Gauge MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 942 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-27

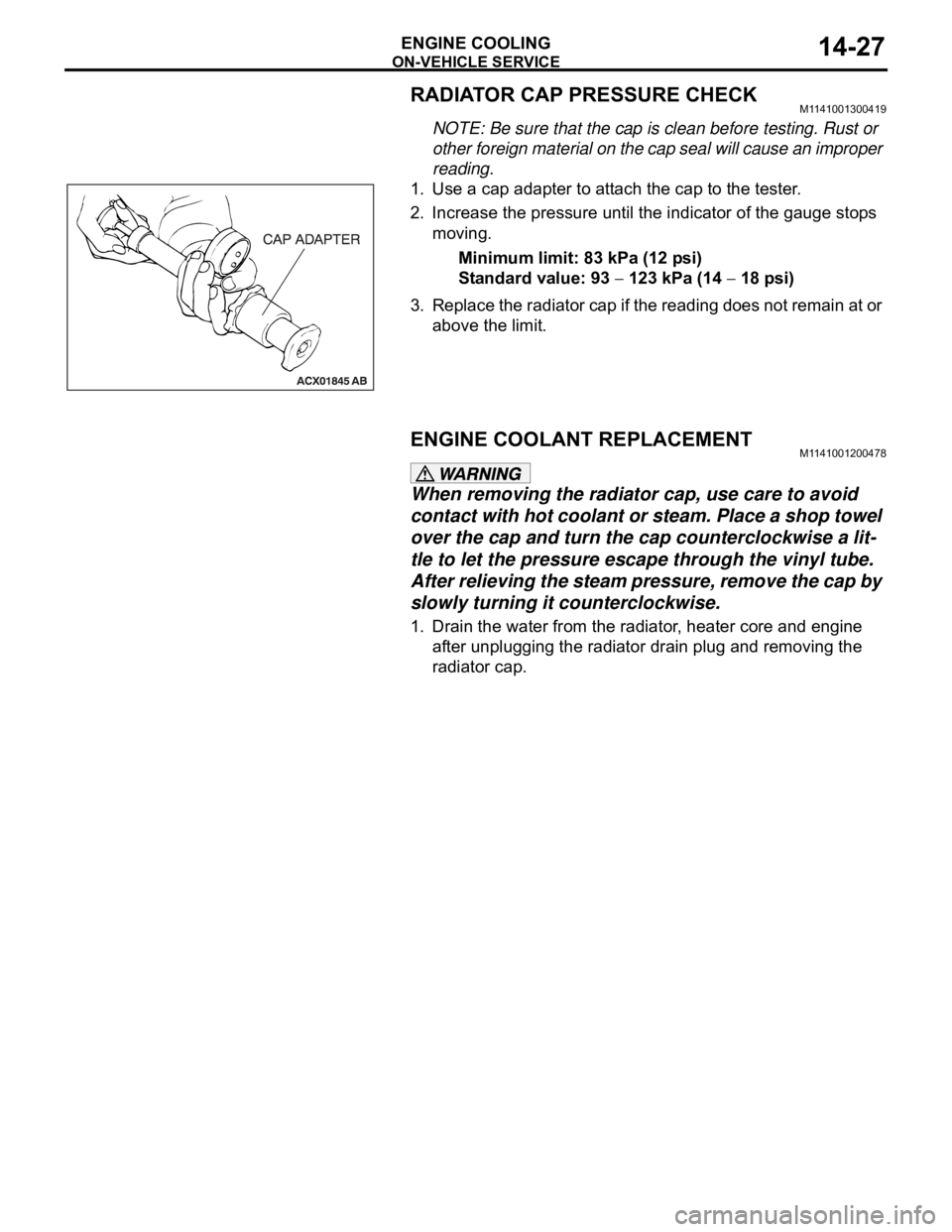

RADIATOR CAP PRESSURE CHECKM1141001300419

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

3. Replace the radiator cap if the reading does not remain at or

above the limit.

ENGINE COOLANT REPLACEMENTM1141001200478

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 968 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

