clutch MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 783 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-82

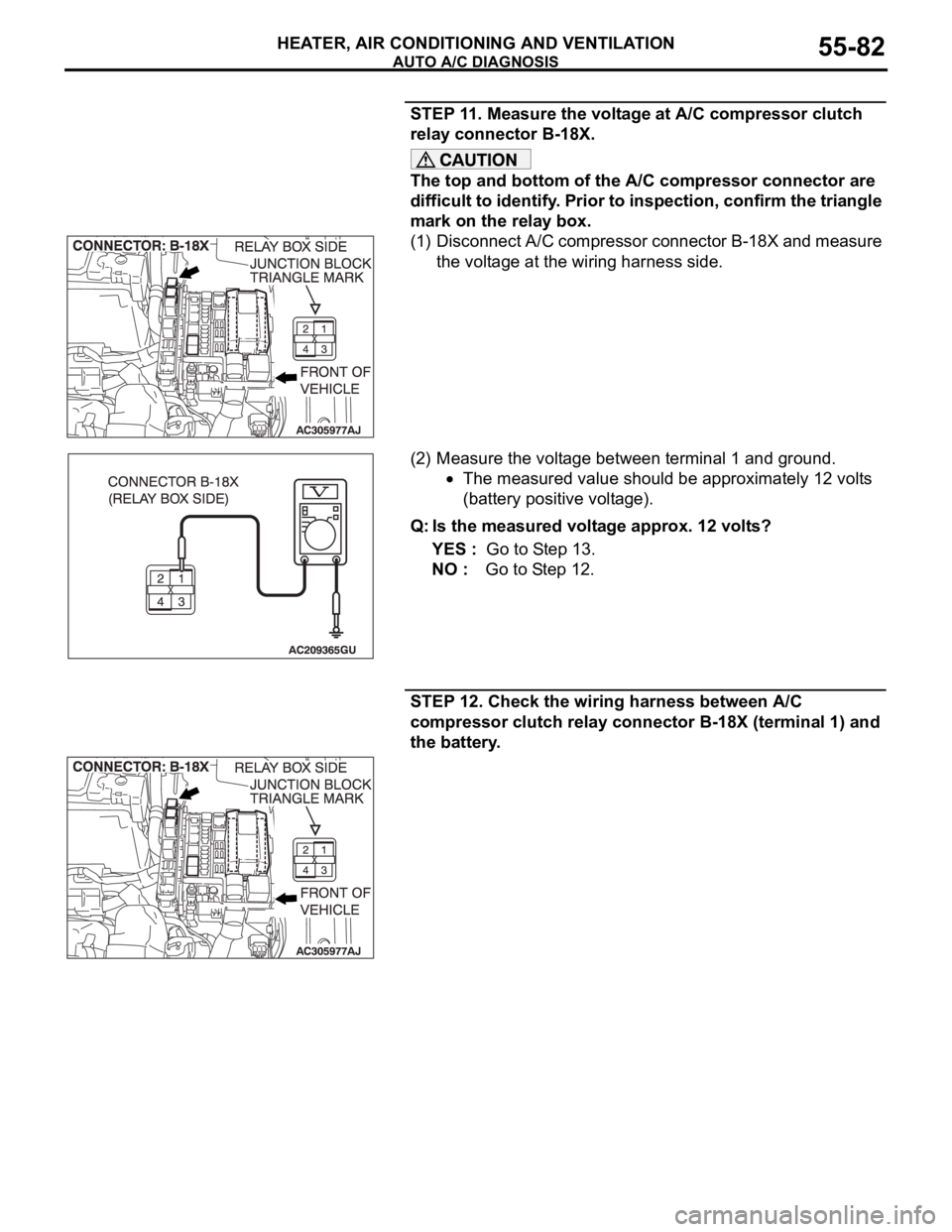

STEP 11. Measure the voltage at A/C compressor clutch

relay connector B-18X.

The top and bottom of the A/C compressor connector are

difficult to identify. Prior to inspection, confirm the triangle

mark on the relay box.

(1) Disconnect A/C compressor connector B-18X and measure

the voltage at the wiring harness side.

(2) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 13.

NO : Go to Step 12.

