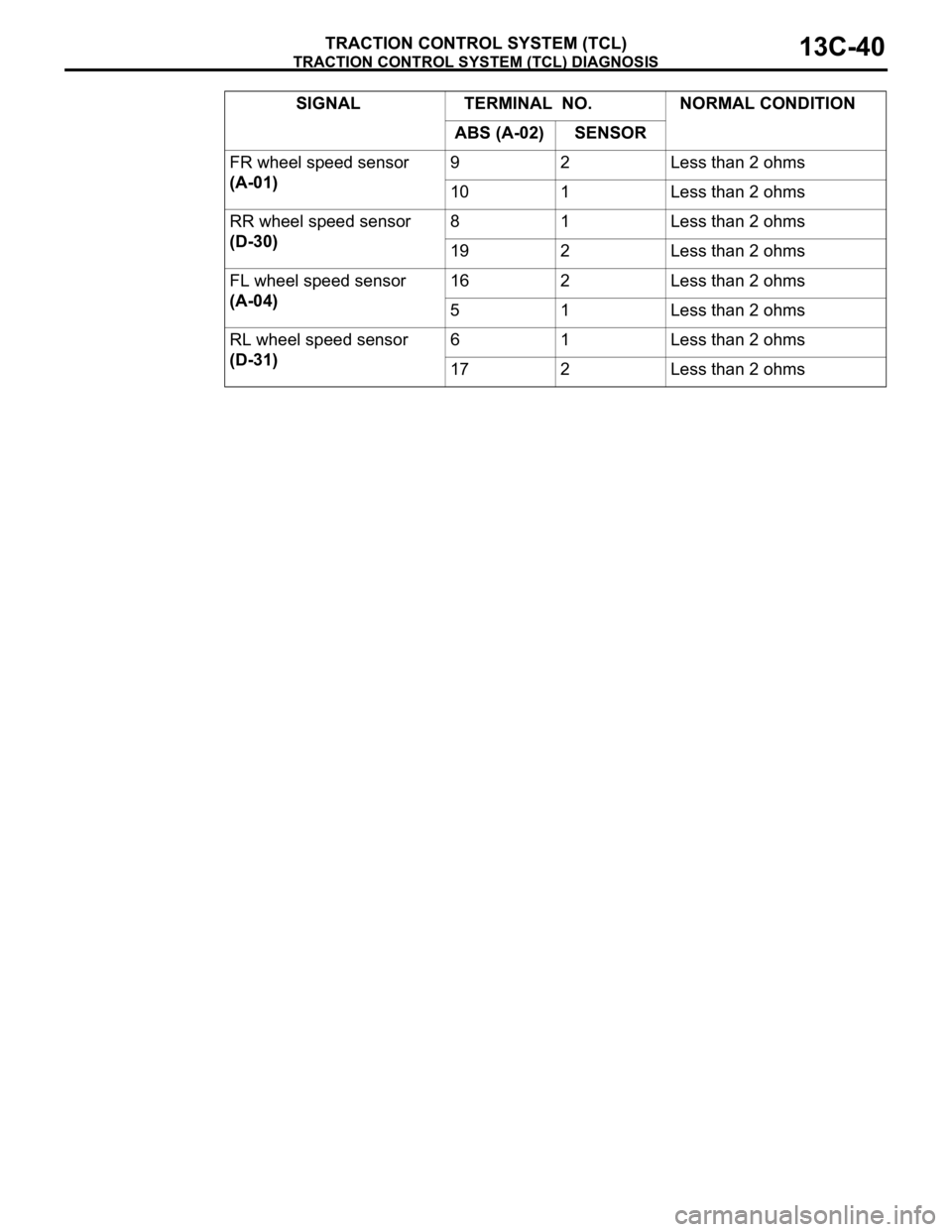

SIGNAL TERMINAL NO. NORMAL CONDITION

ABS (A-02) SENSOR

FR wheel speed sensor

(A-01)9 2 Less than 2 ohms

10 1 Less than 2 ohms

RR wheel speed sensor

(D-30)8 1 Less than 2 ohms

19 2 Less than 2 ohms

FL wheel speed sensor

(A-04)16 2 Less than 2 ohms

5 1 Less than 2 ohms

RL wheel speed sensor

(D-31)6 1 Less than 2 ohms

17 2 Less than 2 ohms

Page 1320 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-41

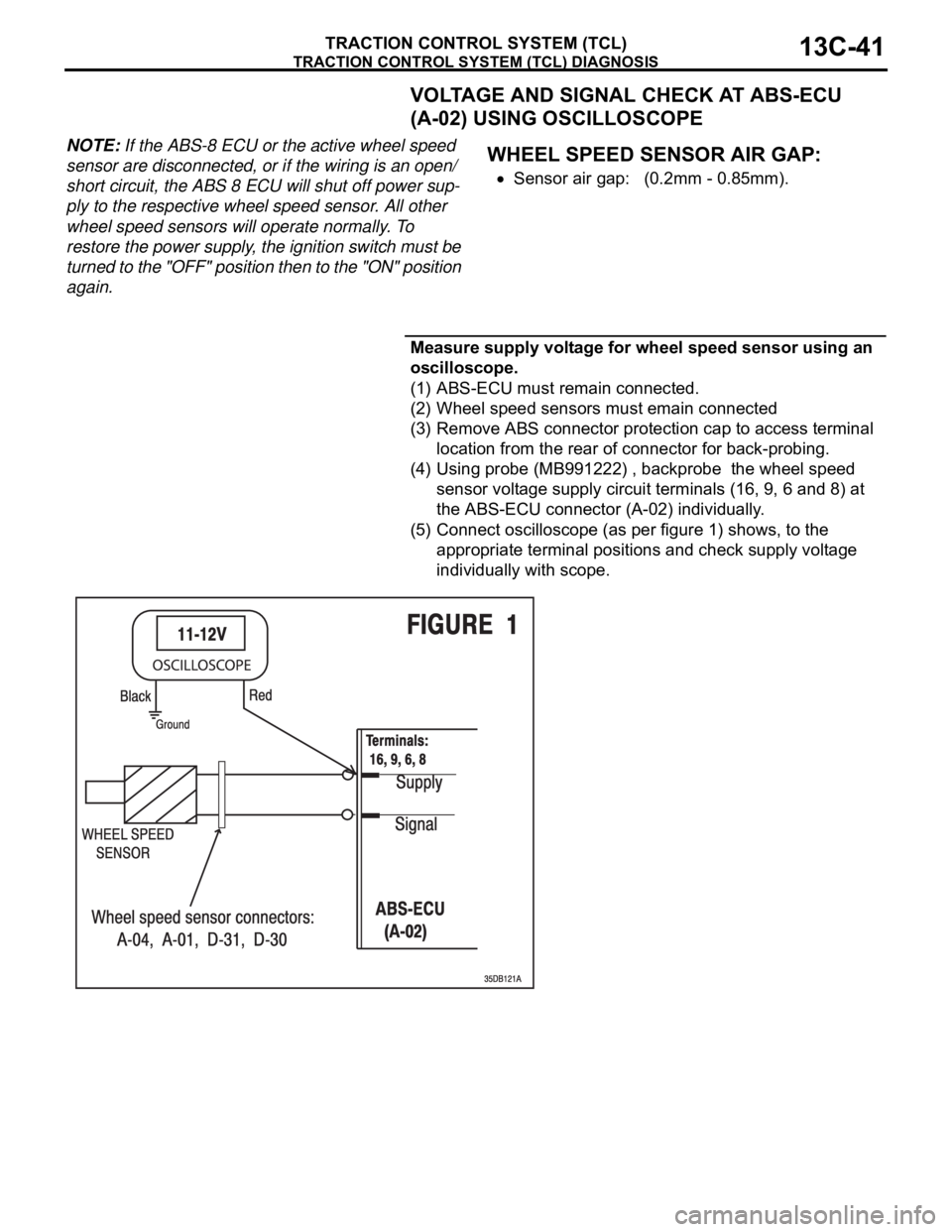

VOLTAGE AND SIGNAL CHECK AT ABS-ECU

(A-02) USING OSCILLOSCOPE

NOTE: If the ABS-8 ECU or the active wheel speed

sensor are disconnected, or if the wiring is an open/

short circuit, the ABS 8 ECU will shut off power sup-

ply to the respective wheel speed sensor. All other

wheel speed sensors will operate normally. To

restore the power supply, the ignition switch must be

turned to the "OFF" position then to the "ON" position

again..

WHEEL SPEED SENSOR AIR GAP:

Sensor air gap: (0.2mm - 0.85mm).

.

Measure supply voltage for wheel speed sensor using an

oscilloscope.

(1) ABS-ECU must remain connected.

