clutch MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 848 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-147

TEST PROCEDURES

1. Select a quiet area for testing.

2. Duplicate problem (customer complaint) as much as

possible.

3. Judge if the noise is abnormal (ie. it is important to

understand the characteristics of the vehicle and its normal

state to judge what is abnormal) - Compare with similar

vehicle if necessary.

4. Detail what and how noise occurs.

5. Find the noise source and verify its transmission by isolating

the subject part from the vehicle.

6. Repair the problem.

7. Explain and report your findings.

DETAILS OF A/C NOISE

POSSIBLE CAUSES, CHECKS AND REPAIRS

NOISE DESCRIPTION WHEN IT OCCURS SOURCE OF NOISE

Rumbling (Bearing noise) With A/C On or Off Magnetic clutch, idler pulley

Clang-Clack noise When compressor is engaged Magnetic clutch operation

Squawking (Belt sliding noise) When compressor is engaged V-belt

Whistling or Whooping noise Immediately after the A/C is

engaged.Expansion valve

Hissing or swishing noise When A/C is engaged, but

decreases as flow is stable Refrigerant flow

Rattling (Internal compressor) When compressor is operating Compressor internal part

Wooing (Resonant noise) With A/C On, occurs at certain

speed.Resonance of accessories

Cooing (Discharge pulsation

noise)With A/C On or Off Resonating noise with the vehicle

body

NOISE DESCRIPTION POSSIBLE CAUSE CHECK REPAIR

Rumbling (Bearing

noise)Bearing damage in rotor Manual rotation of bearing Replace compressor

Rotor slipping on boss Wear on compressor boss

surfaceReplace compressor

Bearing damage in pulley Check alignment between

pulleysReplace compressor

Clang-Clack noise Hub to stator misaligned Wear on inner clutch face Replace compressor

Gap between clutch

surface is too largeCheck Air gap is within

specificationReplace compressor

Squawking (Belt sliding

noise)Oil/water between the belt

and rotor surfaceOil and water

contaminationClean

Low belt tension Belt tension Reset or Replace belt and

set tension to correct

specification

Whistling or Whooping

noiseVibration of expansion

valveExpansion valve Replace TX valve

Page 850 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-149

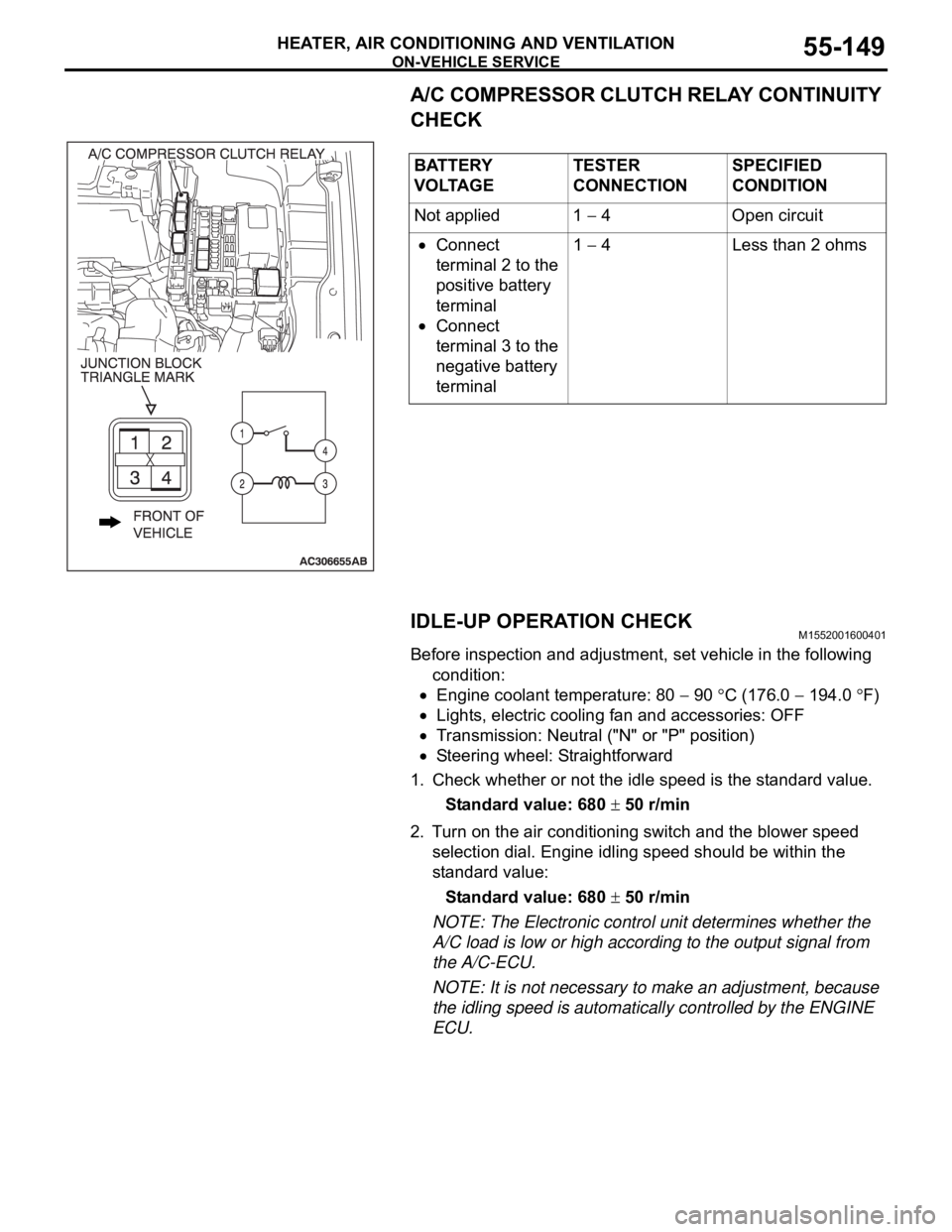

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 853 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-152

REMOVAL SERVICE POINTS

.

