fluid MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1160 of 1500

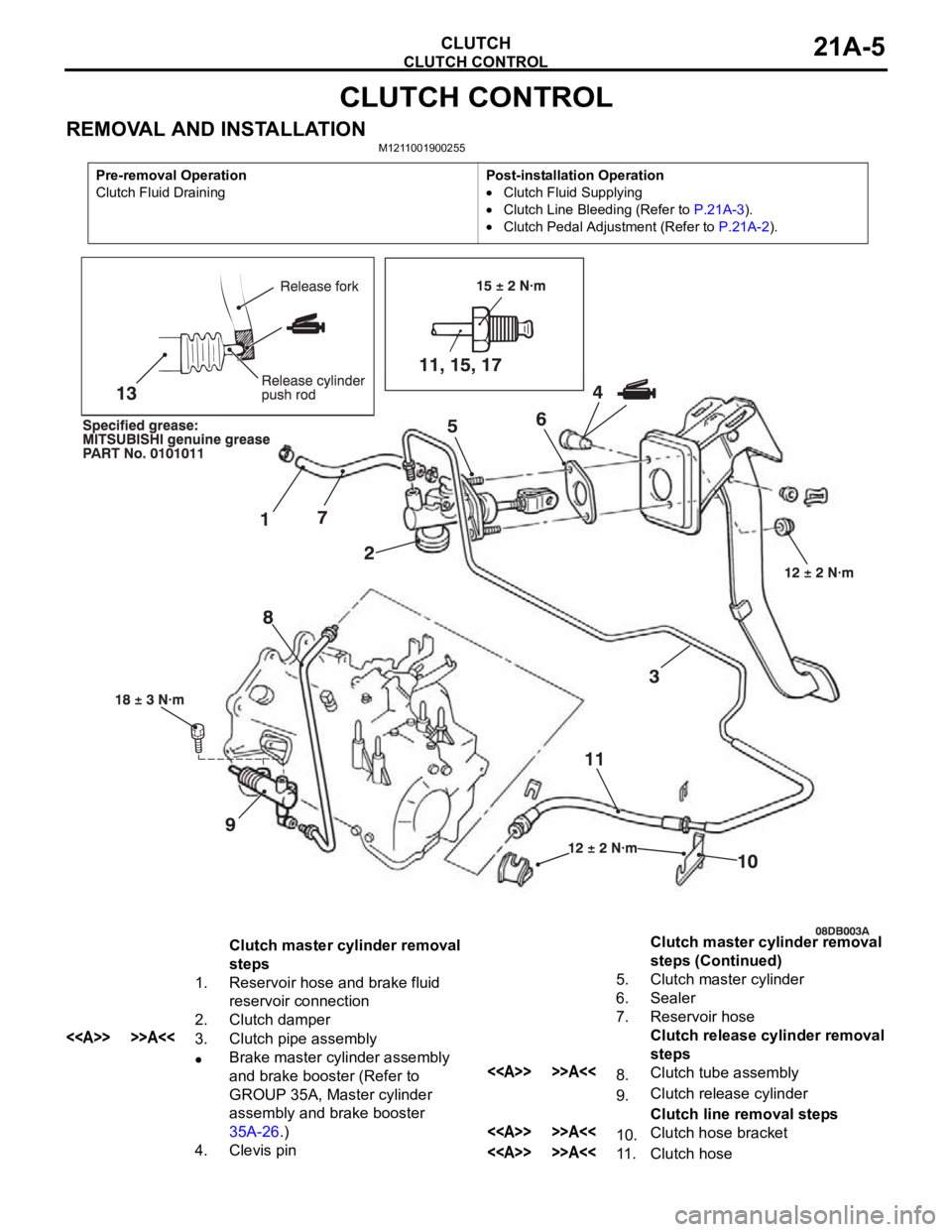

CLUTCH CONTROL

CLUTCH21A-5

CLUTCH CONTROL

REMOVAL AND INSTALLATIONM1211001900255

Pre-removal Operation

Clutch Fluid DrainingPost-installation Operation

Clutch Fluid Supplying

Clutch Line Bleeding (Refer to P.21A-3).

Clutch Pedal Adjustment (Refer to P.21A-2).

Clutch master cylinder removal

steps

1. Reservoir hose and brake fluid

reservoir connection

2. Clutch damper

<> >>A<<3. Clutch pipe assembly

Brake master cylinder assembly

and brake booster (Refer to

GROUP 35A, Master cylinder

assembly and brake booster

35A-26.)

4. Clevis pin5. Clutch master cylinder

6. Sealer

7. Reservoir hose

Clutch release cylinder removal

steps<> >>A<<8.Clutch tube assembly

9.Clutch release cylinder

Clutch line removal steps

<> >>A<<10.Clutch hose bracket

<> >>A<<11. Clutch hoseClutch master cylinder removal

steps (Continued)

Page 1161 of 1500

Page 1166 of 1500

35A-1

GROUP 35A

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .35A-2

BASIC BRAKE SYSTEM DIAGNOSIS35A-3

INTRODUCTION TO BASIC BRAKE

SYSTEM DIAGNOSIS . . . . . . . . . . . . . . . . 35A-3

BASIC BRAKE SYSTEM DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . . . 35A-3

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 35A-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 35A-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .35A-12

ON-VEHICLE SERVICE . . . . . . . . . . .35A-13

BRAKE PEDAL CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 35A-13

BRAKE BOOSTER OPERATING TEST . . . 35A-14

CHECK VALVE OPERATION CHECK . . . . 35A-15

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 35A-16

BRAKE FLUID LEVEL SENSOR CHECK. . 35A-17

DISC BRAKE PAD CHECK AND

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 35A-17

DISC BRAKE ROTOR CHECK . . . . . . . . . . 35A-19

MASTER CYLINDER FUNCTION CHECK . 35A-23

BRAKE PEDAL. . . . . . . . . . . . . . . . . .35A-24

REMOVAL AND INSTALLATION . . . . . . . . 35A-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-25

MASTER CYLINDER ASSEMBLY

AND BRAKE BOOSTER . . . . . . . . . .35A-26

REMOVAL AND INSTALLATION . . . . . . . . 35A-26

MASTER CYLINDER . . . . . . . . . . . . . . . . . 35A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-29

DISC BRAKE ASSEMBLY . . . . . . . . .35A-30

REMOVAL AND INSTALLATION . . . . . . . . 35A-30

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-32

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY AND ASSEMBLY

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-38

SPECIFICATIONS . . . . . . . . . . . . . . .35A-40

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 35A-40

GENERAL SPECIFICATIONS . . . . . . . . . . 35A-40

SERVICE SPECIFICATIONS . . . . . . . . . . . 35A-41

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . 35A-41

Page 1167 of 1500

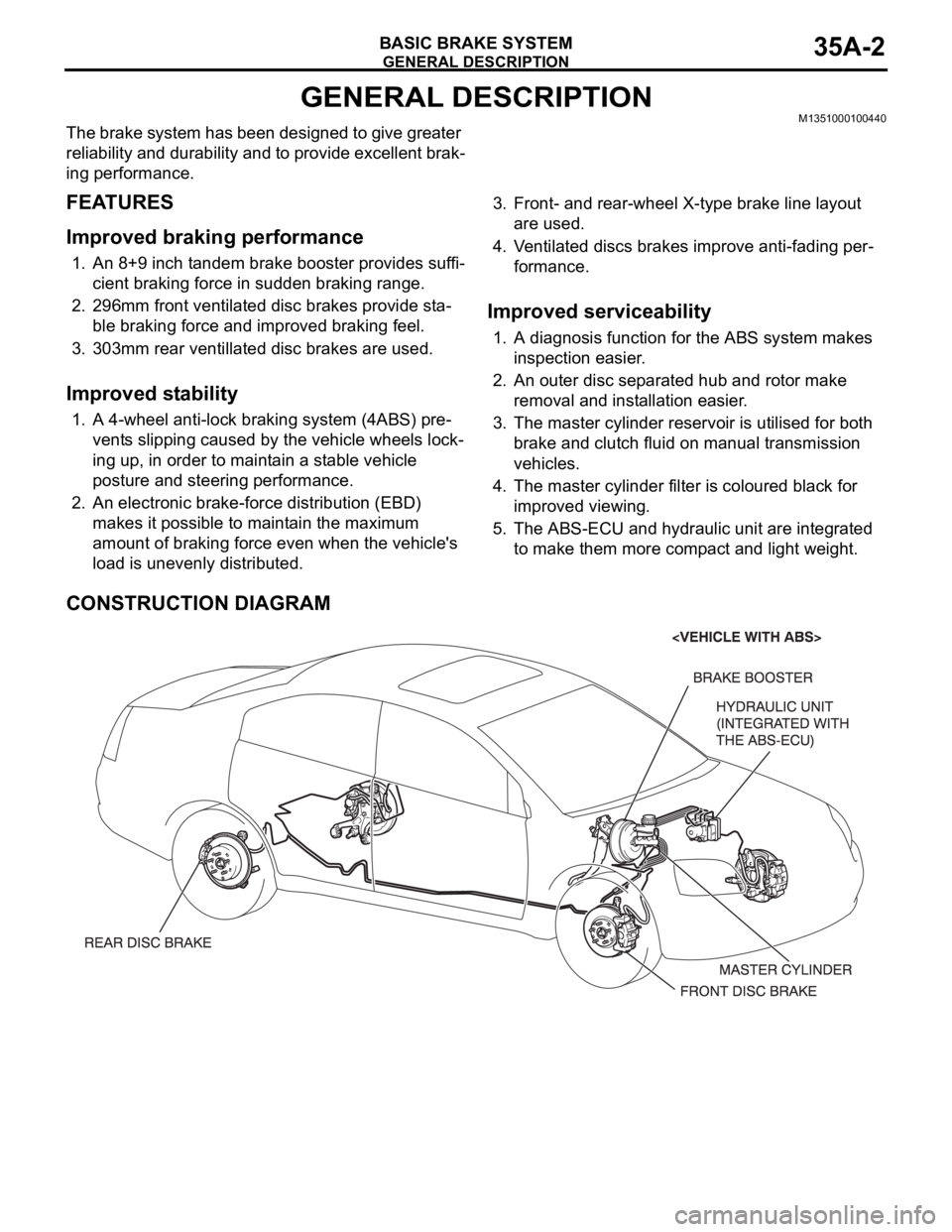

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM35A-2

GENERAL DESCRIPTIONM1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed. 3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM

Page 1169 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-4

STEP 2. Check disc brake pistons for smooth

operation.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete booster vacuum

reserves.

(2) Test each disc brake assembly one at a time.

a. Remove the lower caliper bolt, then remove

caliper from mount.

b. Have an assistant slowly depress the brake

pedal. Confirm piston(s) extend slowly and

smoothly with no jumpiness. Repeat for each

disc brake assembly.

Q: Do (does) the piston(s) move correctly?

YES :

Go to Step 3.

NO : Disassemble and inspect the brake

assembly (Front: refer to P.35A-33, Rear:

refer to P.35A-36). Then go to Step 5.

STEP 3. Check brake disc(s) for runout.

Refer to P.35A-19.

Q: Is runout outside of specifications?

YES :

Repair or replace the brake disc(s) as

necessary. Then go to Step 5.

NO : Go to Step 4.

STEP 4. Check brake discs for correct thickness.

Refer to P.35A-19.

Q: Is the thickness outside of specifications?

YES :

Repair or replace the brake disc(s) as

necessary. Then go to Step 5.

NO : Perform the brake line bleeding. Then go to

St e p 5.

STEP 5. Retest the system.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at Step 1. If a new symptom

appears, refer to the appropriate symptom

chart.

INSPECTION PROCEDURE 2: Insufficient Braking Power

.

DIAGNOSIS

STEP 1. Check that the specified brake fluid is

used, its level is correct, and no contamination is

found.

Q: Is there a fault?

YES :

Refill or replace with the specified brake

fluid DOT 3 or DOT 4. Bleed the brakes if

necessary (Refer to P.35A-16). Then go to

Step 7.

NO : Go to Step 2.

STEP 2. Check for spongy (not firm) brakes.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete the booster

vacuum reserve.

(2) With the brake pedal fully released, depress the

brake pedal slowly until it stops.

(3) With a measuring device (ruler, etc.) next to the

brake pedal, depress the pedal firmly and

measure the distance the pedal traveled.

Q: Is the distance greater than 20 mm (0.8 inch)?

YES :

Bleed the brakes to remove air in the fluid

(Refer to P.35A-16). Then go to Step 7.

NO : Go to Step 3.

STEP 3. Check the brake booster function.

Refer to P.35A-14.

Q: Is there a fault?

YES :

Replace the brake booster. Then go to Step

7.

NO : Go to Step 4.

Page 1170 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-5

STEP 4. Check for pinched or restricted brake

tube or hose.

Q: Is there a pinched or restricted brake tube or hose?

YES :

Replace that complete section of brake tube

or brake hose. Then go to Step 7.

NO : Go to Step 5.

STEP 5. Check for oil, water, etc., on the pad

contact surfaces of all brakes.

Q: Is oil, water, etc., on the pad contact surface?

YES :

Replace the part and determine the

source/cause of foreign material. Recheck

symptom. Then go to Step 7.

NO : The procedure is complete. If condition

persists for vehicles without ABS, go to Step

6.

STEP 7. Recheck symptom.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at step 1. If a new symptom

surfaces, refer to the appropriate symptom

chart.

INSPECTION PROCEDURE 3: Increased Pedal Stroke (Reduced Pedal-to-Floor Board Clearance)

.

DIAGNOSIS

STEP 1. Check for spongy (not firm) brakes.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete booster vacuum

reserve.

(2) With the brake pedal fully released, depress the

brake pedal slowly until it stops.

(3) With a measuring device (ruler, etc.) next to the

brake pedal, depress the pedal firmly and

measure the distance the pedal traveled.

Q: Is the distance greater than 20 mm (0.8 inch)?

YES :

Bleed the brakes to remove air in the fluid

(Refer to P.35A-16). Then go to Step 7.

NO : Go to Step 2.

STEP 2. Check the pad for wear.

Refer to P.35A-17.

Q: Is the pad thickness outside of specifications?

YES :

Replace the part. Then go to Step 7.

NO : Go to Step 3.

STEP 3. Check the vacuum hose and check valve

for damage.

Refer to P.35A-15.

Q: Is there a damage?

YES :

Replace the part. Then go to Step 7.

NO : Go to Step 4.

STEP 4. Check the master cylinder function.

Refer to P.35A-23.

Q: Is there a fault?

YES :

Repair it. Then go to Step 7.

NO : Go to Step 5.

STEP 5. Check for brake fluid leaks.

Q: Is there a leak?

YES :

Check the connection for looseness,

corrosion, etc. Clean and repair as

necessary. If leaking in any tube or hose

section, replace the complete tube or hose.

Then go to Step 7 .

NO : Go to Step 6.

STEP 6. Check for excessive clearance between

the push rod and primary piston.

Refer to P.35A-26.

Q: Is the clearance outside of specifications?

YES :

Adjust the clearance. Then go to Step 7.

NO : Go to Step 7.

STEP 7. Recheck symptom.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at step 1. If a new symptom

surfaces, refer to the symptom chart.

Page 1181 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-16

BLEEDINGM1351001400455

Use only brake fluid DOT 3 or DOT 4. Never mix the speci-

fied brake fluid with other fluid as it will influence the brak-

ing performance significantly.

.

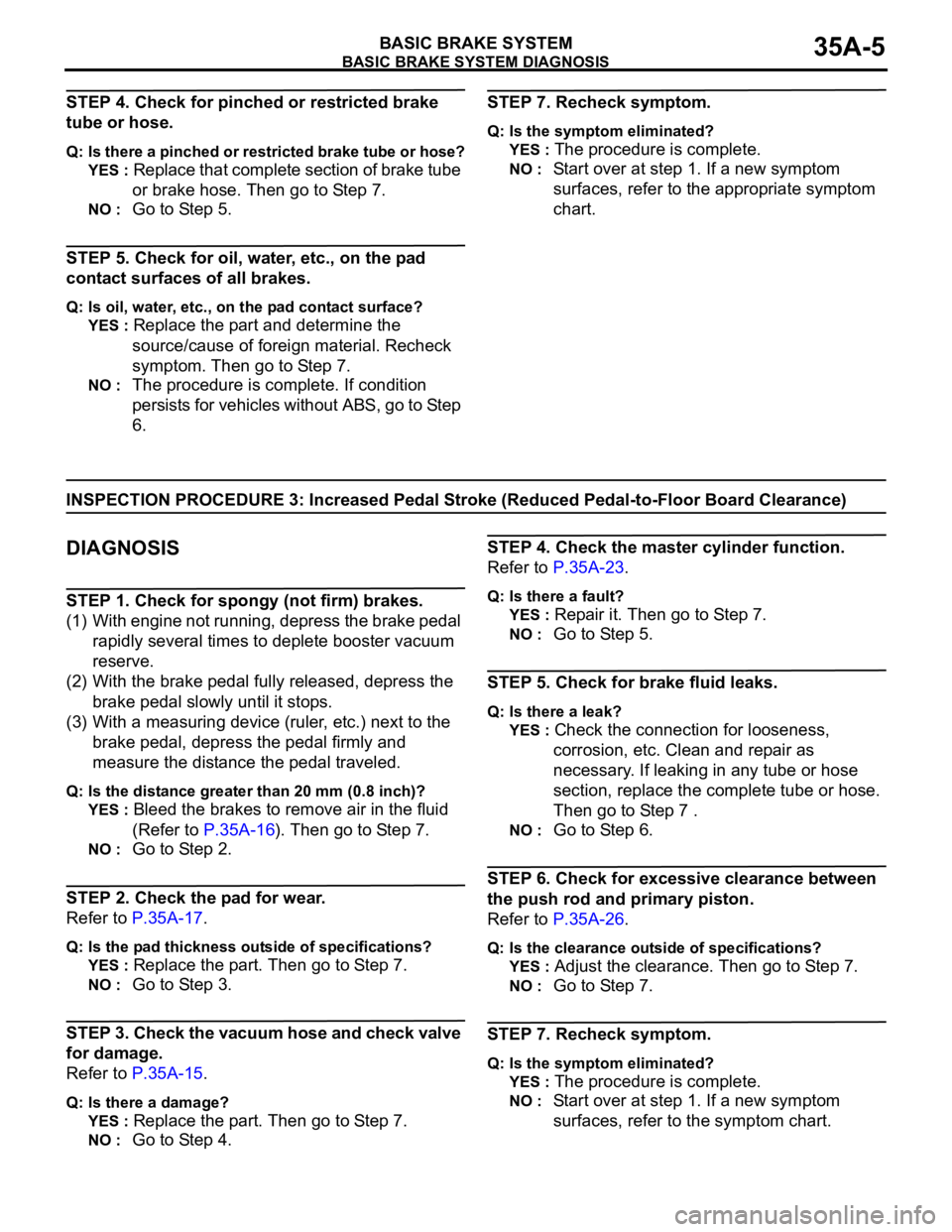

MASTER CYLINDER BLEEDING

The master cylinder used has no check valve, so if bleeding is

carried out by the following procedure, bleeding of air from the

brake pipeline will become easier. (When brake fluid is not con-

tained in the master cylinder).

1. Fill the reserve tank with brake fluid.

2. Keep the brake pedal depressed.

3. Have another person cover the master cylinder outlet with a

finger.

4. With the outlet still closed, release the brake pedal.

5. Repeat steps 2

4 three or four times to fill the inside of the

master cylinder with brake fluid.

.

BRAKE LINE BLEEDING

Start the engine and bleed the air in the sequence shown in the

figure.

Page 1182 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-17

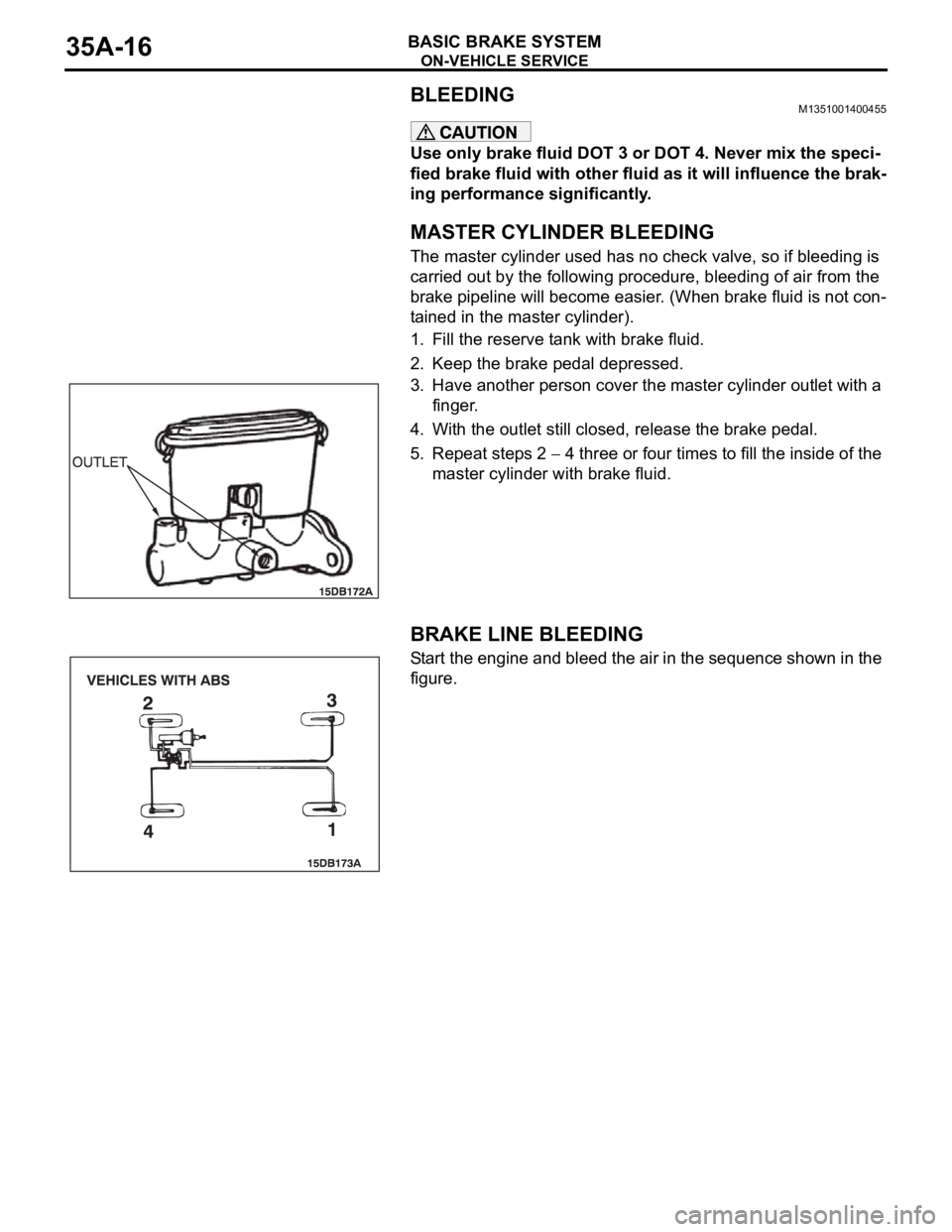

BRAKE FLUID LEVEL SENSOR CHECKM1351009100403

The brake fluid level sensor is in good condition if there is no

continuity when the float surface is above "MIN" and if there is

continuity when the float surface is below "MIN".

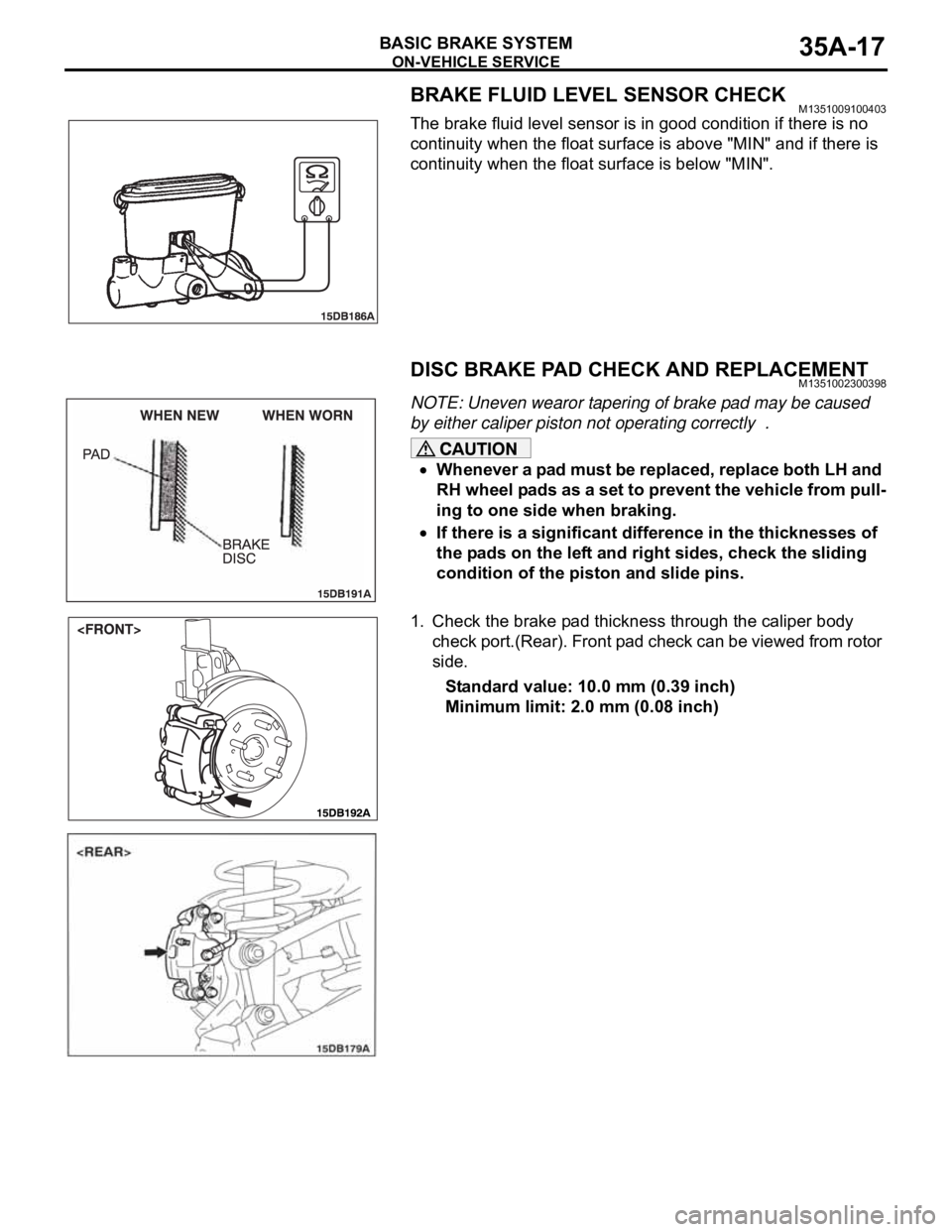

DISC BRAKE PAD CHECK AND REPLACEMENTM1351002300398

NOTE: Uneven wearor tapering of brake pad may be caused

by either caliper piston not operating correctly .

Whenever a pad must be replaced, replace both LH and

RH wheel pads as a set to prevent the vehicle from pull-

ing to one side when braking.

If there is a significant difference in the thicknesses of

the pads on the left and right sides, check the sliding

condition of the piston and slide pins.

1. Check the brake pad thickness through the caliper body

check port.(Rear). Front pad check can be viewed from rotor

side.

Standard value: 10.0 mm (0.39 inch)

Minimum limit: 2.0 mm (0.08 inch)

Page 1188 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-23

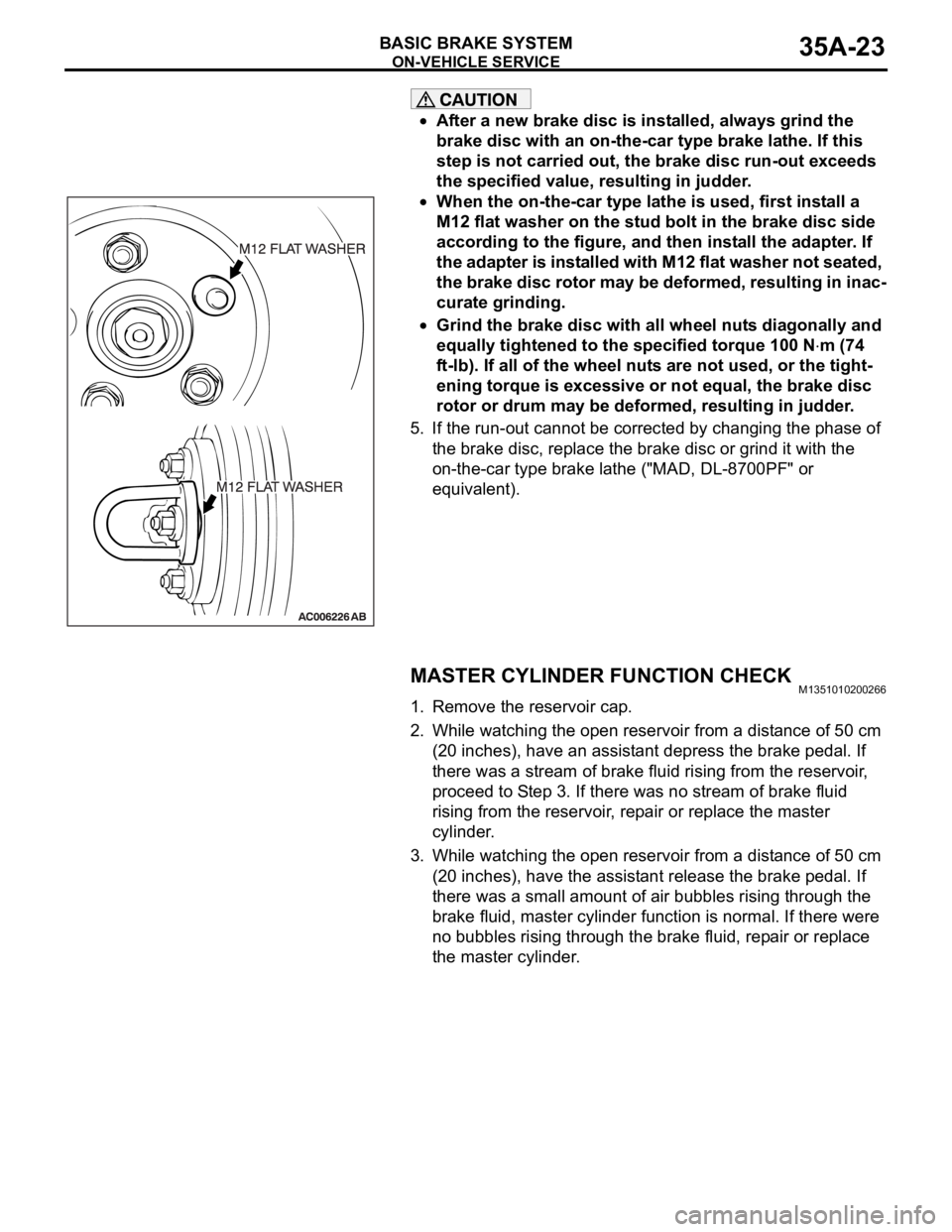

After a new brake disc is installed, always grind the

brake disc with an on-the-car type brake lathe. If this

step is not carried out, the brake disc run-out exceeds

the specified value, resulting in judder.

When the on-the-car type lathe is used, first install a

M12 flat washer on the stud bolt in the brake disc side

according to the figure, and then install the adapter. If

the adapter is installed with M12 flat washer not seated,

the brake disc rotor may be deformed, resulting in inac-

curate grinding.

Grind the brake disc with all wheel nuts diagonally and

equally tightened to the specified torque 100 N

m (74

ft-lb). If all of the wheel nuts are not used, or the tight-

ening torque is excessive or not equal, the brake disc

rotor or drum may be deformed, resulting in judder.

5. If the run-out cannot be corrected by changing the phase of

the brake disc, replace the brake disc or grind it with the

on-the-car type brake lathe ("MAD, DL-8700PF" or

equivalent).

MASTER CYLINDER FUNCTION CHECKM1351010200266

1. Remove the reservoir cap.

2. While watching the open reservoir from a distance of 50 cm

(20 inches), have an assistant depress the brake pedal. If

there was a stream of brake fluid rising from the reservoir,

proceed to Step 3. If there was no stream of brake fluid

rising from the reservoir, repair or replace the master

cylinder.

3. While watching the open reservoir from a distance of 50 cm

(20 inches), have the assistant release the brake pedal. If

there was a small amount of air bubbles rising through the

brake fluid, master cylinder function is normal. If there were

no bubbles rising through the brake fluid, repair or replace

the master cylinder.

Page 1191 of 1500

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-26

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

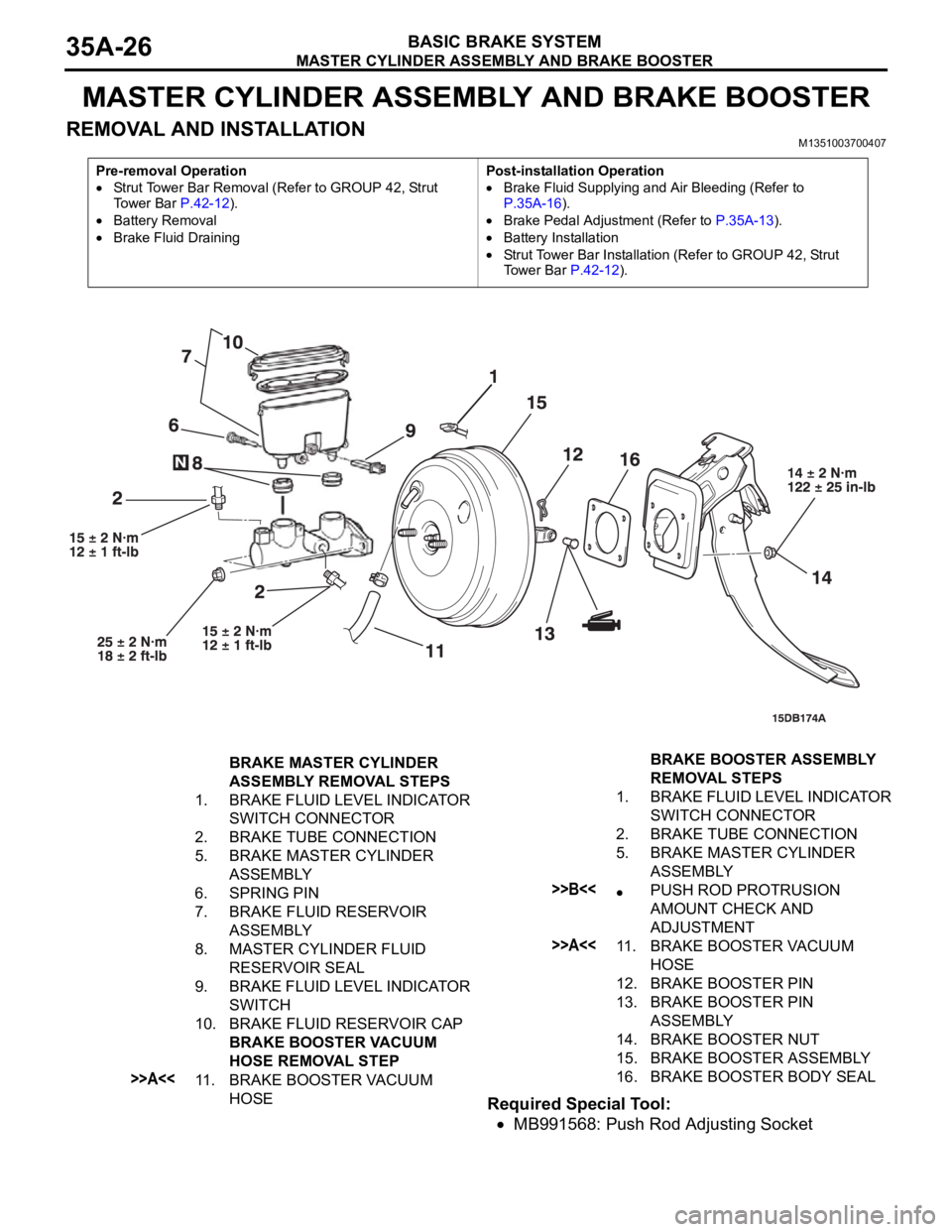

REMOVAL AND INSTALLATIONM1351003700407

Required Special Tool:

MB991568: Push Rod Adjusting Socket

Pre-removal Operation

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Battery Removal

Brake Fluid DrainingPost-installation Operation

Brake Fluid Supplying and Air Bleeding (Refer to

P.35A-16).

Brake Pedal Adjustment (Refer to P.35A-13).

Battery Installation

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

BRAKE MASTER CYLINDER

ASSEMBLY REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

6. SPRING PIN

7. BRAKE FLUID RESERVOIR

ASSEMBLY

8. MASTER CYLINDER FLUID

RESERVOIR SEAL

9. BRAKE FLUID LEVEL INDICATOR

SWITCH

10. BRAKE FLUID RESERVOIR CAP

BRAKE BOOSTER VACUUM

HOSE REMOVAL STEP

>>A<<11. BRAKE BOOSTER VACUUM

HOSE BRAKE BOOSTER ASSEMBLY

REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

>>B<

ADJUSTMENT

>>A<<11. BRAKE BOOSTER VACUUM

HOSE

12. BRAKE BOOSTER PIN

13. BRAKE BOOSTER PIN

ASSEMBLY

14. BRAKE BOOSTER NUT

15. BRAKE BOOSTER ASSEMBLY

16. BRAKE BOOSTER BODY SEAL