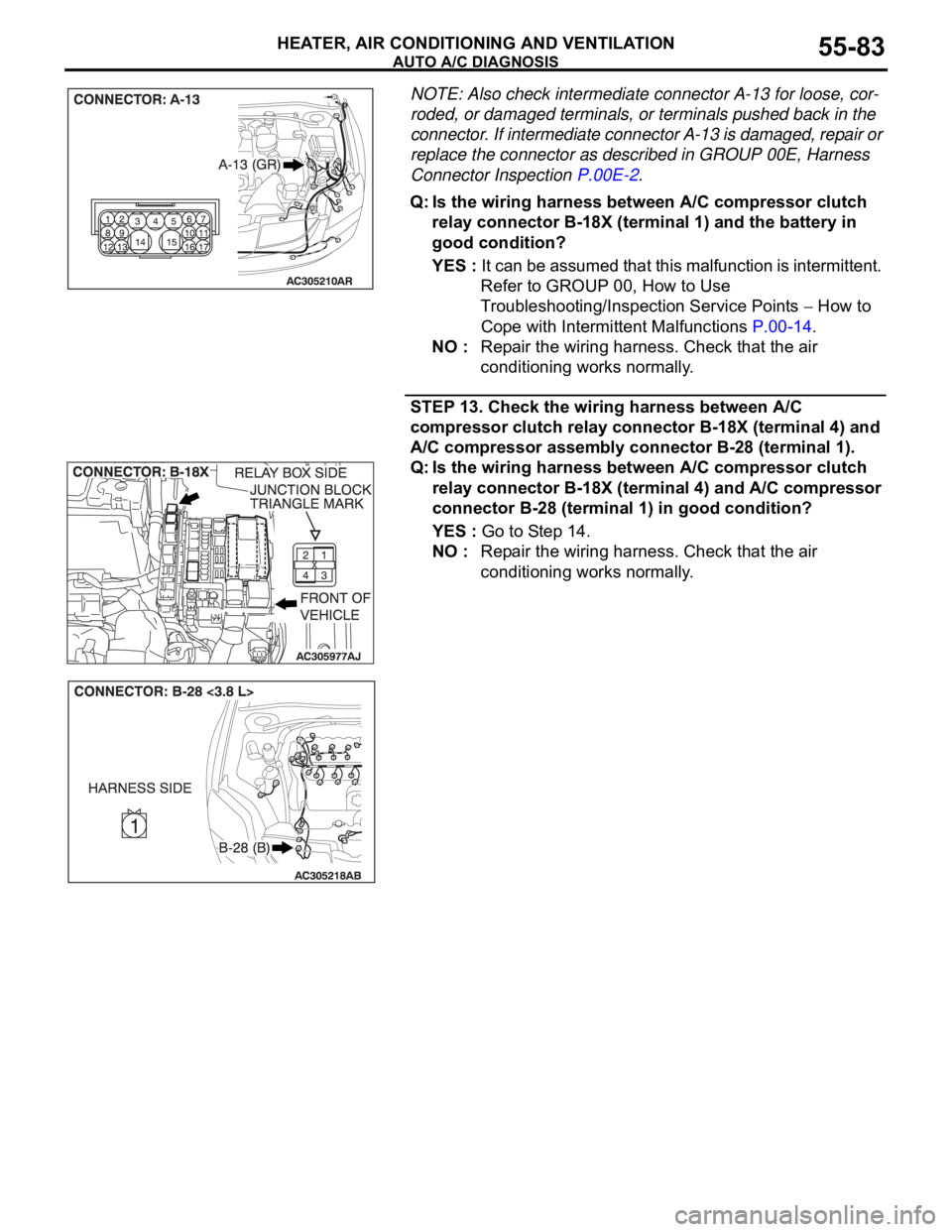

STEP 12. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 1) and

the battery.

Page 784 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-83

NOTE: Also check intermediate connector A-13 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector A-13 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 1) and the battery in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 13. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C compressor assembly connector B-28 (terminal 1).

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C compressor

connector B-28 (terminal 1) in good condition?

YES : Go to Step 14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 785 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-84

