lock MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1111 of 1500

DOOR

BODY42-44

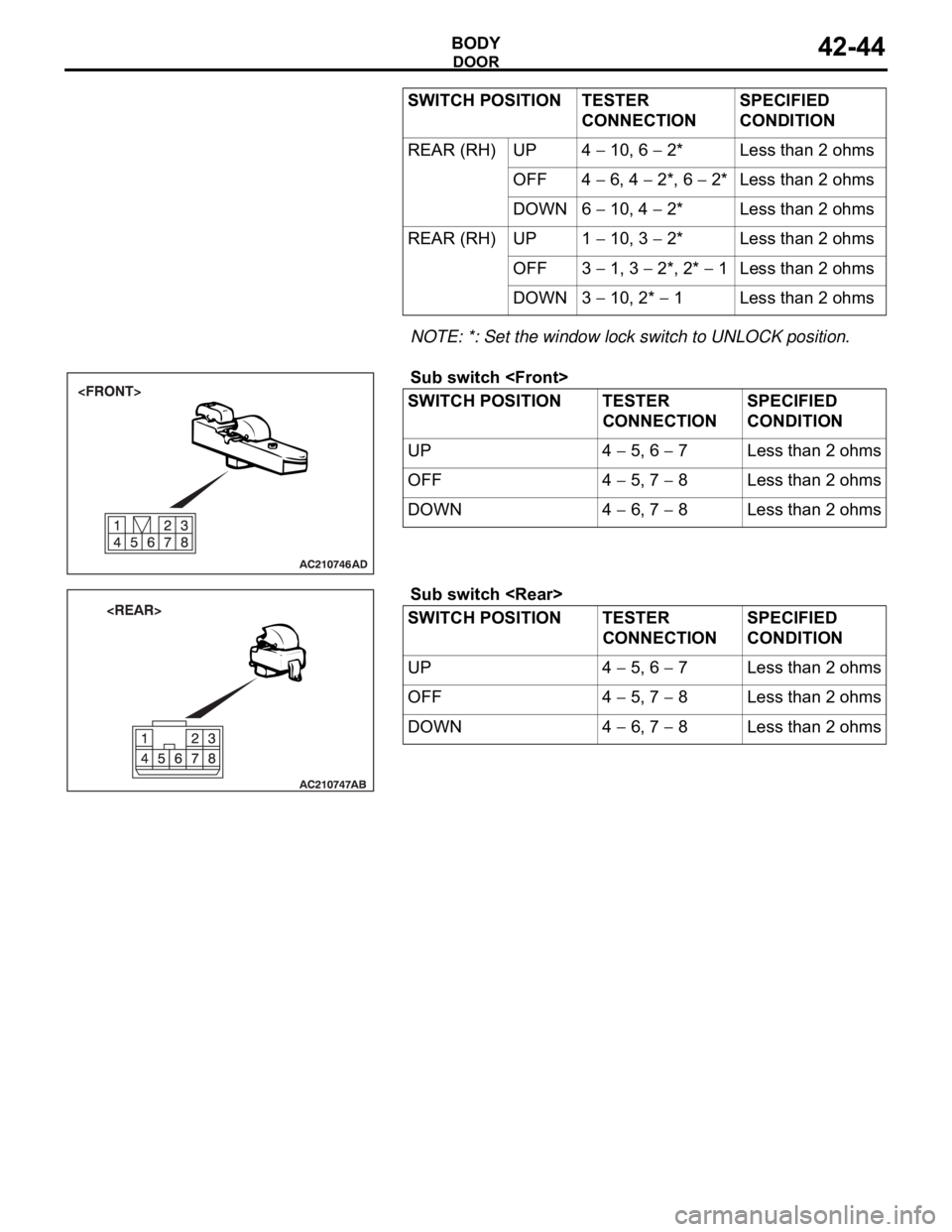

NOTE: *: Set the window lock switch to UNLOCK position.

.Sub switch

Sub switch

10, 6 2* Less than 2 ohms

OFF 4

6, 4 2*, 6 2* Less than 2 ohms

DOWN 6

10, 4 2* Less than 2 ohms

REAR (RH) UP 1

10, 3 2* Less than 2 ohms

OFF 3

1, 3 2*, 2* 1 Less than 2 ohms

DOWN 3

10, 2* 1 Less than 2 ohms

SWITCH POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

UP 4

5, 6 7 Less than 2 ohms

OFF 4

5, 7 8 Less than 2 ohms

DOWN 4

6, 7 8 Less than 2 ohms

SWITCH POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

UP 4

5, 6 7 Less than 2 ohms

OFF 4

5, 7 8 Less than 2 ohms

DOWN 4

6, 7 8 Less than 2 ohms SWITCH POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

Page 1113 of 1500

DOOR

BODY42-46

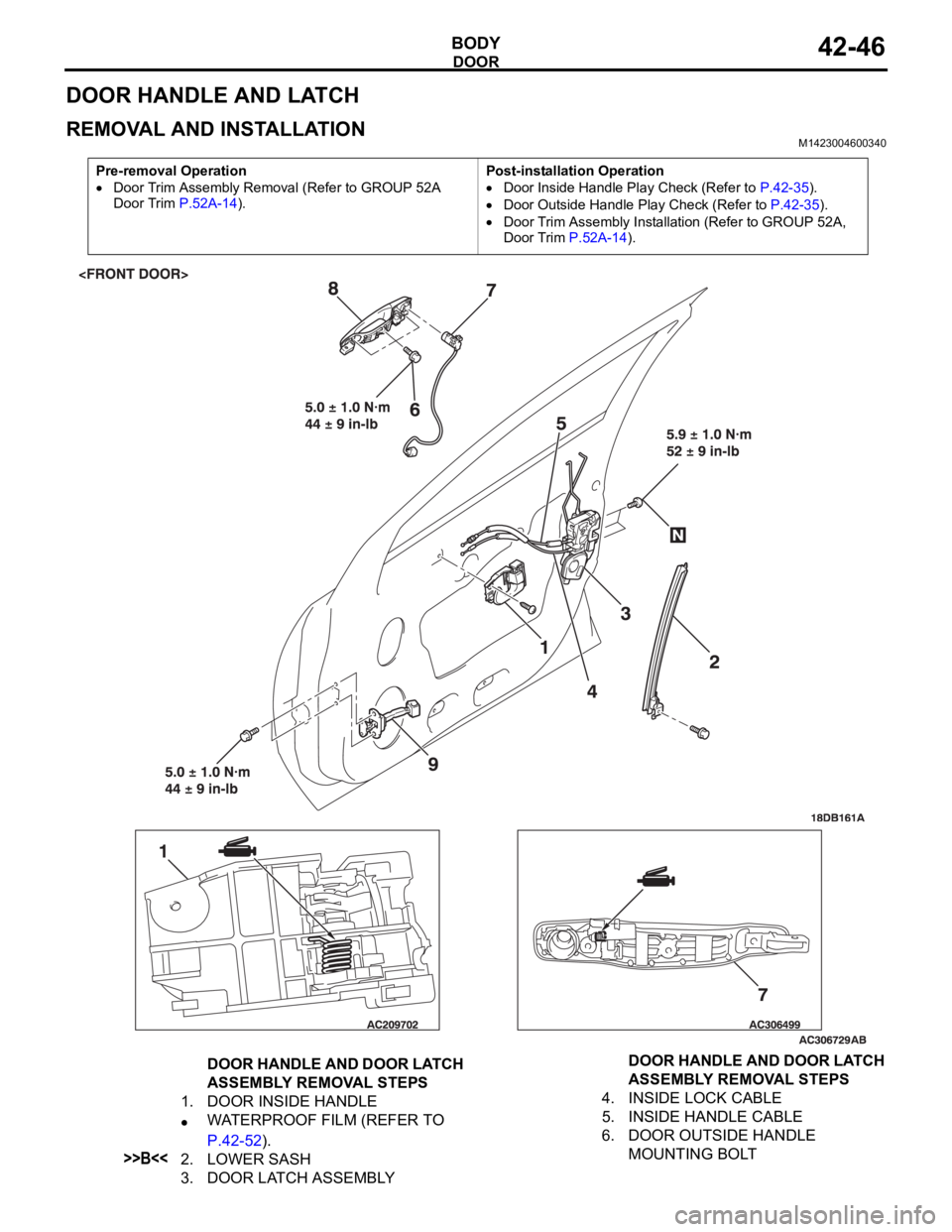

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATIONM1423004600340

Pre-removal Operation

Door Trim Assembly Removal (Refer to GROUP 52A

Door Trim P.52A-14).Post-installation OperationDoor Inside Handle Play Check (Refer to P.42-35).

Door Outside Handle Play Check (Refer to P.42-35).

Door Trim Assembly Installation (Refer to GROUP 52A,

Door Trim P.52A-14).

DOOR HANDLE AND DOOR LATCH

ASSEMBLY REMOVAL STEPS

1. DOOR INSIDE HANDLE

WATERPROOF FILM (REFER TO

P.42-52).

>>B<<2. LOWER SASH

3. DOOR LATCH ASSEMBLY4. INSIDE LOCK CABLE

5. INSIDE HANDLE CABLE

6. DOOR OUTSIDE HANDLE

MOUNTING BOLT DOOR HANDLE AND DOOR LATCH

ASSEMBLY REMOVAL STEPS

Page 1114 of 1500

DOOR

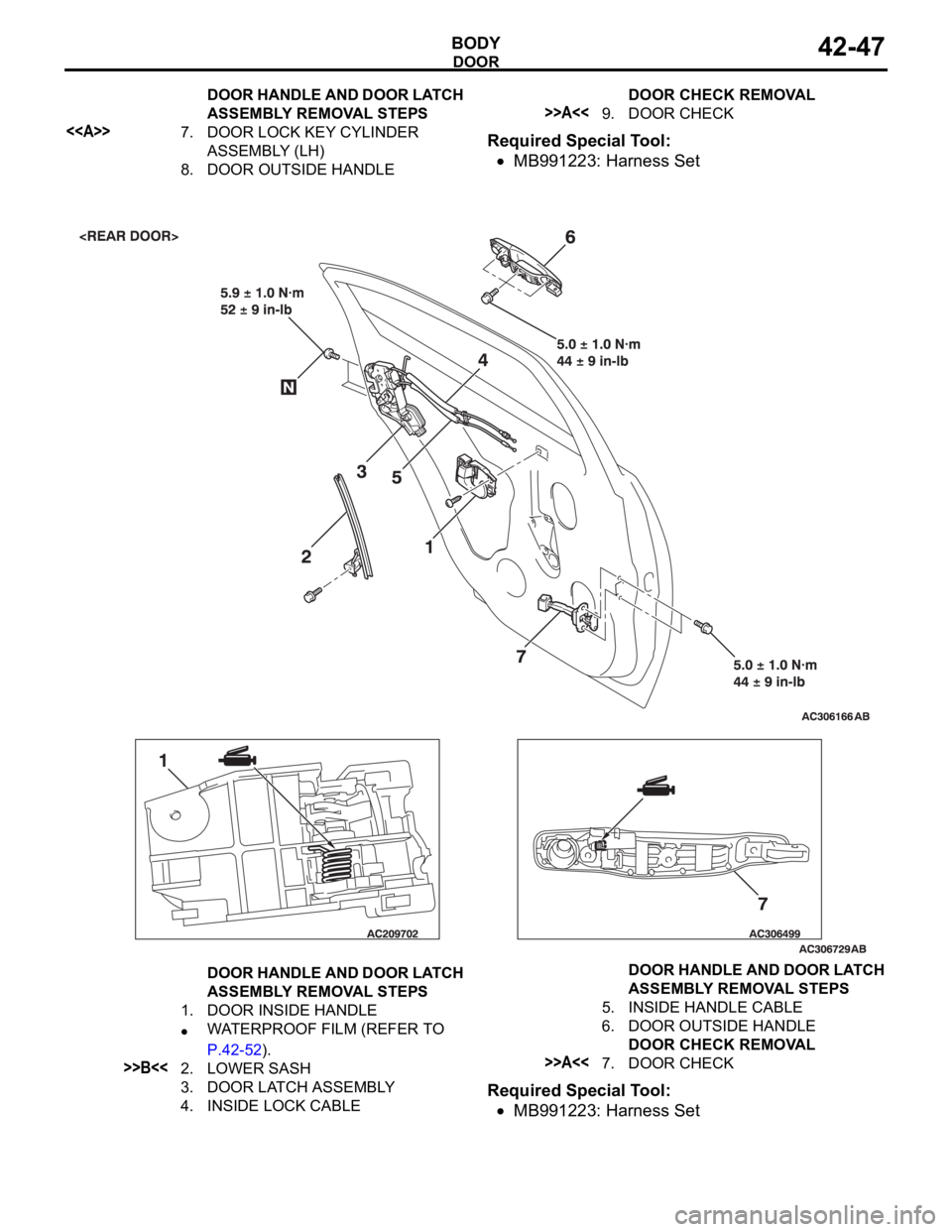

BODY42-47

Required Special Tool:

MB991223: Harness Set

Required Special Tool:

MB991223: Harness Set

<>7. DOOR LOCK KEY CYLINDER

ASSEMBLY (LH)

8. DOOR OUTSIDE HANDLEDOOR HANDLE AND DOOR LATCH

ASSEMBLY REMOVAL STEPS DOOR CHECK REMOVAL

>>A<<9. DOOR CHECK

DOOR HANDLE AND DOOR LATCH

ASSEMBLY REMOVAL STEPS

1. DOOR INSIDE HANDLE

WATERPROOF FILM (REFER TO

P.42-52).

>>B<<2. LOWER SASH

3. DOOR LATCH ASSEMBLY

4. INSIDE LOCK CABLE5. INSIDE HANDLE CABLE

6. DOOR OUTSIDE HANDLE

DOOR CHECK REMOVAL>>A<<7. DOOR CHECKDOOR HANDLE AND DOOR LATCH

ASSEMBLY REMOVAL STEPS

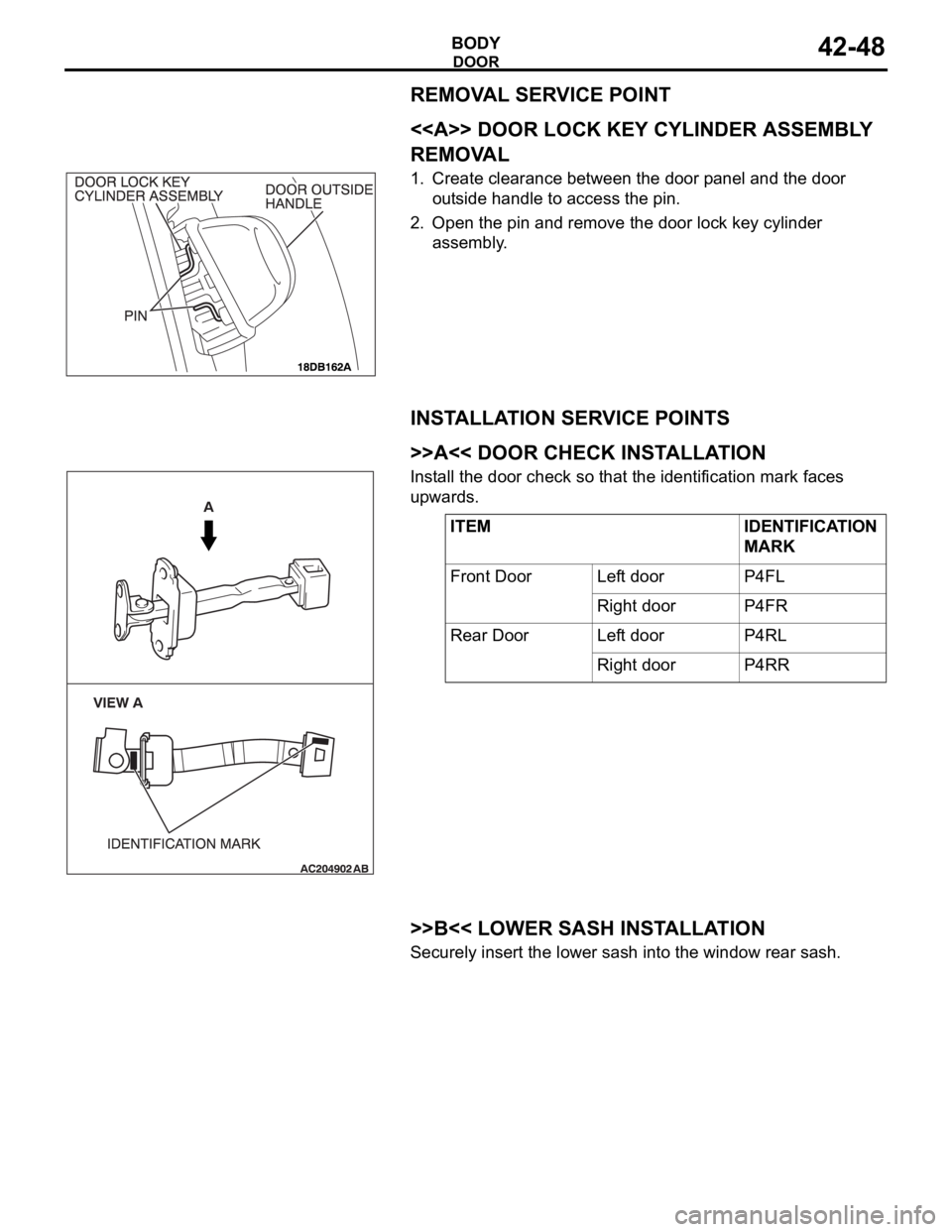

Page 1115 of 1500

Page 1116 of 1500

DOOR

BODY42-49

INSPECTIONM1423004700411

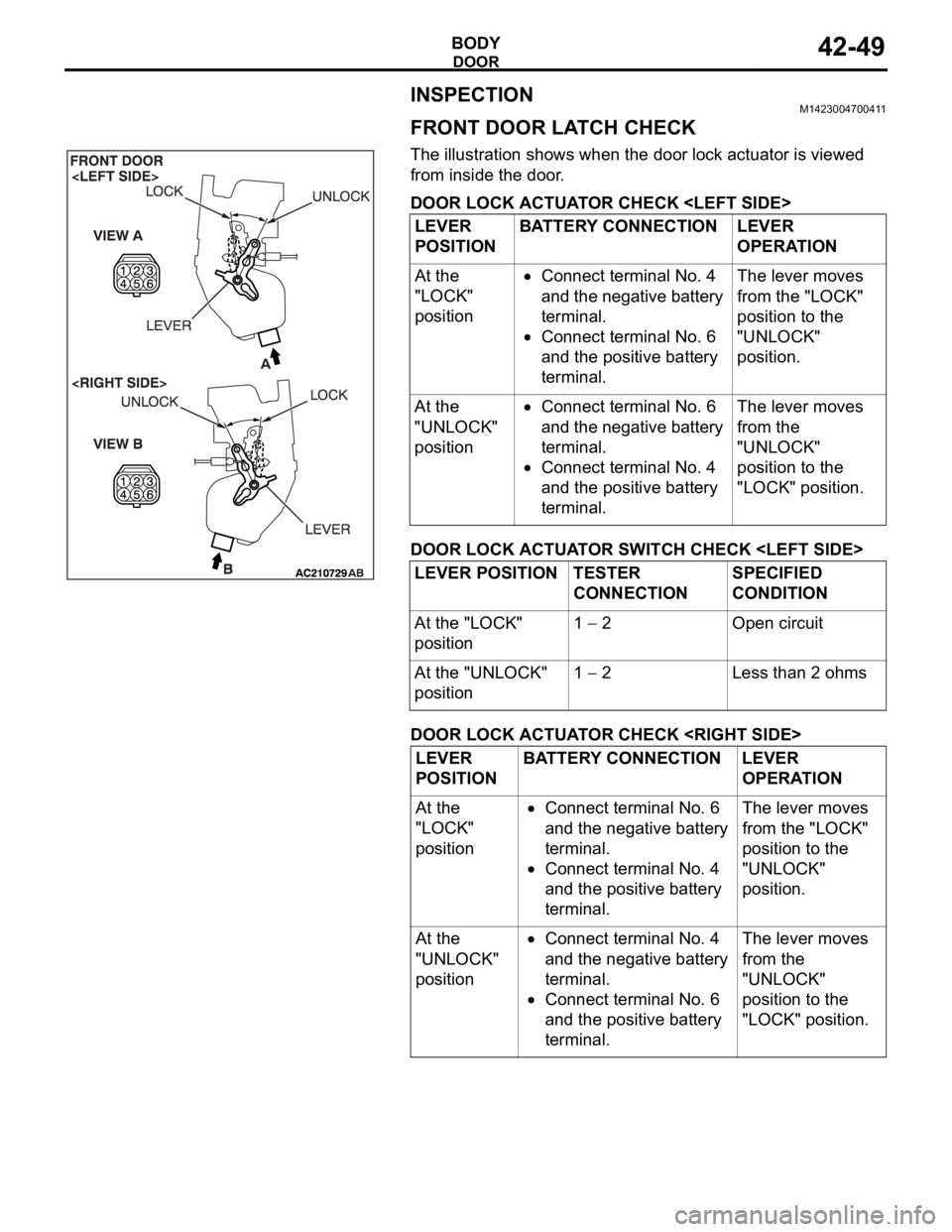

FRONT DOOR LATCH CHECK

The illustration shows when the door lock actuator is viewed

from inside the door.

DOOR LOCK ACTUATOR CHECK

DOOR LOCK ACTUATOR SWITCH CHECK

DOOR LOCK ACTUATOR CHECK

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

LEVER POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

At the "LOCK"

position1

2 Open circuit

At the "UNLOCK"

position1

2 Less than 2 ohms

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

Page 1117 of 1500

DOOR

BODY42-50

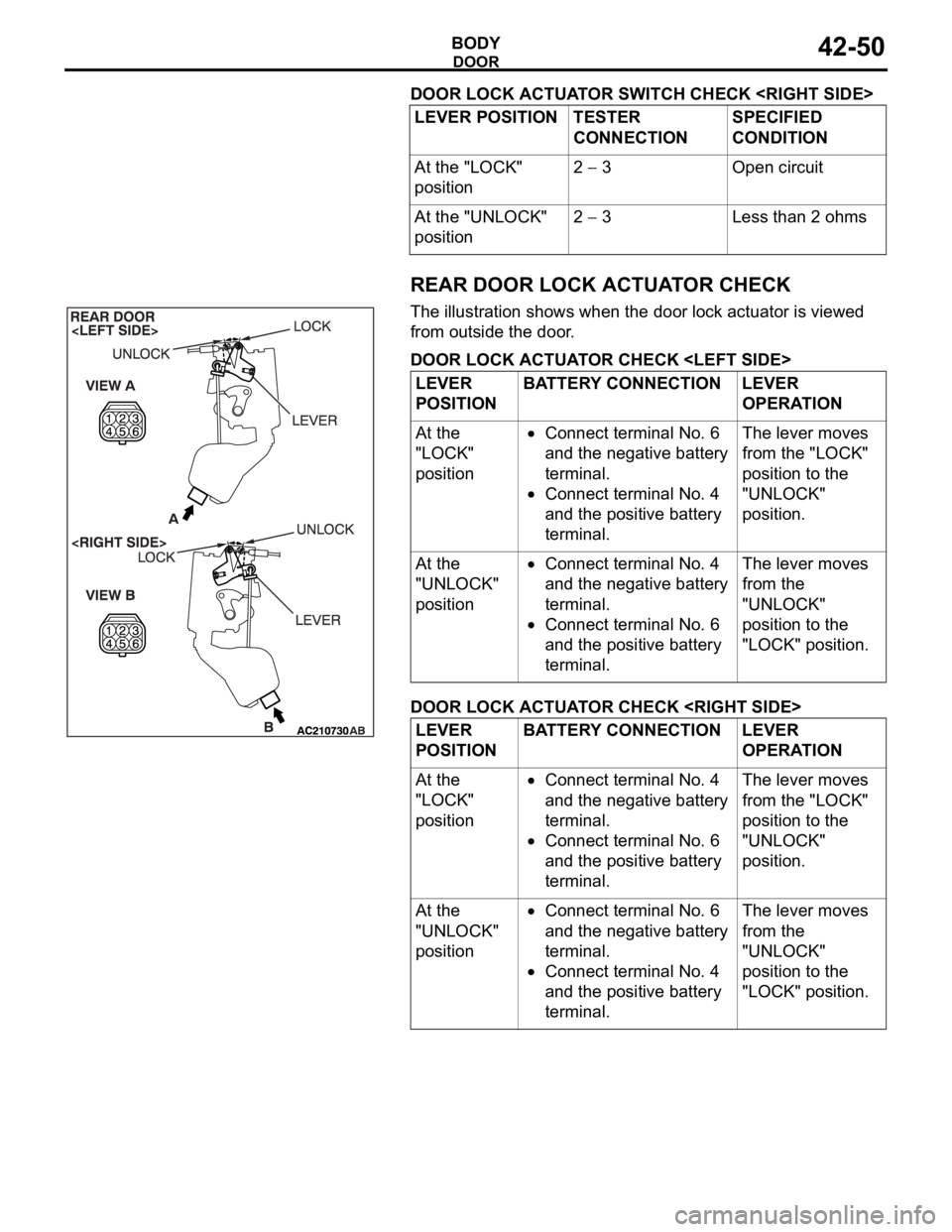

DOOR LOCK ACTUATOR SWITCH CHECK

REAR DOOR LOCK ACTUATOR CHECK

The illustration shows when the door lock actuator is viewed

from outside the door.

DOOR LOCK ACTUATOR CHECK

DOOR LOCK ACTUATOR CHECK

CONNECTIONSPECIFIED

CONDITION

At the "LOCK"

position2

3 Open circuit

At the "UNLOCK"

position2

3 Less than 2 ohms

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

Page 1118 of 1500

DOOR

BODY42-51

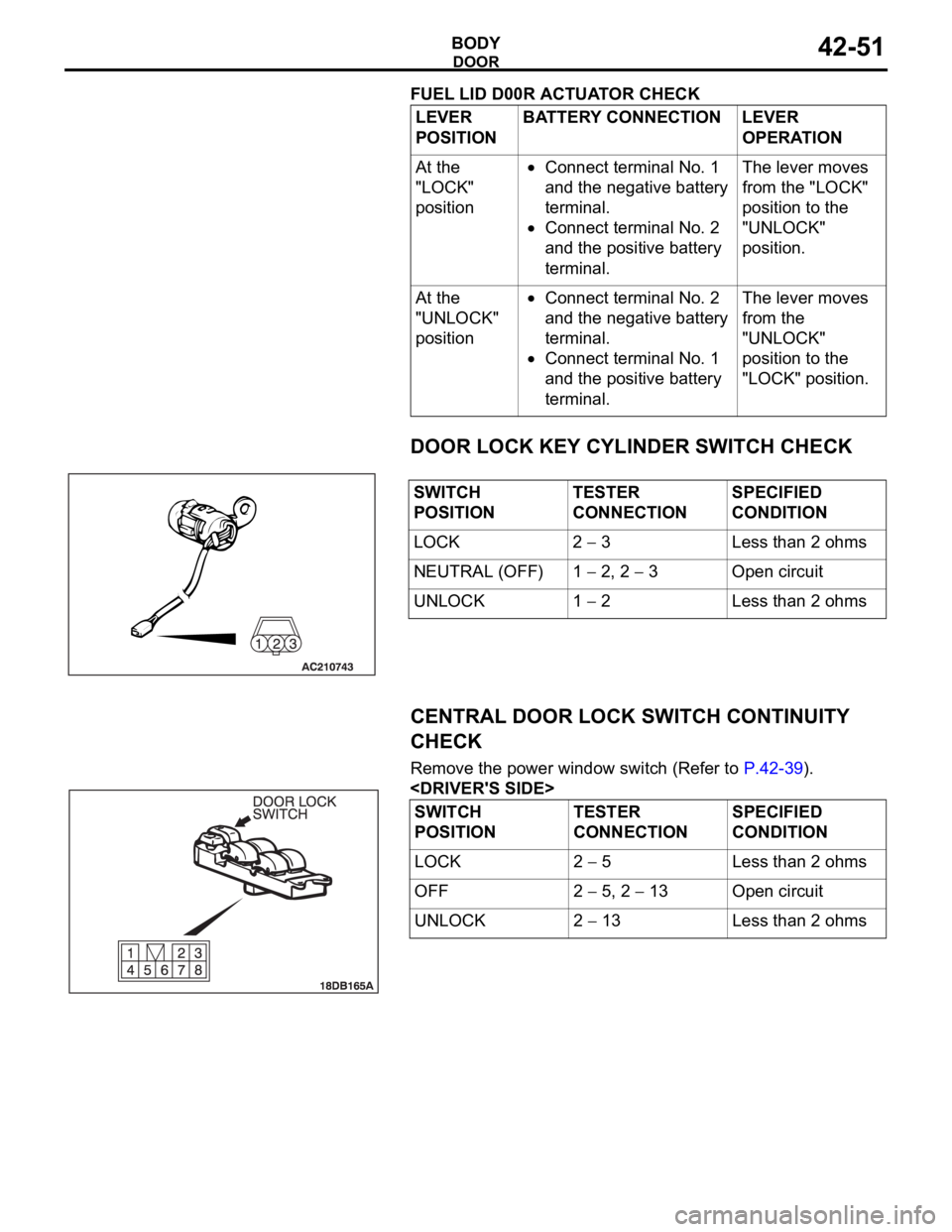

FUEL LID D00R ACTUATOR CHECK

DOOR LOCK KEY CYLINDER SWITCH CHECK

CENTRAL DOOR LOCK SWITCH CONTINUITY

CHECK

Remove the power window switch (Refer to P.42-39).

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 1

and the negative battery

terminal.

Connect terminal No. 2

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 2

and the negative battery

terminal.

Connect terminal No. 1

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

LOCK 2

3 Less than 2 ohms

NEUTRAL (OFF) 1

2, 2 3 Open circuit

UNLOCK 1

2 Less than 2 ohms

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

LOCK 2

5 Less than 2 ohms

OFF 2

5, 2 13 Open circuit

UNLOCK 2

13 Less than 2 ohms

Page 1119 of 1500

DOOR

BODY42-52

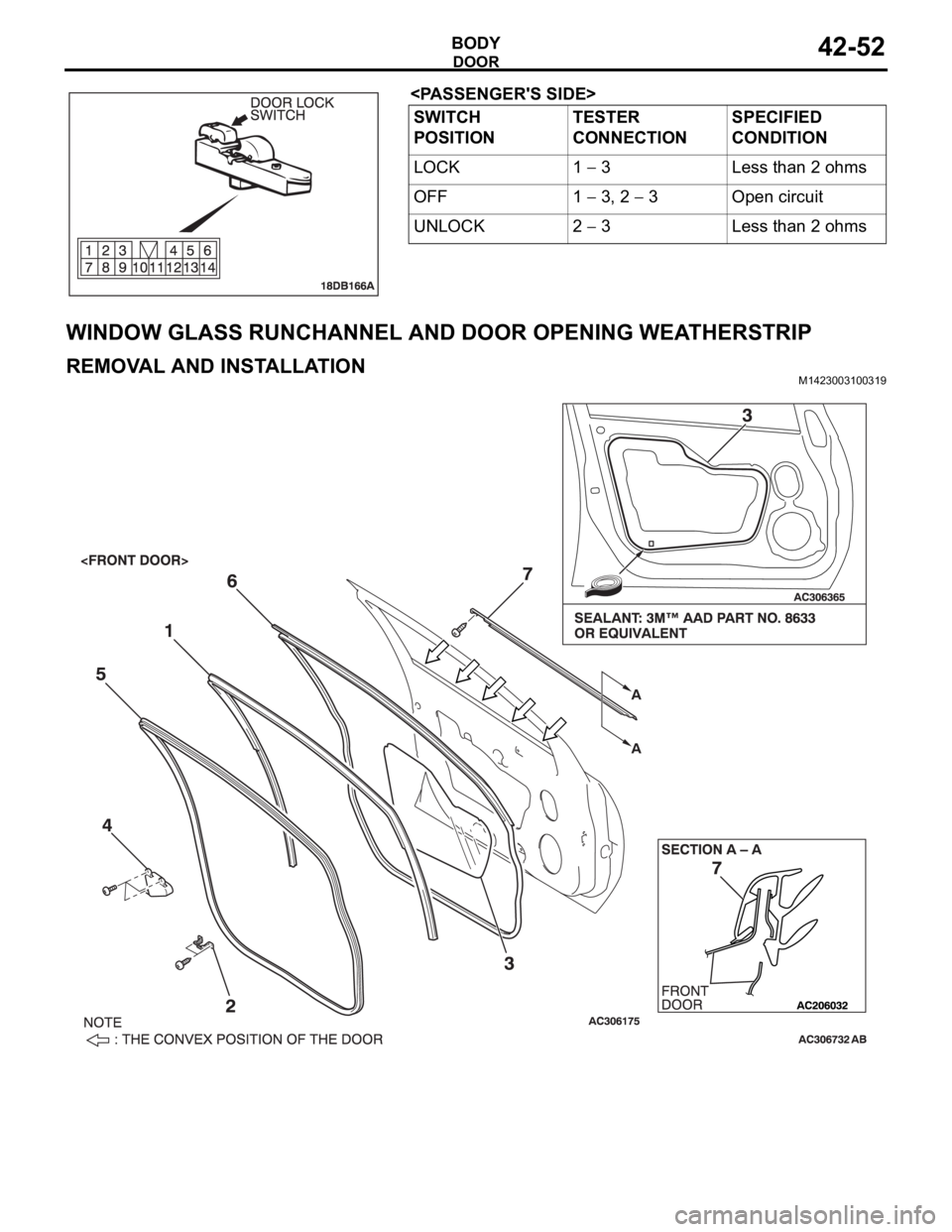

WINDOW GLASS RUNCHANNEL AND DOOR OPENING WEATHERSTRIP

REMOVAL AND INSTALLATIONM1423003100319

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

LOCK 1

3 Less than 2 ohms

OFF 1

3, 2 3 Open circuit

UNLOCK 2

3 Less than 2 ohms

Page 1127 of 1500

TRUNK LID

BODY42-60

TRUNK LID

TRUNK LID DIAGNOSIS

INTRODUCTION TO TRUNK LID DIAGNOSISM1421005800374

Difficult locking and unlocking, uneven clearance and

height, and wind noise from the trunk lid may be

caused by improper adjustment of the trunk lid.

TRUNK LID DIAGNOSTIC TROUBLESHOOTING STRATEGYM1421005900348

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

trunk lid fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1421006000382

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Difficult Locking and Unlocking

DIAGNOSIS

STEP 1. Check the function of trunk lid opening

switch inside glove compartment.

Q: Can the latch unlocking mechanism noise "click"

be heard when operating the switch

YES :

Go to Step 2.

NO : Check switch circuit. Refer to P.42-65.

Then go to Step 2.

STEP 2. Check the engagement of the trunk lid

latch and trunk lid striker.

Q: Are the trunk lid latch and trunk lid striker engaged

correctly?

YES :

Then go to Step 3.

NO : Adjust the trunk lid latch. Refer to P.42-61.

STEP 3. Retest the system.

Q: Does the trunk lid lock operate easily?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 2: Uneven Body Clearance

DIAGNOSIS

STEP 1. Check the clearance around the trunk

lid..

Q: Are the apertures between the trunk lid and the adjacent body panels aligned correctly?

YES :

Then go to Step 2.

NO : Adjust the trunk lid panel assembly. Refer to

P.42-61. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Difficult locking and unlocking 1

P.42-60

Uneven body clearance 2

P.42-60

Uneven height 3

P.42-61

Page 1128 of 1500

TRUNK LID

BODY42-61

STEP 2. Retest the system.

Q: Are the clearances between the body panels even?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 3: Uneven Height

DIAGNOSIS

STEP 1. Check the trunk lid bumper height.

Q: Is the trunk lid bumper height proper?

YES :

Then go to Step 2.

NO : Adjust the trunk lid bumper. Refer to

P.42-62.

STEP 2. Retest the system.

Q: Are the trunk lid and body height even?

YES :

The procedure is complete.

NO : Return to Step 1.

ON-VEHICLE SERVICE

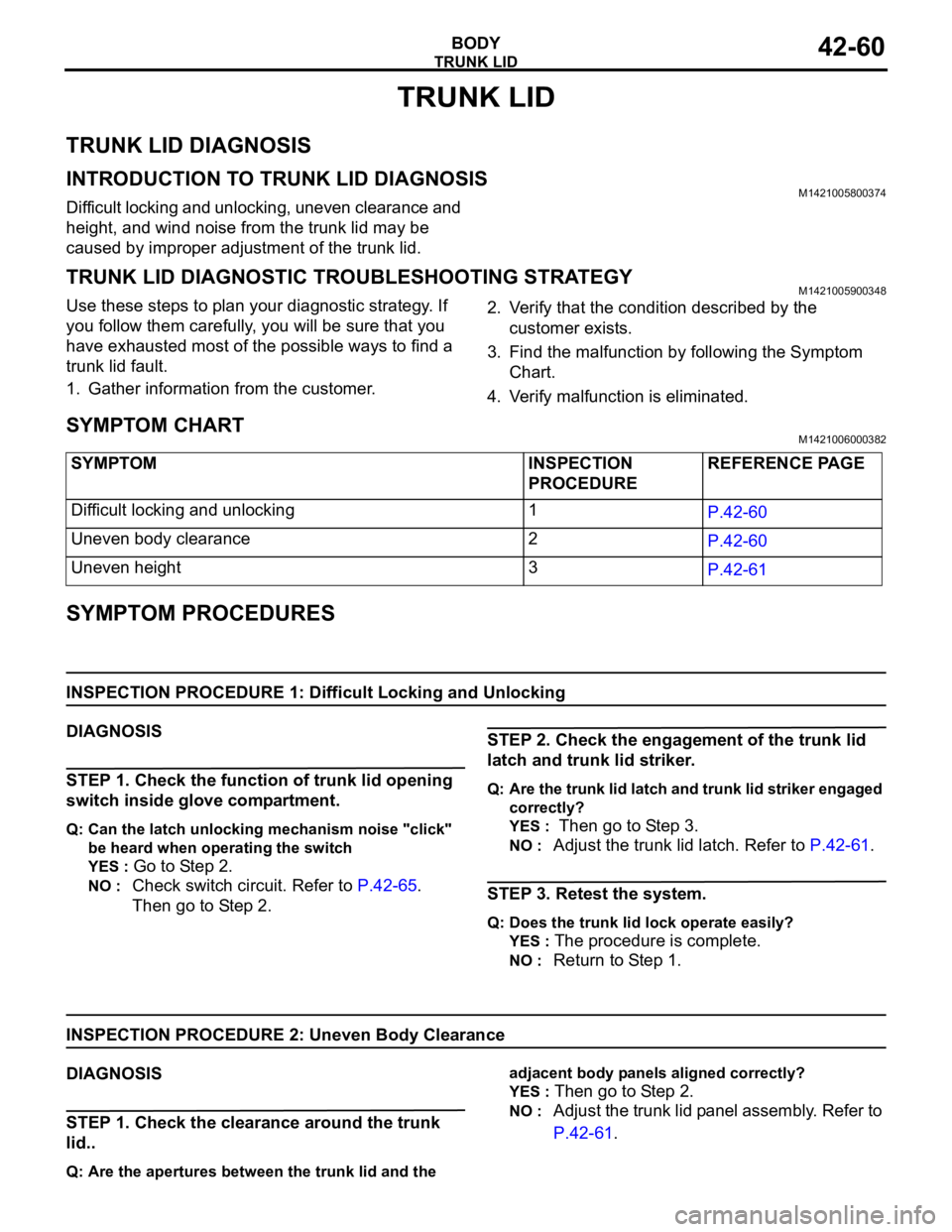

ADJUSTMENT OF CLEARANCE AROUND TRUNK

LID

M1421008100040

Loosen the trunk lid panel assembly mounting bolt and nut, and

move the trunk lid panel assembly to make the clearance

around the trunk lid even.

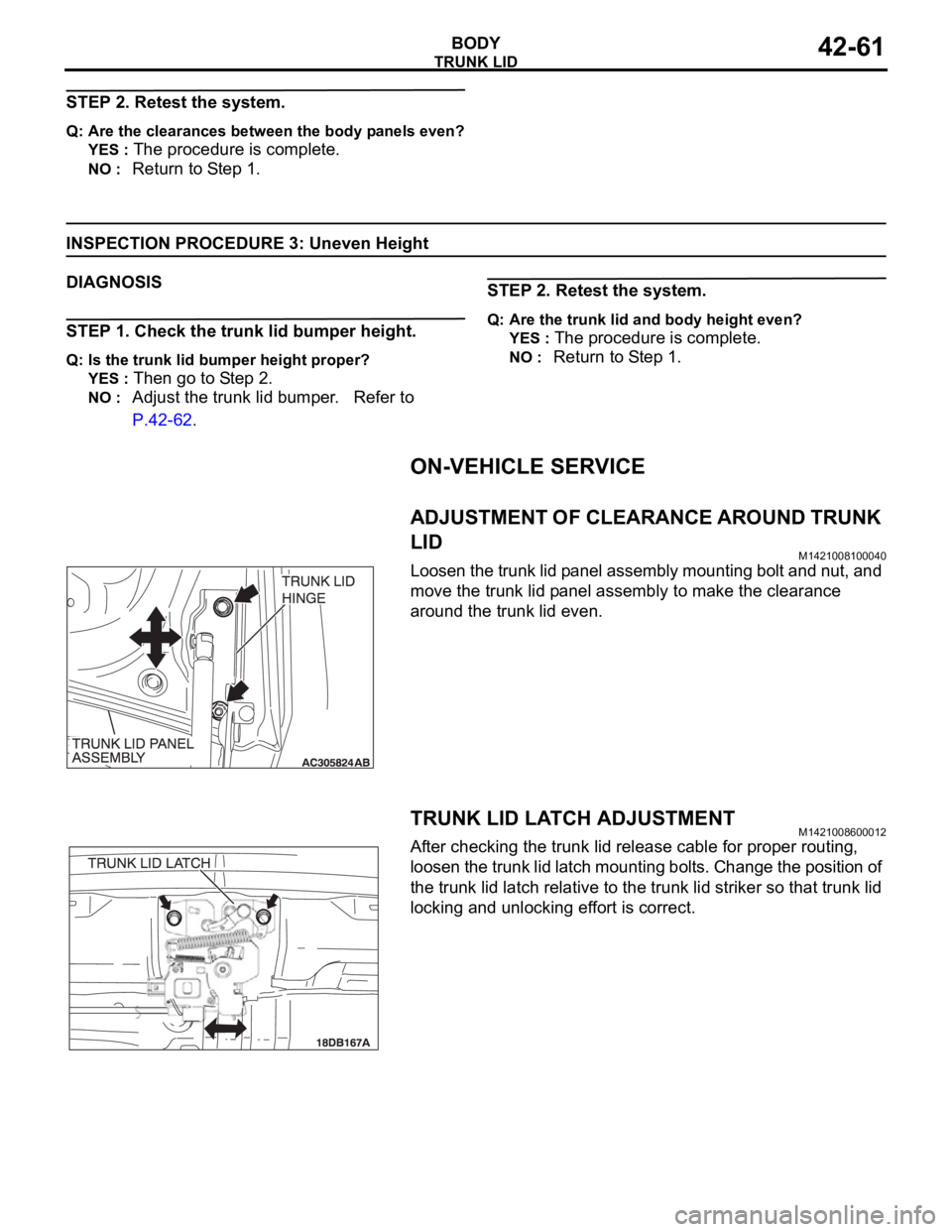

TRUNK LID LATCH ADJUSTMENTM1421008600012

After checking the trunk lid release cable for proper routing,

loosen the trunk lid latch mounting bolts. Change the position of

the trunk lid latch relative to the trunk lid striker so that trunk lid

locking and unlocking effort is correct.