service MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1151 of 1500

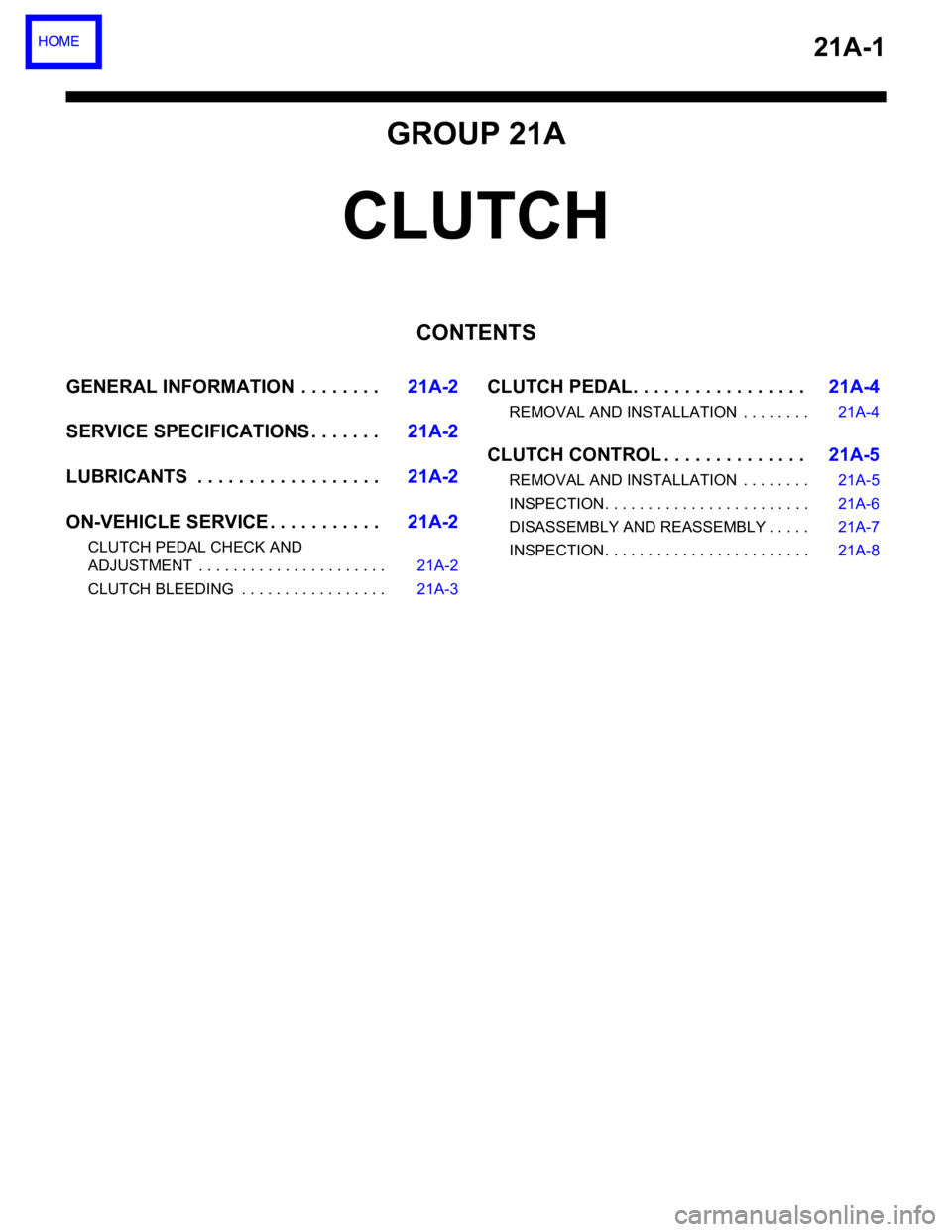

LOOSE PANEL

BODY42-84

DISASSEMBLY SERVICE POINT

.

