automatic transmission MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1467 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-8

FEATURES

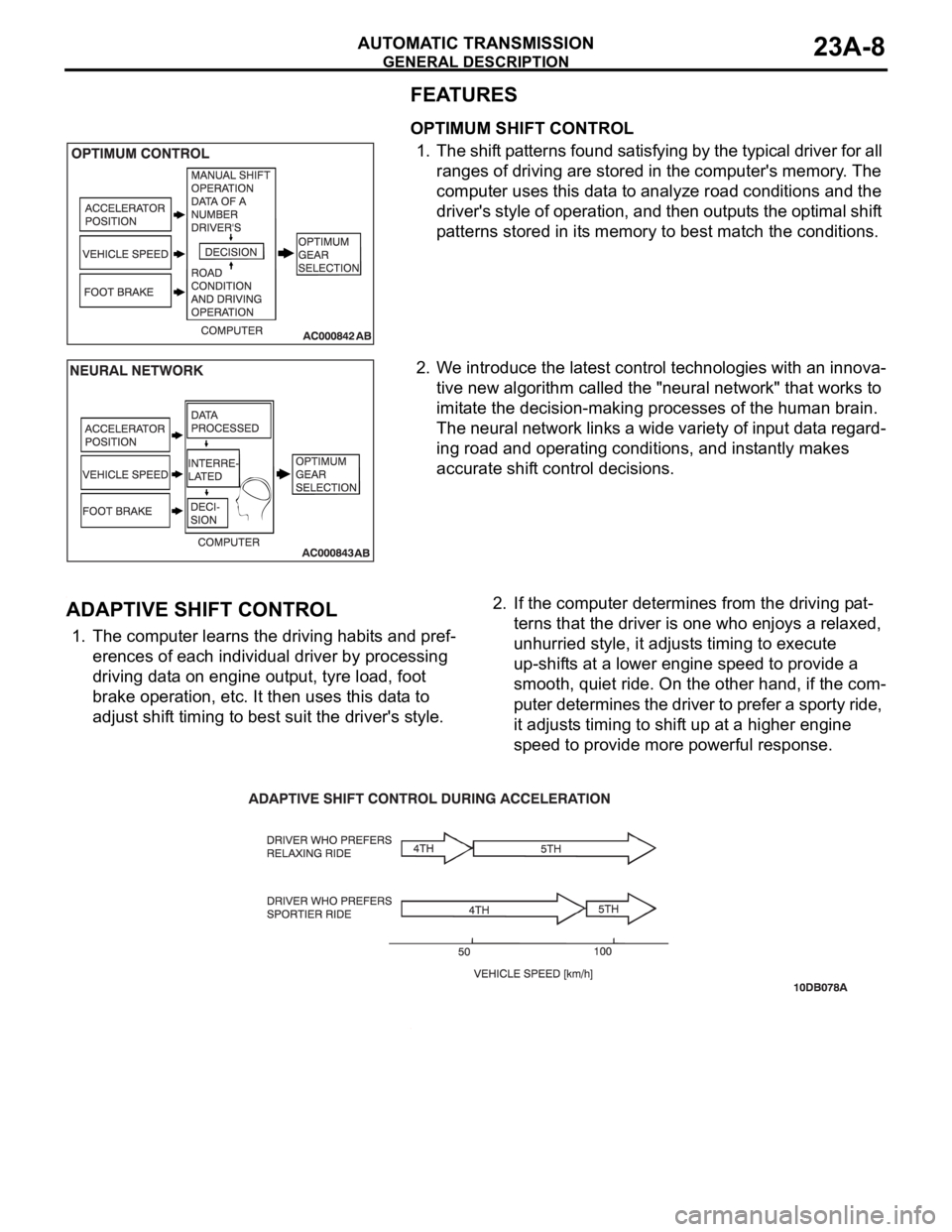

OPTIMUM SHIFT CONTROL

1. The shift patterns found satisfying by the typical driver for all

ranges of driving are stored in the computer's memory. The

computer uses this data to analyze road conditions and the

driver's style of operation, and then outputs the optimal shift

patterns stored in its memory to best match the conditions.

2. We introduce the latest control technologies with an innova-

tive new algorithm called the "neural network" that works to

imitate the decision-making processes of the human brain.

The neural network links a wide variety of input data regard-

ing road and operating conditions, and instantly makes

accurate shift control decisions.

.

ADAPTIVE SHIFT CONTROL

1. The computer learns the driving habits and pref-

erences of each individual driver by processing

driving data on engine output, tyre load, foot

brake operation, etc. It then uses this data to

adjust shift timing to best suit the driver's style.2. If the computer determines from the driving pat-

terns that the driver is one who enjoys a relaxed,

unhurried style, it adjusts timing to execute

up-shifts at a lower engine speed to provide a

smooth, quiet ride. On the other hand, if the com-

puter determines the driver to prefer a sporty ride,

it adjusts timing to shift up at a higher engine

speed to provide more powerful response.

.