(2) Wheel speed sensors must emain connected

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222) , backprobe the wheel speed

sensor voltage supply circuit terminals (16, 9, 6 and 8) at

the ABS-ECU connector (A-02) individually.

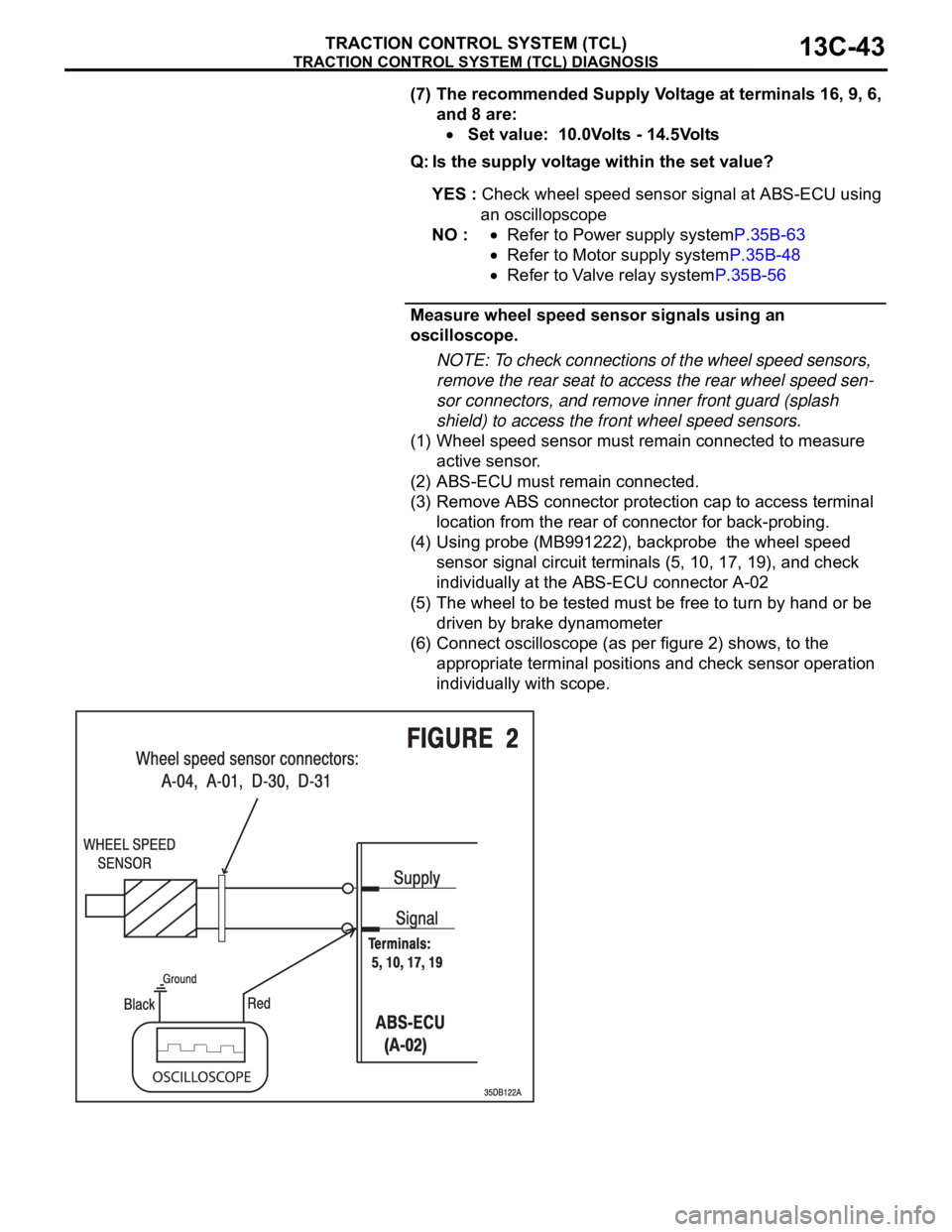

(5) Connect oscilloscope (as per figure 1) shows, to the

appropriate terminal positions and check supply voltage

individually with scope.

Page 1321 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-42

Connect oscilloscope to FL sensor signal terminal (16)

at ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (9) at

ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (6) at

ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (8) at

ABS-ECU (A-02)

(6) Turn the ignition switch to the "ON" position.

