check engine MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 939 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-24

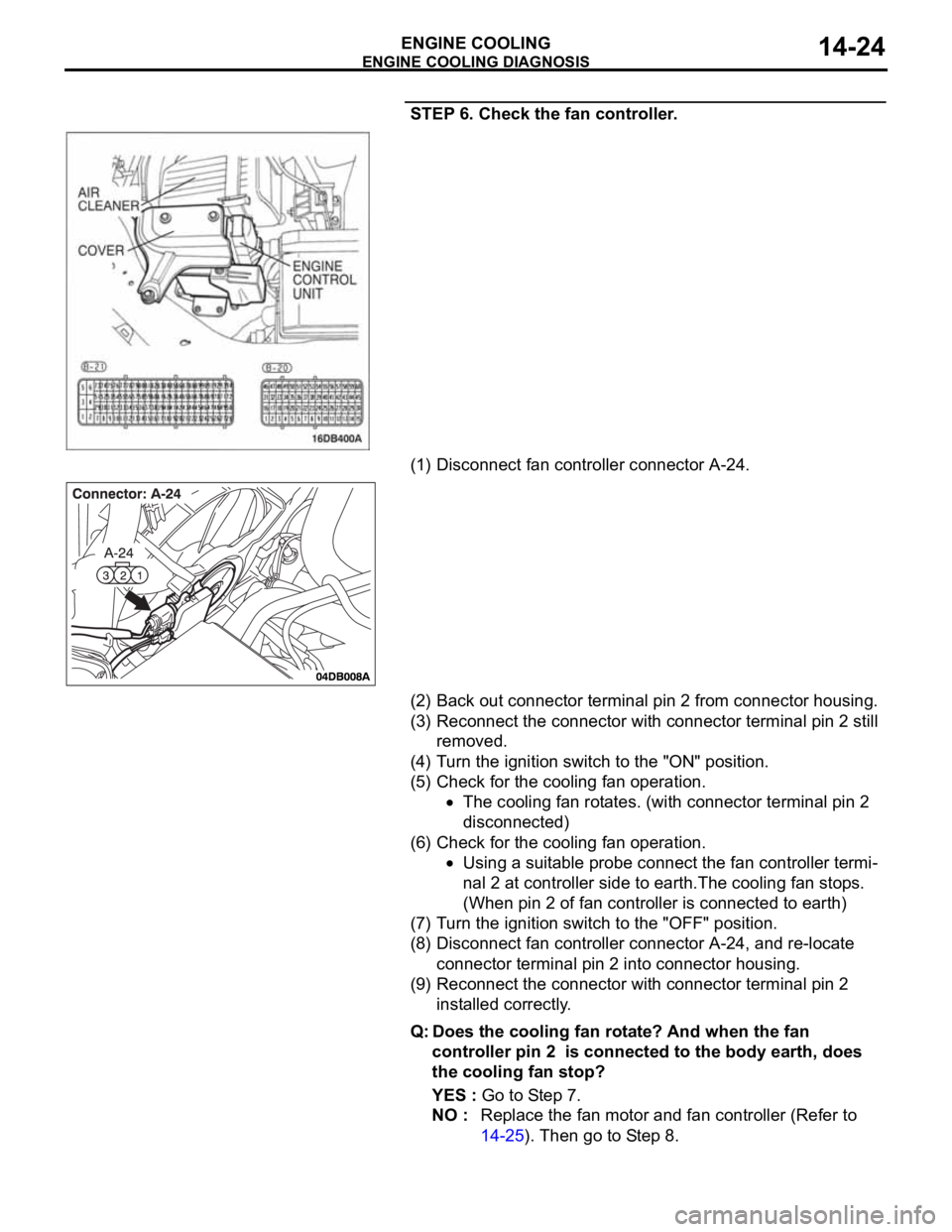

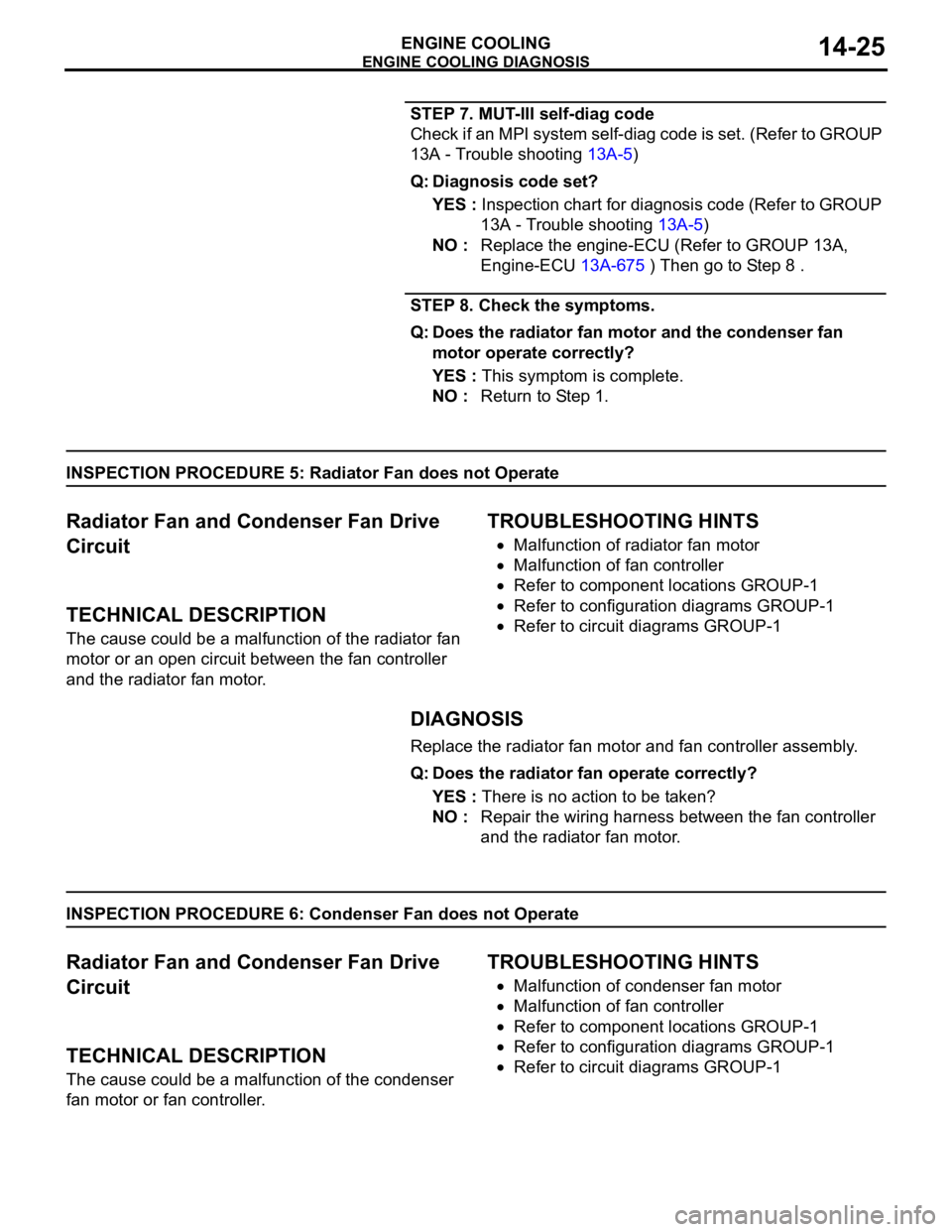

STEP 6. Check the fan controller.

(1) Disconnect fan controller connector A-24.

(2) Back out connector terminal pin 2 from connector housing.

(3) Reconnect the connector with connector terminal pin 2 still

removed.

(4) Turn the ignition switch to the "ON" position.

(5) Check for the cooling fan operation.

The cooling fan rotates. (with connector terminal pin 2

disconnected)

(6) Check for the cooling fan operation.

Using a suitable probe connect the fan controller termi-

nal 2 at controller side to earth.The cooling fan stops.

(When pin 2 of fan controller is connected to earth)

(7) Turn the ignition switch to the "OFF" position.

(8) Disconnect fan controller connector A-24, and re-locate

connector terminal pin 2 into connector housing.

(9) Reconnect the connector with connector terminal pin 2

installed correctly.

Q: Does the cooling fan rotate? And when the fan

controller pin 2 is connected to the body earth, does

the cooling fan stop?

YES : Go to Step 7.

NO : Replace the fan motor and fan controller (Refer to

14-25). Then go to Step 8.

Page 940 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-25

STEP 7. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5)

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-5)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ) Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 5: Radiator Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the radiator fan

motor or an open circuit between the fan controller

and the radiator fan motor.

.

TROUBLESHOOTING HINTS

Malfunction of radiator fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

DIAGNOSIS

Replace the radiator fan motor and fan controller assembly.

Q: Does the radiator fan operate correctly?

YES : There is no action to be taken?

NO : Repair the wiring harness between the fan controller

and the radiator fan motor.

INSPECTION PROCEDURE 6: Condenser Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the condenser

fan motor or fan controller.

.

TROUBLESHOOTING HINTS

Malfunction of condenser fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 941 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-26

DIAGNOSIS

STEP 1. Check the condenser fan motor.

Condenser fan motor check. (Refer to GROUP 55, Condenser

and Condenser Fan Motor.

Q: Is the condenser fan motor in good condition?

YES : Go to Step 2.

NO : Replace the condenser fan motor, then go to Step 3.

STEP 2. Check the fan controller.

Refer to 29.

Q: Is the fan controller in good condition?

YES : Go to Step 3.

NO : Replace the fan motor and fan controller (Refer to

14-25). Then go to Step 3.

STEP 3. Check the symptoms.

Q: Do the condenser fan operate?

YES : This symptom is complete.

NO : Return to Step 1.

ON-VEHICLE SERVICE

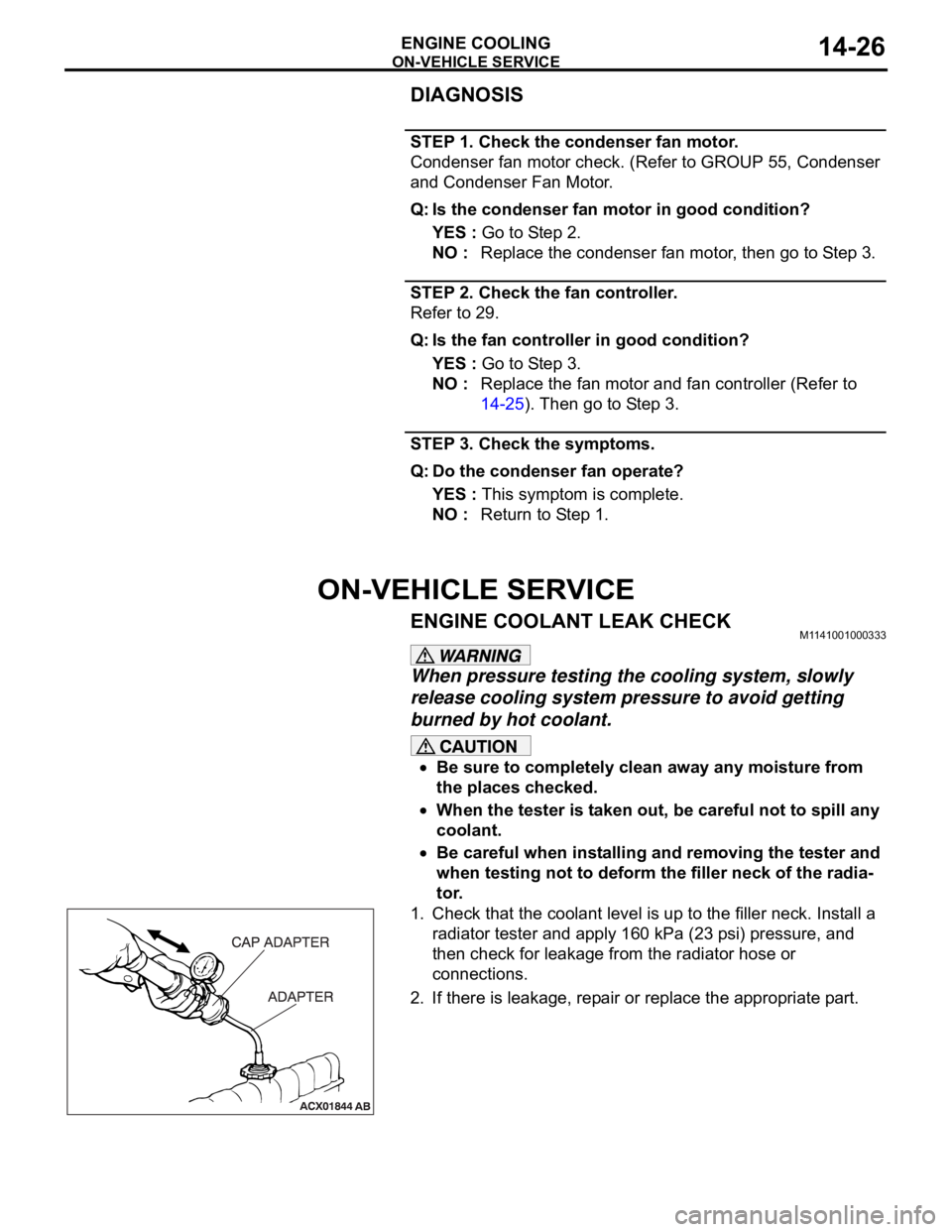

ENGINE COOLANT LEAK CHECKM1141001000333

When pressure testing the cooling system, slowly

release cooling system pressure to avoid getting

burned by hot coolant.

Be sure to completely clean away any moisture from

the places checked.

When the tester is taken out, be careful not to spill any

coolant.

Be careful when installing and removing the tester and

when testing not to deform the filler neck of the radia-

tor.

1. Check that the coolant level is up to the filler neck. Install a

radiator tester and apply 160 kPa (23 psi) pressure, and

then check for leakage from the radiator hose or

connections.

2. If there is leakage, repair or replace the appropriate part.

Page 942 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-27

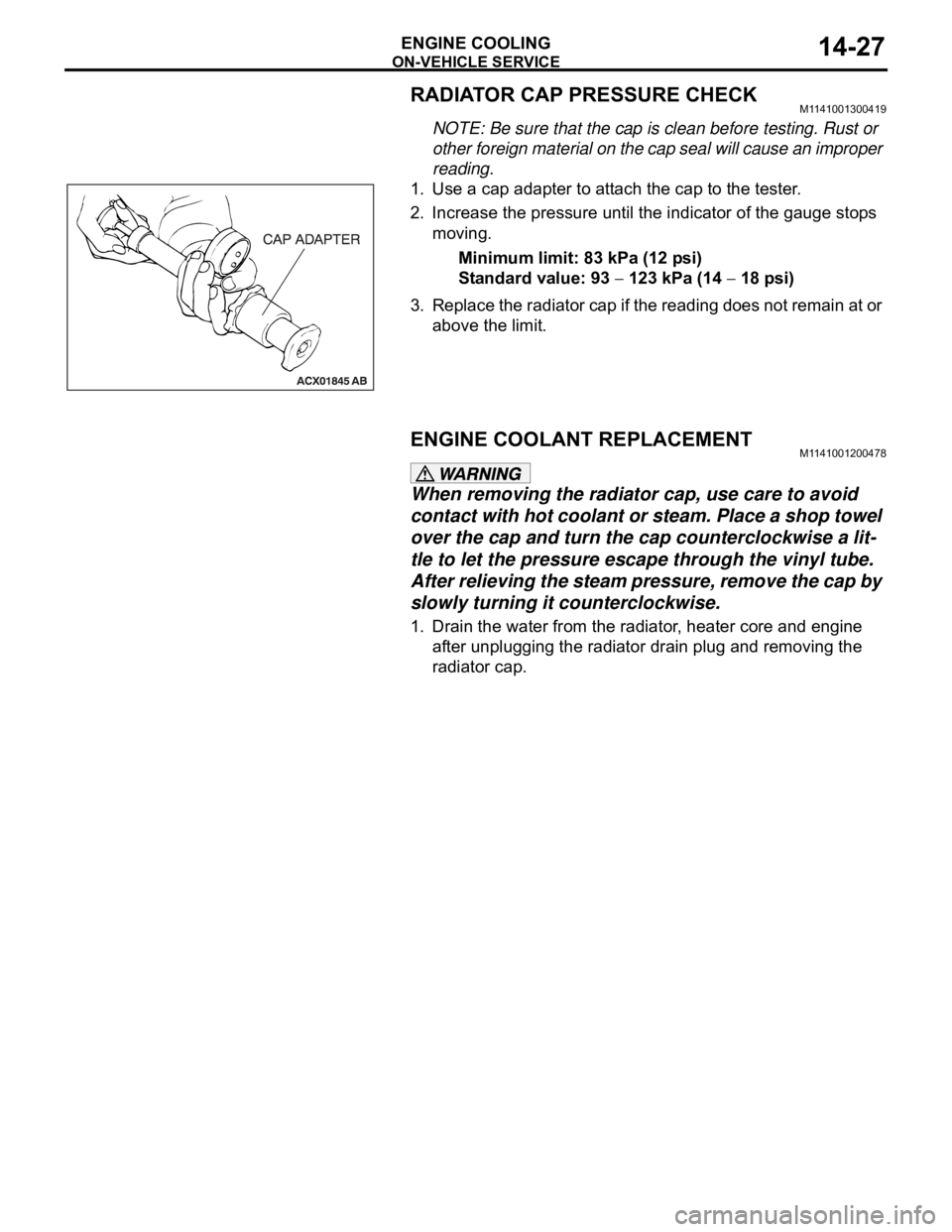

RADIATOR CAP PRESSURE CHECKM1141001300419

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

3. Replace the radiator cap if the reading does not remain at or

above the limit.

ENGINE COOLANT REPLACEMENTM1141001200478

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 944 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-29

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze can

cause corrosion of the aluminum components.

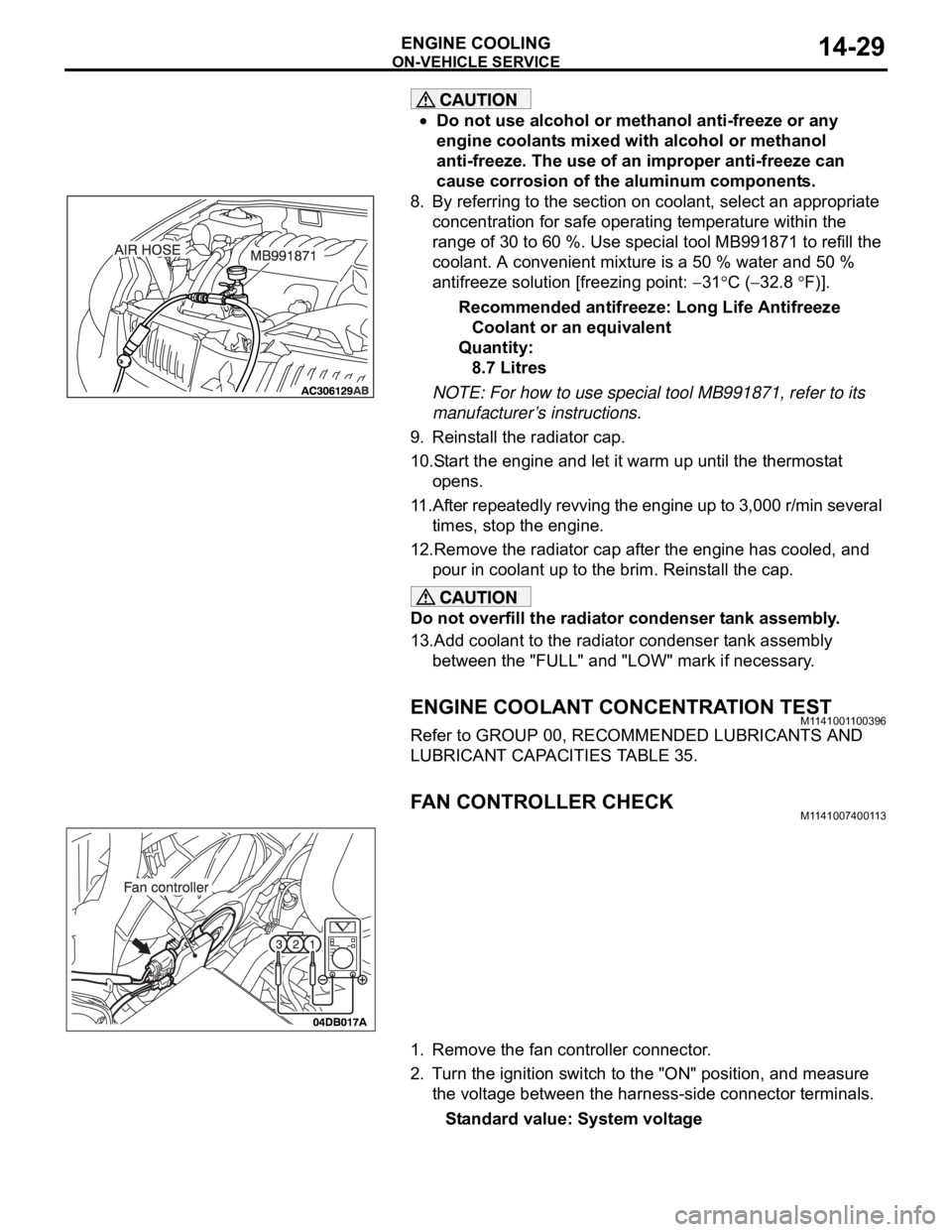

8. By referring to the section on coolant, select an appropriate

concentration for safe operating temperature within the

range of 30 to 60 %. Use special tool MB991871 to refill the

coolant. A convenient mixture is a 50 % water and 50 %

antifreeze solution [freezing point:

31C (32.8 F)].

Recommended antifreeze: Long Life Antifreeze

Coolant or an equivalent

Quantity:

8.7 Litres

NOTE: For how to use special tool MB991871, refer to its

manufacturer’s instructions.

9. Reinstall the radiator cap.

10.Start the engine and let it warm up until the thermostat

opens.

11.After repeatedly revving the engine up to 3,000 r/min several

times, stop the engine.

12.Remove the radiator cap after the engine has cooled, and

pour in coolant up to the brim. Reinstall the cap.

Do not overfill the radiator condenser tank assembly.

13.Add coolant to the radiator condenser tank assembly

between the "FULL" and "LOW" mark if necessary.

ENGINE COOLANT CONCENTRATION TESTM1141001100396

Refer to GROUP 00, RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE 35.

FAN CONTROLLER CHECKM1141007400113

1. Remove the fan controller connector.

2. Turn the ignition switch to the "ON" position, and measure

the voltage between the harness-side connector terminals.

Standard value: System voltage

Page 946 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-31

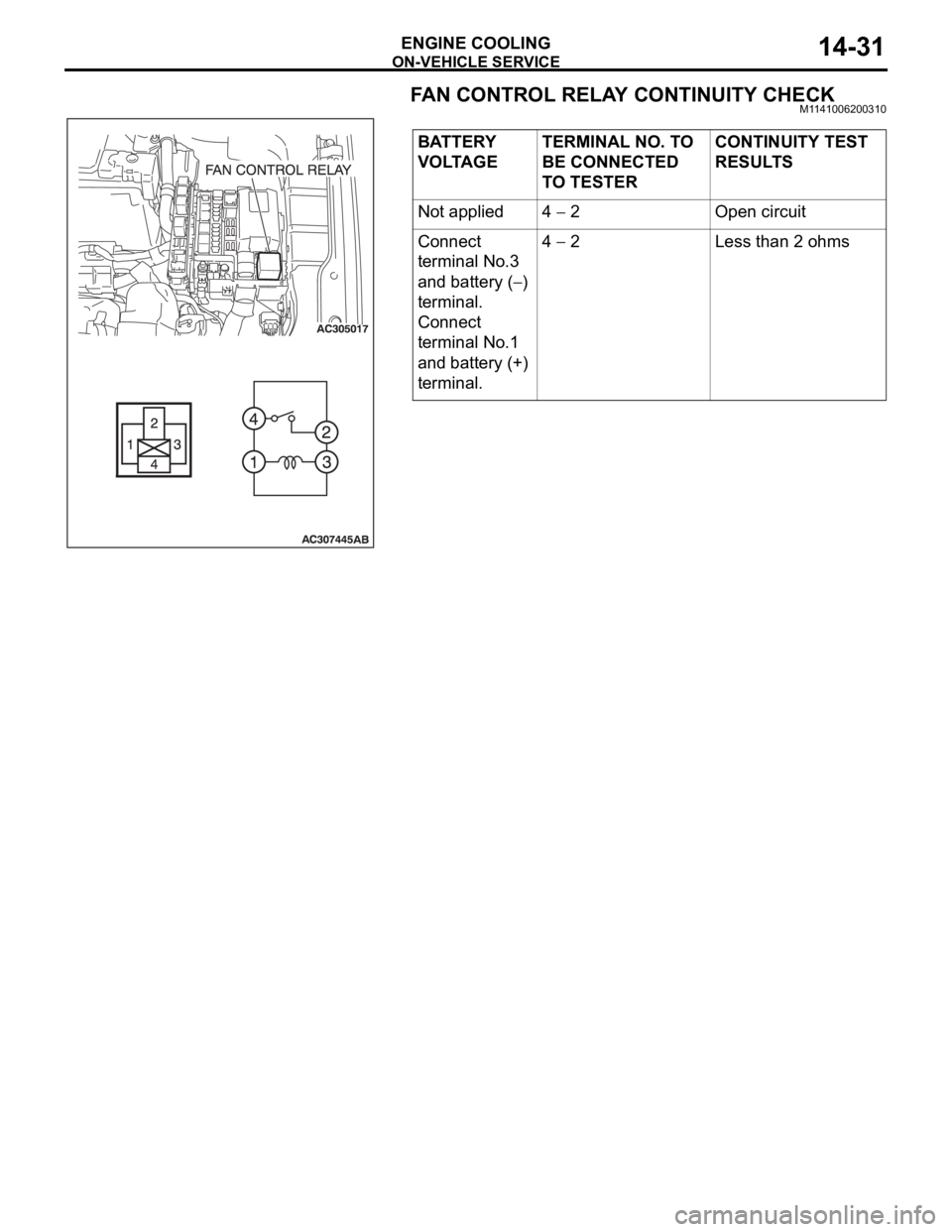

FAN CONTROL RELAY CONTINUITY CHECKM1141006200310

BATTERY

VOLTAGETERMINAL NO. TO

BE CONNECTED

TO TESTERCONTINUITY TEST

RESULTS

Not applied 4

2 Open circuit

Connect

terminal No.3

and battery (

)

terminal.

Connect

terminal No.1

and battery (+)

terminal.4

2 Less than 2 ohms

Page 947 of 1500

RADIATOR

ENGINE COOLING14-32

RADIATOR

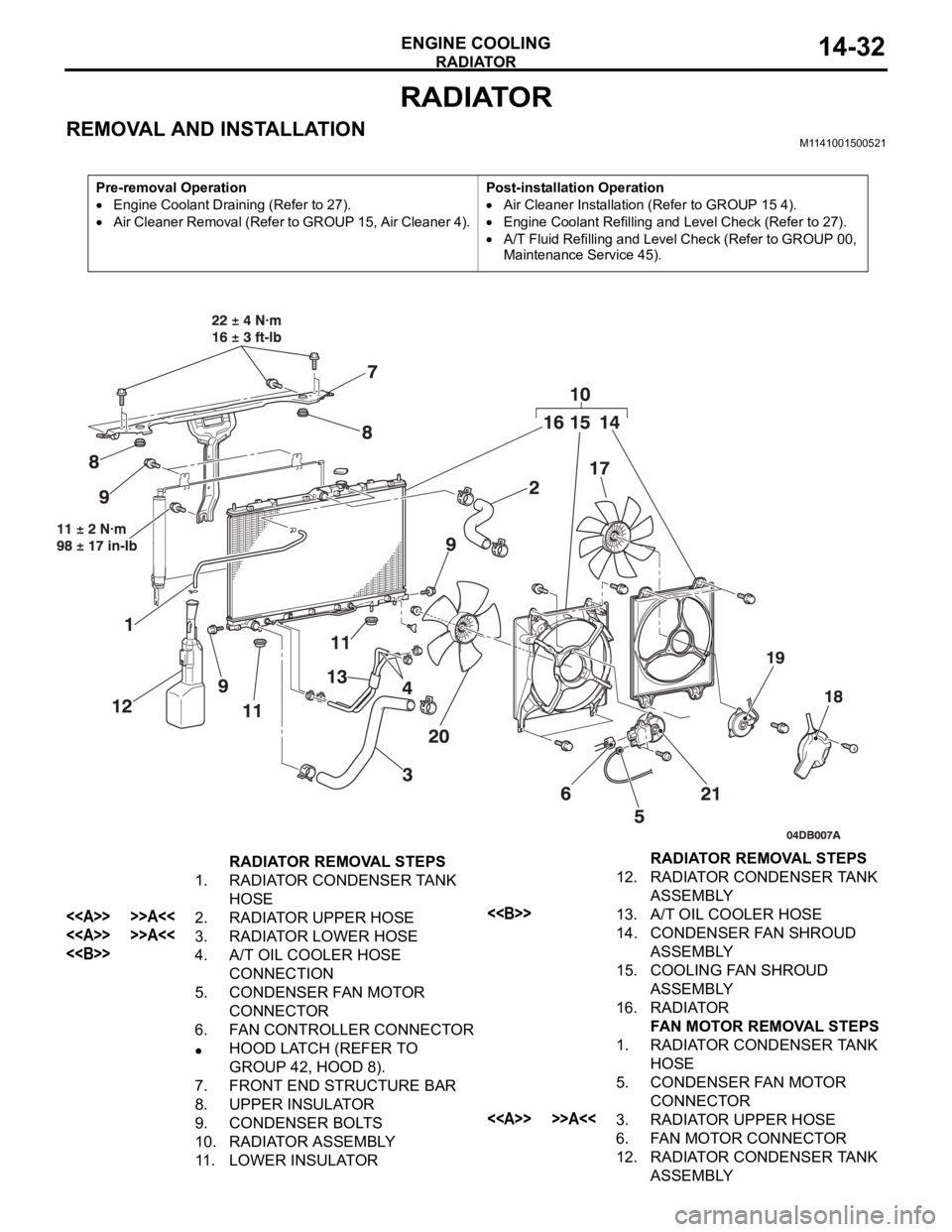

REMOVAL AND INSTALLATIONM1141001500521

Pre-removal Operation

Engine Coolant Draining (Refer to 27).

Air Cleaner Removal (Refer to GROUP 15, Air Cleaner 4).Post-installation Operation

Air Cleaner Installation (Refer to GROUP 15 4).

Engine Coolant Refilling and Level Check (Refer to 27).

A/T Fluid Refilling and Level Check (Refer to GROUP 00,

Maintenance Service 45).

RADIATOR REMOVAL STEPS

1. RADIATOR CONDENSER TANK

HOSE

<> >>A<<2. RADIATOR UPPER HOSE

<> >>A<<3. RADIATOR LOWER HOSE

<>4. A/T OIL COOLER HOSE

CONNECTION

5. CONDENSER FAN MOTOR

CONNECTOR

6. FAN CONTROLLER CONNECTOR

HOOD LATCH (REFER TO

GROUP 42, HOOD 8).

7. FRONT END STRUCTURE BAR

8. UPPER INSULATOR

9. CONDENSER BOLTS

10. RADIATOR ASSEMBLY

11. LOWER INSULATOR12. RADIATOR CONDENSER TANK

ASSEMBLY

<>13. A/T OIL COOLER HOSE

14. CONDENSER FAN SHROUD

ASSEMBLY

15. COOLING FAN SHROUD

ASSEMBLY

16. RADIATOR

FAN MOTOR REMOVAL STEPS

1. RADIATOR CONDENSER TANK

HOSE

5. CONDENSER FAN MOTOR

CONNECTOR

<> >>A<<3. RADIATOR UPPER HOSE

6. FAN MOTOR CONNECTOR

12. RADIATOR CONDENSER TANK

ASSEMBLY RADIATOR REMOVAL STEPS

Page 953 of 1500

THERMOSTAT

ENGINE COOLING14-38

INSPECTIONM1141002500450.

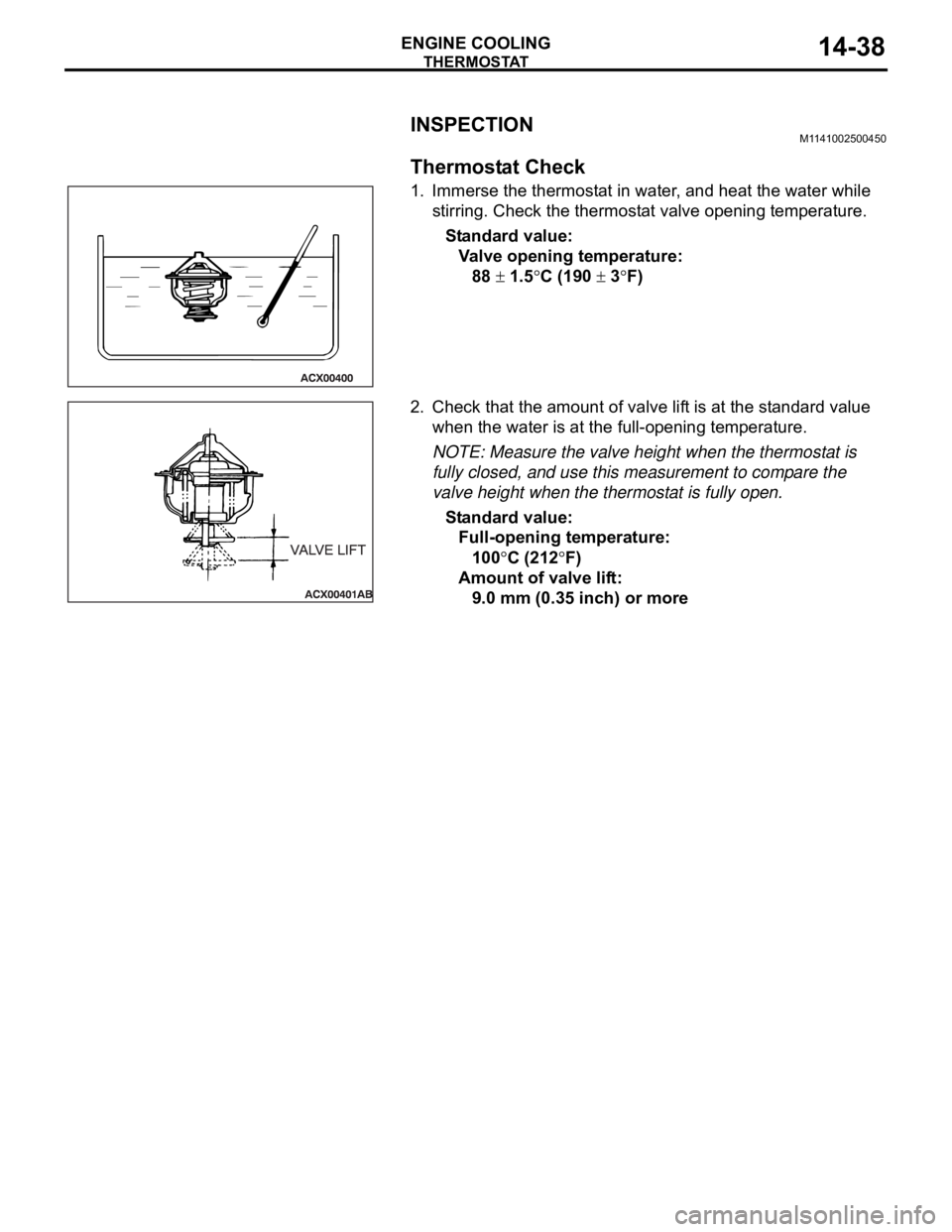

Thermostat Check

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature:

88

1.5C (190 3F)

2. Check that the amount of valve lift is at the standard value

when the water is at the full-opening temperature.

NOTE: Measure the valve height when the thermostat is

fully closed, and use this measurement to compare the

valve height when the thermostat is fully open.

Standard value:

Full-opening temperature:

100

C (212F)

Amount of valve lift:

9.0 mm (0.35 inch) or more

Page 956 of 1500

WATER HOSE AND WATER PIPE

ENGINE COOLING14-41

INSTALLATION SERVICE POINTS

.

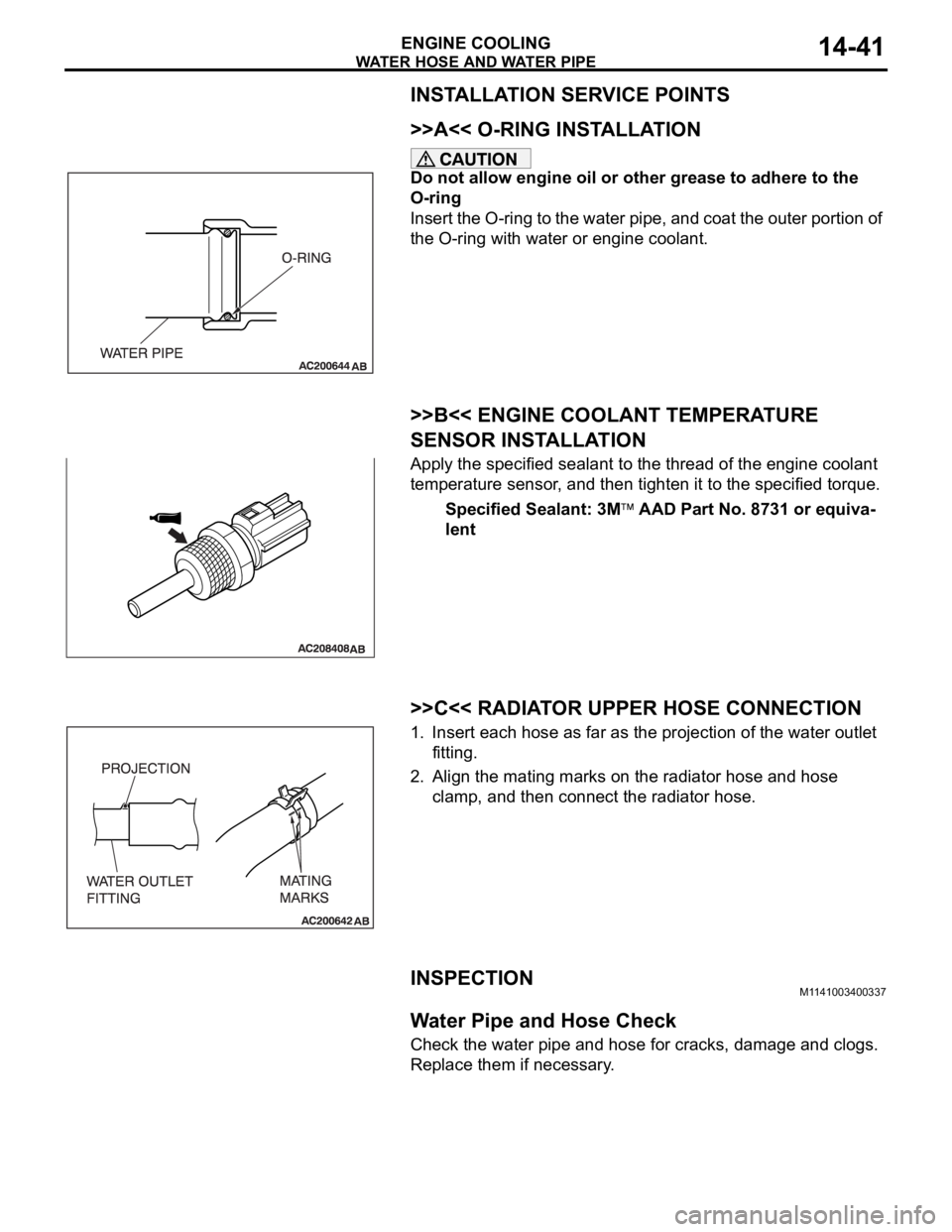

>>A<< O-RING INSTALLATION

Do not allow engine oil or other grease to adhere to the

O-ring

Insert the O-ring to the water pipe, and coat the outer portion of

the O-ring with water or engine coolant.

.

>>B<< ENGINE COOLANT TEMPERATURE

SENSOR INSTALLATION

Apply the specified sealant to the thread of the engine coolant

temperature sensor, and then tighten it to the specified torque.

Specified Sealant: 3M

AAD Part No. 8731 or equiva-

lent

.

>>C<< RADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water outlet

fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTIONM1141003400337.

Water Pipe and Hose Check

Check the water pipe and hose for cracks, damage and clogs.

Replace them if necessary.

Page 961 of 1500

GENERAL DESCRIPTION

INTAKE AND EXHAUST15-2

GENERAL DESCRIPTIONM1151000100446

The exhaust pipe is divided into four parts.

INTAKE AND EXHAUST DIAGNOSIS

INTRODUCTIONM1151006900321

Intake leaks usually create driveability issues that

are not obviously related to the intake system.

Exhaust leaks or abnormal noise is caused by

cracks, gaskets and fittings, or by exhaust pipe or

muffler damage due to impacts during travel. The

exhaust leaks from these sections and causes the

exhaust noise to increase. There may be cases

when the system contacts the body and vibration

noise is generated.

TROUBLESHOOTING STRATEGYM1151007000321

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find an

intake or exhaust system fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1151007100328

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Exhaust Leakage

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the driver’s seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

Q: Is the exhaust leaking?

YES :

Go to Step 2.

NO : The procedure is complete.

STEP 2. Check the gasket for cracks, damage.

Q: Is the gasket damaged?

YES :

Replace the gasket, then go Step 1.

NO : Go to Step 3.

STEP 3. Check for loose coupling sections.

Q: Are there any loose each sections?

YES :

Tighten, then go to Step 1.

NO : There is no action to be taken. SYMPTOM INSPECTION PROCEDURE REFERENCE PAGE

Exhaust Leakage 1

P.15-2

Abnormal Noise 2

P.15-3