belt MITSUBISHI 380 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 848 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-147

TEST PROCEDURES

1. Select a quiet area for testing.

2. Duplicate problem (customer complaint) as much as

possible.

3. Judge if the noise is abnormal (ie. it is important to

understand the characteristics of the vehicle and its normal

state to judge what is abnormal) - Compare with similar

vehicle if necessary.

4. Detail what and how noise occurs.

5. Find the noise source and verify its transmission by isolating

the subject part from the vehicle.

6. Repair the problem.

7. Explain and report your findings.

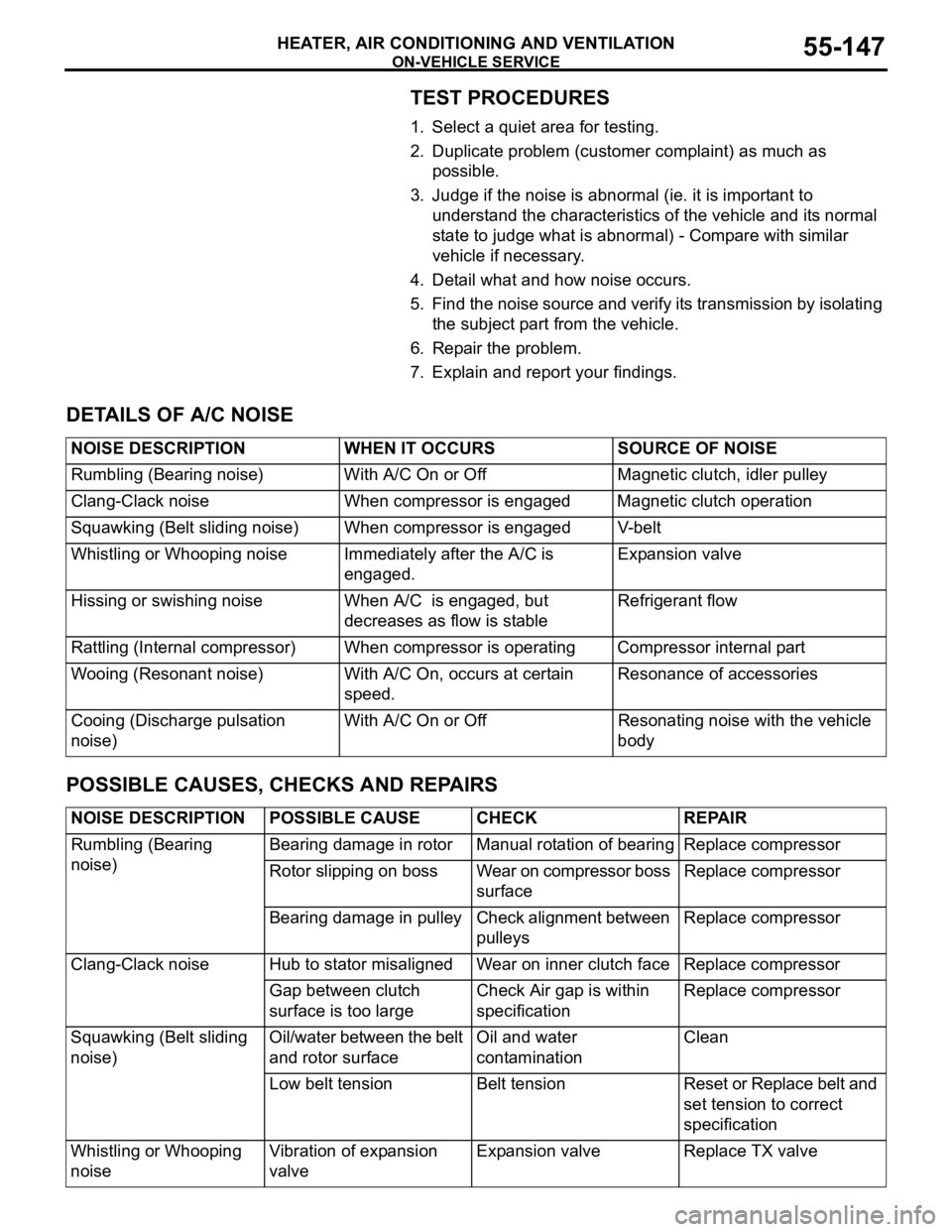

DETAILS OF A/C NOISE

POSSIBLE CAUSES, CHECKS AND REPAIRS

NOISE DESCRIPTION WHEN IT OCCURS SOURCE OF NOISE

Rumbling (Bearing noise) With A/C On or Off Magnetic clutch, idler pulley

Clang-Clack noise When compressor is engaged Magnetic clutch operation

Squawking (Belt sliding noise) When compressor is engaged V-belt

Whistling or Whooping noise Immediately after the A/C is

engaged.Expansion valve

Hissing or swishing noise When A/C is engaged, but

decreases as flow is stable Refrigerant flow

Rattling (Internal compressor) When compressor is operating Compressor internal part

Wooing (Resonant noise) With A/C On, occurs at certain

speed.Resonance of accessories

Cooing (Discharge pulsation

noise)With A/C On or Off Resonating noise with the vehicle

body

NOISE DESCRIPTION POSSIBLE CAUSE CHECK REPAIR

Rumbling (Bearing

noise)Bearing damage in rotor Manual rotation of bearing Replace compressor

Rotor slipping on boss Wear on compressor boss

surfaceReplace compressor

Bearing damage in pulley Check alignment between

pulleysReplace compressor

Clang-Clack noise Hub to stator misaligned Wear on inner clutch face Replace compressor

Gap between clutch

surface is too largeCheck Air gap is within

specificationReplace compressor

Squawking (Belt sliding

noise)Oil/water between the belt

and rotor surfaceOil and water

contaminationClean

Low belt tension Belt tension Reset or Replace belt and

set tension to correct

specification

Whistling or Whooping

noiseVibration of expansion

valveExpansion valve Replace TX valve

Page 865 of 1500

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-164

COMPRESSOR ASSEMBLY AND DRIVE BELT

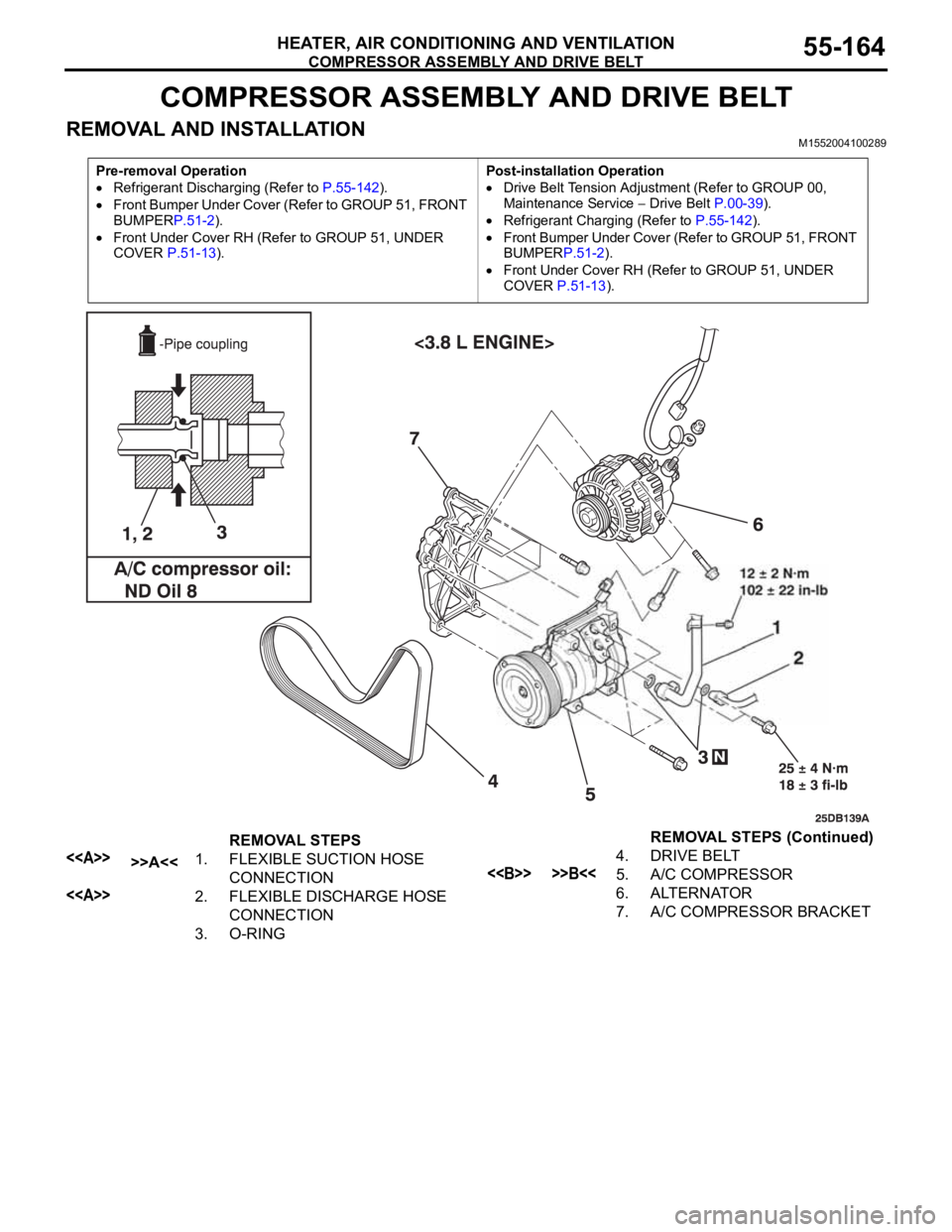

REMOVAL AND INSTALLATIONM1552004100289

Pre-removal Operation

Refrigerant Discharging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).Post-installation Operation

Drive Belt Tension Adjustment (Refer to GROUP 00,

Maintenance Service

Drive Belt P.00-39).

Refrigerant Charging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).

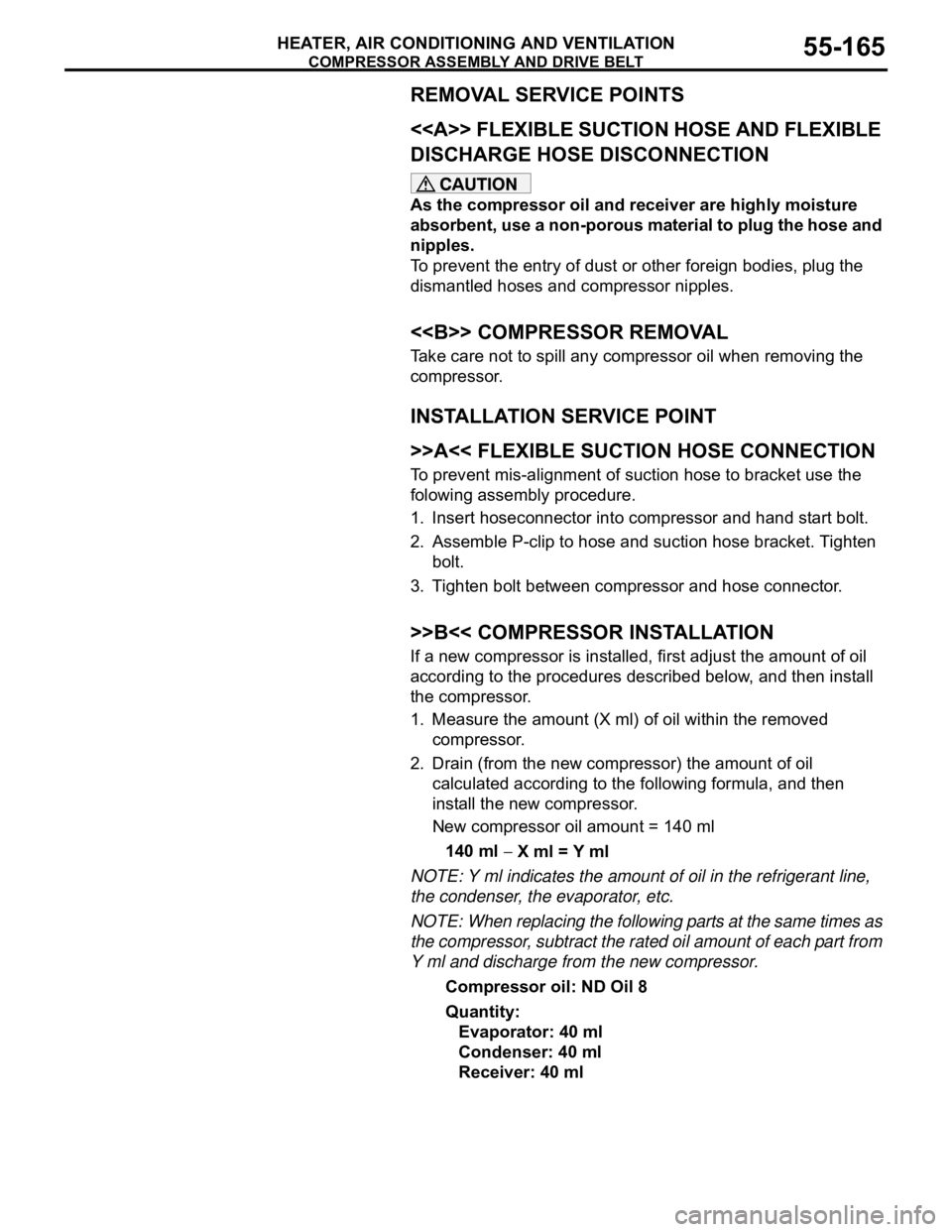

REMOVAL STEPS

<>>>A<<1. FLEXIBLE SUCTION HOSE

CONNECTION

<>2. FLEXIBLE DISCHARGE HOSE

CONNECTION

3. O-RING4. DRIVE BELT

<> >>B<<5. A/C COMPRESSOR

6. ALTERNATOR

7. A/C COMPRESSOR BRACKETREMOVAL STEPS (Continued)

Page 866 of 1500

Page 867 of 1500

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-166

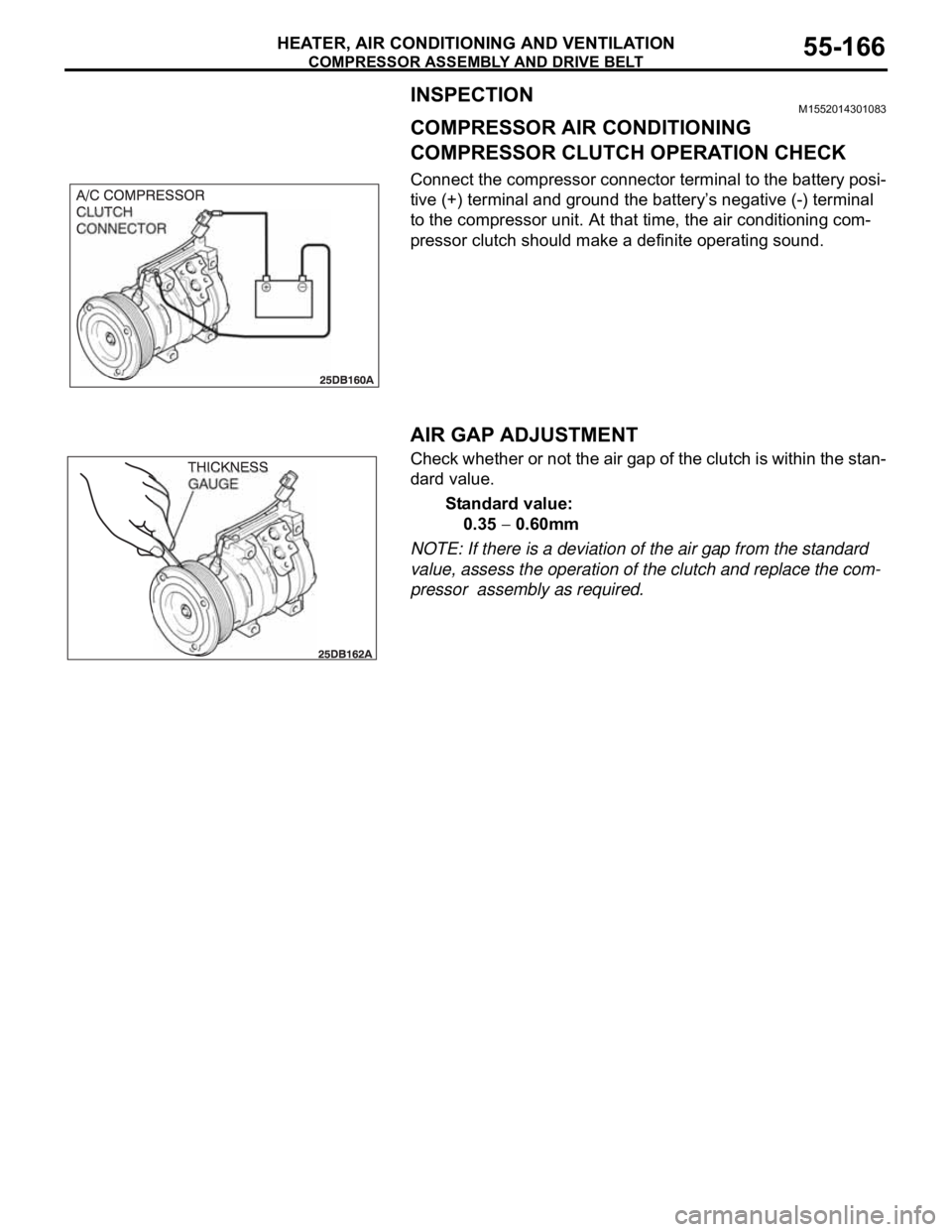

INSPECTIONM1552014301083

COMPRESSOR AIR CONDITIONING

COMPRESSOR CLUTCH OPERATION CHECK

Connect the compressor connector terminal to the battery posi-

tive (+) terminal and ground the battery’s negative (-) terminal

to the compressor unit. At that time, the air conditioning com-

pressor clutch should make a definite operating sound.

.

AIR GAP ADJUSTMENT

Check whether or not the air gap of the clutch is within the stan-

dard value.

Standard value:

0.35

0.60mm

NOTE: If there is a deviation of the air gap from the standard

value, assess the operation of the clutch and replace the com-

pressor assembly as required.

Page 910 of 1500

HOW TO DIAGNOSE

GENERAL

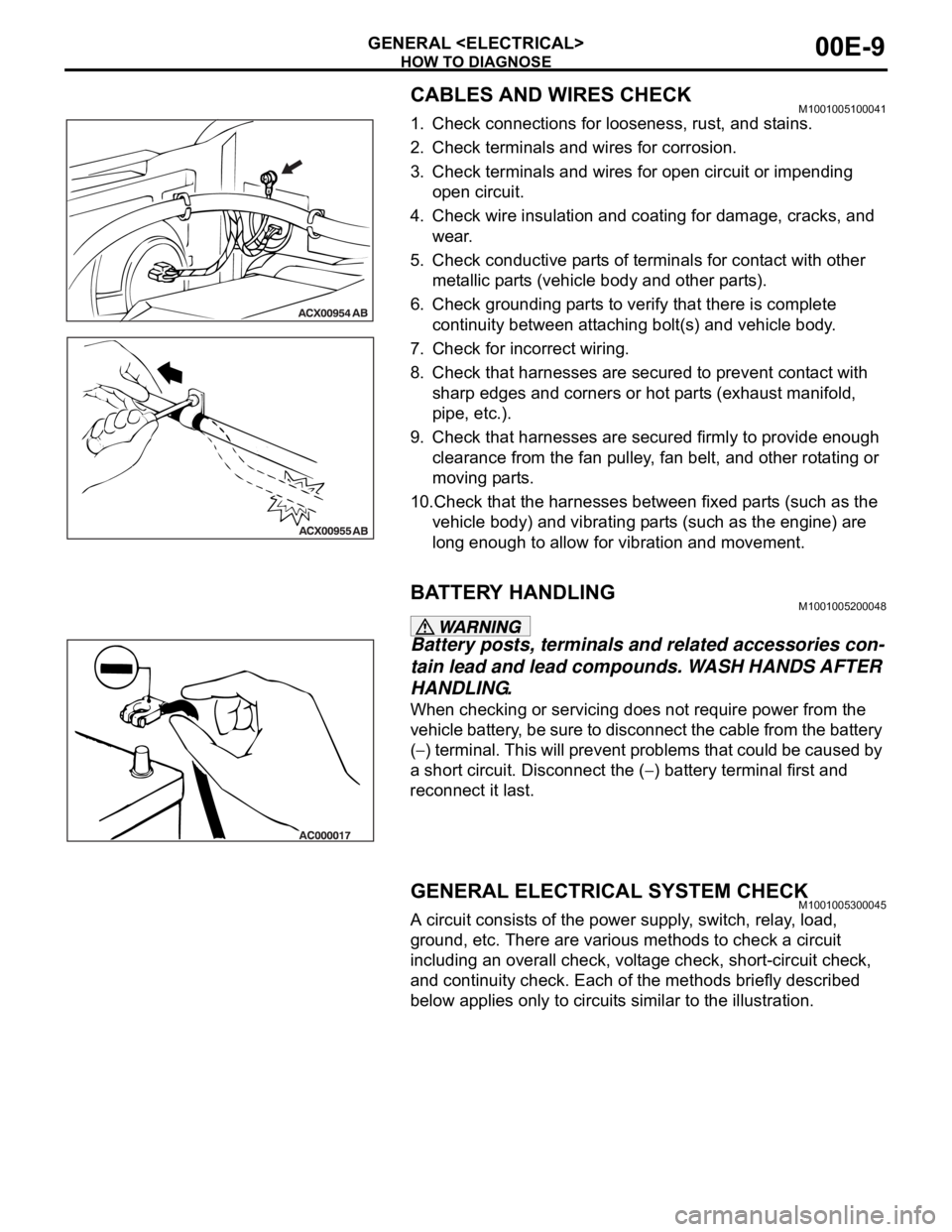

CABLES AND WIRES CHECKM1001005100041

1. Check connections for looseness, rust, and stains.

2. Check terminals and wires for corrosion.

3. Check terminals and wires for open circuit or impending

open circuit.

4. Check wire insulation and coating for damage, cracks, and

wear.

5. Check conductive parts of terminals for contact with other

metallic parts (vehicle body and other parts).

6. Check grounding parts to verify that there is complete

continuity between attaching bolt(s) and vehicle body.

7. Check for incorrect wiring.

8. Check that harnesses are secured to prevent contact with

sharp edges and corners or hot parts (exhaust manifold,

pipe, etc.).

9. Check that harnesses are secured firmly to provide enough

clearance from the fan pulley, fan belt, and other rotating or

moving parts.

10.Check that the harnesses between fixed parts (such as the

vehicle body) and vibrating parts (such as the engine) are

long enough to allow for vibration and movement.

BATTERY HANDLINGM1001005200048

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

When checking or servicing does not require power from the

vehicle battery, be sure to disconnect the cable from the battery

(

) terminal. This will prevent problems that could be caused by

a short circuit. Disconnect the (

) battery terminal first and

reconnect it last.

GENERAL ELECTRICAL SYSTEM CHECKM1001005300045

A circuit consists of the power supply, switch, relay, load,

ground, etc. There are various methods to check a circuit

including an overall check, voltage check, short-circuit check,

and continuity check. Each of the methods briefly described

below applies only to circuits similar to the illustration.

Page 917 of 1500

GENERAL DESCRIPTION

ENGINE COOLING14-2

GENERAL DESCRIPTIONM1141000100401

The cooling system is designed to keep every

part of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pres-

sure forced circulation type in which the water

pump pressurizes coolant and circulates it

throughout the engine. If the coolant temperature exceeds the prescribed temperature, the thermo-

stat opens to circulate the coolant through the

radiator as well so that the heat absorbed by the

coolant may be radiated into the air. The water

pump is of the centrifugal type and is driven by

the drive belt from the crankshaft. The radiator is

the corrugated fin, down flow type.

SPECIAL TOOLM1141000600279

ENGINE COOLING DIAGNOSIS

INTRODUCTIONM1141005300347

The system cools the engine so that it does not over-

heat and maintains the engine at an optimum tem-

perature. The system components are the radiator,

water pump, thermostat, condenser and fan assem-

blies. Possible faults include low coolant, contamina-

tion, belt loosening and component damage.

TROUBLESHOOTING STRATEGYM1141005200340

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure to find

most of the engine cooling faults.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find and repair the malfunction by following the

SYMPTOM CHART.

4. Verify that the malfunction is eliminated. TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB991871

LLC changerGeneral service tool Coolant refilling

Page 919 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-4

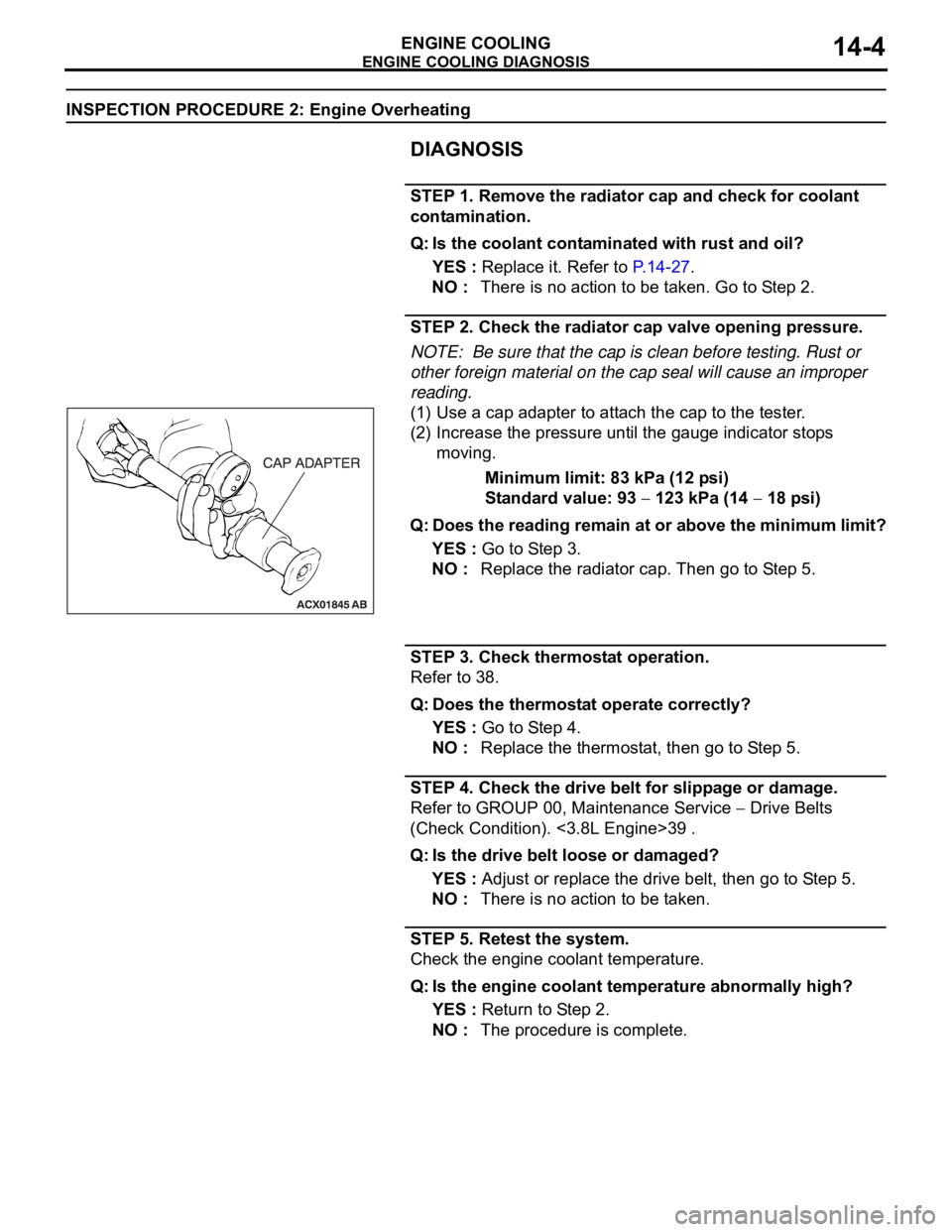

INSPECTION PROCEDURE 2: Engine Overheating

DIAGNOSIS

STEP 1. Remove the radiator cap and check for coolant

contamination.