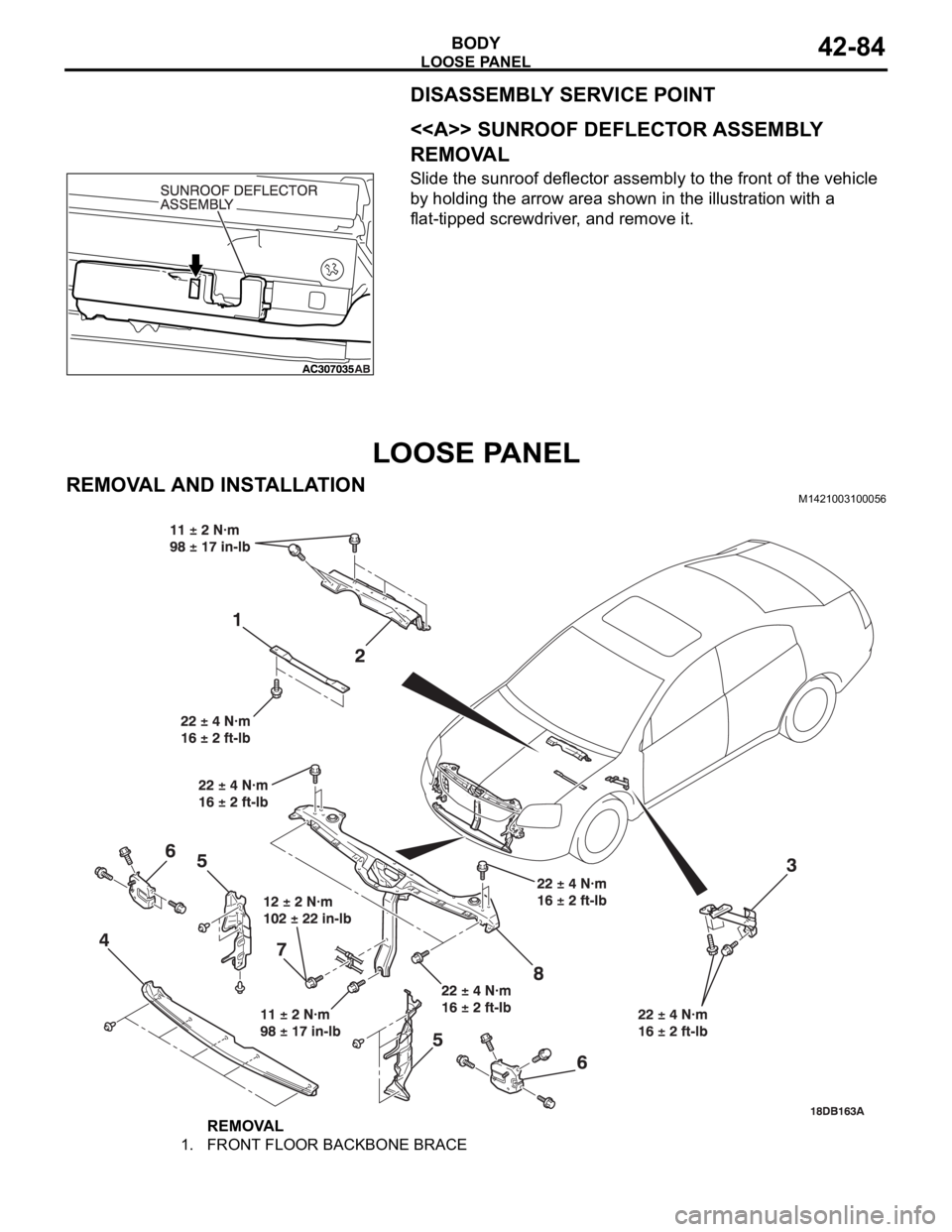

<> SUNROOF DEFLECTOR ASSEMBLY

REMOVAL

Slide the sunroof deflector assembly to the front of the vehicle

by holding the arrow area shown in the illustration with a

flat-tipped screwdriver, and remove it.

LOOSE PANEL

REMOVAL AND INSTALLATIONM1421003100056

REMOVAL

1. FRONT FLOOR BACKBONE BRACE

Page 1154 of 1500

SPECIFICATIONS

BODY42-87

SERVICE SPECIFICATIONSM1421000300299

SEALANT AND ADHESIVESM1421000500204

Door inside handle knob play mm

(in)Front 26.1 - 58.1 (1.028 - 2.287) [Target

value 41 (1.61)]

Rear 30.3 - 58.1 (1.193 - 2.287) [Target

value 41 (1.61)]

Door inside handle lock knob stroke mm (in) 21.6 (0.850)

Door outside handle play mm (in) Front 10

3.5 (0.39 0.138)

Rear 11.2

4 (0.441 0.16)

Power window operation current A 5

1 [Power supply voltage 14.5

0.5V 25

C (77F)]

ITEM STANDARD VALUE

Roof lid glass operation current A 7 or less [at 20

C(68F)]

ITEM SPECIFIED ADHESIVE

Rear window glass 3 M

AAD part No. 8609 super fast urethane and 3 M AAD part No.