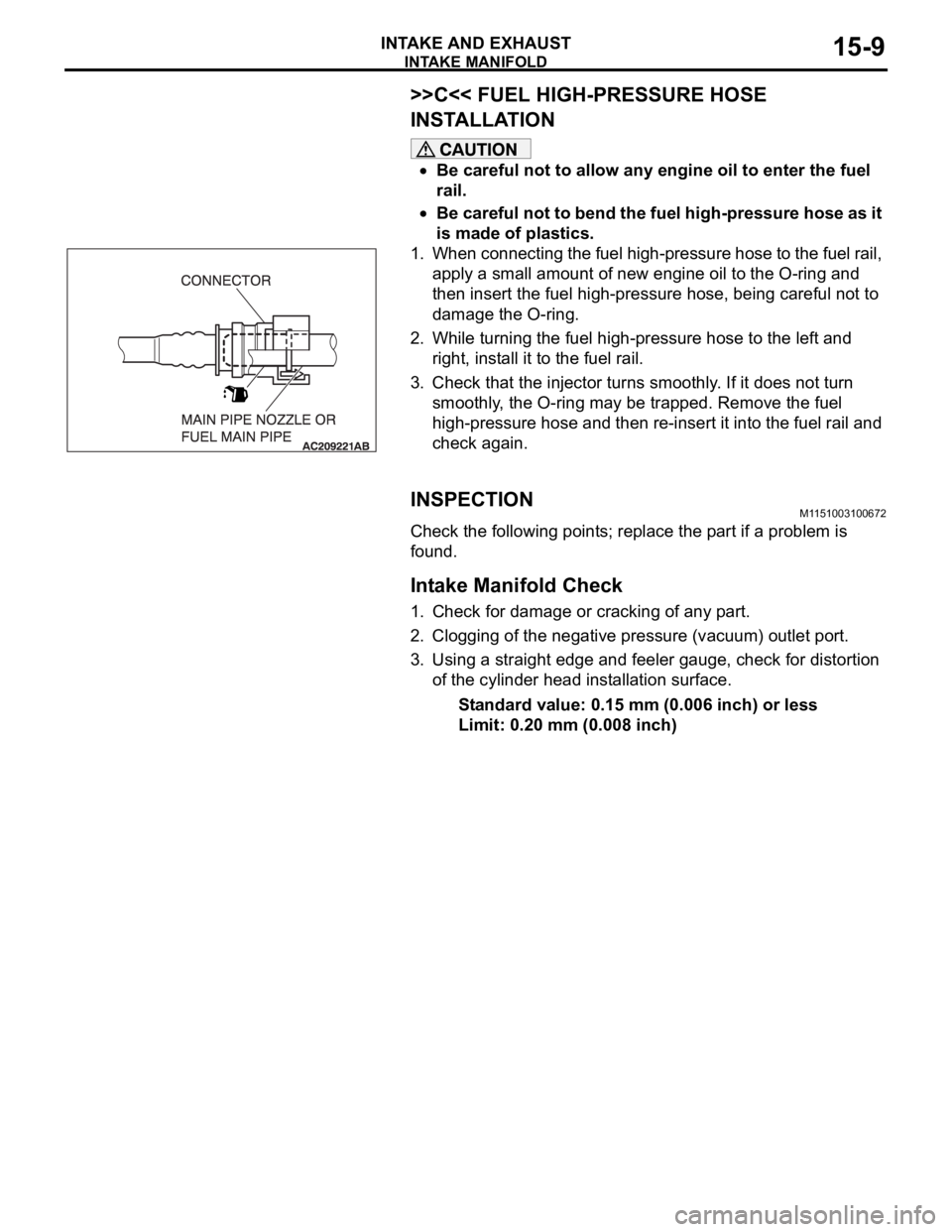

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 972 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-13

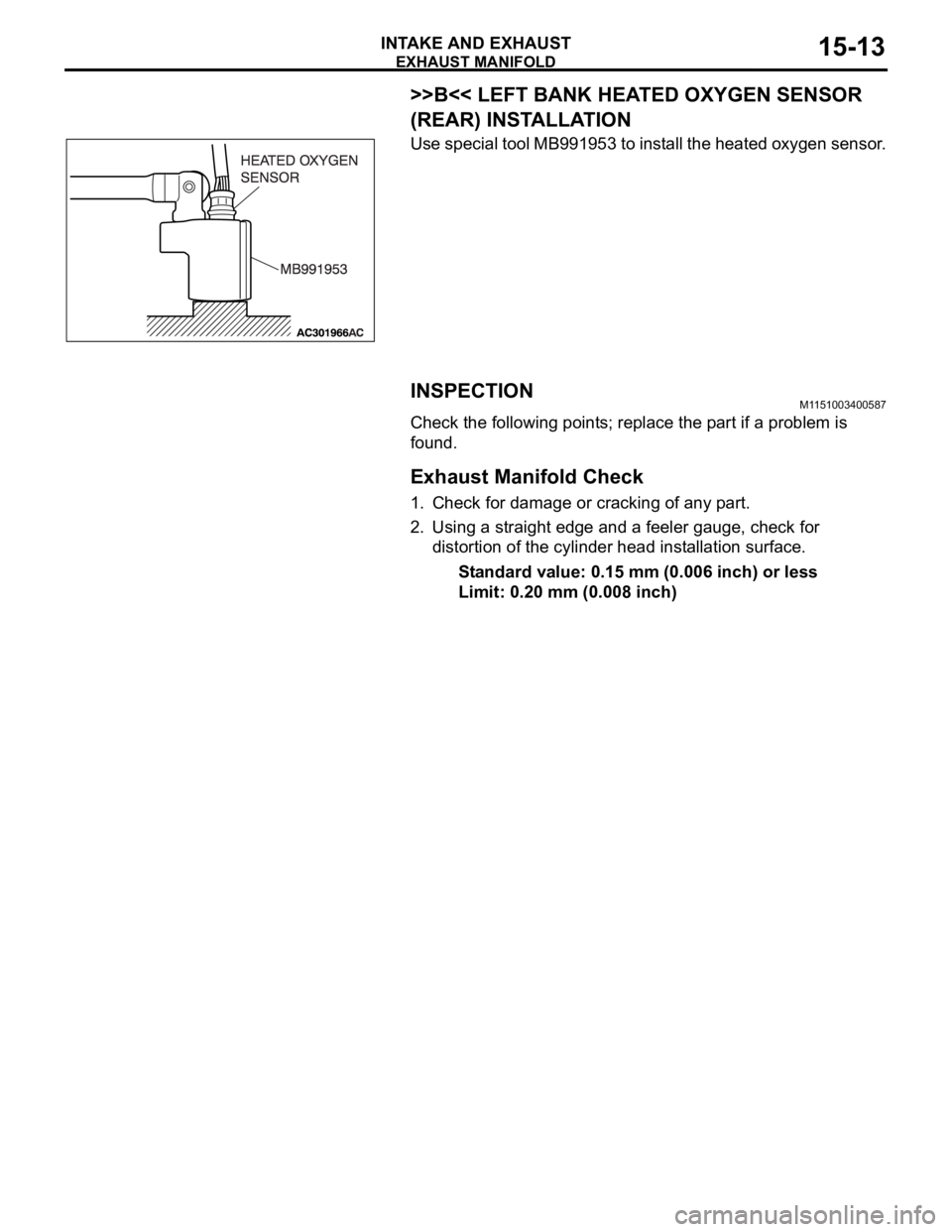

>>B<< LEFT BANK HEATED OXYGEN SENSOR

(REAR) INSTALLATION

Use special tool MB991953 to install the heated oxygen sensor.