<> SUCTION PIPE AND LIQUID PIPE DISCON-

NECTION

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose and

nipples.

To prevent the entry of dust or other foreign bodies, plug the

dismantled hose and the nipples of the expansion valves.

.

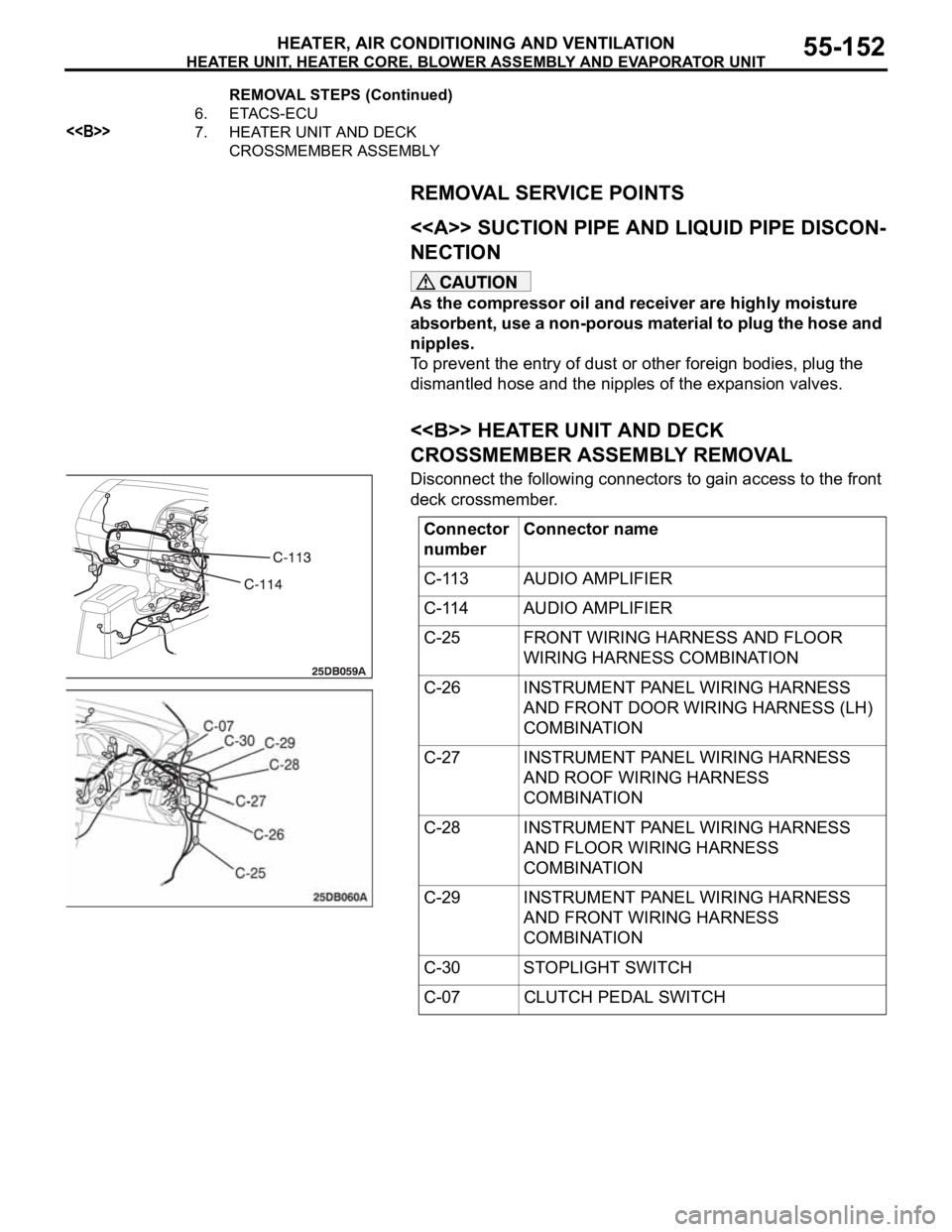

<> HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL

Disconnect the following connectors to gain access to the front

deck crossmember.

6. ETACS-ECU

<>7. HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL STEPS (Continued)

Connector

numberConnector name

C-113 AUDIO AMPLIFIER

C-114 AUDIO AMPLIFIER

C-25 FRONT WIRING HARNESS AND FLOOR

WIRING HARNESS COMBINATION

C-26 INSTRUMENT PANEL WIRING HARNESS

AND FRONT DOOR WIRING HARNESS (LH)

COMBINATION

C-27 INSTRUMENT PANEL WIRING HARNESS

AND ROOF WIRING HARNESS

COMBINATION

C-28 INSTRUMENT PANEL WIRING HARNESS

AND FLOOR WIRING HARNESS

COMBINATION

C-29 INSTRUMENT PANEL WIRING HARNESS

AND FRONT WIRING HARNESS

COMBINATION

C-30 STOPLIGHT SWITCH

C-07 CLUTCH PEDAL SWITCH

Page 867 of 1500

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-166

INSPECTIONM1552014301083

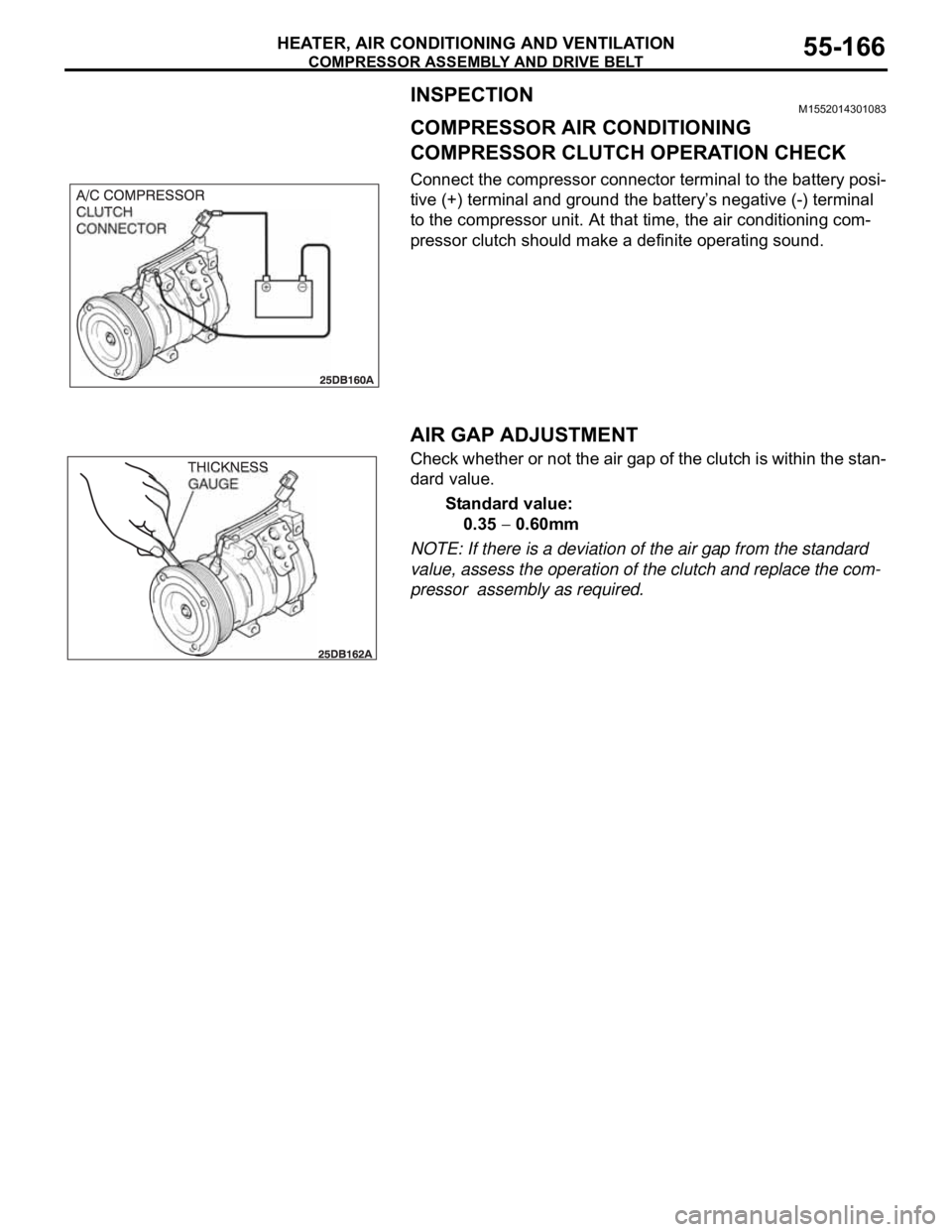

COMPRESSOR AIR CONDITIONING

COMPRESSOR CLUTCH OPERATION CHECK

Connect the compressor connector terminal to the battery posi-

tive (+) terminal and ground the battery’s negative (-) terminal

to the compressor unit. At that time, the air conditioning com-

pressor clutch should make a definite operating sound.

.

AIR GAP ADJUSTMENT

Check whether or not the air gap of the clutch is within the stan-

dard value.

Standard value:

0.35

0.60mm

NOTE: If there is a deviation of the air gap from the standard

value, assess the operation of the clutch and replace the com-

pressor assembly as required.

Page 879 of 1500

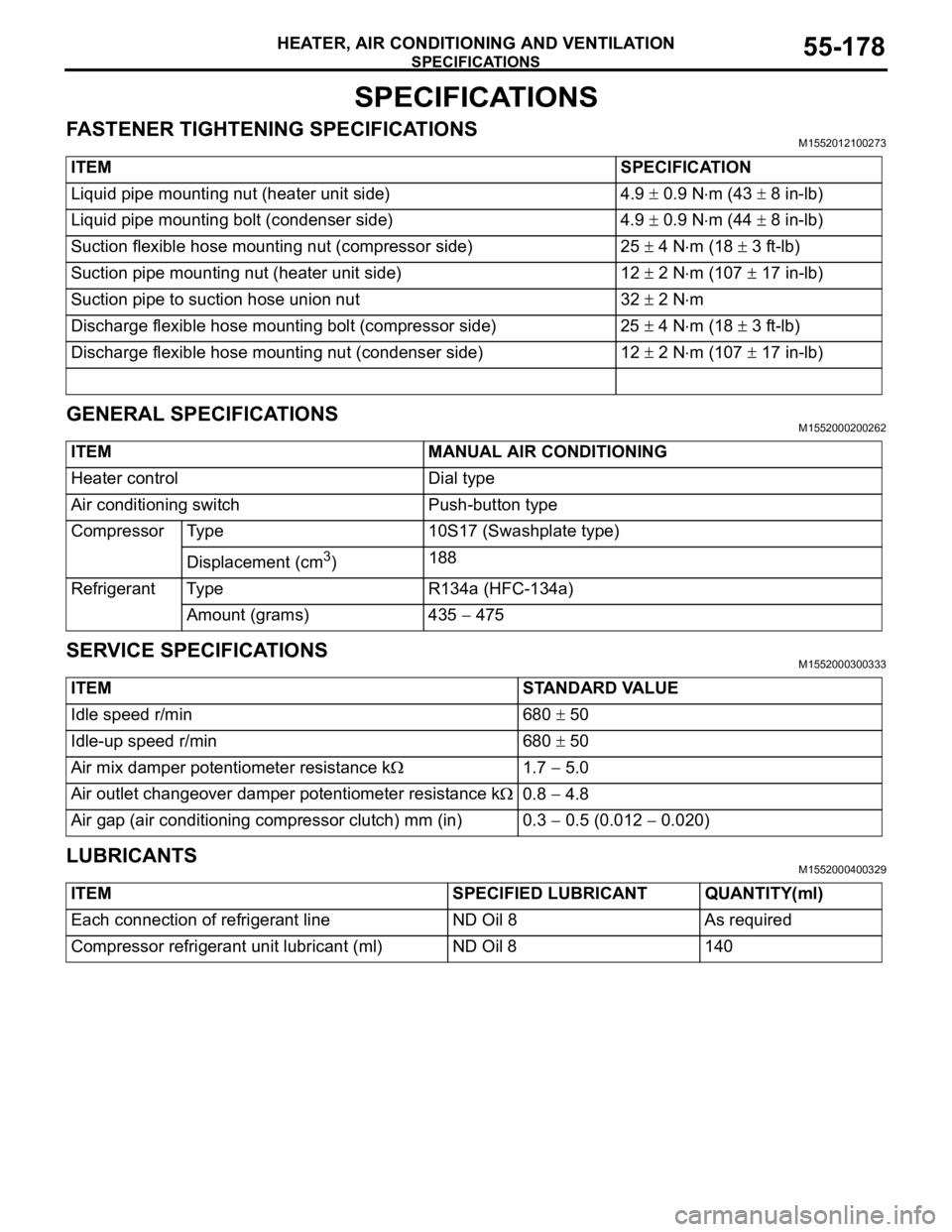

SPECIFICATIONS

HEATER, AIR CONDITIONING AND VENTILATION55-178

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1552012100273

GENERAL SPECIFICATIONSM1552000200262

SERVICE SPECIFICATIONSM1552000300333

LUBRICANTSM1552000400329

ITEM SPECIFICATION

Liquid pipe mounting nut (heater unit side) 4.9

0.9 Nm (43 8 in-lb)

Liquid pipe mounting bolt (condenser side) 4.9

0.9 Nm (44 8 in-lb)

Suction flexible hose mounting nut (compressor side) 25

4 Nm (18 3 ft-lb)

Suction pipe mounting nut (heater unit side) 12

2 Nm (107 17 in-lb)

Suction pipe to suction hose union nut 32

2 Nm

Discharge flexible hose mounting bolt (compressor side) 25

4 Nm (18 3 ft-lb)

Discharge flexible hose mounting nut (condenser side) 12

2 Nm (107 17 in-lb)

ITEM MANUAL AIR CONDITIONING

Heater control Dial type

Air conditioning switch Push-button type

Compressor Type 10S17 (Swashplate type)

Displacement (cm

3)188

Refrigerant Type R134a (HFC-134a)

Amount (grams) 435

475

ITEM STANDARD VALUE

Idle speed r/min 680

50

Idle-up speed r/min 680

50

Air mix damper potentiometer resistance k

1.7 5.0

Air outlet changeover damper potentiometer resistance k

0.8 4.8

Air gap (air conditioning compressor clutch) mm (in) 0.3

0.5 (0.012 0.020)

ITEM SPECIFIED LUBRICANT QUANTITY(ml)

Each connection of refrigerant line ND Oil 8 As required

Compressor refrigerant unit lubricant (ml) ND Oil 8 140

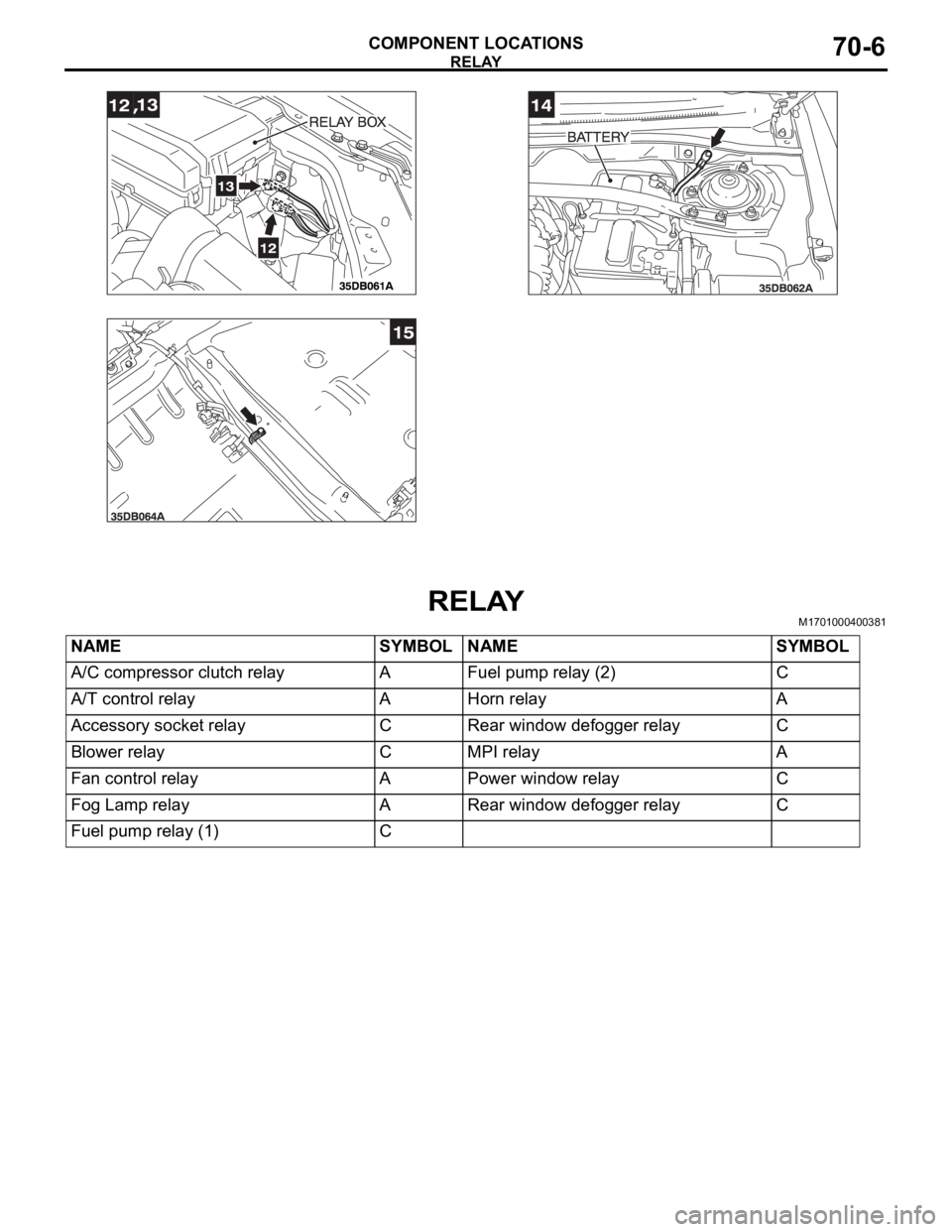

Page 885 of 1500

RELAY

COMPONENT LOCATIONS70-6

RELAYM1701000400381

NAME SYMBOL NAME SYMBOL

A/C compressor clutch relay A Fuel pump relay (2) C

A/T control relay A Horn relay A

Accessory socket relay C Rear window defogger relay C

Blower relay C MPI relay A

Fan control relay A Power window relay C

Fog Lamp relay A Rear window defogger relay C

Fuel pump relay (1) C

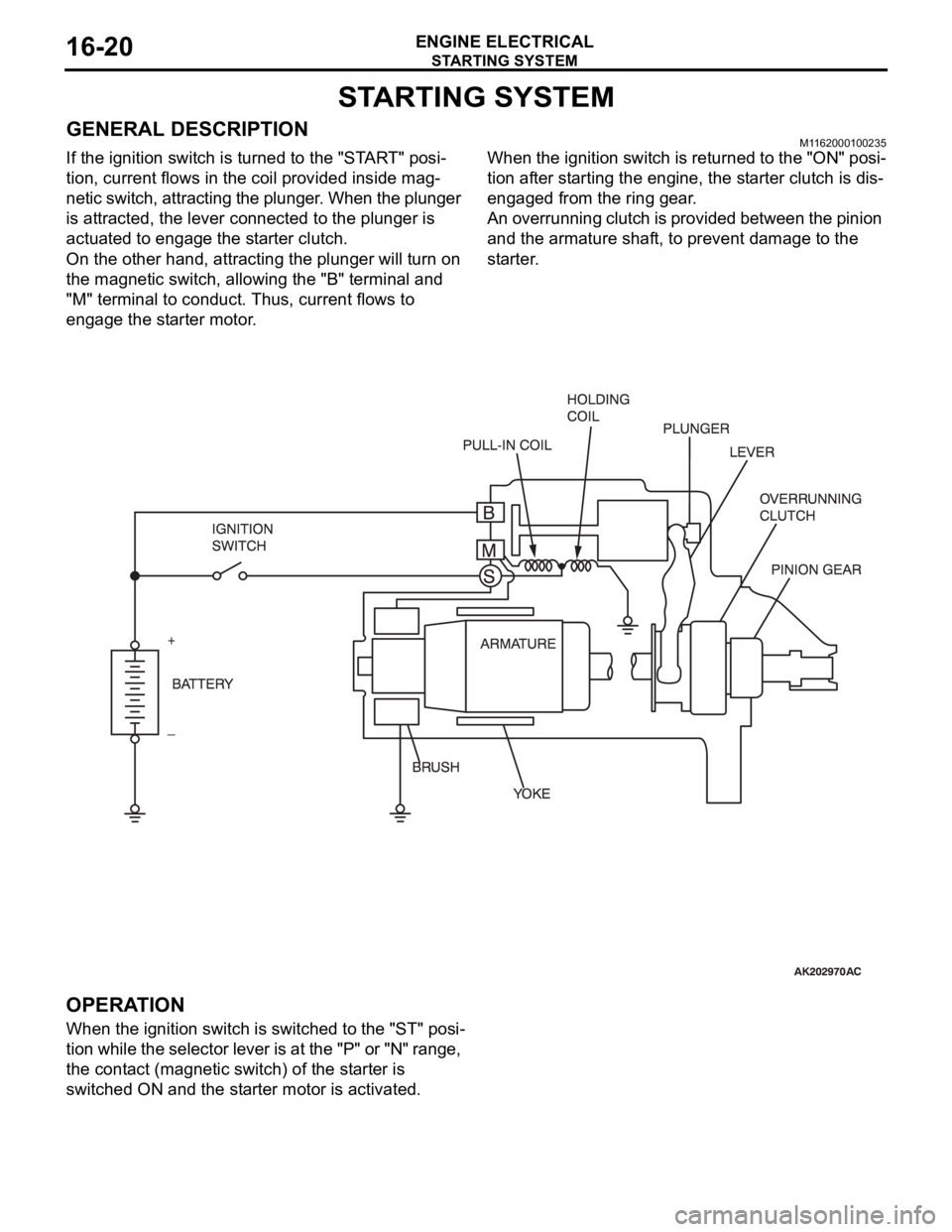

Page 997 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-20

STARTING SYSTEM

GENERAL DESCRIPTIONM1162000100235

If the ignition switch is turned to the "START" posi-

tion, current flows in the coil provided inside mag-

netic switch, attracting the plunger. When the plunger

is attracted, the lever connected to the plunger is

actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

OPERATION

When the ignition switch is switched to the "ST" posi-

tion while the selector lever is at the "P" or "N" range,

the contact (magnetic switch) of the starter is

switched ON and the starter motor is activated.

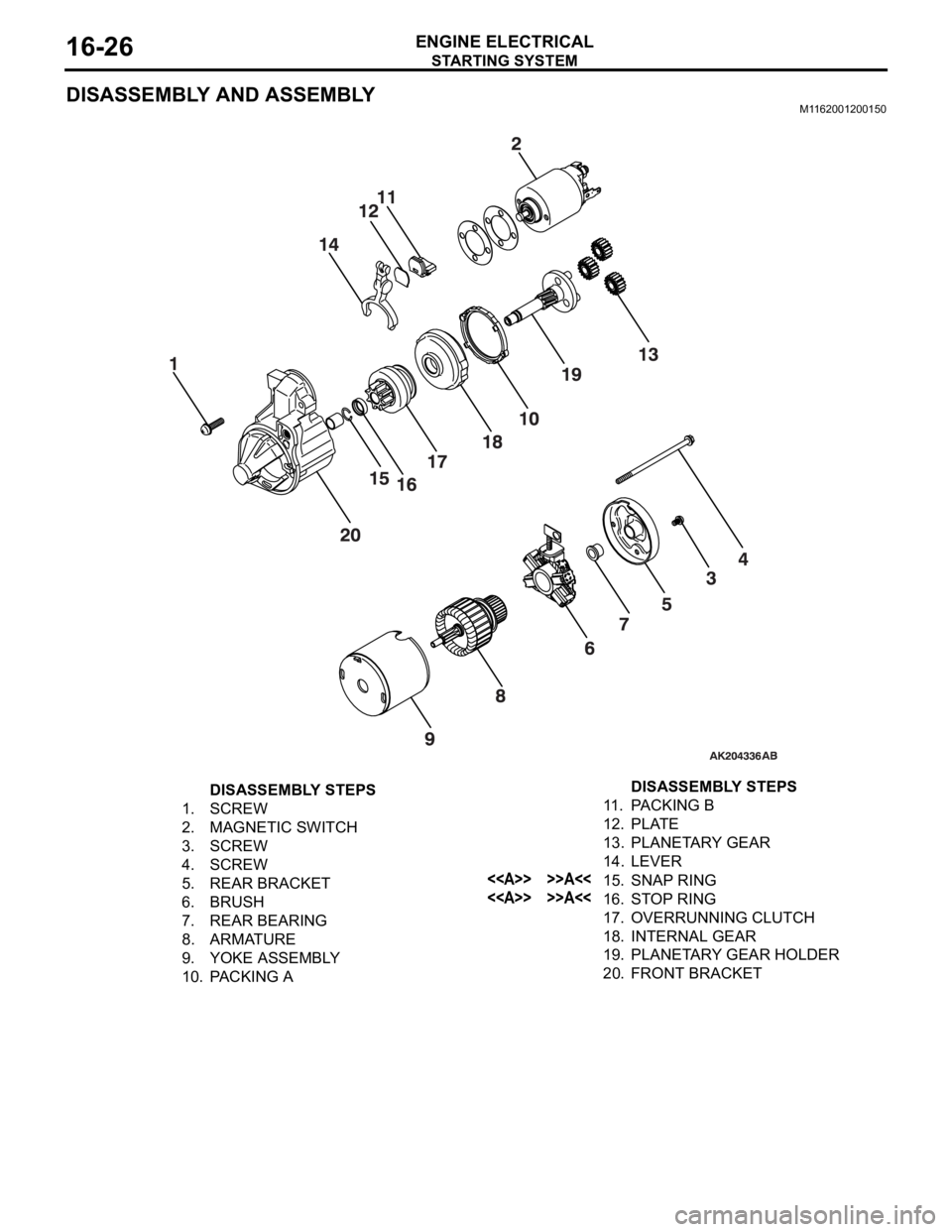

Page 1003 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-26

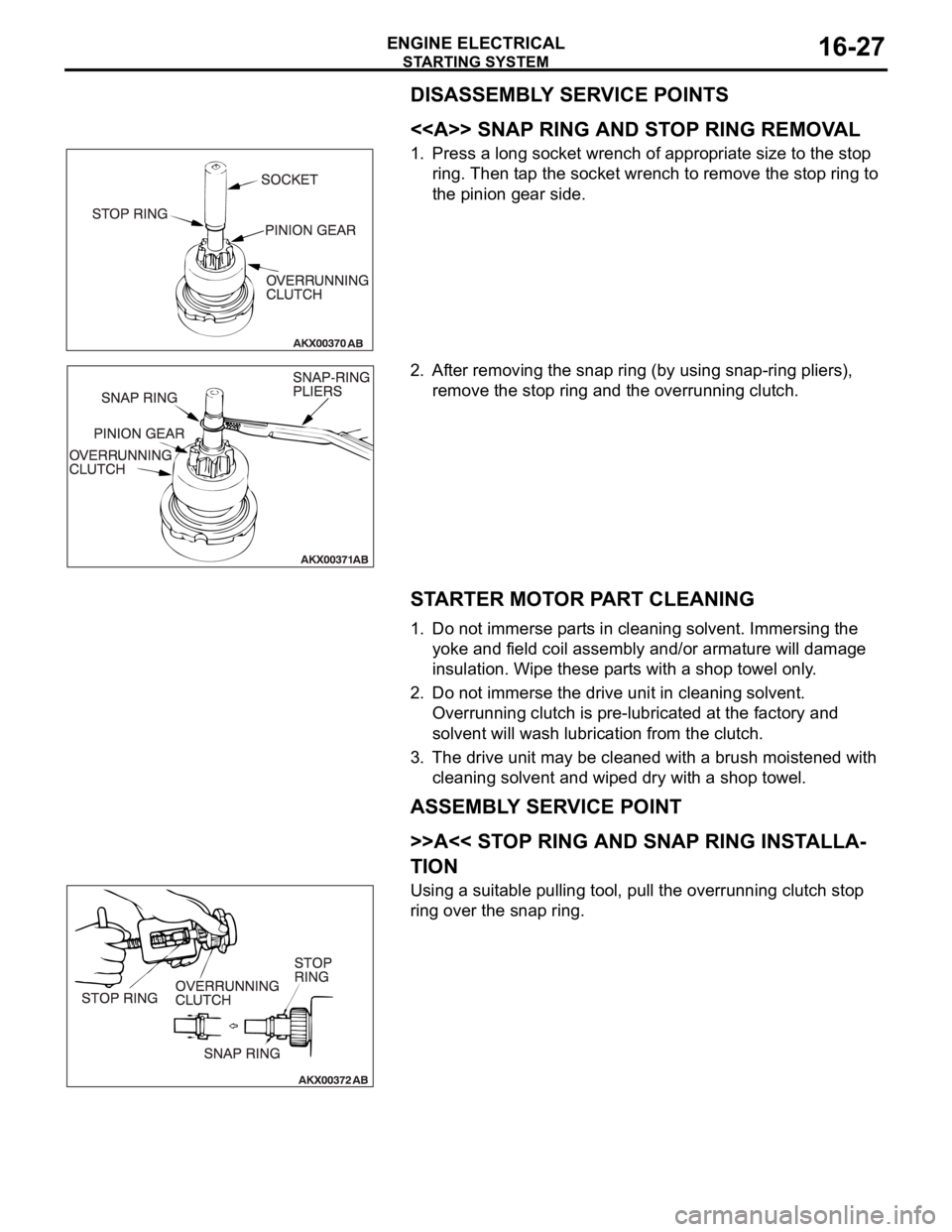

DISASSEMBLY AND ASSEMBLYM1162001200150

DISASSEMBLY STEPS

1. SCREW

2. MAGNETIC SWITCH

3. SCREW

4. SCREW

5. REAR BRACKET

6. BRUSH

7. REAR BEARING

8. ARMATURE

9. YOKE ASSEMBLY

10. PACKING A11 . PA C K I N G B

12. PLATE

13. PLANETARY GEAR

14. LEVER

<> >>A<<15. SNAP RING

<> >>A<<16. STOP RING

17. OVERRUNNING CLUTCH

18. INTERNAL GEAR

19. PLANETARY GEAR HOLDER

20. FRONT BRACKETDISASSEMBLY STEPS

Page 1004 of 1500

Page 1006 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-29

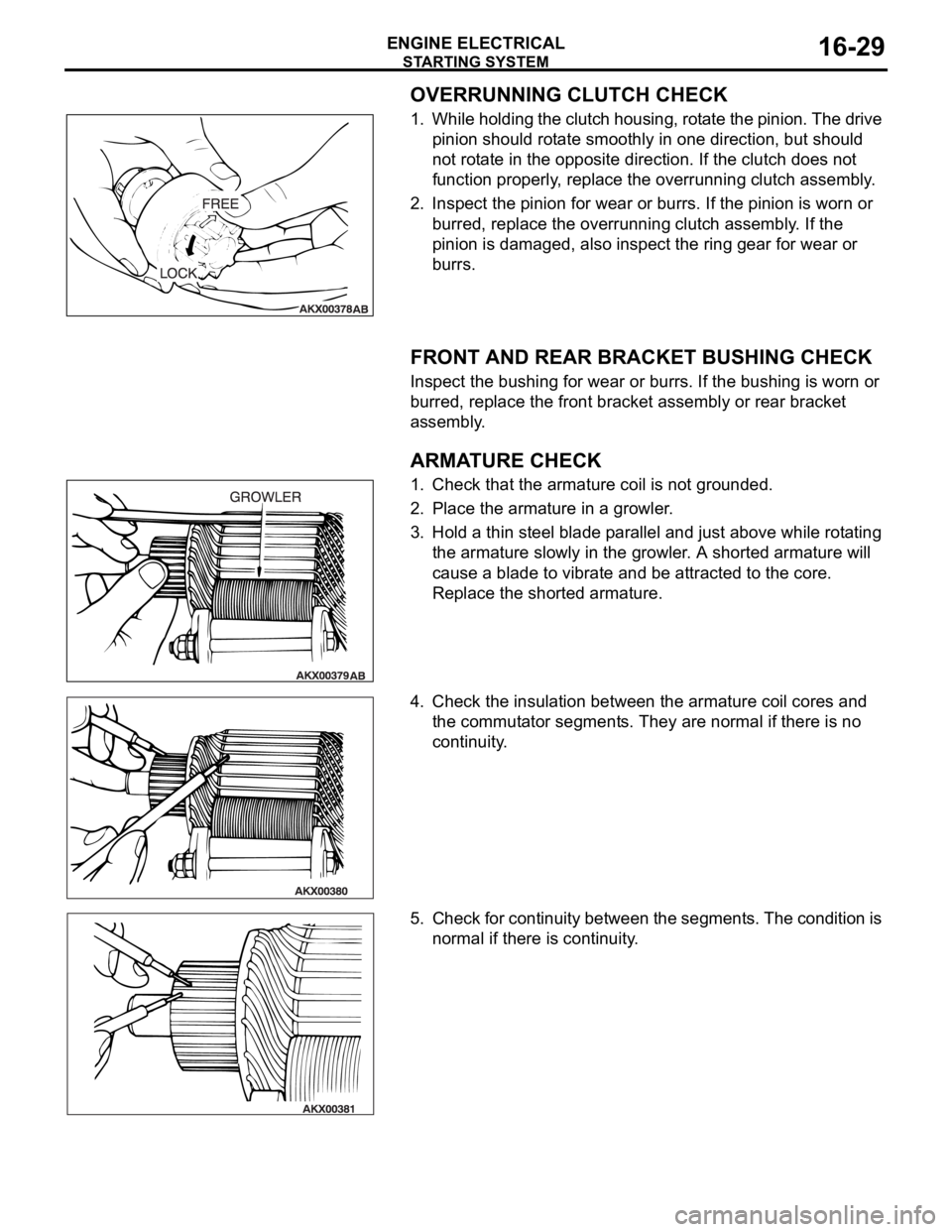

OVERRUNNING CLUTCH CHECK

1. While holding the clutch housing, rotate the pinion. The drive

pinion should rotate smoothly in one direction, but should

not rotate in the opposite direction. If the clutch does not

function properly, replace the overrunning clutch assembly.

2. Inspect the pinion for wear or burrs. If the pinion is worn or

burred, replace the overrunning clutch assembly. If the

pinion is damaged, also inspect the ring gear for wear or

burrs.

.

FRONT AND REAR BRACKET BUSHING CHECK

Inspect the bushing for wear or burrs. If the bushing is worn or

burred, replace the front bracket assembly or rear bracket

assembly.

.

ARMATURE CHECK

1. Check that the armature coil is not grounded.

2. Place the armature in a growler.

3. Hold a thin steel blade parallel and just above while rotating

the armature slowly in the growler. A shorted armature will

cause a blade to vibrate and be attracted to the core.

Replace the shorted armature.

4. Check the insulation between the armature coil cores and

the commutator segments. They are normal if there is no

continuity.

5. Check for continuity between the segments. The condition is

normal if there is continuity.