sensor MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 832 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-131

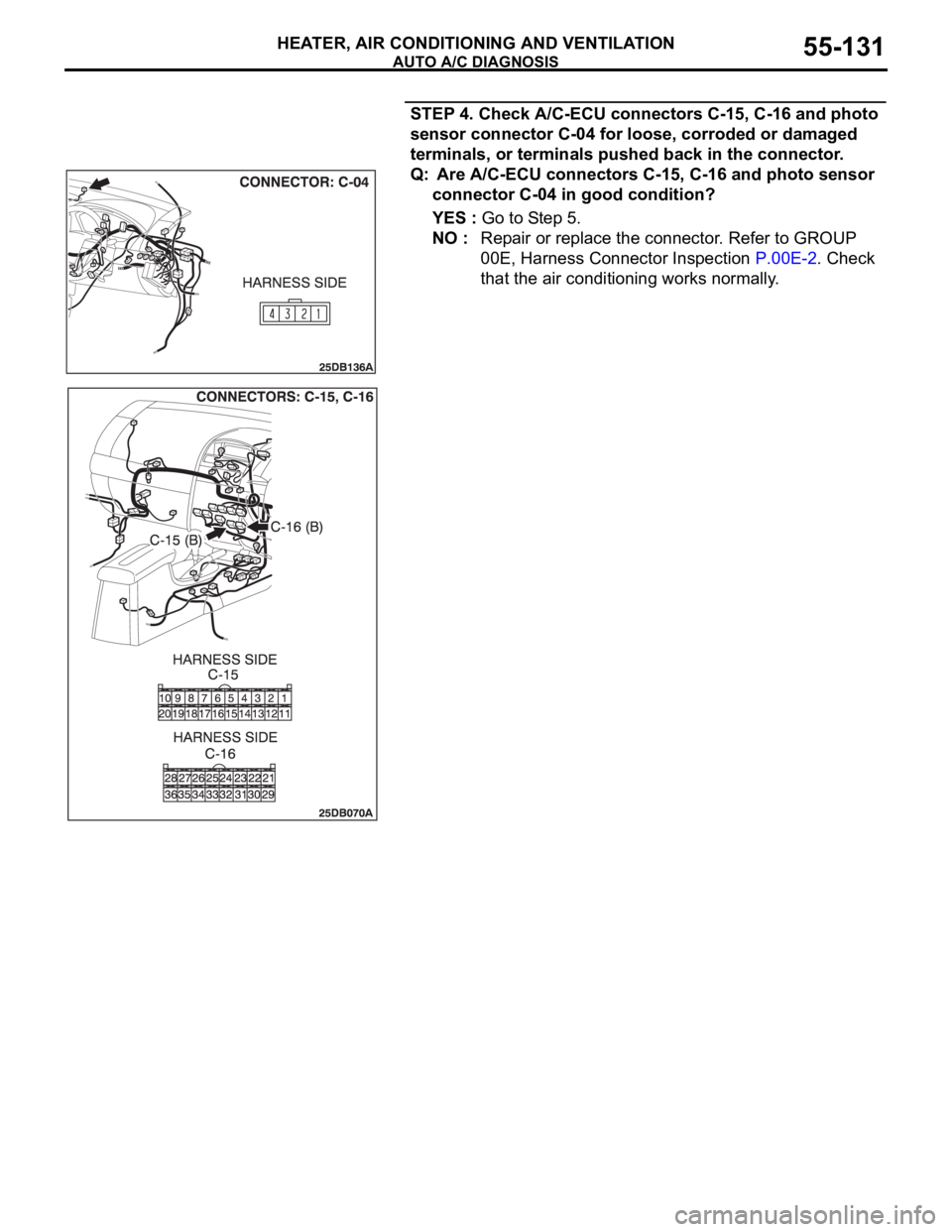

STEP 4. Check A/C-ECU connectors C-15, C-16 and photo

sensor connector C-04 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are A/C-ECU connectors C-15, C-16 and photo sensor

connector C-04 in good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the air conditioning works normally.

