automatic transmission MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1477 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-18

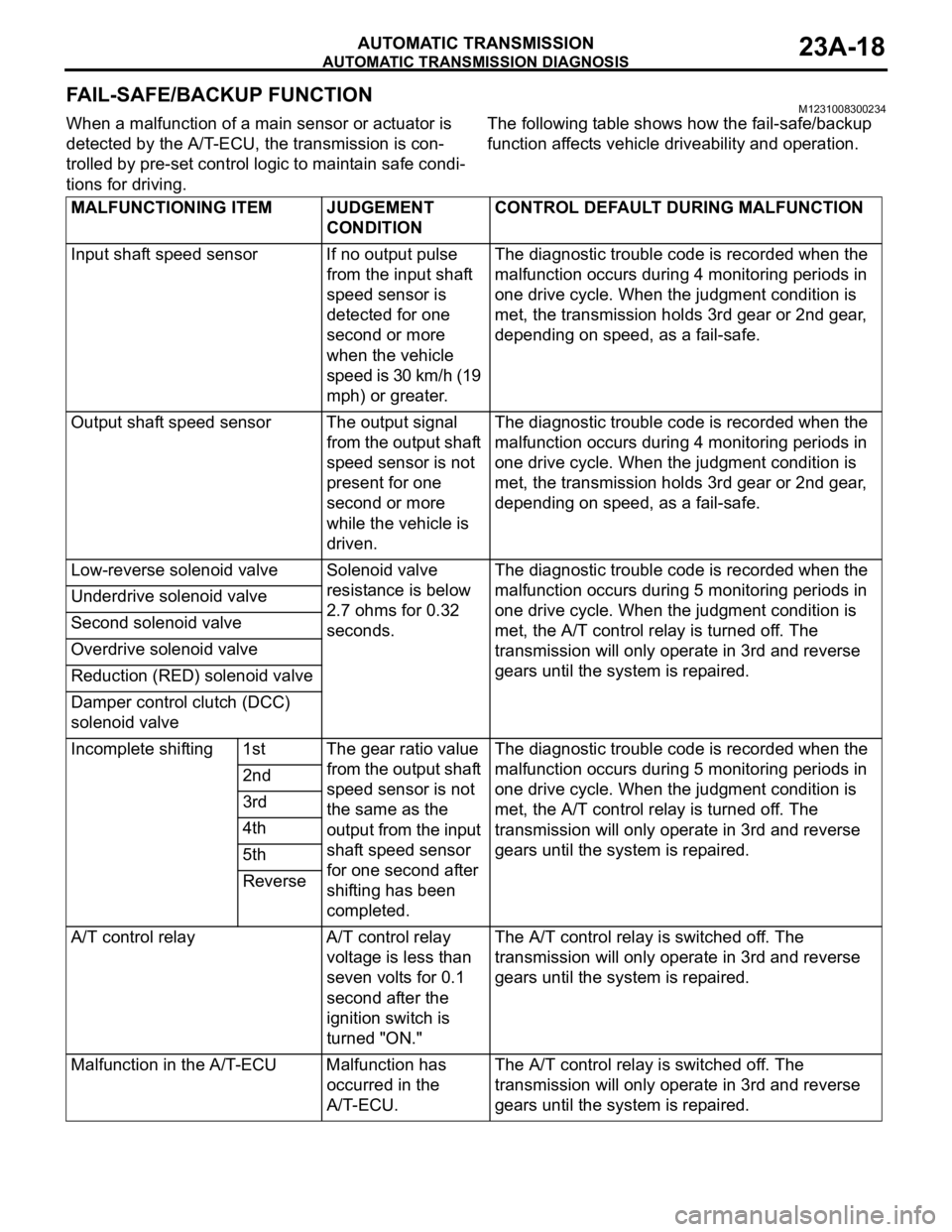

FAIL-SAFE/BACKUP FUNCTIONM1231008300234

When a malfunction of a main sensor or actuator is

detected by the A/T-ECU, the transmission is con-

trolled by pre-set control logic to maintain safe condi-

tions for driving.The following table shows how the fail-safe/backup

function affects vehicle driveability and operation.

MALFUNCTIONING ITEM JUDGEMENT

CONDITIONCONTROL DEFAULT DURING MALFUNCTION

Input shaft speed sensor If no output pulse

from the input shaft

speed sensor is

detected for one

second or more

when the vehicle

speed is 30 km/h (19

mph) or greater.The diagnostic trouble code is recorded when the

malfunction occurs during 4 monitoring periods in

one drive cycle. When the judgment condition is

met, the transmission holds 3rd gear or 2nd gear,

depending on speed, as a fail-safe.

Output shaft speed sensor The output signal

from the output shaft

speed sensor is not

present for one

second or more

while the vehicle is

driven.The diagnostic trouble code is recorded when the

malfunction occurs during 4 monitoring periods in

one drive cycle. When the judgment condition is

met, the transmission holds 3rd gear or 2nd gear,

depending on speed, as a fail-safe.

Low-reverse solenoid valve Solenoid valve

resistance is below

2.7 ohms for 0.32

seconds.The diagnostic trouble code is recorded when the

malfunction occurs during 5 monitoring periods in

one drive cycle. When the judgment condition is

met, the A/T control relay is turned off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired. Underdrive solenoid valve

Second solenoid valve

Overdrive solenoid valve

Reduction (RED) solenoid valve

Damper control clutch (DCC)

solenoid valve

Incomplete shifting 1st The gear ratio value

from the output shaft

speed sensor is not

the same as the

output from the input

shaft speed sensor

for one second after

shifting has been

completed.The diagnostic trouble code is recorded when the

malfunction occurs during 5 monitoring periods in

one drive cycle. When the judgment condition is

met, the A/T control relay is turned off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired. 2nd

3rd

4th

5th

Reverse

A/T control relay A/T control relay

voltage is less than

seven volts for 0.1

second after the

ignition switch is

turned "ON."The A/T control relay is switched off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired.

Malfunction in the A/T-ECU Malfunction has

occurred in the

A/T-ECU.The A/T control relay is switched off. The

transmission will only operate in 3rd and reverse

gears until the system is repaired.

Page 1478 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-19

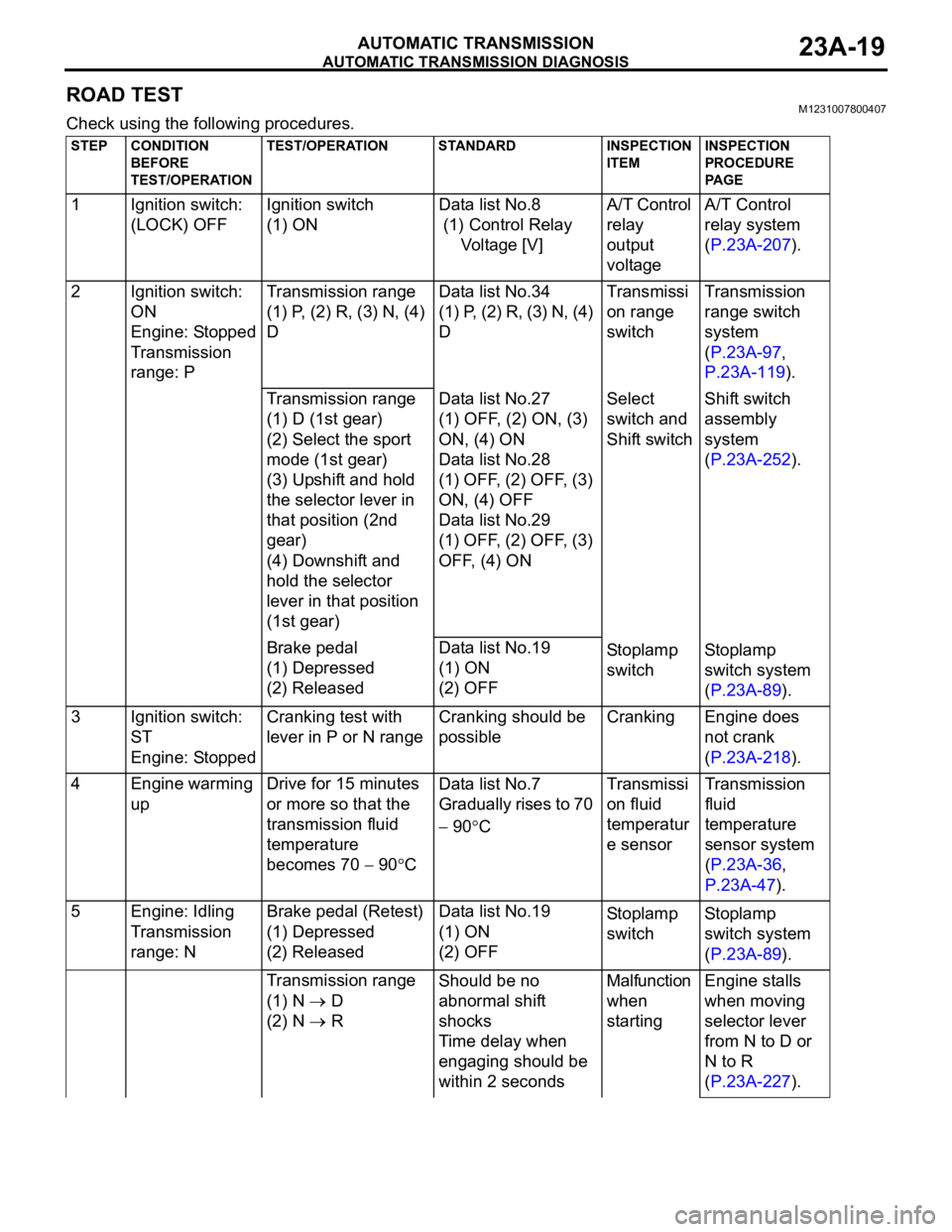

ROAD TESTM1231007800407

Check using the following procedures.

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

1 Ignition switch:

(LOCK) OFFIgnition switch

(1) ONData list No.8

(1) Control Relay

Voltage [V]A/T Control

relay

output

voltageA/T Control

relay system

(P.23A-207).

2 Ignition switch:

ON

Engine: Stopped

Transmission

range: PTransmission range

(1) P, (2) R, (3) N, (4)

DData list No.34

(1) P, (2) R, (3) N, (4)

DTransmissi

on range

switchTransmission

range switch

system

(P.23A-97,

P.23A-119).

Transmission range

(1) D (1st gear)

(2) Select the sport

mode (1st gear)

(3) Upshift and hold

the selector lever in

that position (2nd

gear)

(4) Downshift and

hold the selector

lever in that position

(1st gear)Data list No.27

(1) OFF, (2) ON, (3)

ON, (4) ON

Data list No.28

(1) OFF, (2) OFF, (3)

ON, (4) OFF

Data list No.29

(1) OFF, (2) OFF, (3)

OFF, (4) ONSelect

switch and

Shift switchShift switch

assembly

system

(P.23A-252).

Brake pedal

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

3 Ignition switch:

ST

Engine: StoppedCranking test with

lever in P or N rangeCranking should be

possibleCranking Engine does

not crank

(P.23A-218).

4 Engine warming

upDrive for 15 minutes

or more so that the

transmission fluid

temperature

becomes 70

90CData list No.7

Gradually rises to 70

90CTransmissi

on fluid

temperatur

e sensorTransmission

fluid

temperature

sensor system

(P.23A-36,

P.23A-47).

5 Engine: Idling

Transmission

range: NBrake pedal (Retest)

(1) Depressed

(2) ReleasedData list No.19

(1) ON

(2) OFFSto pl amp

switchSt o pla mp

switch system

(P.23A-89).

Transmission range

(1) N

D

(2) N

RShould be no

abnormal shift

shocks

Time delay when

engaging should be

within 2 secondsMalfunction

when

startingEngine stalls

when moving

selector lever

from N to D or

N to R

(P.23A-227).

Page 1479 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-20

Shift shock

when shifting

from N to D and

long delay

(P.23A-229).

Shift shock

when shifting

from N to R and

long delay

(P.23A-232).

Shift shock

when shifting

from N to D, N

to R and long

delay

(P.23A-235).

Does not

moveDoes not move

forward

(P.23A-220).

Does not move

in reverse

(P.23A-223).

Does not move

(forward or in

reverse)

(P.23A-226).

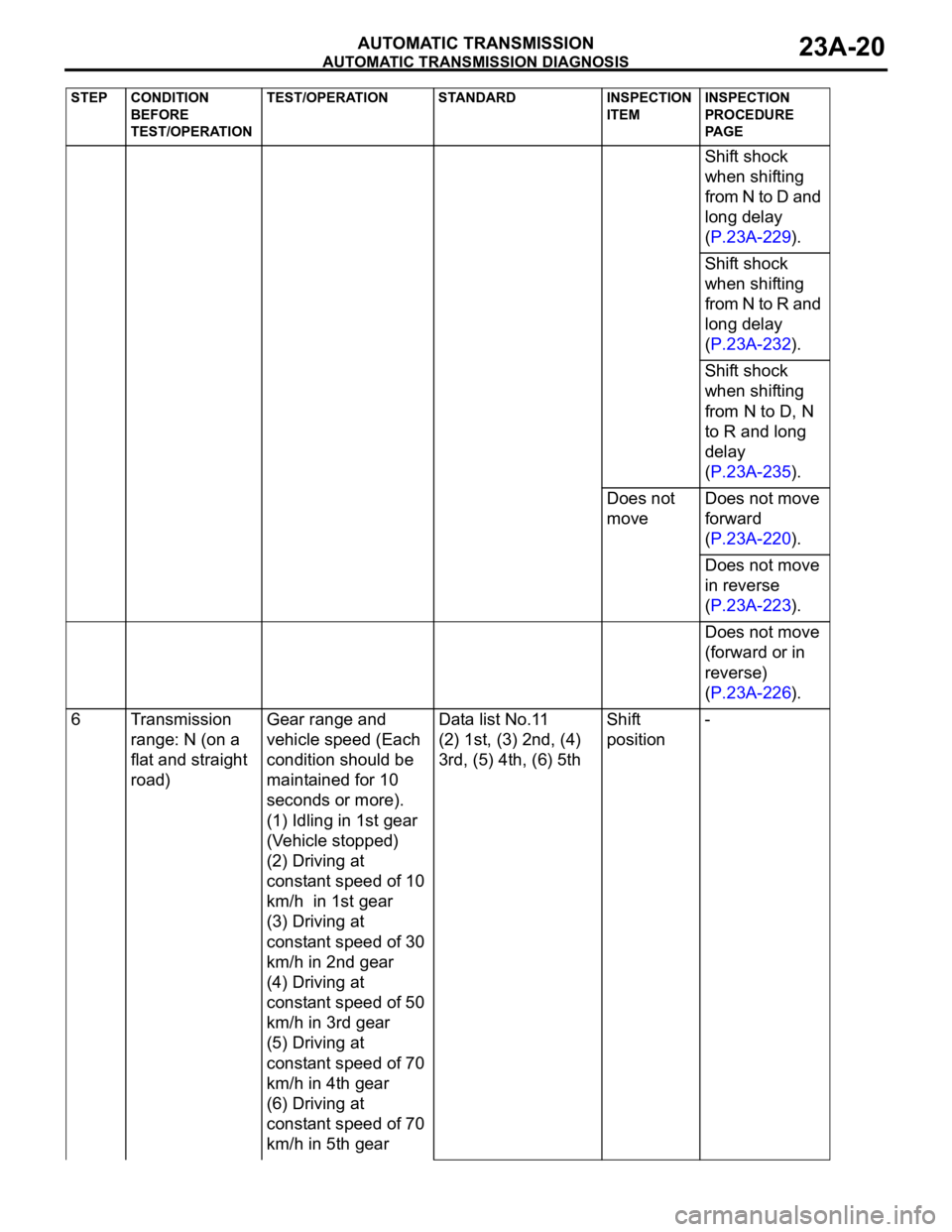

6 Transmission

range: N (on a

flat and straight

road)Gear range and

vehicle speed (Each

condition should be

maintained for 10

seconds or more).

(1) Idling in 1st gear

(Vehicle stopped)

(2) Driving at

constant speed of 10

km/h in 1st gear

(3) Driving at

constant speed of 30

km/h in 2nd gear

(4) Driving at

constant speed of 50

km/h in 3rd gear

(5) Driving at

constant speed of 70

km/h in 4th gear

(6) Driving at

constant speed of 70

km/h in 5th gearData list No.11

(2) 1st, (3) 2nd, (4)

3rd, (5) 4th, (6) 5thShift

position-

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1480 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-21

Data list No.12

(2) 100%, (3) 100%,

(4) 100%, (6) 100%Low-revers

e solenoid

valve duty

%Low-reverse

solenoid valve

system

(P.23A-133).

Data list No.13

(2) 0%, (3) 0%, (4)

0%, (6) 100%Underdrive

solenoid

valve duty

%Underdrive

solenoid valve

system

(P.23A-144).

Data list No.14

(2)100%, (3) 0%, (4)

0%, (6) 0%Second

solenoid

valve duty

%Second

solenoid valve

system

(P.23A-154).

Data list No.15

(2) 100%, (3) 100%,

(4) 0%, (6) 0%Overdrive

solenoid

valve duty

%Overdrive

solenoid valve

system

(P.23A-164).

Data list No.16

(2) 0%, (3) 0%, (4)

100%, (6) 100%Reduction

solenoid

valve duty

%Reduction

solenoid valve

system

(P.23A-174).

Data list No.9

(1) 0km/h

(4) 50km/hVehicle

speed

sensorvehicle speed

sensor system

Data list No.5

(4) 1,600

1,900

r/minInput shaft

speed

sensorInput shaft

speed sensor

system

(P.23A-55).

Data list No.6

(4) 1,600

1,900

r/minOutput

shaft speed

sensorOutput shaft

speed sensor

system

(P.23A-72).

Data list No.17

(3) 0%

(5) 70

90%Damper

control

clutch

solenoid

valve duty

%Damper control

clutch solenoid

system

(P.23A-185,

P.23A-201,

P.23A-204).

Data list No.10

(3) 100-300 rpm

(5) 0-10 rpmDamper

clutch

slippage

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1481 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-22

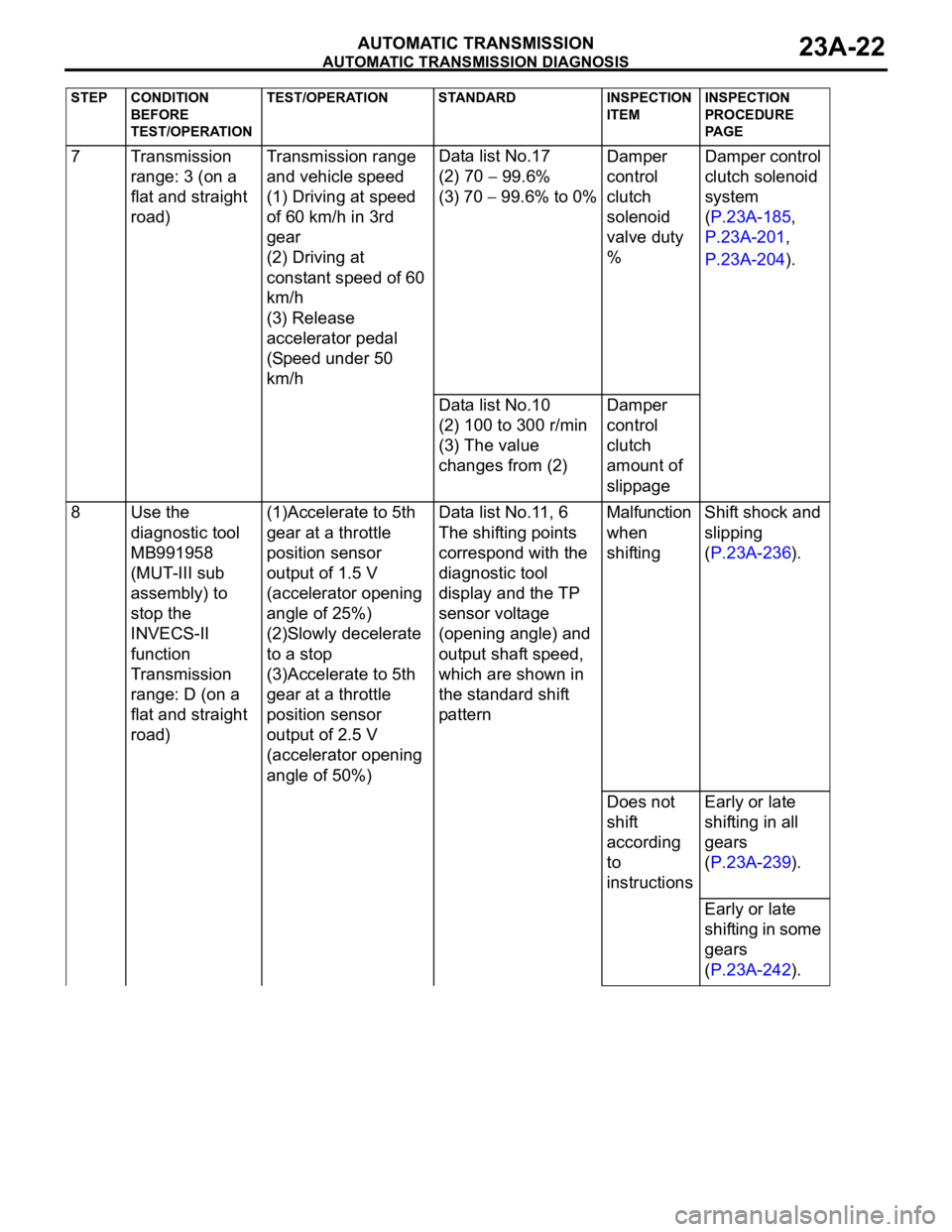

7 Transmission

range: 3 (on a

flat and straight

road)Transmission range

and vehicle speed

(1) Driving at speed

of 60 km/h in 3rd

gear

(2) Driving at

constant speed of 60

km/h

(3) Release

accelerator pedal

(Speed under 50

km/hData list No.17

(2) 70

99.6%

(3) 70

99.6% to 0%Damper

control

clutch

solenoid

valve duty

%Damper control

clutch solenoid

system

(P.23A-185,

P.23A-201,

P.23A-204).

Data list No.10

(2) 100 to 300 r/min

(3) The value

changes from (2)Damper

control

clutch

amount of

slippage

8 Use the

diagnostic tool

MB991958

(MUT-III sub

assembly) to

stop the

INVECS-II

function

Transmission

range: D (on a

flat and straight

road)(1)Accelerate to 5th

gear at a throttle

position sensor

output of 1.5 V

(accelerator opening

angle of 25%)

(2)Slowly decelerate

to a stop

(3)Accelerate to 5th

gear at a throttle

position sensor

output of 2.5 V

(accelerator opening

angle of 50%)Data list No.11, 6

The shifting points

correspond with the

diagnostic tool

display and the TP

sensor voltage

(opening angle) and

output shaft speed,

which are shown in

the standard shift

patternMalfunction

when

shiftingShift shock and

slipping

(P.23A-236).

Does not

shift

according

to

instructionsEarly or late

shifting in all

gears

(P.23A-239).

Early or late

shifting in some

gears

(P.23A-242).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1482 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-23

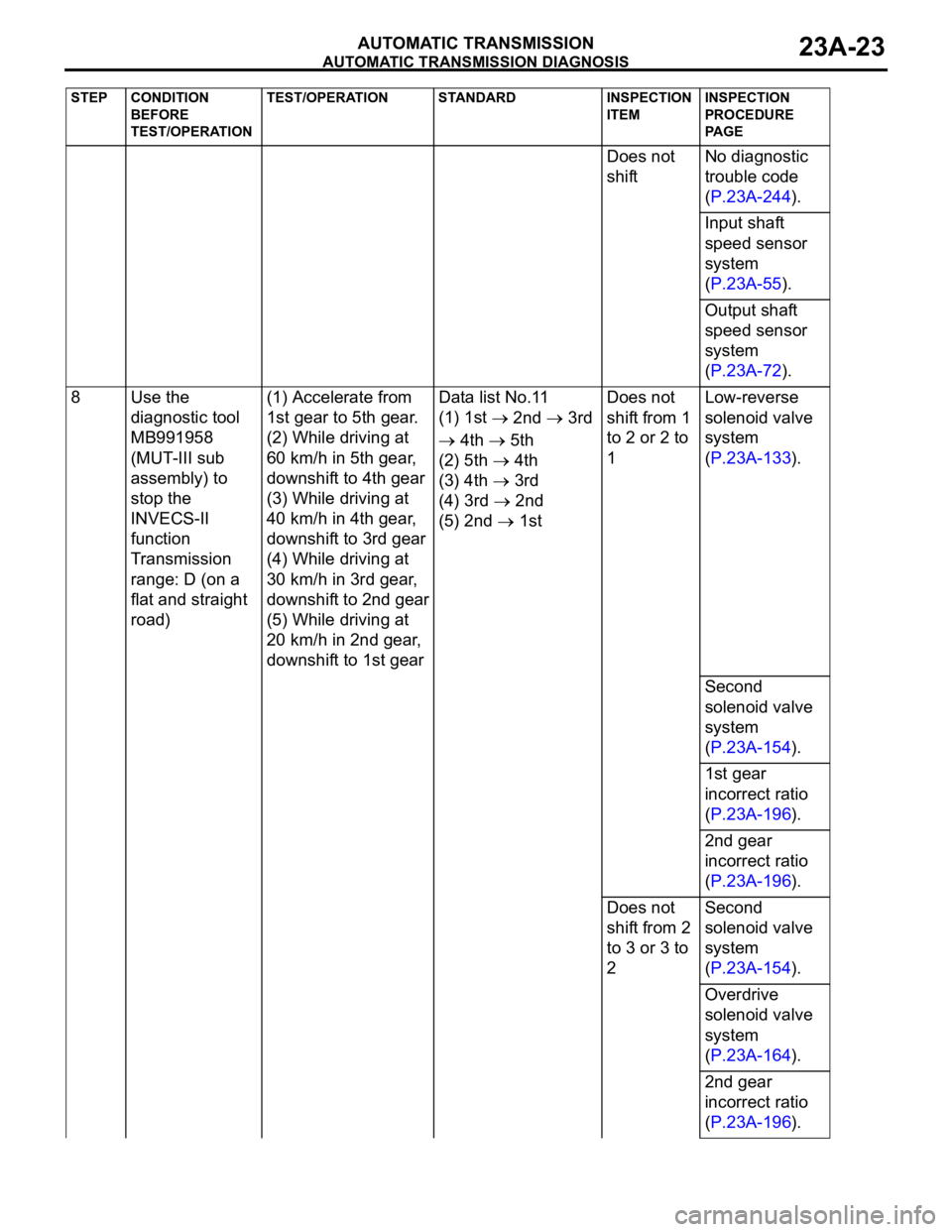

Does not

shiftNo diagnostic

trouble code

(P.23A-244).

Input shaft

speed sensor

system

(P.23A-55).

Output shaft

speed sensor

system

(P.23A-72).

8 Use the

diagnostic tool

MB991958

(MUT-III sub

assembly) to

stop the

INVECS-II

function

Transmission

range: D (on a

flat and straight

road)(1) Accelerate from

1st gear to 5th gear.

(2) While driving at

60 km/h in 5th gear,

downshift to 4th gear

(3) While driving at

40 km/h in 4th gear,

downshift to 3rd gear

(4) While driving at

30 km/h in 3rd gear,

downshift to 2nd gear

(5) While driving at

20 km/h in 2nd gear,

downshift to 1st gearData list No.11

(1) 1st

2nd 3rd

4th 5th

(2) 5th

4th

(3) 4th

3rd

(4) 3rd

2nd

(5) 2nd

1stDoes not

shift from 1

to 2 or 2 to

1Low-reverse

solenoid valve

system

(P.23A-133).

Second

solenoid valve

system

(P.23A-154).

1st gear

incorrect ratio

(P.23A-196).

2nd gear

incorrect ratio

(P.23A-196).

Does not

shift from 2

to 3 or 3 to

2Second

solenoid valve

system

(P.23A-154).

Overdrive

solenoid valve

system

(P.23A-164).

2nd gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1483 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-24

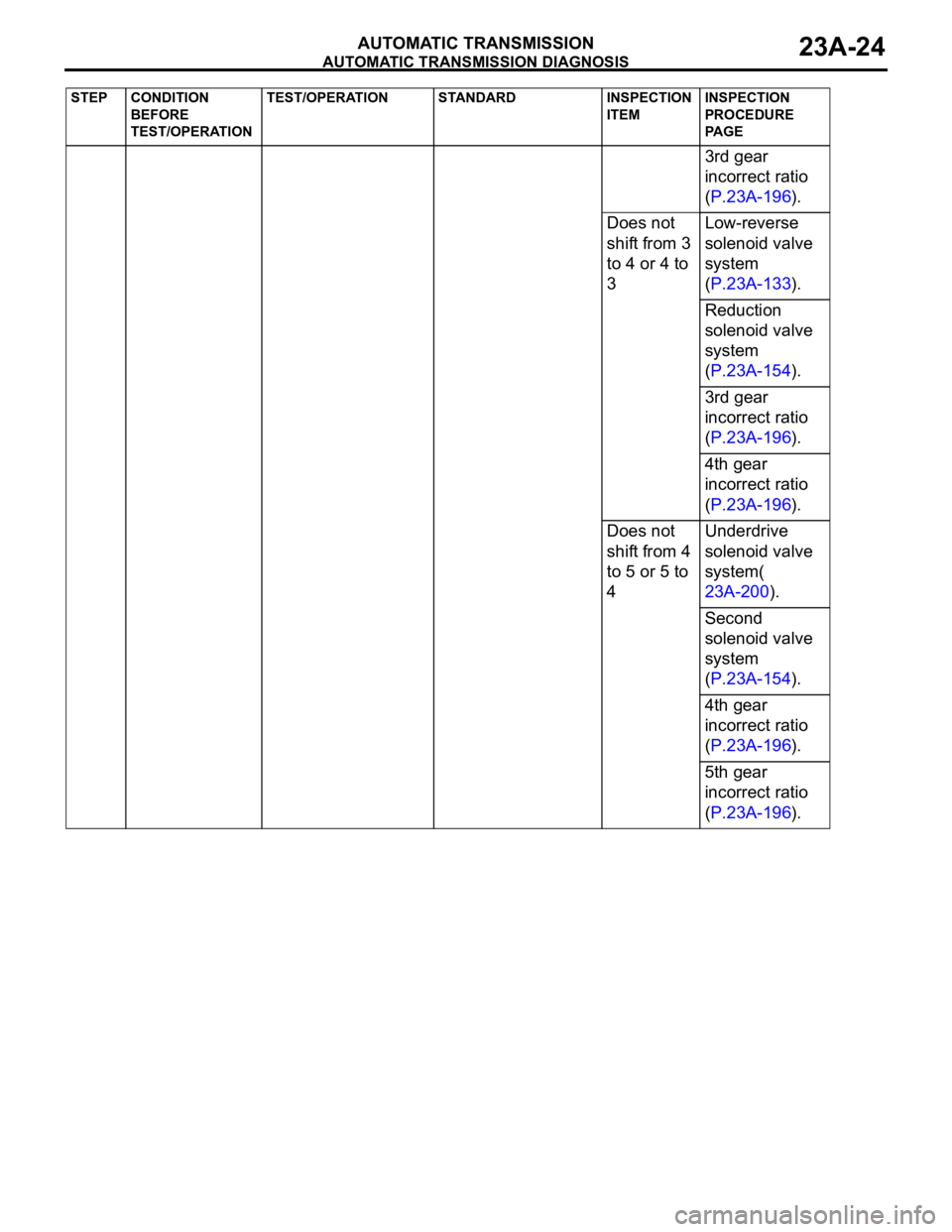

3rd gear

incorrect ratio

(P.23A-196).

Does not

shift from 3

to 4 or 4 to

3Low-reverse

solenoid valve

system

(P.23A-133).

Reduction

solenoid valve

system

(P.23A-154).

3rd gear

incorrect ratio

(P.23A-196).

4th gear

incorrect ratio

(P.23A-196).

Does not

shift from 4

to 5 or 5 to

4Underdrive

solenoid valve

system(

23A-200).

Second

solenoid valve

system

(P.23A-154).

4th gear

incorrect ratio

(P.23A-196).

5th gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1484 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-25

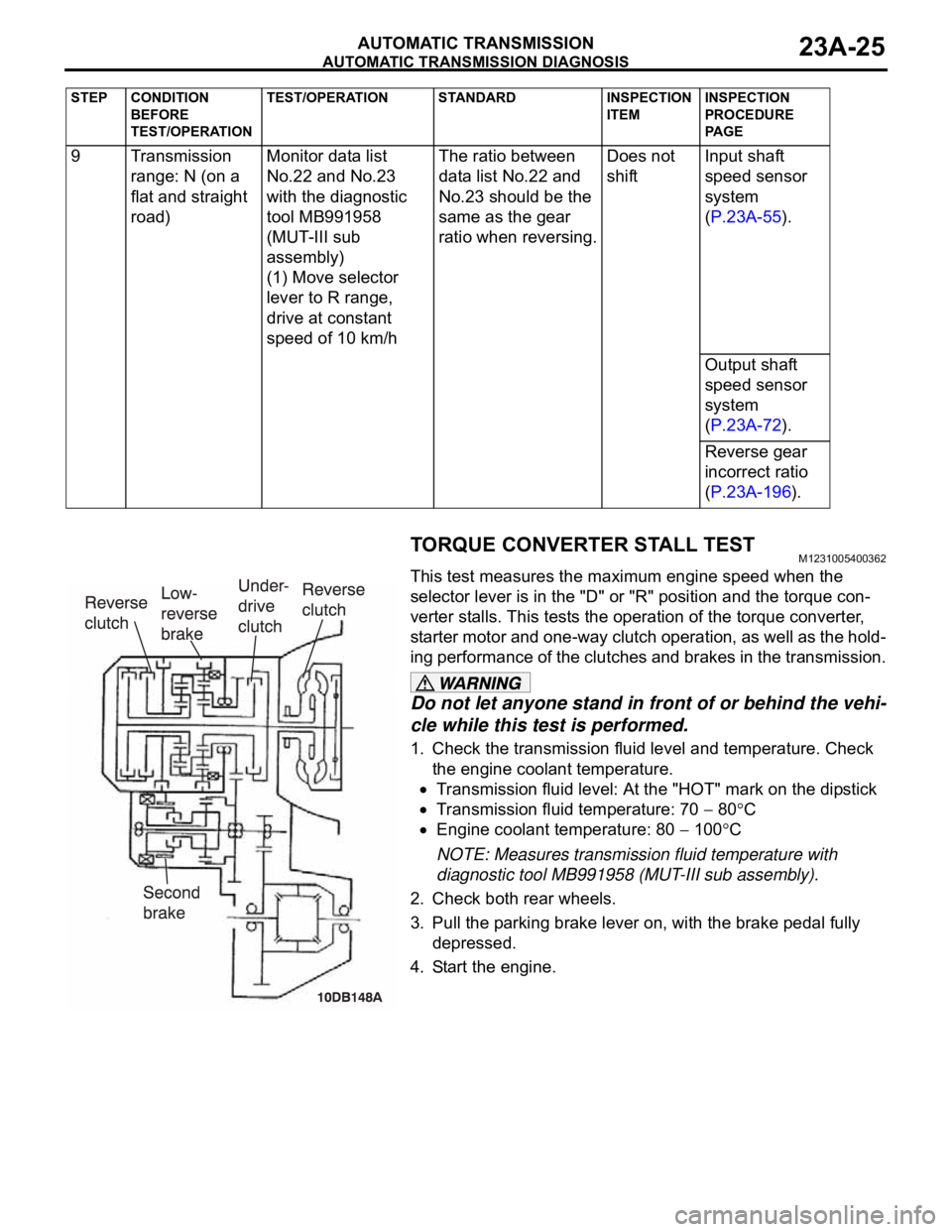

TORQUE CONVERTER STALL TESTM1231005400362

This test measures the maximum engine speed when the

selector lever is in the "D" or "R" position and the torque con-

verter stalls. This tests the operation of the torque converter,

starter motor and one-way clutch operation, as well as the hold-

ing performance of the clutches and brakes in the transmission.

Do not let anyone stand in front of or behind the vehi-

cle while this test is performed.

1. Check the transmission fluid level and temperature. Check

the engine coolant temperature.

Transmission fluid level: At the "HOT" mark on the dipstick

Transmission fluid temperature: 70 80C

Engine coolant temperature: 80 100C

NOTE: Measures transmission fluid temperature with

diagnostic tool MB991958 (MUT-III sub assembly).

2. Check both rear wheels.

3. Pull the parking brake lever on, with the brake pedal fully

depressed.

4. Start the engine. 9 Transmission

range: N (on a

flat and straight

road)Monitor data list

No.22 and No.23

with the diagnostic

tool MB991958

(MUT-III sub

assembly)

(1) Move selector

lever to R range,

drive at constant

speed of 10 km/hThe ratio between

data list No.22 and

No.23 should be the

same as the gear

ratio when reversing.Does not

shiftInput shaft

speed sensor

system

(P.23A-55).

Output shaft

speed sensor

system

(P.23A-72).

Reverse gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1485 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-26

The throttle should not be fully open for any more than

five seconds.

If you repeat the stall test when the transmission fluid

temperature is greater than 80

C, move the selector

lever to the "N" position and let the engine run at

approximately 1,000 r/min for at least one minute. Wait

until the transmission fluid temperature returns to 80

C

or less.

5. Move the selector lever to the "D" position. Fully depress the

accelerator pedal and read the maximum engine speed at

this time.

Standard value: Stall speed: 2,100

2,600 r/min

6. Move the selector lever to the "R" position. Fully depress the

accelerator pedal and read the maximum engine speed.

Standard value: Stall speed: 2,100

2,600 r/min

TORQUE CONVERTER STALL TEST JUDGMENT

RESULTS

1. Stall speed is too high in both "D" and "R" range

Malfunction of the torque converter (Slippage on the splines

of the torque converter and the input shaft)

Low line pressure

Low-reverse brake slippage and malfunction of the one-way

clutch

2. Stall speed is too high in "D" range only

Underdrive clutch slippage

3. Stall speed is too high in "R" range only

Reverse clutch slippage

4. Stall speed is too low in both "D" and "R" ranges

Malfunction of the torque converter (Slippage of the

one-way clutch)

Insufficient engine output

HYDRAULIC PRESSURE TESTSM1231005500392

The transmission fluid temperature should be between 70

80C during the test.

1. Check the transmission fluid level and temperature. Check

engine coolant temperature.

Transmission fluid level: "HOT" mark on the dipstick

Transmission fluid temperature: 70 80C

Engine coolant temperature: 80 100C

2. Raise the vehicle so that the wheels are free to turn.

Page 1486 of 1500

![MITSUBISHI 380 2005 Owners Guide AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha MITSUBISHI 380 2005 Owners Guide AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discha](/img/19/57086/w960_57086-1485.png)

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-27

3. Connect the special tools (3.0 MPa (427 psi) oil pressure

gauge [MD998330] and adapters [MD998332, MD998900])

to each pressure discharge port.

NOTE: .

2ND: Second brake pressure port

UD: Underdrive clutch pressure port

LR: Low-reverse brake pressure port

DR: Torque converter release pressure port

DA: Torque converter apply pressure port

RV: Reverse clutch pressure port

OD: Overdrive clutch pressure port

DIR: Direct clutch pressure port

RED: Reduction clutch pressure port

4. Restart the engine.

5. Check that there are no leaks around the special tool port

adapters.

6. Measure the hydraulic pressure at each port under the

conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard

value ranges.

7. If the pressure is not within the standard value, stop the

engine and refer to the hydraulic pressure test diagnosis

table.

8. Remove the O-ring from the port plug and replace it.

9. Remove the special tool, and install the plugs to the

hydraulic pressure ports.

10.Start the engine and check that there are no leaks around

the plugs.