Page 1468 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-9

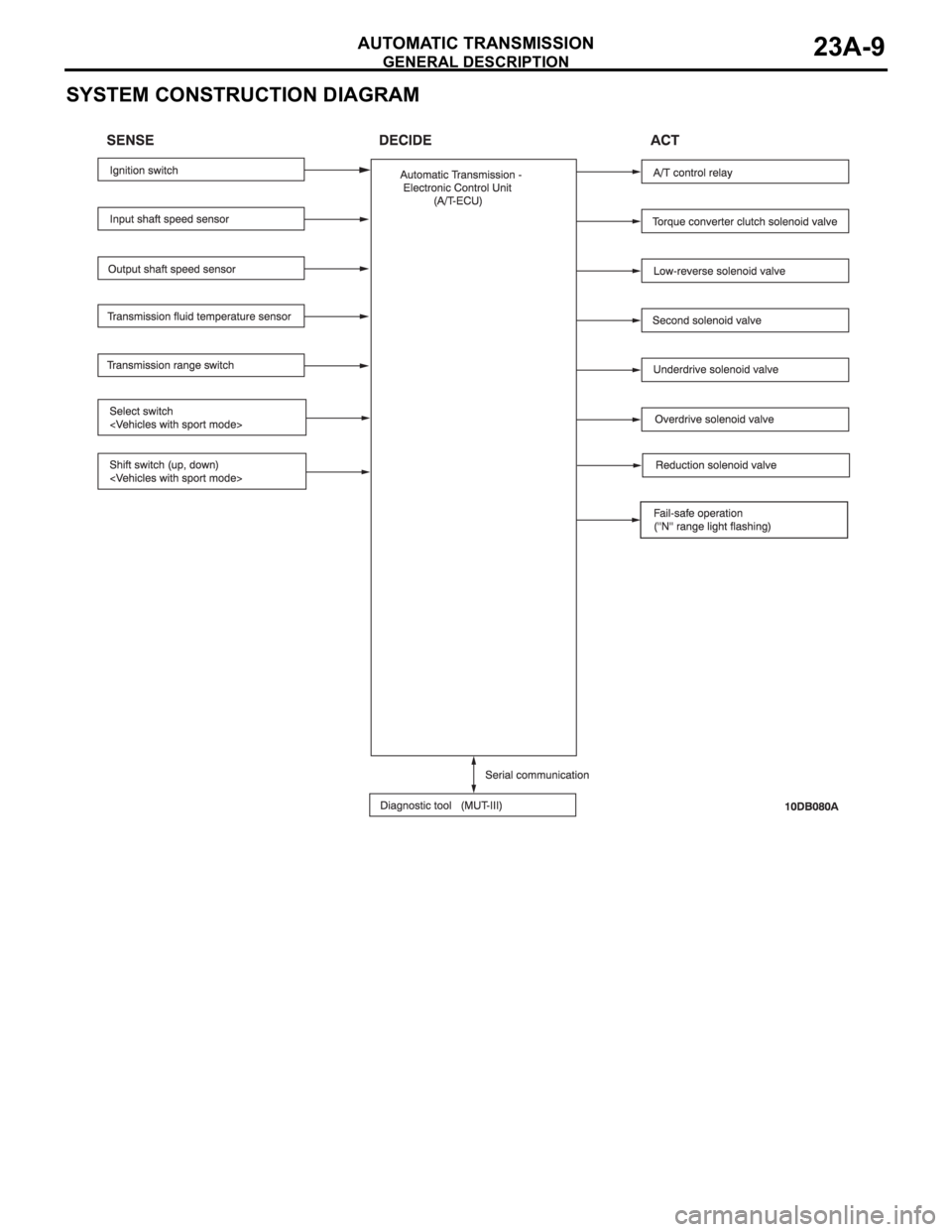

SYSTEM CONSTRUCTION DIAGRAM

Page 1469 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-10

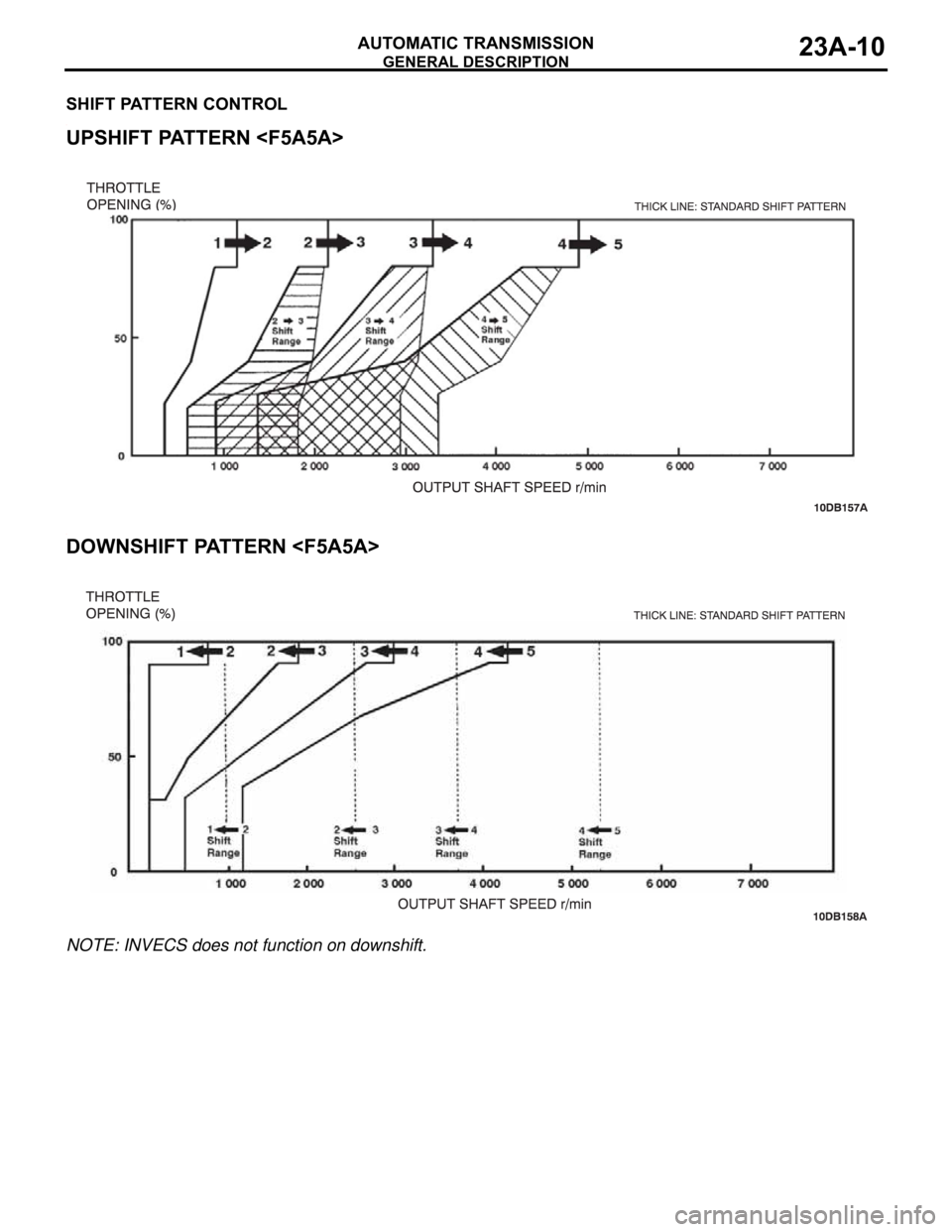

SHIFT PATTERN CONTROL.

UPSHIFT PATTERN

.

DOWNSHIFT PATTERN

NOTE: INVECS does not function on downshift.

Page 1470 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-11

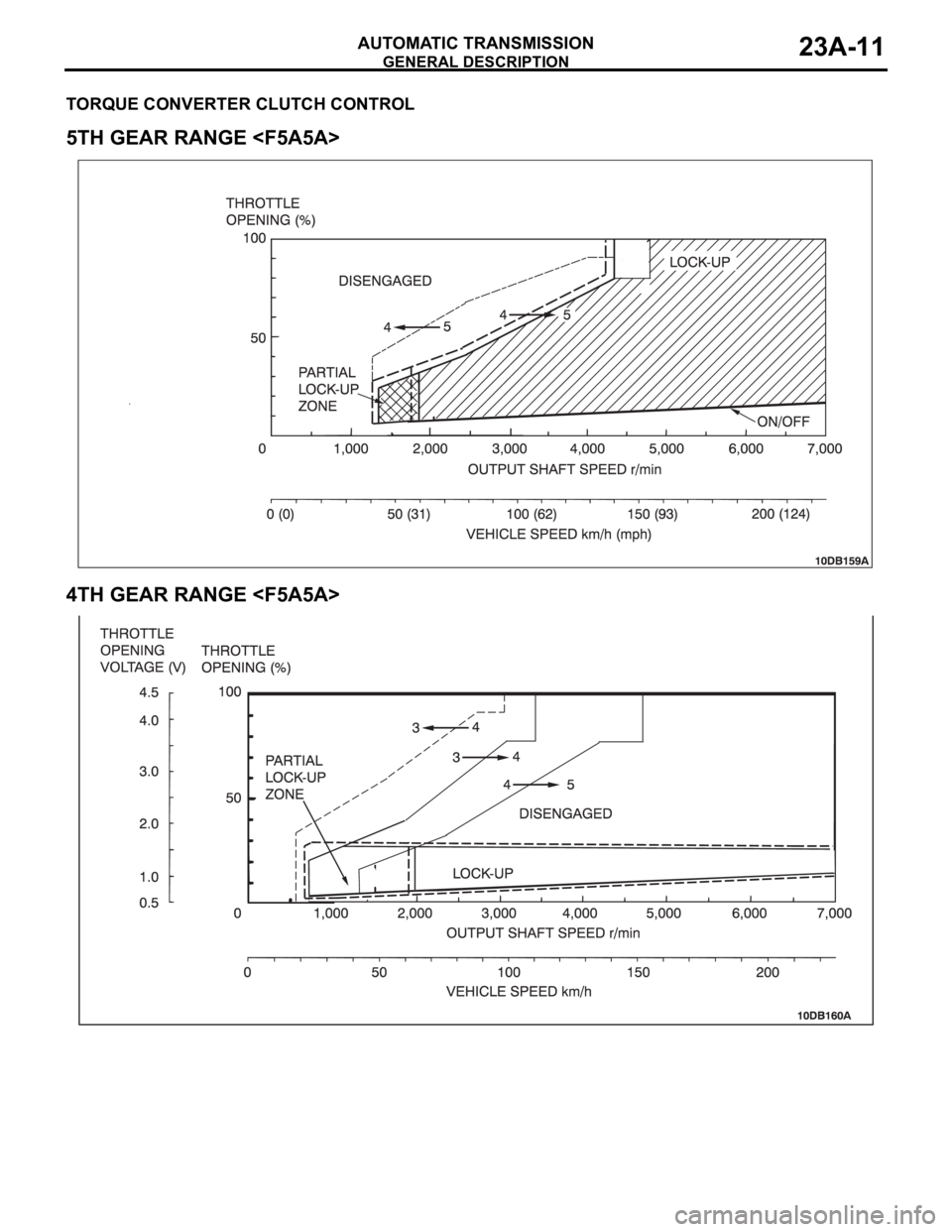

TORQUE CONVERTER CLUTCH CONTROL.

5TH GEAR RANGE

.

4TH GEAR RANGE

Page 1471 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-12

AUTOMATIC TRANSMISSION DIAGNOSIS

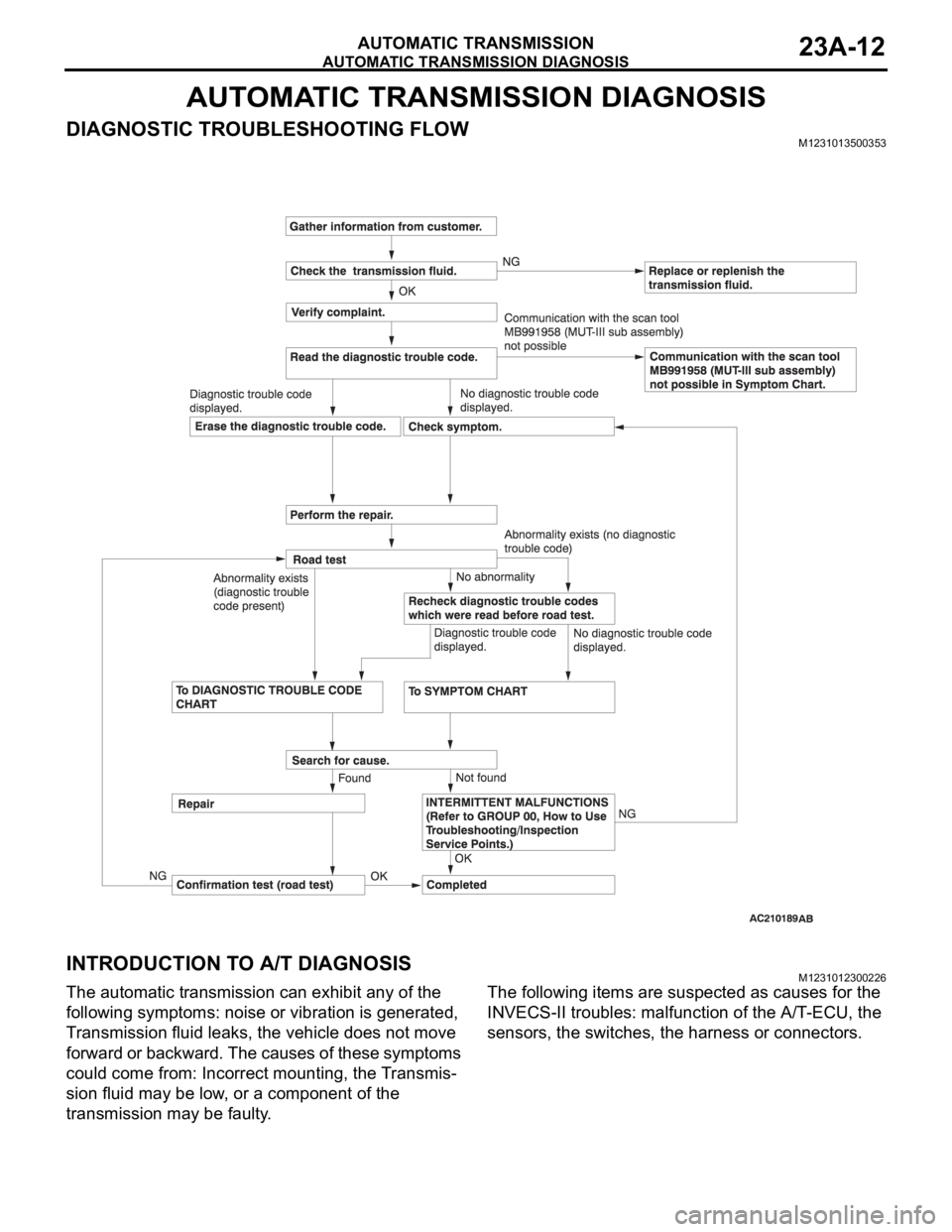

DIAGNOSTIC TROUBLESHOOTING FLOWM1231013500353

INTRODUCTION TO A/T DIAGNOSISM1231012300226

The automatic transmission can exhibit any of the

following symptoms: noise or vibration is generated,

Transmission fluid leaks, the vehicle does not move

forward or backward. The causes of these symptoms

could come from: Incorrect mounting, the Transmis-

sion fluid may be low, or a component of the

transmission may be faulty. The following items are suspected as causes for the

INVECS-II troubles: malfunction of the A/T-ECU, the

sensors, the switches, the harness or connectors.

Page 1472 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-13

A/T DIAGNOSTIC TROUBLESHOOTING STRATEGYM1231007600339

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will find most A/T mal-

functions.

1. Gather as much information as possible about the

complaint from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any A/T Diagnostic Trouble

Codes (DTCs).

4. If you can not verify the condition and there are no

DTCs, the malfunction is intermittent. For

information on how to cope with intermittent

malfunctions, refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunction P.00-14.

5. If you can verify the condition but there are no

DTCs, or the system can not communicate with

diagnostic tool, refer to the Symptom Chart

P.23A-35.6. If there is a DTC, record the number of the code,

then erase the code from memory using

diagnostic tool.

7. Reconfirm the symptom with a Road Test.

8. If a DTC is set again, go to the Inspection Chart

for Diagnostic Trouble Codes.

9. If a DTC is not set again, the malfunction is

intermittent. For information on how to cope with

intermittent malfunctions, refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

How to Cope with Intermittent

Malfunction P.00-14.

10.After repairs are completed, conduct a Road Test

duplicating the complaint conditions to confirm the

malfunction has been eliminated.

