display MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 2 of 1500

GENERAL DESCRIPTION

SIMPLIFIED WIRING SYSTEM (SWS)54B-2

GENERAL DESCRIPTION

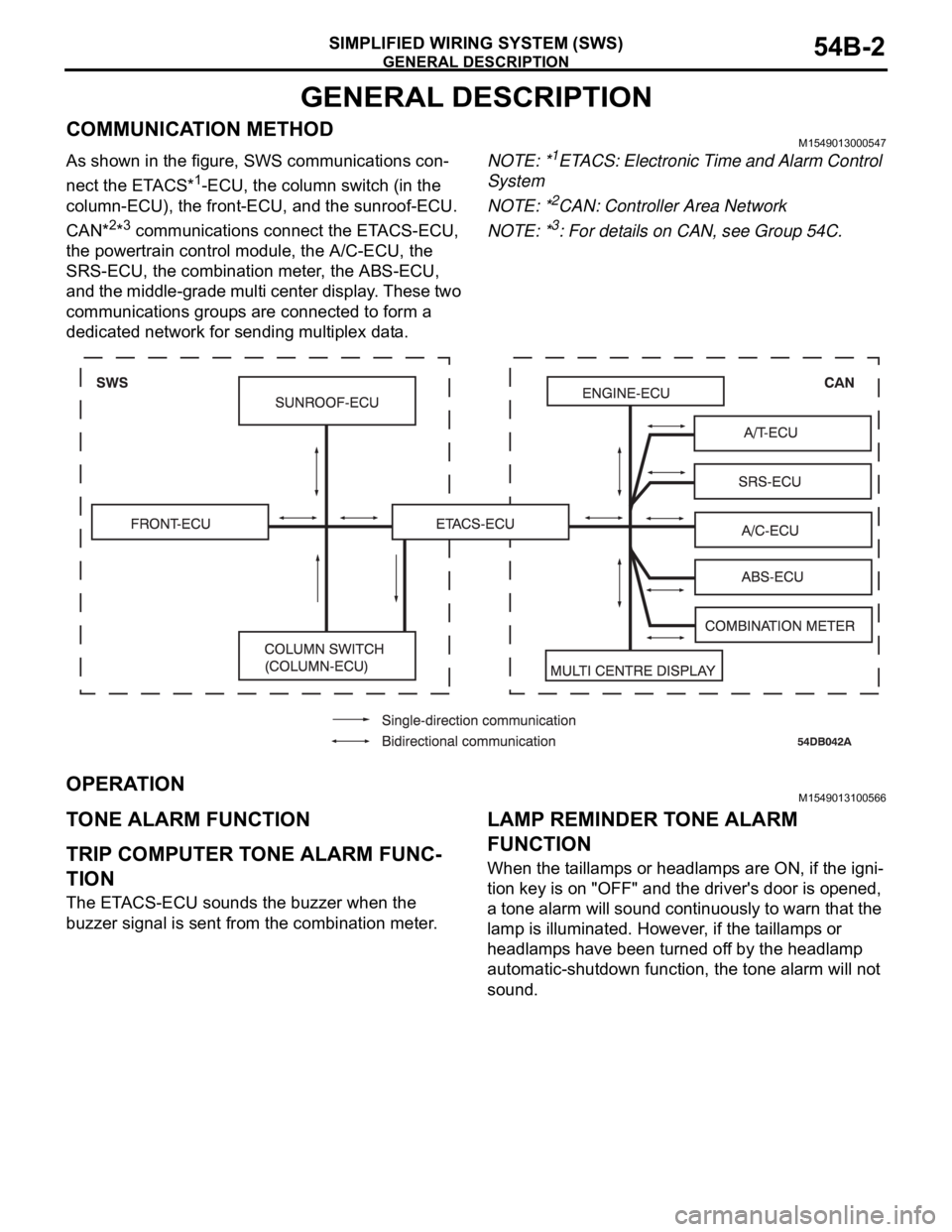

COMMUNICATION METHODM1549013000547

As shown in the figure, SWS communications con-

nect the ETACS*

1-ECU, the column switch (in the

column-ECU), the front-ECU, and the sunroof-ECU.

CAN*

2*3 communications connect the ETACS-ECU,

the powertrain control module, the A/C-ECU, the

SRS-ECU, the combination meter, the ABS-ECU,

and the middle-grade multi center display. These two

communications groups are connected to form a

dedicated network for sending multiplex data.NOTE: *

1ETACS: Electronic Time and Alarm Control

System

NOTE: *

2CAN: Controller Area Network

NOTE: *

3: For details on CAN, see Group 54C.

OPERATIONM1549013100566

TONE ALARM FUNCTION

.

TRIP COMPUTER TONE ALARM FUNC-

TION

The ETACS-ECU sounds the buzzer when the

buzzer signal is sent from the combination meter.

.

LAMP REMINDER TONE ALARM

FUNCTION

When the taillamps or headlamps are ON, if the igni-

tion key is on "OFF" and the driver's door is opened,

a tone alarm will sound continuously to warn that the

lamp is illuminated. However, if the taillamps or

headlamps have been turned off by the headlamp

automatic-shutdown function, the tone alarm will not

sound.

.

Page 3 of 1500

GENERAL DESCRIPTION

SIMPLIFIED WIRING SYSTEM (SWS)54B-3

SEAT BELT TONE ALARM FUNCTION

If any of the following conditions is met with the igni-

tion switch at "ON" or "ST", the ETACS-ECU sounds

the tone alarm by using the driver's seat belt switch

signal and the vehicle speed signal sent from the

combination meter.

Sounds the tone alarm for six seconds when the

ignition switch is turned "ON" with the seat belt

switch on (the driver's seat belt is not fastened).

This is called "Timer function".

Sounds the tone alarm 12 cycles (after 0.5 sec-

onds) if any of the following conditions is met

when sixty seconds or more have elapsed since

the ignition switch is turned "ON". One cycle con-

sists of five-seconds "on" and then three-seconds

"off".

a. The vehicle speed has reached 8 km/h (5

mph) while the seat belt switch is turned on

(driver's seat belt is not fastened) with the

ignition switch "ON.

b. The seat belt switch has been turned on

(driver's seat belt has not been fastened) for

at least ten seconds while the ignition switch

has been turned "ON" and the vehicle speed

has been 8 km/h or more.

NOTE: Once the tone alarm has sounded 12

cycles, it does not sound again until the vehi-

cle speed reduces to 3 km/h (2 mph) or less

even if any of the following conditions is met.

The tone alarm stops sounding if the ignition

switch or the seat belt switch is turned off (the

driver's seat belt is fastened) while the timer

operation is active.

.

DOOR AJAR WARNING BUZZER

The buzzer is sounded 4 times by the ETACS-ECU

to warn the driver if any door is open when the igni-

tion is switched ON and the vehicle speed reaches 8

km/h or faster. The buzzer will continue to sound for

4 times even if the ignition, door status, or vehicle

speed requirements are not maintained.

.

MULTI CENTER DISPLAY OPERATION

TONE

The ETACS-ECU sounds the buzzer when the

buzzer signal is sent from the multi center display.

.

TURN-SIGNAL LAMP BUZZER

The ETACS-ECU sounds the buzzer in sync with the

turn-signal lamps or hazard warning lamps.

CENTRAL DOOR LOCKING SYSTEM

.

CENTRAL DOOR LOCKING SYSTEM

OPERATION

Door unlocking by operating the driver’s door lock

key cylinder:

When the ignition key is inserted in the driver’s

door lock key cylinder and turned clockwise to

unlock the driver’s door, the ETACS-ECU oper-

ates its door unlock relay and passes a current

through the door lock actuator of the driver’s door

for 0.25 seconds to unlock only the driver’s door.

When the ignition key is turned clockwise again,

the ETACS-ECU operates its door unlock relay

and passes a current through the door lock actu-

ators of all doors for 0.25 seconds and to unlock

all doors.

Door locking or unlocking by operating the driver’s or

front passenger’s door lock switch:

When the door is locked by the driver’s or front

passenger’s door lock switch, the ETACS-ECU

operates its door lock relay and passes a current

through the door lock actuators of all doors for

0.25 seconds to lock all doors.

When the door is unlocked by the driver’s or front

passenger's door lock switch, the ETACS-ECU

operates its door unlock relay and passes a cur-

rent through the door lock actuators of all doors

for 0.25 seconds to unlock all doors.

When the door is locked and unlocked by driver’s

or front passenger's door lock switch consecu-

tively, the ETACS-ECU operates its door lock

relay and passes a current through the door lock

actuators of all doors for 0.25 seconds to lock all

doors. Then, the ETACS-ECU operates its door

unlock relay and passes a current through the

door lock actuators of all doors for 0.25 seconds

to unlock all doors. Due to this, there may be a

time lag between the driver’s or front passenger's

door lock switch actuation and the time when all

doors are unlocked.

Page 7 of 1500

GENERAL DESCRIPTION

SIMPLIFIED WIRING SYSTEM (SWS)54B-7

SEAT BELT INDICATOR

If any of the following conditions is met with the igni-

tion switch at "ON" or "ST", the ETACS-ECU illumi-

nates, flashes or extinguishes the seat belt indicator

by using the driver's seat belt switch signal and the

vehicle speed signal sent from the combination

meter.

Illuminates when the ignition switch is at "ON"

and the seat belt switch is turned on (the driver's

seat belt is unfastened).

Flashes and illuminates the indicator 12 cycles

(after 0.5 seconds) if any of the following condi-

tions is met when sixty seconds or more have

elapsed since the ignition switch is turned "ON".

One cycle consists of five-second "flashing" and

then three-second "illumination".

a. The vehicle speed has reached 8 km/h (5

mph) while the seat belt switch is turned on

(driver's seat belt is not fastened) with the

ignition switch "ON.

b. The seat belt switch has been turned on

(driver's seat belt has not been fastened) for

at least ten seconds while the ignition switch

has been turned "ON" and the vehicle speed

has been 8 km/h (5 mph) or more.

NOTE: Once this timer operation has been acti-

vated, it will not be activated again until the

vehicle speed reduces to 3 km/h (2 mph) or

less even if any of the following conditions is

met.

The indicator stops illuminating if the ignition

switch or the seat belt switch is turned off (the

driver's seat belt is fastened) while the timer

operation is active.

DOOR-AJAR INDICATOR LAMP

The combination meter receives the signal sent from

the ETACS-ECU about whether each door or trunk is

open or closed and turns the door ajar indicator lamp

on and off. While the door ajar indicator is illumi-

nated, the door ajar warning function is activated and

the door ajar indicator lamp flashes 4 times. If the

door remains open even after the 4 warning flashes,

the door ajar indicator lamp will be illuminated again.

CONFIGURATION FUNCTION

The following functions can be adjusted by operating

the middle-grade multi center display (if equipped).

Keyless entry horn answerback function

Keyless entry hazard lamp answerback function

Timed locking mechanism

Turn-signal lamp buzzer

Door ajar warning buzzer

Adjustment of door unlocking operation on key-

less entry system

Vehicle speed-dependent wiper function

Headlamp automatic shutdown function

Delay-off time of the dome lamp

Interior lamp automatic shutoff function

Initialisation of above mentioned functions

Page 10 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-10

SWS DIAGNOSIS

GENERAL DESCRIPTION

BEFORE CARRYING OUT TROUBLESHOOTINGM1549014700710

Before carrying out troubleshooting, check the fol-

lowing two items.

Make sure that the ETACS-ECU, the junction

block (J/B), the front-ECU and the engine com-

partment relay box are connected securely.

Make sure that fuses and fusible links related to

relevant systems are not blown.

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

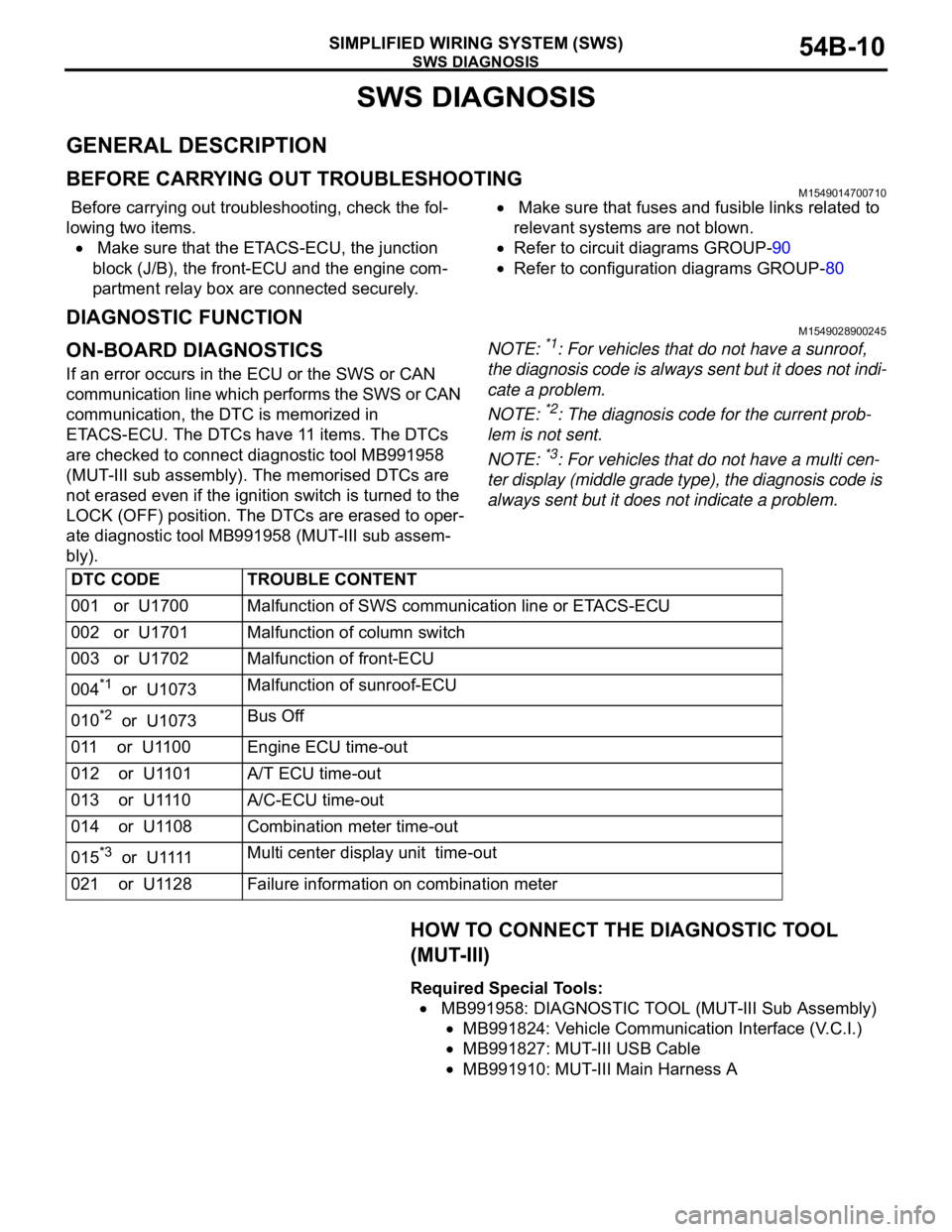

DIAGNOSTIC FUNCTIONM1549028900245

ON-BOARD DIAGNOSTICS

If an error occurs in the ECU or the SWS or CAN

communication line which performs the SWS or CAN

communication, the DTC is memorized in

ETACS-ECU. The DTCs have 11 items. The DTCs

are checked to connect diagnostic tool MB991958

(MUT-III sub assembly). The memorised DTCs are

not erased even if the ignition switch is turned to the

LOCK (OFF) position. The DTCs are erased to oper-

ate diagnostic tool MB991958 (MUT-III sub assem-

bly).NOTE:

*1: For vehicles that do not have a sunroof,

the diagnosis code is always sent but it does not indi-

cate a problem.

NOTE:

*2: The diagnosis code for the current prob-

lem is not sent.

NOTE:

*3: For vehicles that do not have a multi cen-

ter display (middle grade type), the diagnosis code is

always sent but it does not indicate a problem.

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A DTC CODE TROUBLE CONTENT

001 or U1700 Malfunction of SWS communication line or ETACS-ECU

002 or U1701 Malfunction of column switch

003 or U1702 Malfunction of front-ECU

004

*1 or U1073Malfunction of sunroof-ECU

010

*2 or U1073Bus Off

011 or U1100 Engine ECU time-out

012 or U1101 A/T ECU time-out

013 or U1110 A/C-ECU time-out

014 or U1108 Combination meter time-out

015

*3 or U1111Multi center display unit time-out

021 or U1128 Failure information on combination meter

Page 11 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-11

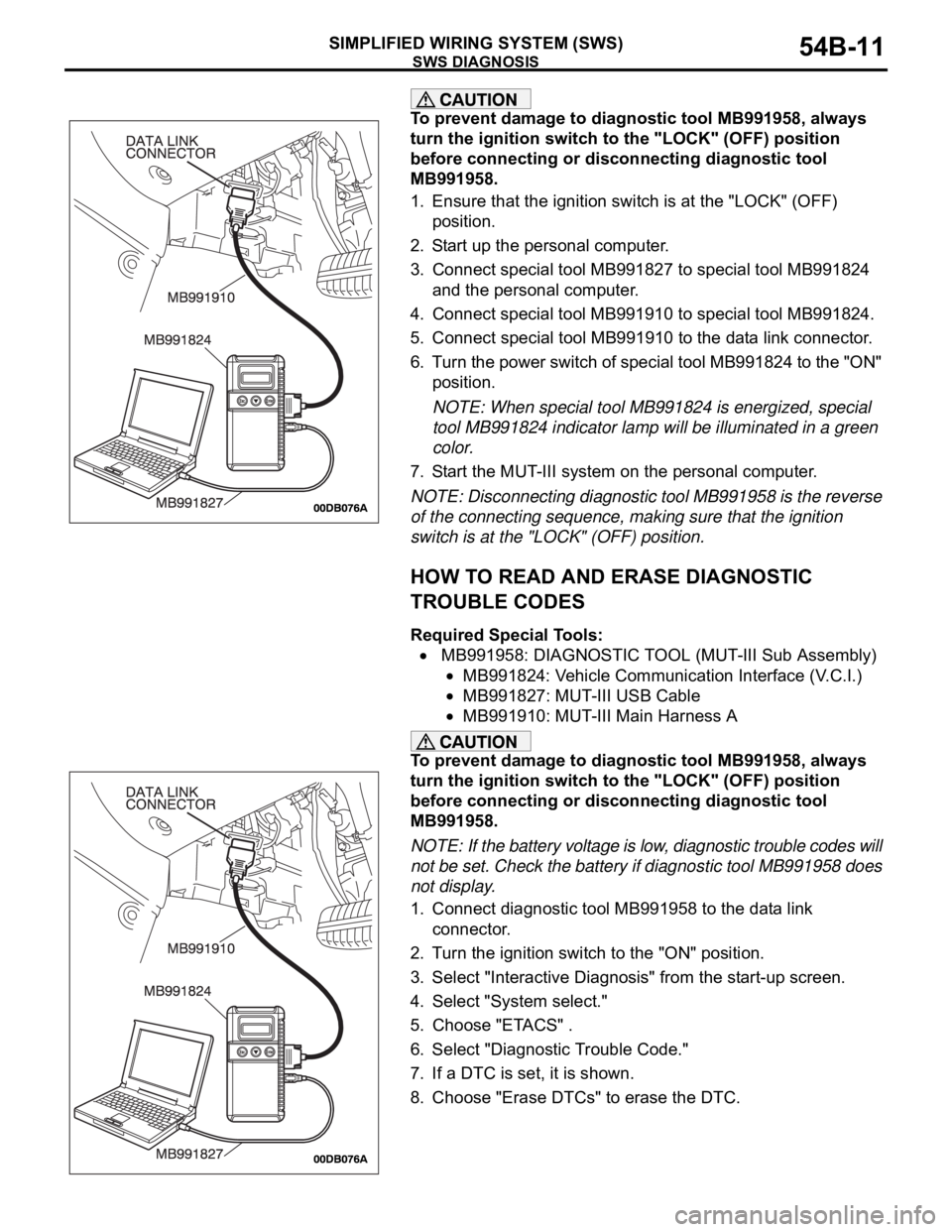

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energized, special

tool MB991824 indicator lamp will be illuminated in a green

color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnecting diagnostic tool MB991958 is the reverse

of the connecting sequence, making sure that the ignition

switch is at the "LOCK" (OFF) position.

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

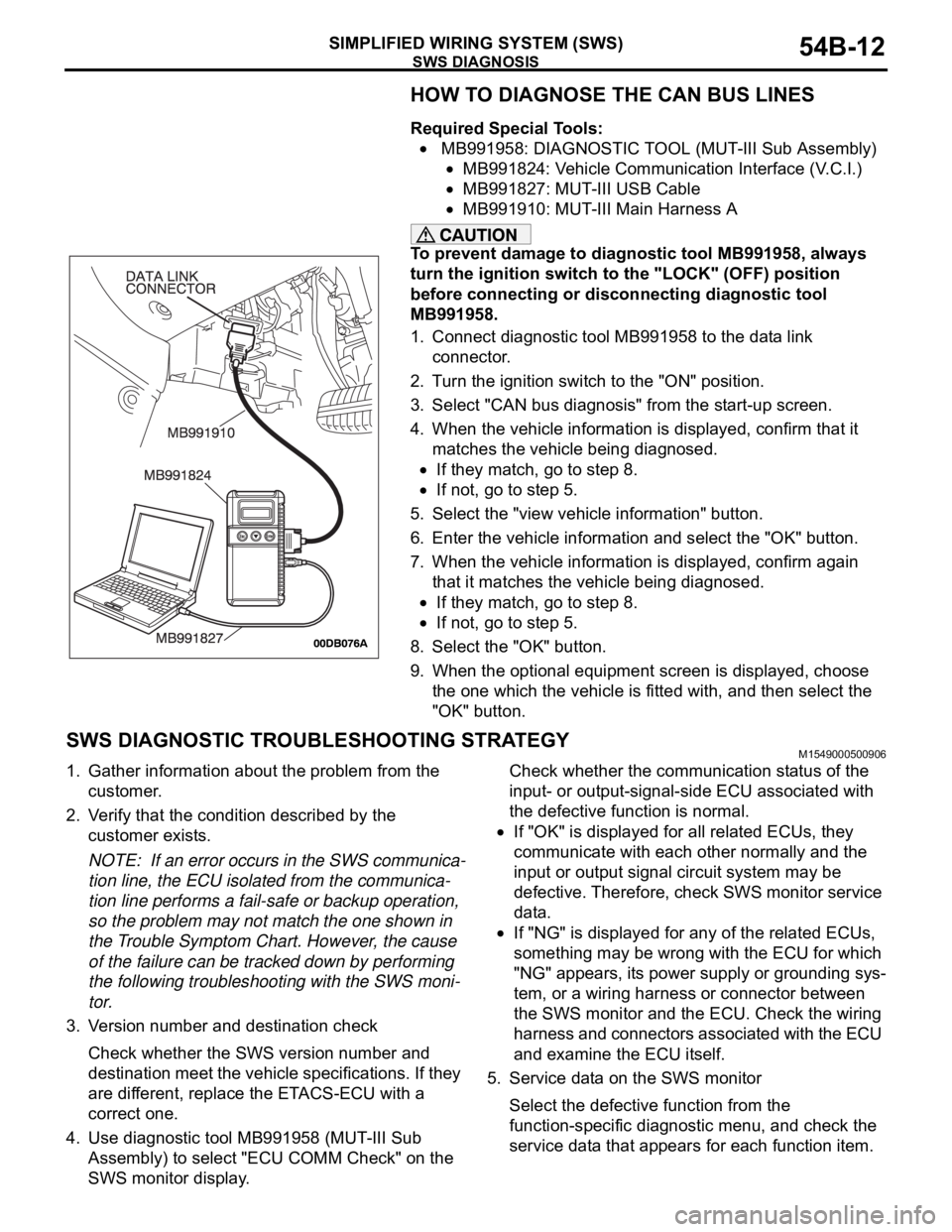

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes will

not be set. Check the battery if diagnostic tool MB991958 does

not display.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ETACS" .

6. Select "Diagnostic Trouble Code."

7. If a DTC is set, it is shown.

8. Choose "Erase DTCs" to erase the DTC.

Page 12 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-12

HOW TO DIAGNOSE THE CAN BUS LINES

Required Special Tools:

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

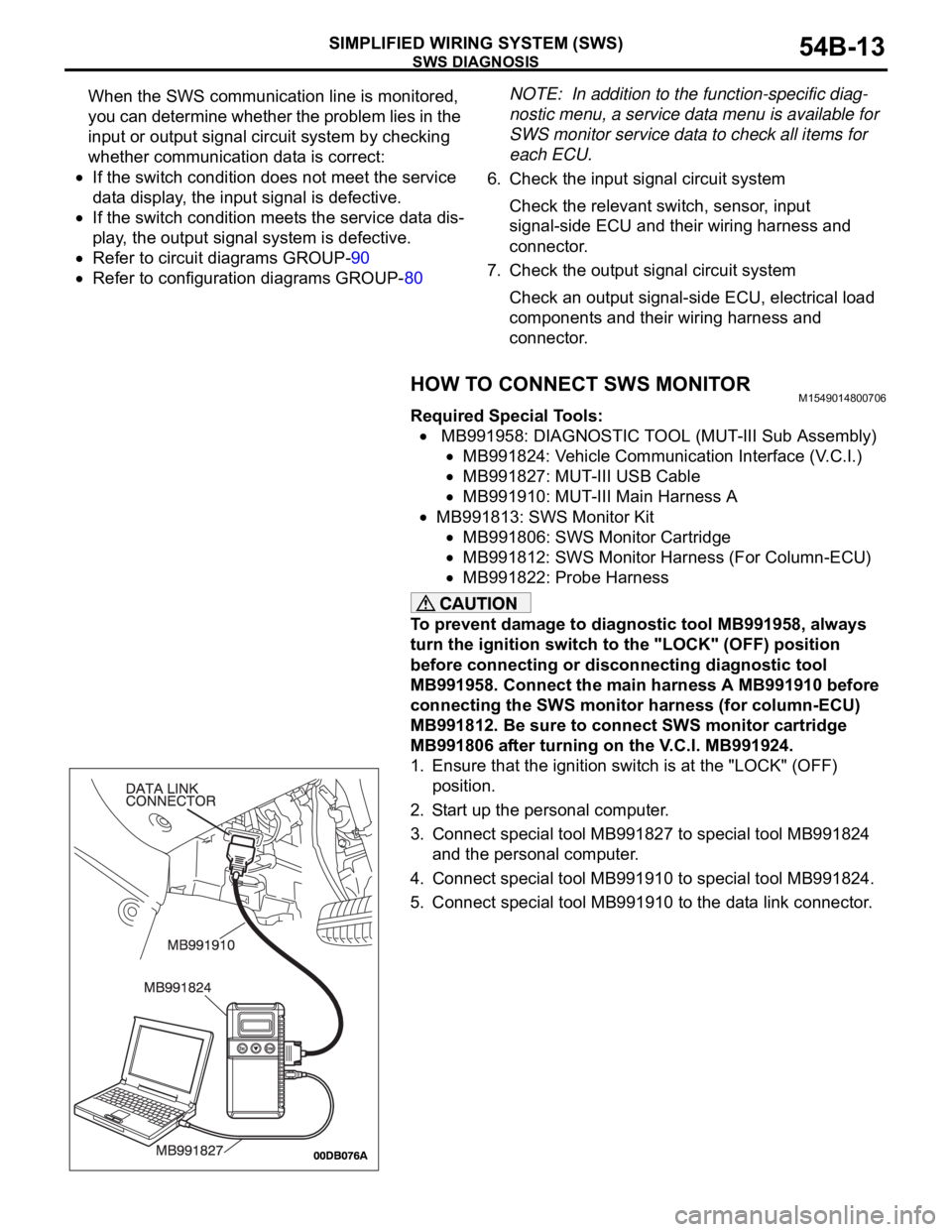

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "CAN bus diagnosis" from the start-up screen.

4. When the vehicle information is displayed, confirm that it

matches the vehicle being diagnosed.

If they match, go to step 8.

If not, go to step 5.

5. Select the "view vehicle information" button.

6. Enter the vehicle information and select the "OK" button.

7. When the vehicle information is displayed, confirm again

that it matches the vehicle being diagnosed.

If they match, go to step 8.

If not, go to step 5.

8. Select the "OK" button.

9. When the optional equipment screen is displayed, choose

the one which the vehicle is fitted with, and then select the

"OK" button.

SWS DIAGNOSTIC TROUBLESHOOTING STRATEGYM1549000500906

1. Gather information about the problem from the

customer.

2. Verify that the condition described by the

customer exists.

NOTE: If an error occurs in the SWS communica-

tion line, the ECU isolated from the communica-

tion line performs a fail-safe or backup operation,

so the problem may not match the one shown in

the Trouble Symptom Chart. However, the cause

of the failure can be tracked down by performing

the following troubleshooting with the SWS moni-

tor.

3. Version number and destination check

Check whether the SWS version number and

destination meet the vehicle specifications. If they

are different, replace the ETACS-ECU with a

correct one.

4. Use diagnostic tool MB991958 (MUT-III Sub

Assembly) to select "ECU COMM Check" on the

SWS monitor display.Check whether the communication status of the

input- or output-signal-side ECU associated with

the defective function is normal.

If "OK" is displayed for all related ECUs, they

communicate with each other normally and the

input or output signal circuit system may be

defective. Therefore, check SWS monitor service

data.

If "NG" is displayed for any of the related ECUs,

something may be wrong with the ECU for which

"NG" appears, its power supply or grounding sys-

tem, or a wiring harness or connector between

the SWS monitor and the ECU. Check the wiring

harness and connectors associated with the ECU

and examine the ECU itself.

5. Service data on the SWS monitor

Select the defective function from the

function-specific diagnostic menu, and check the

service data that appears for each function item.

Page 13 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-13

When the SWS communication line is monitored,

you can determine whether the problem lies in the

input or output signal circuit system by checking

whether communication data is correct:

If the switch condition does not meet the service

data display, the input signal is defective.

If the switch condition meets the service data dis-

play, the output signal system is defective.

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80NOTE: In addition to the function-specific diag-

nostic menu, a service data menu is available for

SWS monitor service data to check all items for

each ECU.

6. Check the input signal circuit system

Check the relevant switch, sensor, input

signal-side ECU and their wiring harness and

connector.

7. Check the output signal circuit system

Check an output signal-side ECU, electrical load

components and their wiring harness and

connector.

HOW TO CONNECT SWS MONITORM1549014800706

Required Special Tools:

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Probe Harness

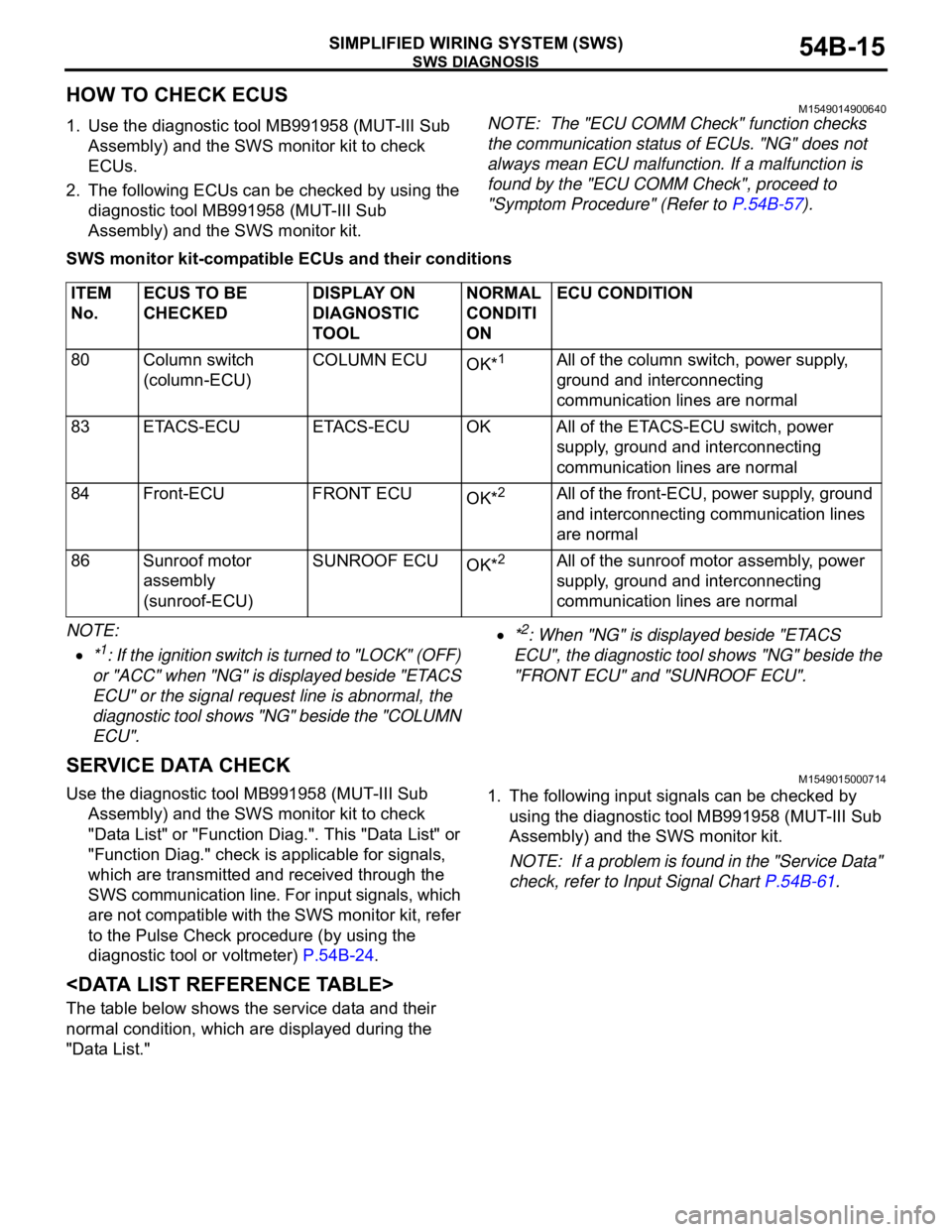

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958. Connect the main harness A MB991910 before

connecting the SWS monitor harness (for column-ECU)

MB991812. Be sure to connect SWS monitor cartridge

MB991806 after turning on the V.C.I. MB991924.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

Page 15 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-15

HOW TO CHECK ECUSM1549014900640

1. Use the diagnostic tool MB991958 (MUT-III Sub

Assembly) and the SWS monitor kit to check

ECUs.

2. The following ECUs can be checked by using the

diagnostic tool MB991958 (MUT-III Sub

Assembly) and the SWS monitor kit.NOTE: The "ECU COMM Check" function checks

the communication status of ECUs. "NG" does not

always mean ECU malfunction. If a malfunction is

found by the "ECU COMM Check", proceed to

"Symptom Procedure" (Refer to P.54B-57).

SWS monitor kit-compatible ECUs and their conditions

NOTE: .

*1: If the ignition switch is turned to "LOCK" (OFF)

or "ACC" when "NG" is displayed beside "ETACS

ECU" or the signal request line is abnormal, the

diagnostic tool shows "NG" beside the "COLUMN

ECU".

*2: When "NG" is displayed beside "ETACS

ECU", the diagnostic tool shows "NG" beside the

"FRONT ECU" and "SUNROOF ECU".

SERVICE DATA CHECKM1549015000714

Use the diagnostic tool MB991958 (MUT-III Sub

Assembly) and the SWS monitor kit to check

"Data List" or "Function Diag.". This "Data List" or

"Function Diag." check is applicable for signals,

which are transmitted and received through the

SWS communication line. For input signals, which

are not compatible with the SWS monitor kit, refer

to the Pulse Check procedure (by using the

diagnostic tool or voltmeter) P.54B-24.1. The following input signals can be checked by

using the diagnostic tool MB991958 (MUT-III Sub

Assembly) and the SWS monitor kit.

NOTE: If a problem is found in the "Service Data"

check, refer to Input Signal Chart P.54B-61.

The table below shows the service data and their

normal condition, which are displayed during the

"Data List."

.

ITEM

No.ECUS TO BE

CHECKEDDISPLAY ON

DIAGNOSTIC

TOOLNORMAL

CONDITI

ONECU CONDITION

80 Column switch

(column-ECU)COLUMN ECU

OK*

1All of the column switch, power supply,

ground and interconnecting

communication lines are normal

83 ETACS-ECU ETACS-ECU OK All of the ETACS-ECU switch, power

supply, ground and interconnecting

communication lines are normal

84 Front-ECU FRONT ECU

OK*

2All of the front-ECU, power supply, ground

and interconnecting communication lines

are normal

86 Sunroof motor

assembly

(sunroof-ECU)SUNROOF ECU

OK*

2All of the sunroof motor assembly, power

supply, ground and interconnecting

communication lines are normal

Page 16 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-16

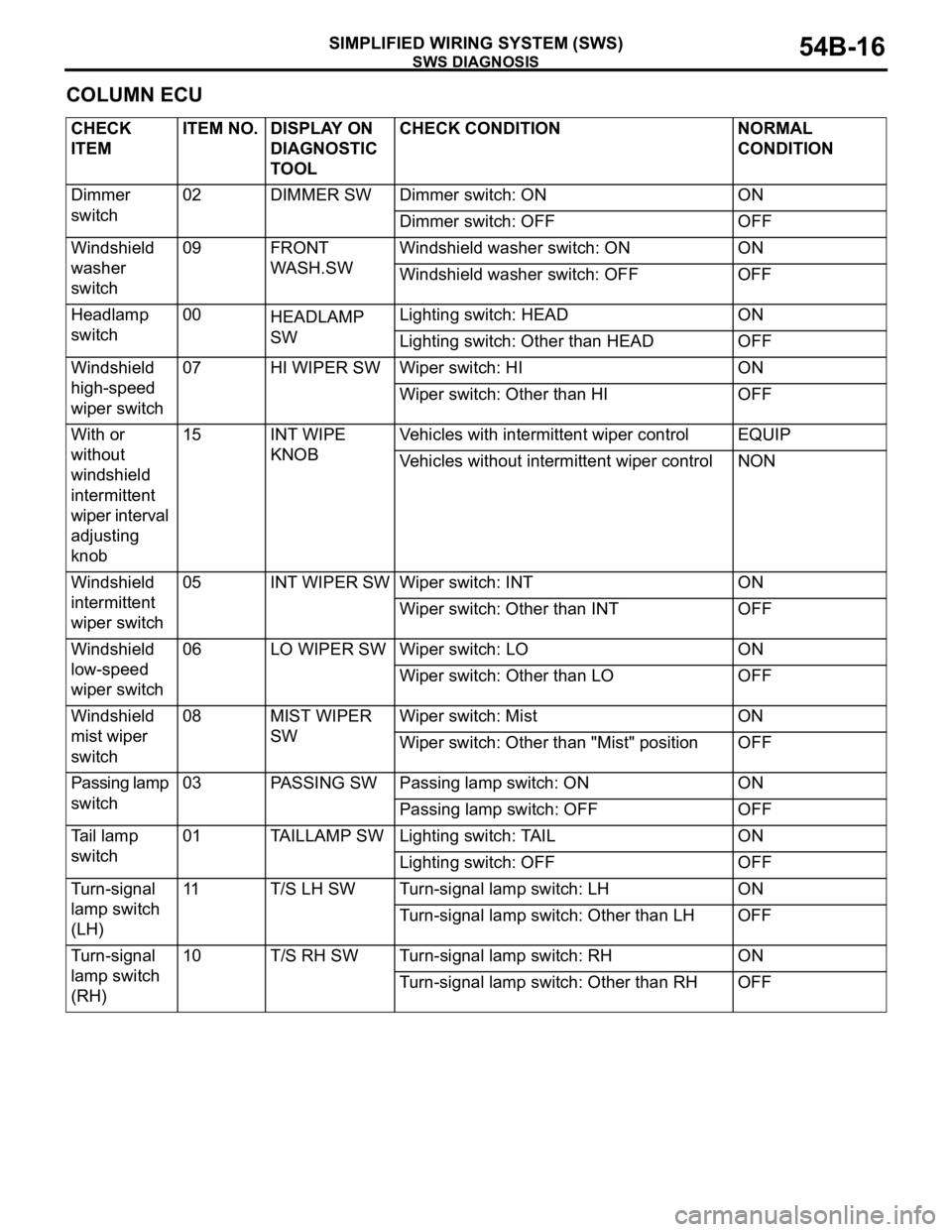

COLUMN ECU

.

CHECK

ITEMITEM NO. DISPLAY ON

DIAGNOSTIC

TOOLCHECK CONDITION NORMAL

CONDITION

Dimmer

switch02 DIMMER SW Dimmer switch: ON ON

Dimmer switch: OFF OFF

Windshield

washer

switch09 FRONT

WASH.SWWindshield washer switch: ON ON

Windshield washer switch: OFF OFF

Headlamp

switch00

HEADLAMP

SWLighting switch: HEAD ON

Lighting switch: Other than HEAD OFF

Windshield

high-speed

wiper switch07 HI WIPER SW Wiper switch: HI ON

Wiper switch: Other than HI OFF

With or

without

windshield

intermittent

wiper interval

adjusting

knob15 INT WIPE

KNOBVehicles with intermittent wiper control EQUIP

Vehicles without intermittent wiper control NON

Windshield

intermittent

wiper switch05 INT WIPER SW Wiper switch: INT ON

Wiper switch: Other than INT OFF

Windshield

low-speed

wiper switch06 LO WIPER SW Wiper switch: LO ON

Wiper switch: Other than LO OFF

Windshield

mist wiper

switch08 MIST WIPER

SWWiper switch: Mist ON

Wiper switch: Other than "Mist" position OFF

Passing lamp

switch03 PASSING SW Passing lamp switch: ON ON

Passing lamp switch: OFF OFF

Ta i l l a m p

switch01 TAILLAMP SW Lighting switch: TAIL ON

Lighting switch: OFF OFF

Turn-signal

lamp switch

(LH)11 T/S LH SW Turn-signal lamp switch: LH ON

Turn-signal lamp switch: Other than LH OFF

Turn-signal

lamp switch

(RH)10 T/S RH SW Turn-signal lamp switch: RH ON

Turn-signal lamp switch: Other than RH OFF

Page 17 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-17

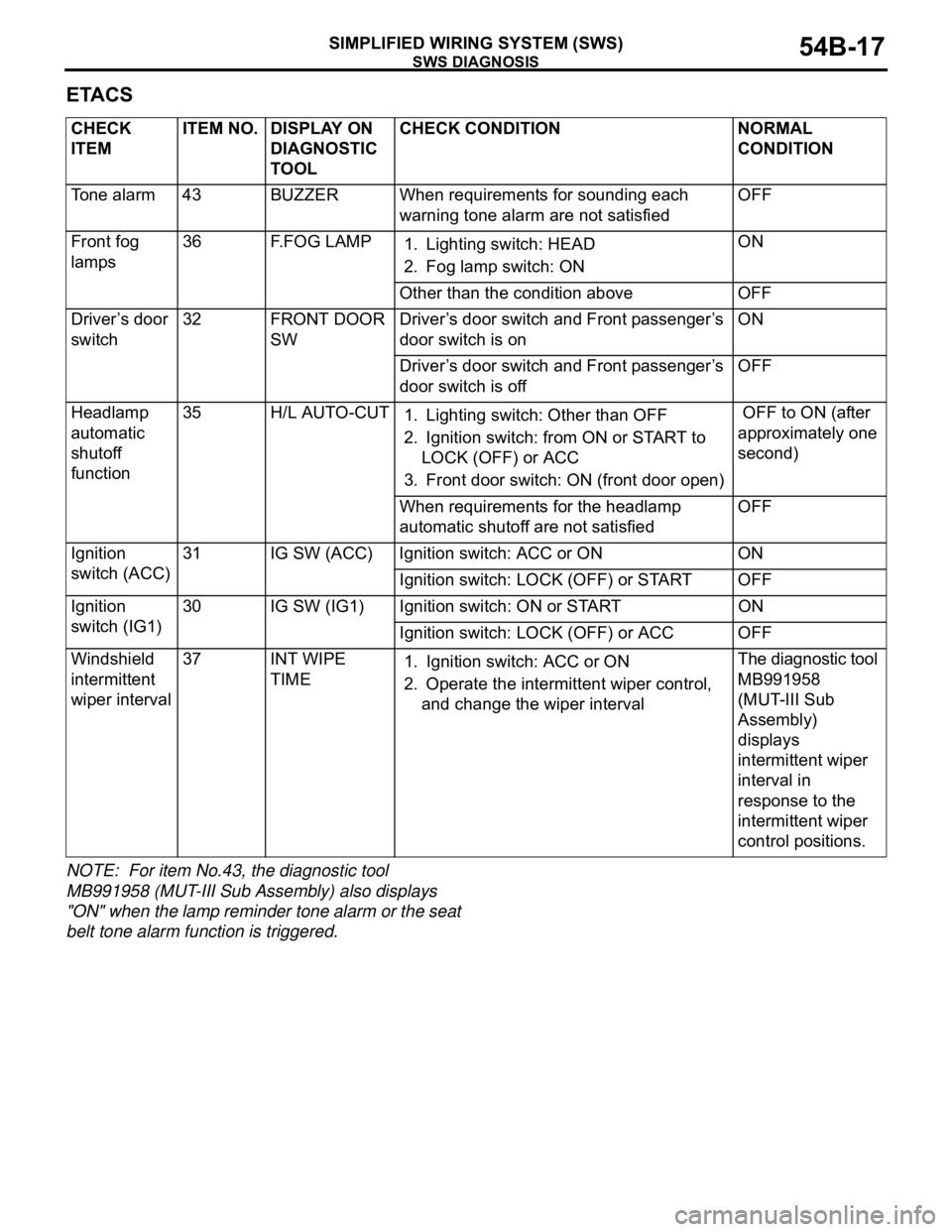

ETACS

NOTE: For item No.43, the diagnostic tool

MB991958 (MUT-III Sub Assembly) also displays

"ON" when the lamp reminder tone alarm or the seat

belt tone alarm function is triggered.

.

CHECK

ITEMITEM NO. DISPLAY ON

DIAGNOSTIC

TOOLCHECK CONDITION NORMAL

CONDITION

Tone alarm 43 BUZZER When requirements for sounding each

warning tone alarm are not satisfiedOFF

Front fog

lamps36 F.FOG LAMP

1. Lighting switch: HEAD

2. Fog lamp switch: ONON

Other than the condition above OFF

Driver’s door

switch32 FRONT DOOR

SWDriver’s door switch and Front passenger’s

door switch is on ON

Driver’s door switch and Front passenger’s

door switch is offOFF

Headlamp

automatic

shutoff

function35 H/L AUTO-CUT

1. Lighting switch: Other than OFF

2. Ignition switch: from ON or START to

LOCK (OFF) or ACC

3. Front door switch: ON (front door open) OFF to ON (after

approximately one

second)

When requirements for the headlamp

automatic shutoff are not satisfiedOFF

Ignition

switch (ACC)31 IG SW (ACC) Ignition switch: ACC or ON ON

Ignition switch: LOCK (OFF) or START OFF

Ignition

switch (IG1)30 IG SW (IG1) Ignition switch: ON or START ON

Ignition switch: LOCK (OFF) or ACC OFF

Windshield

intermittent

wiper interval37 INT WIPE

TIME1. Ignition switch: ACC or ON

2. Operate the intermittent wiper control,

and change the wiper intervalThe diagnostic tool

MB991958

(MUT-III Sub

Assembly)

displays

intermittent wiper

interval in

response to the

intermittent wiper

control positions.