Gauge MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1420 of 1500

FRONT AXLE DIAGNOSIS

FRONT AXLE26-3

2. Verify that the condition described by the

customer exists.3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1261005700269

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Noise during Wheel Rotation

DIAGNOSIS

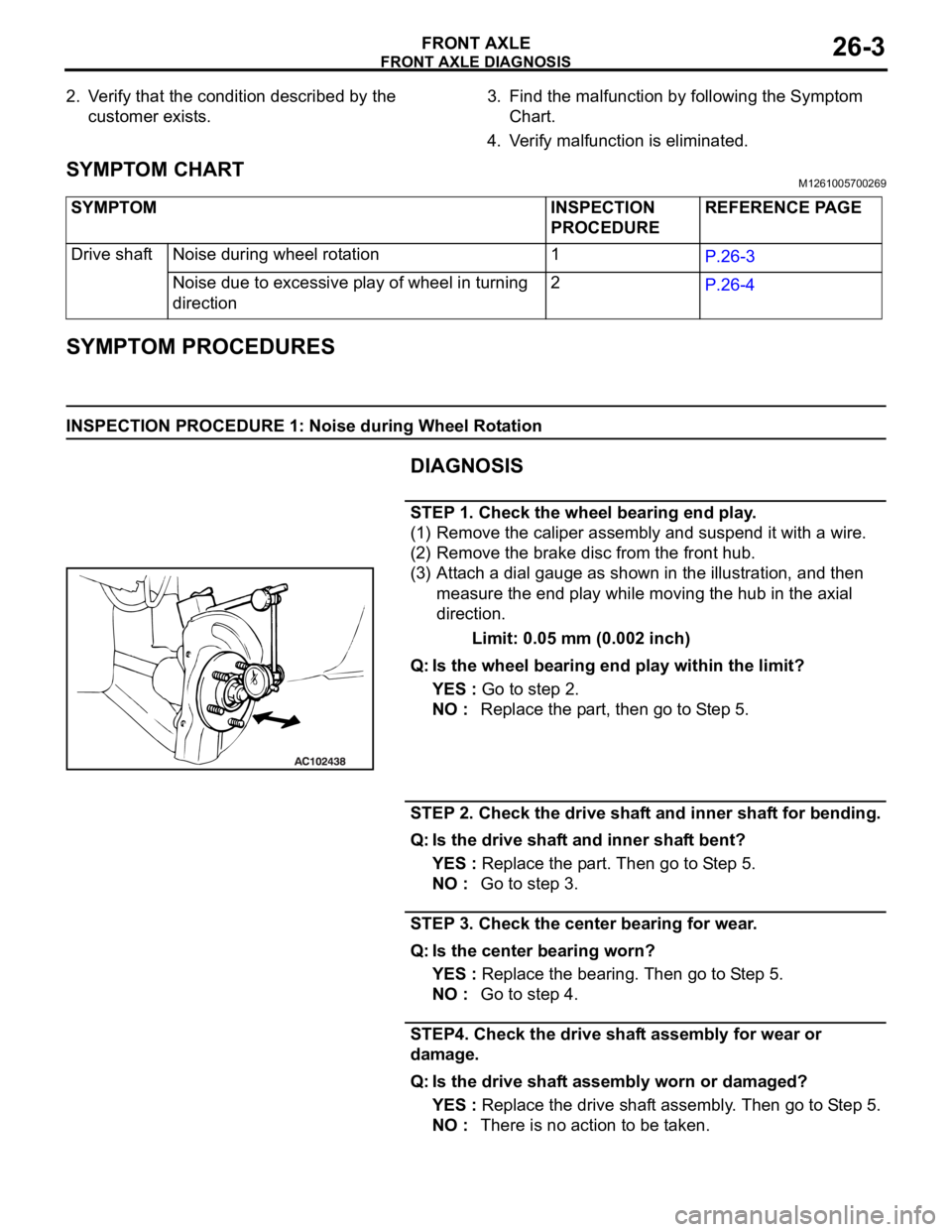

STEP 1. Check the wheel bearing end play.

(1) Remove the caliper assembly and suspend it with a wire.

(2) Remove the brake disc from the front hub.

(3) Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the axial

direction.

Limit: 0.05 mm (0.002 inch)

Q: Is the wheel bearing end play within the limit?