8608 super fast urethane primer or equivalent

Windshield

ITEM SPECIFIED SEALANT REMARK

Waterproof film 3 M

AAD Part No. 8633 or equivalent Ribbon sealer

ITEM SPECIFIED ADHESIVE TAPE

Front door opening outer

weatherstripAdhesive tape: Double-sided tape [7 mm (0.28 in) width, 85 mm (3.35

in) length and 0.8 mm (0.03 in) thickness]

Rear door opening outer

weatherstripAdhesive tape: Double-sided tape [7 mm (0.28 in) width, 50 mm (1.97

in) length and 0.8 mm (0.031 in) thickness]

ITEM SPECIFIED SEALANT REMARK

Trunk lid hinge 3 M

AAD part No. 8531 Heavy drip check sealer,

3 M

AAD part No. 8646 Automotive joint and

seam sealer or equivalentBody sealer

Page 1156 of 1500

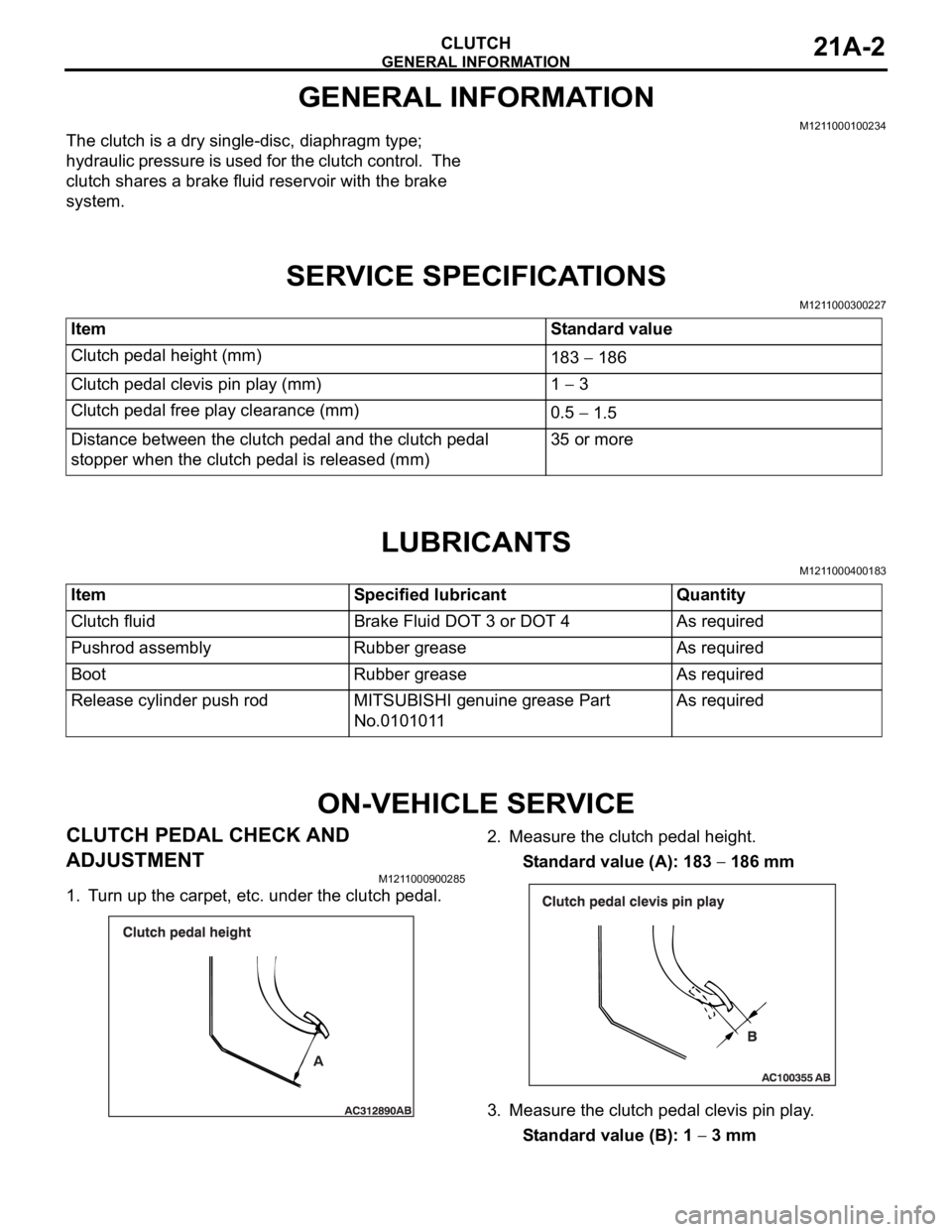

21A-1

