Ignition MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 441 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-441

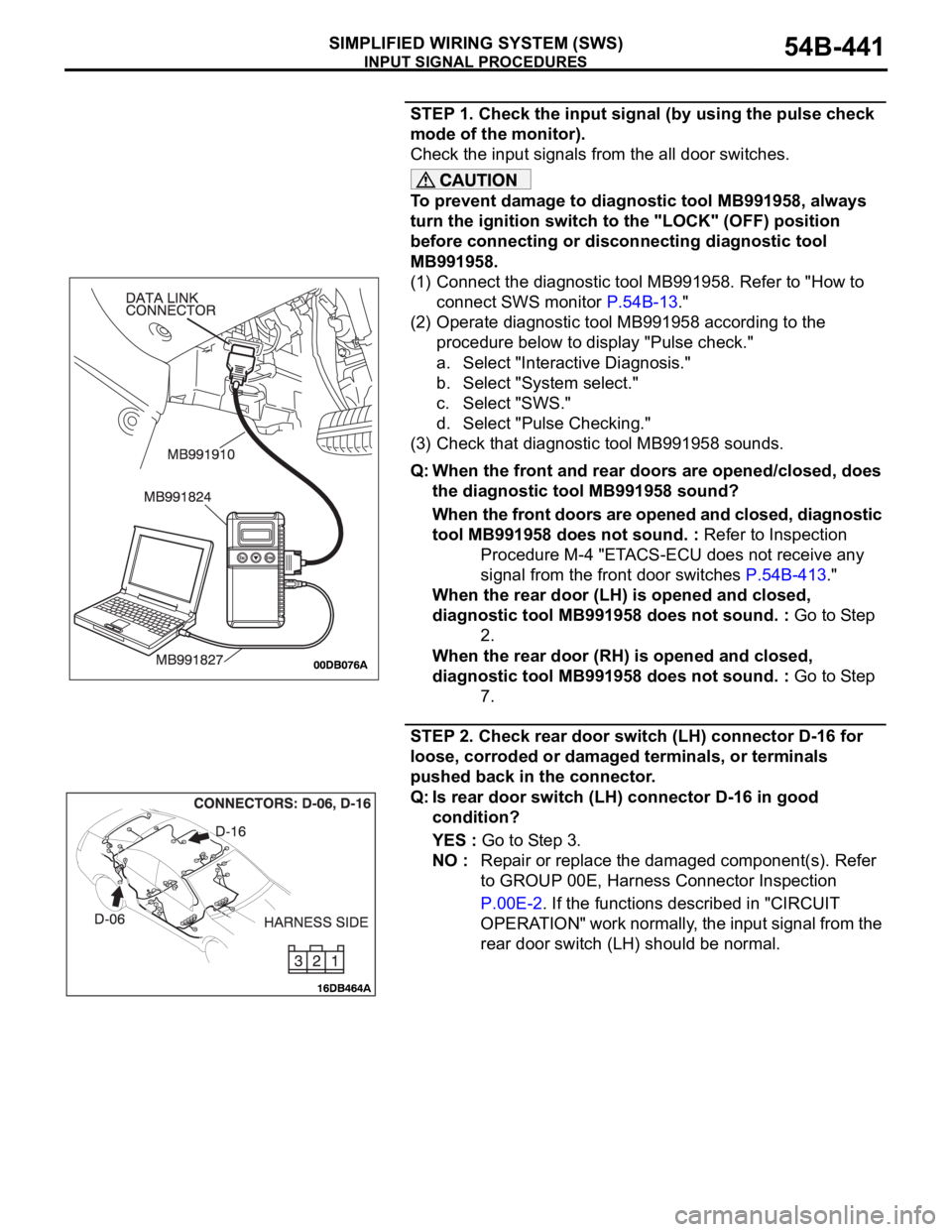

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the all door switches.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the front and rear doors are opened/closed, does

the diagnostic tool MB991958 sound?

When the front doors are opened and closed, diagnostic

tool MB991958 does not sound. : Refer to Inspection

Procedure M-4 "ETACS-ECU does not receive any

signal from the front door switches P.54B-413."

When the rear door (LH) is opened and closed,

diagnostic tool MB991958 does not sound. : Go to Step

2.

When the rear door (RH) is opened and closed,

diagnostic tool MB991958 does not sound. : Go to Step

7.

STEP 2. Check rear door switch (LH) connector D-16 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is rear door switch (LH) connector D-16 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

rear door switch (LH) should be normal.

