service MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1042 of 1500

GARNISHES AND MOLDINGS

EXTERIOR51-9

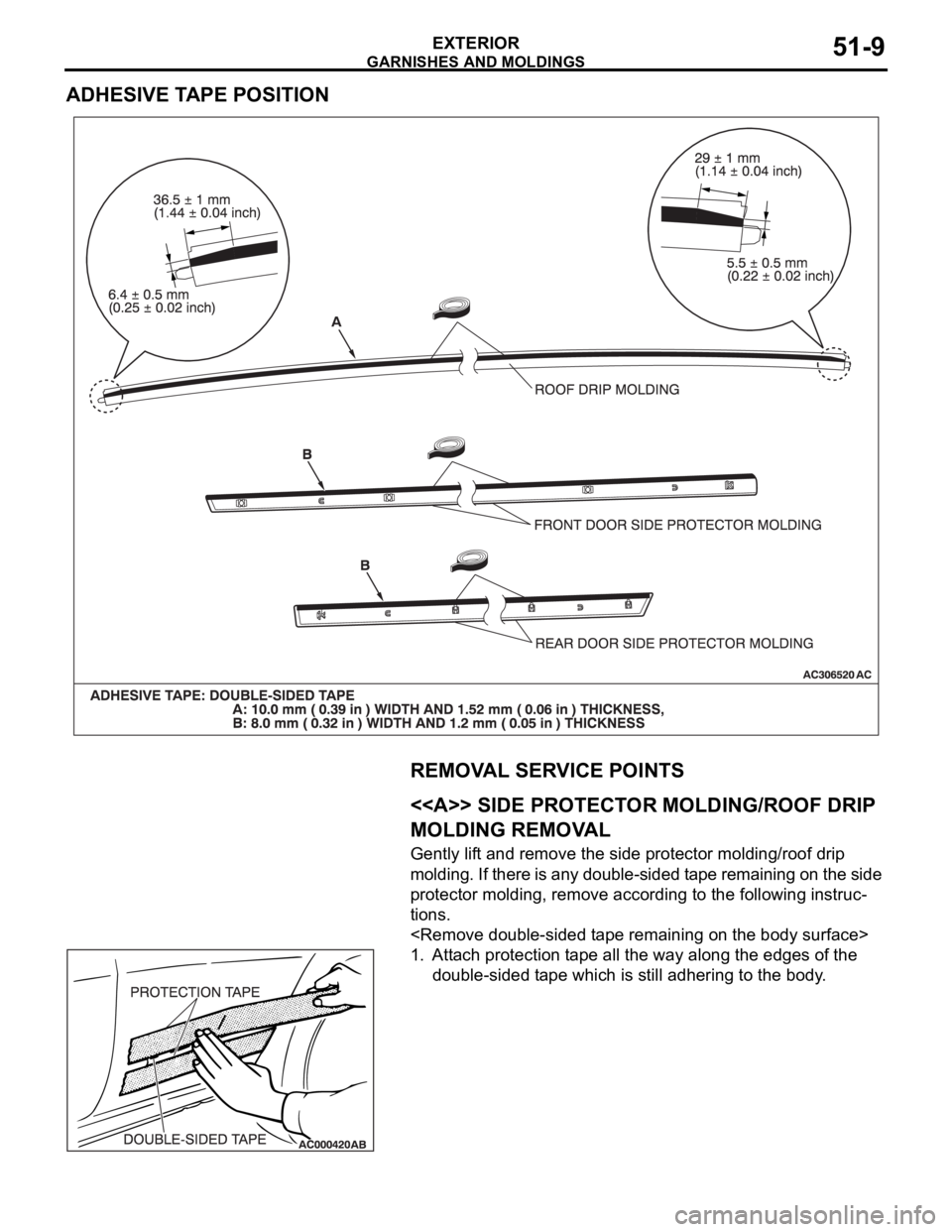

ADHESIVE TAPE POSITION

REMOVAL SERVICE POINTS

.

<> SIDE PROTECTOR MOLDING/ROOF DRIP

MOLDING REMOVAL

Gently lift and remove the side protector molding/roof drip

molding. If there is any double-sided tape remaining on the side

protector molding, remove according to the following instruc-

tions.

1. Attach protection tape all the way along the edges of the

double-sided tape which is still adhering to the body.