INSPECTIONM1151003400587

Check the following points; replace the part if a problem is

found.

.

Exhaust Manifold Check

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 1001 of 1500

Page 1005 of 1500

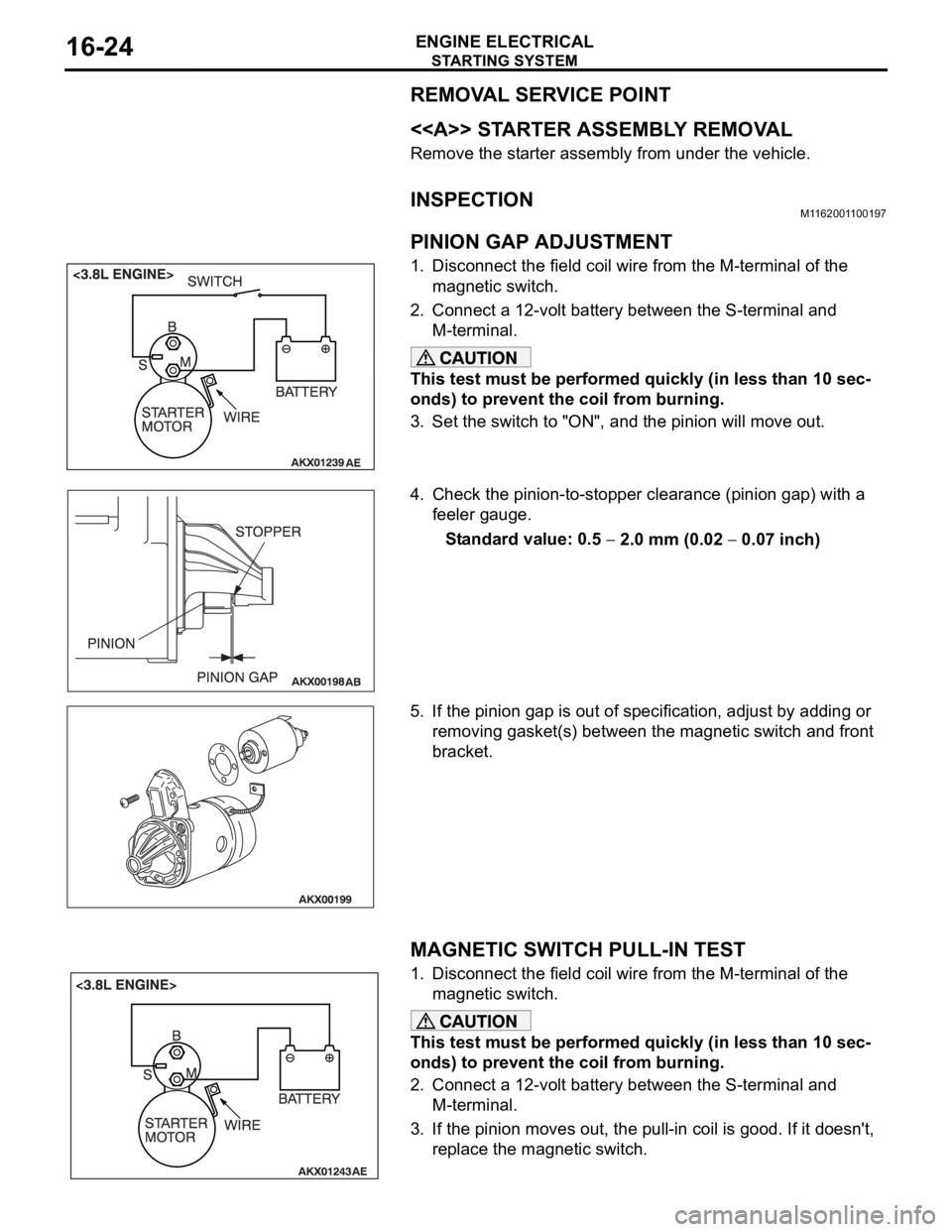

STARTING SYSTEM

ENGINE ELECTRICAL16-28

INSPECTIONM1162001300102.

