light MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 706 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-5

AUTO A/C DIAGNOSIS

INTRODUCTIONM1554006200062

After air is taken in through the damper, it is fed to

the evaporator by the blower fan and motor and

cooled. The air cooled by the air mix damper is

mixed appropriately with the warmed air to achieve a

comfortable temperature. If the A/C does not operate

or the cooled air is not discharged, the system com-

ponents or relay may be faulty.

AUTOMATIC AIR CONDITIONING TROUBLESHOOTING STRATEGYM1554004700157

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

heater, air conditioning and ventilation fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

DIAGNOSTIC FUNCTIONM1552019800046

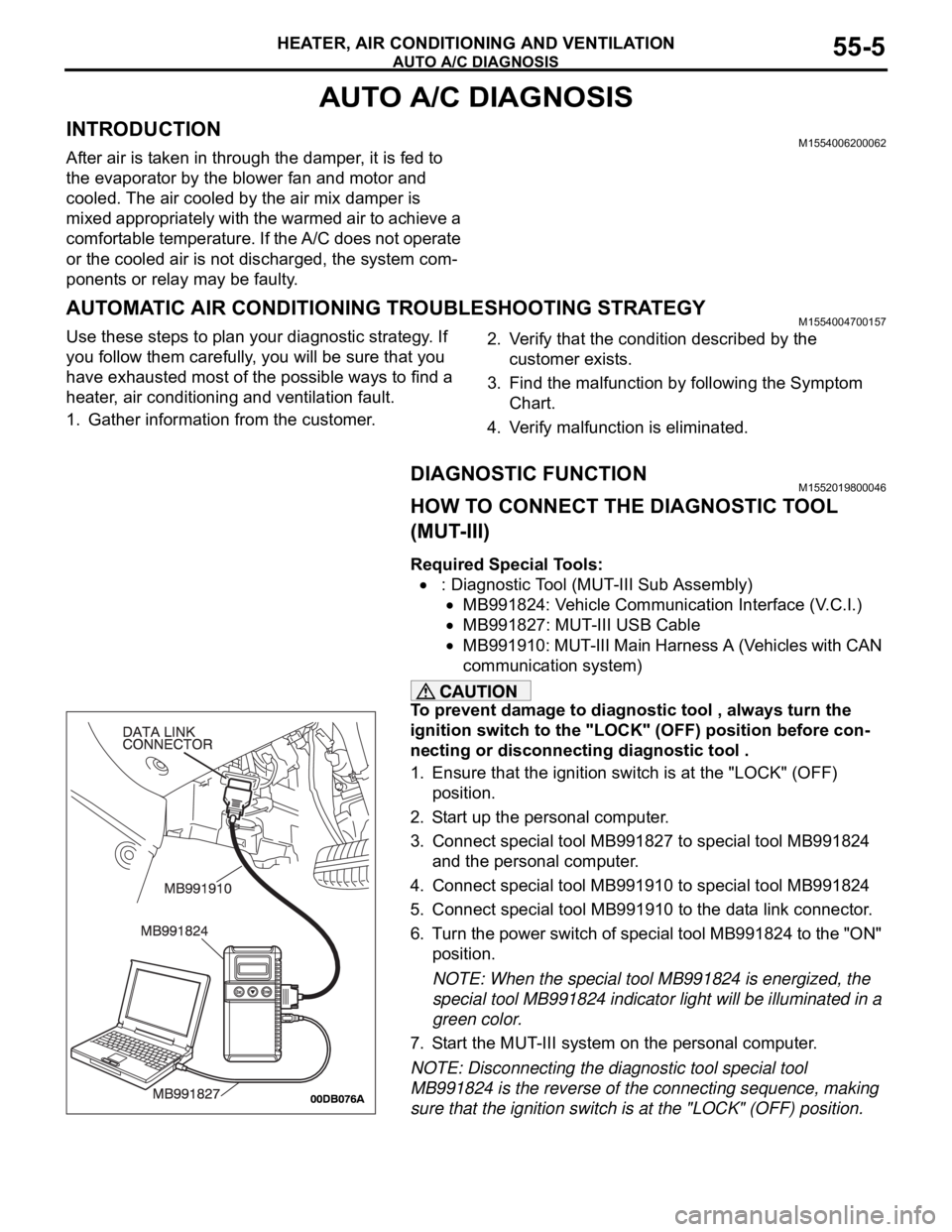

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When the special tool MB991824 is energized, the

special tool MB991824 indicator light will be illuminated in a

green color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnecting the diagnostic tool special tool

MB991824 is the reverse of the connecting sequence, making

sure that the ignition switch is at the "LOCK" (OFF) position.