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1323 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-44

Connect oscilloscope to FL sensor signal terminal (5) at

ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (10)

at ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (17)

at ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (19)

at ABS-ECU (A-02)

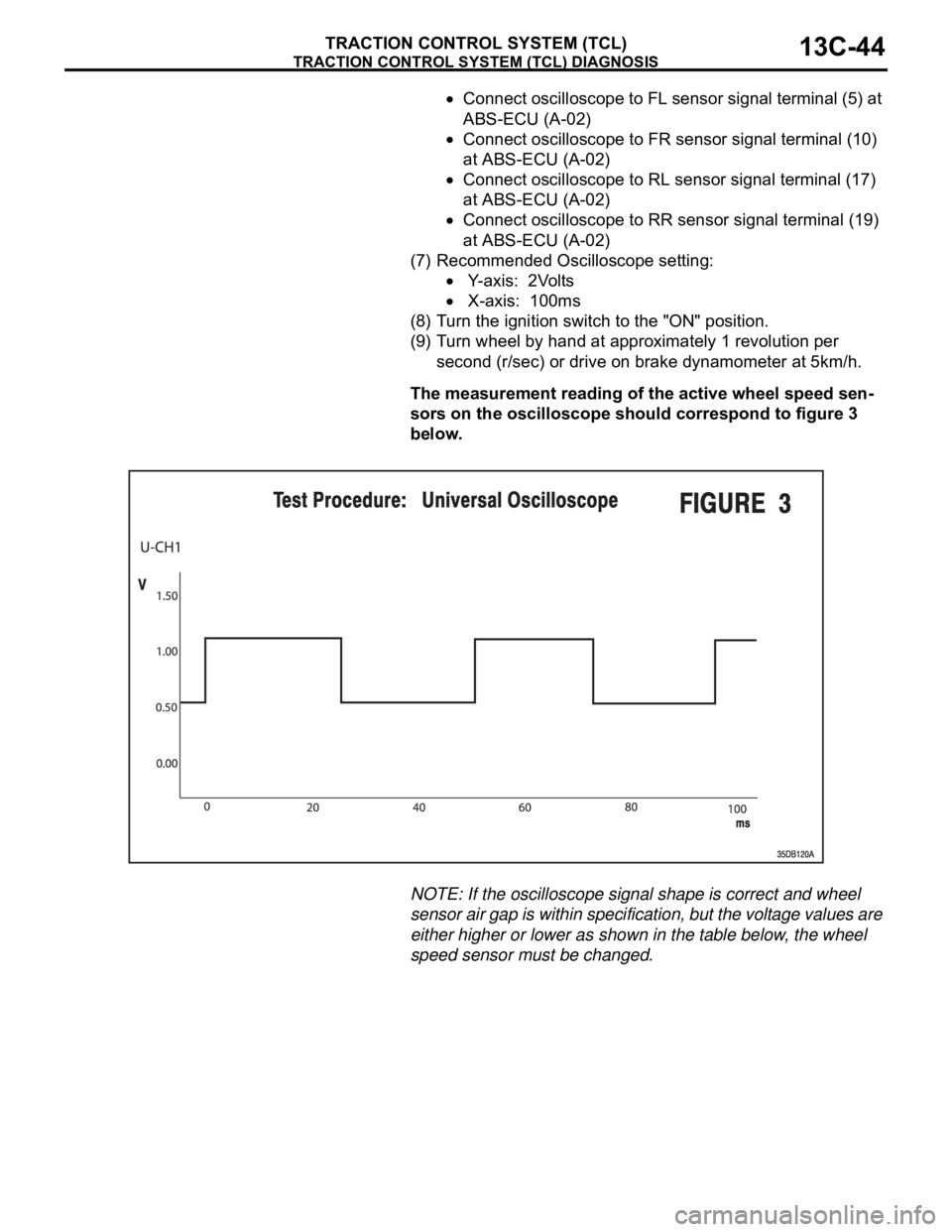

(7) Recommended Oscilloscope setting:

Y-axis: 2Volts

X-axis: 100ms

(8) Turn the ignition switch to the "ON" position.

(9) Turn wheel by hand at approximately 1 revolution per

second (r/sec) or drive on brake dynamometer at 5km/h.

The measurement reading of the active wheel speed sen-

sors on the oscilloscope should correspond to figure 3

below.

NOTE: If the oscilloscope signal shape is correct and wheel

sensor air gap is within specification, but the voltage values are

either higher or lower as shown in the table below, the wheel

speed sensor must be changed.