Q: Is the coolant contaminated with rust and oil?

YES : Replace it. Refer to P.14-27.

NO : There is no action to be taken. Go to Step 2.

STEP 2. Check the radiator cap valve opening pressure.

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

(1) Use a cap adapter to attach the cap to the tester.

(2) Increase the pressure until the gauge indicator stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

Q: Does the reading remain at or above the minimum limit?

YES : Go to Step 3.

NO : Replace the radiator cap. Then go to Step 5.

STEP 3. Check thermostat operation.

Refer to 38.

Q: Does the thermostat operate correctly?

YES : Go to Step 4.

NO : Replace the thermostat, then go to Step 5.

STEP 4. Check the drive belt for slippage or damage.

Refer to GROUP 00, Maintenance Service

Drive Belts

(Check Condition). <3.8L Engine>39 .

Q: Is the drive belt loose or damaged?

YES : Adjust or replace the drive belt, then go to Step 5.

NO : There is no action to be taken.

STEP 5. Retest the system.

Check the engine coolant temperature.

Q: Is the engine coolant temperature abnormally high?

YES : Return to Step 2.

NO : The procedure is complete.

Page 954 of 1500

WATE R P U M P

ENGINE COOLING14-39

WAT E R P U M P

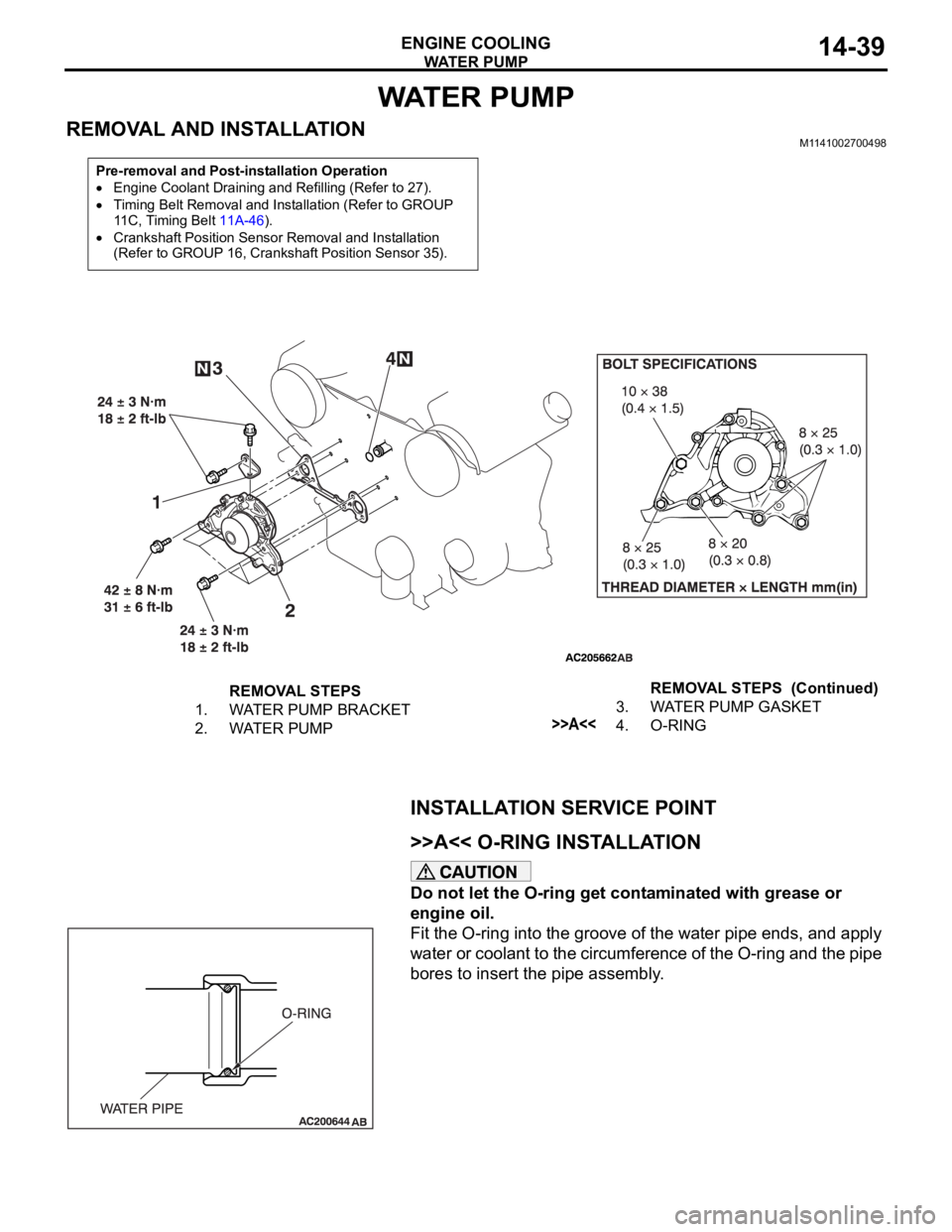

REMOVAL AND INSTALLATIONM1141002700498

INSTALLATION SERVICE POINT

.

>>A<< O-RING INSTALLATION

Do not let the O-ring get contaminated with grease or

engine oil.

Fit the O-ring into the groove of the water pipe ends, and apply

water or coolant to the circumference of the O-ring and the pipe

bores to insert the pipe assembly.

Pre-removal and Post-installation Operation

Engine Coolant Draining and Refilling (Refer to 27).

Timing Belt Removal and Installation (Refer to GROUP

11C, Timing Belt 11A-46).

Crankshaft Position Sensor Removal and Installation

(Refer to GROUP 16, Crankshaft Position Sensor 35).

REMOVAL STEPS

1. WATER PUMP BRACKET

2. WATER PUMP3. WATER PUMP GASKET

>>A<<4. O-RINGREMOVAL STEPS (Continued)

Page 966 of 1500

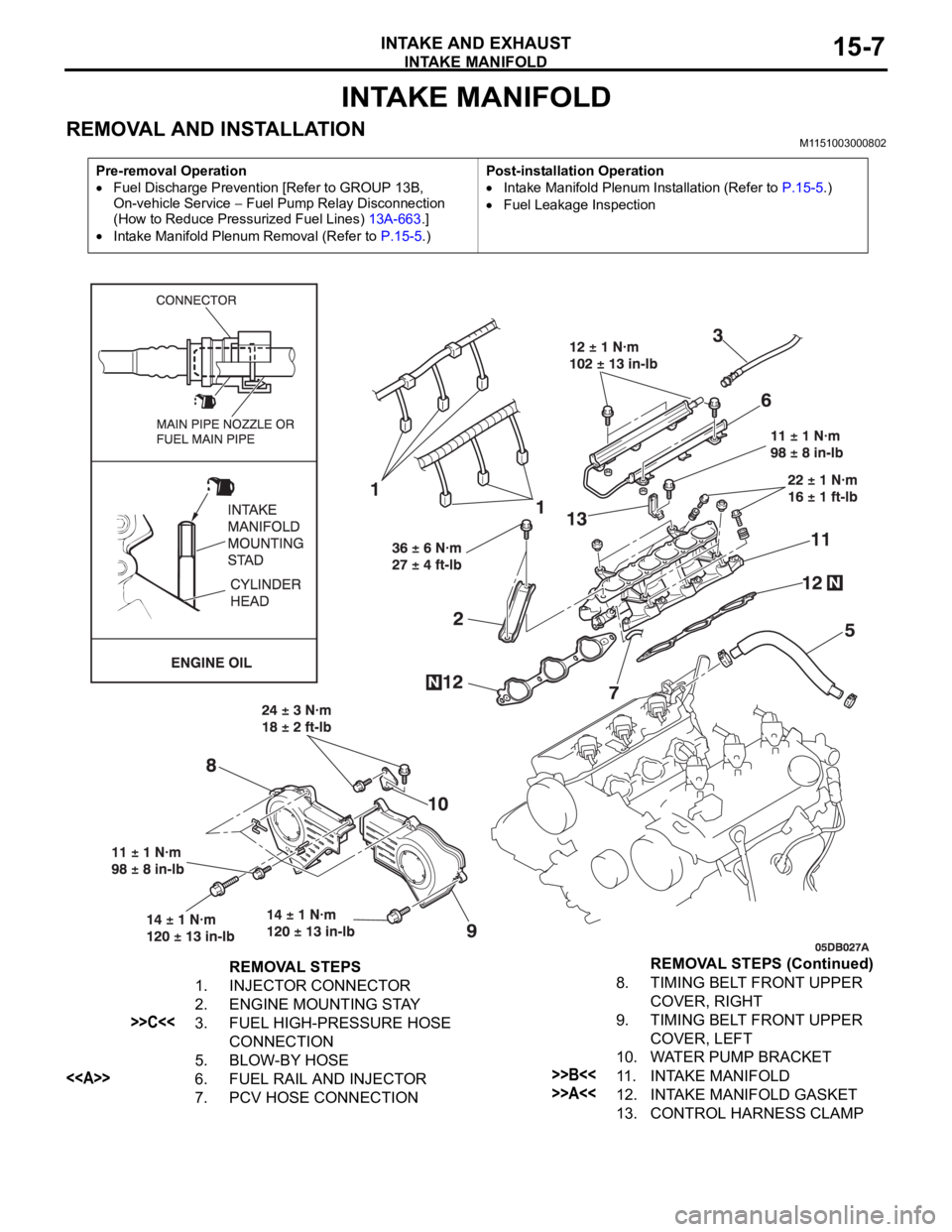

INTAKE MANIFOLD

INTAKE AND EXHAUST15-7

INTAKE MANIFOLD

REMOVAL AND INSTALLATION M1151003000802

Pre-removal Operation

Fuel Discharge Prevention [Refer to GROUP 13B,

On-vehicle Service

Fuel Pump Relay Disconnection

(How to Reduce Pressurized Fuel Lines) 13A-663.]

Intake Manifold Plenum Removal (Refer to P.15-5.)Post-installation Operation

Intake Manifold Plenum Installation (Refer to P.15-5.)

Fuel Leakage Inspection

REMOVAL STEPS

1. INJECTOR CONNECTOR

2. ENGINE MOUNTING STAY

>>C<<3. FUEL HIGH-PRESSURE HOSE

CONNECTION

5. BLOW-BY HOSE

<>6. FUEL RAIL AND INJECTOR

7. PCV HOSE CONNECTION8. TIMING BELT FRONT UPPER

COVER, RIGHT

9. TIMING BELT FRONT UPPER

COVER, LEFT

10. WATER PUMP BRACKET>>B<<11. INTAKE MANIFOLD

>>A<<12. INTAKE MANIFOLD GASKET

13. CONTROL HARNESS CLAMPREMOVAL STEPS (Continued)

Page 975 of 1500

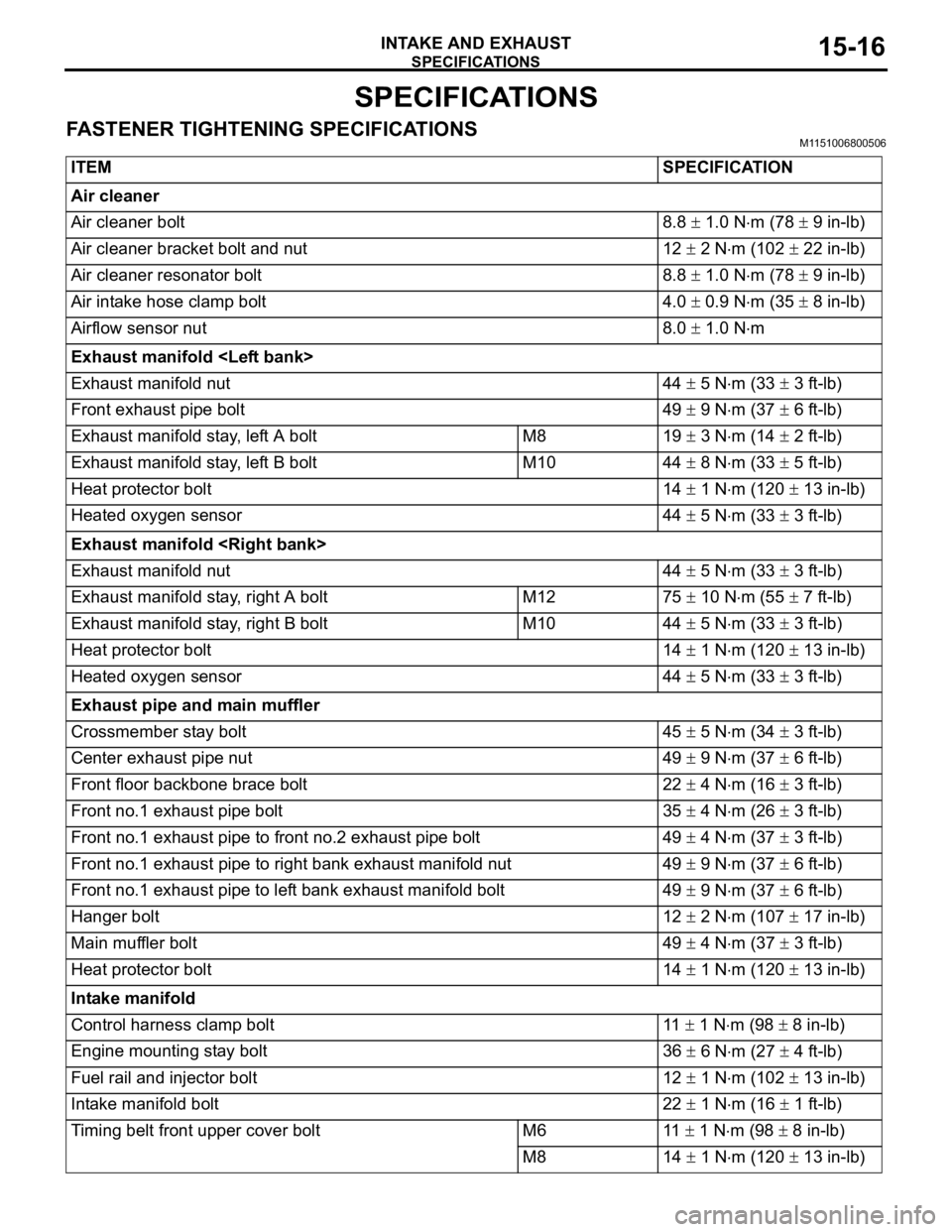

SPECIFICATIONS

INTAKE AND EXHAUST15-16

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1151006800506

ITEMSPECIFICATION

Air cleaner

Air cleaner bolt 8.8

1.0 Nm (78 9 in-lb)

Air cleaner bracket bolt and nut 12

2 Nm (102 22 in-lb)

Air cleaner resonator bolt 8.8

1.0 Nm (78 9 in-lb)

Air intake hose clamp bolt 4.0

0.9 Nm (35 8 in-lb)

Airflow sensor nut 8.0

1.0 Nm

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Front exhaust pipe bolt 49

9 Nm (37 6 ft-lb)

Exhaust manifold stay, left A bolt M8 19

3 Nm (14 2 ft-lb)

Exhaust manifold stay, left B bolt M10 44

8 Nm (33 5 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Exhaust manifold stay, right A bolt M12 75

10 Nm (55 7 ft-lb)

Exhaust manifold stay, right B bolt M10 44

5 Nm (33 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust pipe and main muffler

Crossmember stay bolt 45

5 Nm (34 3 ft-lb)

Center exhaust pipe nut 49

9 Nm (37 6 ft-lb)

Front floor backbone brace bolt 22

4 Nm (16 3 ft-lb)

Front no.1 exhaust pipe bolt 35

4 Nm (26 3 ft-lb)

Front no.1 exhaust pipe to front no.2 exhaust pipe bolt 49

4 Nm (37 3 ft-lb)

Front no.1 exhaust pipe to right bank exhaust manifold nut 49

9 Nm (37 6 ft-lb)

Front no.1 exhaust pipe to left bank exhaust manifold bolt 49

9 Nm (37 6 ft-lb)

Hanger bolt 12

2 Nm (107 17 in-lb)

Main muffler bolt 49

4 Nm (37 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Intake manifold

Control harness clamp bolt 11

1 Nm (98 8 in-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Fuel rail and injector bolt 12

1 Nm (102 13 in-lb)

Intake manifold bolt 22

1 Nm (16 1 ft-lb)

Timing belt front upper cover bolt M6 11

1 Nm (98 8 in-lb)

M8 14

1 Nm (120 13 in-lb)