GROUP 21A

CLUTCH

CONTENTS

GENERAL INFORMATION . . . . . . . .21A-2

SERVICE SPECIFICATIONS . . . . . . .21A-2

LUBRICANTS . . . . . . . . . . . . . . . . . .21A-2

ON-VEHICLE SERVICE . . . . . . . . . . .21A-2

CLUTCH PEDAL CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 21A-2

CLUTCH BLEEDING . . . . . . . . . . . . . . . . . 21A-3

CLUTCH PEDAL. . . . . . . . . . . . . . . . .21A-4

REMOVAL AND INSTALLATION . . . . . . . . 21A-4

CLUTCH CONTROL . . . . . . . . . . . . . .21A-5

REMOVAL AND INSTALLATION . . . . . . . . 21A-5

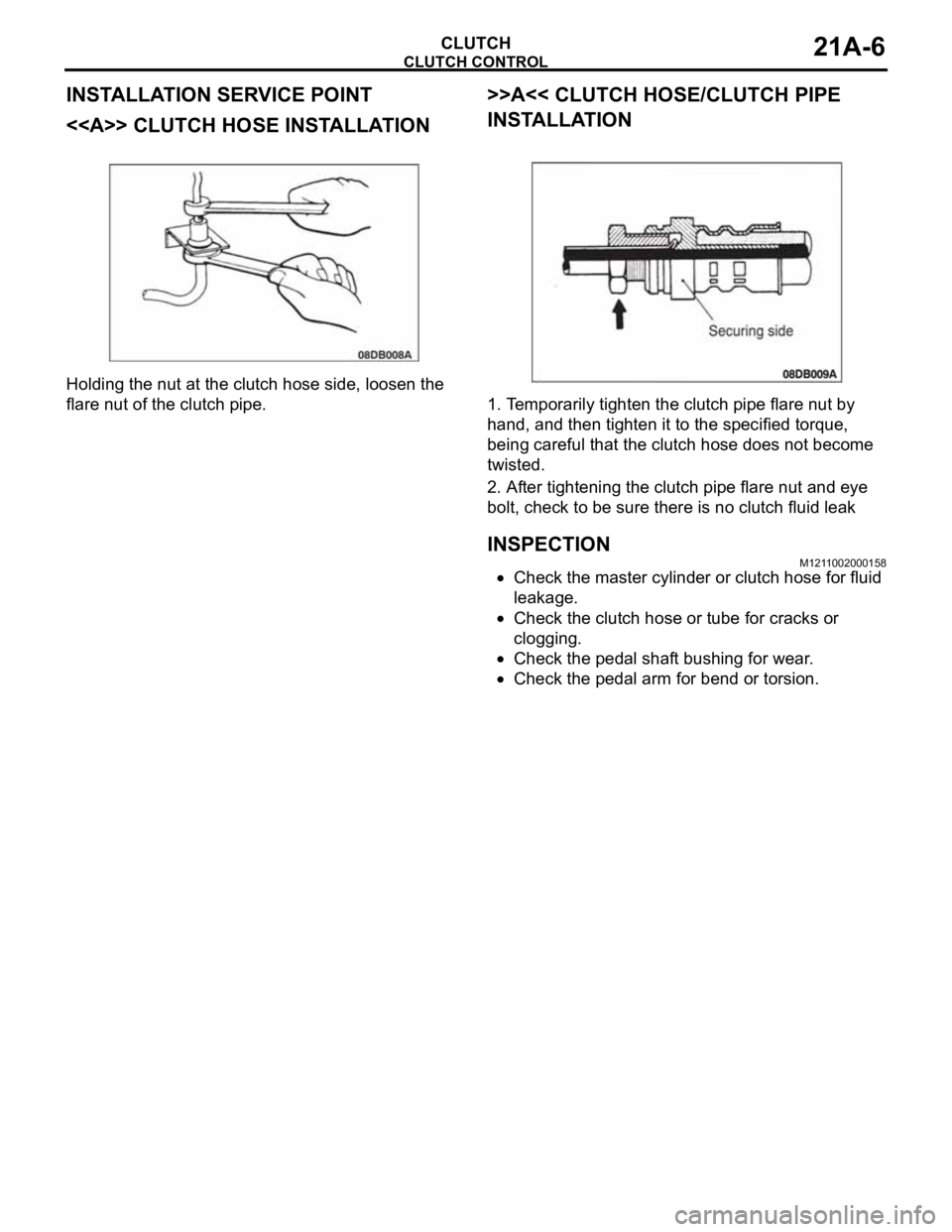

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 21A-6

DISASSEMBLY AND REASSEMBLY . . . . . 21A-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 21A-8