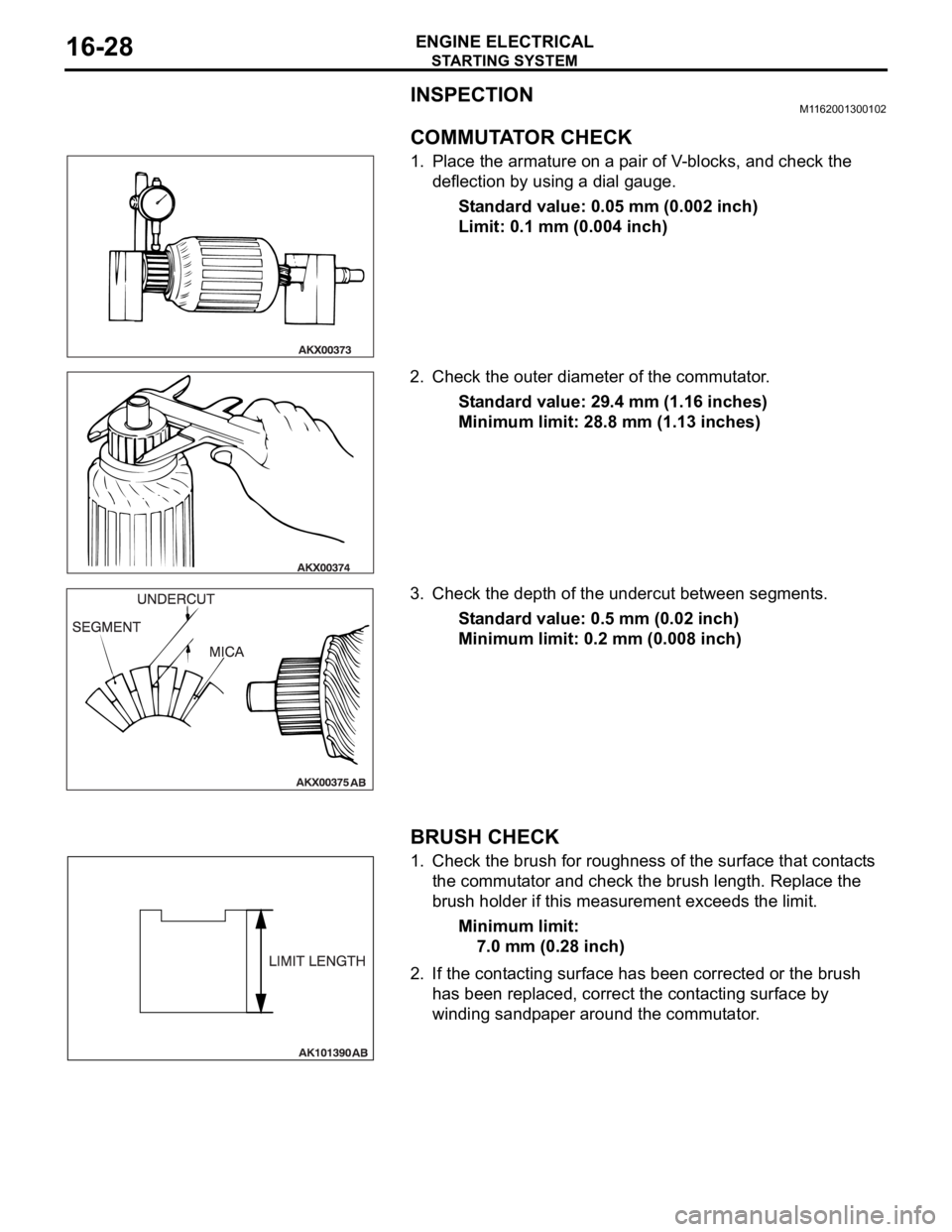

COMMUTATOR CHECK

1. Place the armature on a pair of V-blocks, and check the

deflection by using a dial gauge.

Standard value: 0.05 mm (0.002 inch)

Limit: 0.1 mm (0.004 inch)

2. Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.16 inches)

Minimum limit: 28.8 mm (1.13 inches)

3. Check the depth of the undercut between segments.

Standard value: 0.5 mm (0.02 inch)

Minimum limit: 0.2 mm (0.008 inch)

.

BRUSH CHECK

1. Check the brush for roughness of the surface that contacts

the commutator and check the brush length. Replace the

brush holder if this measurement exceeds the limit.

Minimum limit:

7.0 mm (0.28 inch)

2. If the contacting surface has been corrected or the brush

has been replaced, correct the contacting surface by

winding sandpaper around the commutator.

.