Page 1043 of 1500

GARNISHES AND MOLDINGS

EXTERIOR51-10

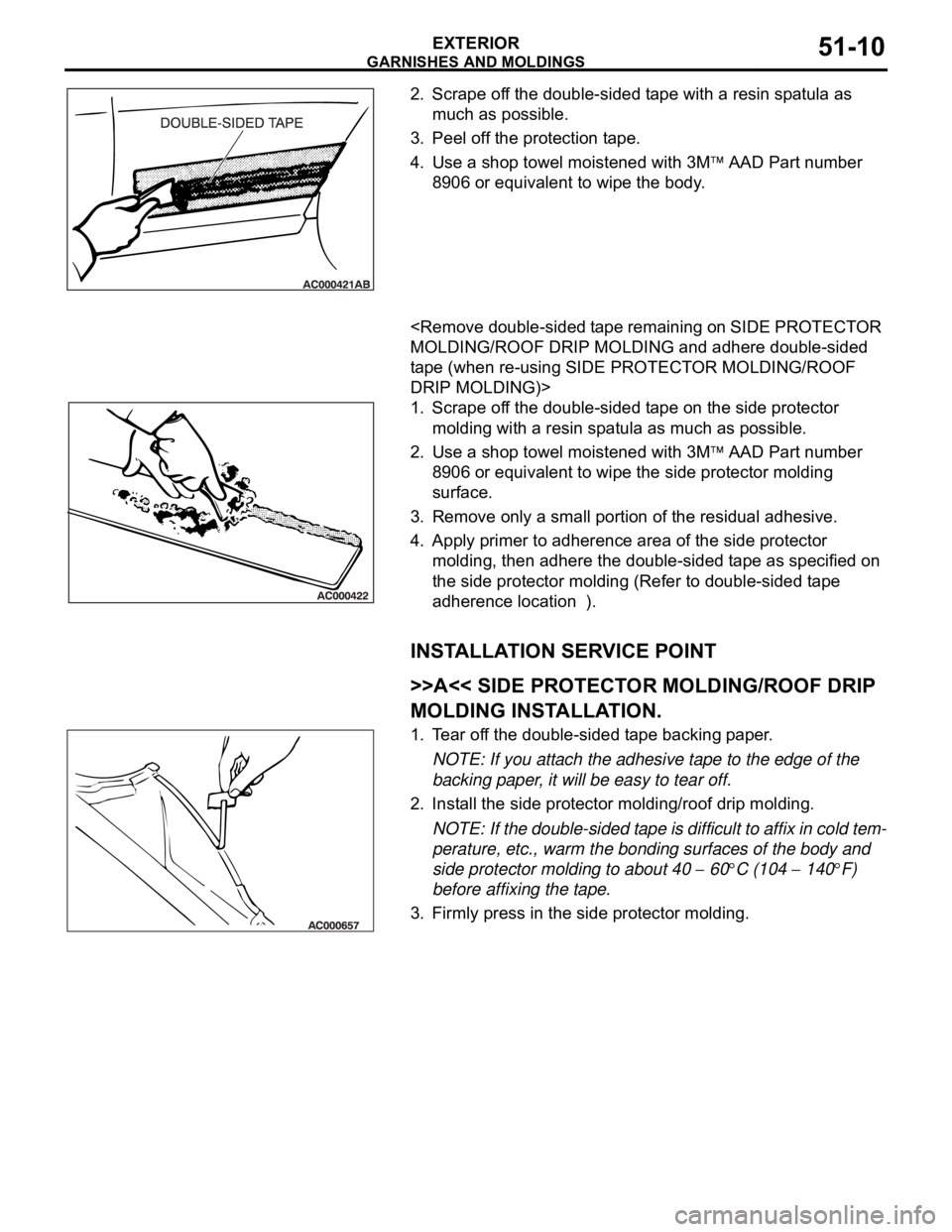

2. Scrape off the double-sided tape with a resin spatula as

much as possible.

3. Peel off the protection tape.

4. Use a shop towel moistened with 3M

AAD Part number

8906 or equivalent to wipe the body.

.

tape (when re-using SIDE PROTECTOR MOLDING/ROOF

DRIP MOLDING)>

1. Scrape off the double-sided tape on the side protector

molding with a resin spatula as much as possible.

2. Use a shop towel moistened with 3M

AAD Part number

8906 or equivalent to wipe the side protector molding

surface.

3. Remove only a small portion of the residual adhesive.

4. Apply primer to adherence area of the side protector

molding, then adhere the double-sided tape as specified on

the side protector molding (Refer to double-sided tape

adherence location ).

INSTALLATION SERVICE POINT

.

>>A<< SIDE PROTECTOR MOLDING/ROOF DRIP

MOLDING INSTALLATION.

1. Tear off the double-sided tape backing paper.

NOTE: If you attach the adhesive tape to the edge of the

backing paper, it will be easy to tear off.

2. Install the side protector molding/roof drip molding.

NOTE: If the double-sided tape is difficult to affix in cold tem-

perature, etc., warm the bonding surfaces of the body and

side protector molding to about 40

60C (104 140F)

before affixing the tape.

3. Firmly press in the side protector molding.

Page 1048 of 1500

WINDSHIELD WIPER AND WASHER

EXTERIOR51-15

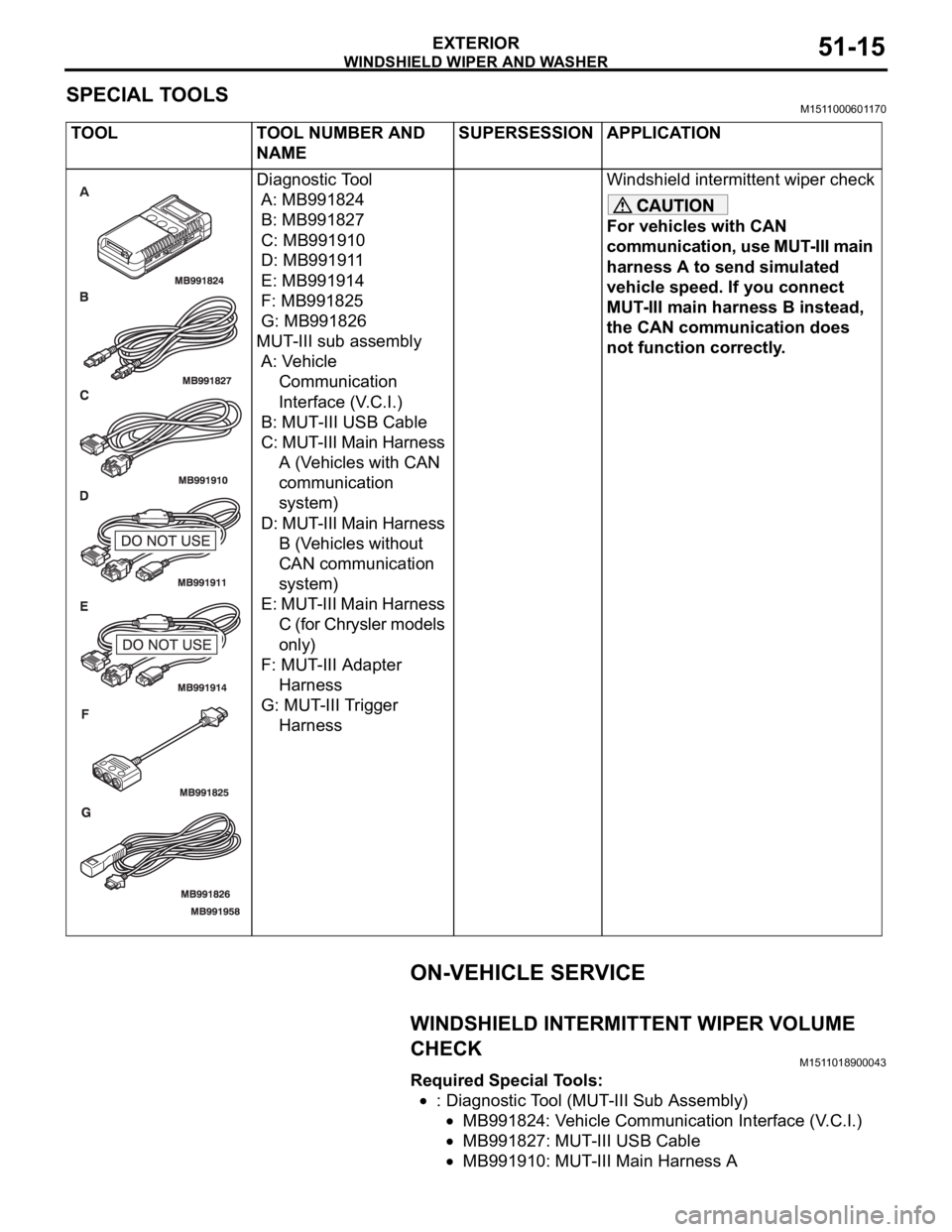

SPECIAL TOOLSM1511000601170

ON-VEHICLE SERVICE

WINDSHIELD INTERMITTENT WIPER VOLUME

CHECK

M1511018900043

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

Diagnostic Tool

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III sub assembly

A: Vehicle

Communication

Interface (V.C.I.)

B: MUT-III USB Cable

C: MUT-III Main Harness

A (Vehicles with CAN

communication

system)

D: MUT-III Main Harness

B (Vehicles without

CAN communication

system)

E: MUT-III Main Harness

C (for Chrysler models

only)

F: MUT-III Adapter

Harness

G: MUT-III Trigger

HarnessWindshield intermittent wiper check

For vehicles with CAN

communication, use MUT-III main

harness A to send simulated

vehicle speed. If you connect

MUT-III main harness B instead,

the CAN communication does

not function correctly.

Page 1052 of 1500

WINDSHIELD WIPER AND WASHER

EXTERIOR51-19

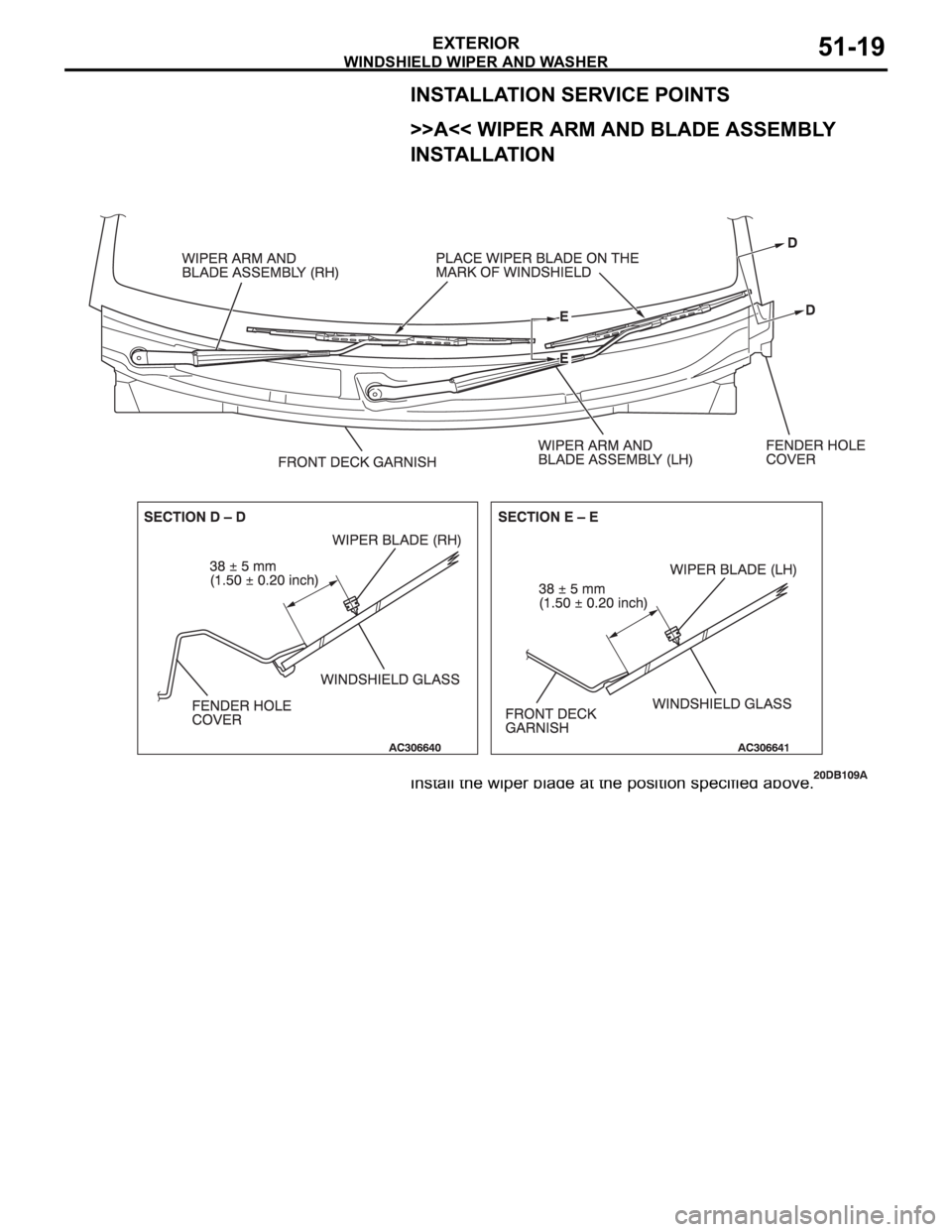

INSTALLATION SERVICE POINTS

.

>>A<< WIPER ARM AND BLADE ASSEMBLY

INSTALLATION

Install the wiper blade at the position specified above.

.

Page 1059 of 1500

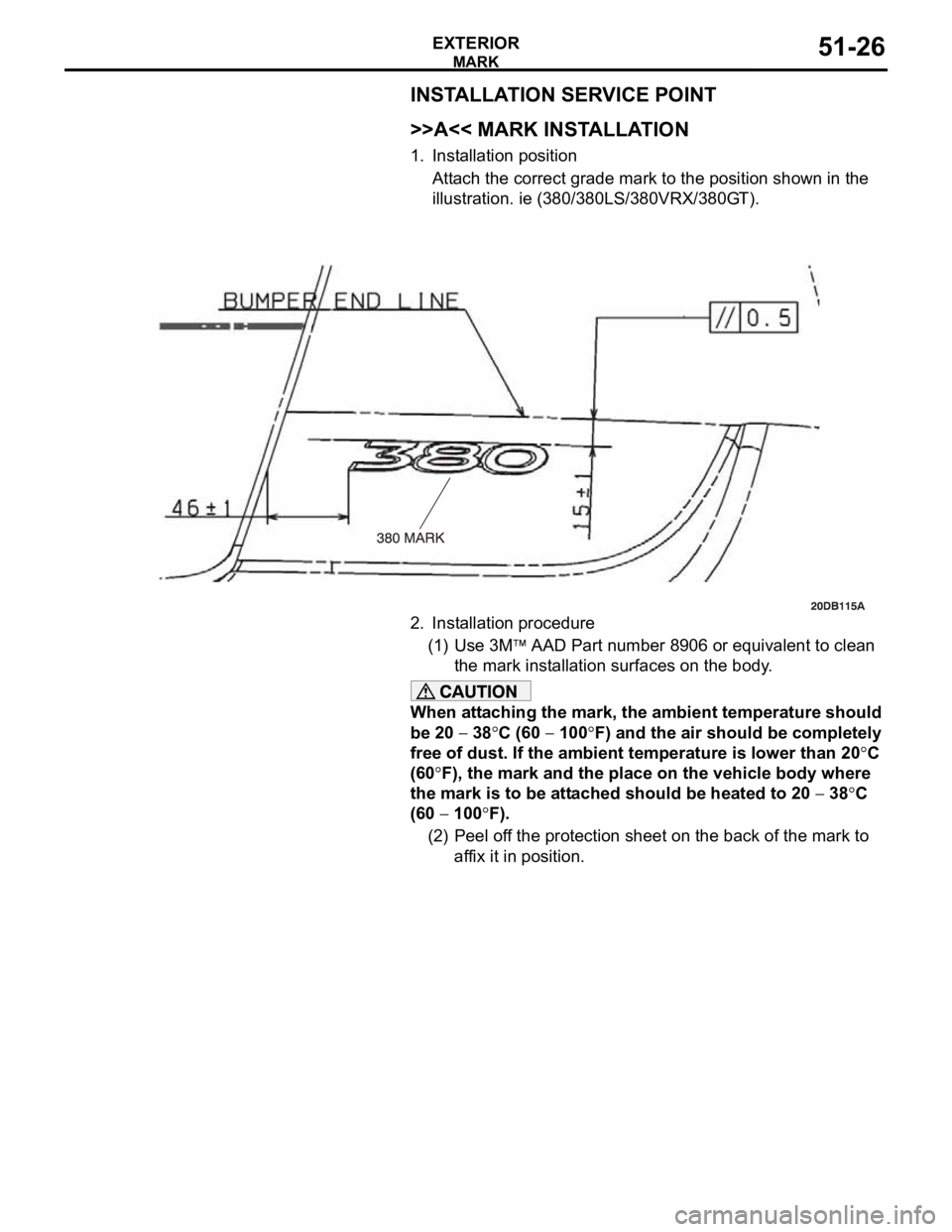

MARK

EXTERIOR51-26

INSTALLATION SERVICE POINT

.