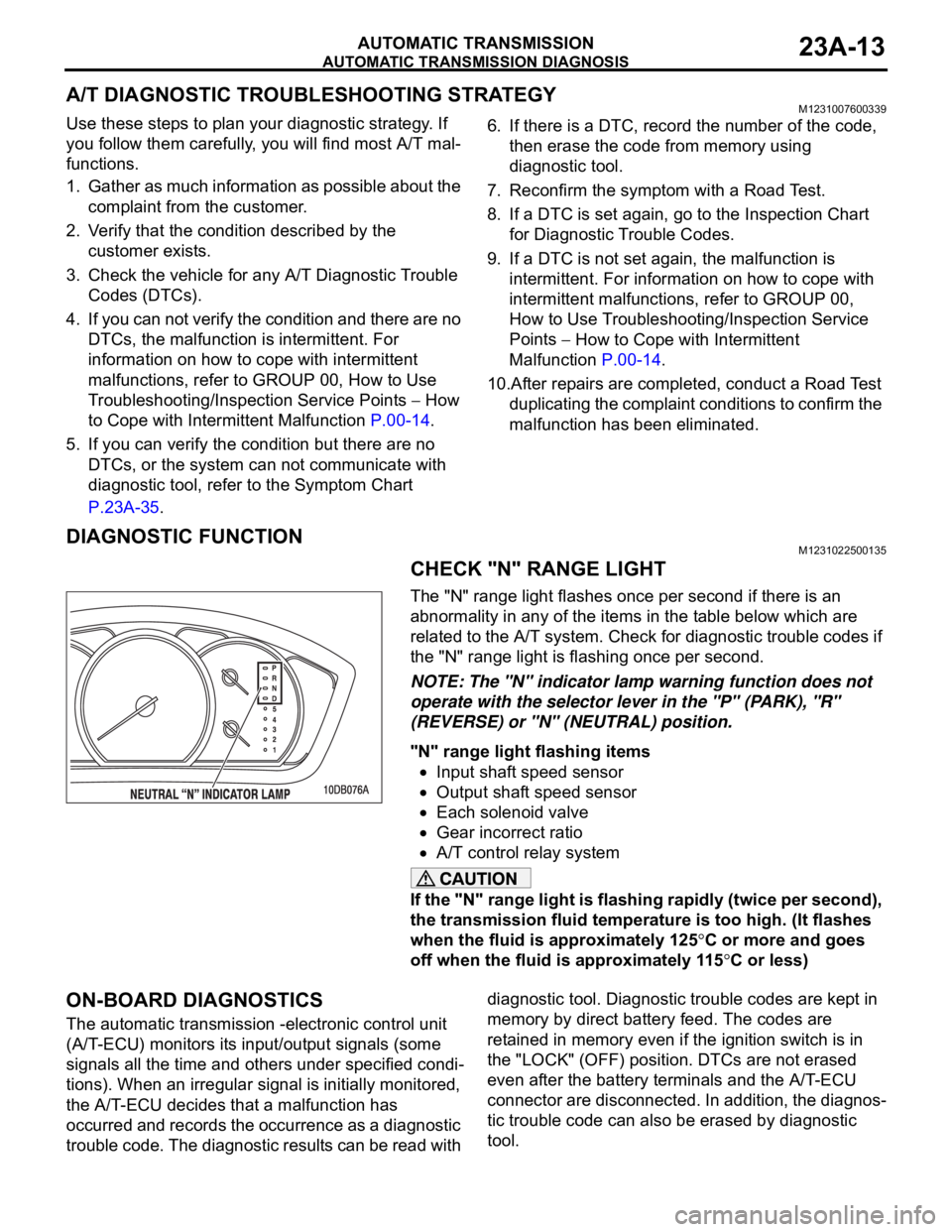

DIAGNOSTIC FUNCTIONM1231022500135

CHECK "N" RANGE LIGHT

The "N" range light flashes once per second if there is an

abnormality in any of the items in the table below which are

related to the A/T system. Check for diagnostic trouble codes if

the "N" range light is flashing once per second.

NOTE: The "N" indicator lamp warning function does not

operate with the selector lever in the "P" (PARK), "R"

(REVERSE) or "N" (NEUTRAL) position.

"N" range light flashing items

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Gear incorrect ratio

A/T control relay system

If the "N" range light is flashing rapidly (twice per second),

the transmission fluid temperature is too high. (It flashes

when the fluid is approximately 125

C or more and goes

off when the fluid is approximately 115

C or less)

ON-BOARD DIAGNOSTICS

The automatic transmission -electronic control unit

(A/T-ECU) monitors its input/output signals (some

signals all the time and others under specified condi-

tions). When an irregular signal is initially monitored,

the A/T-ECU decides that a malfunction has

occurred and records the occurrence as a diagnostic

trouble code. The diagnostic results can be read with diagnostic tool. Diagnostic trouble codes are kept in

memory by direct battery feed. The codes are

retained in memory even if the ignition switch is in

the "LOCK" (OFF) position. DTCs are not erased

even after the battery terminals and the A/T-ECU

connector are disconnected. In addition, the diagnos-

tic trouble code can also be erased by diagnostic

tool.

Page 1473 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-14

NOTE: If a sensor is disconnected when the ignition

switch is in the "ON" position, a diagnostic trouble

code is stored in memory. In this case, erase the

DTC using diagnostic tool.The diagnostic items are displayed in numeric order.

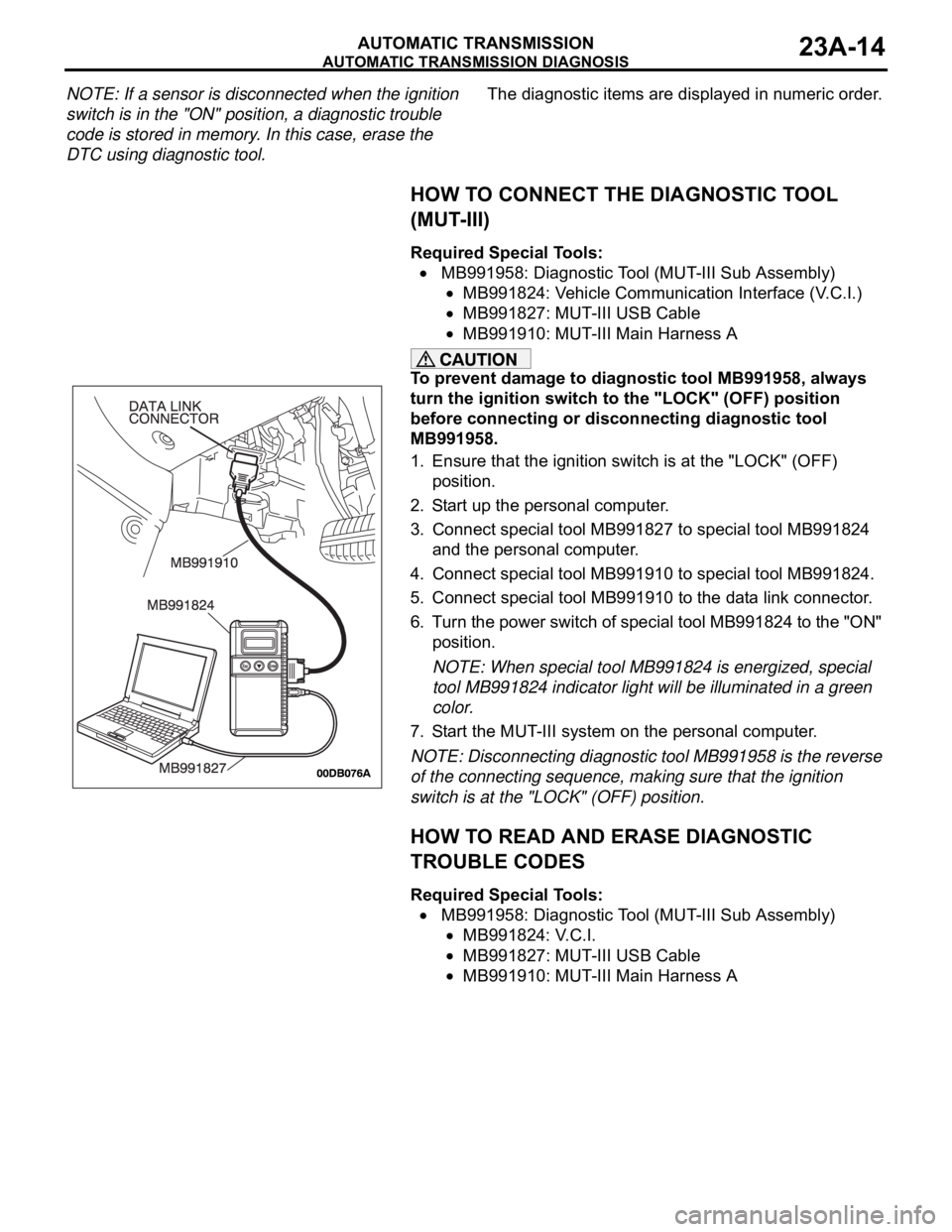

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energized, special

tool MB991824 indicator light will be illuminated in a green

color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnecting diagnostic tool MB991958 is the reverse

of the connecting sequence, making sure that the ignition

switch is at the "LOCK" (OFF) position.

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1474 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-15

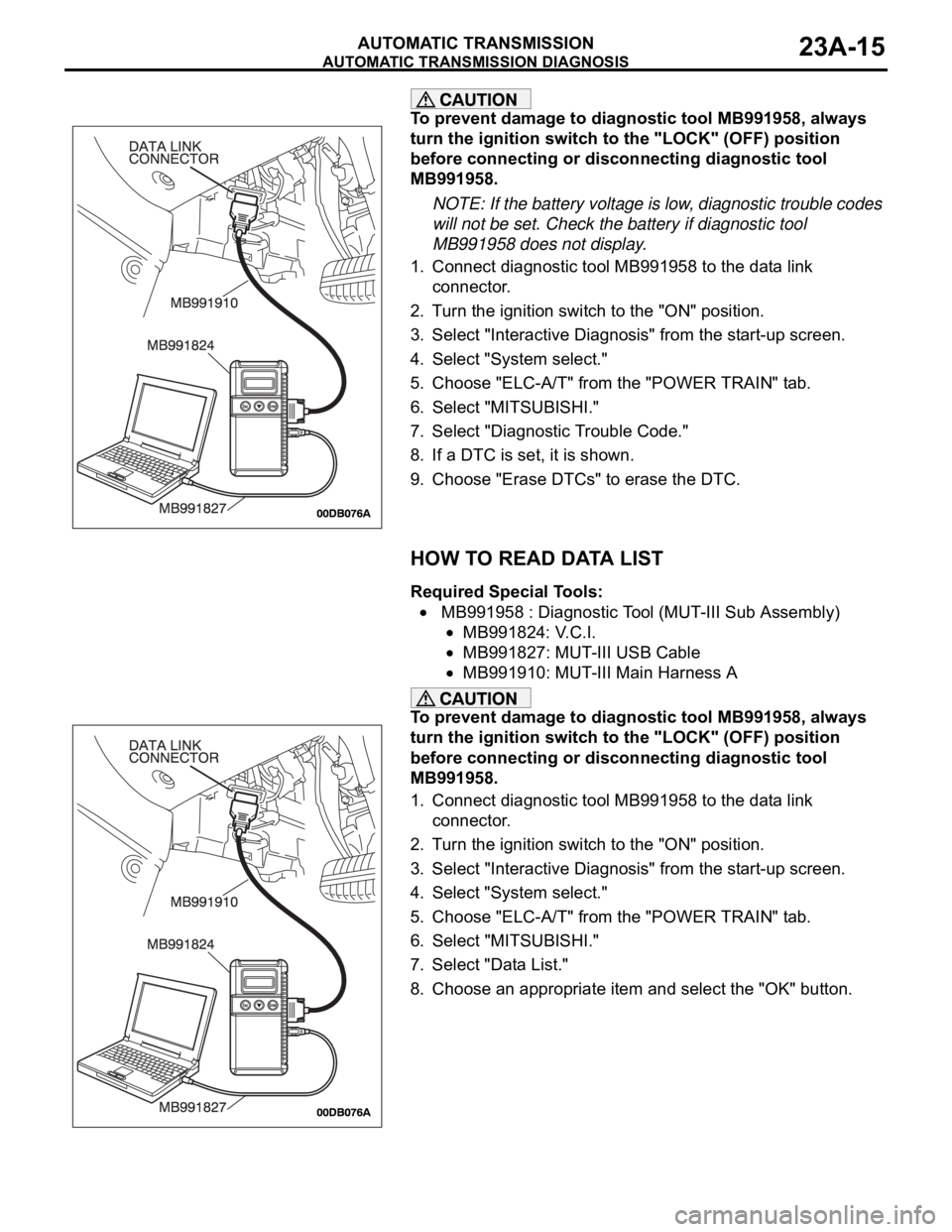

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes

will not be set. Check the battery if diagnostic tool

MB991958 does not display.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ELC-A/T" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Diagnostic Trouble Code."

8. If a DTC is set, it is shown.

9. Choose "Erase DTCs" to erase the DTC.

HOW TO READ DATA LIST

Required Special Tools:

MB991958 : Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ELC-A/T" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Data List."

8. Choose an appropriate item and select the "OK" button.

Page 1475 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-16

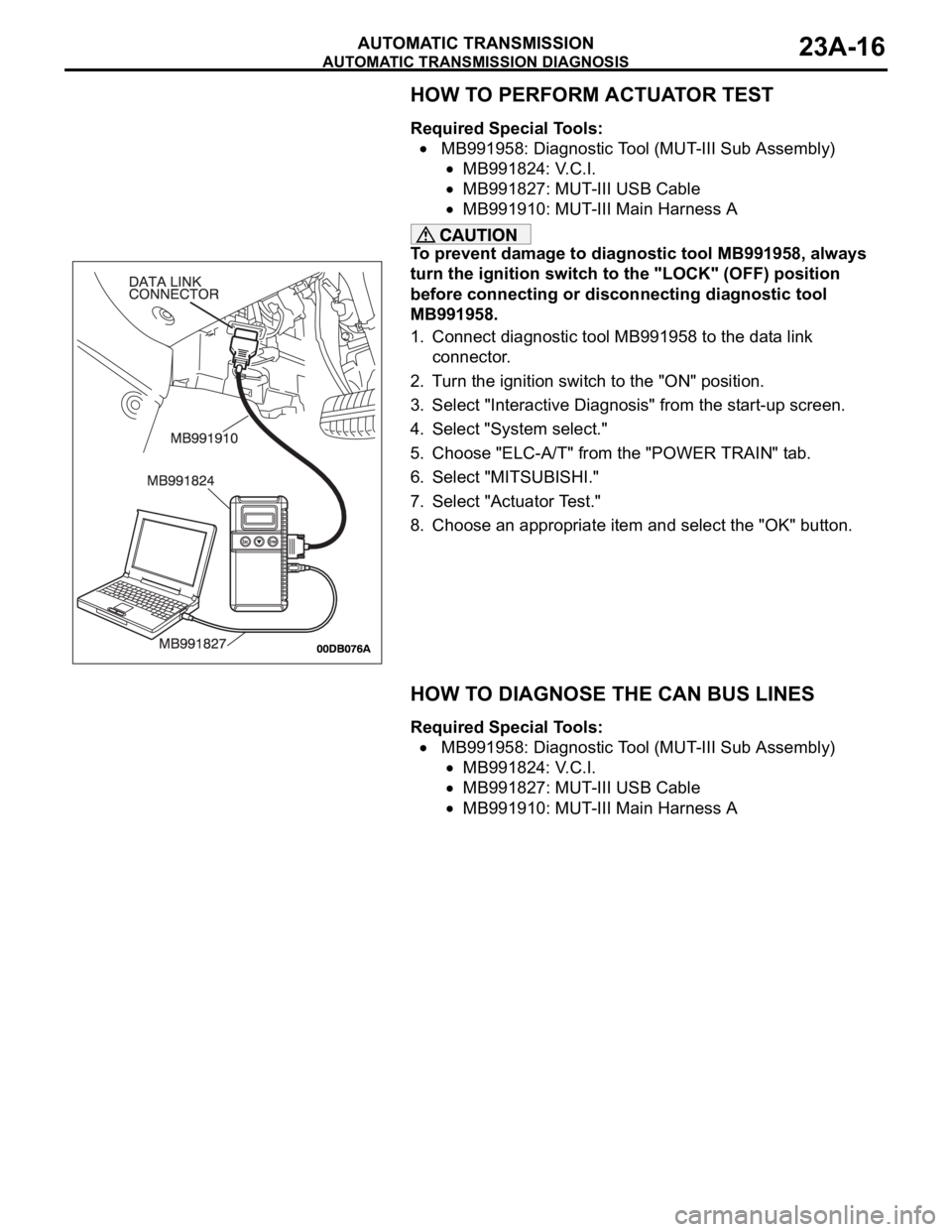

HOW TO PERFORM ACTUATOR TEST

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ELC-A/T" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Actuator Test."