YES : Go to step 2.

NO : Replace the part, then go to Step 5.

STEP 2. Check the drive shaft and inner shaft for bending.

Q: Is the drive shaft and inner shaft bent?

YES : Replace the part. Then go to Step 5.

NO : Go to step 3.

STEP 3. Check the center bearing for wear.

Q: Is the center bearing worn?

YES : Replace the bearing. Then go to Step 5.

NO : Go to step 4.

STEP4. Check the drive shaft assembly for wear or

damage.

Q: Is the drive shaft assembly worn or damaged?

YES : Replace the drive shaft assembly. Then go to Step 5.

NO : There is no action to be taken. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Drive shaft Noise during wheel rotation 1

P.26-3

Noise due to excessive play of wheel in turning

direction2

P.26-4

Page 1425 of 1500

ON-VEHICLE SERVICE

FRONT AXLE26-8

ON-VEHICLE SERVICE

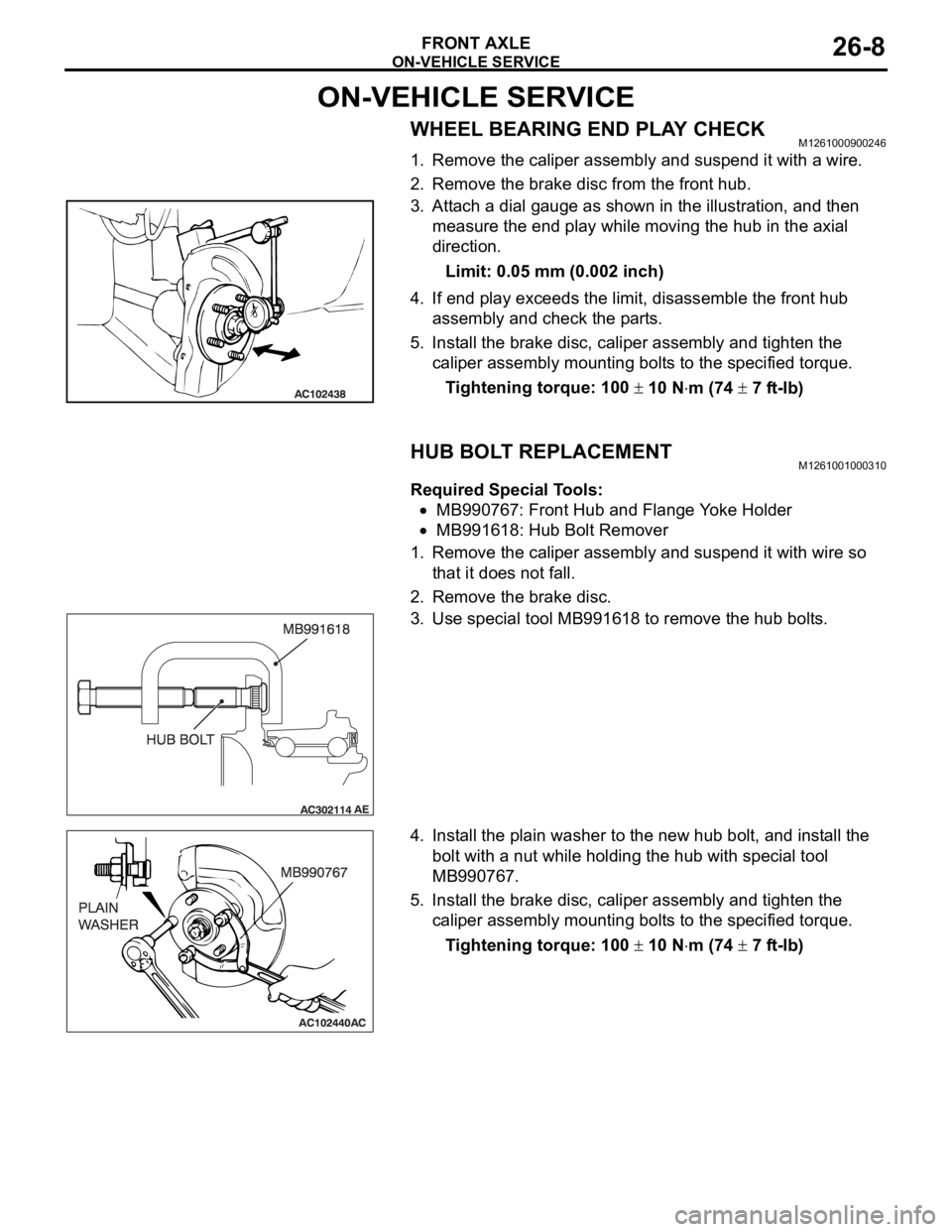

WHEEL BEARING END PLAY CHECKM1261000900246

1. Remove the caliper assembly and suspend it with a wire.

2. Remove the brake disc from the front hub.

3. Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the axial

direction.

Limit: 0.05 mm (0.002 inch)

4. If end play exceeds the limit, disassemble the front hub

assembly and check the parts.

5. Install the brake disc, caliper assembly and tighten the

caliper assembly mounting bolts to the specified torque.

Tightening torque: 100

10 Nm (74 7 ft-lb)

HUB BOLT REPLACEMENTM1261001000310

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB991618: Hub Bolt Remover

1. Remove the caliper assembly and suspend it with wire so

that it does not fall.

2. Remove the brake disc.

3. Use special tool MB991618 to remove the hub bolts.

4. Install the plain washer to the new hub bolt, and install the

bolt with a nut while holding the hub with special tool

MB990767.

5. Install the brake disc, caliper assembly and tighten the

caliper assembly mounting bolts to the specified torque.

