lock MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1428 of 1500

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-11

<

LOWER ARM BALL JOINT AND TIE ROD END)

REMOVAL

Do not remove the nut from ball joint. Loosen it and use

the special tool to avoid possible damage to ball joint

threads.

Hang the special tool with cord to prevent it from fall-

ing.

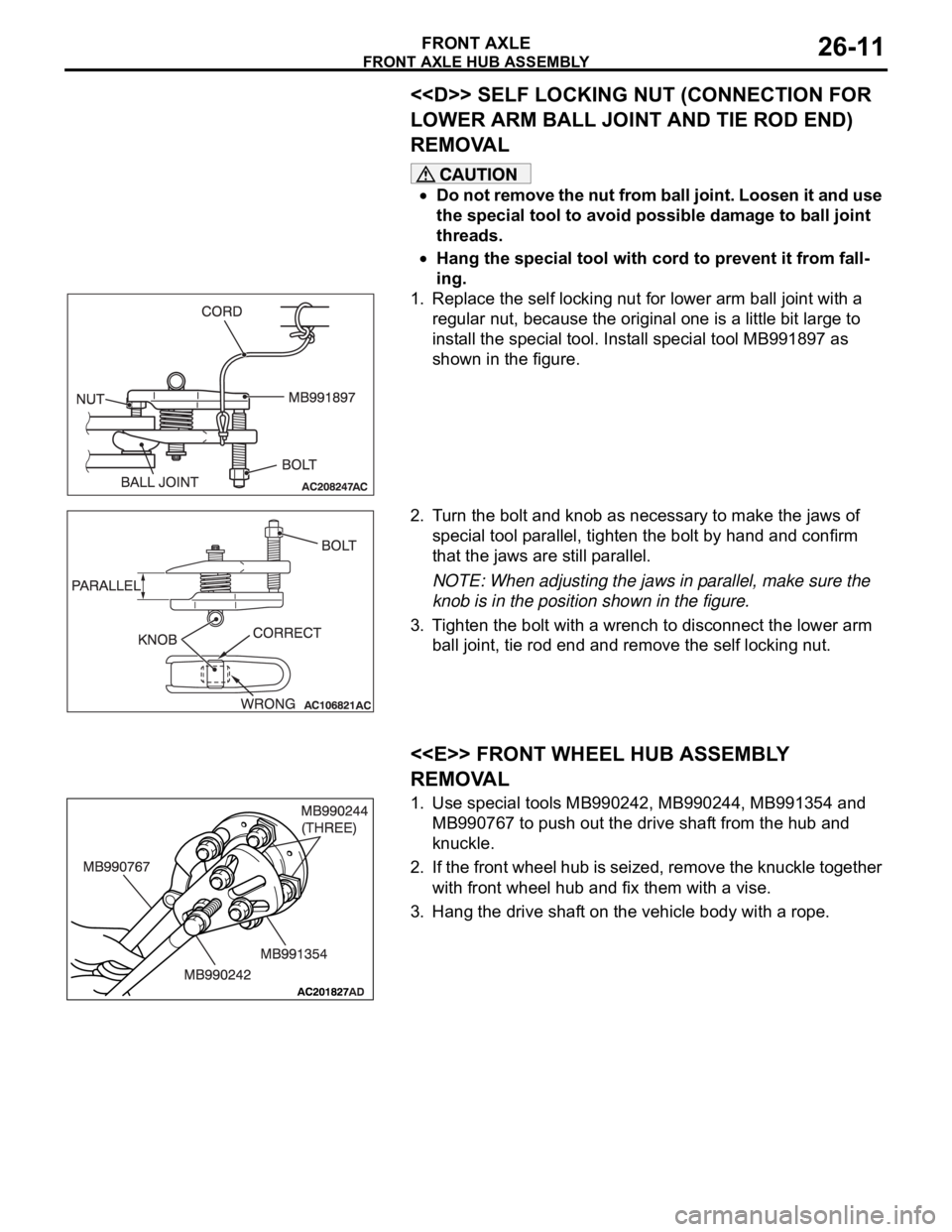

1. Replace the self locking nut for lower arm ball joint with a

regular nut, because the original one is a little bit large to

install the special tool. Install special tool MB991897 as

shown in the figure.

2. Turn the bolt and knob as necessary to make the jaws of

special tool parallel, tighten the bolt by hand and confirm

that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make sure the

knob is in the position shown in the figure.

3. Tighten the bolt with a wrench to disconnect the lower arm

ball joint, tie rod end and remove the self locking nut.

.