8. Choose an appropriate item and select the "OK" button.

HOW TO DIAGNOSE THE CAN BUS LINES

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1476 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-17

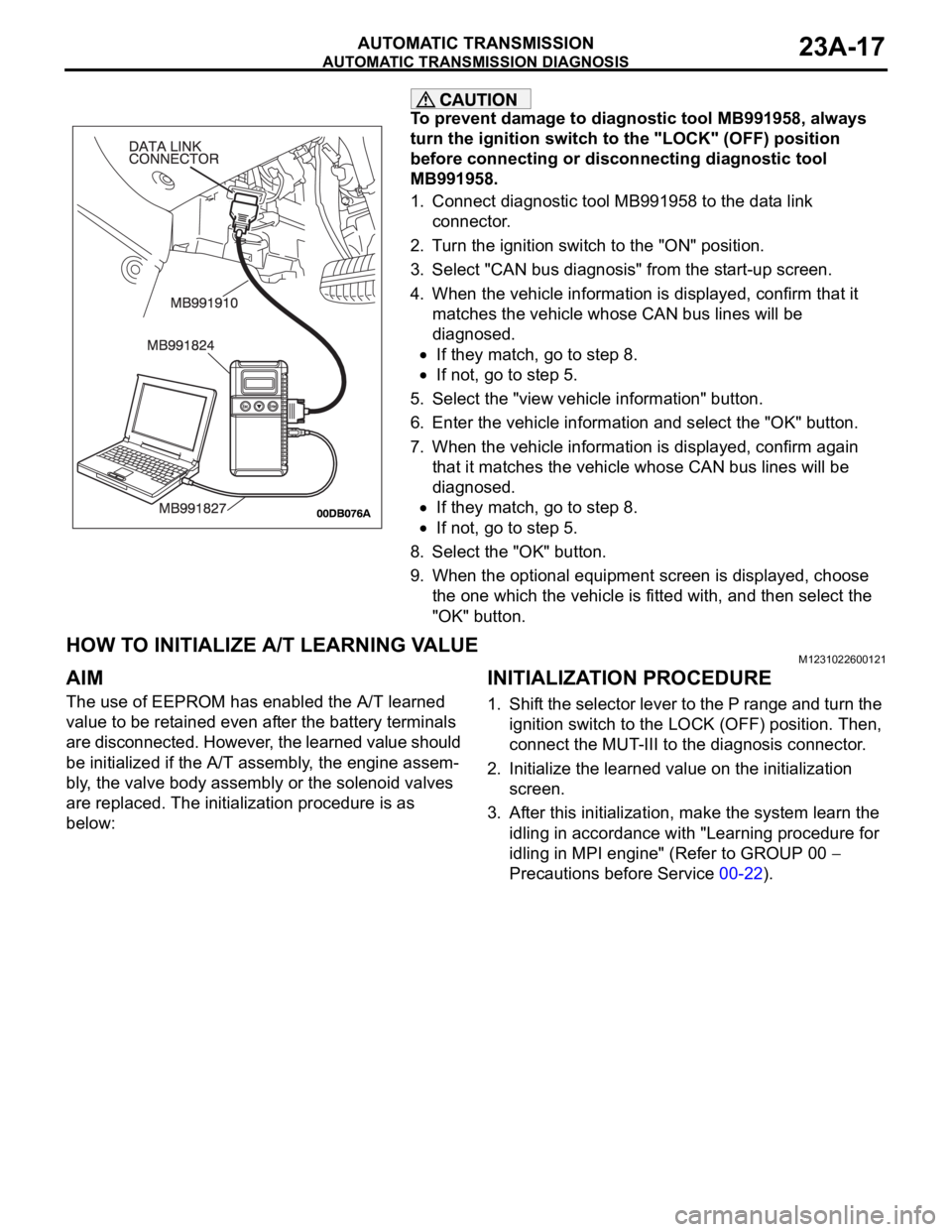

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "CAN bus diagnosis" from the start-up screen.

4. When the vehicle information is displayed, confirm that it

matches the vehicle whose CAN bus lines will be

diagnosed.

If they match, go to step 8.

If not, go to step 5.

5. Select the "view vehicle information" button.

6. Enter the vehicle information and select the "OK" button.

7. When the vehicle information is displayed, confirm again

that it matches the vehicle whose CAN bus lines will be

diagnosed.

If they match, go to step 8.

If not, go to step 5.

8. Select the "OK" button.

9. When the optional equipment screen is displayed, choose

the one which the vehicle is fitted with, and then select the

"OK" button.

HOW TO INITIALIZE A/T LEARNING VALUEM1231022600121

AIM

The use of EEPROM has enabled the A/T learned

value to be retained even after the battery terminals

are disconnected. However, the learned value should

be initialized if the A/T assembly, the engine assem-

bly, the valve body assembly or the solenoid valves

are replaced. The initialization procedure is as

below:

INITIALIZATION PROCEDURE

1. Shift the selector lever to the P range and turn the

ignition switch to the LOCK (OFF) position. Then,

connect the MUT-III to the diagnosis connector.

2. Initialize the learned value on the initialization

screen.

3. After this initialization, make the system learn the

idling in accordance with "Learning procedure for

idling in MPI engine" (Refer to GROUP 00

Precautions before Service 00-22).