Page 1175 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-10

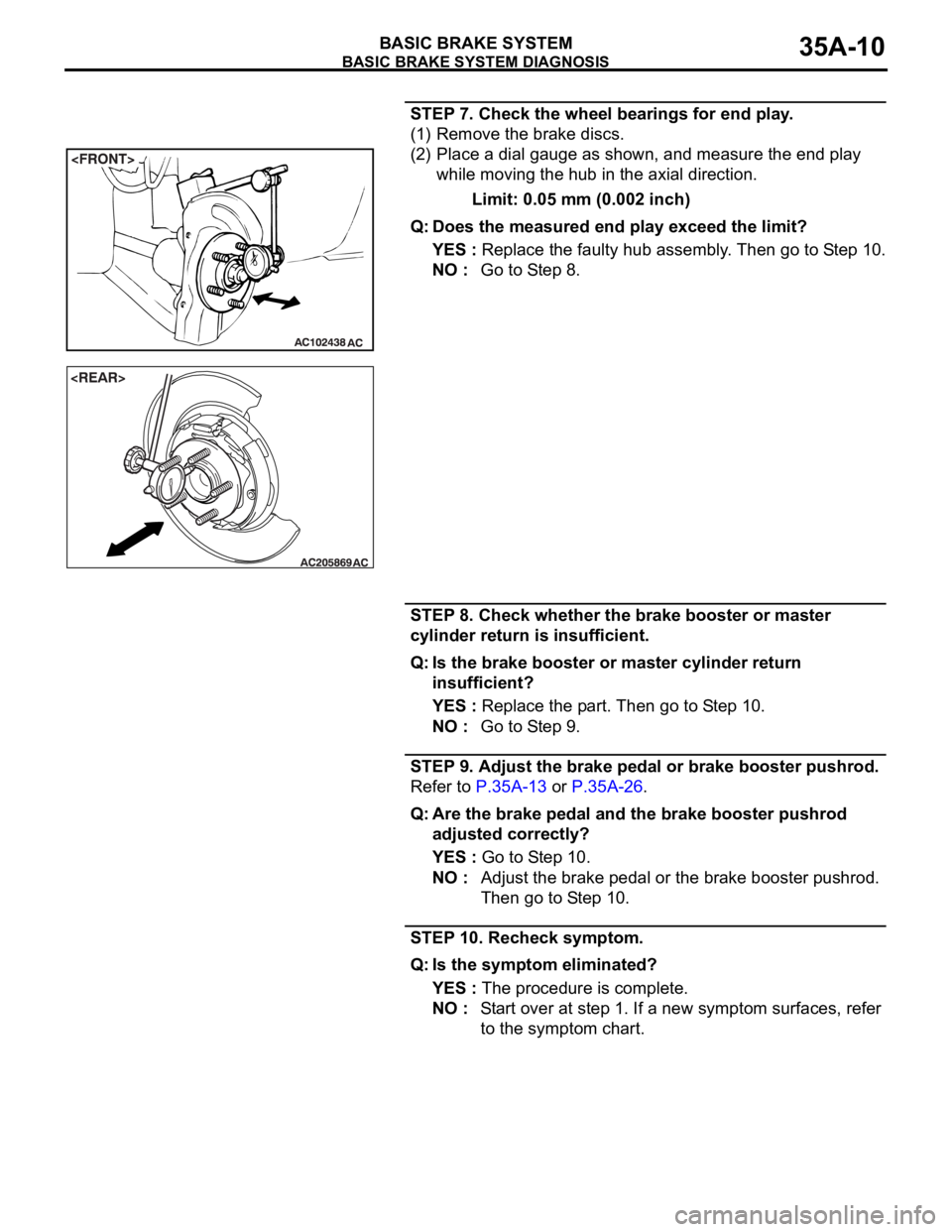

STEP 7. Check the wheel bearings for end play.

(1) Remove the brake discs.

(2) Place a dial gauge as shown, and measure the end play

while moving the hub in the axial direction.

Limit: 0.05 mm (0.002 inch)

Q: Does the measured end play exceed the limit?

YES : Replace the faulty hub assembly. Then go to Step 10.

NO : Go to Step 8.

STEP 8. Check whether the brake booster or master

cylinder return is insufficient.

Q: Is the brake booster or master cylinder return

insufficient?

YES : Replace the part. Then go to Step 10.

NO : Go to Step 9.

STEP 9. Adjust the brake pedal or brake booster pushrod.

Refer to P.35A-13 or P.35A-26.

Q: Are the brake pedal and the brake booster pushrod

adjusted correctly?

YES : Go to Step 10.

NO : Adjust the brake pedal or the brake booster pushrod.

Then go to Step 10.

