engine coolant MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 957 of 1500

SPECIFICATIONS

ENGINE COOLING14-42

SPECIFICATIONS

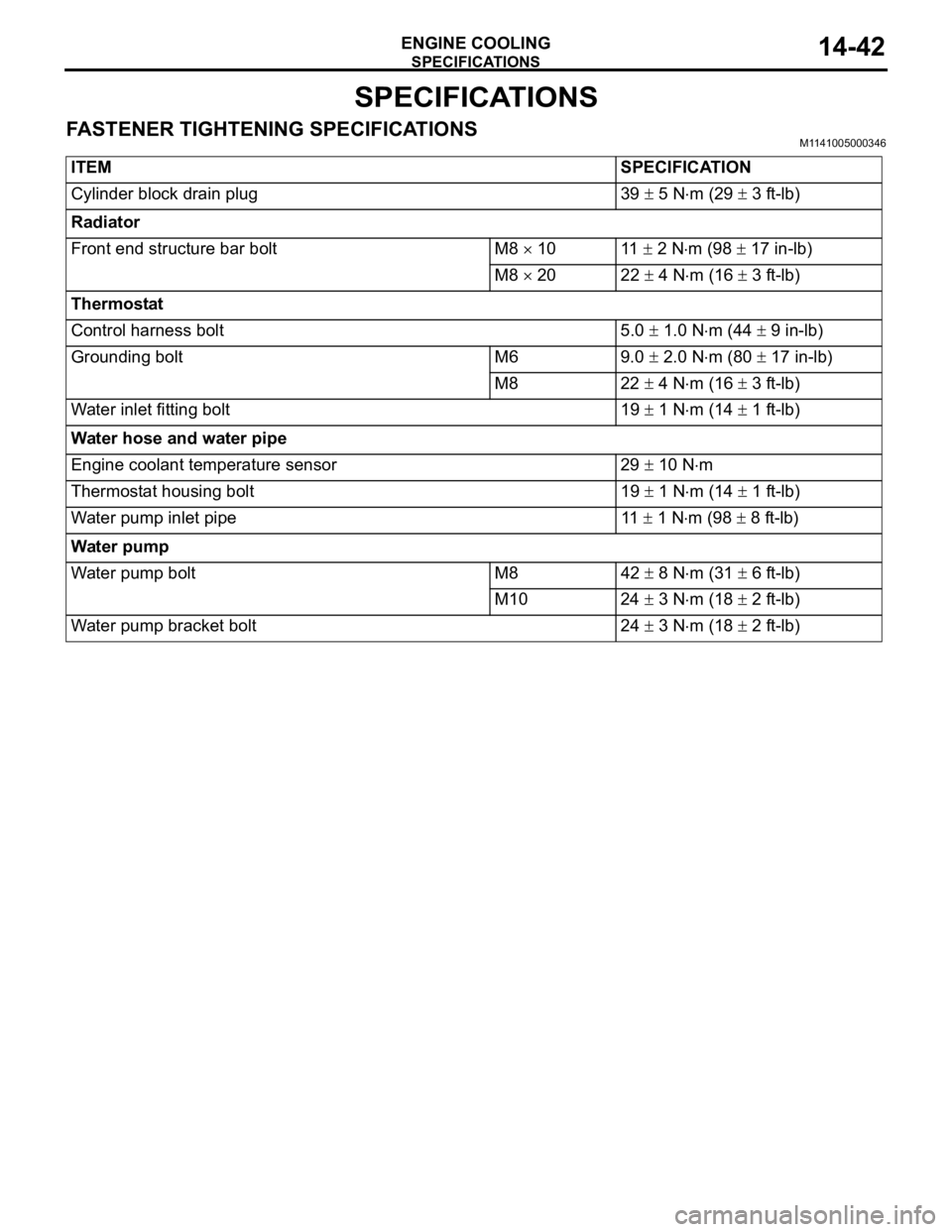

FASTENER TIGHTENING SPECIFICATIONSM1141005000346

ITEM SPECIFICATION

Cylinder block drain plug 39

5 Nm (29 3 ft-lb)

Radiator

Front end structure bar bolt M8

10 11 2 Nm (98 17 in-lb)

M8

20 22 4 Nm (16 3 ft-lb)