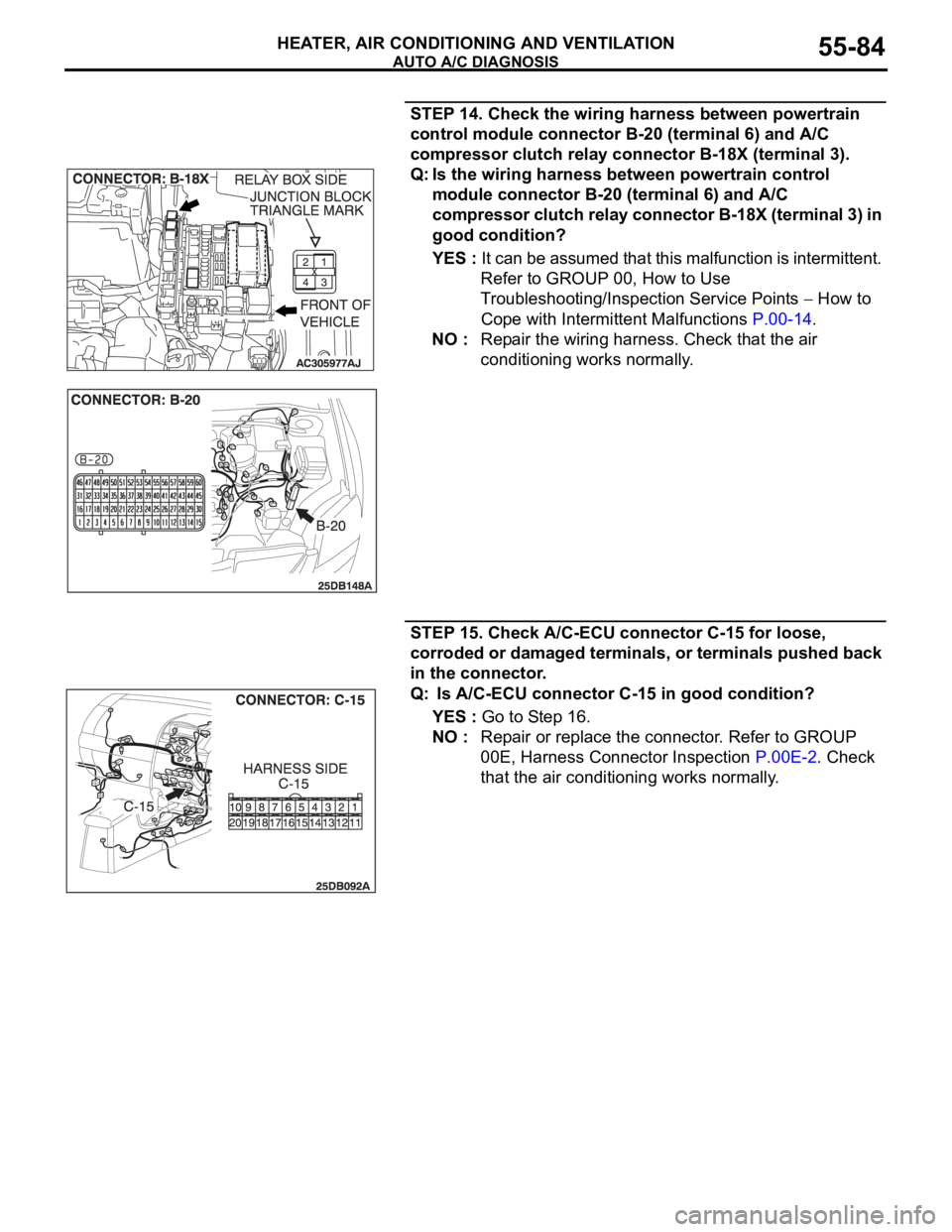

STEP 14. Check the wiring harness between powertrain

control module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3).

Q: Is the wiring harness between powertrain control

module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3) in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 15. Check A/C-ECU connector C-15 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is A/C-ECU connector C-15 in good condition?

YES : Go to Step 16.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the air conditioning works normally.

Page 787 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-86

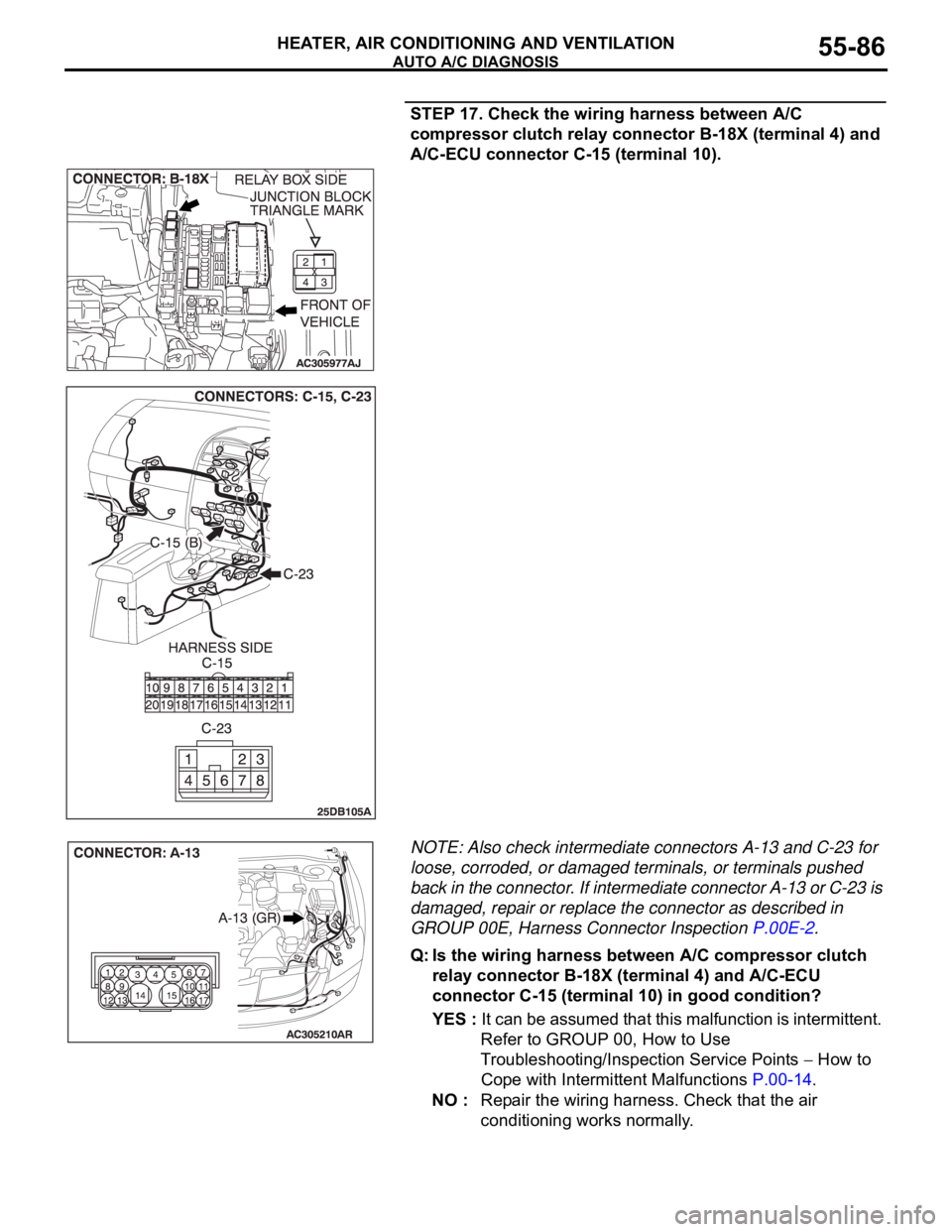

STEP 17. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C-ECU connector C-15 (terminal 10).