>>A<< MARK INSTALLATION

1. Installation position

Attach the correct grade mark to the position shown in the

illustration. ie (380/380LS/380VRX/380GT).

2. Installation procedure

(1) Use 3M

AAD Part number 8906 or equivalent to clean

the mark installation surfaces on the body.

When attaching the mark, the ambient temperature should

be 20

38C (60 100F) and the air should be completely

free of dust. If the ambient temperature is lower than 20

C

(60

F), the mark and the place on the vehicle body where

the mark is to be attached should be heated to 20

38C

(60

100F).

(2) Peel off the protection sheet on the back of the mark to

affix it in position.

Page 1062 of 1500

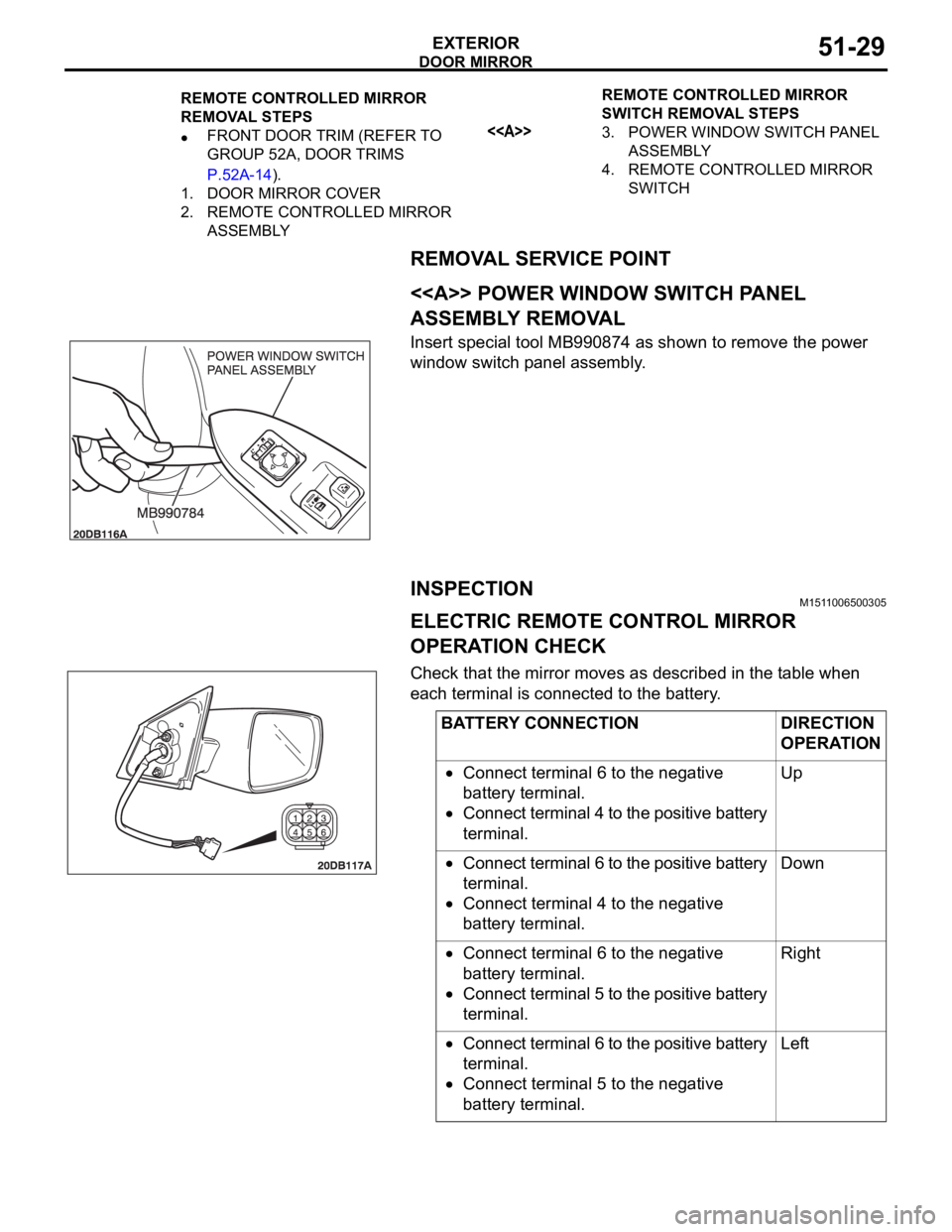

DOOR MIRROR

EXTERIOR51-29

REMOVAL SERVICE POINT

.

<> POWER WINDOW SWITCH PANEL

ASSEMBLY REMOVAL

Insert special tool MB990874 as shown to remove the power

window switch panel assembly.

INSPECTIONM1511006500305

ELECTRIC REMOTE CONTROL MIRROR

OPERATION CHECK

Check that the mirror moves as described in the table when

each terminal is connected to the battery.

REMOTE CONTROLLED MIRROR

REMOVAL STEPS

FRONT DOOR TRIM (REFER TO

GROUP 52A, DOOR TRIMS

P.52A-14).

1. DOOR MIRROR COVER

2. REMOTE CONTROLLED MIRROR

ASSEMBLYREMOTE CONTROLLED MIRROR

SWITCH REMOVAL STEPS<>3. POWER WINDOW SWITCH PANEL

ASSEMBLY

4. REMOTE CONTROLLED MIRROR

SWITCH

BATTERY CONNECTION DIRECTION

OPERATION

Connect terminal 6 to the negative

battery terminal.

Connect terminal 4 to the positive battery

terminal.Up

Connect terminal 6 to the positive battery

terminal.

Connect terminal 4 to the negative

battery terminal.Down

Connect terminal 6 to the negative

battery terminal.

Connect terminal 5 to the positive battery

terminal.Right

Connect terminal 6 to the positive battery

terminal.

Connect terminal 5 to the negative

battery terminal.Left

Page 1064 of 1500

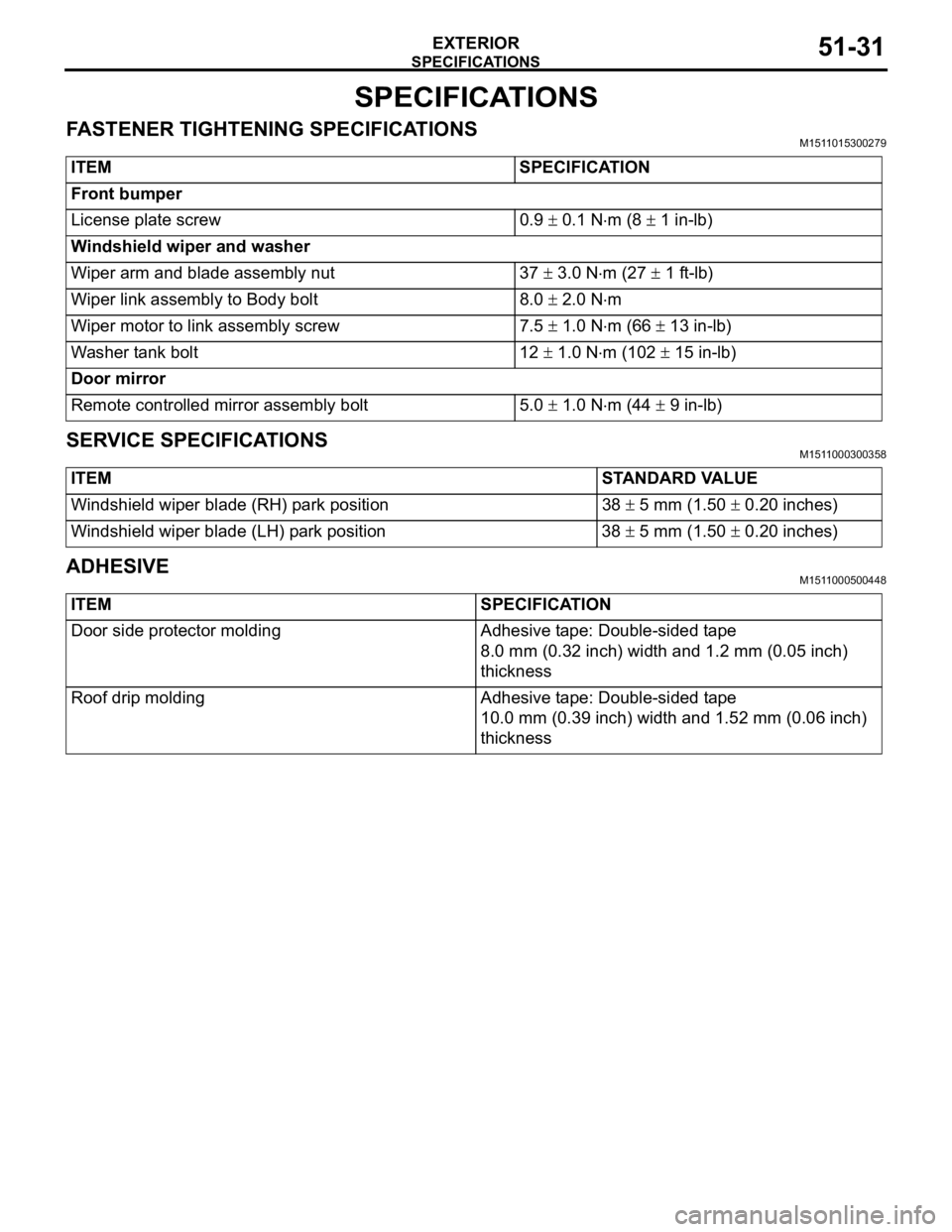

SPECIFICATIONS

EXTERIOR51-31

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1511015300279

SERVICE SPECIFICATIONSM1511000300358

ADHESIVEM1511000500448

ITEM SPECIFICATION

Front bumper

License plate screw 0.9

0.1 Nm (8 1 in-lb)

Windshield wiper and washer

Wiper arm and blade assembly nut 37

3.0 Nm (27 1 ft-lb)

Wiper link assembly to Body bolt 8.0

2.0 Nm

Wiper motor to link assembly screw 7.5

1.0 Nm (66 13 in-lb)

Washer tank bolt 12

1.0 Nm (102 15 in-lb)

Door mirror

Remote controlled mirror assembly bolt 5.0

1.0 Nm (44 9 in-lb)

ITEM STANDARD VALUE

Windshield wiper blade (RH) park position 38

5 mm (1.50 0.20 inches)

Windshield wiper blade (LH) park position 38

5 mm (1.50 0.20 inches)

ITEM SPECIFICATION

Door side protector molding Adhesive tape: Double-sided tape

8.0 mm (0.32 inch) width and 1.2 mm (0.05 inch)

thickness

Roof drip molding Adhesive tape: Double-sided tape

10.0 mm (0.39 inch) width and 1.52 mm (0.06 inch)

thickness

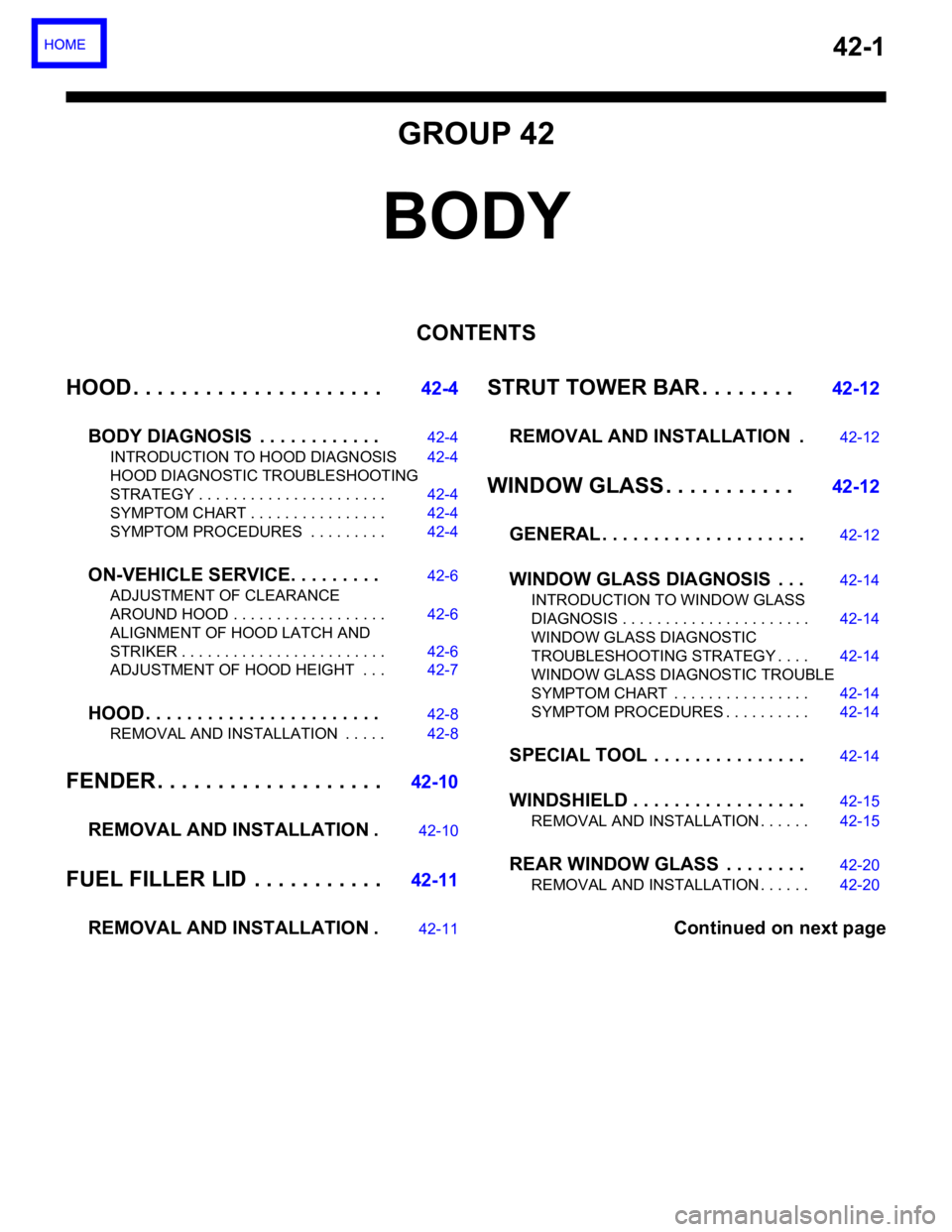

Page 1068 of 1500

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .

42-4

BODY DIAGNOSIS . . . . . . . . . . . .

42-4

INTRODUCTION TO HOOD DIAGNOSIS42-4

HOOD DIAGNOSTIC TROUBLESHOOTING

STRATEGY . . . . . . . . . . . . . . . . . . . . . . 42-4

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-4

SYMPTOM PROCEDURES . . . . . . . . . 42-4

ON-VEHICLE SERVICE. . . . . . . . .42-6

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-6

ALIGNMENT OF HOOD LATCH AND

STRIKER . . . . . . . . . . . . . . . . . . . . . . . . 42-6

ADJUSTMENT OF HOOD HEIGHT . . . 42-7

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION . . . . . 42-8

FENDER . . . . . . . . . . . . . . . . . . .42-10

REMOVAL AND INSTALLATION .

42-10

FUEL FILLER LID . . . . . . . . . . .42-11

REMOVAL AND INSTALLATION .

42-11

STRUT TOWER BAR . . . . . . . . 42-12

REMOVAL AND INSTALLATION .

42-12

WINDOW GLASS . . . . . . . . . . . 42-12

GENERAL . . . . . . . . . . . . . . . . . . . .

42-12

WINDOW GLASS DIAGNOSIS . . .42-14

INTRODUCTION TO WINDOW GLASS

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-14

WINDOW GLASS DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-14

WINDOW GLASS DIAGNOSTIC TROUBLE

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-14

SYMPTOM PROCEDURES . . . . . . . . . . 42-14

SPECIAL TOOL . . . . . . . . . . . . . . .42-14

WINDSHIELD . . . . . . . . . . . . . . . . .42-15

REMOVAL AND INSTALLATION . . . . . . 42-15

REAR WINDOW GLASS . . . . . . . .42-20

REMOVAL AND INSTALLATION . . . . . . 42-20

Continued on next page

Page 1069 of 1500

BODY42-2

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-23

GENERAL DESCRIPTION . . . . . .

42-23

CENTRAL DOOR LOCKING SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

POWER WINDOW DIAGNOSIS . . . . . . 42-23

DOOR DIAGNOSIS . . . . . . . . . . . . . . . . 42-23

INTRODUCTION TO GLASS AND DOOR

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

GLASS AND DOOR DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . 42-23

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-24

SYMPTOM PROCEDURES . . . . . . . . . 42-24

HOW TO LOCATE WIND NOISE . . . . . 42-27

SPECIAL TOOLS. . . . . . . . . . . . . .42-28

ON-VEHICLE SERVICE. . . . . . . . .42-30

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-30

DOOR WINDOW GLASS ADJUSTMENT42-31

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-32

POWER WINDOW TIMER FUNCTION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-32

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-33

POWER WINDOW RELAY CHECK . . . 42-33

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

POWER WINDOW CHECK . . . . . . . . . . 42-34

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR OUTSIDE HANDLE PLAY CHECK42-35

DOOR INSIDE HANDLE PLAY CHECK 42-35

DOOR ASSEMBLY . . . . . . . . . . . .42-37

REMOVAL AND INSTALLATION . . . . . 42-37

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-38

DOOR GLASS AND REGULATOR42-39

REMOVAL AND INSTALLATION . . . . . 42-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-43

DOOR HANDLE AND LATCH . . . .42-46

REMOVAL AND INSTALLATION . . . . . 42-46

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-49

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-52

REMOVAL AND INSTALLATION . . . . . . 42-52

TRUNK LID. . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSIS . . . . . . . .

42-60

INTRODUCTION TO TRUNK LID

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-60

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-60

SYMPTOM PROCEDURES . . . . . . . . . . 42-60

ON-VEHICLE SERVICE . . . . . . . . .42-61

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-61

TRUNK LID LATCH ADJUSTMENT. . . . 42-61

TRUNK LID HEIGHT ADJUSTMENT . . . 42-62

TRUNK LID . . . . . . . . . . . . . . . . . . .42-63

REMOVAL AND INSTALLATION . . . . . . 42-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-65

KEYLESS ENTRY SYSTEM 42-67

GENERAL DESCRIPTION . . . . . . .

42-67

KEYLESS ENTRY SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . .

42-68

SPECIAL TOOL . . . . . . . . . . . . . . .42-68

ON-VEHICLE SERVICE . . . . . . . . .42-69

TRANSMITTER BATTERY CHECK . . . . 42-69

HOW TO REPLACE THE TRANSMITTER

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . 42-70

KEYLESS ENTRY SYSTEM INSPECTION42-71

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION . . . . . . . . . . . 42-71

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-72

HOW TO REGISTER SECRET CODE . 42-73

Continued on next page

Page 1070 of 1500

42-3

SUNROOF ASSEMBLY . . . . . . . . . . .42-75

GENERAL DESCRIPTION . . . . . .

42-75

SUNROOF DIAGNOSIS . . . . . . . .42-75

SPECIAL TOOL . . . . . . . . . . . . . . .42-75

ON-VEHICLE SERVICE. . . . . . . . .42-75

WATER TEST . . . . . . . . . . . . . . . . . . . . 42-75

SUNROOF TIMER FUNCTION CHECK 42-76

SUNROOF FIT ADJUSTMENT . . . . . . . 42-76

SUNROOF CHECK . . . . . . . . . . . . . . . . 42-76

ROOF LID GLASS OPERATION

CURRENT CHECK . . . . . . . . . . . . . . . . 42-76

SUNROOF INITIALIZATION . . . . . . . . . 42-77

SUNROOF OPERATION CHECK . . . . . 42-77

SUNROOF ASSEMBLY. . . . . . . . .42-80

REMOVAL AND INSTALLATION . . . . . 42-80INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-82

DISASSEMBLY AND ASSEMBLY . . . . . 42-83

LOOSE PANEL . . . . . . . . . . . . 42-84

REMOVAL AND INSTALLATION .

42-84

SPECIFICATIONS . . . . . . . . . . 42-86

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . .

42-86

SERVICE SPECIFICATIONS . . . . .42-87

SEALANT AND ADHESIVES . . . . .42-87

COMPONENT IDENTIFICATIONS .42-88