Page 1157 of 1500

GENERAL INFORMATION

CLUTCH21A-2

GENERAL INFORMATION

M1211000100234

The clutch is a dry single-disc, diaphragm type;

hydraulic pressure is used for the clutch control. The

clutch shares a brake fluid reservoir with the brake

system.

SERVICE SPECIFICATIONS

M1211000300227

LUBRICANTS

M1211000400183

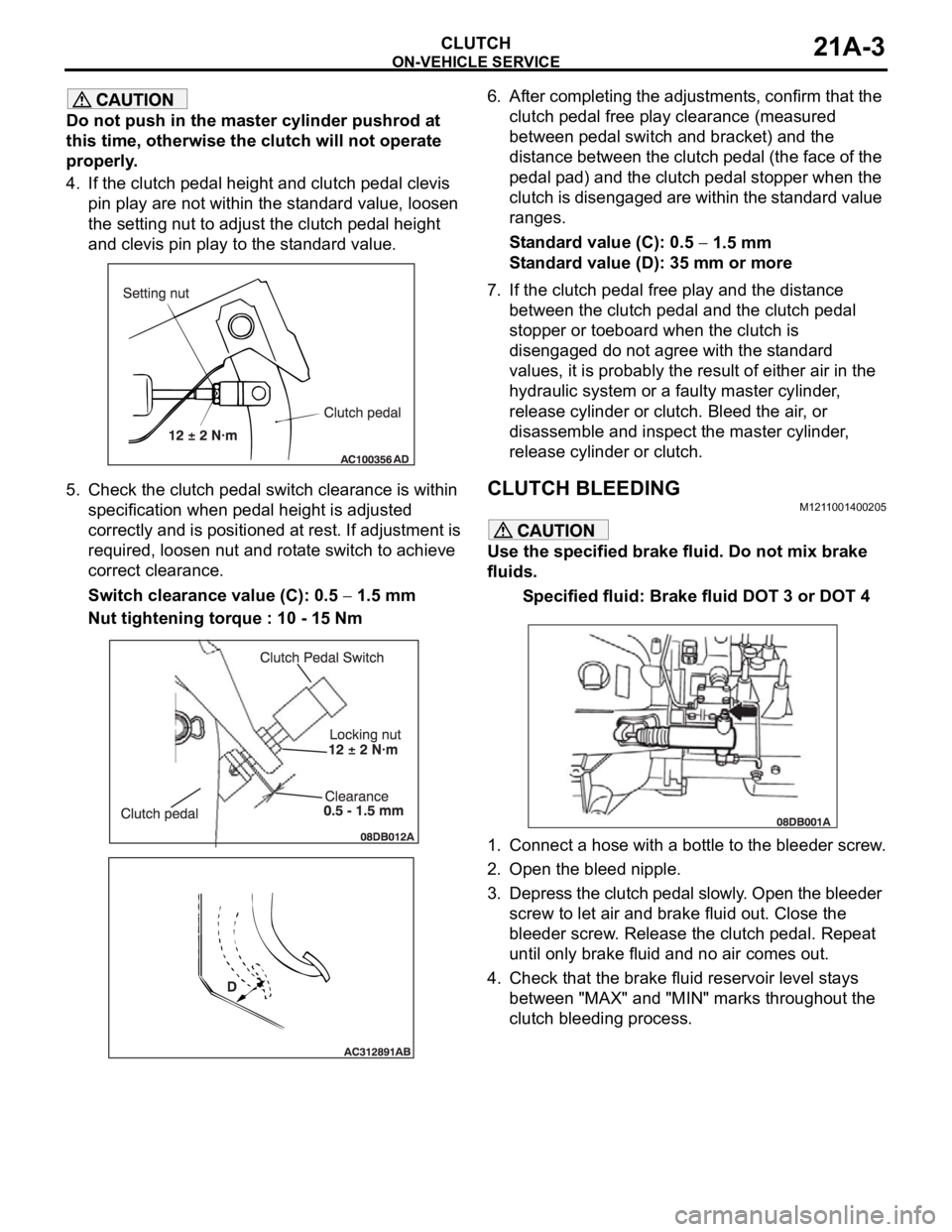

ON-VEHICLE SERVICE

CLUTCH PEDAL CHECK AND

ADJUSTMENT

M1211000900285

1. Turn up the carpet, etc. under the clutch pedal.2. Measure the clutch pedal height.

Standard value (A): 183

186 mm

3. Measure the clutch pedal clevis pin play.

Standard value (B): 1

3 mm Item Standard value

Clutch pedal height (mm)

183

186

Clutch pedal clevis pin play (mm) 1

3

Clutch pedal free play clearance (mm)

0.5

1.5

Distance between the clutch pedal and the clutch pedal

stopper when the clutch pedal is released (mm)35 or more

Item Specified lubricant Quantity

Clutch fluid Brake Fluid DOT 3 or DOT 4 As required

Pushrod assembly Rubber grease As required

Boot Rubber grease As required

Release cylinder push rod MITSUBISHI genuine grease Part

No.0101011As required

Page 1158 of 1500

ON-VEHICLE SERVICE

CLUTCH21A-3

Do not push in the master cylinder pushrod at

this time, otherwise the clutch will not operate

properly.

4. If the clutch pedal height and clutch pedal clevis

pin play are not within the standard value, loosen

the setting nut to adjust the clutch pedal height

and clevis pin play to the standard value.

5. Check the clutch pedal switch clearance is within