Tightening torque: 100

10 Nm (74 7 ft-lb)

Page 1450 of 1500

REAR AXLE DIAGNOSIS

REAR AXLE27-3

SYMPTOM PROCEDURESM1271004400222

INSPECTION PROCEDURE 1: Abnormal Noise

DIAGNOSIS

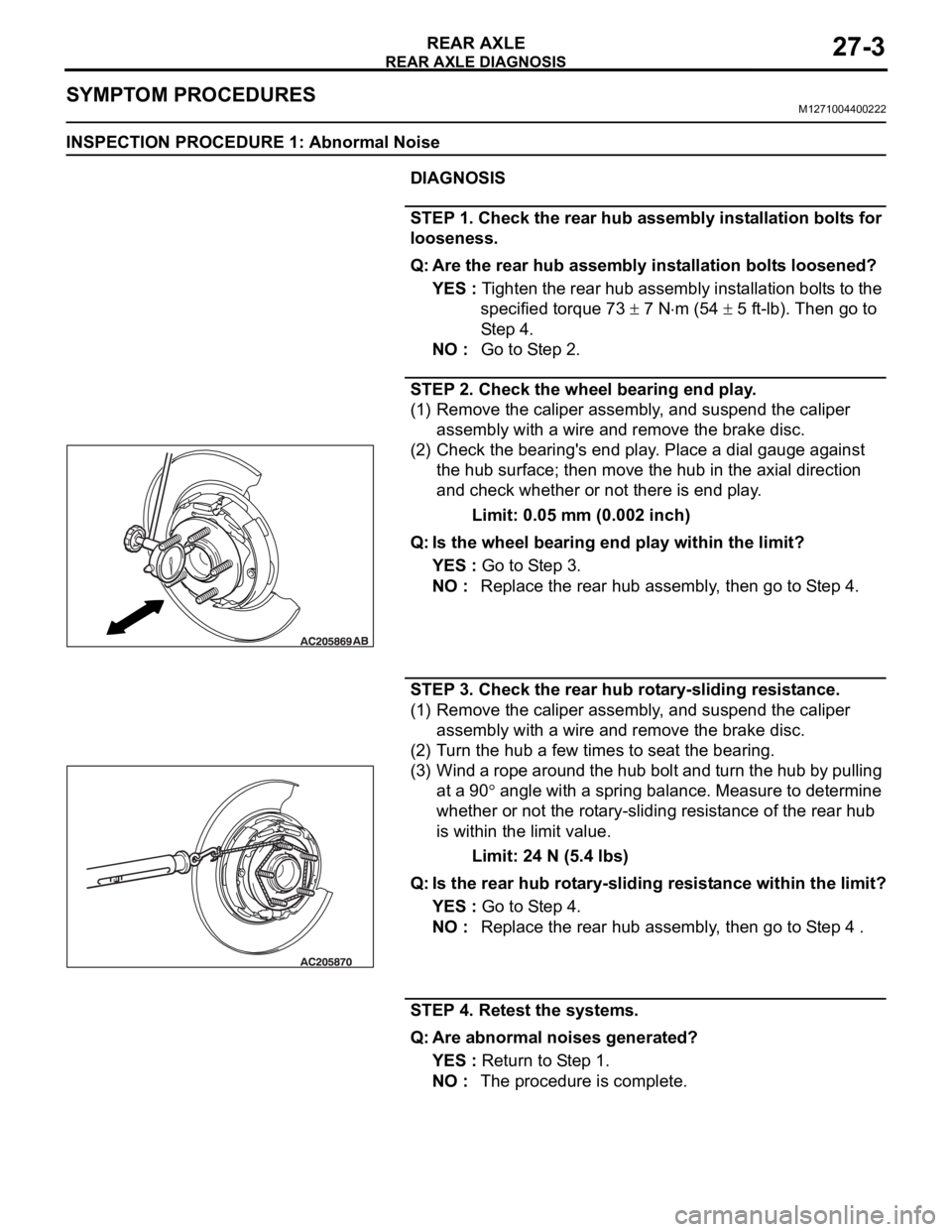

STEP 1. Check the rear hub assembly installation bolts for

looseness.

Q: Are the rear hub assembly installation bolts loosened?

YES : Tighten the rear hub assembly installation bolts to the

specified torque 73

7 Nm (54 5 ft-lb). Then go to

St e p 4 .

NO : Go to Step 2.

STEP 2. Check the wheel bearing end play.

(1) Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

(2) Check the bearing's end play. Place a dial gauge against

the hub surface; then move the hub in the axial direction

and check whether or not there is end play.

Limit: 0.05 mm (0.002 inch)

Q: Is the wheel bearing end play within the limit?

YES : Go to Step 3.

NO : Replace the rear hub assembly, then go to Step 4.

STEP 3. Check the rear hub rotary-sliding resistance.

(1) Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

(2) Turn the hub a few times to seat the bearing.

(3) Wind a rope around the hub bolt and turn the hub by pulling

at a 90

angle with a spring balance. Measure to determine

whether or not the rotary-sliding resistance of the rear hub

is within the limit value.

Limit: 24 N (5.4 lbs)

Q: Is the rear hub rotary-sliding resistance within the limit?

YES : Go to Step 4.

NO : Replace the rear hub assembly, then go to Step 4 .

STEP 4. Retest the systems.

Q: Are abnormal noises generated?

YES : Return to Step 1.

NO : The procedure is complete.

Page 1451 of 1500

SPECIAL TOOLS

REAR AXLE27-4

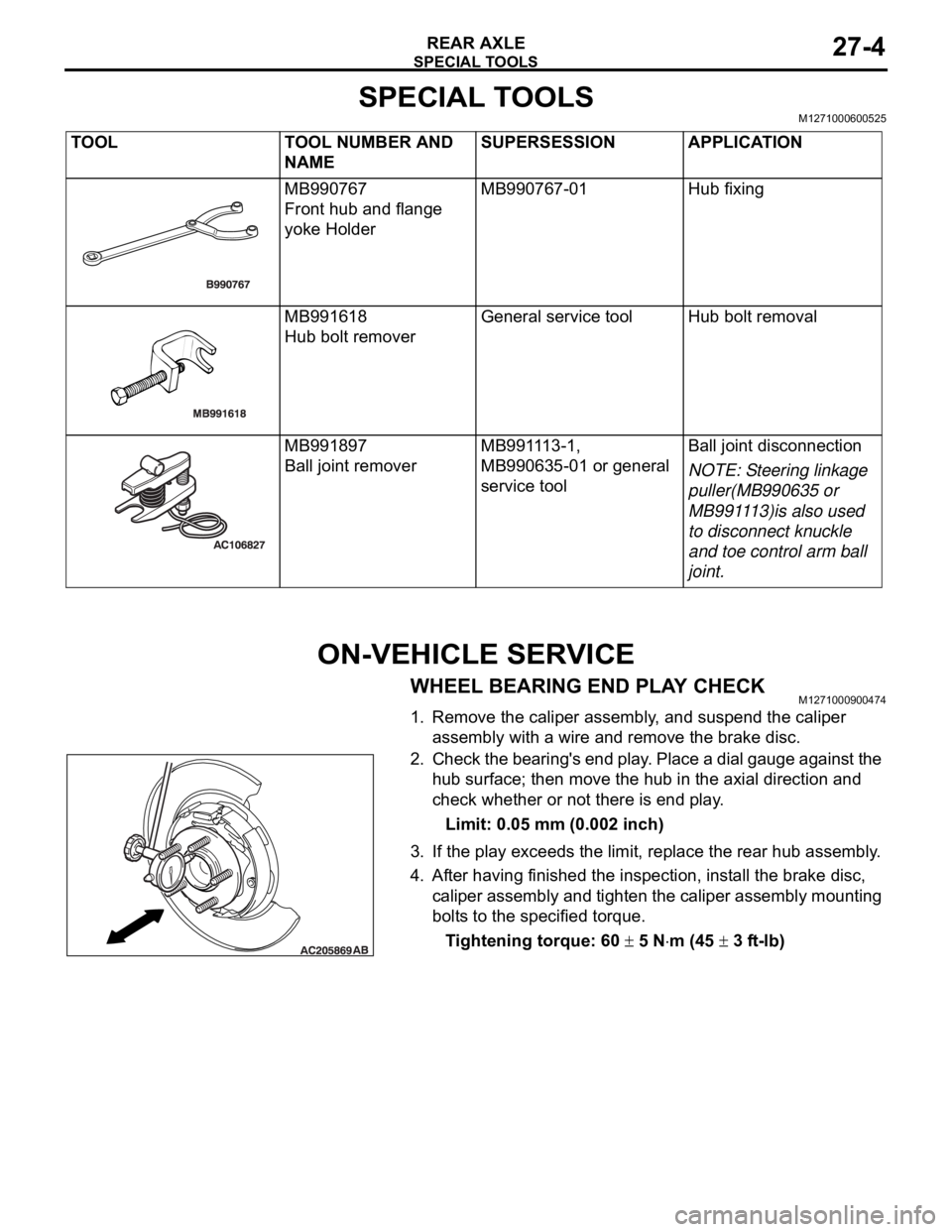

SPECIAL TOOLSM1271000600525

ON-VEHICLE SERVICE

WHEEL BEARING END PLAY CHECKM1271000900474

1. Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

2. Check the bearing's end play. Place a dial gauge against the

hub surface; then move the hub in the axial direction and

check whether or not there is end play.

Limit: 0.05 mm (0.002 inch)

3. If the play exceeds the limit, replace the rear hub assembly.

4. After having finished the inspection, install the brake disc,

caliper assembly and tighten the caliper assembly mounting

bolts to the specified torque.

Tightening torque: 60

5 Nm (45 3 ft-lb) TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990767

Front hub and flange

yoke HolderMB990767-01 Hub fixing

MB991618

Hub bolt removerGeneral service tool Hub bolt removal

MB991897

Ball joint removerMB991113-1,

MB990635-01 or general

service toolBall joint disconnection

NOTE: Steering linkage

puller(MB990635 or

MB991113)is also used

to disconnect knuckle

and toe control arm ball

joint.

Page 1486 of 1500

![MITSUBISHI 380 2005 Owners Manual AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha MITSUBISHI 380 2005 Owners Manual AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha](/img/19/57086/w960_57086-1485.png)

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discharge port.

NOTE: .

2ND: Second brake pressure port

UD: Underdrive clutch pressure port

LR: Low-reverse brake pressure port

DR: Torque converter release pressure port

DA: Torque converter apply pressure port

RV: Reverse clutch pressure port

OD: Overdrive clutch pressure port

DIR: Direct clutch pressure port

RED: Reduction clutch pressure port

4. Restart the engine.

5. Check that there are no leaks around the special tool port

adapters.

6. Measure the hydraulic pressure at each port under the

conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard

value ranges.

7. If the pressure is not within the standard value, stop the

engine and refer to the hydraulic pressure test diagnosis

table.

8. Remove the O-ring from the port plug and replace it.

9. Remove the special tool, and install the plugs to the

hydraulic pressure ports.

10.Start the engine and check that there are no leaks around

the plugs.