Page 769 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-68

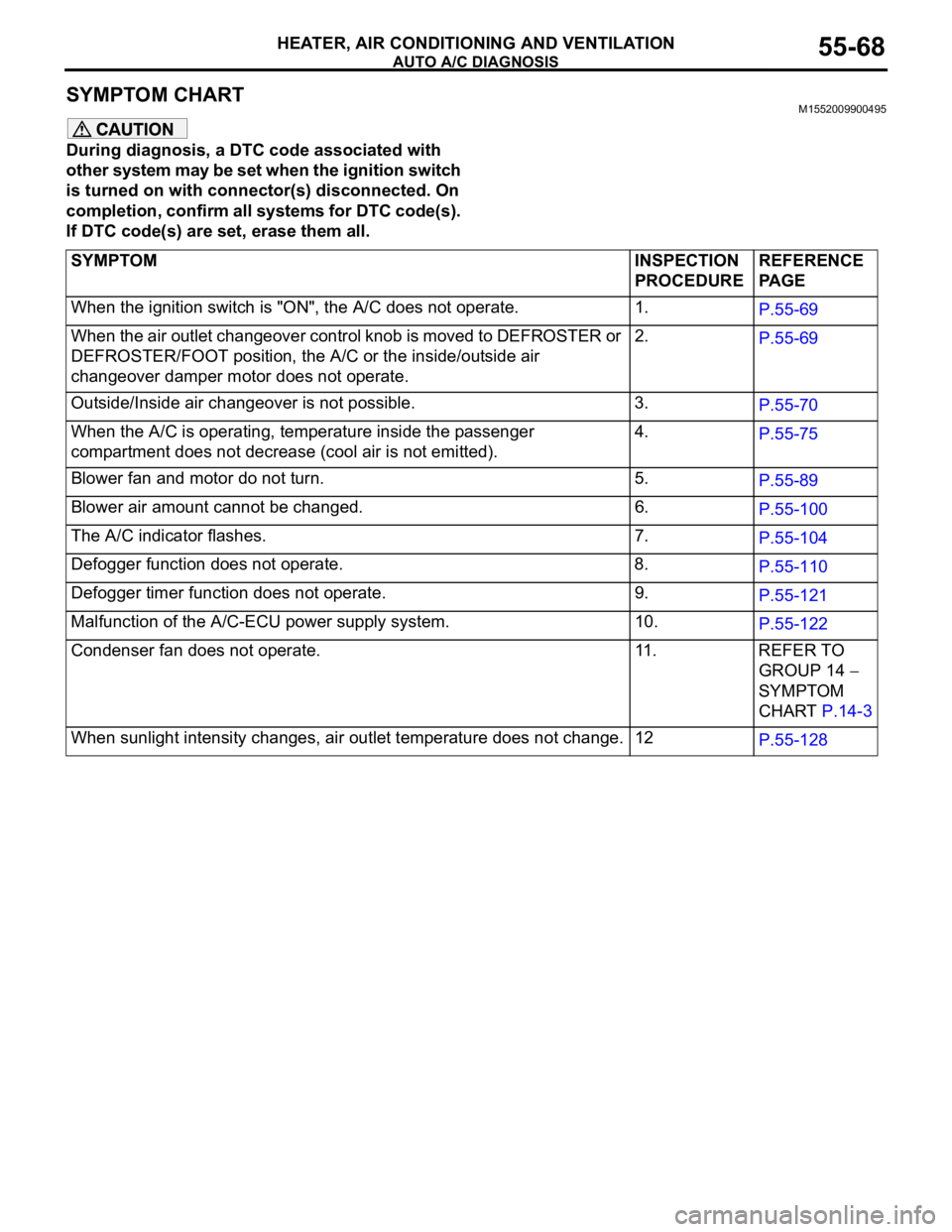

SYMPTOM CHART M1552009900495

During diagnosis, a DTC code associated with

other system may be set when the ignition switch

is turned on with connector(s) disconnected. On

completion, confirm all systems for DTC code(s).

If DTC code(s) are set, erase them all.

SYMPTOM INSPECTION

PROCEDUREREFERENCE

PA G E

When the ignition switch is "ON", the A/C does not operate. 1.

P.55-69

When the air outlet changeover control knob is moved to DEFROSTER or

DEFROSTER/FOOT position, the A/C or the inside/outside air

changeover damper motor does not operate.2.

P.55-69

Outside/Inside air changeover is not possible. 3.

P.55-70

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).4.

P.55-75

Blower fan and motor do not turn. 5.

P.55-89

Blower air amount cannot be changed. 6.

P.55-100

The A/C indicator flashes. 7.

P.55-104

Defogger function does not operate. 8.

P.55-110

Defogger timer function does not operate. 9.

P.55-121

Malfunction of the A/C-ECU power supply system. 10.

P.55-122

Condenser fan does not operate. 11. REFER TO

GROUP 14

SYMPTOM

CHART P.14-3

When sunlight intensity changes, air outlet temperature does not change. 12

P.55-128

Page 829 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-128

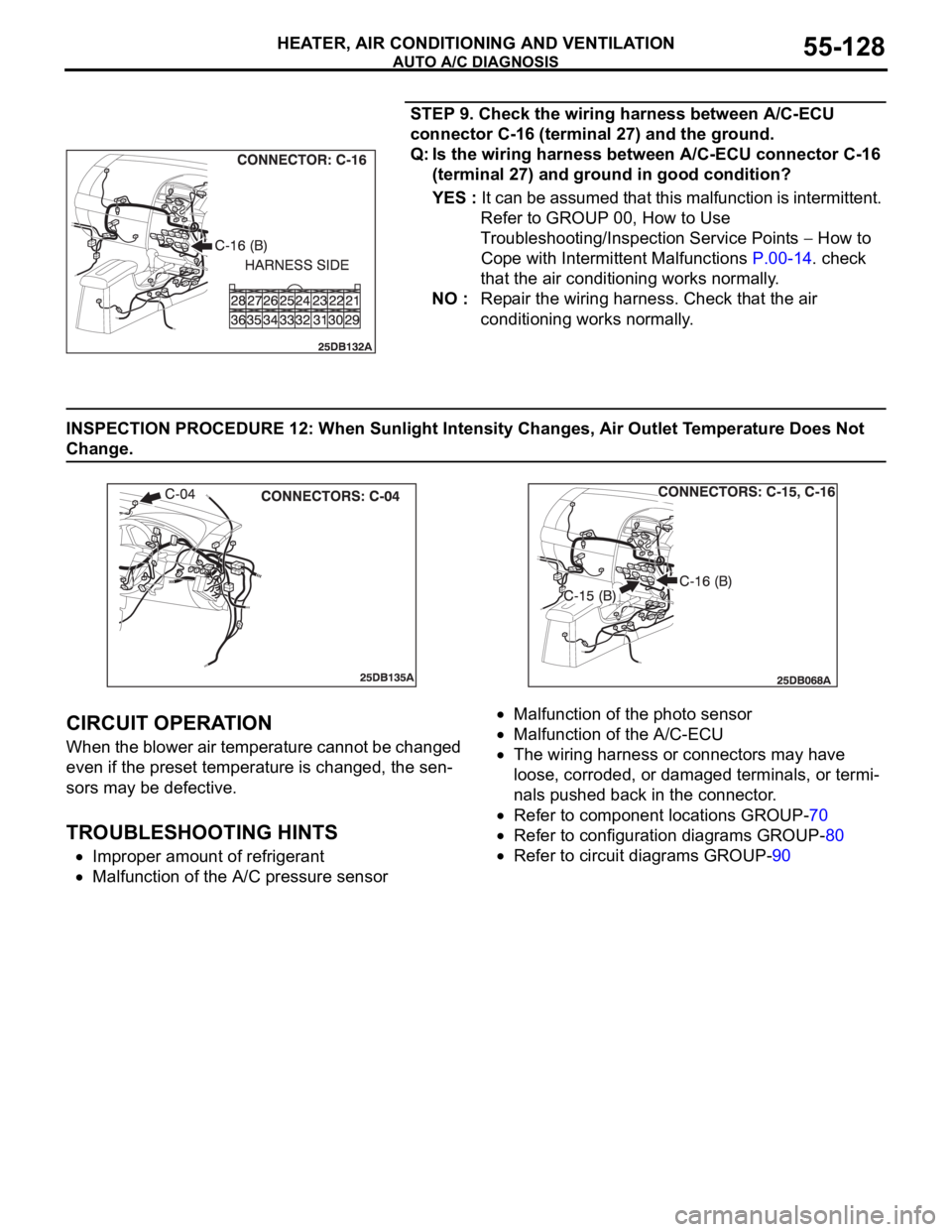

STEP 9. Check the wiring harness between A/C-ECU

connector C-16 (terminal 27) and the ground.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 27) and ground in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14. check

that the air conditioning works normally.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

INSPECTION PROCEDURE 12: When Sunlight Intensity Changes, Air Outlet Temperature Does Not

Change.

.

CIRCUIT OPERATION

When the blower air temperature cannot be changed

even if the preset temperature is changed, the sen-

sors may be defective.

.

TROUBLESHOOTING HINTS

Improper amount of refrigerant

Malfunction of the A/C pressure sensor

Malfunction of the photo sensor

Malfunction of the A/C-ECU

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

Page 834 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-133

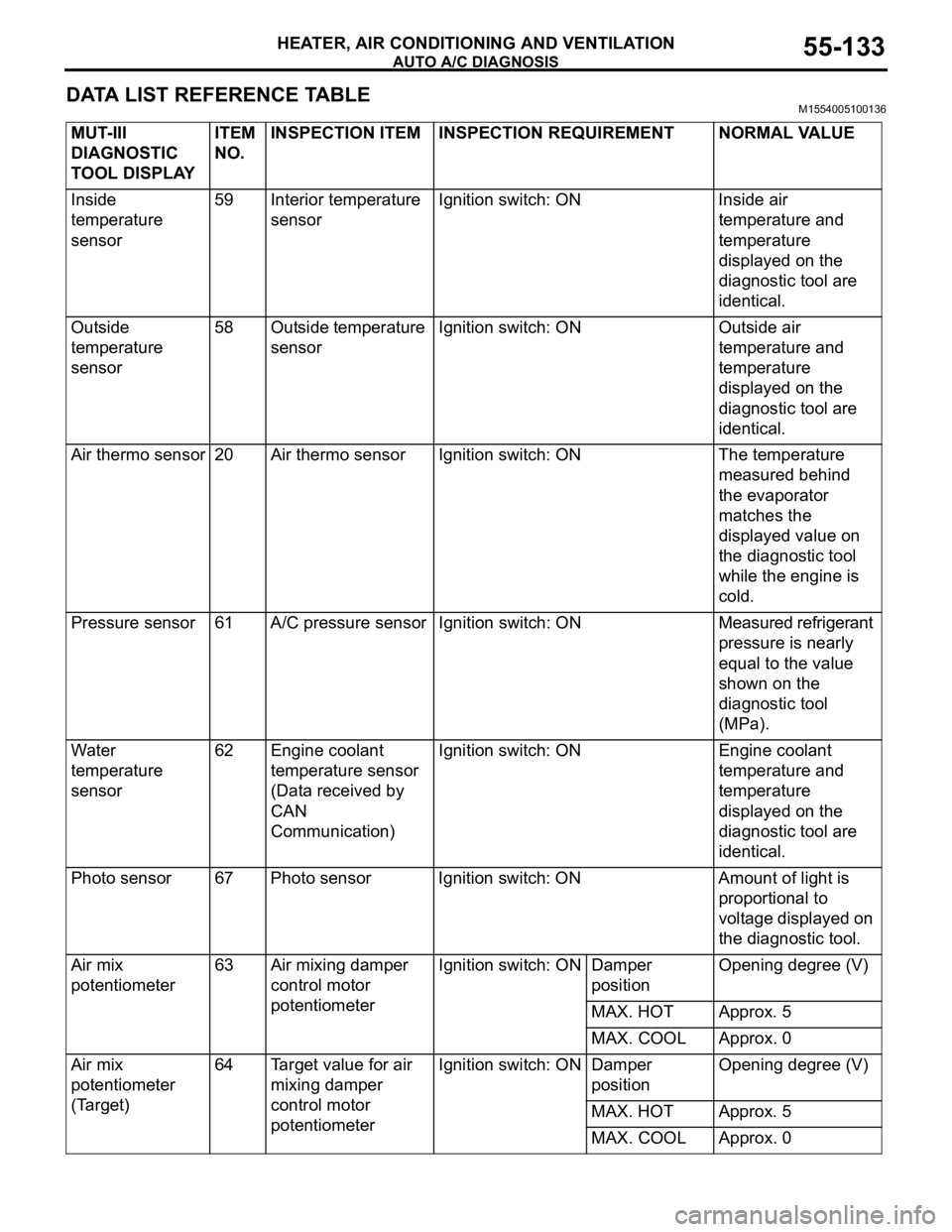

DATA LIST REFERENCE TABLEM1554005100136

MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Inside

temperature

sensor59 Interior temperature

sensorIgnition switch: ON Inside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Outside

temperature

sensor58 Outside temperature

sensorIgnition switch: ON Outside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Air thermo sensor 20 Air thermo sensor Ignition switch: ON The temperature

measured behind

the evaporator

matches the

displayed value on

the diagnostic tool

while the engine is

cold.

Pressure sensor 61 A/C pressure sensor Ignition switch: ON Measured refrigerant

pressure is nearly

equal to the value

shown on the

diagnostic tool

(MPa).

Water

temperature

sensor62 Engine coolant

temperature sensor

(Data received by

CAN

Communication)Ignition switch: ON Engine coolant

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Photo sensor 67 Photo sensor Ignition switch: ON Amount of light is

proportional to

voltage displayed on

the diagnostic tool.

Air mix

potentiometer63 Air mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Air mix

potentiometer

(Target)64 Target value for air

mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Page 836 of 1500

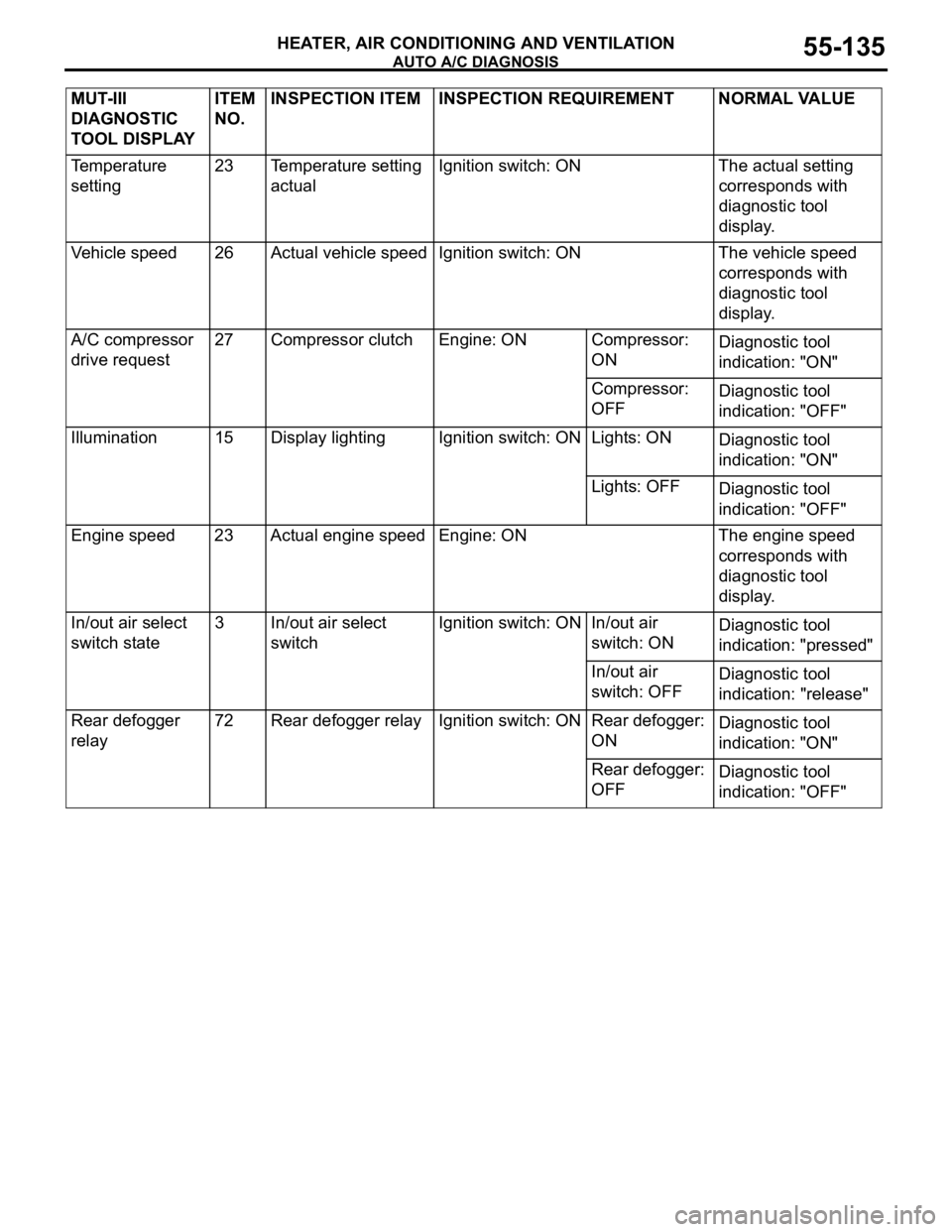

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-135

Temperature

setting23 Temperature setting

actualIgnition switch: ON The actual setting

corresponds with

diagnostic tool

display.

Vehicle speed 26 Actual vehicle speed Ignition switch: ON The vehicle speed

corresponds with

diagnostic tool

display.

A/C compressor

drive request27 Compressor clutch Engine: ON

Compressor:

ONDiagnostic tool

indication: "ON"

Compressor:

OFFDiagnostic tool

indication: "OFF"

Illumination 15 Display lighting Ignition switch: ON

Lights: ON

Diagnostic tool

indication: "ON"

Lights: OFF

Diagnostic tool

indication: "OFF"

Engine speed 23 Actual engine speed Engine: ON The engine speed

corresponds with

diagnostic tool

display.

In/out air select

switch state3 In/out air select

switch Ignition switch: ON In/out air

switch: ONDiagnostic tool

indication: "pressed"

In/out air

switch: OFFDiagnostic tool

indication: "release"

Rear defogger

relay72 Rear defogger relay Ignition switch: ON

Rear defogger:

ONDiagnostic tool

indication: "ON"

Rear defogger:

OFFDiagnostic tool

indication: "OFF" MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

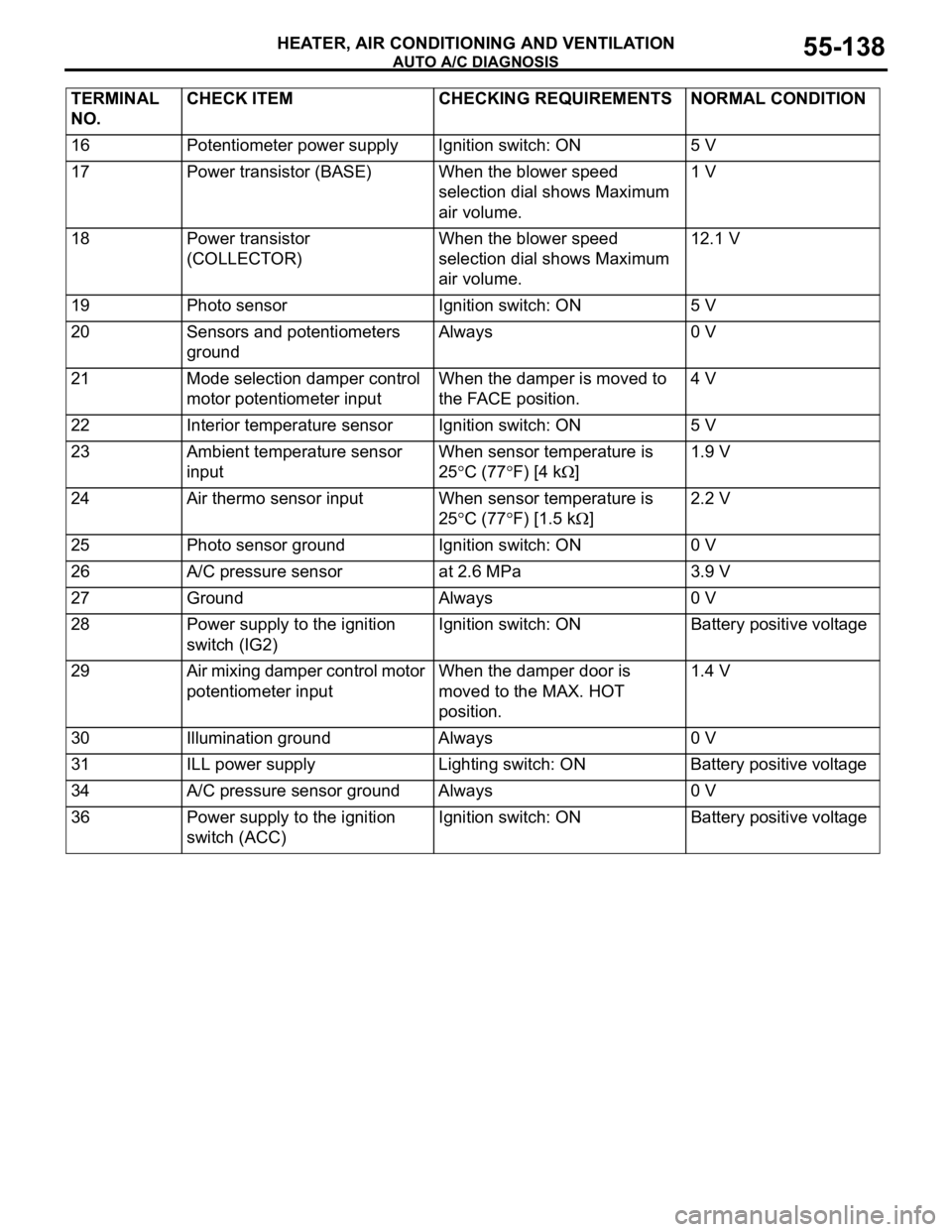

Page 839 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-138

16 Potentiometer power supply Ignition switch: ON 5 V

17 Power transistor (BASE) When the blower speed

selection dial shows Maximum

air volume.1 V

18 Power transistor

(COLLECTOR)When the blower speed

selection dial shows Maximum

air volume.12.1 V

19 Photo sensor Ignition switch: ON 5 V

20 Sensors and potentiometers

groundAlways 0 V

21 Mode selection damper control

motor potentiometer inputWhen the damper is moved to

the FACE position. 4 V

22 Interior temperature sensor Ignition switch: ON 5 V

23 Ambient temperature sensor

inputWhen sensor temperature is

25

C (77F) [4 k]1.9 V

24 Air thermo sensor input When sensor temperature is

25

C (77F) [1.5 k]2.2 V

25 Photo sensor ground Ignition switch: ON 0 V

26 A/C pressure sensor at 2.6 MPa 3.9 V

27 Ground Always 0 V

28 Power supply to the ignition

switch (IG2)Ignition switch: ON Battery positive voltage

29 Air mixing damper control motor

potentiometer inputWhen the damper door is

moved to the MAX. HOT

position.1.4 V

30 Illumination ground Always 0 V

31 ILL power supply Lighting switch: ON Battery positive voltage

34 A/C pressure sensor ground Always 0 V

36 Power supply to the ignition

switch (ACC)Ignition switch: ON Battery positive voltage TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

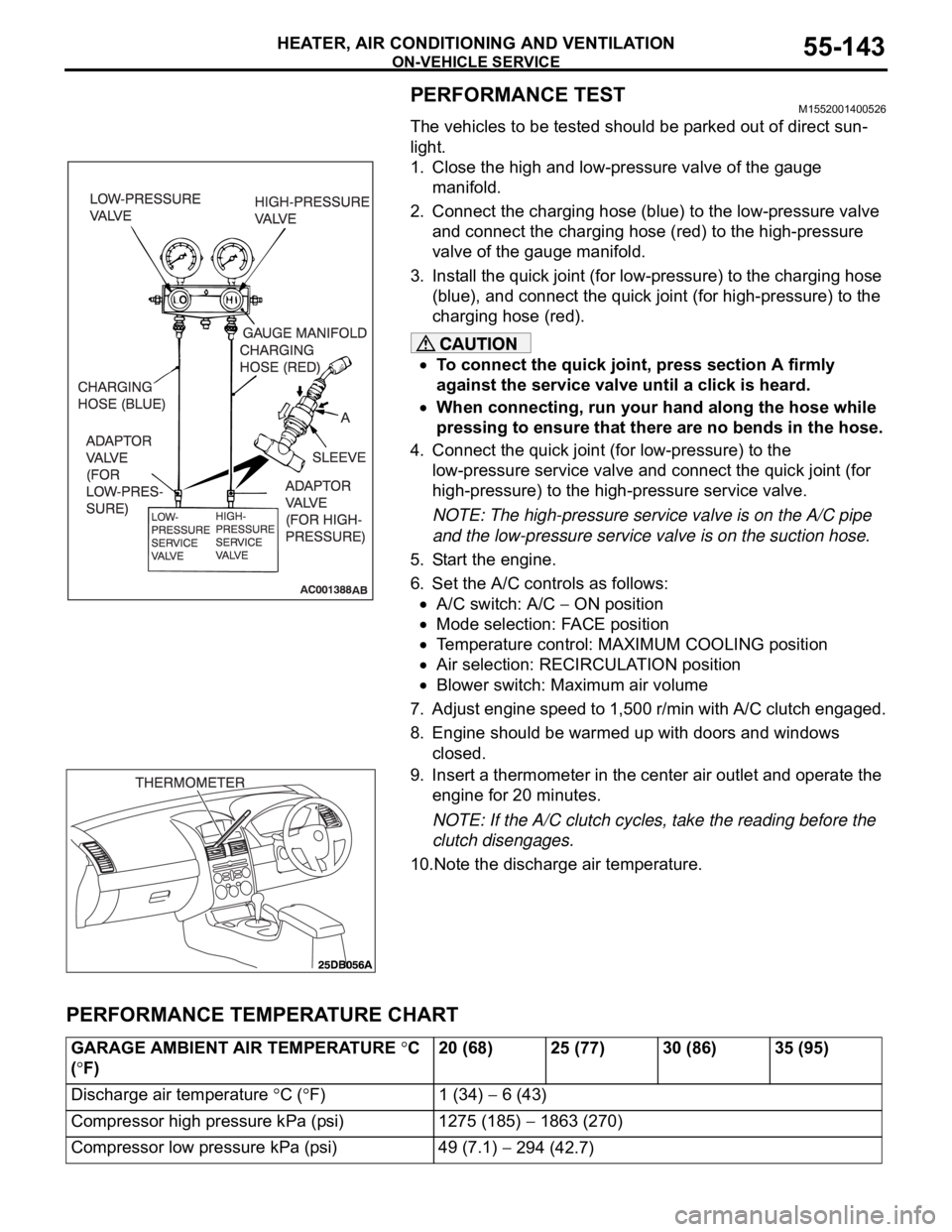

Page 844 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-143

PERFORMANCE TEST M1552001400526

The vehicles to be tested should be parked out of direct sun-

light.

1. Close the high and low-pressure valve of the gauge

manifold.

2. Connect the charging hose (blue) to the low-pressure valve

and connect the charging hose (red) to the high-pressure

valve of the gauge manifold.

3. Install the quick joint (for low-pressure) to the charging hose

(blue), and connect the quick joint (for high-pressure) to the

charging hose (red).

To connect the quick joint, press section A firmly

against the service valve until a click is heard.

When connecting, run your hand along the hose while

pressing to ensure that there are no bends in the hose.

4. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick joint (for

high-pressure) to the high-pressure service valve.

NOTE: The high-pressure service valve is on the A/C pipe

and the low-pressure service valve is on the suction hose.

5. Start the engine.

6. Set the A/C controls as follows:

A/C switch: A/C ON position

Mode selection: FACE position

Temperature control: MAXIMUM COOLING position

Air selection: RECIRCULATION position

Blower switch: Maximum air volume

7. Adjust engine speed to 1,500 r/min with A/C clutch engaged.

8. Engine should be warmed up with doors and windows

closed.

9. Insert a thermometer in the center air outlet and operate the

engine for 20 minutes.

NOTE: If the A/C clutch cycles, take the reading before the

clutch disengages.

10.Note the discharge air temperature.

PERFORMANCE TEMPERATURE CHART

GARAGE AMBIENT AIR TEMPERATURE C

(

F)20 (68) 25 (77) 30 (86) 35 (95)

Discharge air temperature

C (F) 1 (34) 6 (43)

Compressor high pressure kPa (psi) 1275 (185)

1863 (270)

Compressor low pressure kPa (psi) 49 (7.1)

294 (42.7)

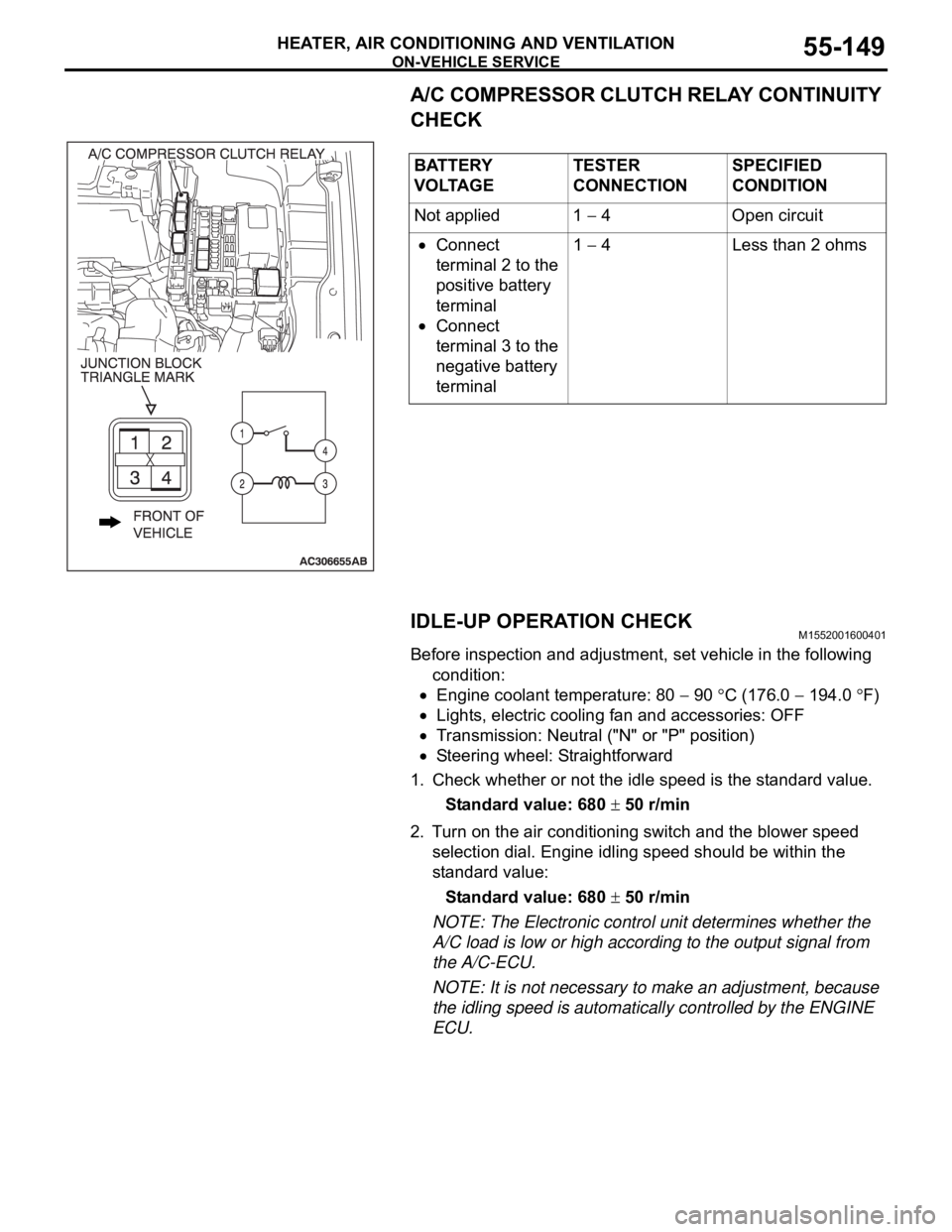

Page 850 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-149

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 853 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-152

REMOVAL SERVICE POINTS

.

<> SUCTION PIPE AND LIQUID PIPE DISCON-

NECTION

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose and

nipples.

To prevent the entry of dust or other foreign bodies, plug the

dismantled hose and the nipples of the expansion valves.

.

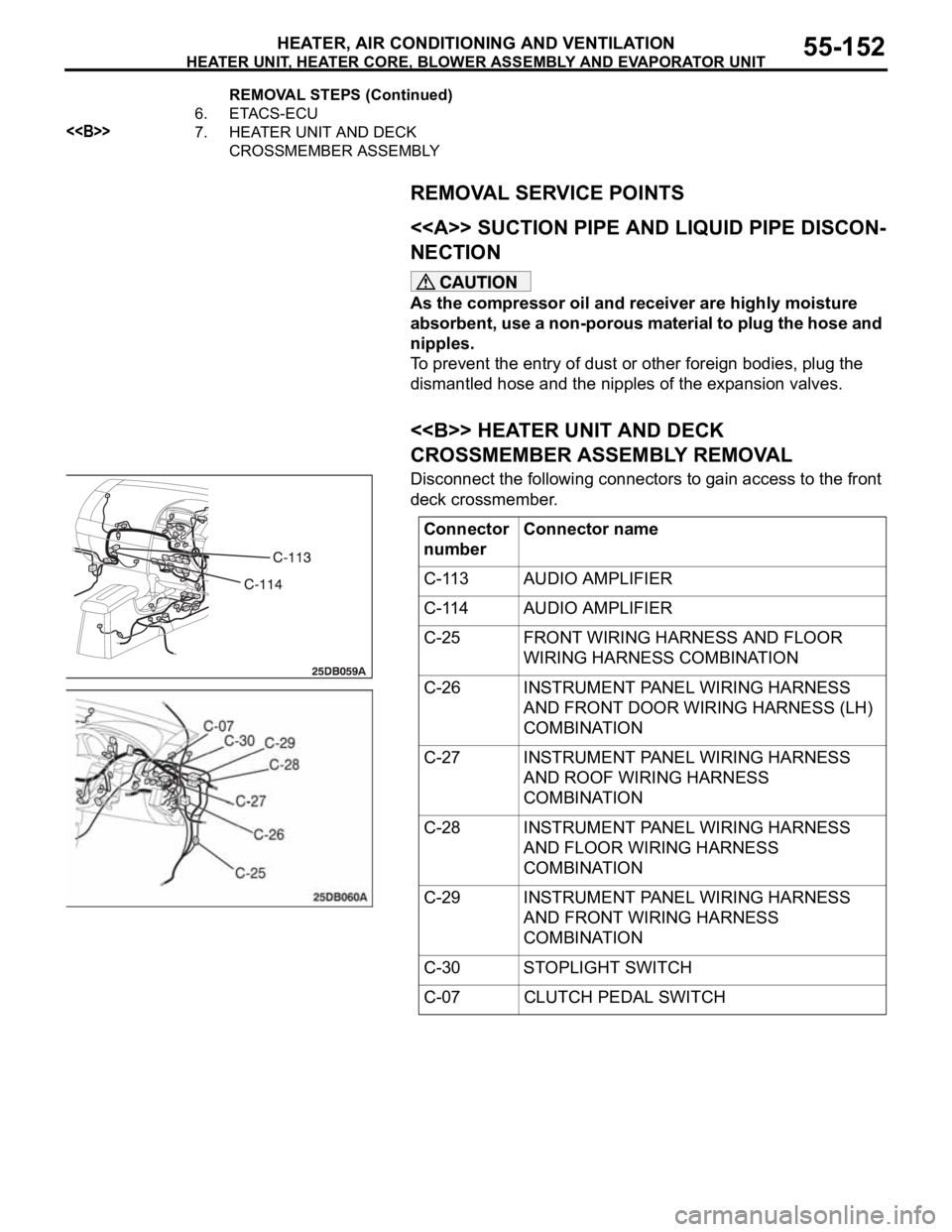

<> HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL

Disconnect the following connectors to gain access to the front

deck crossmember.

6. ETACS-ECU

<>7. HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL STEPS (Continued)

Connector

numberConnector name

C-113 AUDIO AMPLIFIER

C-114 AUDIO AMPLIFIER

C-25 FRONT WIRING HARNESS AND FLOOR

WIRING HARNESS COMBINATION

C-26 INSTRUMENT PANEL WIRING HARNESS

AND FRONT DOOR WIRING HARNESS (LH)

COMBINATION

C-27 INSTRUMENT PANEL WIRING HARNESS

AND ROOF WIRING HARNESS

COMBINATION

C-28 INSTRUMENT PANEL WIRING HARNESS

AND FLOOR WIRING HARNESS

COMBINATION

C-29 INSTRUMENT PANEL WIRING HARNESS

AND FRONT WIRING HARNESS

COMBINATION

C-30 STOPLIGHT SWITCH

C-07 CLUTCH PEDAL SWITCH

Page 905 of 1500

HOW TO DIAGNOSE

GENERAL

INSPECTIONM1001004600139

1. Sight and sound checks

Check relay operation, blower motor rotation, light

illumination, etc. Listen for a "click" when some relay covers

are pushed down.

2. Simple checks

For example, if a headlight does not come on and a faulty

fuse or poor grounding is suspected, replace the fuse with a

new one. Or use a jumper wire to ground the light to the

body. Determine which part(s) is/are responsible for the

problem.

3. Checking with instruments

Use an appropriate instrument in an adequate range and

read the indication correctly.