NOTE: Also check intermediate connectors A-13 and C-23 for

loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If intermediate connector A-13 or C-23 is

damaged, repair or replace the connector as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C-ECU

connector C-15 (terminal 10) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 788 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-87

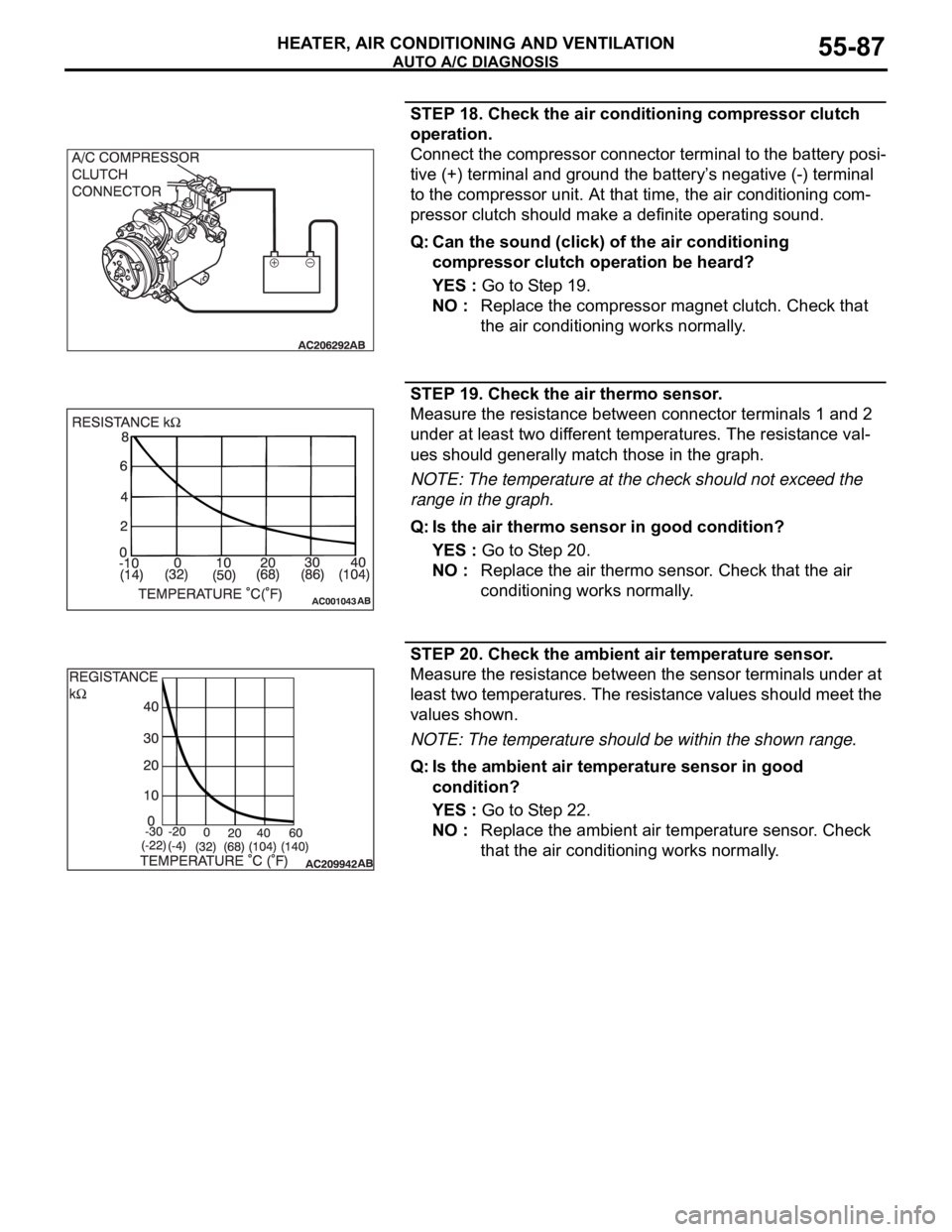

STEP 18. Check the air conditioning compressor clutch

operation.

Connect the compressor connector terminal to the battery posi-

tive (+) terminal and ground the battery’s negative (-) terminal

to the compressor unit. At that time, the air conditioning com-

pressor clutch should make a definite operating sound.

Q: Can the sound (click) of the air conditioning

compressor clutch operation be heard?

YES : Go to Step 19.

NO : Replace the compressor magnet clutch. Check that

the air conditioning works normally.