Page 833 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-132

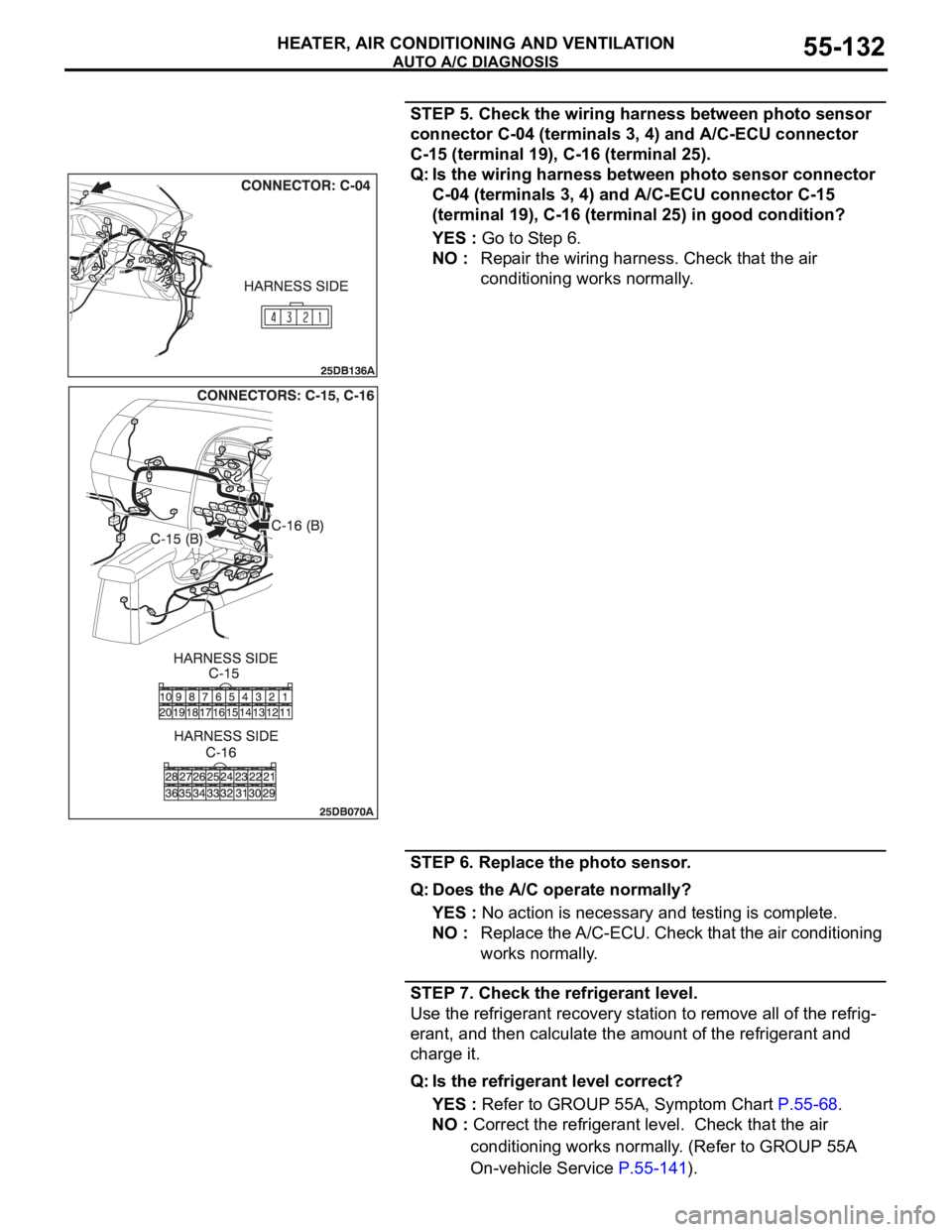

STEP 5. Check the wiring harness between photo sensor

connector C-04 (terminals 3, 4) and A/C-ECU connector

C-15 (terminal 19), C-16 (terminal 25).

Q: Is the wiring harness between photo sensor connector

C-04 (terminals 3, 4) and A/C-ECU connector C-15

(terminal 19), C-16 (terminal 25) in good condition?

YES : Go to Step 6.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 6. Replace the photo sensor.

Q: Does the A/C operate normally?

YES : No action is necessary and testing is complete.

NO : Replace the A/C-ECU. Check that the air conditioning

works normally.

STEP 7. Check the refrigerant level.

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

Q: Is the refrigerant level correct?

YES : Refer to GROUP 55A, Symptom Chart P.55-68.

NO : Correct the refrigerant level. Check that the air

conditioning works normally. (Refer to GROUP 55A

On-vehicle Service P.55-141).

Page 834 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-133

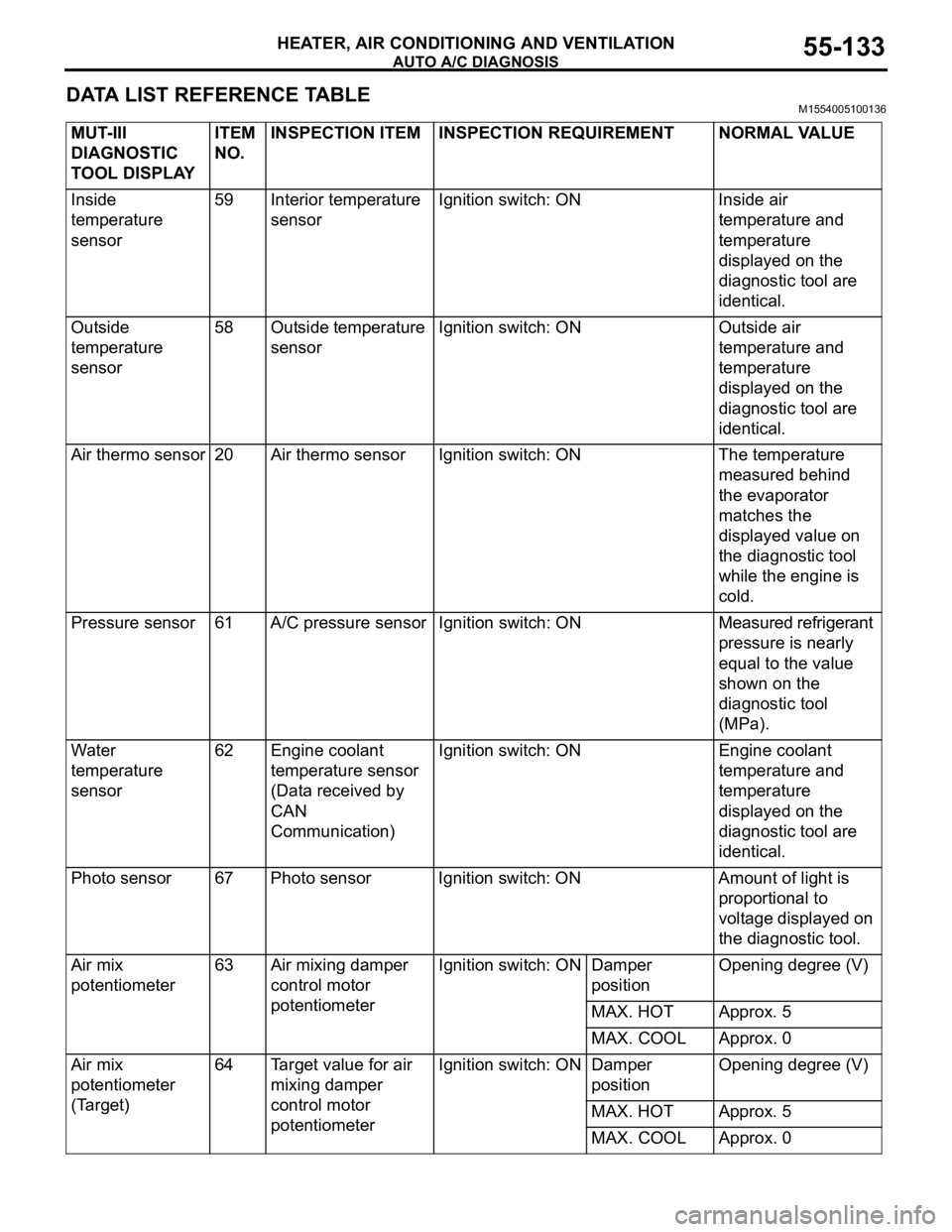

DATA LIST REFERENCE TABLEM1554005100136

MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Inside

temperature

sensor59 Interior temperature

sensorIgnition switch: ON Inside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Outside

temperature

sensor58 Outside temperature

sensorIgnition switch: ON Outside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Air thermo sensor 20 Air thermo sensor Ignition switch: ON The temperature

measured behind

the evaporator

matches the

displayed value on

the diagnostic tool

while the engine is

cold.

Pressure sensor 61 A/C pressure sensor Ignition switch: ON Measured refrigerant

pressure is nearly

equal to the value

shown on the

diagnostic tool

(MPa).

Water

temperature

sensor62 Engine coolant

temperature sensor

(Data received by

CAN

Communication)Ignition switch: ON Engine coolant

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Photo sensor 67 Photo sensor Ignition switch: ON Amount of light is

proportional to

voltage displayed on

the diagnostic tool.

Air mix

potentiometer63 Air mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Air mix

potentiometer

(Target)64 Target value for air

mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Page 838 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-137

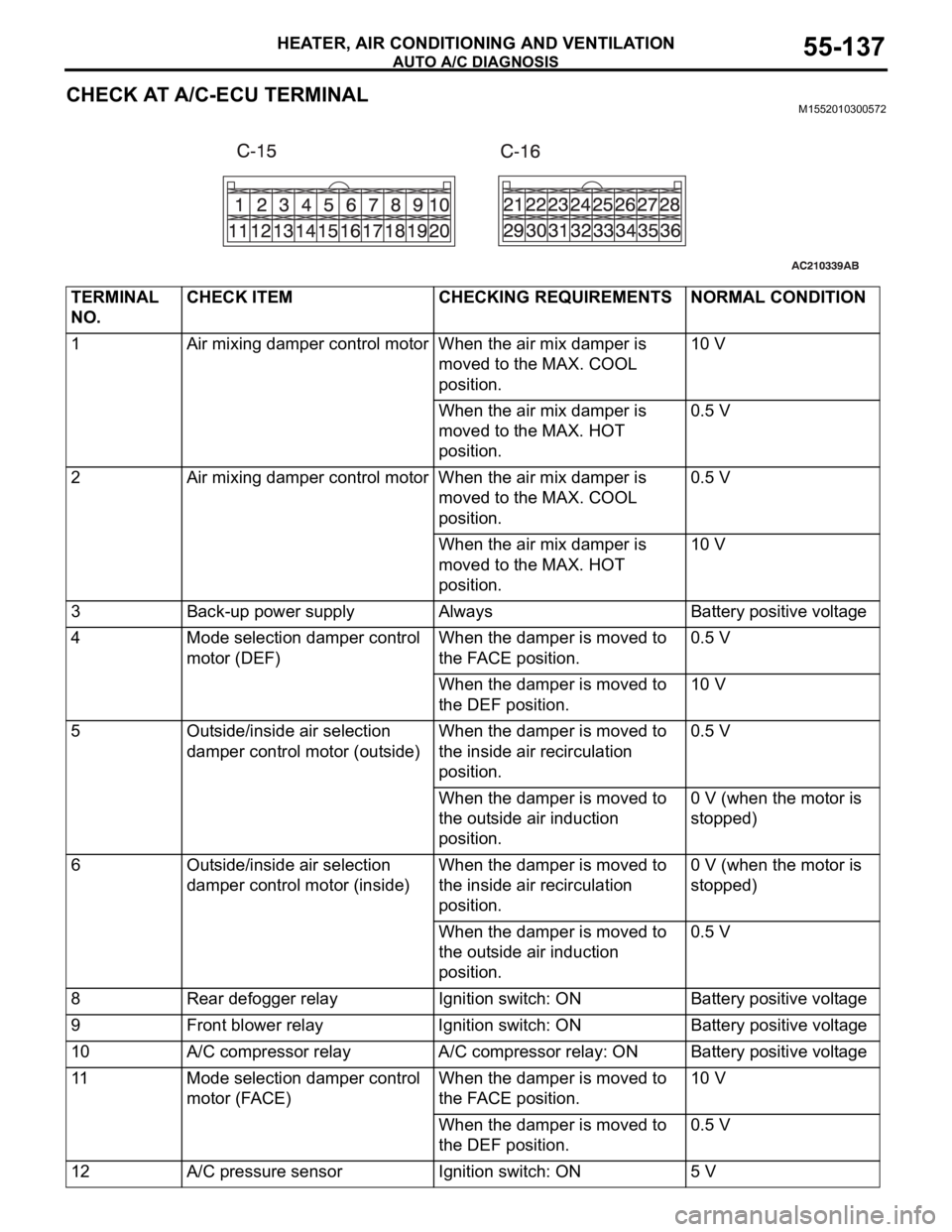

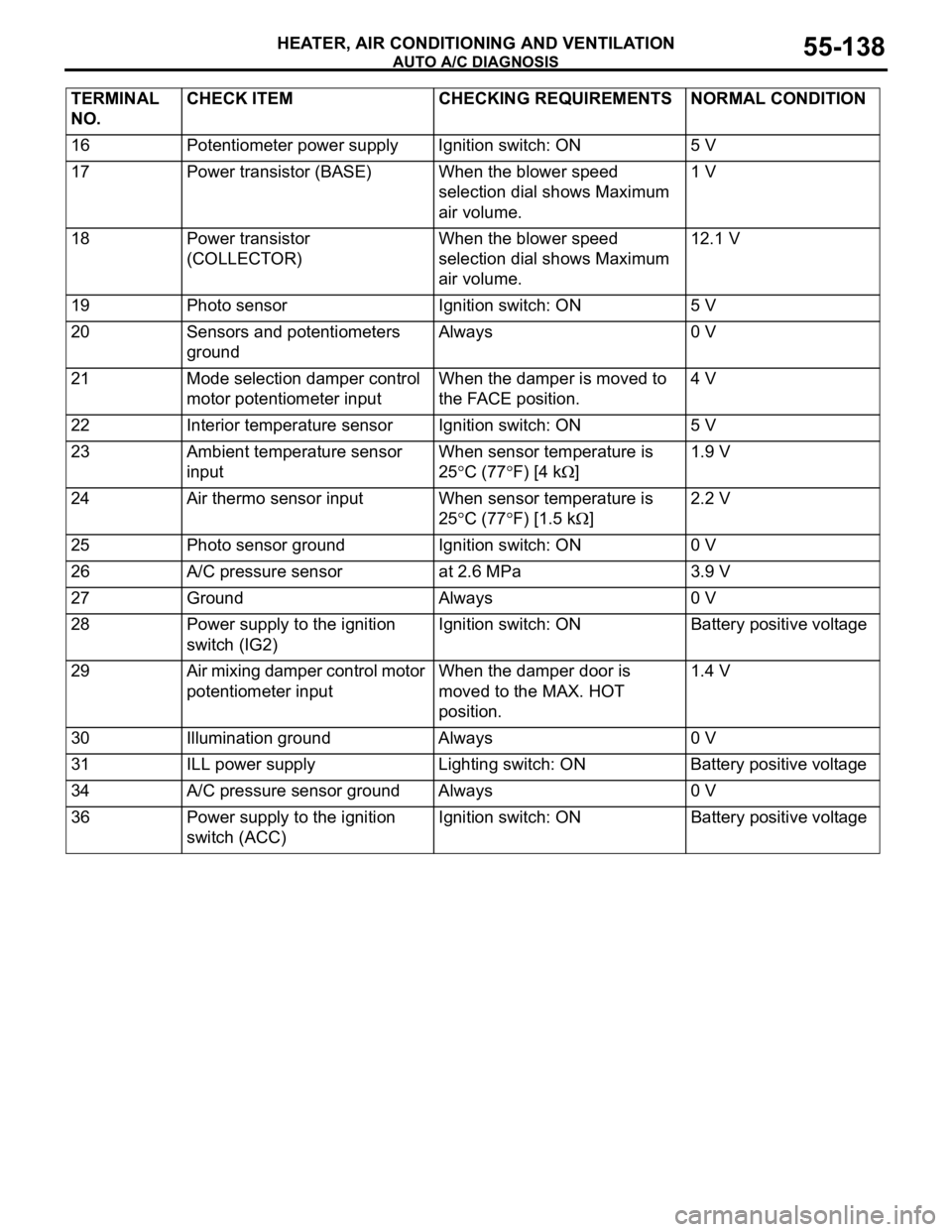

CHECK AT A/C-ECU TERMINALM1552010300572

TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

1 Air mixing damper control motor When the air mix damper is

moved to the MAX. COOL

position. 10 V

When the air mix damper is

moved to the MAX. HOT

position. 0.5 V

2 Air mixing damper control motor When the air mix damper is

moved to the MAX. COOL

position. 0.5 V

When the air mix damper is

moved to the MAX. HOT

position. 10 V

3 Back-up power supply Always Battery positive voltage

4 Mode selection damper control

motor (DEF)When the damper is moved to

the FACE position. 0.5 V

When the damper is moved to

the DEF position. 10 V

5 Outside/inside air selection

damper control motor (outside)When the damper is moved to

the inside air recirculation

position.0.5 V

When the damper is moved to

the outside air induction

position.0 V (when the motor is