<

REMOVAL

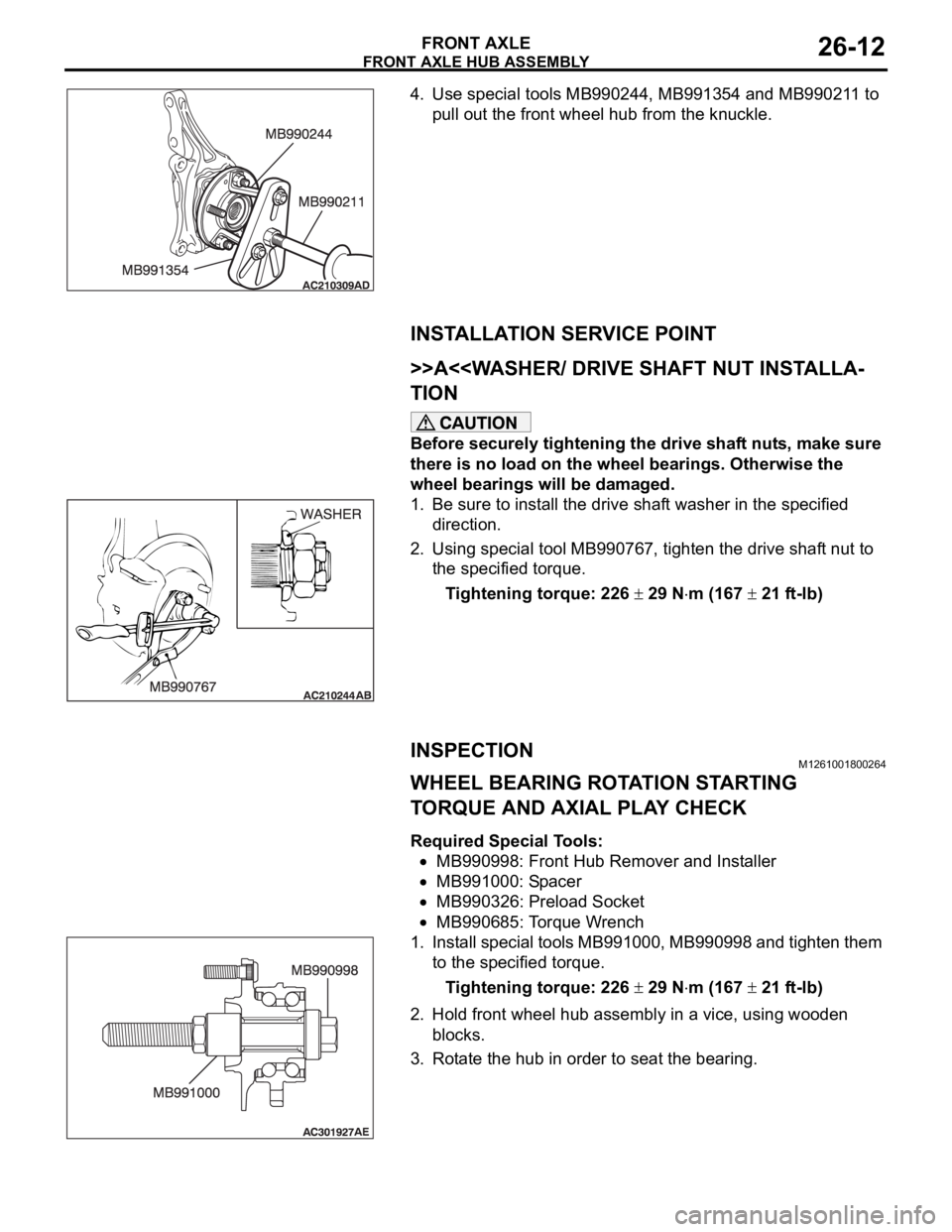

1. Use special tools MB990242, MB990244, MB991354 and

MB990767 to push out the drive shaft from the hub and

knuckle.

2. If the front wheel hub is seized, remove the knuckle together

with front wheel hub and fix them with a vise.

3. Hang the drive shaft on the vehicle body with a rope.

Page 1429 of 1500

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-12

4. Use special tools MB990244, MB991354 and MB990211 to

pull out the front wheel hub from the knuckle.

INSTALLATION SERVICE POINT

.

>>A<

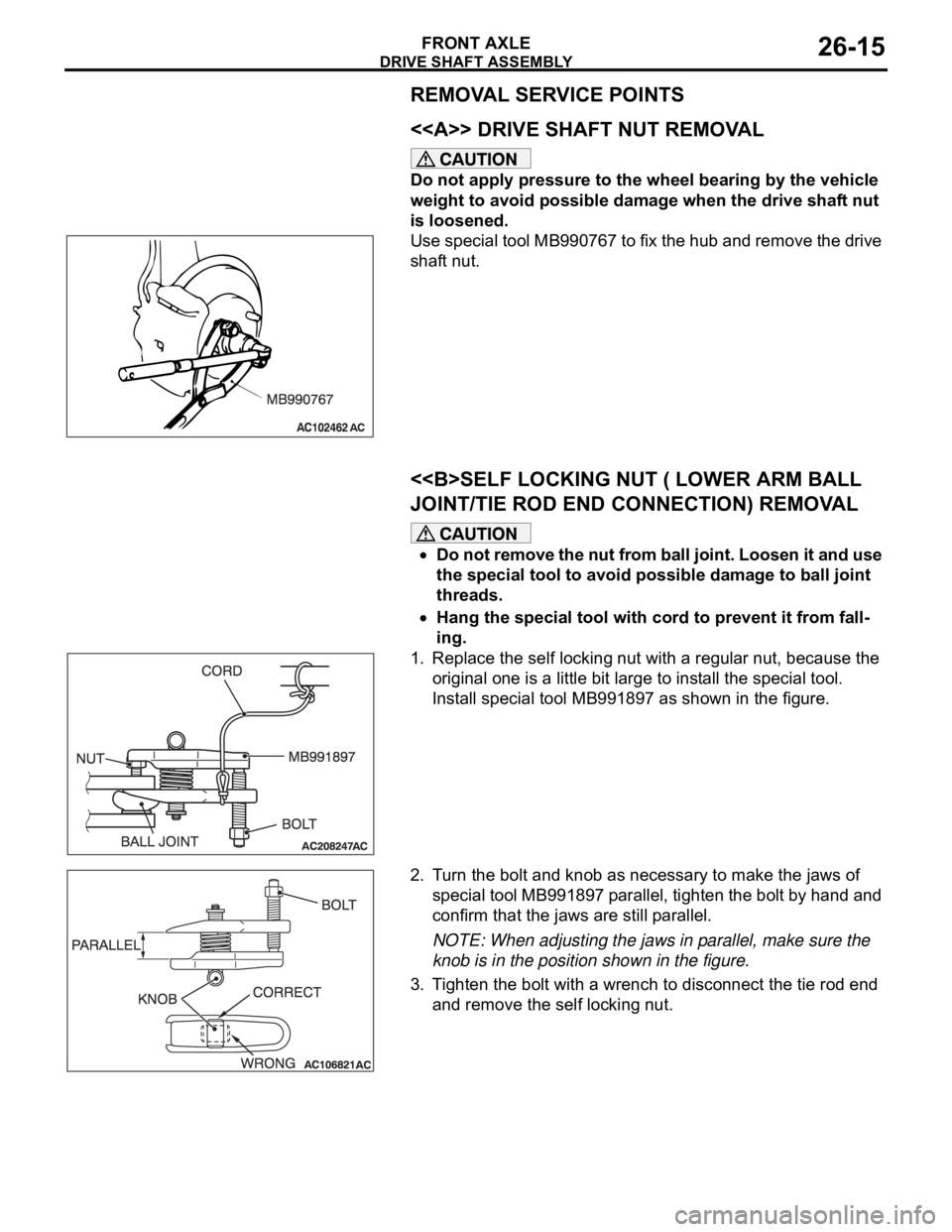

Before securely tightening the drive shaft nuts, make sure

there is no load on the wheel bearings. Otherwise the

wheel bearings will be damaged.

1. Be sure to install the drive shaft washer in the specified

direction.

2. Using special tool MB990767, tighten the drive shaft nut to

the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

INSPECTIONM1261001800264

WHEEL BEARING ROTATION STARTING

TORQUE AND AXIAL PLAY CHECK

Required Special Tools:

MB990998: Front Hub Remover and Installer

MB991000: Spacer

MB990326: Preload Socket

MB990685: Torque Wrench

1. Install special tools MB991000, MB990998 and tighten them

to the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

2. Hold front wheel hub assembly in a vice, using wooden

blocks.

3. Rotate the hub in order to seat the bearing.

Page 1431 of 1500

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB991897: Ball Joint Remover

MB990242: Puller Shaft Puller

MB990244: Puller Bar

MB991354: Puller Body

MB990998: Front Hub Remover and Installer

MB991000: Spacer

REMOVAL STEPS

1. SPLIT PIN

<> >>B<<2. DRIVE SHAFT NUT

3. WASHER

4. FRONT WHEEL SPEED SENSOR

BRACKET

5. FRONT WHEEL SPEED SENSOR

6. BRAKE HOSE BRACKET

<>7. SELF LOCKING NUT (LOWER

ARM BALL JOINT CONNECTION)

<>8. SELF LOCKING NUT (TIE ROD

END CONNECTION)

<

<

SHAFT ASSEMBLY RH

11. CIRCLIPREMOVAL STEPS (Continued)

Page 1432 of 1500

Page 1446 of 1500

SPECIFICATIONS

FRONT AXLE26-29

SPECIFICATIONS

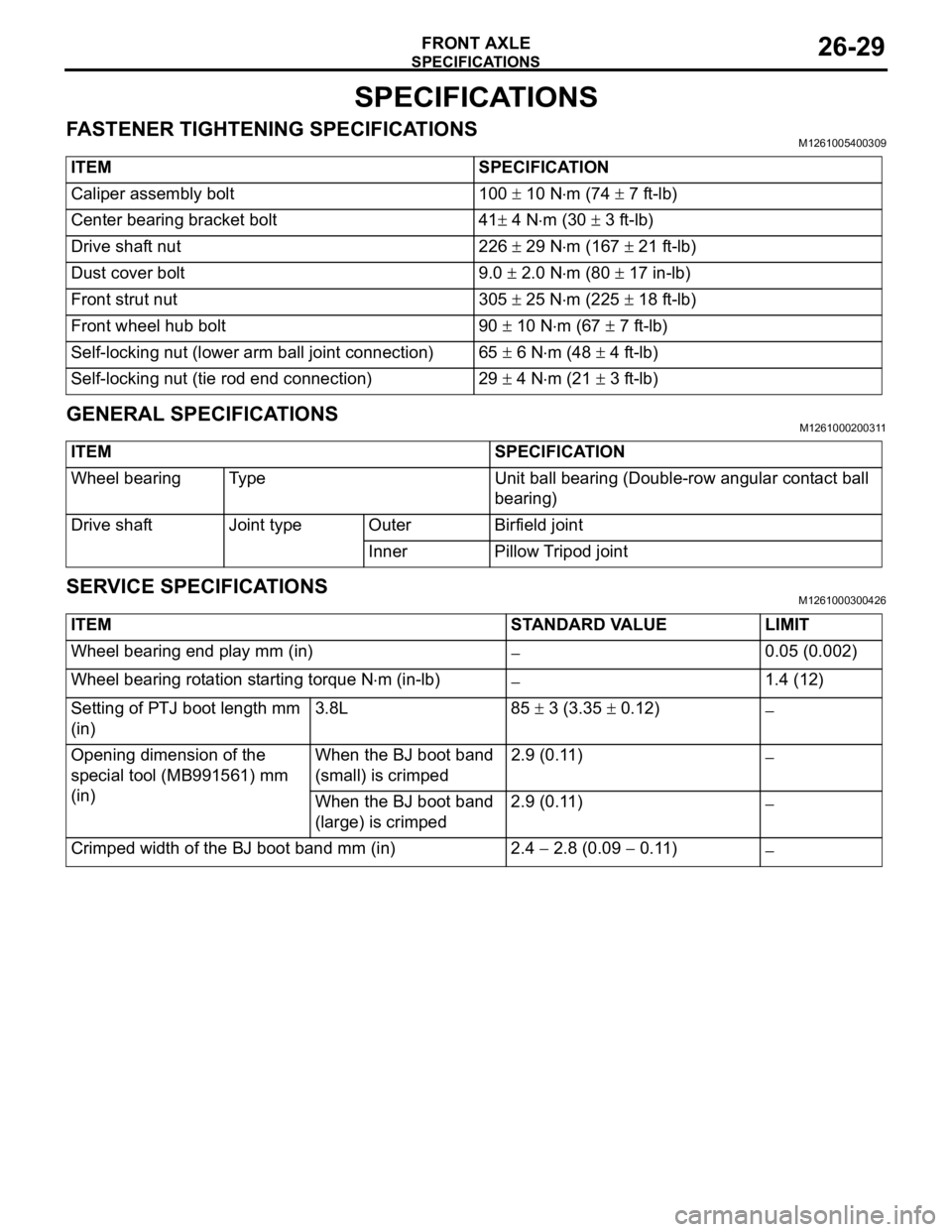

FASTENER TIGHTENING SPECIFICATIONSM1261005400309

GENERAL SPECIFICATIONSM1261000200311

SERVICE SPECIFICATIONSM1261000300426

ITEM SPECIFICATION

Caliper assembly bolt 100

10 Nm (74 7 ft-lb)

Center bearing bracket bolt 41

4 Nm (30 3 ft-lb)

Drive shaft nut 226

29 Nm (167 21 ft-lb)

Dust cover bolt 9.0

2.0 Nm (80 17 in-lb)

Front strut nut 305

25 Nm (225 18 ft-lb)

Front wheel hub bolt 90

10 Nm (67 7 ft-lb)

Self-locking nut (lower arm ball joint connection) 65

6 Nm (48 4 ft-lb)

Self-locking nut (tie rod end connection) 29

4 Nm (21 3 ft-lb)

ITEM SPECIFICATION

Wheel bearing Type Unit ball bearing (Double-row angular contact ball

bearing)

Drive shaft Joint type Outer Birfield joint

Inner Pillow Tripod joint

ITEM STANDARD VALUE LIMIT

Wheel bearing end play mm (in)

0.05 (0.002)

Wheel bearing rotation starting torque N

m (in-lb)1.4 (12)

Setting of PTJ boot length mm

(in)3.8L 85

3 (3.35 0.12)

Opening dimension of the

special tool (MB991561) mm

(in)When the BJ boot band

(small) is crimped2.9 (0.11)

When the BJ boot band

(large) is crimped2.9 (0.11)

Crimped width of the BJ boot band mm (in) 2.4 2.8 (0.09 0.11)

Page 1455 of 1500

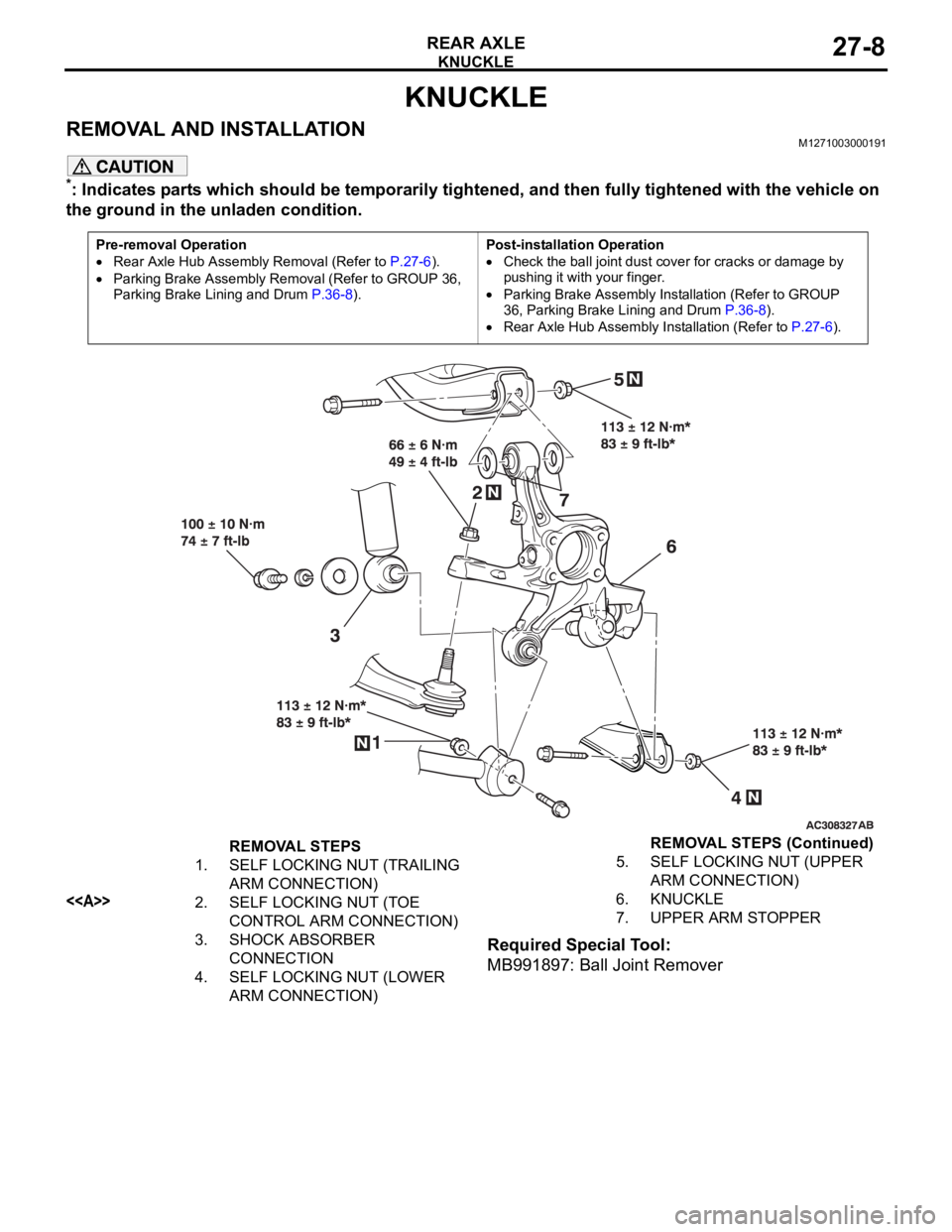

KNUCKLE

REAR AXLE27-8

KNUCKLE

REMOVAL AND INSTALLATIONM1271003000191

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the ground in the unladen condition.

Required Special Tool:

MB991897: Ball Joint Remover

Pre-removal Operation

Rear Axle Hub Assembly Removal (Refer to P.27-6).

Parking Brake Assembly Removal (Refer to GROUP 36,

Parking Brake Lining and Drum P.36-8).Post-installation Operation

Check the ball joint dust cover for cracks or damage by

pushing it with your finger.

Parking Brake Assembly Installation (Refer to GROUP

36, Parking Brake Lining and Drum P.36-8).

Rear Axle Hub Assembly Installation (Refer to P.27-6).

REMOVAL STEPS

1. SELF LOCKING NUT (TRAILING

ARM CONNECTION)

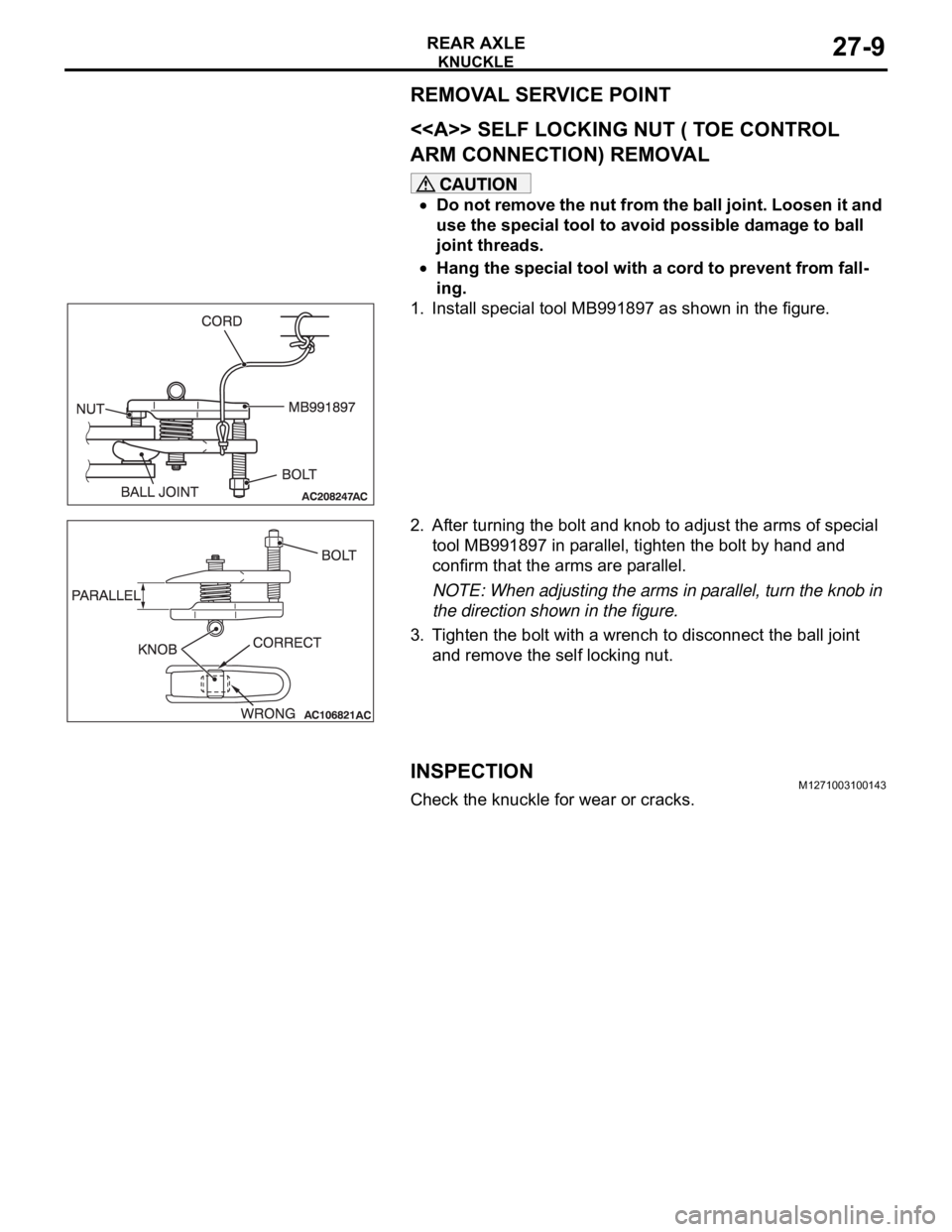

<>2. SELF LOCKING NUT (TOE

CONTROL ARM CONNECTION)

3. SHOCK ABSORBER

CONNECTION

4. SELF LOCKING NUT (LOWER

ARM CONNECTION)5. SELF LOCKING NUT (UPPER

ARM CONNECTION)

6. KNUCKLE

7. UPPER ARM STOPPERREMOVAL STEPS (Continued)

Page 1456 of 1500

Page 1457 of 1500

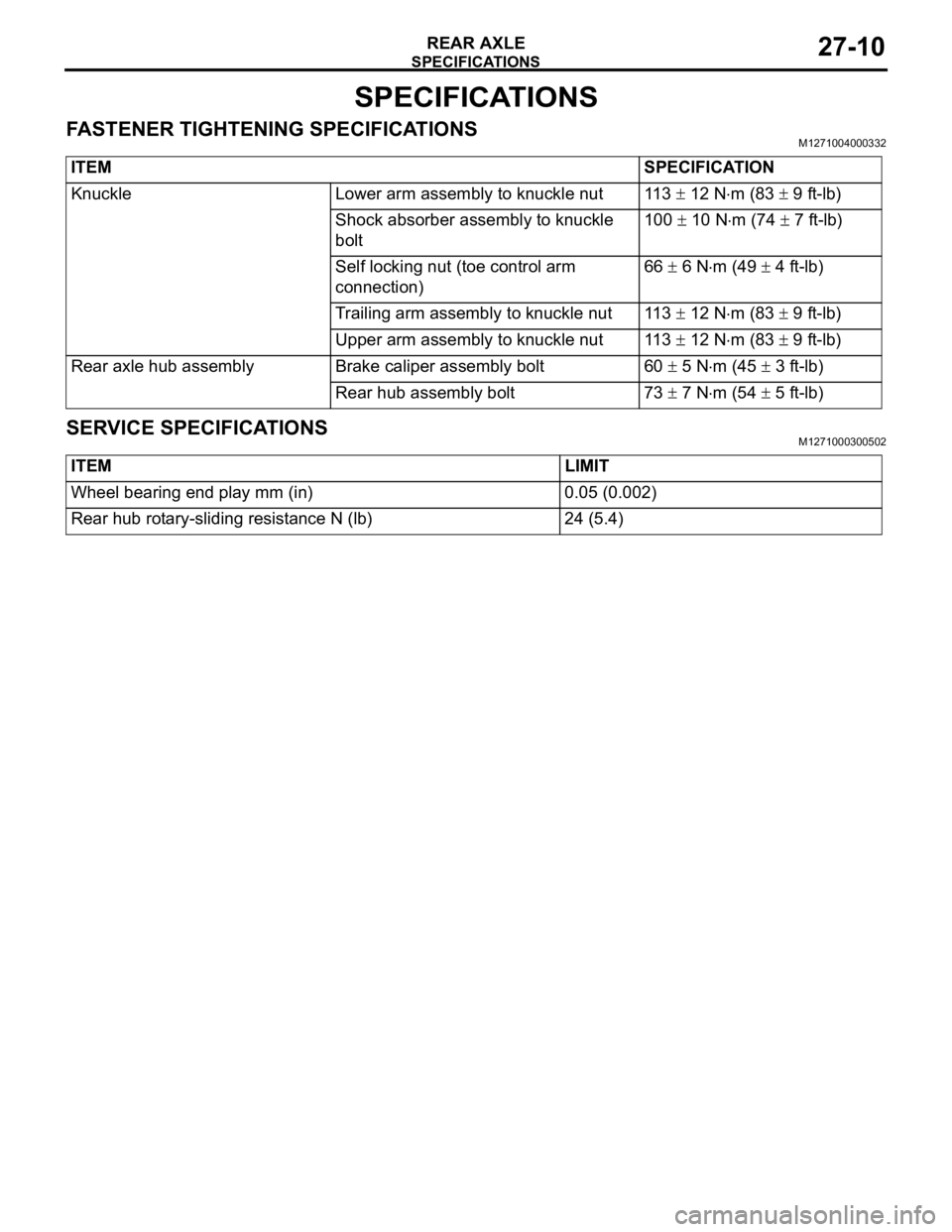

SPECIFICATIONS

REAR AXLE27-10

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1271004000332

SERVICE SPECIFICATIONSM1271000300502

ITEM SPECIFICATION

Knuckle Lower arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Shock absorber assembly to knuckle

bolt100

10 Nm (74 7 ft-lb)

Self locking nut (toe control arm

connection)66

6 Nm (49 4 ft-lb)

Trailing arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Upper arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Rear axle hub assembly Brake caliper assembly bolt 60

5 Nm (45 3 ft-lb)

Rear hub assembly bolt 73

7 Nm (54 5 ft-lb)

ITEM LIMIT

Wheel bearing end play mm (in) 0.05 (0.002)

Rear hub rotary-sliding resistance N (lb) 24 (5.4)

Page 1462 of 1500

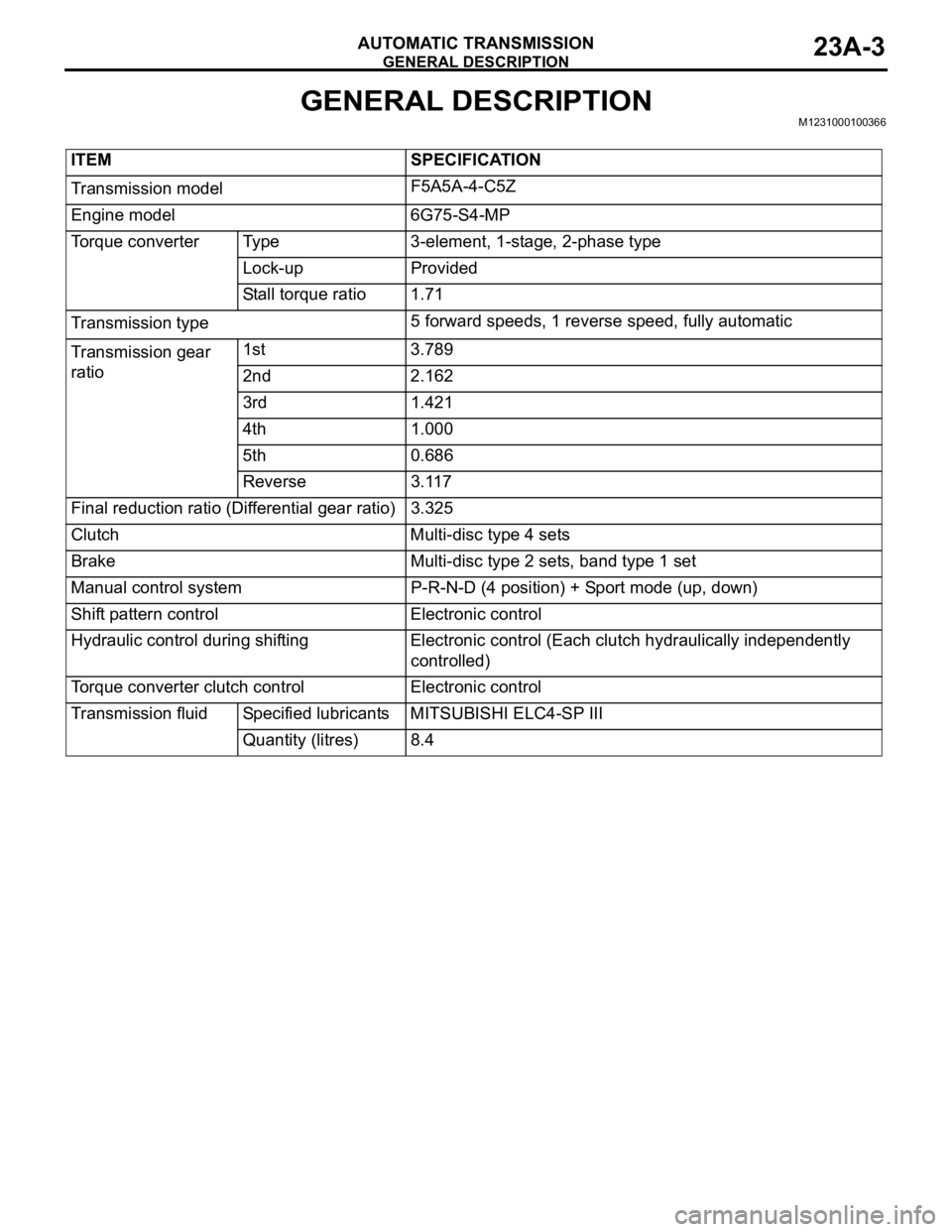

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-3

GENERAL DESCRIPTIONM1231000100366

ITEM SPECIFICATION

Transmission modelF5A5A-4-C5Z

Engine model 6G75-S4-MP

Torque converter Type 3-element, 1-stage, 2-phase type

Lock-up Provided

Stall torque ratio 1.71

Transmission type5 forward speeds, 1 reverse speed, fully automatic

Transmission gear

ratio1st 3.789

2nd 2.162

3rd 1.421

4th 1.000

5th 0.686

Reverse 3.117

Final reduction ratio (Differential gear ratio) 3.325

Clutch Multi-disc type 4 sets

Brake Multi-disc type 2 sets, band type 1 set

Manual control system P-R-N-D (4 position) + Sport mode (up, down)

Shift pattern control Electronic control

Hydraulic control during shifting Electronic control (Each clutch hydraulically independently

controlled)

Torque converter clutch control Electronic control

Transmission fluid Specified lubricants MITSUBISHI ELC4-SP III

Quantity (litres) 8.4

Page 1463 of 1500

GENERAL DESCRIPTION

AUTOMATIC TRANSMISSION23A-4

TRANSMISSION

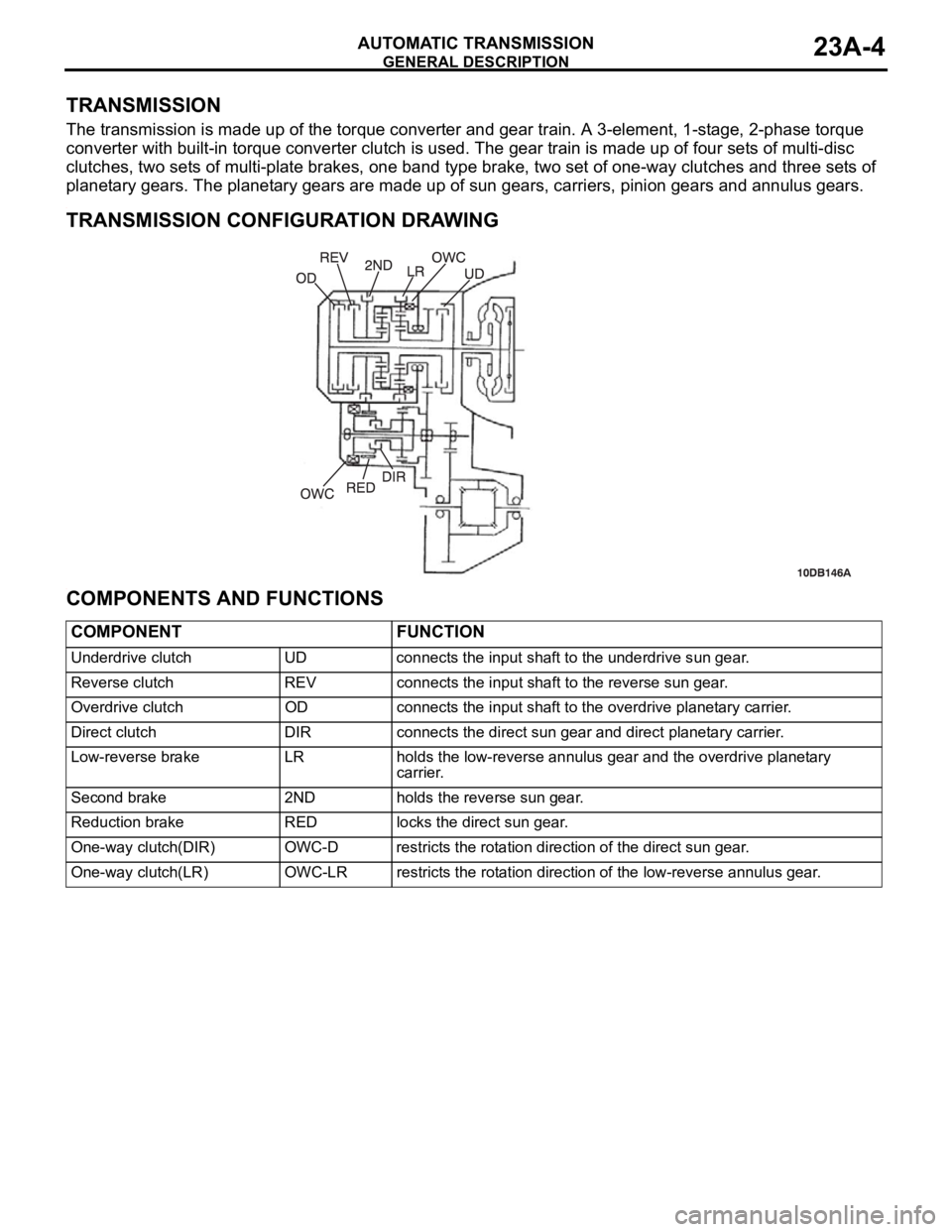

The transmission is made up of the torque converter and gear train. A 3-element, 1-stage, 2-phase torque

converter with built-in torque converter clutch is used. The gear train is made up of four sets of multi-disc

clutches, two sets of multi-plate brakes, one band type brake, two set of one-way clutches and three sets of

planetary gears. The planetary gears are made up of sun gears, carriers, pinion gears and annulus gears.

.

TRANSMISSION CONFIGURATION DRAWING

.

COMPONENTS AND FUNCTIONS

COMPONENT FUNCTION

Underdrive clutch UD connects the input shaft to the underdrive sun gear.

Reverse clutch REV connects the input shaft to the reverse sun gear.

Overdrive clutch OD connects the input shaft to the overdrive planetary carrier.

Direct clutch DIR connects the direct sun gear and direct planetary carrier.

Low-reverse brake LR holds the low-reverse annulus gear and the overdrive planetary

carrier.

Second brake 2ND holds the reverse sun gear.

Reduction brake RED locks the direct sun gear.

One-way clutch(DIR) OWC-D restricts the rotation direction of the direct sun gear.

One-way clutch(LR) OWC-LR restricts the rotation direction of the low-reverse annulus gear.