Page 452 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-452

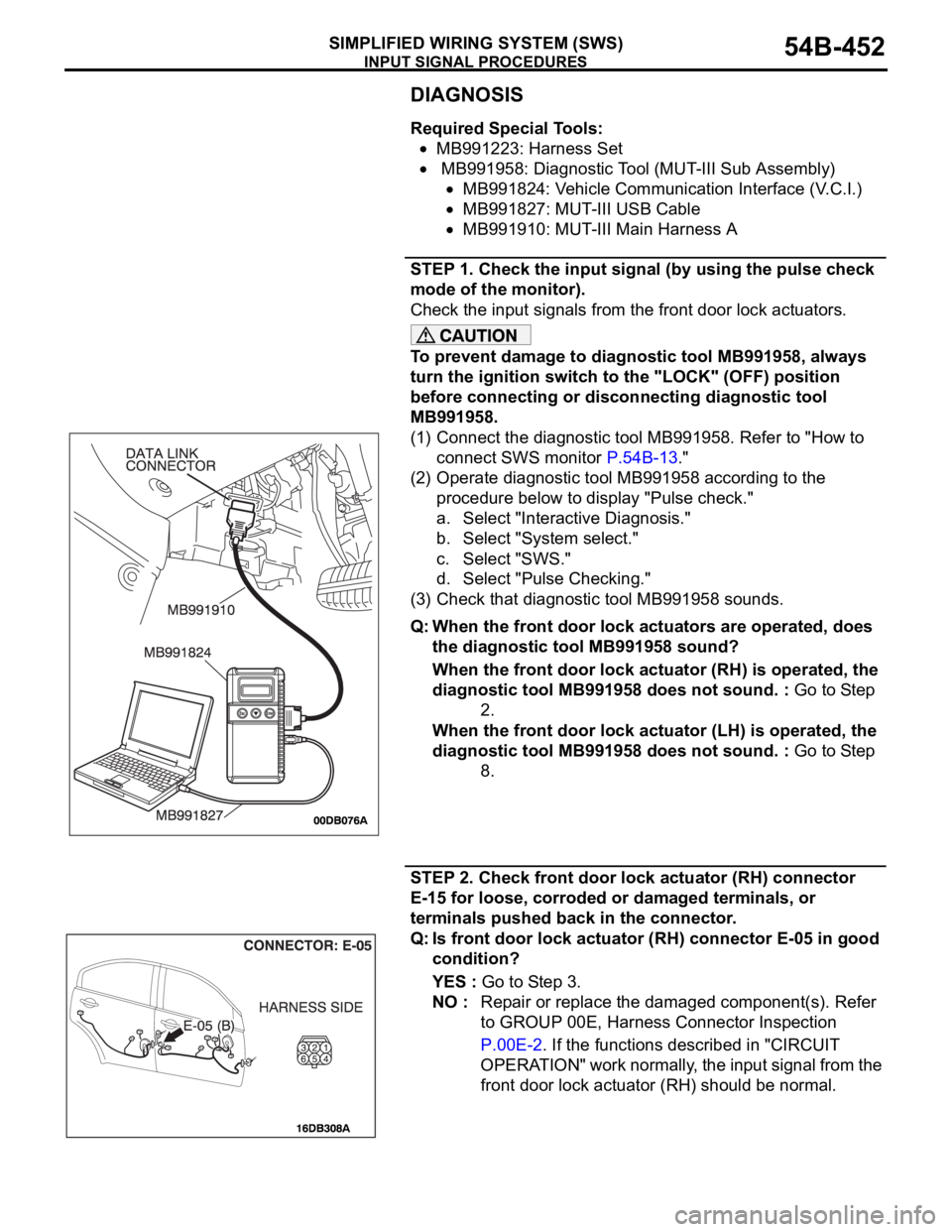

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the front door lock actuators.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the front door lock actuators are operated, does

the diagnostic tool MB991958 sound?

When the front door lock actuator (RH) is operated, the

diagnostic tool MB991958 does not sound. : Go to Step

2.

When the front door lock actuator (LH) is operated, the

diagnostic tool MB991958 does not sound. : Go to Step

8.

STEP 2. Check front door lock actuator (RH) connector

E-15 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front door lock actuator (RH) connector E-05 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

front door lock actuator (RH) should be normal.

Page 461 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-461

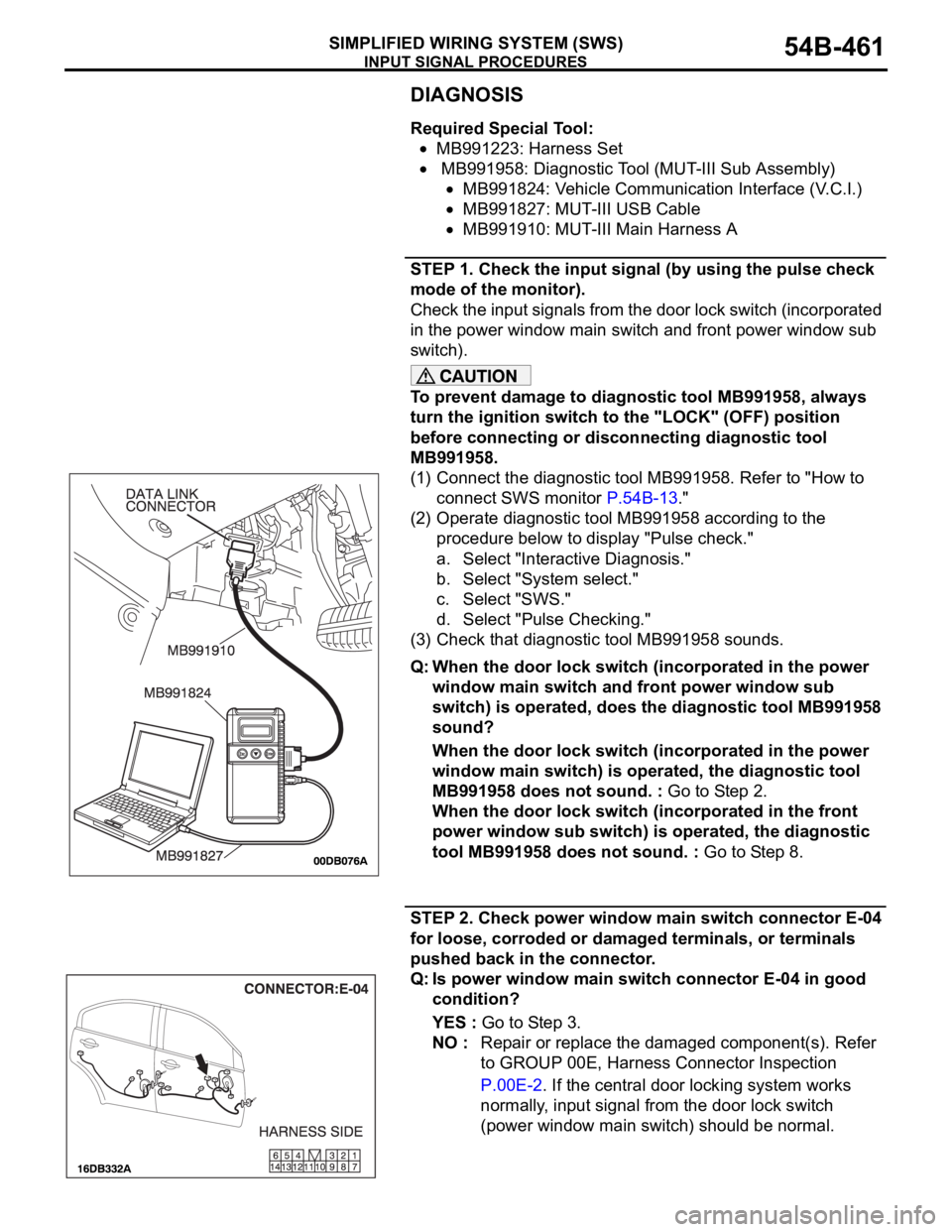

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the door lock switch (incorporated

in the power window main switch and front power window sub

switch).

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the door lock switch (incorporated in the power

window main switch and front power window sub

switch) is operated, does the diagnostic tool MB991958

sound?

When the door lock switch (incorporated in the power

window main switch) is operated, the diagnostic tool

MB991958 does not sound. : Go to Step 2.

When the door lock switch (incorporated in the front

power window sub switch) is operated, the diagnostic

tool MB991958 does not sound. : Go to Step 8.

STEP 2. Check power window main switch connector E-04

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window main switch connector E-04 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the central door locking system works

normally, input signal from the door lock switch

(power window main switch) should be normal.

Page 474 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-474

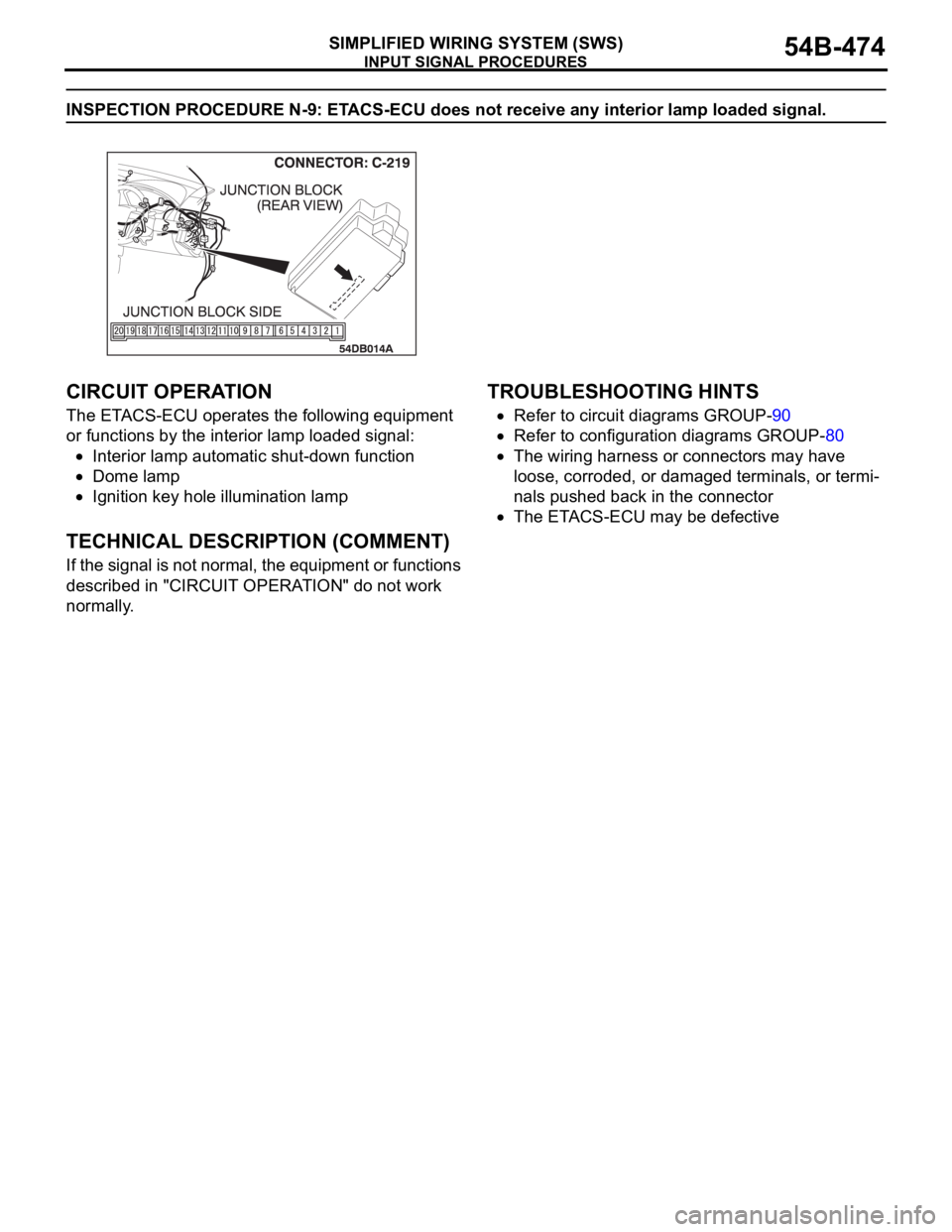

INSPECTION PROCEDURE N-9: ETACS-ECU does not receive any interior lamp loaded signal.

.

CIRCUIT OPERATION

The ETACS-ECU operates the following equipment

or functions by the interior lamp loaded signal:

Interior lamp automatic shut-down function

Dome lamp

Ignition key hole illumination lamp

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the equipment or functions

described in "CIRCUIT OPERATION" do not work

normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 477 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-477

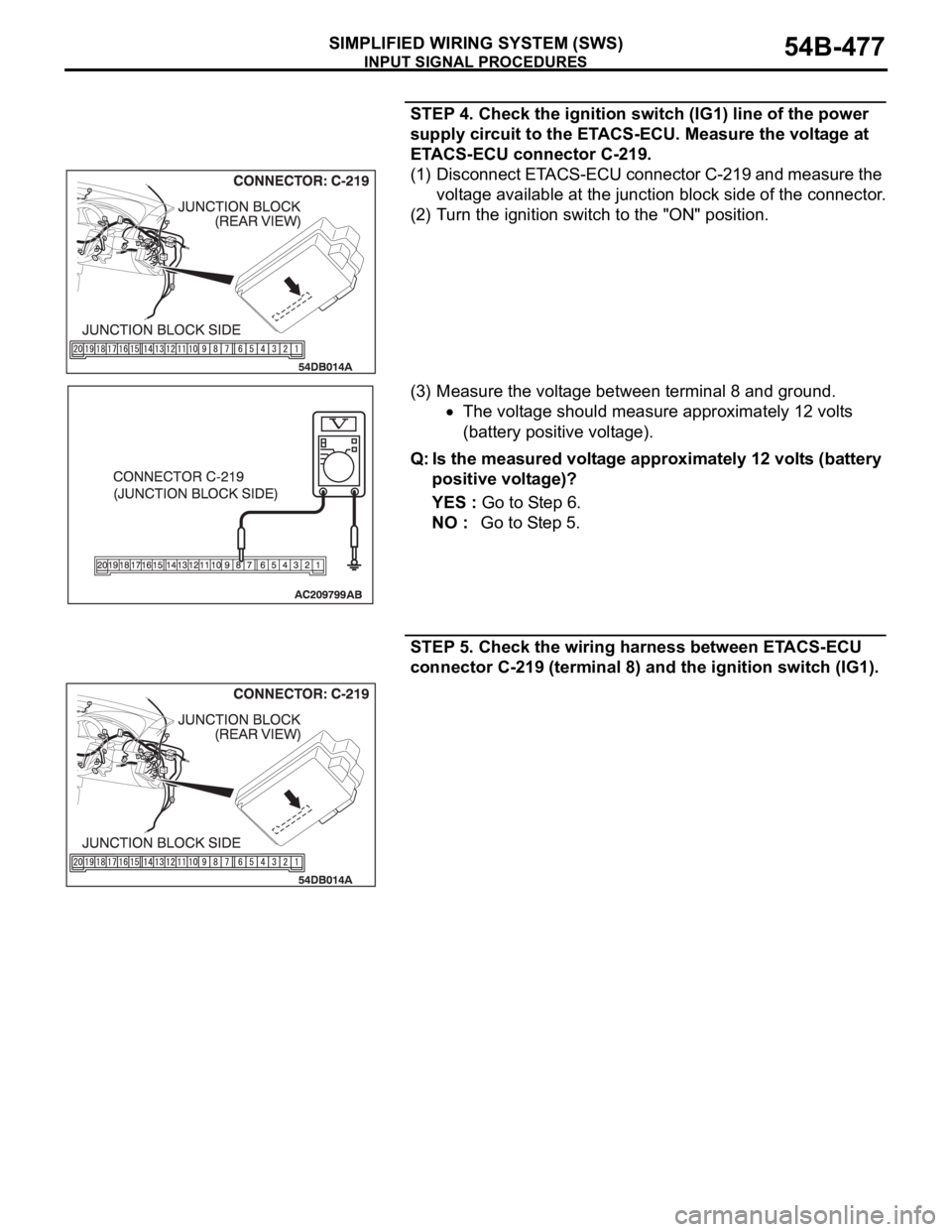

STEP 4. Check the ignition switch (IG1) line of the power

supply circuit to the ETACS-ECU. Measure the voltage at

ETACS-ECU connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

voltage available at the junction block side of the connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 8 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 6.

NO : Go to Step 5.

STEP 5. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 8) and the ignition switch (IG1).

Page 478 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-478

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 8) and the ignition switch (IG1) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. If the

functions or equipment described in "CIRCUIT

OPERATION" work normally, the interior lamp loaded

signal should be normal.

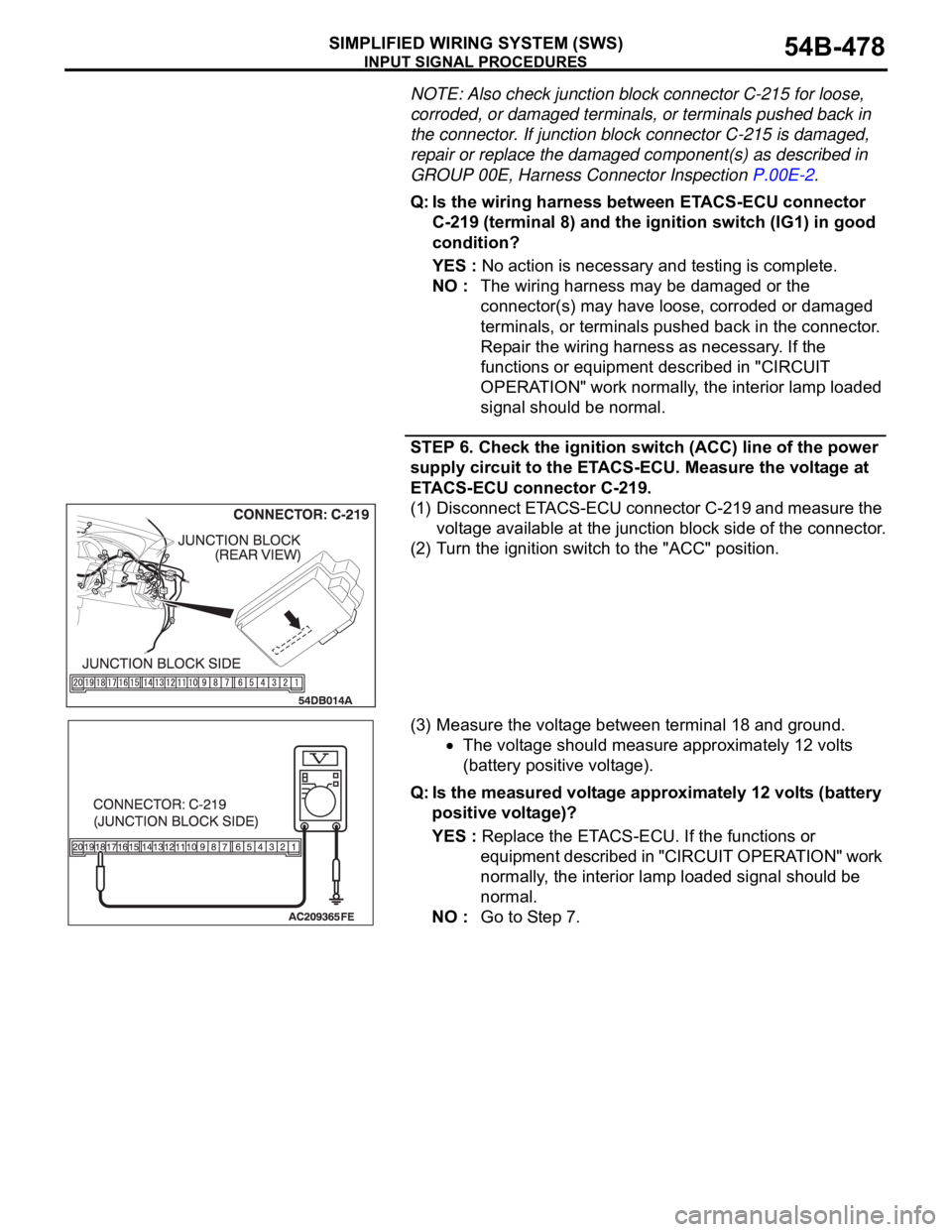

STEP 6. Check the ignition switch (ACC) line of the power

supply circuit to the ETACS-ECU. Measure the voltage at

ETACS-ECU connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

voltage available at the junction block side of the connector.

(2) Turn the ignition switch to the "ACC" position.

(3) Measure the voltage between terminal 18 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the ETACS-ECU. If the functions or

equipment described in "CIRCUIT OPERATION" work

normally, the interior lamp loaded signal should be

normal.

NO : Go to Step 7.

Page 479 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-479

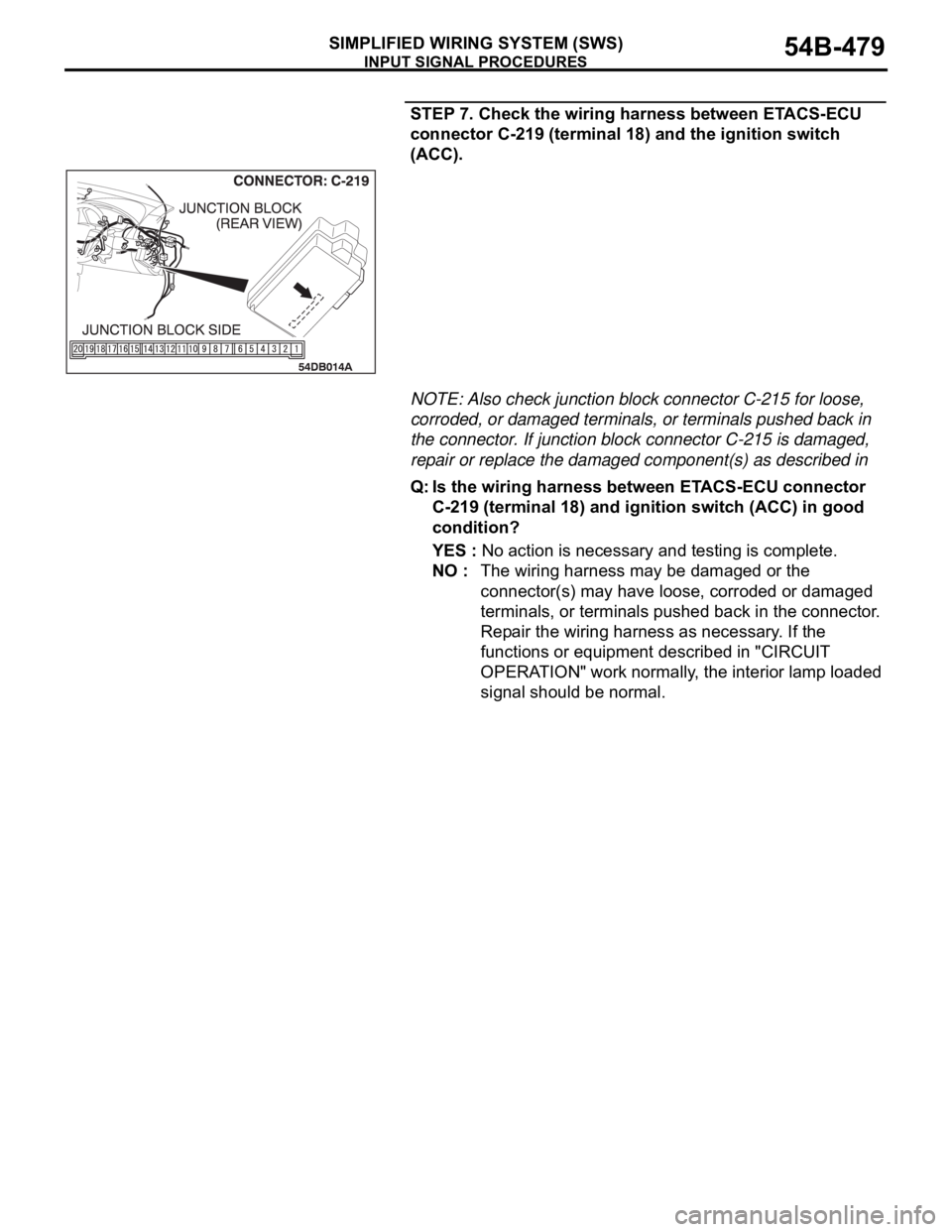

STEP 7. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 18) and the ignition switch

(ACC).

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the damaged component(s) as described in

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 18) and ignition switch (ACC) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. If the

functions or equipment described in "CIRCUIT

OPERATION" work normally, the interior lamp loaded

signal should be normal.

Page 480 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-480

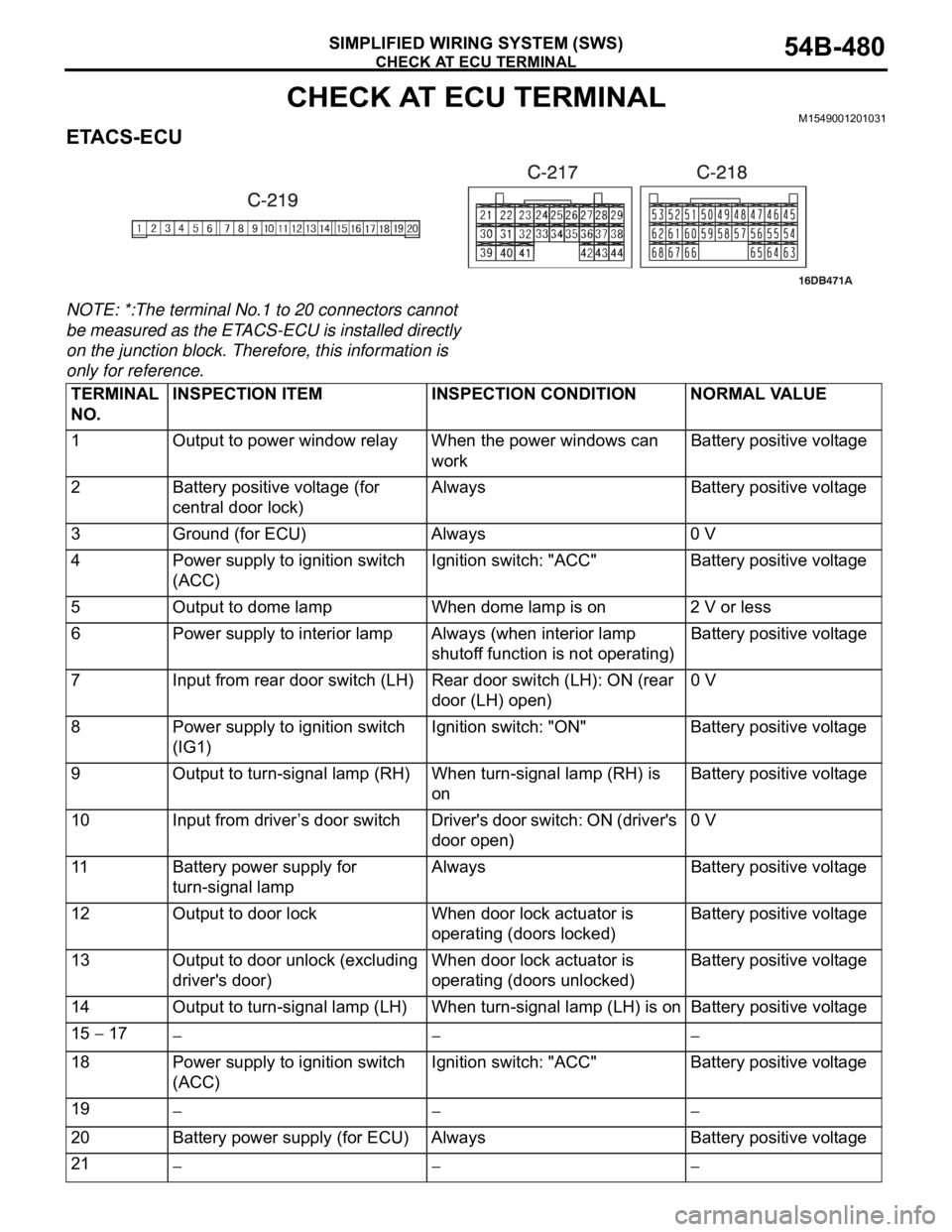

CHECK AT ECU TERMINALM1549001201031

ETACS-ECU

NOTE: *:The terminal No.1 to 20 connectors cannot

be measured as the ETACS-ECU is installed directly

on the junction block. Therefore, this information is

only for reference.

TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

1 Output to power window relay When the power windows can

workBattery positive voltage

2 Battery positive voltage (for

central door lock)Always Battery positive voltage

3 Ground (for ECU) Always 0 V

4 Power supply to ignition switch

(ACC)Ignition switch: "ACC" Battery positive voltage

5 Output to dome lamp When dome lamp is on 2 V or less

6 Power supply to interior lamp Always (when interior lamp

shutoff function is not operating)Battery positive voltage

7 Input from rear door switch (LH) Rear door switch (LH): ON (rear

door (LH) open)0 V

8 Power supply to ignition switch

(IG1)Ignition switch: "ON" Battery positive voltage

9 Output to turn-signal lamp (RH) When turn-signal lamp (RH) is

onBattery positive voltage

10 Input from driver’s door switch Driver's door switch: ON (driver's

door open)0 V

11 Battery power supply for

turn-signal lampAlways Battery positive voltage

12 Output to door lock When door lock actuator is

operating (doors locked)Battery positive voltage

13 Output to door unlock (excluding

driver's door)When door lock actuator is

operating (doors unlocked) Battery positive voltage

14 Output to turn-signal lamp (LH) When turn-signal lamp (LH) is on Battery positive voltage

15

17

18 Power supply to ignition switch

(ACC)Ignition switch: "ACC" Battery positive voltage

19

20 Battery power supply (for ECU) Always Battery positive voltage

21

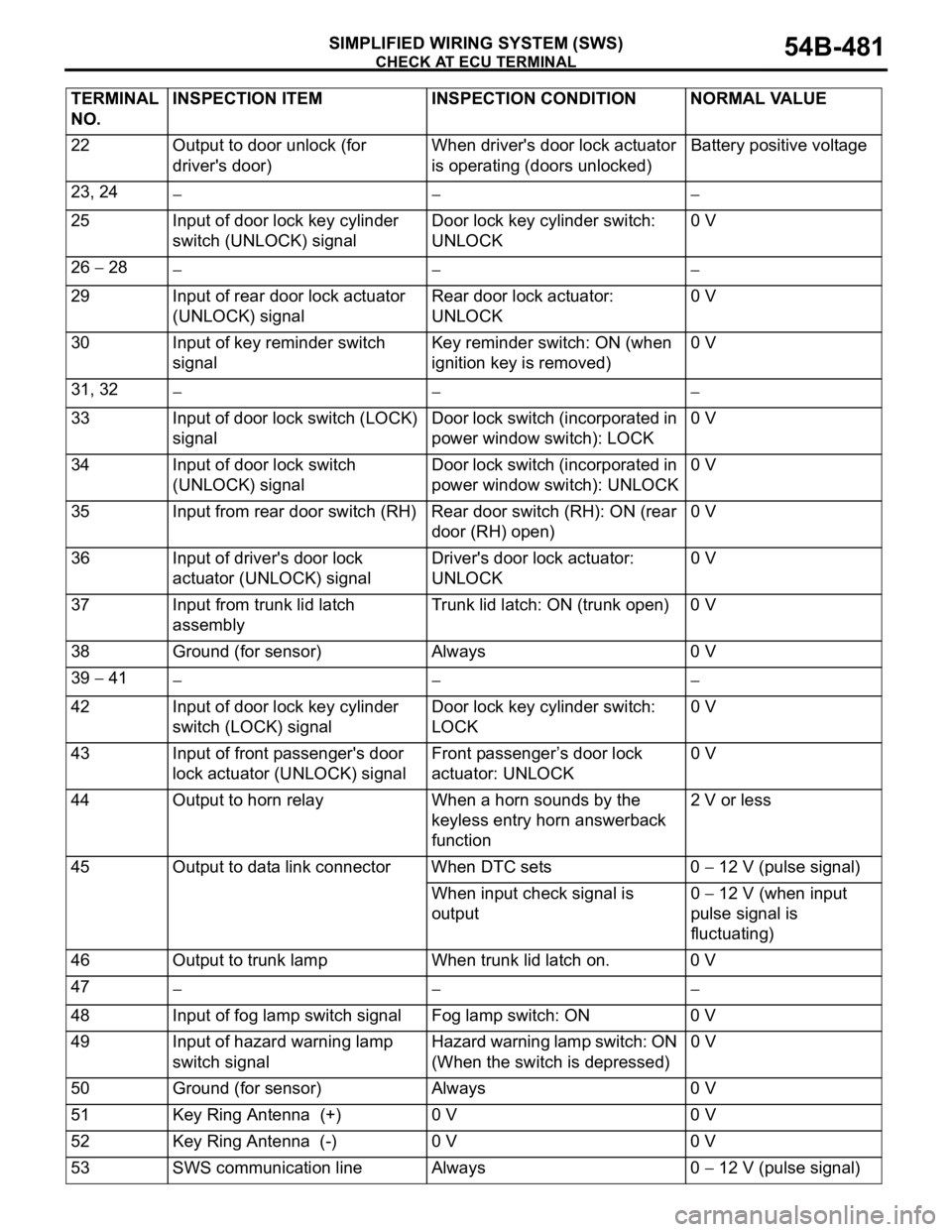

Page 481 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-481

22 Output to door unlock (for

driver's door)When driver's door lock actuator

is operating (doors unlocked)Battery positive voltage

23, 24

25 Input of door lock key cylinder

switch (UNLOCK) signalDoor lock key cylinder switch:

UNLOCK0 V

26

28

29 Input of rear door lock actuator

(UNLOCK) signalRear door lock actuator:

UNLOCK0 V

30 Input of key reminder switch

signalKey reminder switch: ON (when

ignition key is removed)0 V

31, 32

33 Input of door lock switch (LOCK)

signalDoor lock switch (incorporated in

power window switch): LOCK0 V

34 Input of door lock switch

(UNLOCK) signalDoor lock switch (incorporated in

power window switch): UNLOCK0 V

35 Input from rear door switch (RH) Rear door switch (RH): ON (rear

door (RH) open)0 V

36 Input of driver's door lock

actuator (UNLOCK) signalDriver's door lock actuator:

UNLOCK0 V

37 Input from trunk lid latch

assemblyTrunk lid latch: ON (trunk open) 0 V

38 Ground (for sensor) Always 0 V

39

41

42 Input of door lock key cylinder

switch (LOCK) signalDoor lock key cylinder switch:

LOCK0 V

43 Input of front passenger's door

lock actuator (UNLOCK) signalFront passenger’s door lock

actuator: UNLOCK0 V

44 Output to horn relay When a horn sounds by the

keyless entry horn answerback

function2 V or less

45 Output to data link connector When DTC sets 0

12 V (pulse signal)

When input check signal is

output0

12 V (when input

pulse signal is

fluctuating)

46 Output to trunk lamp When trunk lid latch on. 0 V

47

48 Input of fog lamp switch signal Fog lamp switch: ON 0 V

49 Input of hazard warning lamp

switch signalHazard warning lamp switch: ON

(When the switch is depressed)0 V

50 Ground (for sensor) Always 0 V

51 Key Ring Antenna (+) 0 V 0 V

52 Key Ring Antenna (-) 0 V 0 V

53 SWS communication line Always 0

12 V (pulse signal) TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

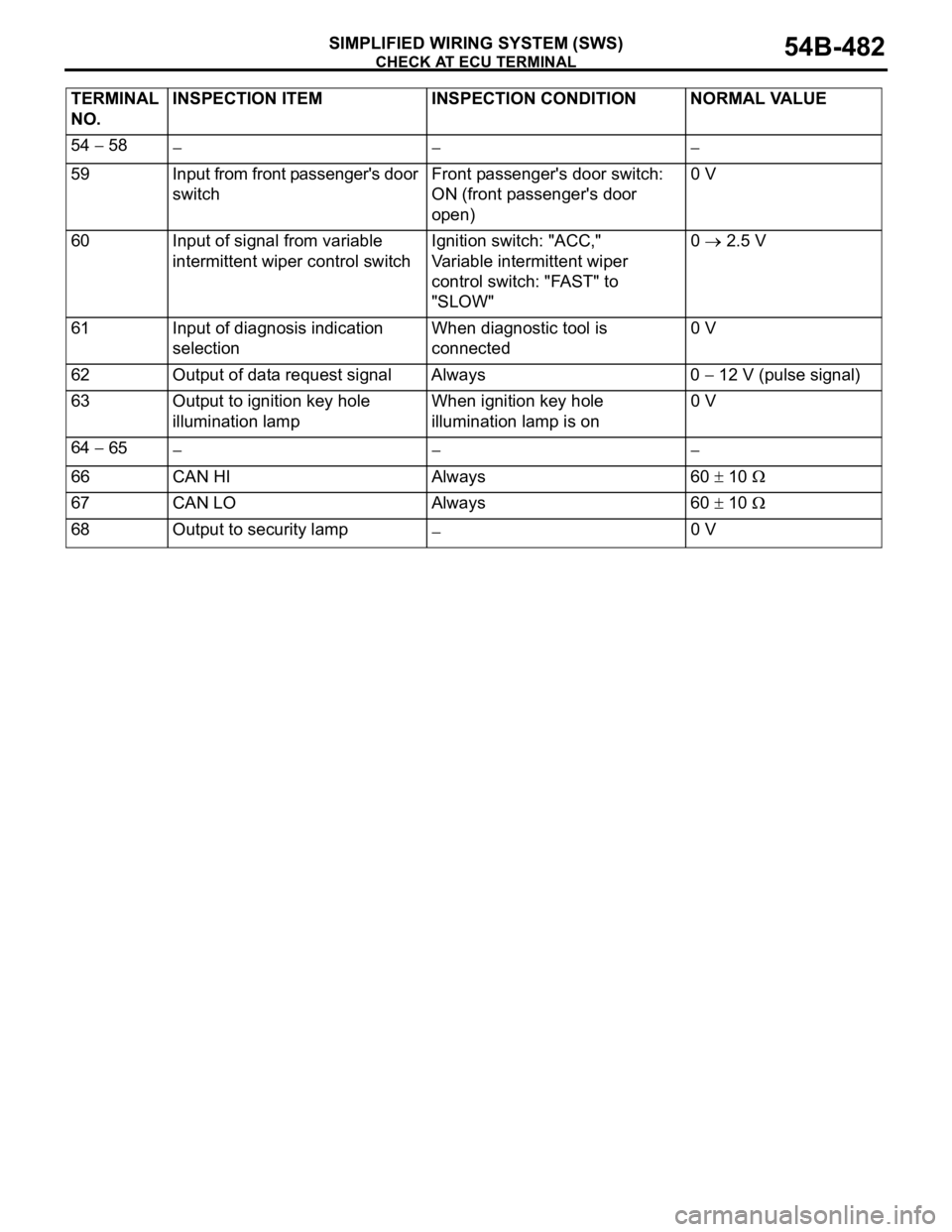

Page 482 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-482

54 58

59 Input from front passenger's door

switchFront passenger's door switch:

ON (front passenger's door

open)0 V

60 Input of signal from variable

intermittent wiper control switchIgnition switch: "ACC,"

Variable intermittent wiper

control switch: "FAST" to

"SLOW"0

2.5 V

61 Input of diagnosis indication

selectionWhen diagnostic tool is

connected0 V

62 Output of data request signal Always 0

12 V (pulse signal)

63 Output to ignition key hole

illumination lampWhen ignition key hole

illumination lamp is on0 V

64

65

66 CAN HI Always 60 10

67 CAN LO Always 60 10

68 Output to security lamp 0 V TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE