wheel MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 495 of 1500

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-6

6. RADIO AND CD PLAYER,

ASSEMBLY

7. RADIO, CD PLAYER AND CD

CHANGER ASSEMBLY

8. CONSOLE METER HOOD

11. MULTI-CENTER DISPLAY

ASSEMBLY

12. INSTRUMENT DIGITAL CLOCK

ASSEMBLY

13. CENTER CONSOLE ASSEMBLY

14. INSTURMENT PANEL GARNISH

15. COMBINATION METER

ASSEMBLY

FRONT PILLAR TRIM (REFER TO

P.52A-11.)

16. FRONT SPEAKER GARNISH

17. TWEETER

18. INSTRUMENT PANEL SIDE

COVER

19. INSTRUMETN PANEL SIDE AIR

OUTLET

AIR BAG MODULE ASSEMBLY

(DRIVER’S SIDE) (REFER TO

GROUP 52B, AIR BAG MODULE

AND CLOCK SPRING P.52B-237.)

STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37,

STEERING WHEEL P.37-23.)

20. STEERING COLUMN COVERREMOVAL STEPS (Continued)

<>CLOCK SPRING CONNECTOR

<>COLUMN SWITHC CONNECTOR

CLOCK SPRING AND COLUMN

SWITCH ASSEMBLY (REFER TO

GROUP 37, STEERING SHAFT

P.37-25.)

21. INTERIOR TEMPERATURE

SENSOR (GROUP 55B,

SENSORS 55-160.)

22. INSTRUMENT PANEL FRONT

END GARNISH

23. PHOTO SENSOR (GROUP 55B,

SENSORS 55-160.) AND

SECURITY LED.

FLOOR CONSOLE ASSEMBLY

(REFER TO P.52A-10.)

COWL SIDE TRIM (REFER TO

P.52A-11.)

<>AIR BAG MODULE CONNECTOR

(PASSENGER’S SIDE) (REFER

TO GROUP 52B, AIR BAG

MODULE AND CLOCK SPRING

P.52B-237.)

25. INSTRUMENT PANEL ASSEMBLYREMOVAL STEPS (Continued)

Page 553 of 1500

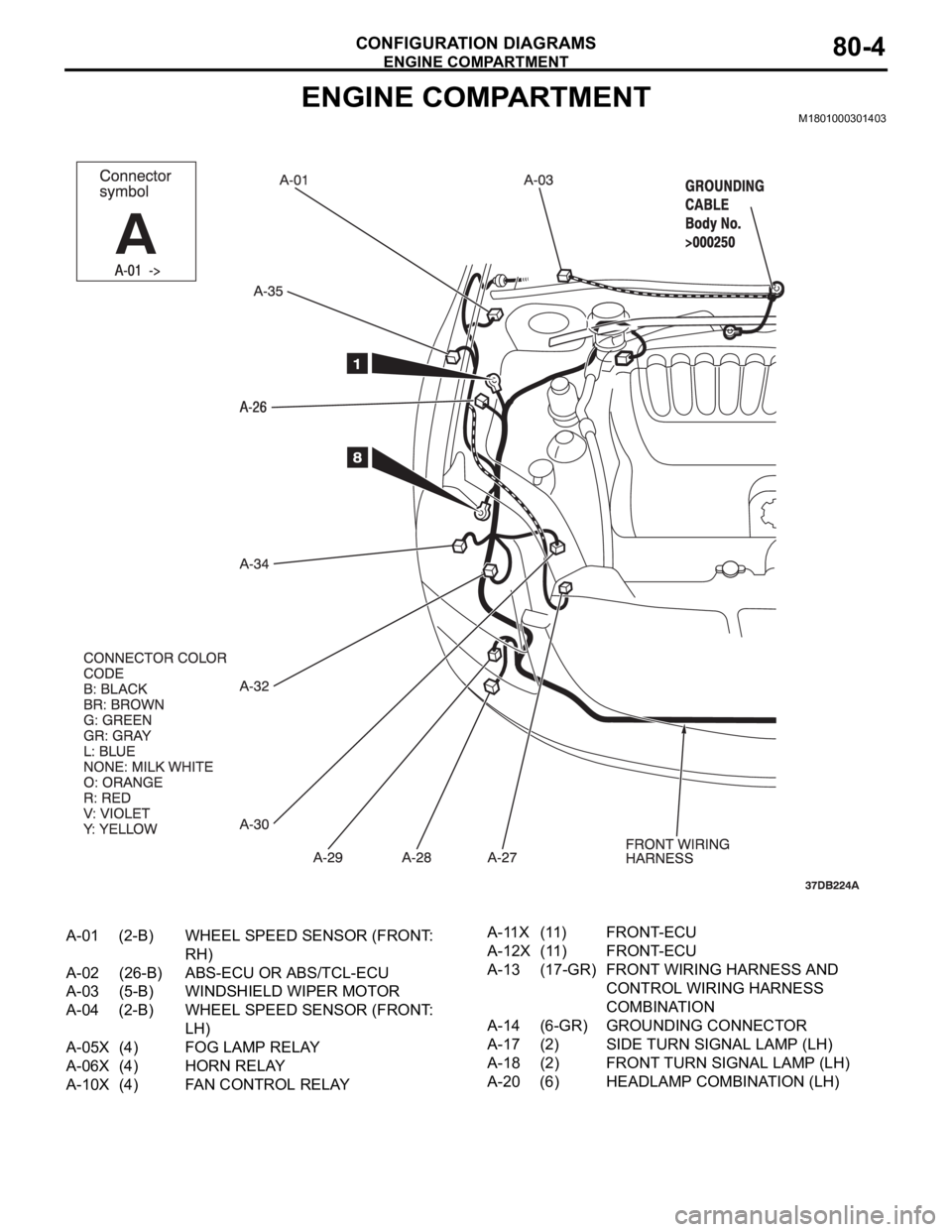

ENGINE COMPARTMENT

CONFIGURATION DIAGRAMS80-4

ENGINE COMPARTMENTM1801000301403

A-01 (2-B) WHEEL SPEED SENSOR (FRONT:

RH)

A-02 (26-B) ABS-ECU OR ABS/TCL-ECU

A-03 (5-B) WINDSHIELD WIPER MOTOR

A-04 (2-B) WHEEL SPEED SENSOR (FRONT:

LH)

A-05X (4) FOG LAMP RELAY

A-06X (4) HORN RELAY

A-10X (4) FAN CONTROL RELAYA-11X (11) FRONT-ECU

A-12X (11) FRONT-ECU

A-13 (17-GR) FRONT WIRING HARNESS AND

CONTROL WIRING HARNESS

COMBINATION

A-14 (6-GR) GROUNDING CONNECTOR

A-17 (2) SIDE TURN SIGNAL LAMP (LH)

A-18 (2) FRONT TURN SIGNAL LAMP (LH)

A-20 (6) HEADLAMP COMBINATION (LH)

Page 571 of 1500

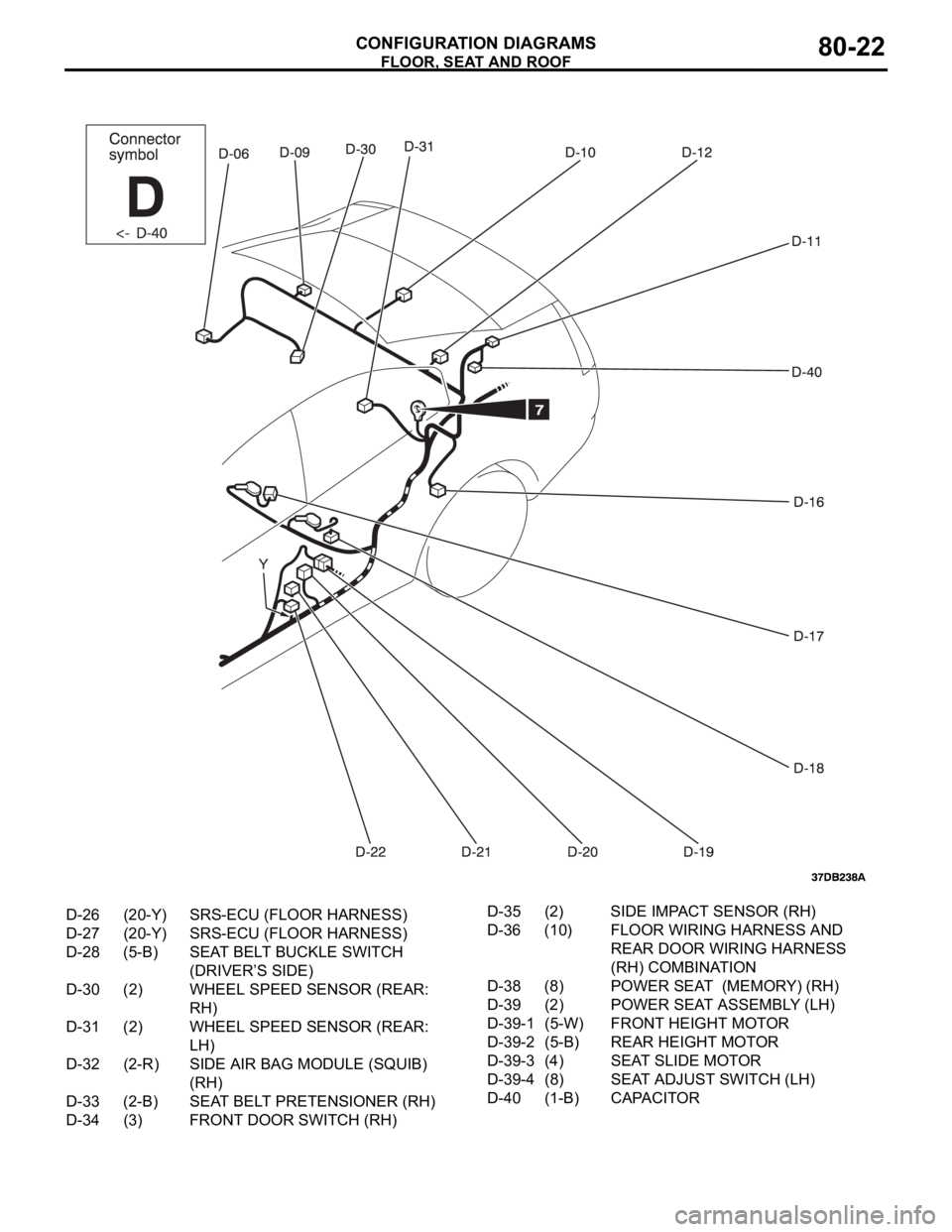

FLOOR, SEAT AND ROOF

CONFIGURATION DIAGRAMS80-22

D-26 (20-Y) SRS-ECU (FLOOR HARNESS)

D-27 (20-Y) SRS-ECU (FLOOR HARNESS)

D-28 (5-B) SEAT BELT BUCKLE SWITCH

(DRIVER’S SIDE)

D-30 (2) WHEEL SPEED SENSOR (REAR:

RH)

D-31 (2) WHEEL SPEED SENSOR (REAR:

LH)

D-32 (2-R) SIDE AIR BAG MODULE (SQUIB)

(RH)

D-33 (2-B) SEAT BELT PRETENSIONER (RH)

D-34 (3) FRONT DOOR SWITCH (RH)D-35 (2) SIDE IMPACT SENSOR (RH)

D-36 (10) FLOOR WIRING HARNESS AND

REAR DOOR WIRING HARNESS

(RH) COMBINATION

D-38 (8) POWER SEAT (MEMORY) (RH)

D-39 (2) POWER SEAT ASSEMBLY (LH)

D-39-1 (5-W) FRONT HEIGHT MOTOR

D-39-2 (5-B) REAR HEIGHT MOTOR

D-39-3 (4) SEAT SLIDE MOTOR

D-39-4 (8) SEAT ADJUST SWITCH (LH)

D-40 (1-B) CAPACITOR

Page 850 of 1500

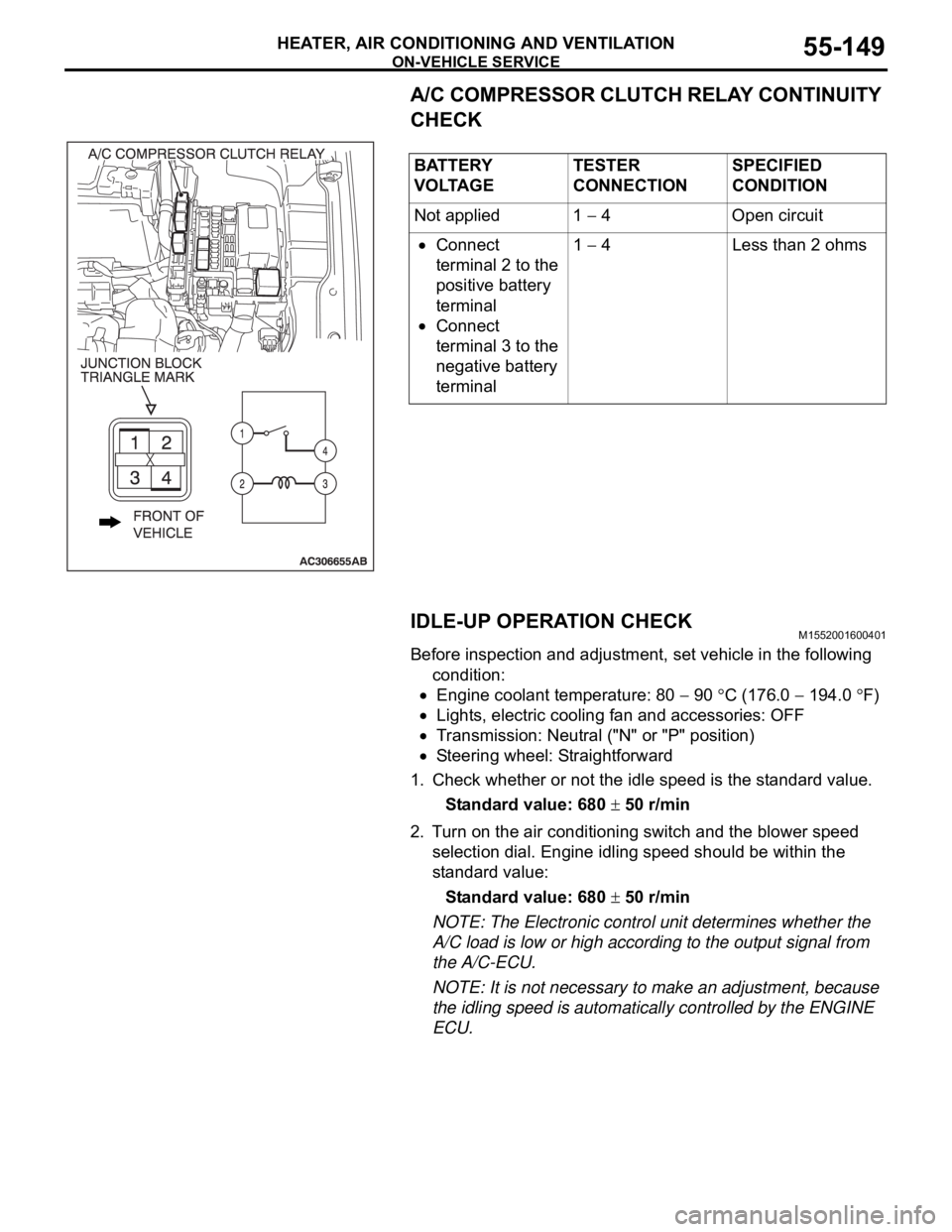

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-149

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 888 of 1500

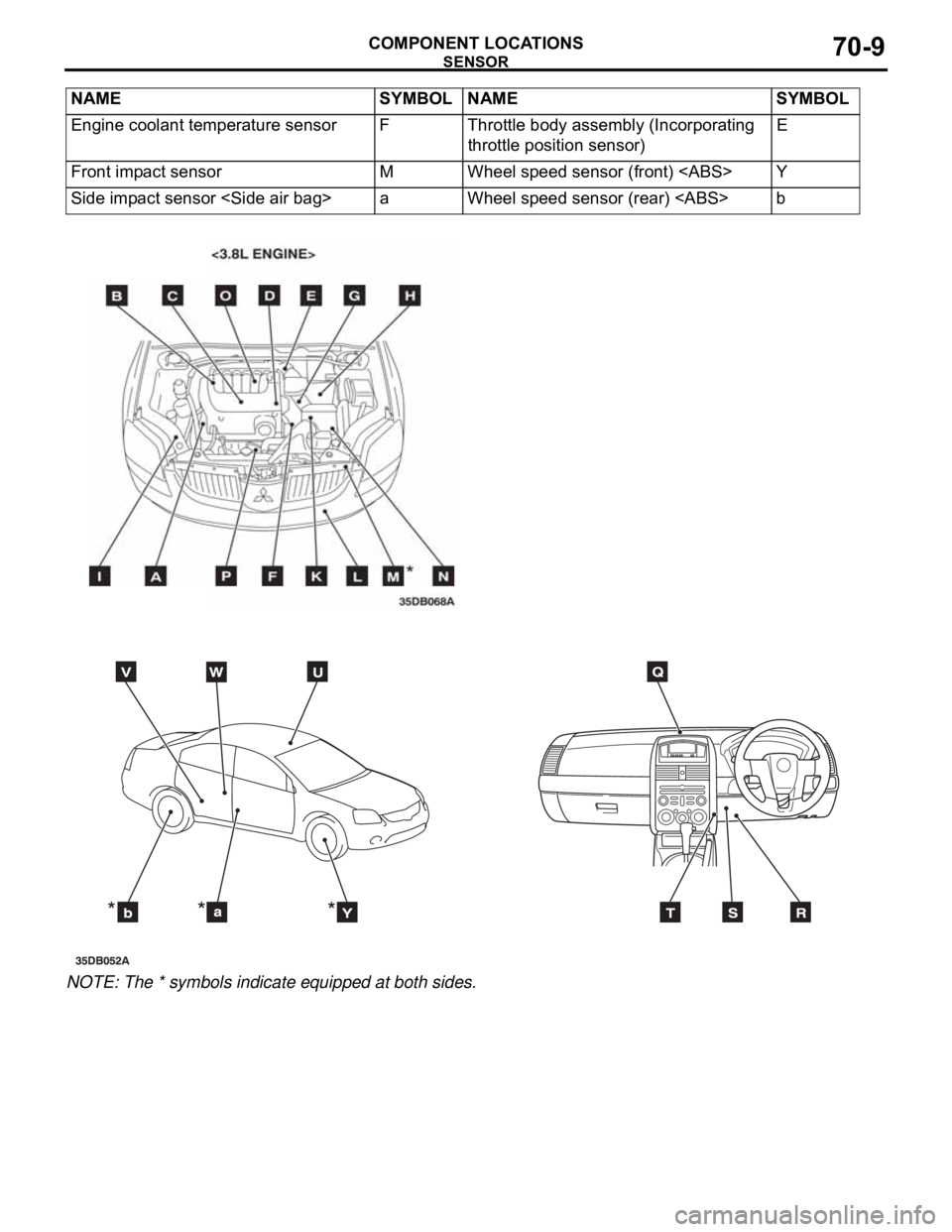

SENSOR

COMPONENT LOCATIONS70-9

NOTE: The * symbols indicate equipped at both sides.Engine coolant temperature sensor F Throttle body assembly (Incorporating

throttle position sensor)E

Front impact sensor M Wheel speed sensor (front)

Side impact sensor

Page 1026 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-9

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200551

Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions (P.52B-16), Air bag Module and Clock Spring (P.52B-237). Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

Pre-removal Operation

Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Hoses Removal and Installation (Refer to

GROUP 37, Power Steering Hoses P.37A-57).

Air Bag Module and Steering Wheel Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-23).

Clock Spring Removal (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Floor Console Assembly Removal (Refer to GROUP 52A,

Floor Console Assembly P.52A-10).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Removal

(Refer to GROUP 52A, Trims P.52A-11).

Trunk Lid Release Handle Cover Removal (Refer to

GROUP 42, Trunk Lid P.42-63).

Accelerator Stopper Removal (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Front Floor Carpet Removal

Centremember Removal (Refer to P.32-7).Post-installation Operation

Centremember Installation (Refer to P.32-7).

Front Floor Carpet Installation

Accelerator Stopper Installation (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Trunk Lid Release Handle Cover Installation (Refer to

GROUP 42, Trunk Lid P.42-63).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Installa-

tion (Refer to GROUP 52A, Trims P.52A-11).

Floor Console Assembly Installation (Refer to GROUP

52A, Floor Console Assembly P.52A-10).

Clock Spring Installation (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Steering Wheel Assembly and Air Bag Module Installation

(Refer to P.37-23).

Check the dust cover for cracks or damage by pushing it

with your finger.

Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Fluid Line Bleeding (Refer to P.37-18).

Checking Steering Wheel Position with Wheels Straight

Ahead.

Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

Front Wheel Alignment Check and

Adjustment P.33-6).

Page 1167 of 1500

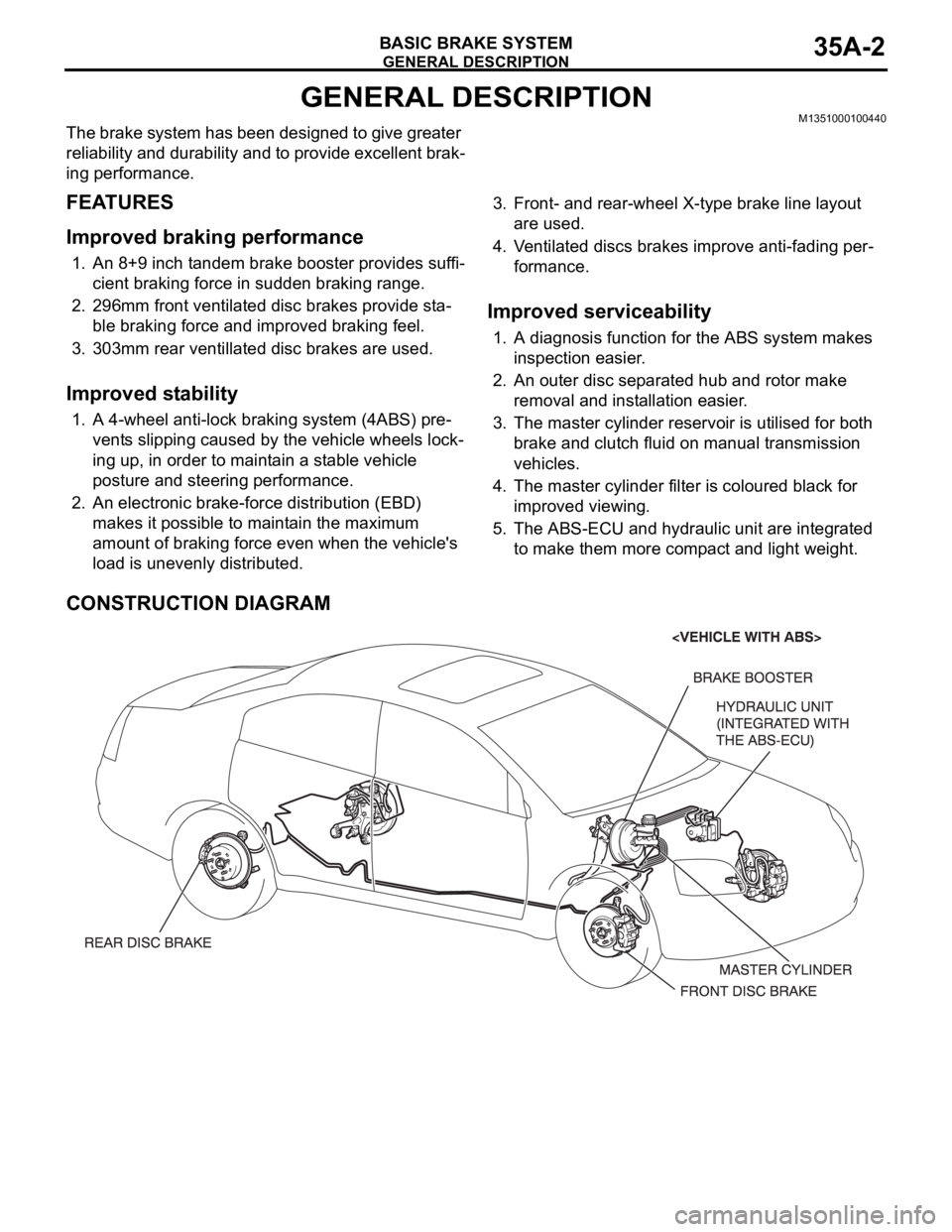

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM35A-2

GENERAL DESCRIPTIONM1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed. 3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM

Page 1172 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-7

STEP 6. Check the master cylinder piston return spring for

damage and return port for clogging.

Refer to P.35A-28.

Q: Is there damage?

YES : Replace the part. Then go to Step 9.

NO : Go to Step 7.

STEP 7. Check port for clogging.

Q: Is the port clogged?

YES : Repair it. Then go to Step 9.

NO : Go to Step 8.

STEP 8. Check disc brake pistons for sticking.

Depress the brake pedal, then release. Confirm each wheel

spins freely.

Q: Does any wheel stick?

YES : Inspect that brake assembly. Then go to Step 9.

NO : Go to Step 9.

STEP 9. Recheck symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

INSPECTION PROCEDURE 5: Scraping or Grinding Noise when Brakes are Applied

.

DIAGNOSIS

STEP 1. Check the front brakes, then rear brakes, for

metal-to-metal condition.

Q: Is any metal-to-metal contact evident?

YES : Repair or replace the components. Then go to Step 6.

NO : Go to Step 2.

STEP 2. Check for interference between the caliper and

wheel.

Q: Is there any interference?

YES : Repair or replace the part. Then go to Step 6.

NO : Go to Step 3.

Page 1175 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-10

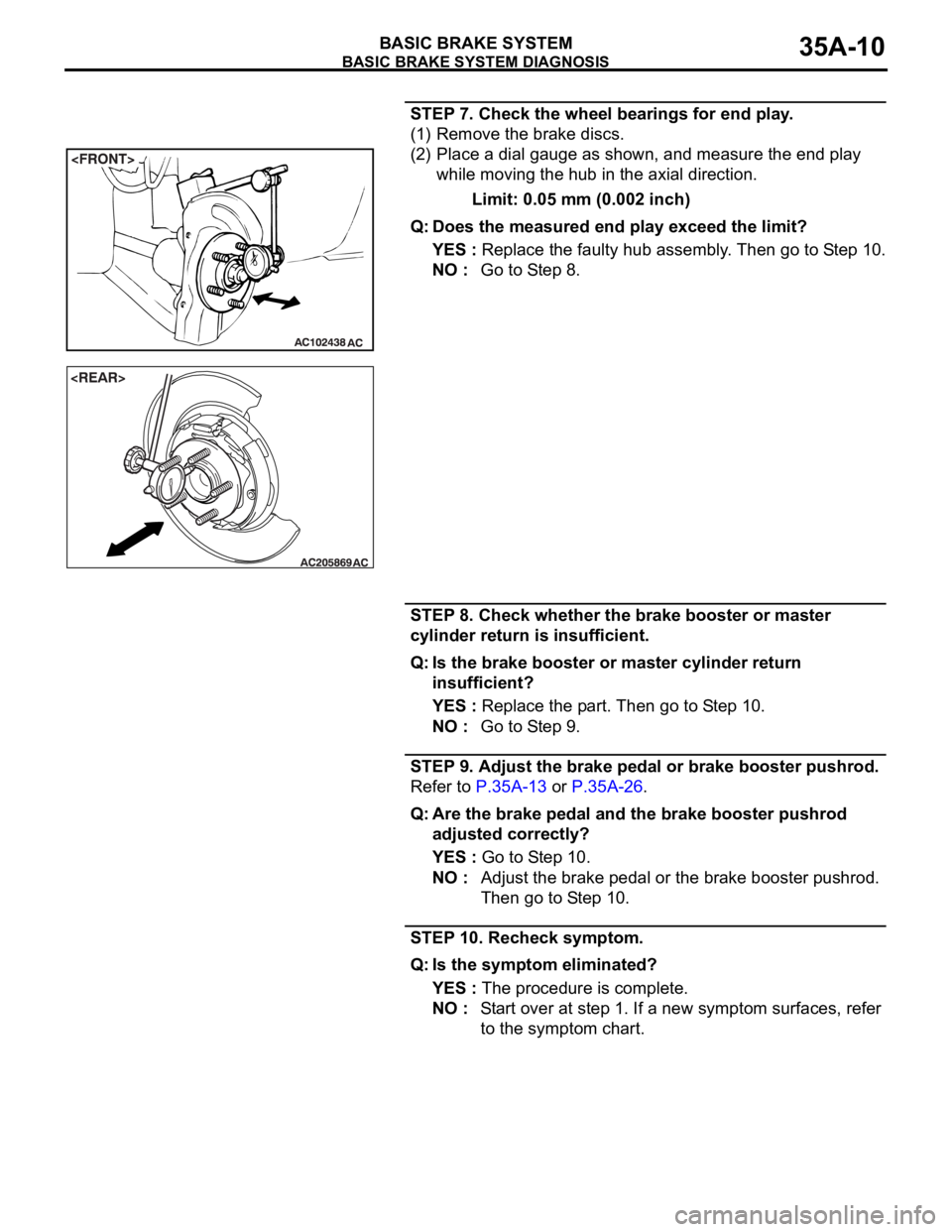

STEP 7. Check the wheel bearings for end play.

(1) Remove the brake discs.

(2) Place a dial gauge as shown, and measure the end play

while moving the hub in the axial direction.

Limit: 0.05 mm (0.002 inch)

Q: Does the measured end play exceed the limit?

YES : Replace the faulty hub assembly. Then go to Step 10.

NO : Go to Step 8.

STEP 8. Check whether the brake booster or master

cylinder return is insufficient.

Q: Is the brake booster or master cylinder return

insufficient?

YES : Replace the part. Then go to Step 10.

NO : Go to Step 9.

STEP 9. Adjust the brake pedal or brake booster pushrod.

Refer to P.35A-13 or P.35A-26.

Q: Are the brake pedal and the brake booster pushrod

adjusted correctly?

YES : Go to Step 10.

NO : Adjust the brake pedal or the brake booster pushrod.

Then go to Step 10.

STEP 10. Recheck symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

Page 1176 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-11

INSPECTION PROCEDURE 8: Groaning, Clicking or Rattling Noise when Brakes are not Applied.

DIAGNOSIS

.

STEP 1. Check whether foreign material has entered the

wheel covers.

Q: Is there any foreign material?

YES : Remove it. Then go to Step 5.

NO : Go to Step 2.

STEP 2. Check for looseness of the wheel nuts.

Q: Are the wheel nuts loose?

YES : Tighten to 98

10 Nm (73 7 ft-lb). Then go to Step

5 .

NO : Go to Step 3.

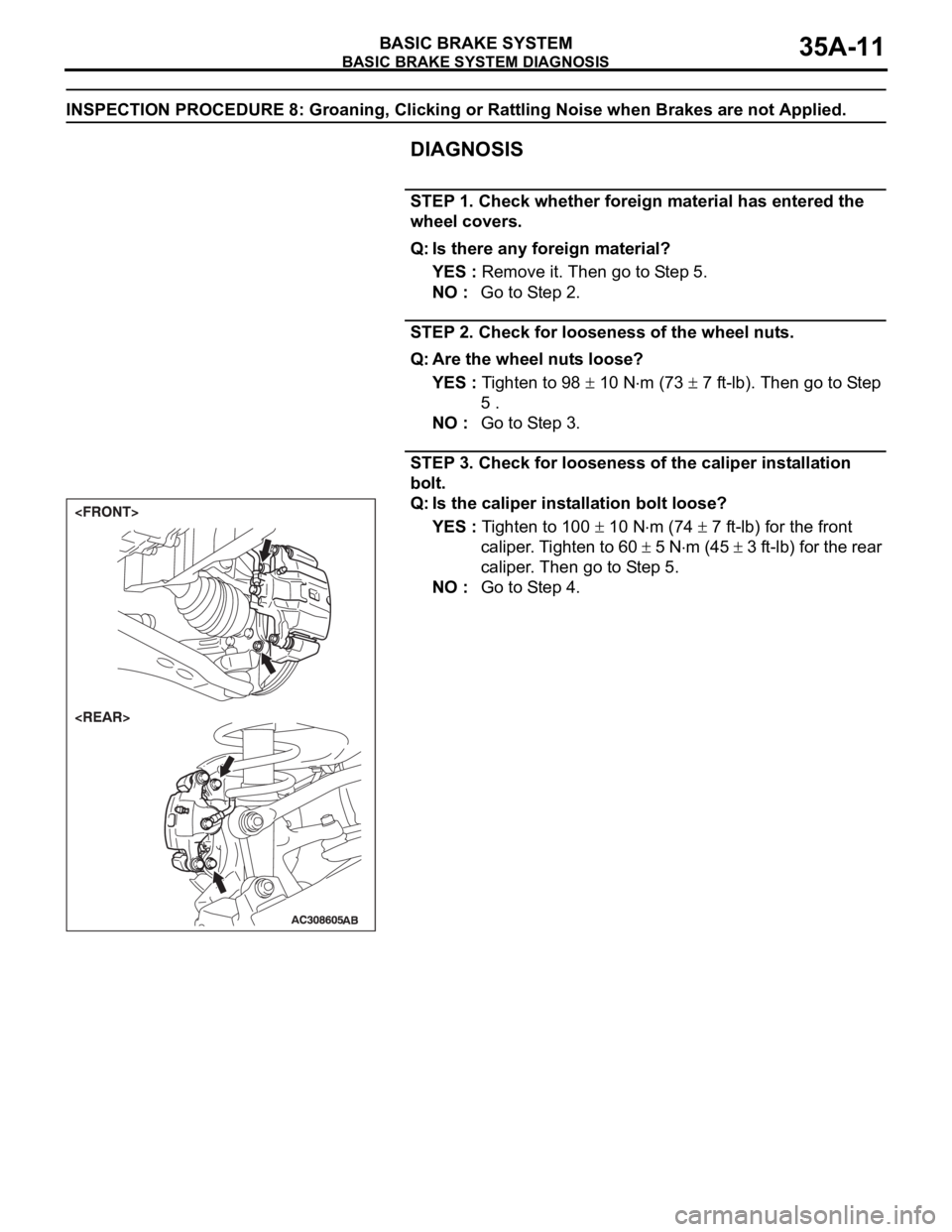

STEP 3. Check for looseness of the caliper installation

bolt.

Q: Is the caliper installation bolt loose?

YES : Tighten to 100

10 Nm (74 7 ft-lb) for the front

caliper. Tighten to 60

5 Nm (45 3 ft-lb) for the rear

caliper. Then go to Step 5.

NO : Go to Step 4.