specification when pedal height is adjusted

correctly and is positioned at rest. If adjustment is

required, loosen nut and rotate switch to achieve

correct clearance.

Switch clearance value (C): 0.5

1.5 mm

Nut tightening torque : 10 - 15 Nm6. After completing the adjustments, confirm that the

clutch pedal free play clearance (measured

between pedal switch and bracket) and the

distance between the clutch pedal (the face of the

pedal pad) and the clutch pedal stopper when the

clutch is disengaged are within the standard value

ranges.

Standard value (C): 0.5

1.5 mm

Standard value (D): 35 mm or more

7. If the clutch pedal free play and the distance

between the clutch pedal and the clutch pedal

stopper or toeboard when the clutch is

disengaged do not agree with the standard

values, it is probably the result of either air in the

hydraulic system or a faulty master cylinder,

release cylinder or clutch. Bleed the air, or

disassemble and inspect the master cylinder,

release cylinder or clutch.

CLUTCH BLEEDINGM1211001400205

Use the specified brake fluid. Do not mix brake

fluids.

Specified fluid: Brake fluid DOT 3 or DOT 4

1. Connect a hose with a bottle to the bleeder screw.

2. Open the bleed nipple.

3. Depress the clutch pedal slowly. Open the bleeder

screw to let air and brake fluid out. Close the

bleeder screw. Release the clutch pedal. Repeat

until only brake fluid and no air comes out.

4. Check that the brake fluid reservoir level stays

between "MAX" and "MIN" marks throughout the

clutch bleeding process.