Thermostat

Control harness bolt 5.0

1.0 Nm (44 9 in-lb)

Grounding bolt M6 9.0

2.0 Nm (80 17 in-lb)

M8 22

4 Nm (16 3 ft-lb)

Water inlet fitting bolt 19

1 Nm (14 1 ft-lb)

Water hose and water pipe

Engine coolant temperature sensor 29

10 Nm

Thermostat housing bolt 19

1 Nm (14 1 ft-lb)

Water pump inlet pipe 11

1 Nm (98 8 ft-lb)

Water pump

Water pump bolt M8 42

8 Nm (31 6 ft-lb)

M10 24

3 Nm (18 2 ft-lb)

Water pump bracket bolt 24

3 Nm (18 2 ft-lb)

Page 958 of 1500

SPECIFICATIONS

ENGINE COOLING14-43

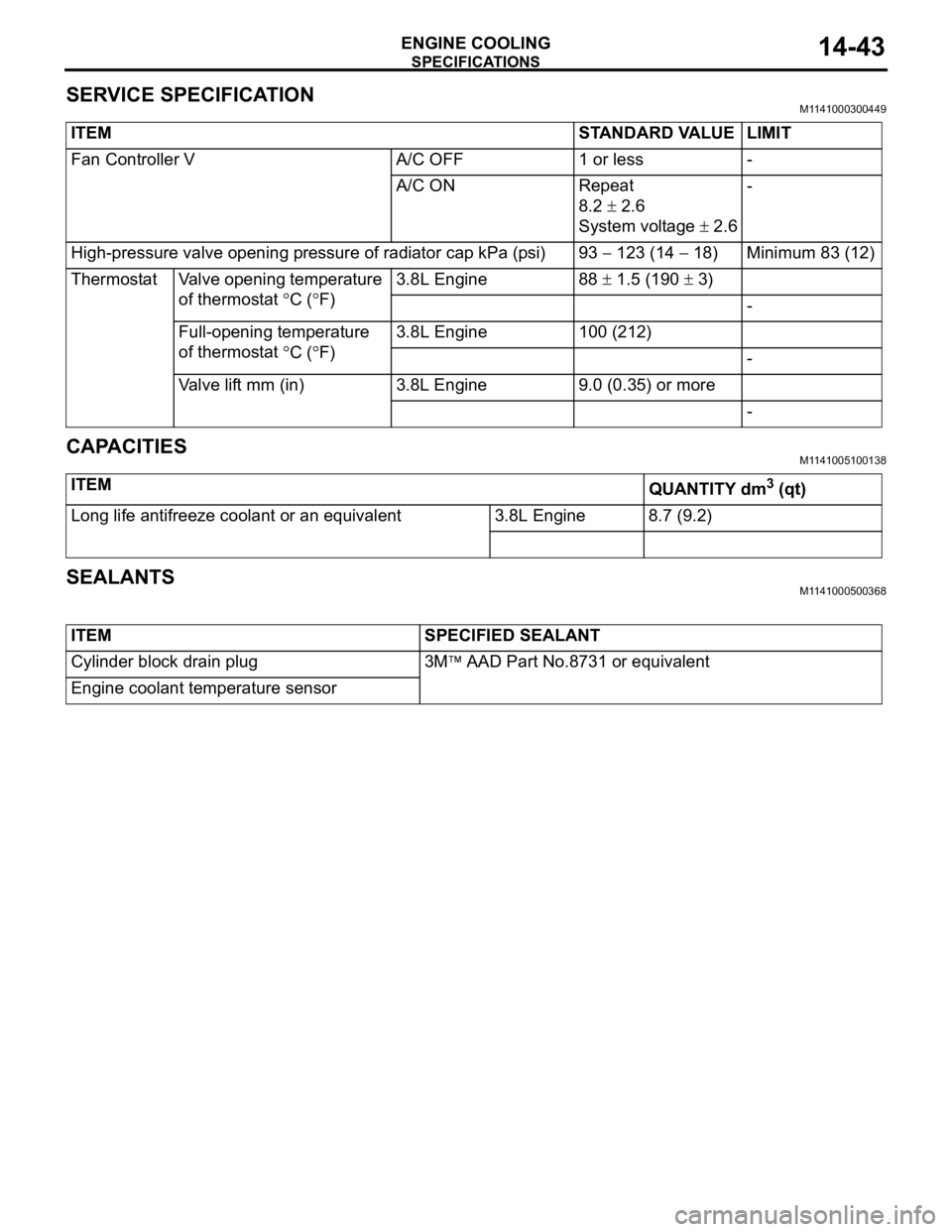

SERVICE SPECIFICATIONM1141000300449

CAPACITIESM1141005100138

SEALANTSM1141000500368

ITEM STANDARD VALUE LIMIT

Fan Controller V A/C OFF 1 or less -

A/C ON Repeat

8.2

2.6

System voltage

2.6-

High-pressure valve opening pressure of radiator cap kPa (psi) 93

123 (14 18) Minimum 83 (12)

Thermostat Valve opening temperature

of thermostat

C (F)3.8L Engine 88

1.5 (190 3)

-

Full-opening temperature

of thermostat

C (F)3.8L Engine 100 (212)

-

Valve lift mm (in) 3.8L Engine 9.0 (0.35) or more

-

ITEM

QUANTITY dm3 (qt)

Long life antifreeze coolant or an equivalent 3.8L Engine 8.7 (9.2)

ITEM SPECIFIED SEALANT

Cylinder block drain plug 3M

AAD Part No.8731 or equivalent

Engine coolant temperature sensor

Page 964 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-5

INTAKE MANIFOLD PLENUM

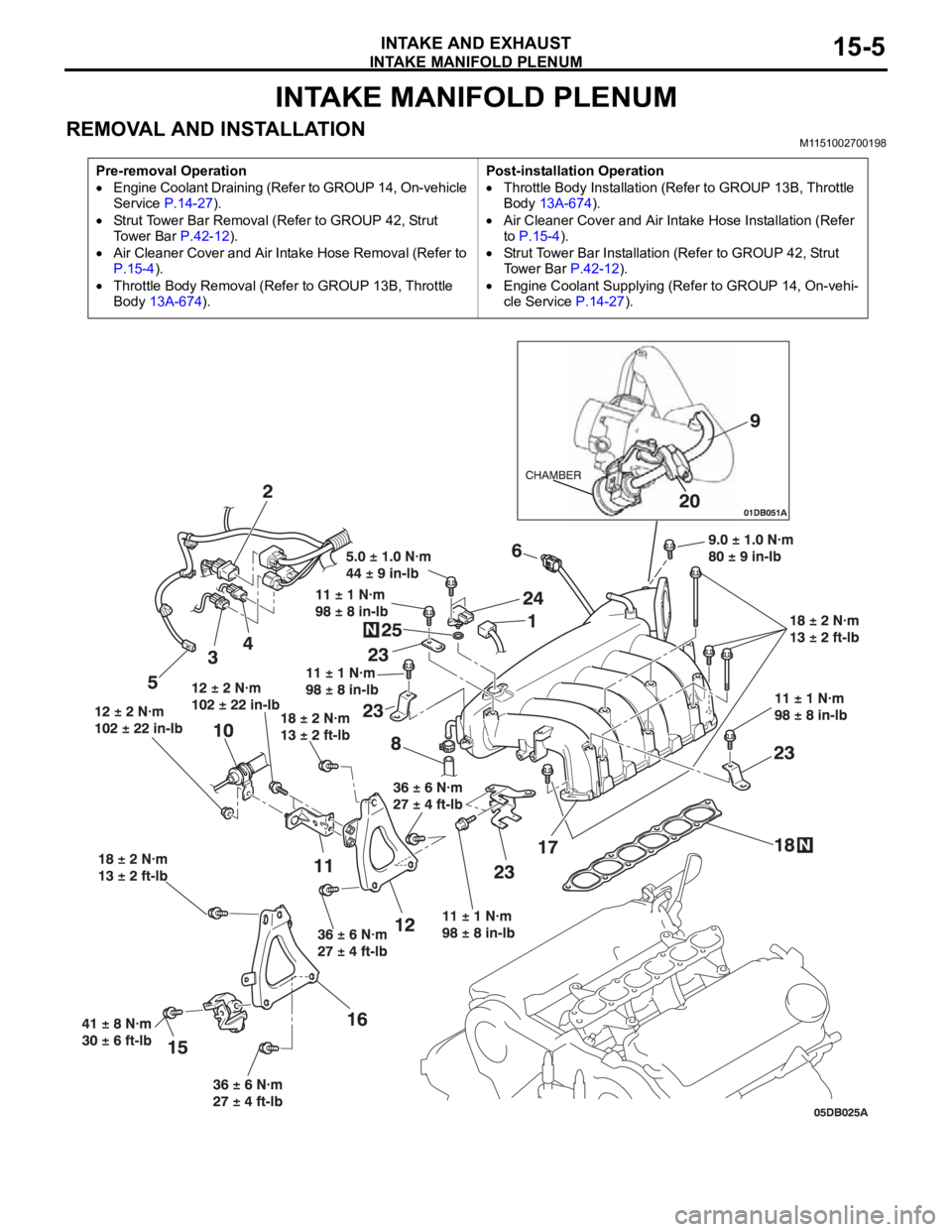

REMOVAL AND INSTALLATION M1151002700198

Pre-removal Operation

Engine Coolant Draining (Refer to GROUP 14, On-vehicle

Service P.14-27).

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Air Cleaner Cover and Air Intake Hose Removal (Refer to

P.15-4).

Throttle Body Removal (Refer to GROUP 13B, Throttle

Body 13A-674).Post-installation Operation

Throttle Body Installation (Refer to GROUP 13B, Throttle

Body 13A-674).

Air Cleaner Cover and Air Intake Hose Installation (Refer

to P.15-4).

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

Engine Coolant Supplying (Refer to GROUP 14, On-vehi-

cle Service P.14-27).

Page 970 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

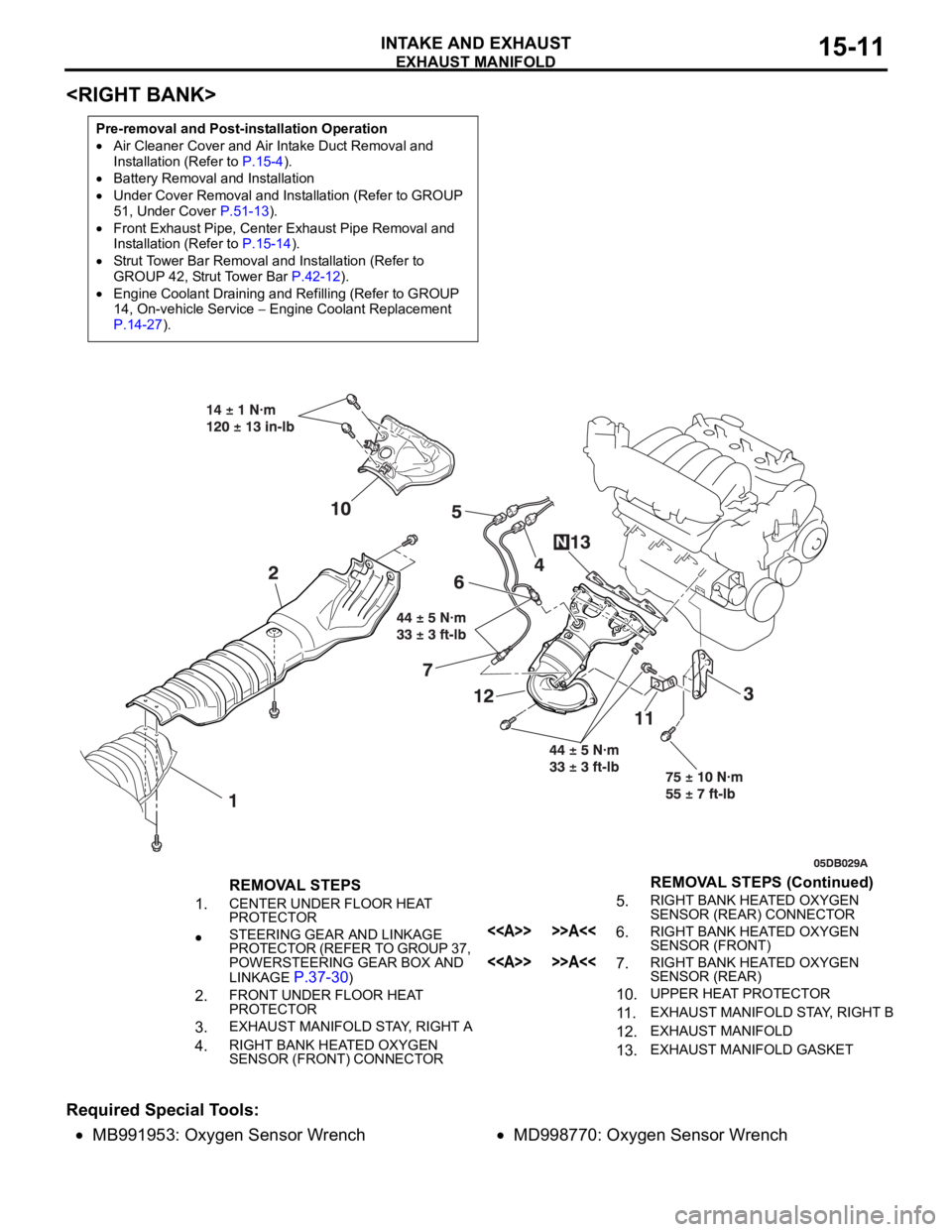

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)

Page 1223 of 1500

GENERAL00-2

MAINTENANCE SERVICE . . . . . . . .00-37

1. FUEL SYSTEM (TANK, PIPE LINE AND

CONNECTION, AND FUEL TANK FILLER

TUBE CAP) (CHECK FOR LEAKS) . . . . . . 00-37

2. FUEL HOSES (CHECK CONDITION) . . 00-37

3. AIR CLEANER FILTER (REPLACE). . . . 00-37

4. EVAPORATIVE EMISSION SYSTEM

(EXCEPT EVAPORATIVE EMISSION

CANISTER) (CHECK FOR CLOGGING) . . 00-37

5. SPARK PLUGS (REPLACE). . . . . . . . . . 00-38

7. TIMING BELT (REPLACE) . . . . . . . . . . . 00-38

8. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK) . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-39

9. EXHAUST SYSTEM (CONNECTIONS

PORTION OF MUFFLER, MUFFLER PIPES

AND CONVERTER HEAT SHIELDS) (CHECK

AND SERVICE AS REQUIRED) . . . . . . . . . 00-44

10. ENGINE OIL (CHANGE) . . . . . . . . . . . . 00-4411. ENGINE OIL FILTER (REPLACE) . . . . 00-44

12. TRANSMISSION FLUID . . . . . . . . . . . . 00-45

13. ENGINE COOLANT (CHANGE) . . . . . . 00-47

14. COOLANT HOSES (RADIATOR HOSE,

HEATER HOSE) (INSPECT). . . . . . . . . . . . 00-49

15. DISC BRAKE PADS, ROTORS

(INSPECT FOR WEAR) . . . . . . . . . . . . . . . 00-49

16. BRAKE HOSES (CHECK FOR

DETERIORATION OR LEAKS) . . . . . . . . . . 00-49

17. BALL JOINT AND STEERING LINKAGE

SEALS (INSPECT FOR GREASE LEAKS

AND DAMAGE) . . . . . . . . . . . . . . . . . . . . . . 00-50

18. DRIVE SHAFT BOOTS (INSPECT FOR

GREASE LEAKS AND DAMAGE) . . . . . . . . 00-50

19. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE) . . . . . . . . . . 00-51

20. SRS AIR BAG (INSPECT FOR SRS

SYSTEM). . . . . . . . . . . . . . . . . . . . . . . . . . . 00-51

21. TYRES (ROTATE). . . . . . . . . . . . . . . . . 00-58

Page 1245 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-24

SERVICING ELECTRICAL SYSTEMM1001011900057

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Note the following before proceeding with working on the

electrical system.

Never perform unauthorized modifications to any electrical

device or wiring. Such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result in

a fire in the vehicle.

Before connecting or disconnecting the negative bat-

tery cable, be sure to turn the ignition switch to the

"LOCK" (OFF) position and turn off the lights (If this is

not done, there is the possibility of semiconductor

parts being damaged).

After completion of the work (and the negative battery

terminals is connected), warm up the engine and allow

it to idle for approximately 10 minutes under the condi-

tions described below in order to stabilize engine con-

trol conditions, and then check to be sure that the idle

is satisfactory.

Engine coolant temperature: 85 to 95C (185 to

203

F)

Lights and all accessories: OFF

Transaxle: "N" or "P" position

Steering wheel: straight-forward position

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

VEHICLE WASHINGM1001012000057

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least approximately 50 cm (20

inches) from any plastic parts and all opening parts (doors, lug-

gage compartment, etc.).

Page 1256 of 1500

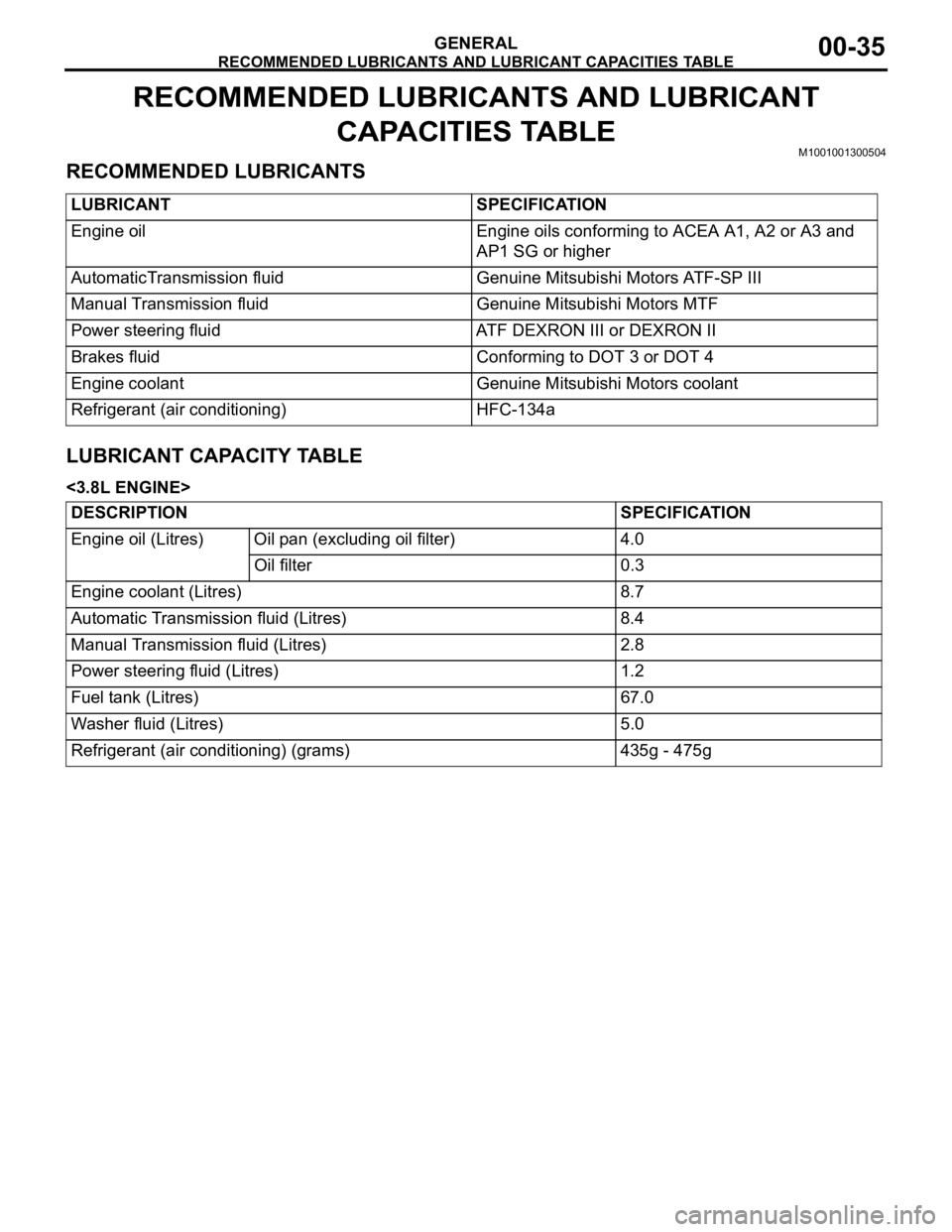

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

GENERAL00-35

RECOMMENDED LUBRICANTS AND LUBRICANT

CAPACITIES TABLE

M1001001300504

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITY TABLE

<3.8L ENGINE>LUBRICANT SPECIFICATION

Engine oil Engine oils conforming to ACEA A1, A2 or A3 and

AP1 SG or higher

AutomaticTransmission fluid Genuine Mitsubishi Motors ATF-SP III

Manual Transmission fluid Genuine Mitsubishi Motors MTF

Power steering fluid ATF DEXRON III or DEXRON II

Brakes fluid Conforming to DOT 3 or DOT 4

Engine coolant Genuine Mitsubishi Motors coolant

Refrigerant (air conditioning) HFC-134a

DESCRIPTION SPECIFICATION

Engine oil (Litres) Oil pan (excluding oil filter) 4.0

Oil filter 0.3

Engine coolant (Litres) 8.7

Automatic Transmission fluid (Litres) 8.4

Manual Transmission fluid (Litres) 2.8

Power steering fluid (Litres) 1.2

Fuel tank (Litres) 67.0

Washer fluid (Litres) 5.0

Refrigerant (air conditioning) (grams) 435g - 475g

Page 1257 of 1500

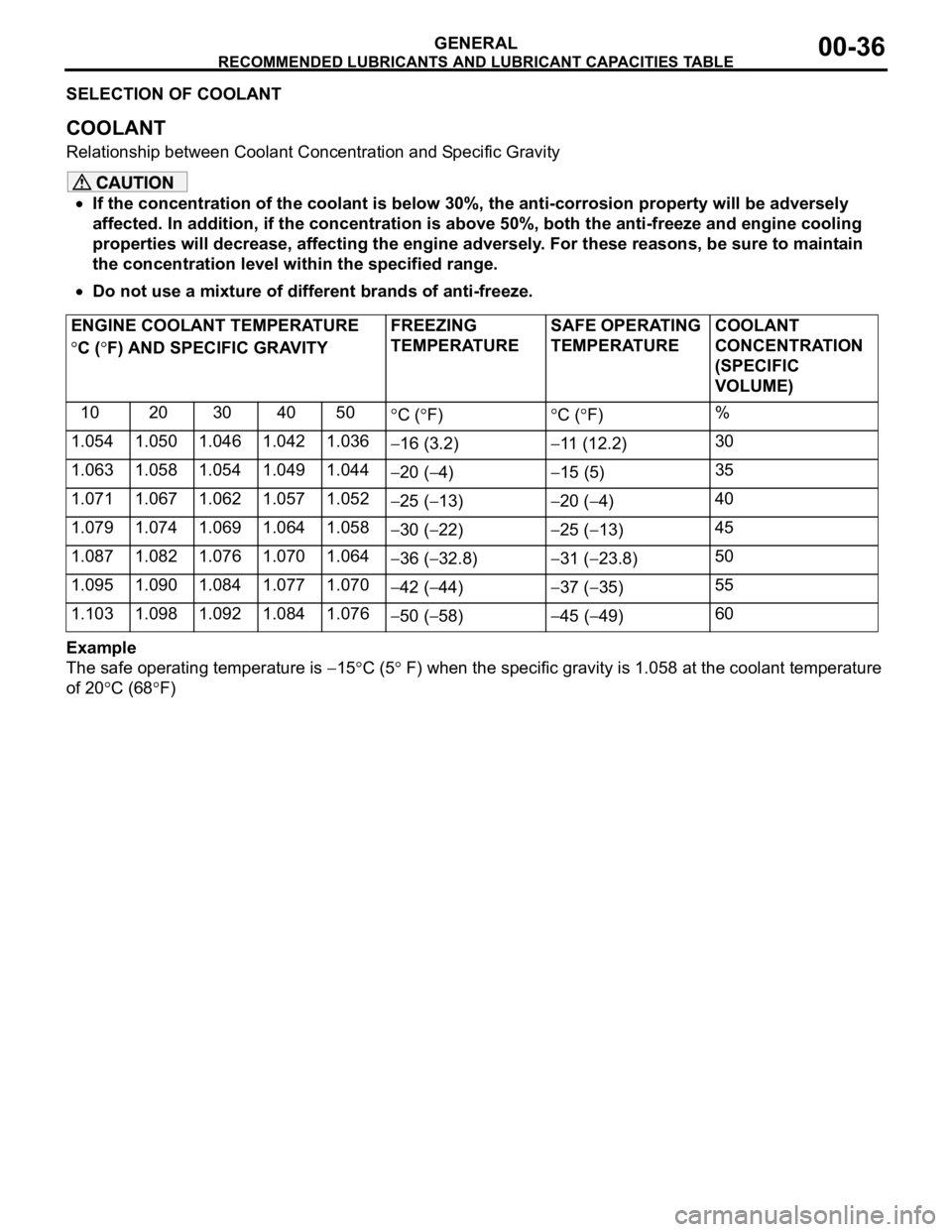

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

GENERAL00-36

SELECTION OF COOLANT

.

COOLANT

Relationship between Coolant Concentration and Specific Gravity

If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is above 50%, both the anti-freeze and engine cooling

properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain

the concentration level within the specified range.

Do not use a mixture of different brands of anti-freeze.

Example

The safe operating temperature is

15C (5 F) when the specific gravity is 1.058 at the coolant temperature

of 20

C (68F) ENGINE COOLANT TEMPERATURE

C (F) AND SPECIFIC GRAVITYFREEZING

TEMPERATURESAFE OPERATING

TEMPERATURECOOLANT

CONCENTRATION

(SPECIFIC

VOLUME)

10 20 30 40 50

C (F)C (F)%

1.054 1.050 1.046 1.042 1.036

16 (3.2)11 ( 1 2 . 2 )30

1.063 1.058 1.054 1.049 1.044

20 (4)15 (5)35

1.071 1.067 1.062 1.057 1.052

25 (13)20 (4)40

1.079 1.074 1.069 1.064 1.058

30 (22)25 (13)45

1.087 1.082 1.076 1.070 1.064

36 (32.8)31 (23.8)50

1.095 1.090 1.084 1.077 1.070

42 (44)37 (35)55

1.103 1.098 1.092 1.084 1.076

50 (58)45 (49)60

Page 1265 of 1500

MAINTENANCE SERVICE

GENERAL00-44

8. EXHAUST SYSTEM (CONNECTIONS PORTION

OF MUFFLER, MUFFLER PIPES AND

CONVERTER HEAT SHIELDS) (CHECK AND

SERVICE AS REQUIRED)

M1001005800299

1. Check for holes and exhaust gas leaks due to damage,

corrosion, etc.

2. Check the joints and connections for looseness and exhaust

gas leaks.

3. Check the rubber hangers and brackets for damage.

9. ENGINE OIL (CHANGE)M1001002600360

Use the specified oil. (Refer to P.00-35.)

Use care as oil could be hot.

1. After warming up the engine, remove the oil filler cap.

2. Remove the drain plug to allow the engine oil to drain.

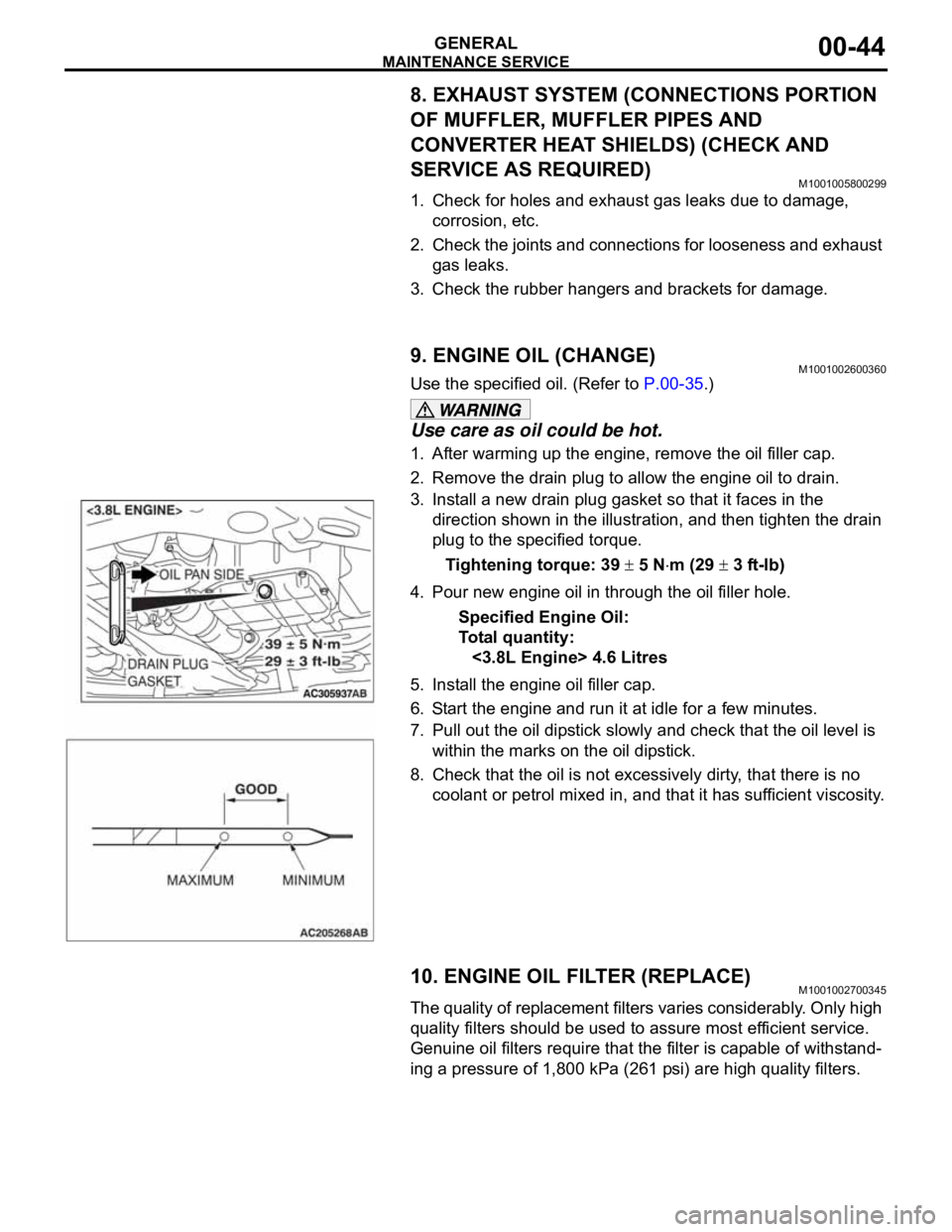

3. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the drain

plug to the specified torque.

Tightening torque: 39

5 Nm (29 3 ft-lb)

4. Pour new engine oil in through the oil filler hole.

Specified Engine Oil:

To ta l q u a n t i t y :

<3.8L Engine> 4.6 Litres

5. Install the engine oil filler cap.

6. Start the engine and run it at idle for a few minutes.

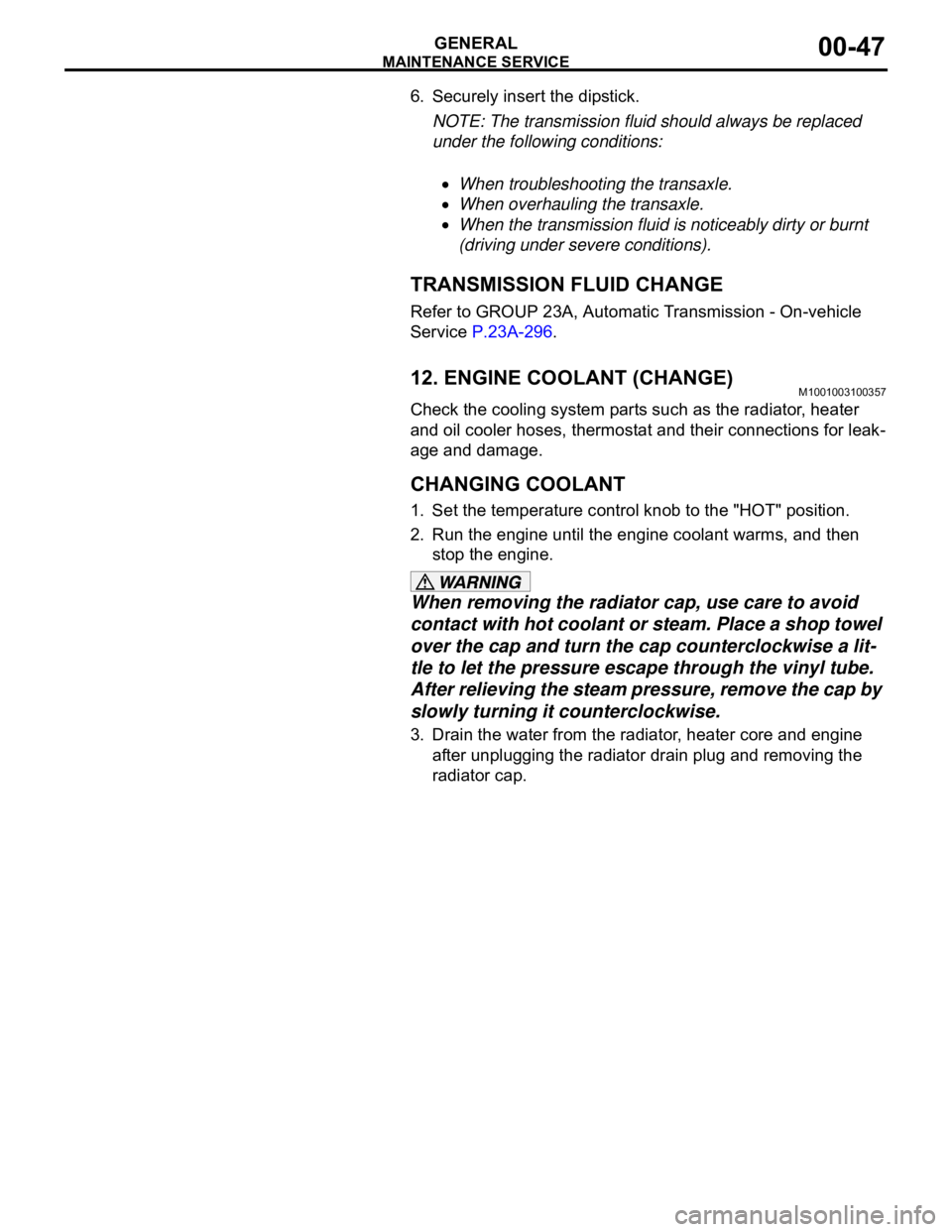

7. Pull out the oil dipstick slowly and check that the oil level is

within the marks on the oil dipstick.

8. Check that the oil is not excessively dirty, that there is no

coolant or petrol mixed in, and that it has sufficient viscosity.

10. ENGINE OIL FILTER (REPLACE)M1001002700345

The quality of replacement filters varies considerably. Only high

quality filters should be used to assure most efficient service.

Genuine oil filters require that the filter is capable of withstand-

ing a pressure of 1,800 kPa (261 psi) are high quality filters.

.

Page 1268 of 1500

MAINTENANCE SERVICE

GENERAL00-47

6. Securely insert the dipstick.

NOTE: The transmission fluid should always be replaced

under the following conditions:

.

When troubleshooting the transaxle.

When overhauling the transaxle.

When the transmission fluid is noticeably dirty or burnt

(driving under severe conditions).

TRANSMISSION FLUID CHANGE

Refer to GROUP 23A, Automatic Transmission - On-vehicle

Service P.23A-296.

12. ENGINE COOLANT (CHANGE)M1001003100357

Check the cooling system parts such as the radiator, heater

and oil cooler hoses, thermostat and their connections for leak-

age and damage.

.

CHANGING COOLANT

1. Set the temperature control knob to the "HOT" position.

2. Run the engine until the engine coolant warms, and then

stop the engine.

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

3. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.