stopped)

6 Outside/inside air selection

damper control motor (inside)When the damper is moved to

the inside air recirculation

position.0 V (when the motor is

stopped)

When the damper is moved to

the outside air induction

position.0.5 V

8 Rear defogger relay Ignition switch: ON Battery positive voltage

9 Front blower relay Ignition switch: ON Battery positive voltage

10 A/C compressor relay A/C compressor relay: ON Battery positive voltage

11 Mode selection damper control

motor (FACE)When the damper is moved to

the FACE position. 10 V

When the damper is moved to

the DEF position. 0.5 V

12 A/C pressure sensor Ignition switch: ON 5 V

Page 839 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-138

16 Potentiometer power supply Ignition switch: ON 5 V

17 Power transistor (BASE) When the blower speed

selection dial shows Maximum

air volume.1 V

18 Power transistor

(COLLECTOR)When the blower speed

selection dial shows Maximum

air volume.12.1 V

19 Photo sensor Ignition switch: ON 5 V

20 Sensors and potentiometers

groundAlways 0 V

21 Mode selection damper control

motor potentiometer inputWhen the damper is moved to

the FACE position. 4 V

22 Interior temperature sensor Ignition switch: ON 5 V

23 Ambient temperature sensor

inputWhen sensor temperature is

25

C (77F) [4 k]1.9 V

24 Air thermo sensor input When sensor temperature is

25

C (77F) [1.5 k]2.2 V

25 Photo sensor ground Ignition switch: ON 0 V

26 A/C pressure sensor at 2.6 MPa 3.9 V

27 Ground Always 0 V

28 Power supply to the ignition

switch (IG2)Ignition switch: ON Battery positive voltage

29 Air mixing damper control motor

potentiometer inputWhen the damper door is

moved to the MAX. HOT

position.1.4 V

30 Illumination ground Always 0 V

31 ILL power supply Lighting switch: ON Battery positive voltage

34 A/C pressure sensor ground Always 0 V

36 Power supply to the ignition

switch (ACC)Ignition switch: ON Battery positive voltage TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

Page 840 of 1500

SPECIAL TOOLS

HEATER, AIR CONDITIONING AND VENTILATION55-139

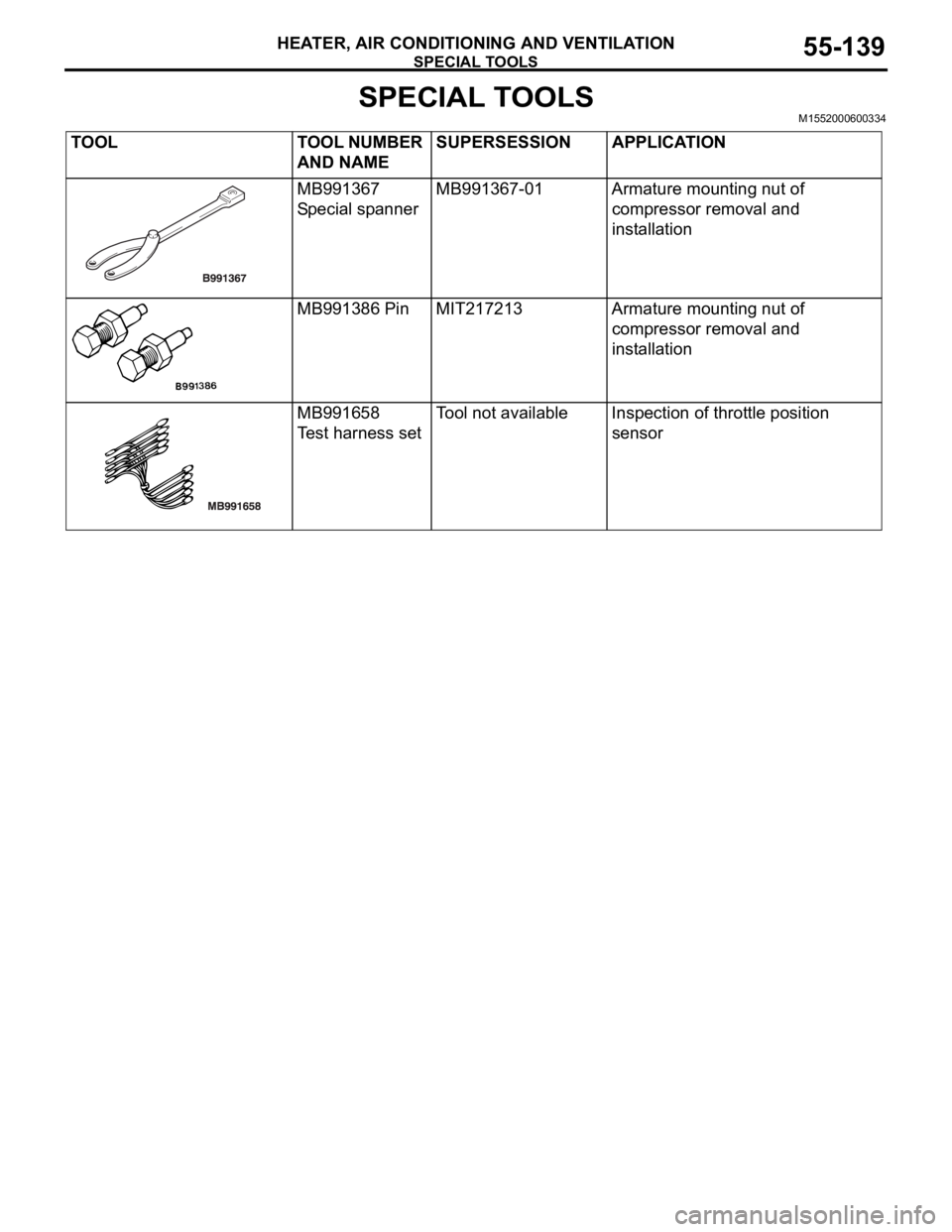

SPECIAL TOOLSM1552000600334

TOOL TOOL NUMBER

AND NAMESUPERSESSION APPLICATION

MB991367

Special spannerMB991367-01 Armature mounting nut of

compressor removal and

installation

MB991386 Pin MIT217213 Armature mounting nut of

compressor removal and

installation

MB991658

Test harness setTool not available Inspection of throttle position

sensor

Page 842 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-141

ON-VEHICLE SERVICE

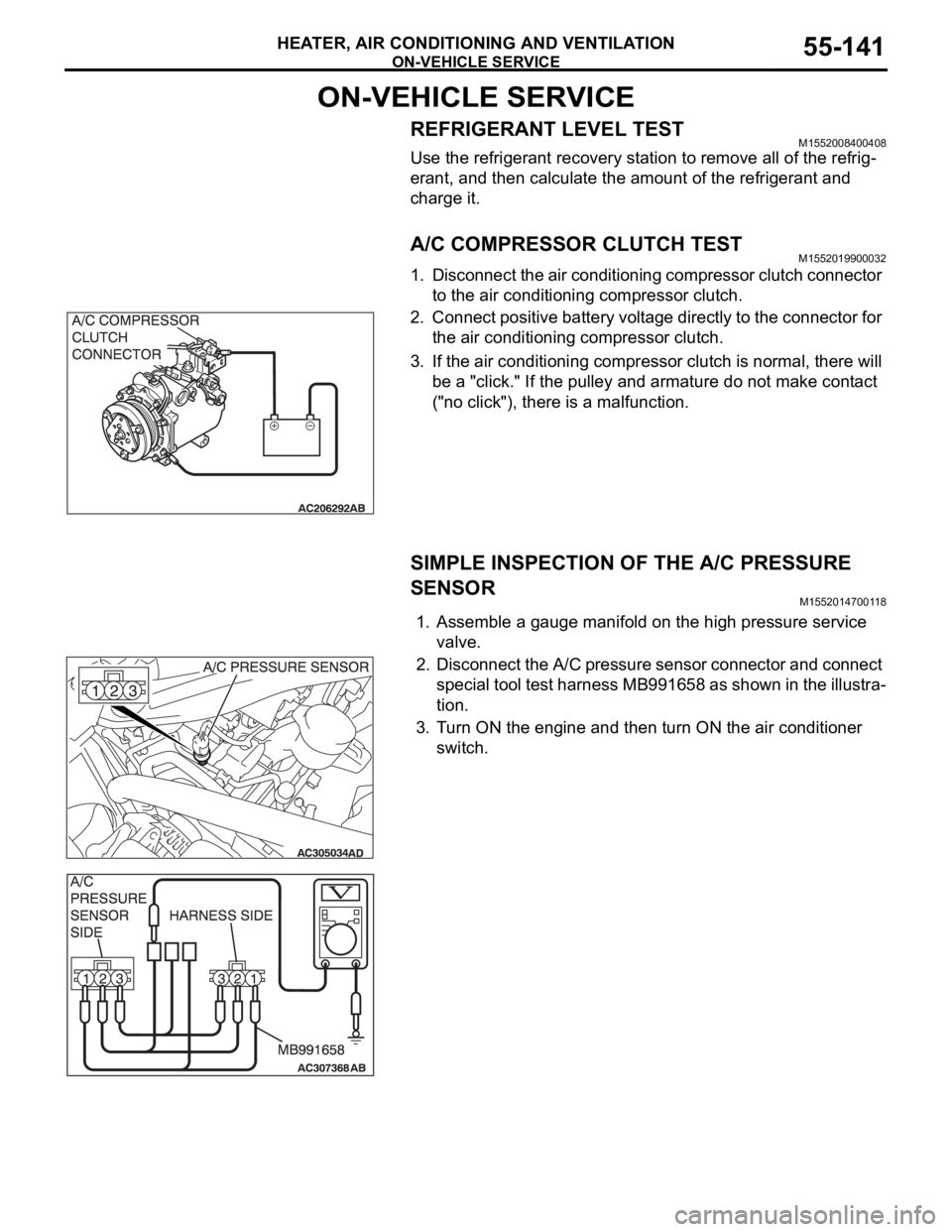

REFRIGERANT LEVEL TESTM1552008400408

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

A/C COMPRESSOR CLUTCH TESTM1552019900032

1. Disconnect the air conditioning compressor clutch connector

to the air conditioning compressor clutch.

2. Connect positive battery voltage directly to the connector for

the air conditioning compressor clutch.

3. If the air conditioning compressor clutch is normal, there will

be a "click." If the pulley and armature do not make contact

("no click"), there is a malfunction.

SIMPLE INSPECTION OF THE A/C PRESSURE

SENSOR

M1552014700118

1. Assemble a gauge manifold on the high pressure service

valve.

2. Disconnect the A/C pressure sensor connector and connect

special tool test harness MB991658 as shown in the illustra-

tion.

3. Turn ON the engine and then turn ON the air conditioner

switch.

Page 843 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-142

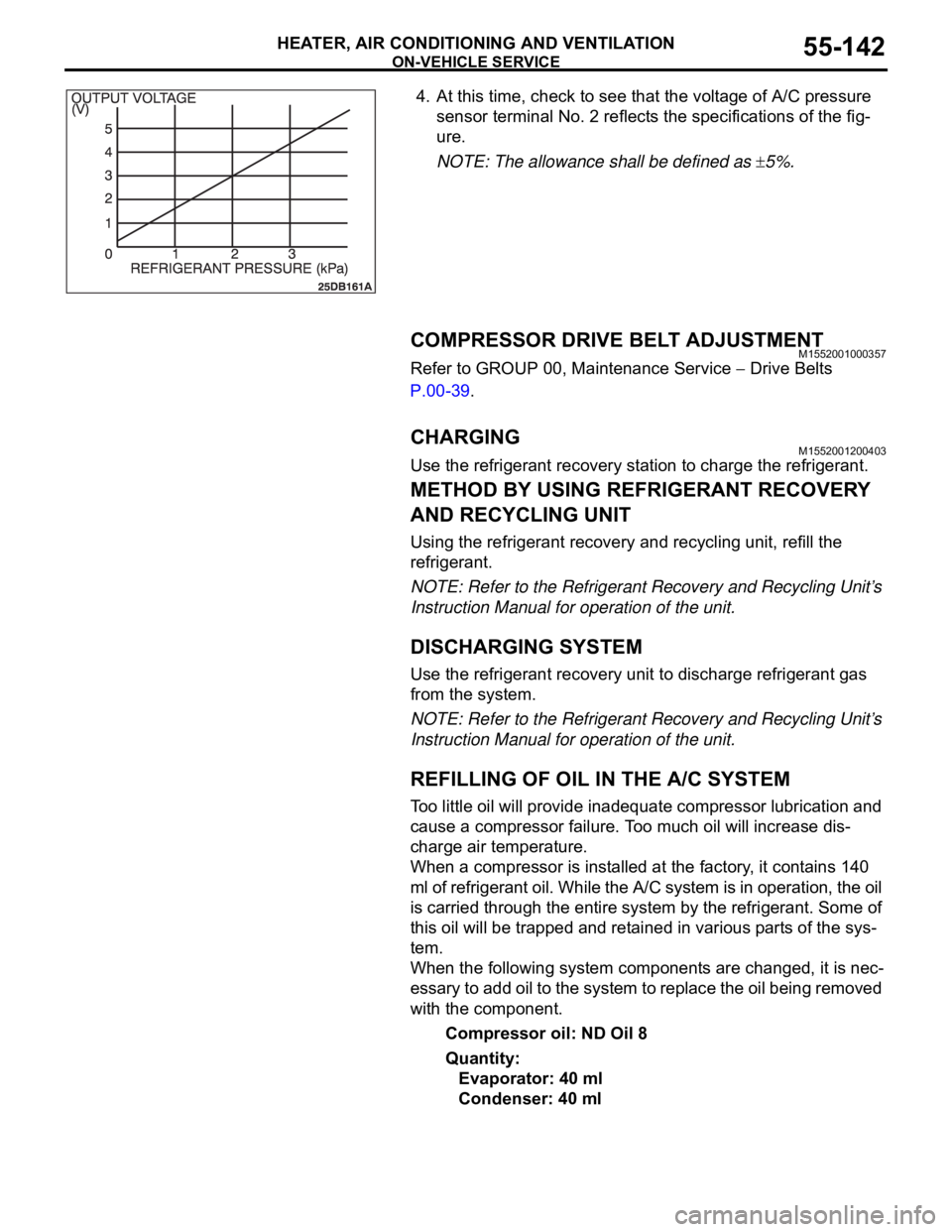

4. At this time, check to see that the voltage of A/C pressure

sensor terminal No. 2 reflects the specifications of the fig-

ure.

NOTE: The allowance shall be defined as

5%.

COMPRESSOR DRIVE BELT ADJUSTMENTM1552001000357

Refer to GROUP 00, Maintenance Service Drive Belts

P.00-39.

CHARGING M1552001200403

Use the refrigerant recovery station to charge the refrigerant.

METHOD BY USING REFRIGERANT RECOVERY

AND RECYCLING UNIT

Using the refrigerant recovery and recycling unit, refill the

refrigerant.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

DISCHARGING SYSTEM

Use the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

REFILLING OF OIL IN THE A/C SYSTEM

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will increase dis-

charge air temperature.

When a compressor is installed at the factory, it contains 140

ml of refrigerant oil. While the A/C system is in operation, the oil

is carried through the entire system by the refrigerant. Some of

this oil will be trapped and retained in various parts of the sys-

tem.

When the following system components are changed, it is nec-

essary to add oil to the system to replace the oil being removed

with the component.

Compressor oil: ND Oil 8

Quantity:

Evaporator: 40 ml

Condenser: 40 ml

Page 845 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-144

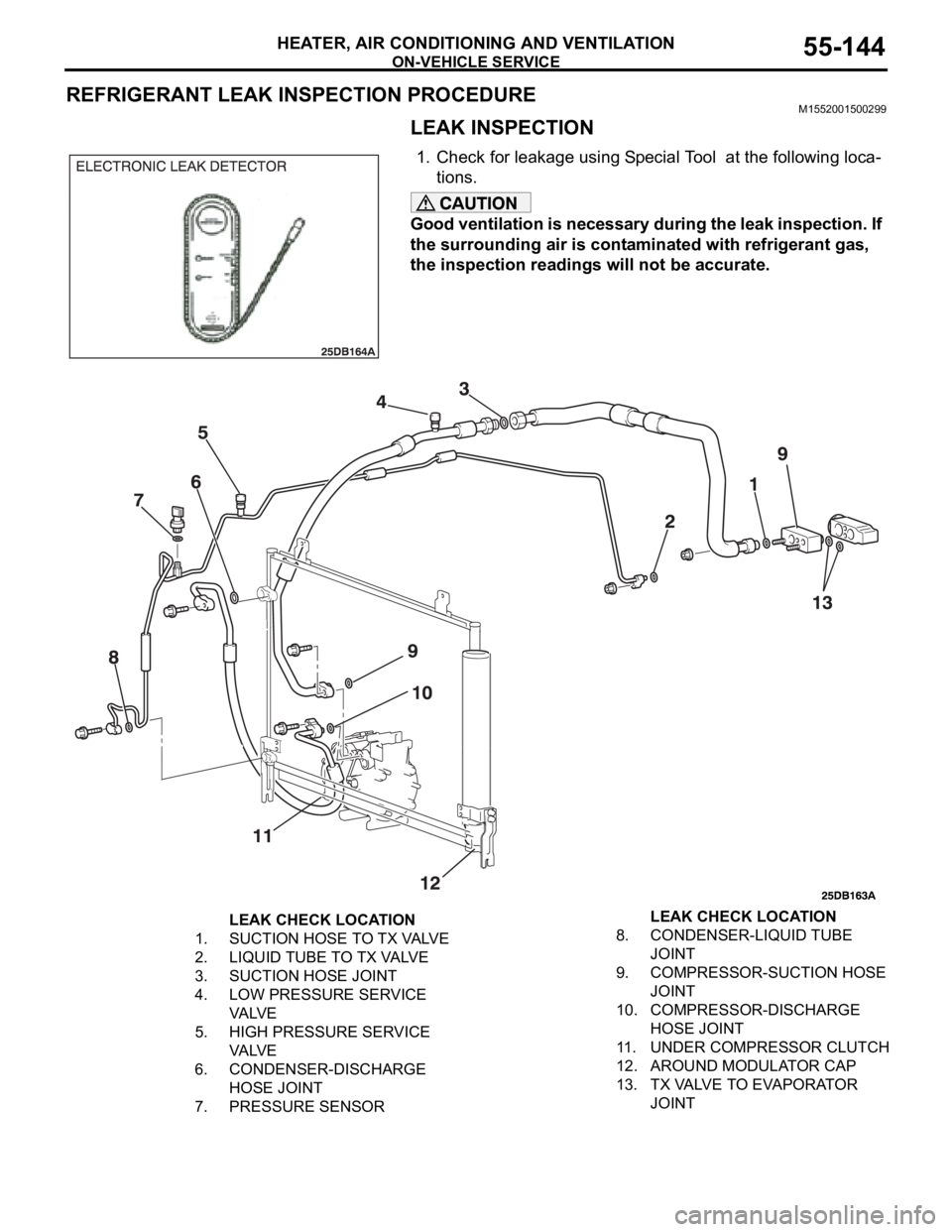

REFRIGERANT LEAK INSPECTION PROCEDUREM1552001500299

LEAK INSPECTION

1. Check for leakage using Special Tool at the following loca-

tions.

Good ventilation is necessary during the leak inspection. If

the surrounding air is contaminated with refrigerant gas,

the inspection readings will not be accurate.

LEAK CHECK LOCATION

1. SUCTION HOSE TO TX VALVE

2. LIQUID TUBE TO TX VALVE

3. SUCTION HOSE JOINT

4. LOW PRESSURE SERVICE

VA LV E

5. HIGH PRESSURE SERVICE

VA LV E

6. CONDENSER-DISCHARGE

HOSE JOINT

7. PRESSURE SENSOR8. CONDENSER-LIQUID TUBE

JOINT

9. COMPRESSOR-SUCTION HOSE

JOINT

10. COMPRESSOR-DISCHARGE

HOSE JOINT

11. UNDER COMPRESSOR CLUTCH

12. AROUND MODULATOR CAP

13. TX VALVE TO EVAPORATOR

JOINT LEAK CHECK LOCATION

Page 855 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-154

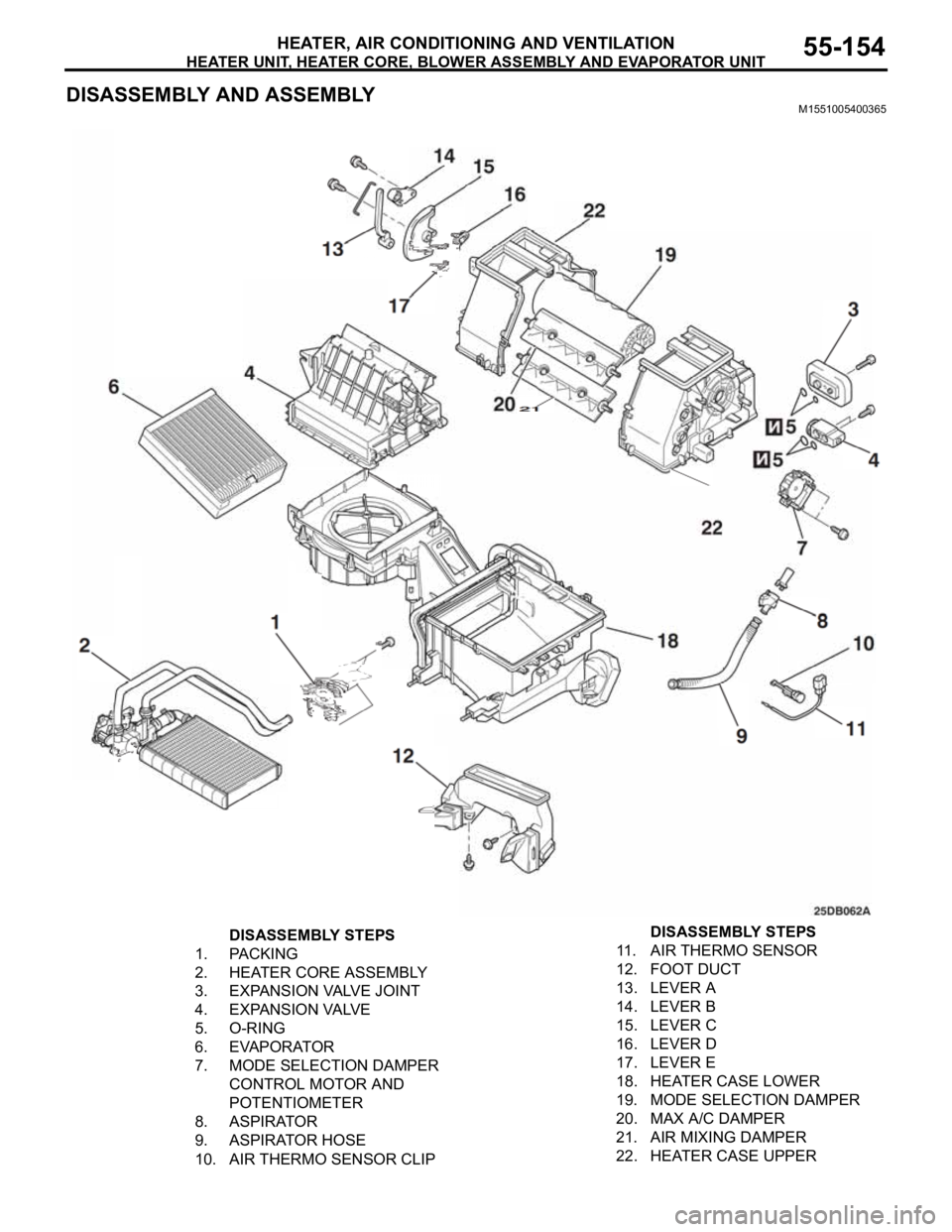

DISASSEMBLY AND ASSEMBLYM1551005400365

DISASSEMBLY STEPS

1. PACKING

2. HEATER CORE ASSEMBLY

3. EXPANSION VALVE JOINT

4. EXPANSION VALVE

5. O-RING

6. EVAPORATOR

7. MODE SELECTION DAMPER

CONTROL MOTOR AND

POTENTIOMETER

8. ASPIRATOR

9. ASPIRATOR HOSE

10. AIR THERMO SENSOR CLIP11. AIR THERMO SENSOR

12. FOOT DUCT

13. LEVER A

14. LEVER B

15. LEVER C

16. LEVER D

17. LEVER E

18. HEATER CASE LOWER

19. MODE SELECTION DAMPER

20. MAX A/C DAMPER

21. AIR MIXING DAMPER

22. HEATER CASE UPPERDISASSEMBLY STEPS