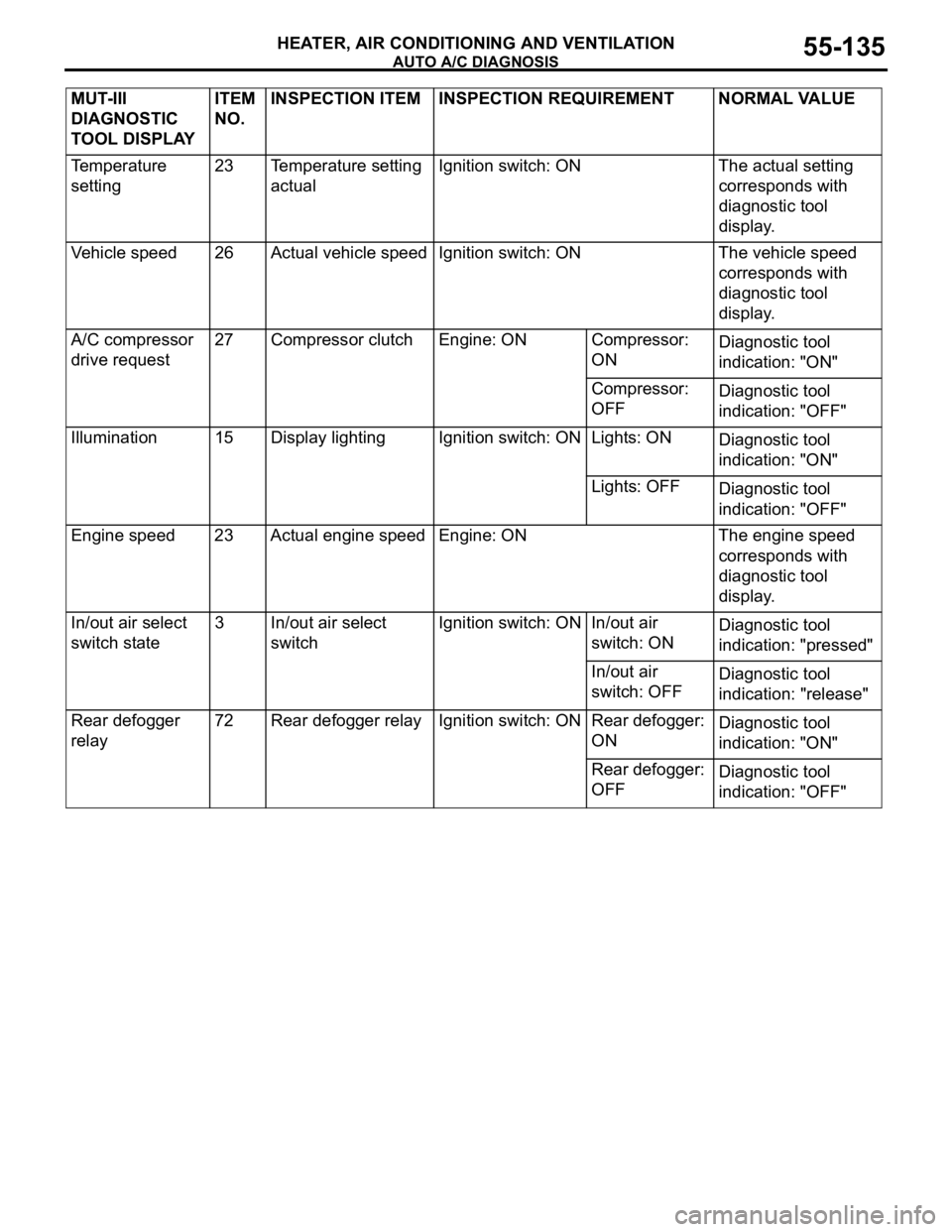

STEP 19. Check the air thermo sensor.

Measure the resistance between connector terminals 1 and 2

under at least two different temperatures. The resistance val-

ues should generally match those in the graph.

NOTE: The temperature at the check should not exceed the

range in the graph.

Q: Is the air thermo sensor in good condition?

YES : Go to Step 20.

NO : Replace the air thermo sensor. Check that the air

conditioning works normally.

STEP 20. Check the ambient air temperature sensor.

Measure the resistance between the sensor terminals under at

least two temperatures. The resistance values should meet the

values shown.

NOTE: The temperature should be within the shown range.

Q: Is the ambient air temperature sensor in good

condition?

YES : Go to Step 22.

NO : Replace the ambient air temperature sensor. Check

that the air conditioning works normally.

Page 836 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-135

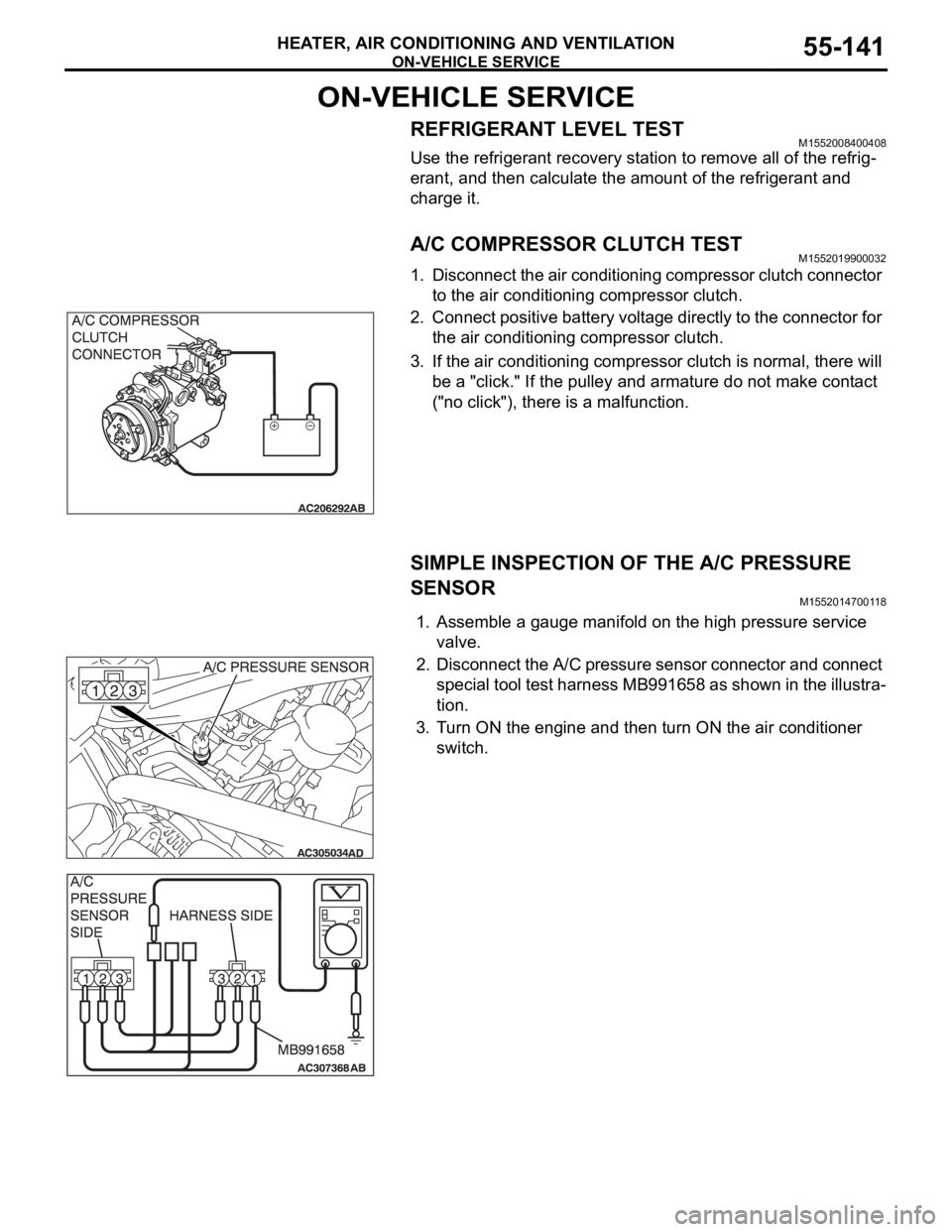

Temperature

setting23 Temperature setting

actualIgnition switch: ON The actual setting

corresponds with

diagnostic tool

display.

Vehicle speed 26 Actual vehicle speed Ignition switch: ON The vehicle speed

corresponds with

diagnostic tool

display.

A/C compressor

drive request27 Compressor clutch Engine: ON

Compressor:

ONDiagnostic tool

indication: "ON"

Compressor:

OFFDiagnostic tool

indication: "OFF"

Illumination 15 Display lighting Ignition switch: ON

Lights: ON

Diagnostic tool

indication: "ON"

Lights: OFF

Diagnostic tool

indication: "OFF"

Engine speed 23 Actual engine speed Engine: ON The engine speed

corresponds with

diagnostic tool

display.

In/out air select

switch state3 In/out air select

switch Ignition switch: ON In/out air

switch: ONDiagnostic tool

indication: "pressed"

In/out air

switch: OFFDiagnostic tool

indication: "release"

Rear defogger

relay72 Rear defogger relay Ignition switch: ON

Rear defogger:

ONDiagnostic tool

indication: "ON"

Rear defogger:

OFFDiagnostic tool

indication: "OFF" MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Page 842 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-141

ON-VEHICLE SERVICE

REFRIGERANT LEVEL TESTM1552008400408

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

A/C COMPRESSOR CLUTCH TESTM1552019900032

1. Disconnect the air conditioning compressor clutch connector

to the air conditioning compressor clutch.

2. Connect positive battery voltage directly to the connector for

the air conditioning compressor clutch.

3. If the air conditioning compressor clutch is normal, there will

be a "click." If the pulley and armature do not make contact

("no click"), there is a malfunction.

SIMPLE INSPECTION OF THE A/C PRESSURE

SENSOR

M1552014700118

1. Assemble a gauge manifold on the high pressure service

valve.

2. Disconnect the A/C pressure sensor connector and connect

special tool test harness MB991658 as shown in the illustra-

tion.

3. Turn ON the engine and then turn ON the air conditioner

switch.