Page 1161 of 1500

Page 1163 of 1500

CLUTCH CONTROL

CLUTCH21A-8

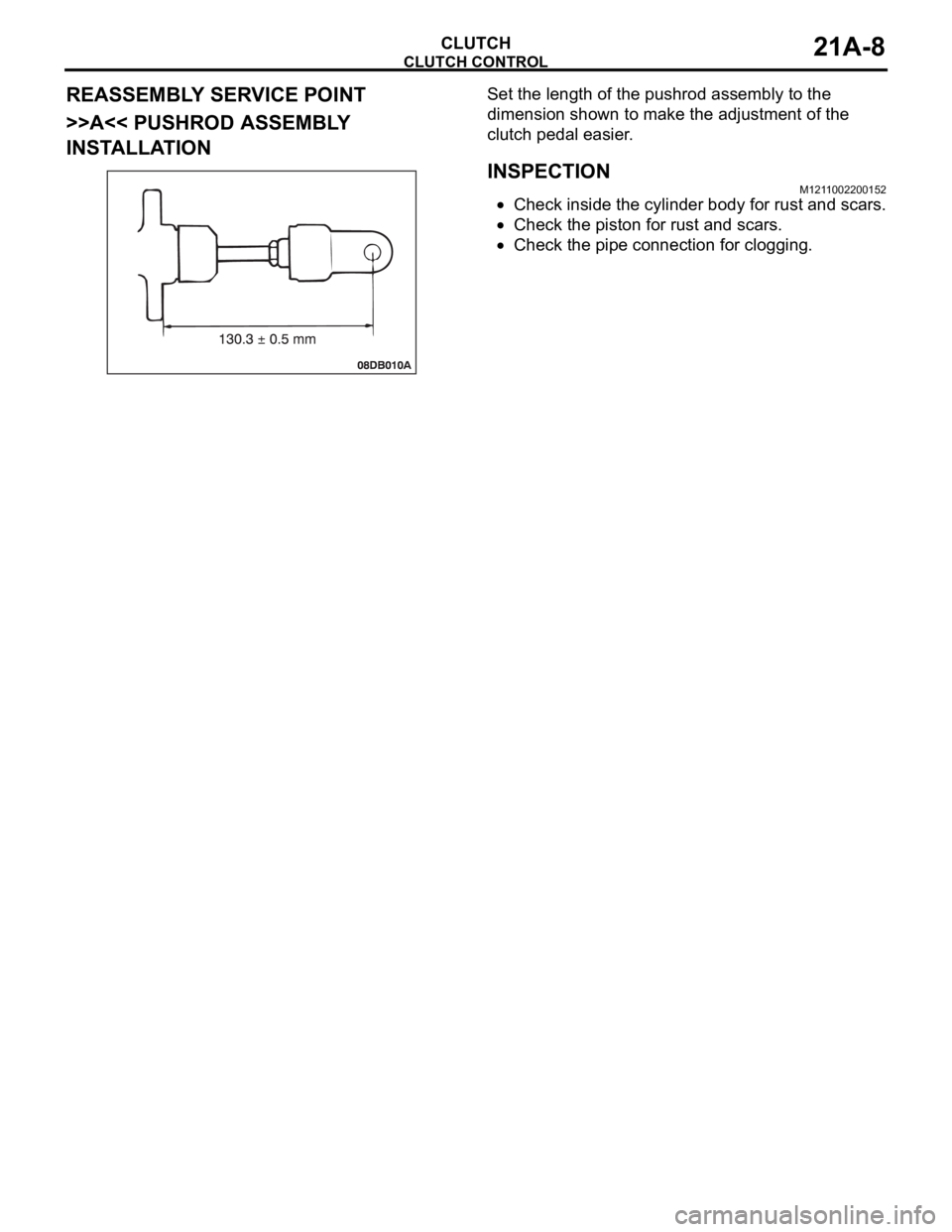

REASSEMBLY SERVICE POINT

>>A<< PUSHROD ASSEMBLY

INSTALLATIONSet the length of the pushrod assembly to the

dimension shown to make the adjustment of the

clutch pedal easier.

INSPECTIONM1211002200152

Check inside the cylinder body for rust and scars.

Check the piston for rust and scars.

Check the pipe connection for clogging.

Page 1164 of 1500

35-1

GROUP 35

SERVICE BRAKES

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35A

ANTI-LOCK BRAKING SYSTEM (ABS). . . . . . . . . . . . . . . . . . .35B

Page 1166 of 1500

35A-1

GROUP 35A

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .35A-2

BASIC BRAKE SYSTEM DIAGNOSIS35A-3

INTRODUCTION TO BASIC BRAKE

SYSTEM DIAGNOSIS . . . . . . . . . . . . . . . . 35A-3

BASIC BRAKE SYSTEM DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . . . 35A-3

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 35A-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 35A-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .35A-12

ON-VEHICLE SERVICE . . . . . . . . . . .35A-13

BRAKE PEDAL CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 35A-13

BRAKE BOOSTER OPERATING TEST . . . 35A-14

CHECK VALVE OPERATION CHECK . . . . 35A-15

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 35A-16

BRAKE FLUID LEVEL SENSOR CHECK. . 35A-17

DISC BRAKE PAD CHECK AND

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 35A-17

DISC BRAKE ROTOR CHECK . . . . . . . . . . 35A-19

MASTER CYLINDER FUNCTION CHECK . 35A-23

BRAKE PEDAL. . . . . . . . . . . . . . . . . .35A-24

REMOVAL AND INSTALLATION . . . . . . . . 35A-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-25

MASTER CYLINDER ASSEMBLY

AND BRAKE BOOSTER . . . . . . . . . .35A-26

REMOVAL AND INSTALLATION . . . . . . . . 35A-26

MASTER CYLINDER . . . . . . . . . . . . . . . . . 35A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-29

DISC BRAKE ASSEMBLY . . . . . . . . .35A-30

REMOVAL AND INSTALLATION . . . . . . . . 35A-30

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-32

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY AND ASSEMBLY

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-38

SPECIFICATIONS . . . . . . . . . . . . . . .35A-40

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 35A-40

GENERAL SPECIFICATIONS . . . . . . . . . . 35A-40

SERVICE SPECIFICATIONS . . . . . . . . . . . 35A-41

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . 35A-41

Page 1167 of 1500

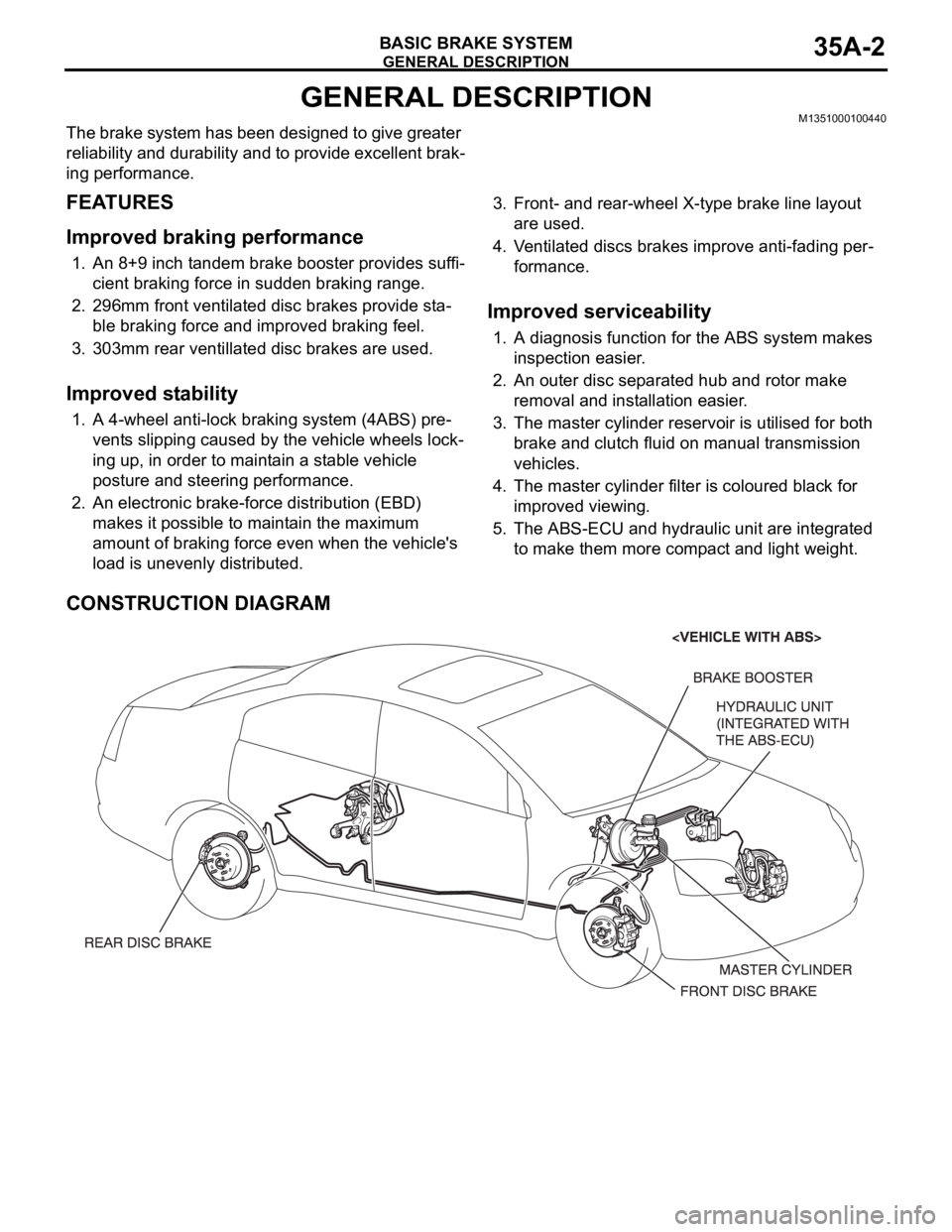

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM35A-2

GENERAL DESCRIPTIONM1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed. 3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM