MAINTENANCE SERVICE

GENERAL00-55

The SRS may not activate if any of the above compo-

nents are not installed properly, which could result in

serious injury or death to the vehicle's driver and

front passenger.

11.Check the steering wheel for excessive free play.

Replace any part if it fails visual inspection (Refer to

GROUP 52B, Air Bag Module and Clock Spring P.52B-237).

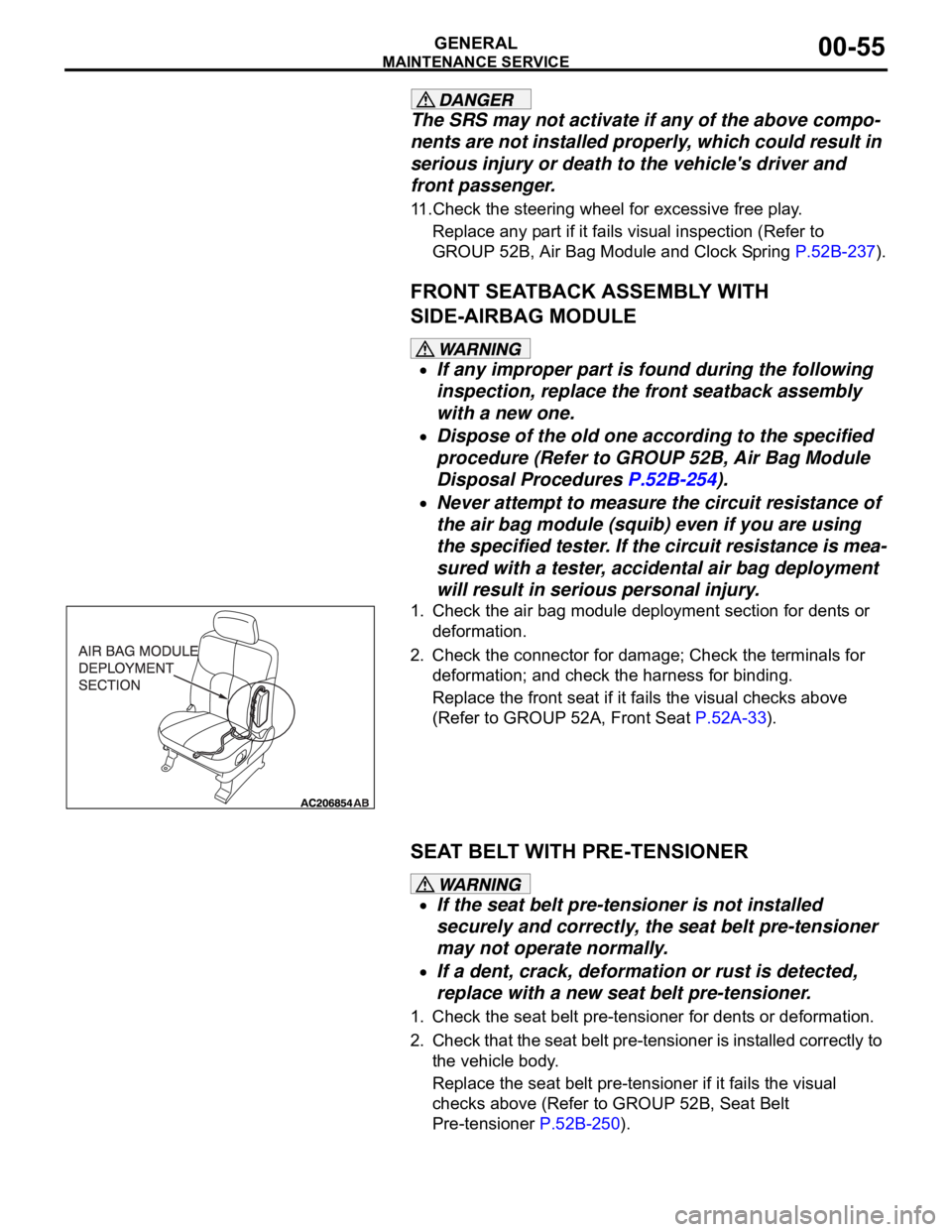

FRONT SEATBACK ASSEMBLY WITH

SIDE-AIRBAG MODULE

If any improper part is found during the following

inspection, replace the front seatback assembly

with a new one.

Dispose of the old one according to the specified

procedure (Refer to GROUP 52B, Air Bag Module

Disposal Procedures P.52B-254).

Never attempt to measure the circuit resistance of

the air bag module (squib) even if you are using

the specified tester. If the circuit resistance is mea-

sured with a tester, accidental air bag deployment

will result in serious personal injury.

1. Check the air bag module deployment section for dents or

deformation.

2. Check the connector for damage; Check the terminals for

deformation; and check the harness for binding.

Replace the front seat if it fails the visual checks above

(Refer to GROUP 52A, Front Seat P.52A-33).

SEAT BELT WITH PRE-TENSIONER

If the seat belt pre-tensioner is not installed

securely and correctly, the seat belt pre-tensioner

may not operate normally.

If a dent, crack, deformation or rust is detected,

replace with a new seat belt pre-tensioner.

1. Check the seat belt pre-tensioner for dents or deformation.

2. Check that the seat belt pre-tensioner is installed correctly to

the vehicle body.

Replace the seat belt pre-tensioner if it fails the visual

checks above (Refer to GROUP 52B, Seat Belt

Pre-tensioner P.52B-250).

MAINTENANCE SERVICE

GENERAL00-56

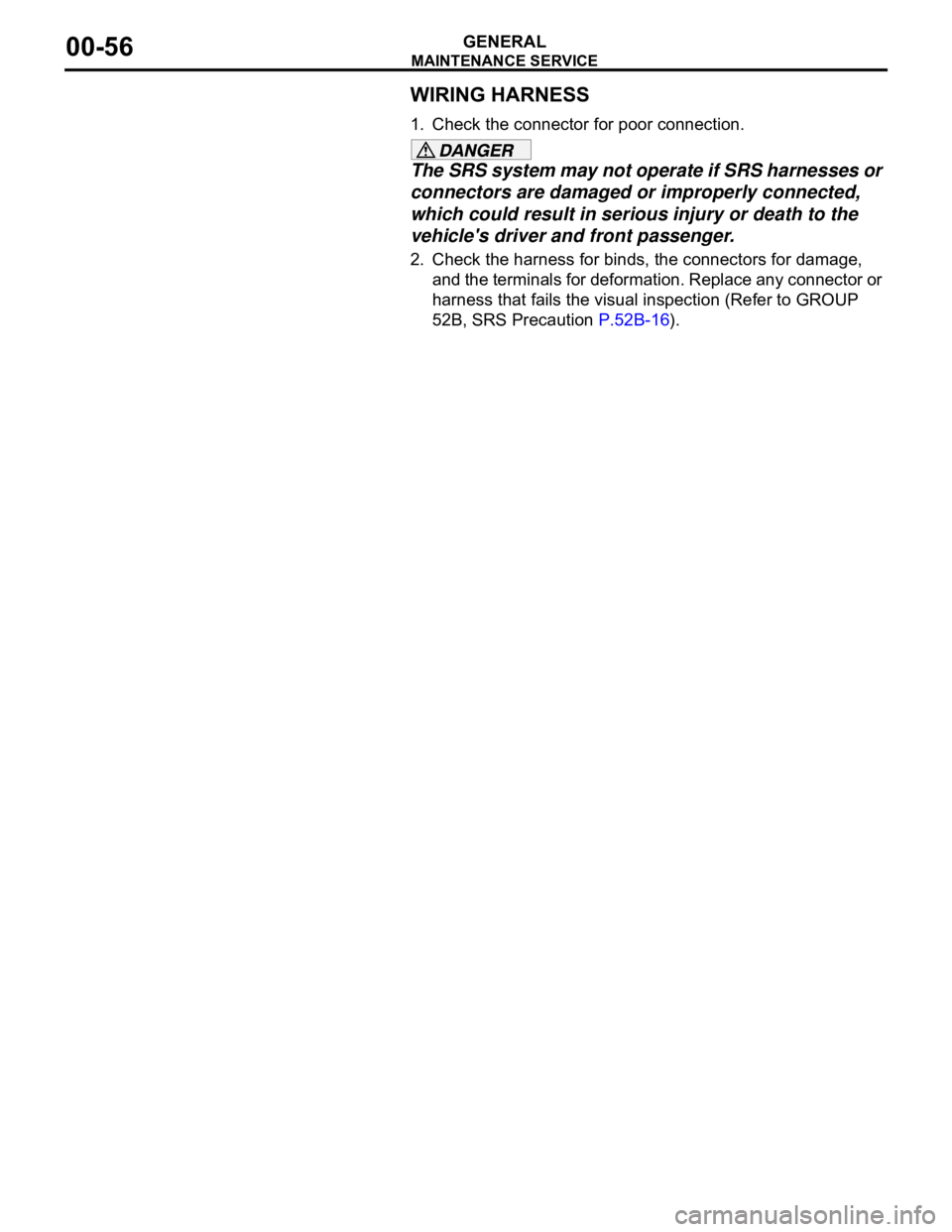

WIRING HARNESS

1. Check the connector for poor connection.

The SRS system may not operate if SRS harnesses or

connectors are damaged or improperly connected,

which could result in serious injury or death to the

vehicle's driver and front passenger.

2. Check the harness for binds, the connectors for damage,

and the terminals for deformation. Replace any connector or

harness that fails the visual inspection (Refer to GROUP

52B, SRS Precaution P.52B-16).

MAINTENANCE SERVICE

GENERAL00-58

20. TYRES (ROTATE)M1001008900303

Rotate tyres regularly to equalize tyre wear and help extend

tyre life. Recommended tyre rotation is every 12,000 km under

normal driving conditions and every 9,600 km in severe driving

conditions.

Timing for the rotation may vary according to vehicle condition,

road surface conditions, and individual driver's habits.

When rotating tyres, check for uneven wear, damage, and

wheel alignment. Abnormal wear is usually caused by incorrect

tyre pressure, improper wheel alignment, out-of balance

wheels, or severe braking.

The first rotation is the most important, to achieve more uniform

wear for all tyres on the vehicle.