Page 844 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-143

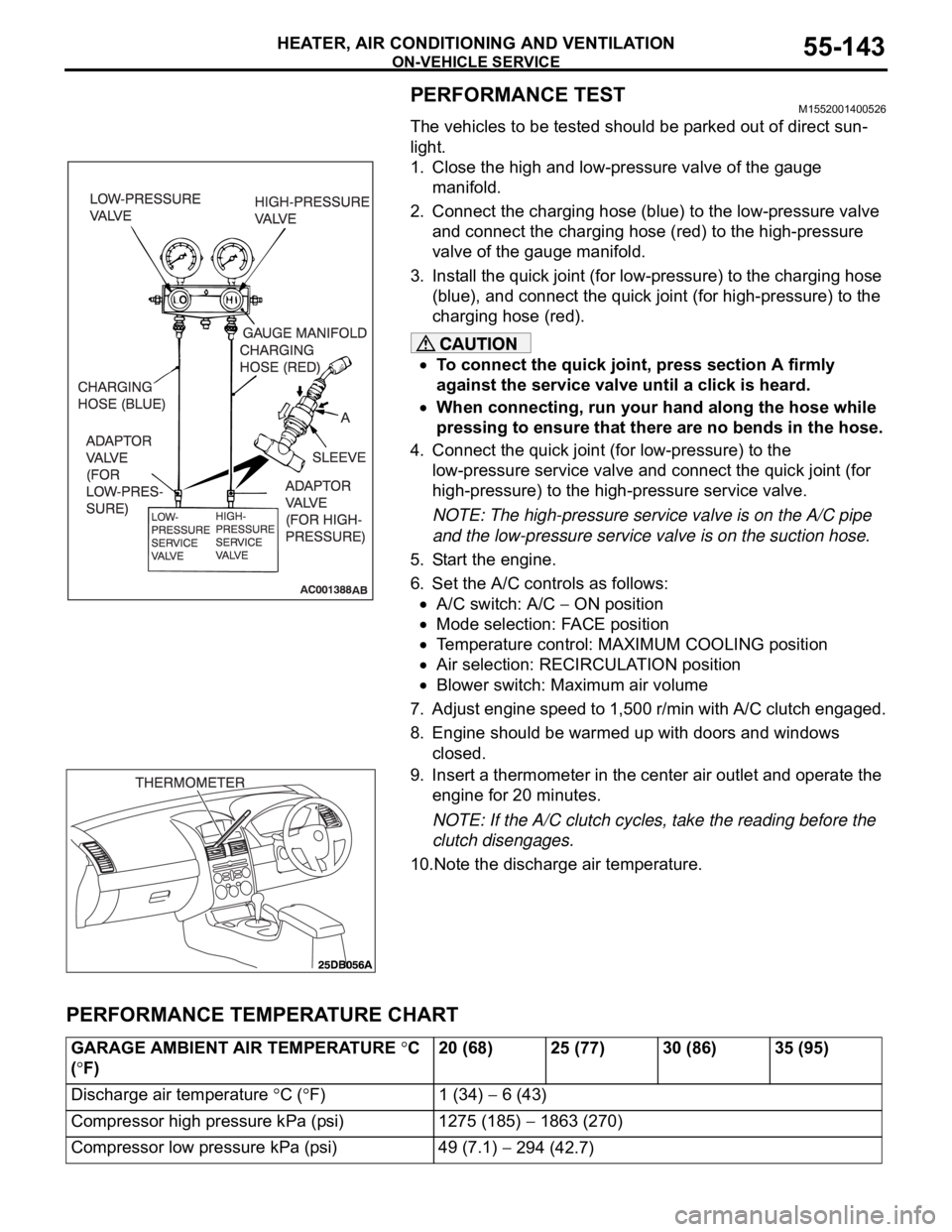

PERFORMANCE TEST M1552001400526

The vehicles to be tested should be parked out of direct sun-

light.

1. Close the high and low-pressure valve of the gauge

manifold.

2. Connect the charging hose (blue) to the low-pressure valve

and connect the charging hose (red) to the high-pressure

valve of the gauge manifold.

3. Install the quick joint (for low-pressure) to the charging hose

(blue), and connect the quick joint (for high-pressure) to the

charging hose (red).

To connect the quick joint, press section A firmly

against the service valve until a click is heard.

When connecting, run your hand along the hose while

pressing to ensure that there are no bends in the hose.

4. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick joint (for

high-pressure) to the high-pressure service valve.

NOTE: The high-pressure service valve is on the A/C pipe

and the low-pressure service valve is on the suction hose.

5. Start the engine.

6. Set the A/C controls as follows:

A/C switch: A/C ON position

Mode selection: FACE position

Temperature control: MAXIMUM COOLING position

Air selection: RECIRCULATION position

Blower switch: Maximum air volume

7. Adjust engine speed to 1,500 r/min with A/C clutch engaged.

8. Engine should be warmed up with doors and windows

closed.

9. Insert a thermometer in the center air outlet and operate the

engine for 20 minutes.

NOTE: If the A/C clutch cycles, take the reading before the

clutch disengages.

10.Note the discharge air temperature.

PERFORMANCE TEMPERATURE CHART

GARAGE AMBIENT AIR TEMPERATURE C

(

F)20 (68) 25 (77) 30 (86) 35 (95)

Discharge air temperature

C (F) 1 (34) 6 (43)

Compressor high pressure kPa (psi) 1275 (185)

1863 (270)

Compressor low pressure kPa (psi) 49 (7.1)

294 (42.7)

Page 845 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-144

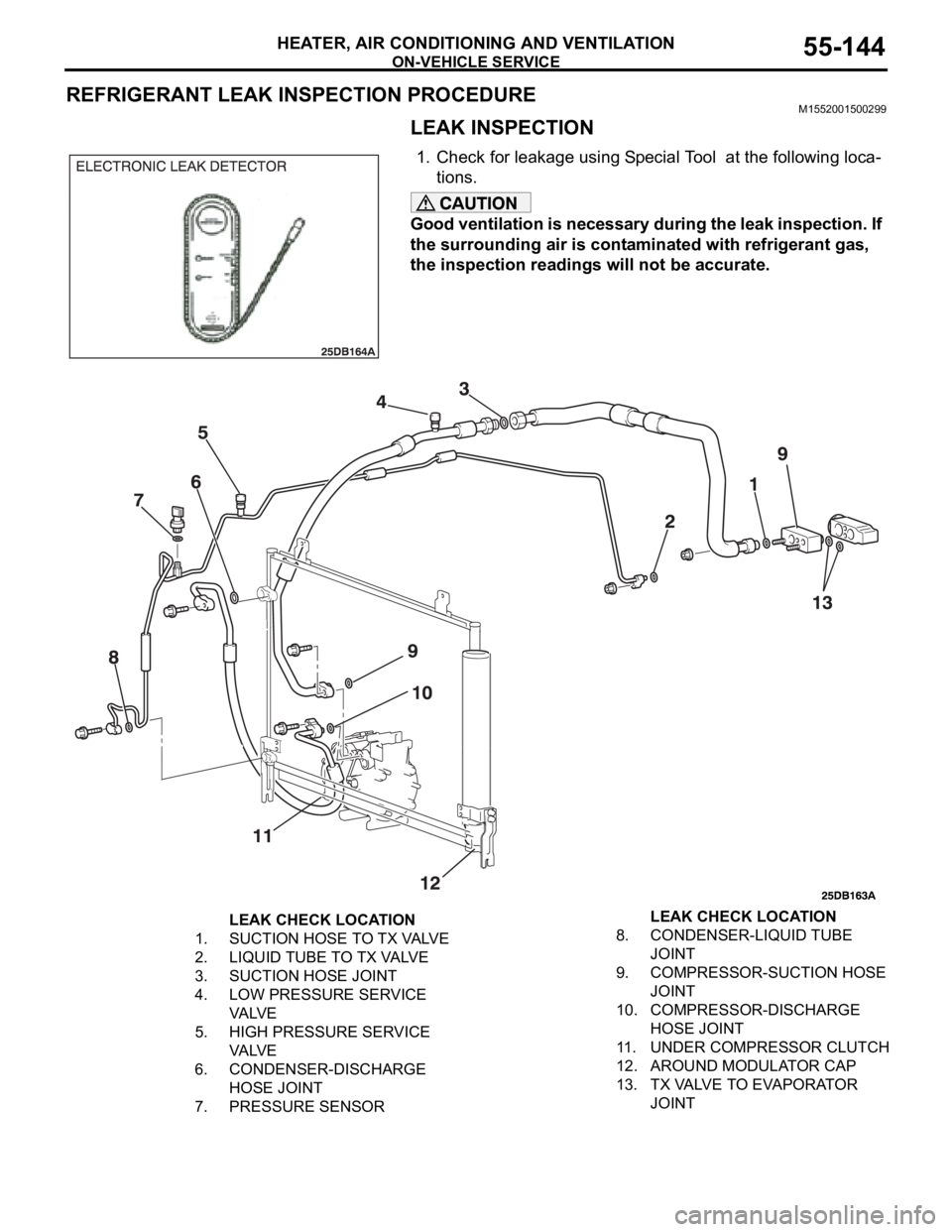

REFRIGERANT LEAK INSPECTION PROCEDUREM1552001500299

LEAK INSPECTION

1. Check for leakage using Special Tool at the following loca-

tions.

Good ventilation is necessary during the leak inspection. If

the surrounding air is contaminated with refrigerant gas,

the inspection readings will not be accurate.

LEAK CHECK LOCATION

1. SUCTION HOSE TO TX VALVE

2. LIQUID TUBE TO TX VALVE

3. SUCTION HOSE JOINT

4. LOW PRESSURE SERVICE

VA LV E

5. HIGH PRESSURE SERVICE

VA LV E

6. CONDENSER-DISCHARGE

HOSE JOINT

7. PRESSURE SENSOR8. CONDENSER-LIQUID TUBE

JOINT

9. COMPRESSOR-SUCTION HOSE

JOINT

10. COMPRESSOR-DISCHARGE

HOSE JOINT

11. UNDER COMPRESSOR CLUTCH

12. AROUND MODULATOR CAP

13. TX VALVE TO EVAPORATOR

JOINT LEAK CHECK LOCATION

Page 847 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-146

Sharper bends will reduce the flow of refrigerant. The flexible

hose lines should be routed so that they are at least 80 mm

(3.1 inches) from the exhaust manifold. It is good practice to

inspect all flexible hose lines at least once a year to make sure

they are in good condition and properly routed.

On standard plumbing fittings with O-rings, these O-rings are

not reusable.

AIR CONDITIONING NOISE TEST

You must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neu-

tral, engine temperature or any other special conditions.

Noises that develop during A/C operation can often be mislead-

ing. For example: what sounds like a failed front bearing or

connecting rod, may be caused by loose bolts, nuts, mounting

brackets, or a loose clutch assembly. Verify accessory drive

belt tension (power steering or generator).

Improper accessory drive belt tension can cause a misleading

noise when the compressor is engaged and little or no noise

when the compressor is disengaged.

Drive belts are speed-sensitive. That is, at different engine

speeds, and depending upon belt tension, belts can develop

unusual noises that are often mistaken for mechanical prob-

lems within the compressor.

Normal air conditioning operation will generate some level of

operational noise. To judge what is normal and abnormal,

requires an understanding of the air conditioning system. This

test is to detail the most common noise complaints and the

repair methods.

VEHICLE CONDITION

1. Ensure the system is not over or under charged.(Refer to

P.55-142).

2. Tighten all compressor mounting bolts, clutch mounting

bolts and compressor drive belt.

3. Inspect layout of the system is correct, ie no interference

between hoses and all retaining clamps are in place.