STEP 10. Recheck symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

Page 1177 of 1500

SPECIAL TOOLS

BASIC BRAKE SYSTEM35A-12

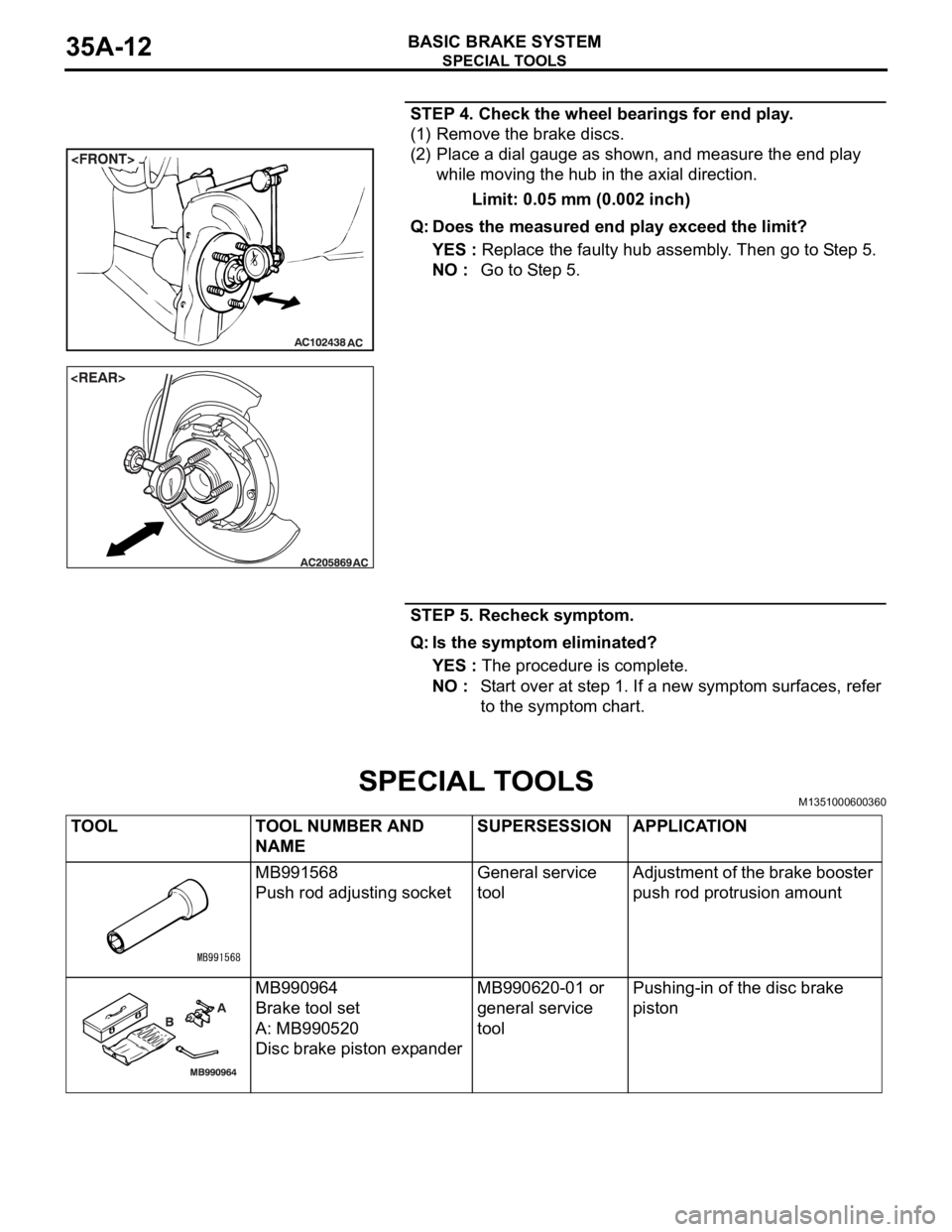

STEP 4. Check the wheel bearings for end play.

(1) Remove the brake discs.

(2) Place a dial gauge as shown, and measure the end play

while moving the hub in the axial direction.

Limit: 0.05 mm (0.002 inch)

Q: Does the measured end play exceed the limit?

YES : Replace the faulty hub assembly. Then go to Step 5.

NO : Go to Step 5.

STEP 5. Recheck symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

SPECIAL TOOLSM1351000600360

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB991568

Push rod adjusting socketGeneral service

toolAdjustment of the brake booster

push rod protrusion amount

MB990964

Brake tool set

A: MB990520

Disc brake piston expanderMB990620-01 or

general service

toolPushing-in of the disc brake

piston

Page 1187 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-22

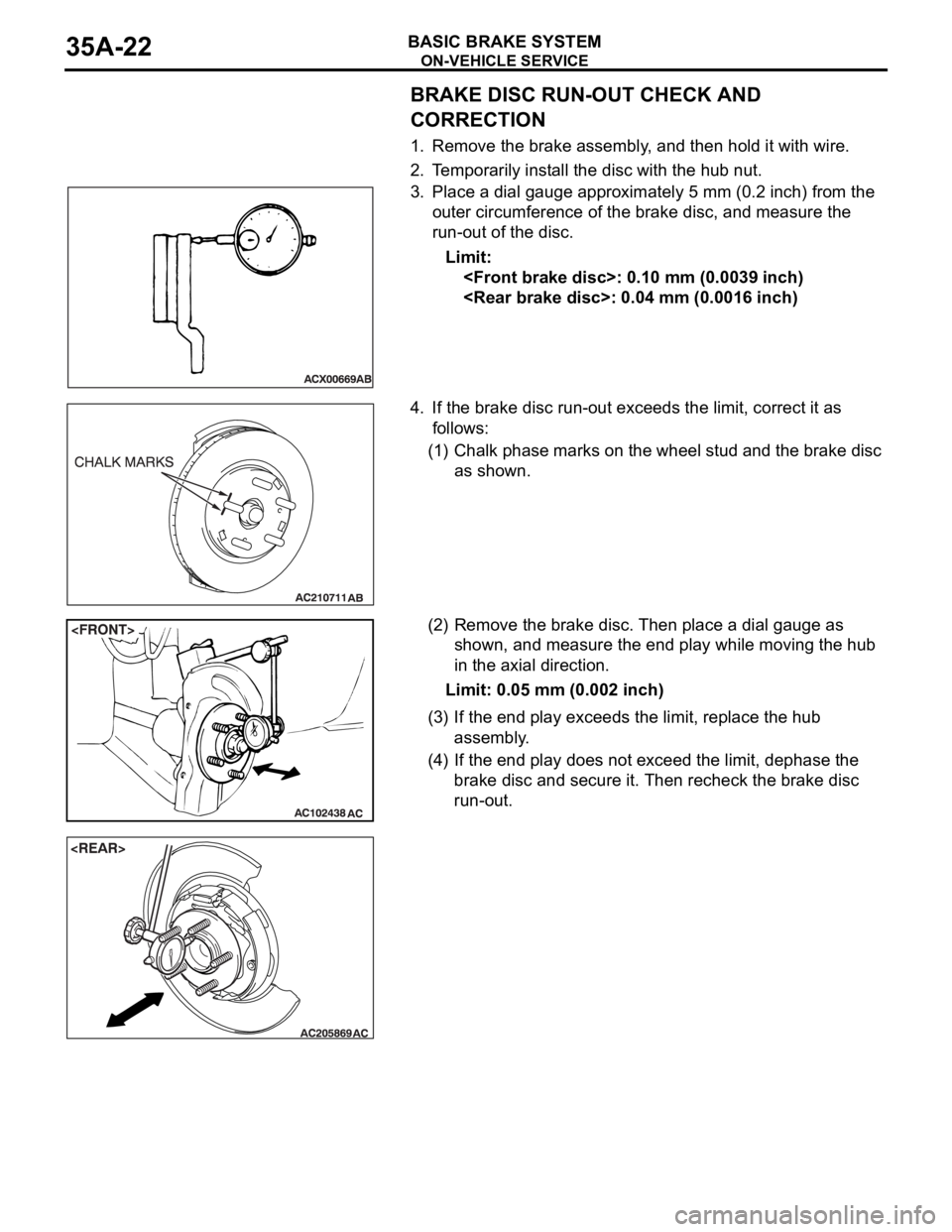

BRAKE DISC RUN-OUT CHECK AND

CORRECTION

1. Remove the brake assembly, and then hold it with wire.

2. Temporarily install the disc with the hub nut.

3. Place a dial gauge approximately 5 mm (0.2 inch) from the

outer circumference of the brake disc, and measure the

run-out of the disc.

Limit:

4. If the brake disc run-out exceeds the limit, correct it as

follows:

(1) Chalk phase marks on the wheel stud and the brake disc

as shown.

(2) Remove the brake disc. Then place a dial gauge as

shown, and measure the end play while moving the hub

in the axial direction.

Limit: 0.05 mm (0.002 inch)

(3) If the end play exceeds the limit, replace the hub

assembly.

(4) If the end play does not exceed the limit, dephase the

brake disc and secure it. Then recheck the brake disc

run-out.

Page 1262 of 1500

MAINTENANCE SERVICE

GENERAL00-41

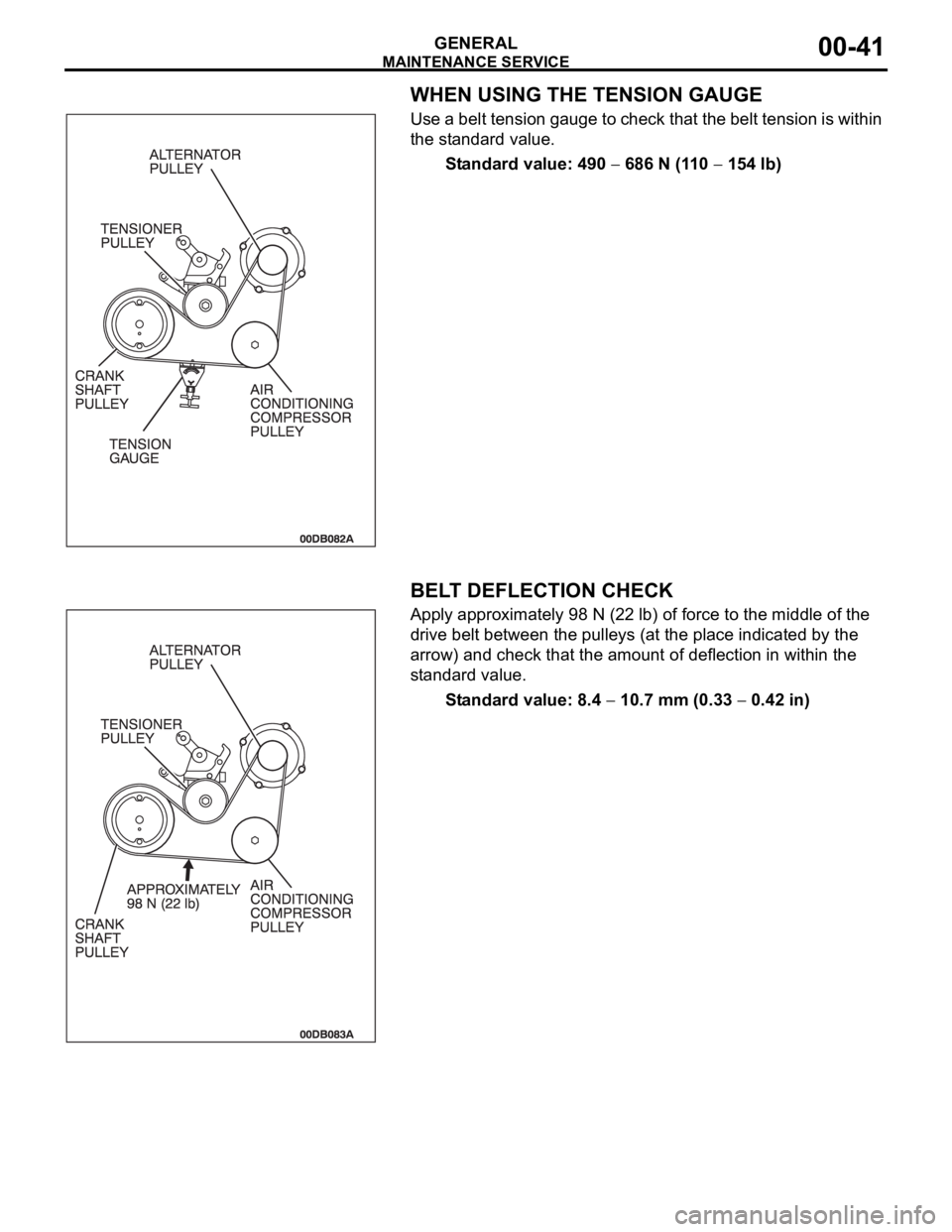

WHEN USING THE TENSION GAUGE

Use a belt tension gauge to check that the belt tension is within

the standard value.

Standard value: 490

686 N (110 154 lb)

.

BELT DEFLECTION CHECK

Apply approximately 98 N (22 lb) of force to the middle of the

drive belt between the pulleys (at the place indicated by the

arrow) and check that the amount of deflection in within the

standard value.

Standard value: 8.4

10.7 mm (0.33 0.42 in)

Page 1264 of 1500

MAINTENANCE SERVICE

GENERAL00-43

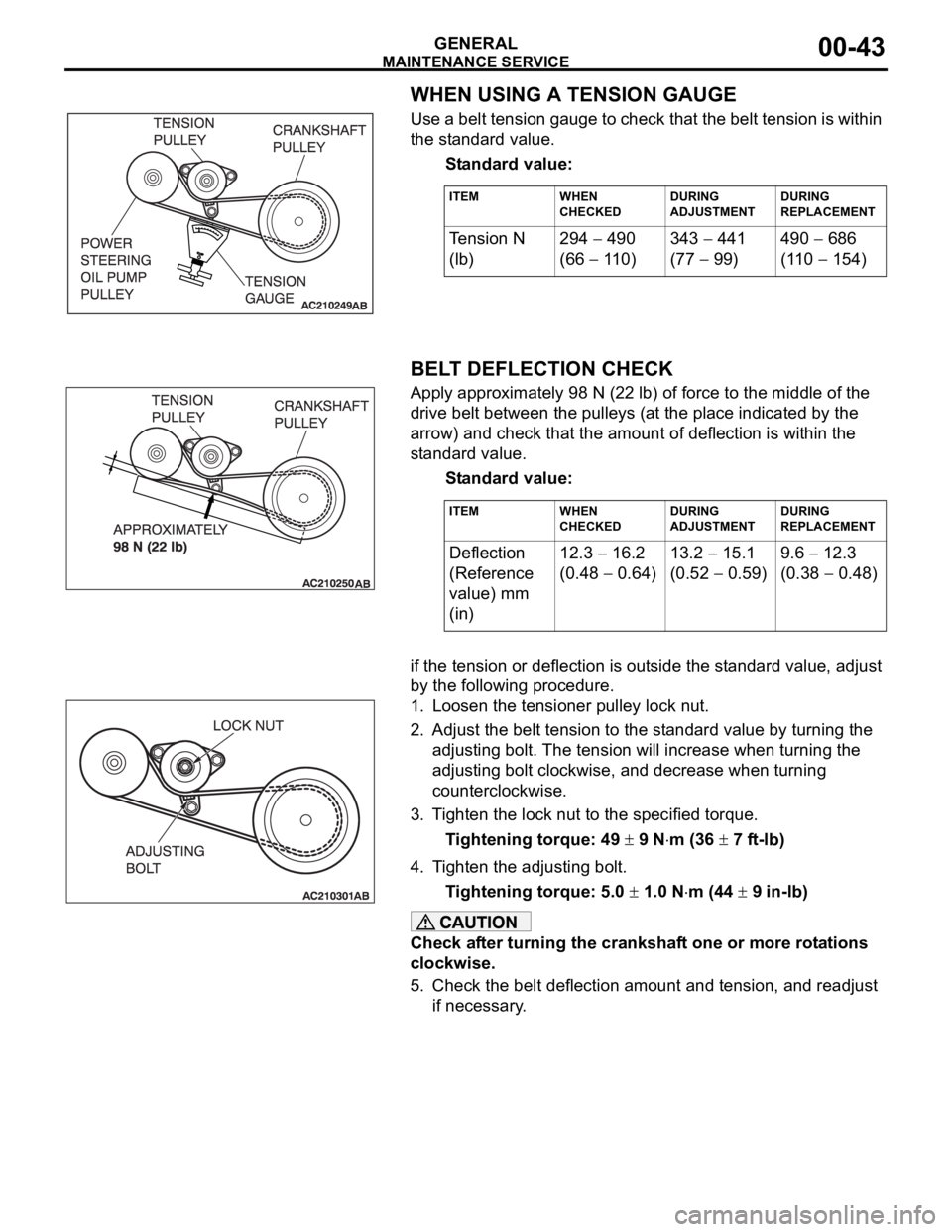

WHEN USING A TENSION GAUGE

Use a belt tension gauge to check that the belt tension is within

the standard value.

Standard value:

.

BELT DEFLECTION CHECK

Apply approximately 98 N (22 lb) of force to the middle of the

drive belt between the pulleys (at the place indicated by the

arrow) and check that the amount of deflection is within the

standard value.

Standard value:

.if the tension or deflection is outside the standard value, adjust

by the following procedure.

1. Loosen the tensioner pulley lock nut.

2. Adjust the belt tension to the standard value by turning the

adjusting bolt. The tension will increase when turning the

adjusting bolt clockwise, and decrease when turning

counterclockwise.

3. Tighten the lock nut to the specified torque.

Tightening torque: 49

9 Nm (36 7 ft-lb)

4. Tighten the adjusting bolt.

Tightening torque: 5.0

1.0 Nm (44 9 in-lb)

Check after turning the crankshaft one or more rotations

clockwise.

5. Check the belt deflection amount and tension, and readjust

if necessary.

ITEM WHEN

CHECKEDDURING

ADJUSTMENTDURING

REPLACEMENT

Te n s i o n N

(lb)294 490

(66

110)343

441

(77

99)490

686

(110

154)

ITEM WHEN

CHECKEDDURING

ADJUSTMENTDURING

REPLACEMENT

Deflection

(Reference

value) mm

(in)12.3 16.2

(0.48

0.64)13.2

15.1

(0.52

0.59)9.6

12.3

(0.38

0.48)