fuel MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 605 of 1500

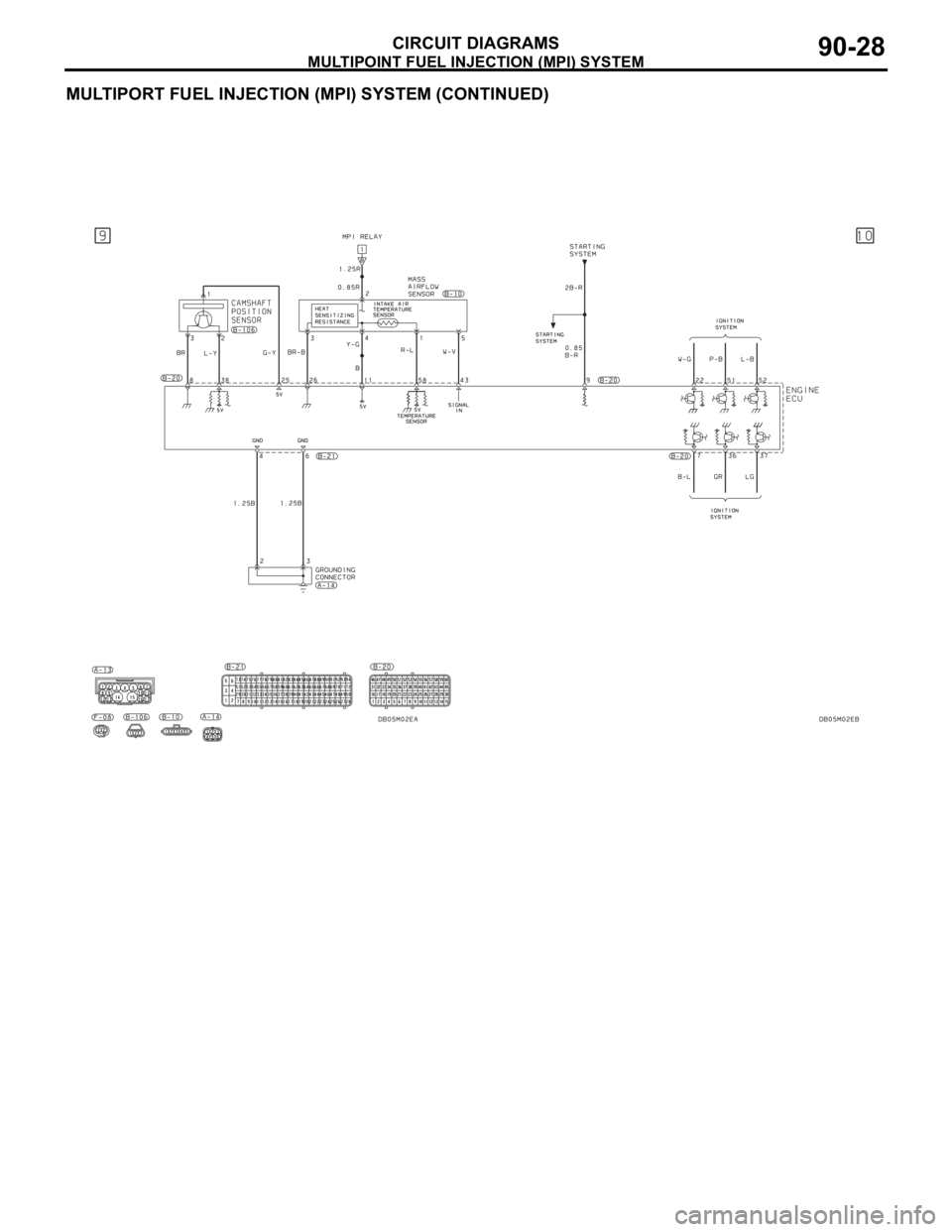

MULTIPOINT FUEL INJECTION (MPI) SYSTEM

CIRCUIT DIAGRAMS90-28

MULTIPORT FUEL INJECTION (MPI) SYSTEM (CONTINUED)

Page 637 of 1500

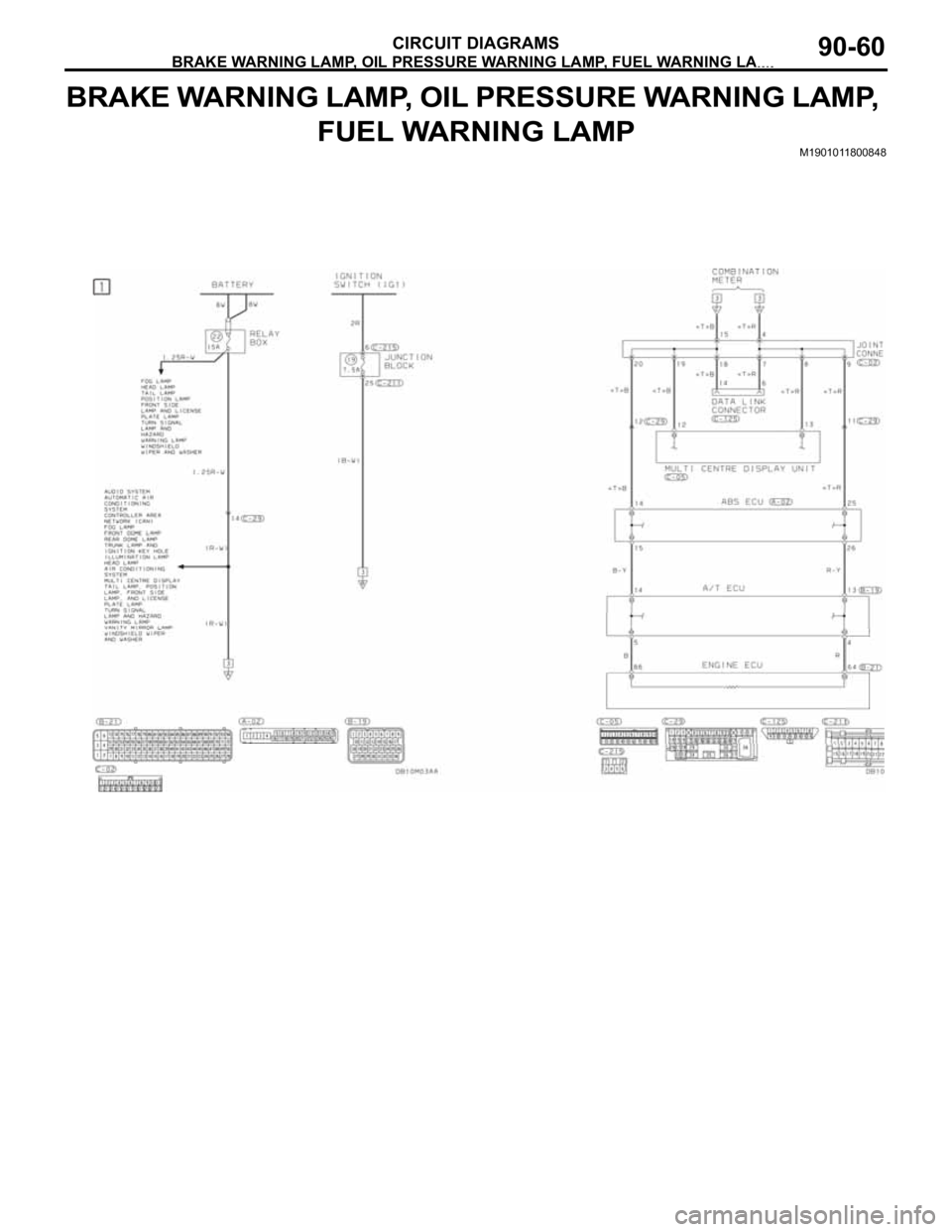

BRAKE WARNING LAMP, OIL PRESSURE WARNING LAMP, FUEL WARNING LAMP

CIRCUIT DIAGRAMS90-60

BRAKE WARNING LAMP, OIL PRESSURE WARNING LAMP,

FUEL WARNING LAMP

M1901011800848

Page 638 of 1500

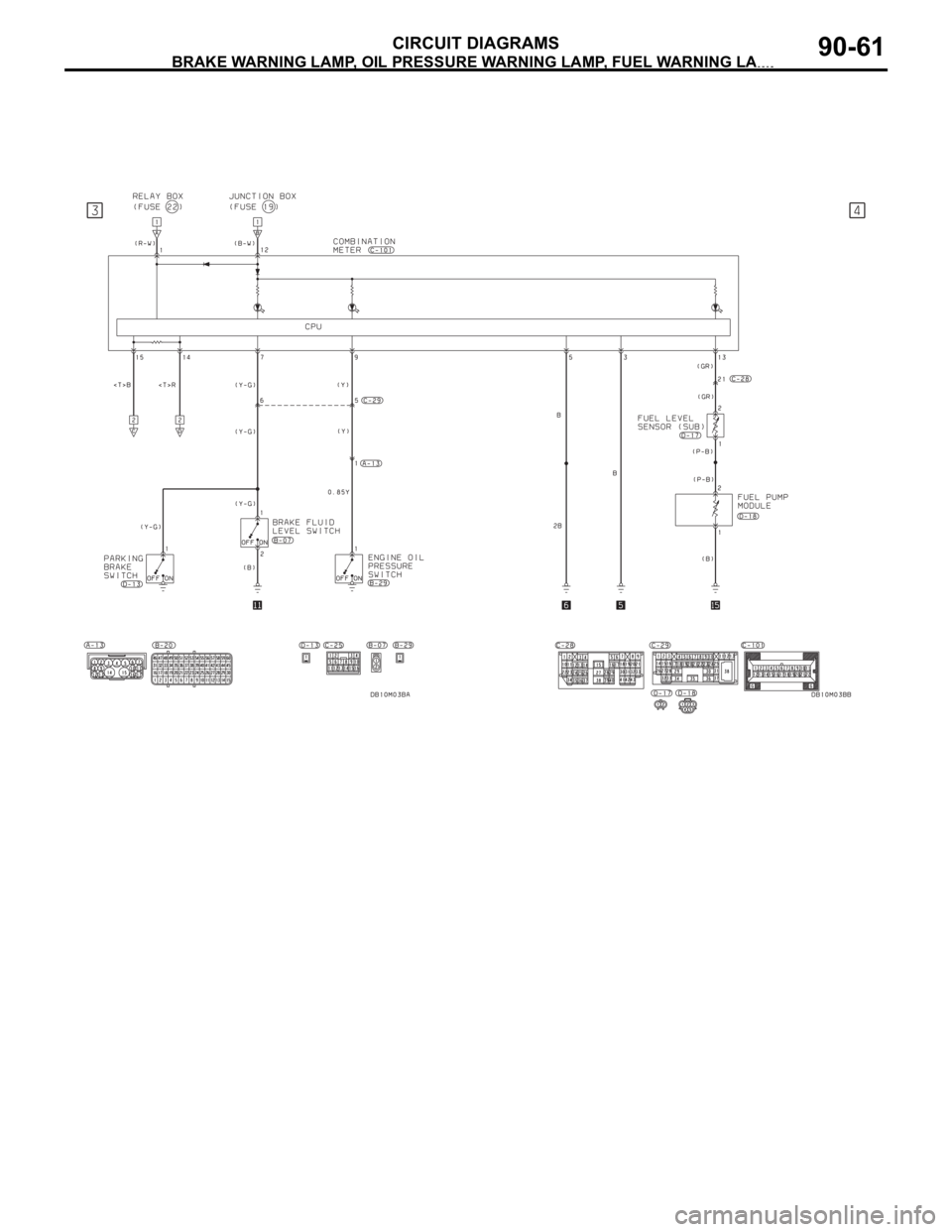

BRAKE WARNING LAMP, OIL PRESSURE WARNING LAMP, FUEL WARNING LAMP

CIRCUIT DIAGRAMS90-61

Page 885 of 1500

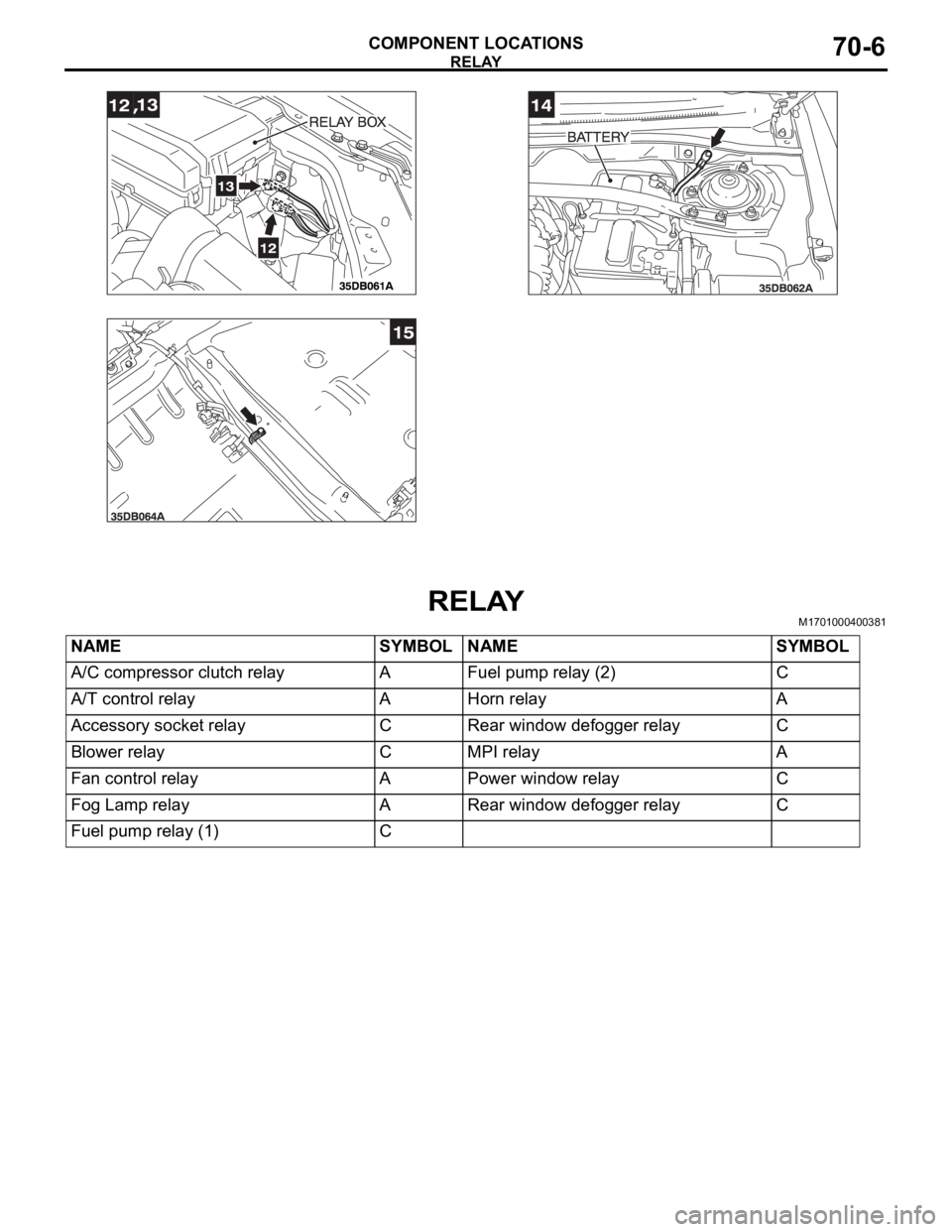

RELAY

COMPONENT LOCATIONS70-6

RELAYM1701000400381

NAME SYMBOL NAME SYMBOL

A/C compressor clutch relay A Fuel pump relay (2) C

A/T control relay A Horn relay A

Accessory socket relay C Rear window defogger relay C

Blower relay C MPI relay A

Fan control relay A Power window relay C

Fog Lamp relay A Rear window defogger relay C

Fuel pump relay (1) C

Page 887 of 1500

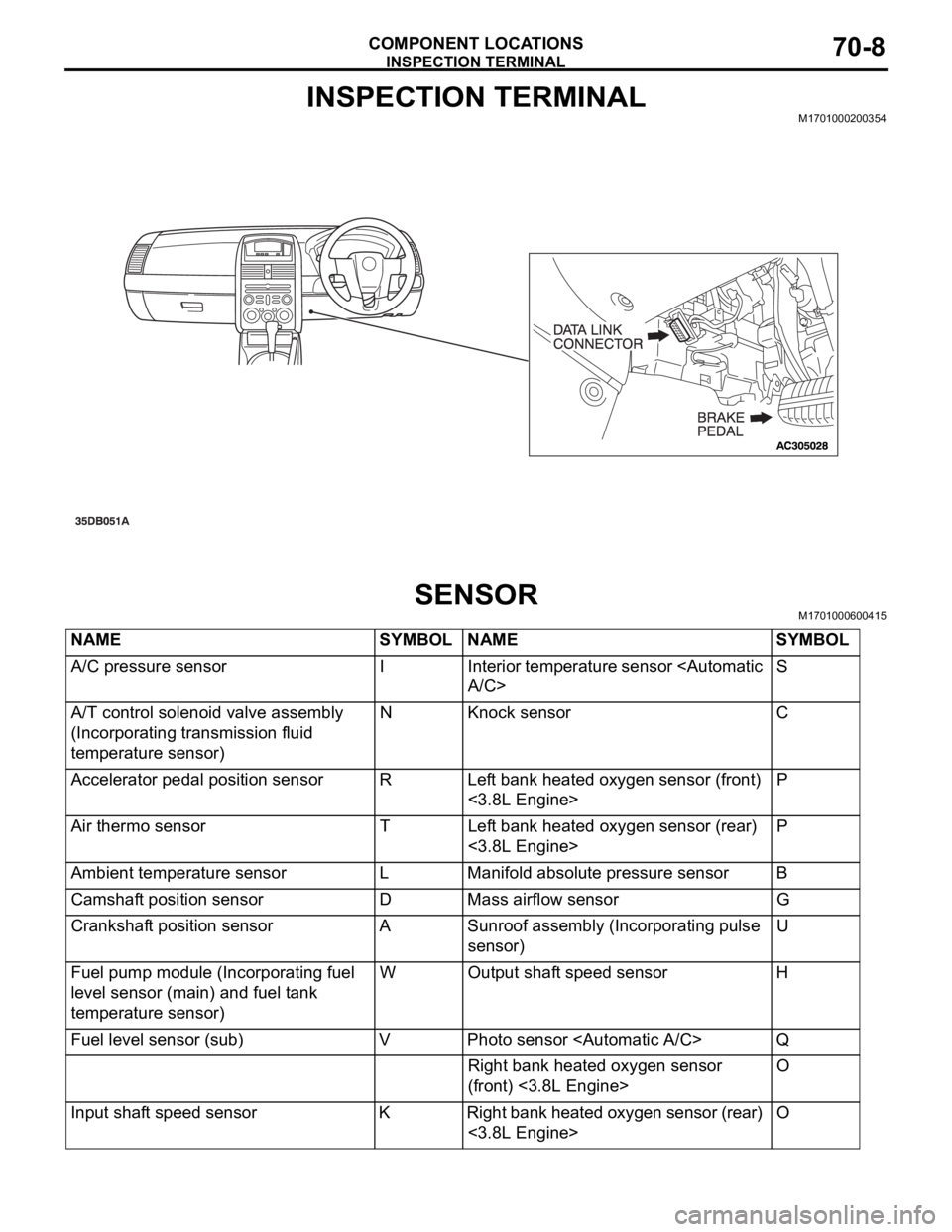

INSPECTION TERMINAL

COMPONENT LOCATIONS70-8

INSPECTION TERMINALM1701000200354

SENSORM1701000600415

NAME SYMBOL NAME SYMBOL

A/C pressure sensor I Interior temperature sensor

A/T control solenoid valve assembly

(Incorporating transmission fluid

temperature sensor)N Knock sensor C

Accelerator pedal position sensor R Left bank heated oxygen sensor (front)

<3.8L Engine>P

Air thermo sensor T Left bank heated oxygen sensor (rear)

<3.8L Engine>P

Ambient temperature sensor L Manifold absolute pressure sensor B

Camshaft position sensor D Mass airflow sensor G

Crankshaft position sensor A Sunroof assembly (Incorporating pulse

sensor)U

Fuel pump module (Incorporating fuel

level sensor (main) and fuel tank

temperature sensor)W Output shaft speed sensor H

Fuel level sensor (sub) V Photo sensor

Right bank heated oxygen sensor

(front) <3.8L Engine>O

Input shaft speed sensor K Right bank heated oxygen sensor (rear)

<3.8L Engine>O

Page 966 of 1500

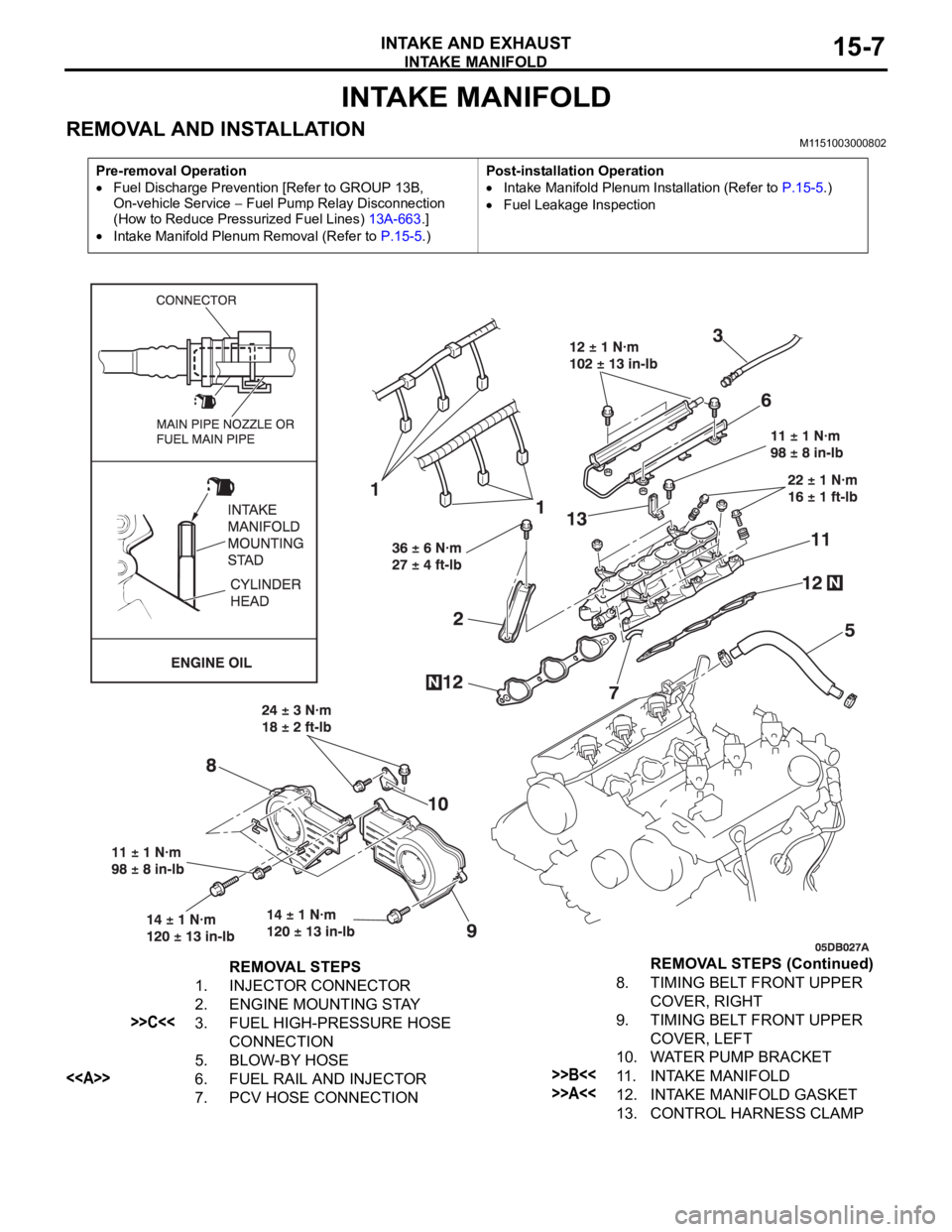

INTAKE MANIFOLD

INTAKE AND EXHAUST15-7

INTAKE MANIFOLD

REMOVAL AND INSTALLATION M1151003000802

Pre-removal Operation

Fuel Discharge Prevention [Refer to GROUP 13B,

On-vehicle Service

Fuel Pump Relay Disconnection

(How to Reduce Pressurized Fuel Lines) 13A-663.]

Intake Manifold Plenum Removal (Refer to P.15-5.)Post-installation Operation

Intake Manifold Plenum Installation (Refer to P.15-5.)

Fuel Leakage Inspection

REMOVAL STEPS

1. INJECTOR CONNECTOR

2. ENGINE MOUNTING STAY

>>C<<3. FUEL HIGH-PRESSURE HOSE

CONNECTION

5. BLOW-BY HOSE

<>6. FUEL RAIL AND INJECTOR

7. PCV HOSE CONNECTION8. TIMING BELT FRONT UPPER

COVER, RIGHT

9. TIMING BELT FRONT UPPER

COVER, LEFT

10. WATER PUMP BRACKET>>B<<11. INTAKE MANIFOLD

>>A<<12. INTAKE MANIFOLD GASKET

13. CONTROL HARNESS CLAMPREMOVAL STEPS (Continued)

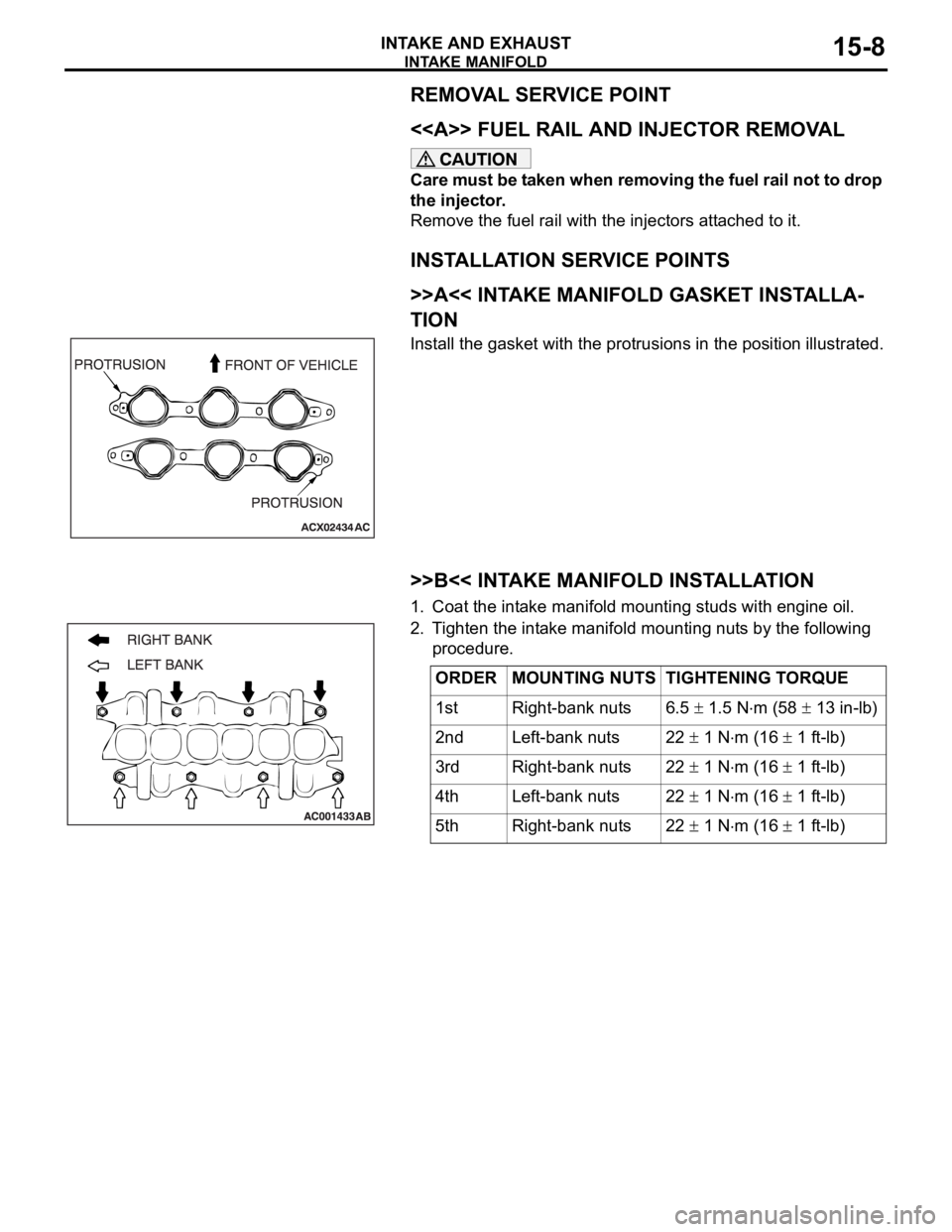

Page 967 of 1500

Page 968 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

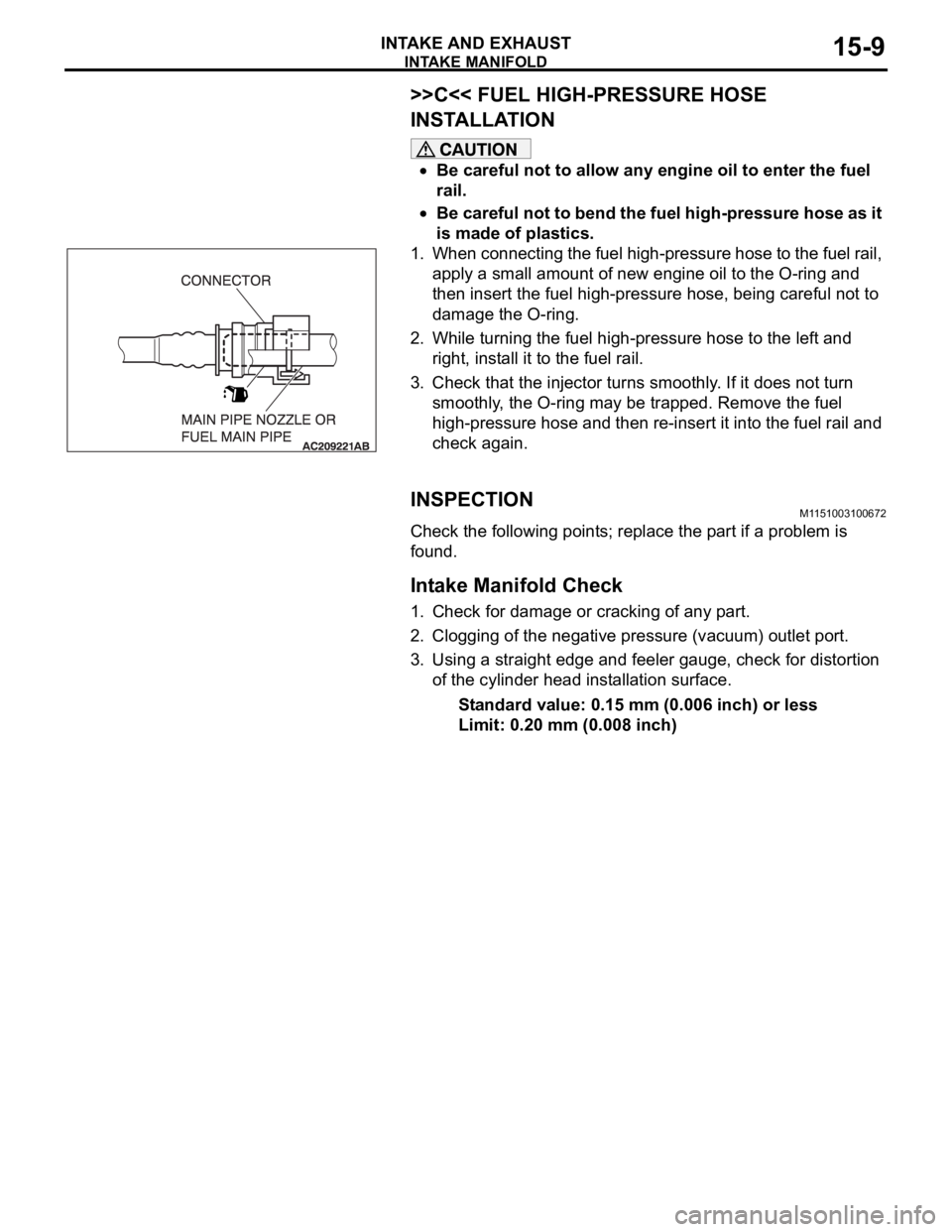

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 975 of 1500

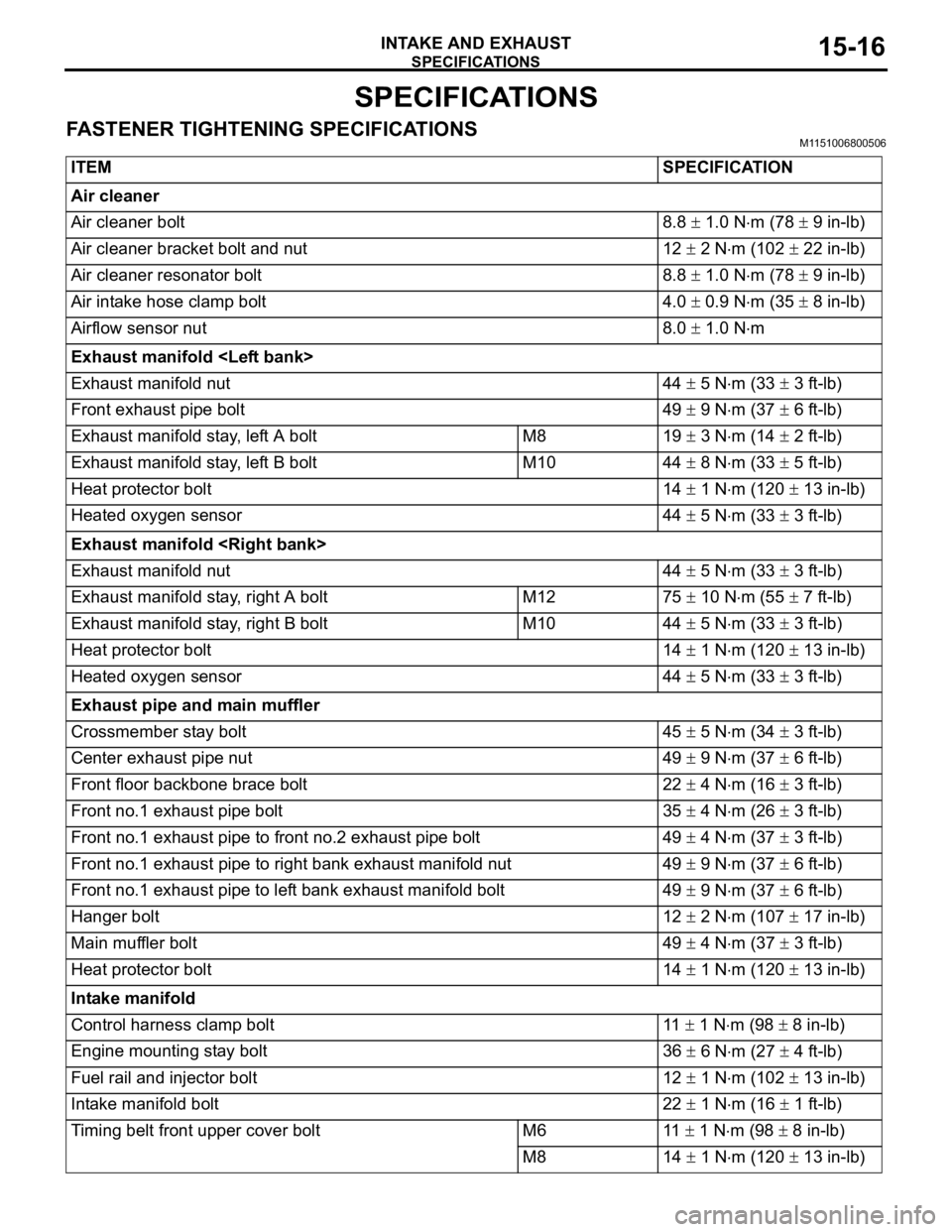

SPECIFICATIONS

INTAKE AND EXHAUST15-16

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1151006800506

ITEMSPECIFICATION

Air cleaner

Air cleaner bolt 8.8

1.0 Nm (78 9 in-lb)

Air cleaner bracket bolt and nut 12

2 Nm (102 22 in-lb)

Air cleaner resonator bolt 8.8

1.0 Nm (78 9 in-lb)

Air intake hose clamp bolt 4.0

0.9 Nm (35 8 in-lb)

Airflow sensor nut 8.0

1.0 Nm

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Front exhaust pipe bolt 49

9 Nm (37 6 ft-lb)

Exhaust manifold stay, left A bolt M8 19

3 Nm (14 2 ft-lb)

Exhaust manifold stay, left B bolt M10 44

8 Nm (33 5 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Exhaust manifold stay, right A bolt M12 75

10 Nm (55 7 ft-lb)

Exhaust manifold stay, right B bolt M10 44

5 Nm (33 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust pipe and main muffler

Crossmember stay bolt 45

5 Nm (34 3 ft-lb)

Center exhaust pipe nut 49

9 Nm (37 6 ft-lb)

Front floor backbone brace bolt 22

4 Nm (16 3 ft-lb)

Front no.1 exhaust pipe bolt 35

4 Nm (26 3 ft-lb)

Front no.1 exhaust pipe to front no.2 exhaust pipe bolt 49

4 Nm (37 3 ft-lb)

Front no.1 exhaust pipe to right bank exhaust manifold nut 49

9 Nm (37 6 ft-lb)

Front no.1 exhaust pipe to left bank exhaust manifold bolt 49

9 Nm (37 6 ft-lb)

Hanger bolt 12

2 Nm (107 17 in-lb)

Main muffler bolt 49

4 Nm (37 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Intake manifold

Control harness clamp bolt 11

1 Nm (98 8 in-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Fuel rail and injector bolt 12

1 Nm (102 13 in-lb)

Intake manifold bolt 22

1 Nm (16 1 ft-lb)

Timing belt front upper cover bolt M6 11

1 Nm (98 8 in-lb)

M8 14

1 Nm (120 13 in-lb)

Page 1008 of 1500

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

ON-VEHICLE SERVICE

KNOCK CONTROL SYSTEM CHECKM1163001800081

Check the knock sensor circuit if diagnostic trouble code, No.

P0325 is shown.

Refer to GROUP 13B, Multiport Fuel Injection (MPI)

Multiport

Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Pro-

cedures

DTC P0325 : Knock Sensor Circuit 13A-346.

IGNITION COIL CHECK M1163001200380

Check by the following procedure, and replace the coil if there

is a malfunction.

.

PRIMARY COIL AND IGNITION POWER

TRANSISTOR CONTINUITY CHECK

NOTE: No test can be performed on the Primary side of coil.

.

SECONDARY COIL CHECK

NOTE: It is impossible to check the secondary coil through the

continuity check as a diode is integrated in the secondary coil

circuit of this ignition coil. Accordingly, check the secondary coil

in the following procedure.

1. Disconnect the ignition coil connector.

2. Remove the ignition coil and install a new spark plug to the

ignition coil.

3. Connect the ignition coil connector.

4. Disable vehicle fuel pump by removing fuel pump relay or

disconnecting fuel pump connector D-18 (under rear seat).

5. Ground the side electrode of the spark plug and crank the

engine.

6. Check that spark is produced between the electrodes of the

spark plug.

7. If no spark is produced, replace the ignition coil with a new

one and recheck.

8. If spark is produced with the new ignition coil, replace the

old one as it is faulty. If no spark is produced again, the

ignition circuit is suspected as faulty. Check the ignition

circuit.