sensor MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 957 of 1500

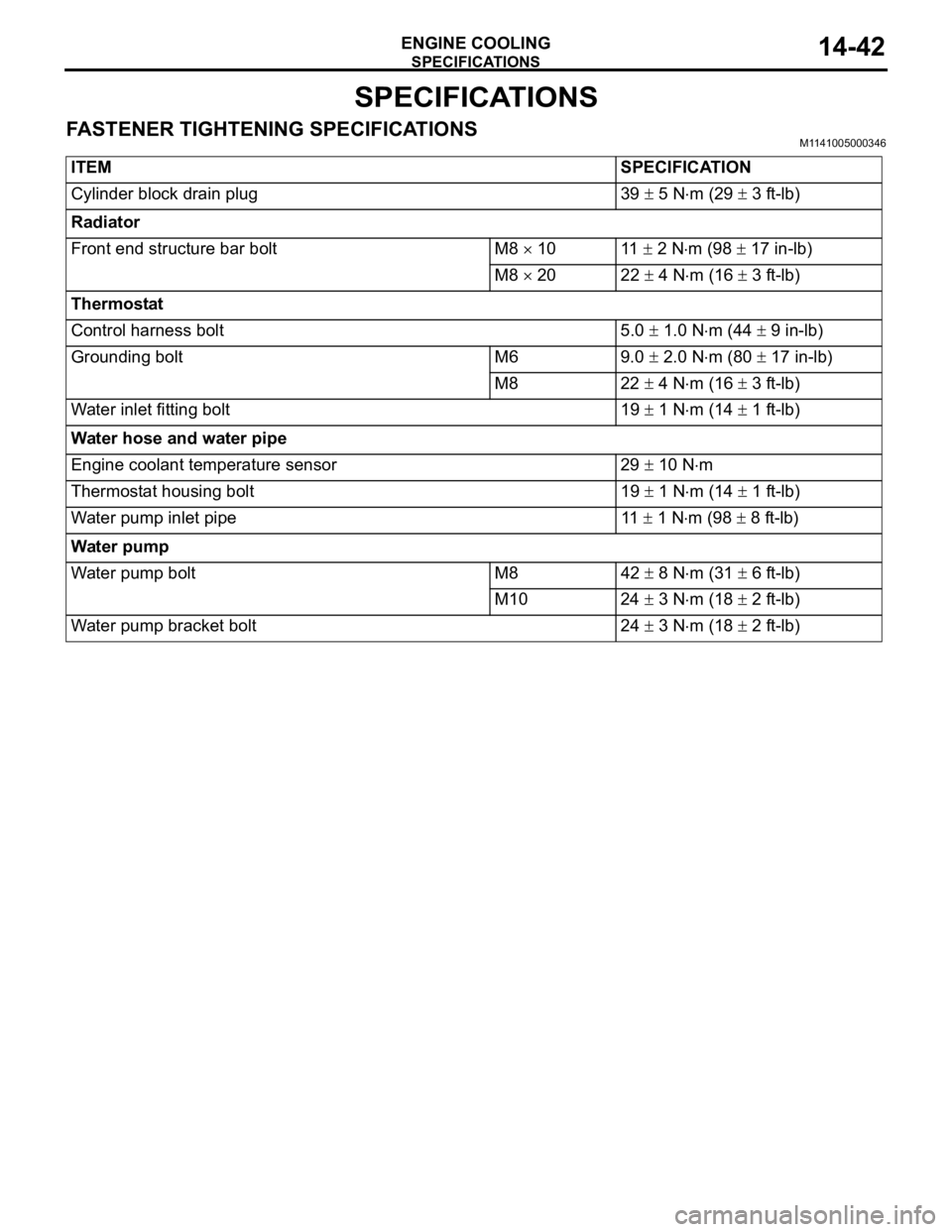

SPECIFICATIONS

ENGINE COOLING14-42

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1141005000346

ITEM SPECIFICATION

Cylinder block drain plug 39

5 Nm (29 3 ft-lb)

Radiator

Front end structure bar bolt M8

10 11 2 Nm (98 17 in-lb)

M8

20 22 4 Nm (16 3 ft-lb)

Thermostat

Control harness bolt 5.0

1.0 Nm (44 9 in-lb)

Grounding bolt M6 9.0

2.0 Nm (80 17 in-lb)

M8 22

4 Nm (16 3 ft-lb)

Water inlet fitting bolt 19

1 Nm (14 1 ft-lb)

Water hose and water pipe

Engine coolant temperature sensor 29

10 Nm

Thermostat housing bolt 19

1 Nm (14 1 ft-lb)

Water pump inlet pipe 11

1 Nm (98 8 ft-lb)

Water pump

Water pump bolt M8 42

8 Nm (31 6 ft-lb)

M10 24

3 Nm (18 2 ft-lb)

Water pump bracket bolt 24

3 Nm (18 2 ft-lb)

Page 958 of 1500

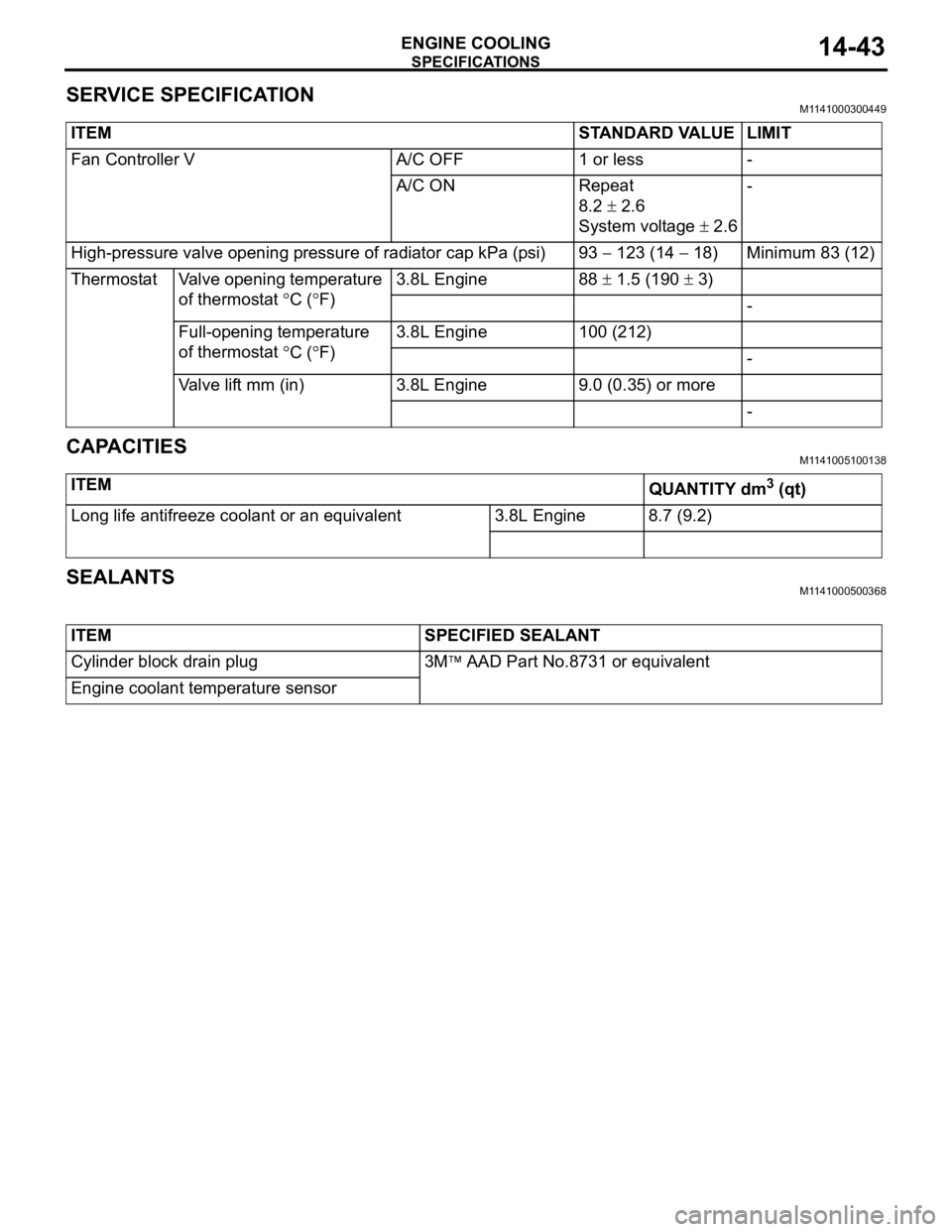

SPECIFICATIONS

ENGINE COOLING14-43

SERVICE SPECIFICATIONM1141000300449

CAPACITIESM1141005100138

SEALANTSM1141000500368

ITEM STANDARD VALUE LIMIT

Fan Controller V A/C OFF 1 or less -

A/C ON Repeat

8.2

2.6

System voltage

2.6-

High-pressure valve opening pressure of radiator cap kPa (psi) 93

123 (14 18) Minimum 83 (12)

Thermostat Valve opening temperature

of thermostat

C (F)3.8L Engine 88

1.5 (190 3)

-

Full-opening temperature

of thermostat

C (F)3.8L Engine 100 (212)

-

Valve lift mm (in) 3.8L Engine 9.0 (0.35) or more

-

ITEM

QUANTITY dm3 (qt)

Long life antifreeze coolant or an equivalent 3.8L Engine 8.7 (9.2)

ITEM SPECIFIED SEALANT

Cylinder block drain plug 3M

AAD Part No.8731 or equivalent

Engine coolant temperature sensor

Page 962 of 1500

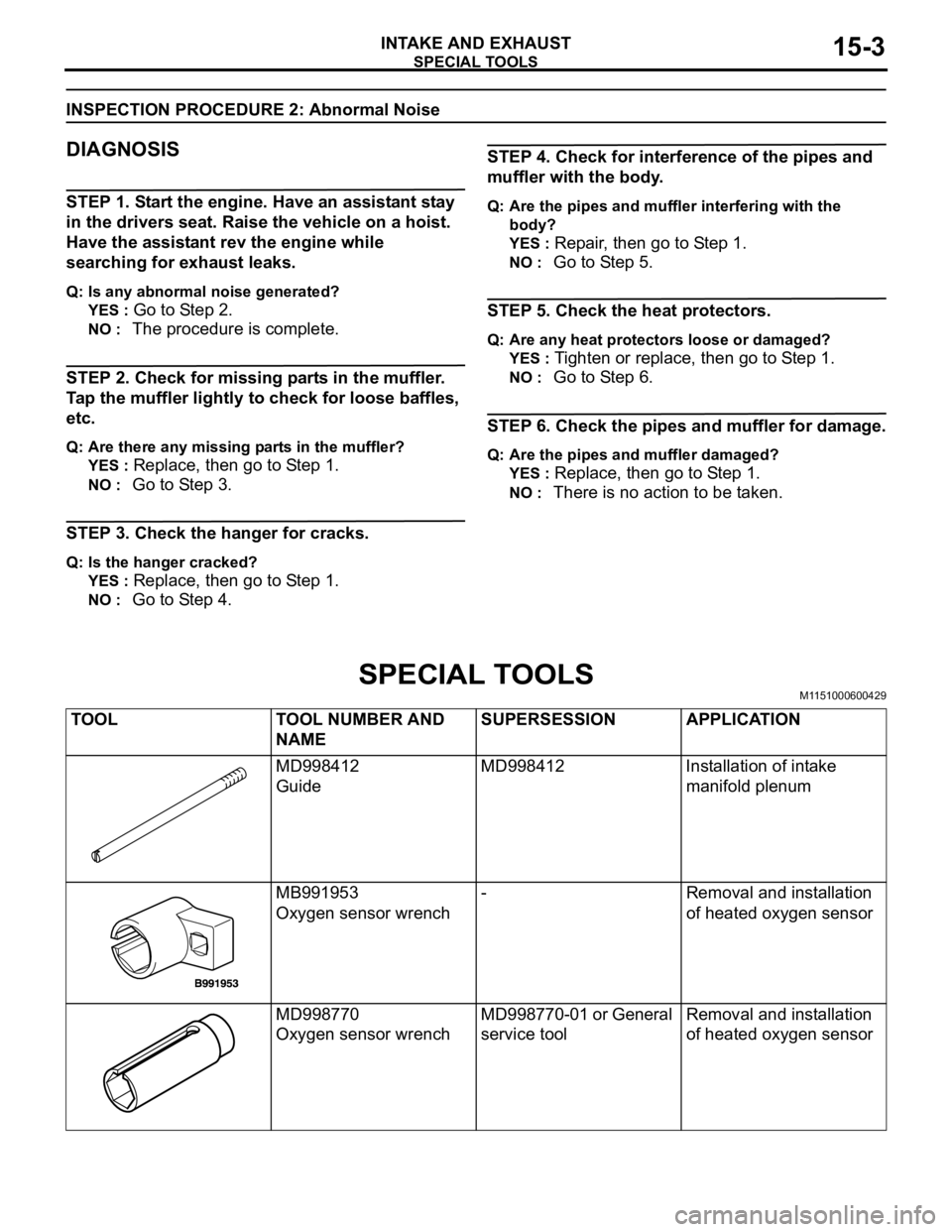

SPECIAL TOOLS

INTAKE AND EXHAUST15-3

INSPECTION PROCEDURE 2: Abnormal Noise

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the drivers seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

Q: Is any abnormal noise generated?

YES :

Go to Step 2.

NO : The procedure is complete.

STEP 2. Check for missing parts in the muffler.

Tap the muffler lightly to check for loose baffles,

etc.

Q: Are there any missing parts in the muffler?

YES :

Replace, then go to Step 1.

NO : Go to Step 3.

STEP 3. Check the hanger for cracks.

Q: Is the hanger cracked?

YES :

Replace, then go to Step 1.

NO : Go to Step 4.

STEP 4. Check for interference of the pipes and

muffler with the body.

Q: Are the pipes and muffler interfering with the

body?

YES :

Repair, then go to Step 1.

NO : Go to Step 5.

STEP 5. Check the heat protectors.

Q: Are any heat protectors loose or damaged?

YES :

Tighten or replace, then go to Step 1.

NO : Go to Step 6.

STEP 6. Check the pipes and muffler for damage.

Q: Are the pipes and muffler damaged?

YES :

Replace, then go to Step 1.

NO : There is no action to be taken.

SPECIAL TOOLSM1151000600429

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MD998412

GuideMD998412 Installation of intake

manifold plenum

MB991953

Oxygen sensor wrench- Removal and installation

of heated oxygen sensor

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval and installation

of heated oxygen sensor

Page 963 of 1500

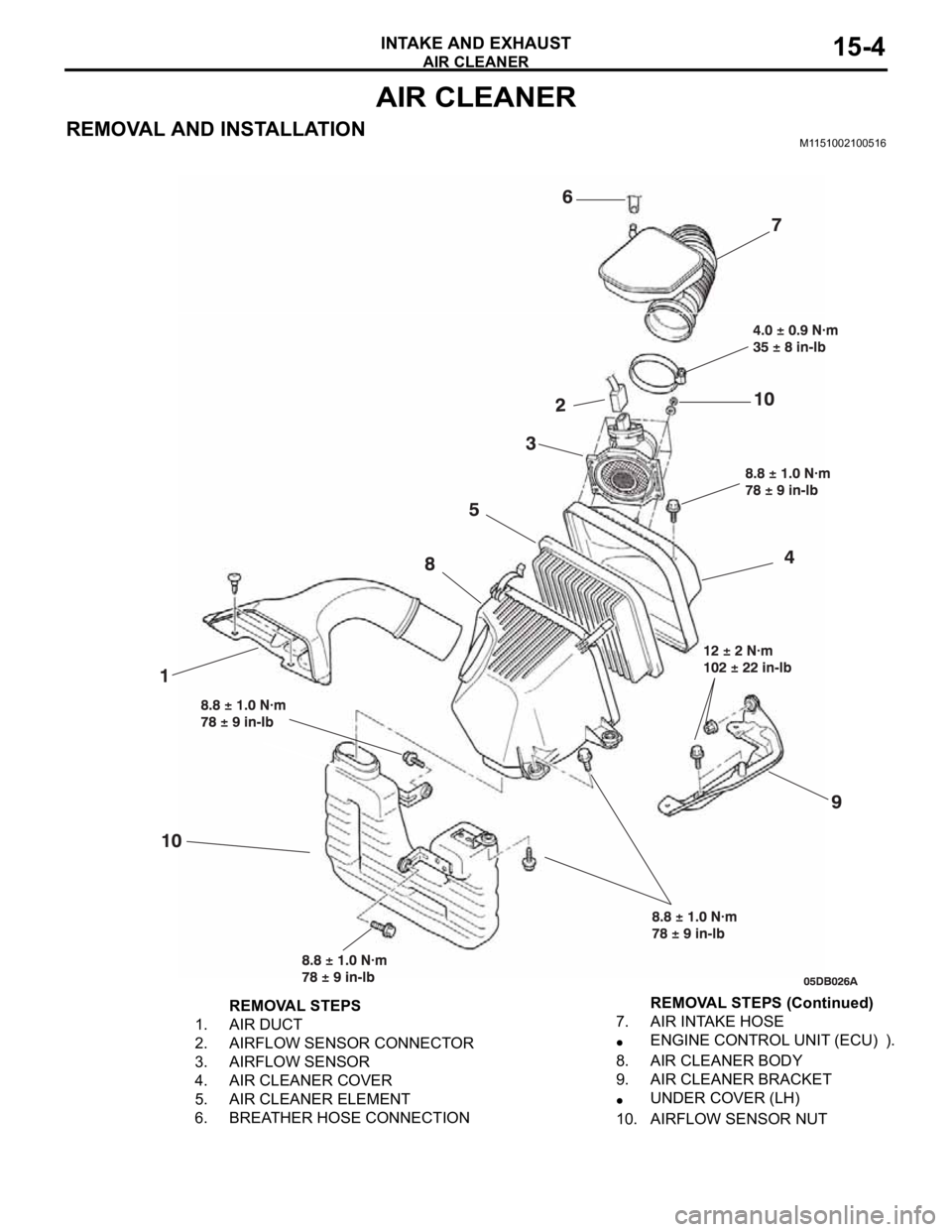

AIR CLEANER

INTAKE AND EXHAUST15-4

AIR CLEANER

REMOVAL AND INSTALLATIONM1151002100516

REMOVAL STEPS

1. AIR DUCT

2. AIRFLOW SENSOR CONNECTOR

3. AIRFLOW SENSOR

4. AIR CLEANER COVER

5. AIR CLEANER ELEMENT

6. BREATHER HOSE CONNECTION7. AIR INTAKE HOSE

ENGINE CONTROL UNIT (ECU) ).

8. AIR CLEANER BODY

9. AIR CLEANER BRACKET

UNDER COVER (LH)

10. AIRFLOW SENSOR NUTREMOVAL STEPS (Continued)

Page 965 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-6

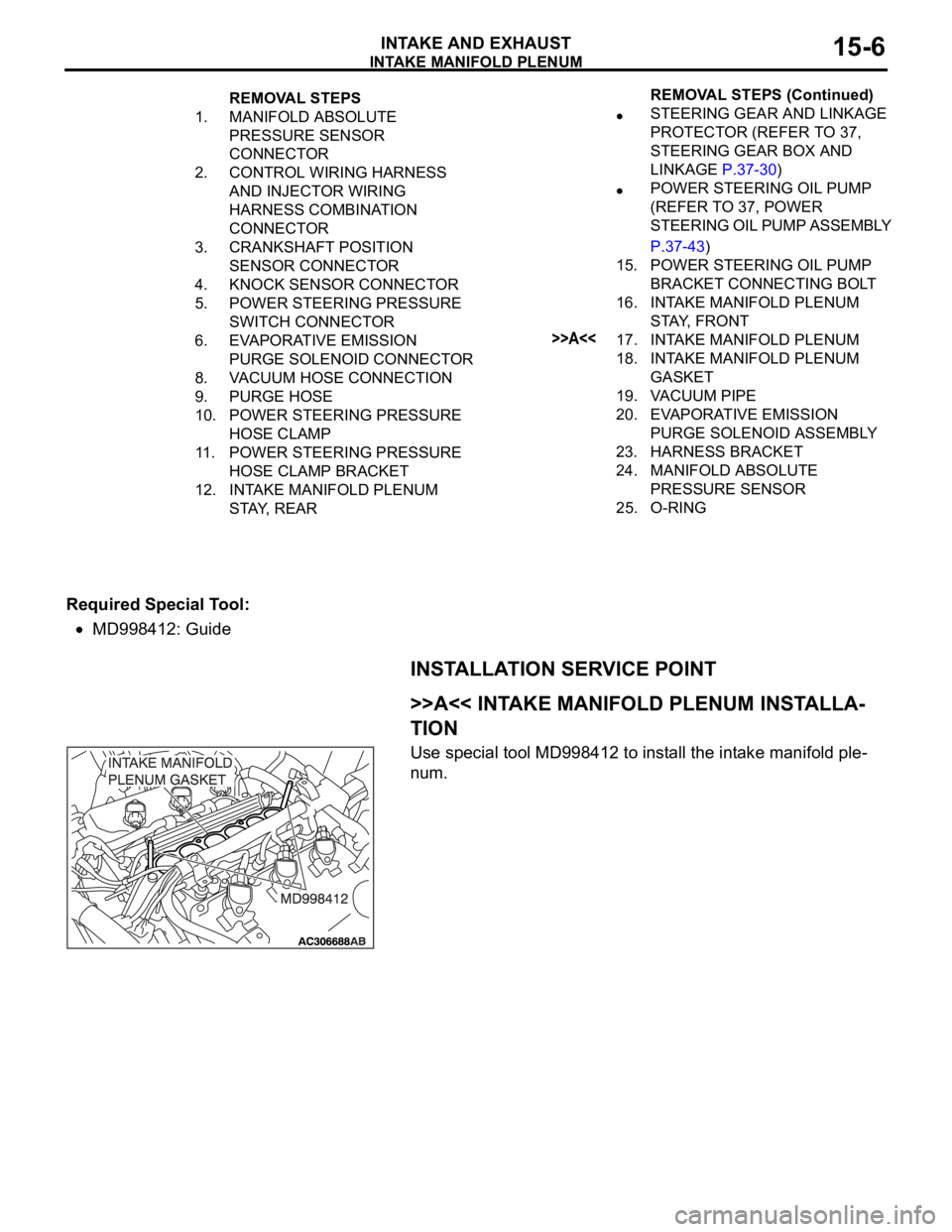

Required Special Tool:

MD998412: Guide

INSTALLATION SERVICE POINT

.

>>A<< INTAKE MANIFOLD PLENUM INSTALLA-

TION

Use special tool MD998412 to install the intake manifold ple-

num.

REMOVAL STEPS

1. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

2. CONTROL WIRING HARNESS

AND INJECTOR WIRING

HARNESS COMBINATION

CONNECTOR

3. CRANKSHAFT POSITION

SENSOR CONNECTOR

4. KNOCK SENSOR CONNECTOR

5. POWER STEERING PRESSURE

SWITCH CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR

8. VACUUM HOSE CONNECTION

9. PURGE HOSE

10. POWER STEERING PRESSURE

HOSE CLAMP

11. POWER STEERING PRESSURE

HOSE CLAMP BRACKET

12. INTAKE MANIFOLD PLENUM

STAY, REARSTEERING GEAR AND LINKAGE

PROTECTOR (REFER TO 37,

STEERING GEAR BOX AND

LINKAGE P.37-30)

POWER STEERING OIL PUMP

(REFER TO 37, POWER

STEERING OIL PUMP ASSEMBLY

P.37-43)

15. POWER STEERING OIL PUMP

BRACKET CONNECTING BOLT

16. INTAKE MANIFOLD PLENUM

STAY, FRONT

>>A<<17. INTAKE MANIFOLD PLENUM

18. INTAKE MANIFOLD PLENUM

GASKET

19. VACUUM PIPE

20. EVAPORATIVE EMISSION

PURGE SOLENOID ASSEMBLY

23. HARNESS BRACKET

24. MANIFOLD ABSOLUTE

PRESSURE SENSOR

25. O-RINGREMOVAL STEPS (Continued)

Page 969 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-10

EXHAUST MANIFOLD

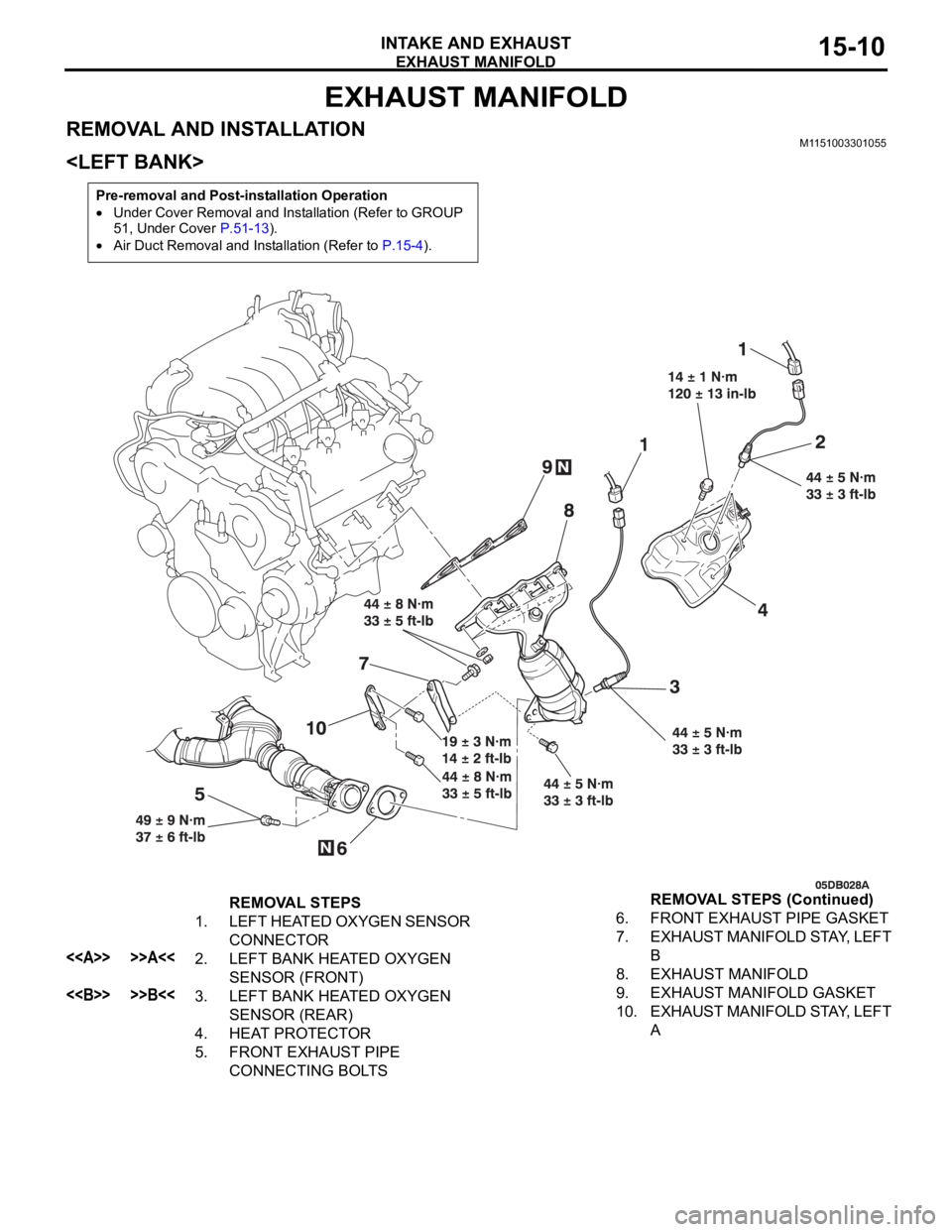

REMOVAL AND INSTALLATION M1151003301055

Pre-removal and Post-installation Operation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Air Duct Removal and Installation (Refer to P.15-4).

REMOVAL STEPS

1. LEFT HEATED OXYGEN SENSOR

CONNECTOR

<> >>A<<2. LEFT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>B<<3. LEFT BANK HEATED OXYGEN

SENSOR (REAR)

4. HEAT PROTECTOR

5. FRONT EXHAUST PIPE

CONNECTING BOLTS6. FRONT EXHAUST PIPE GASKET

7. EXHAUST MANIFOLD STAY, LEFT

B

8. EXHAUST MANIFOLD

9. EXHAUST MANIFOLD GASKET

10. EXHAUST MANIFOLD STAY, LEFT

A REMOVAL STEPS (Continued)

Page 970 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

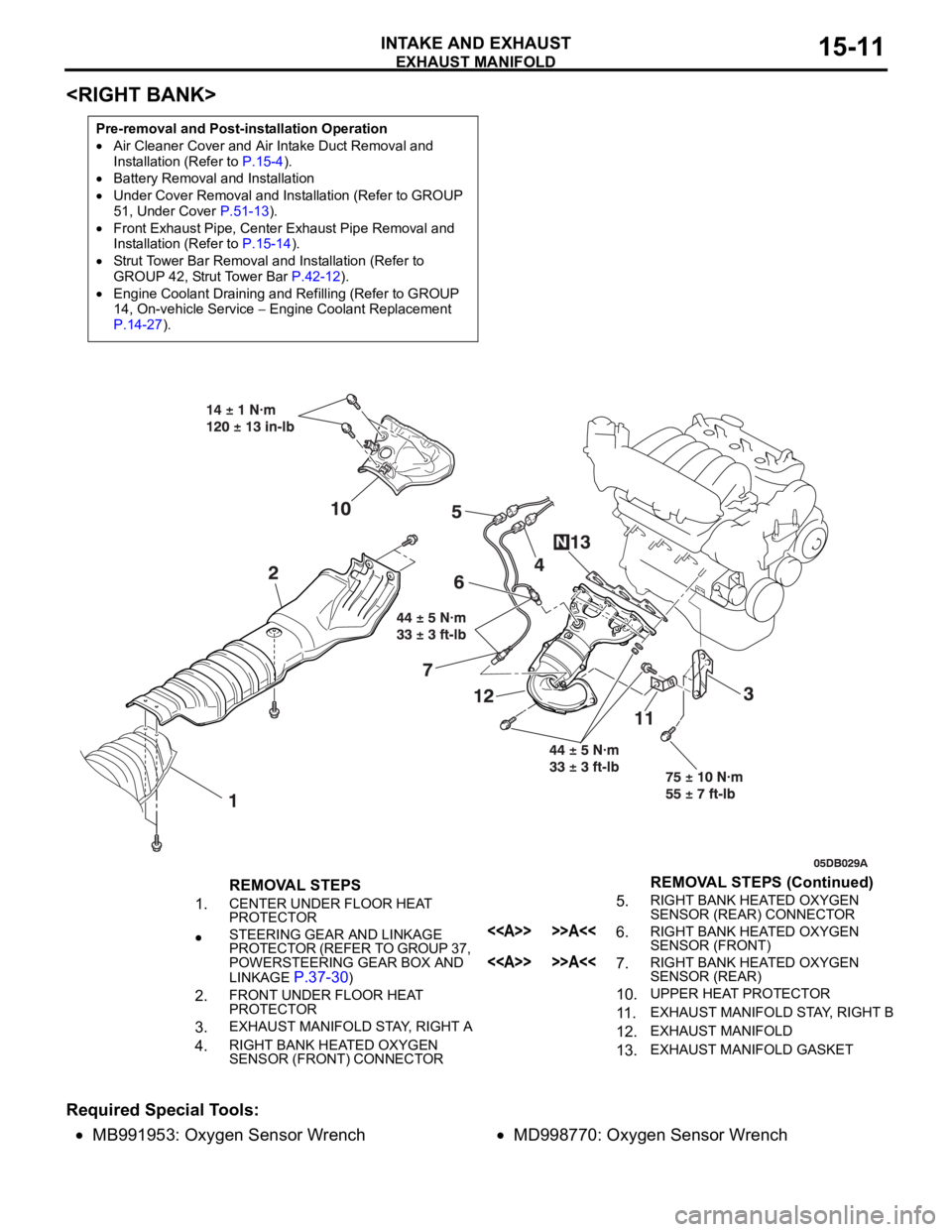

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)

Page 971 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-12

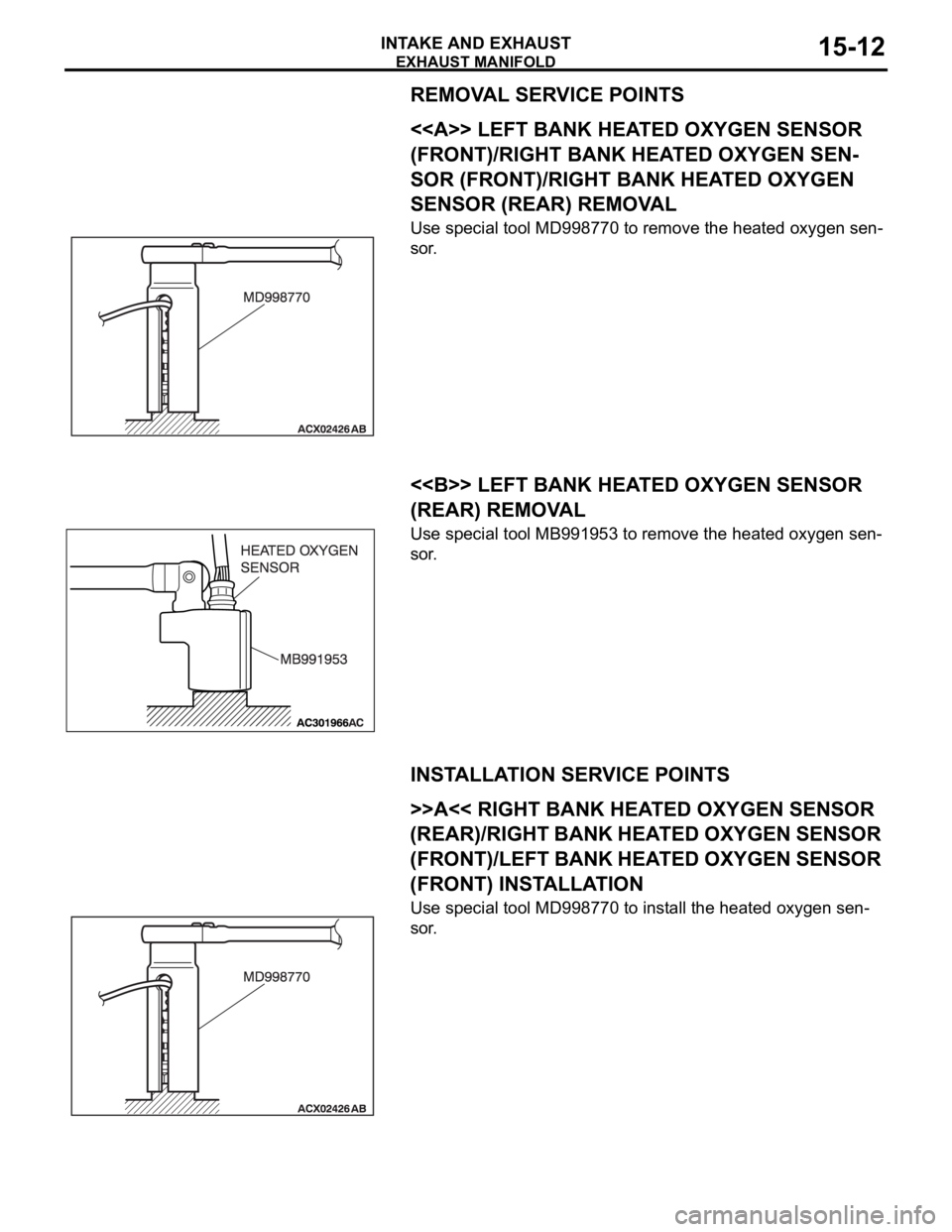

REMOVAL SERVICE POINTS

.

<> LEFT BANK HEATED OXYGEN SENSOR

(FRONT)/RIGHT BANK HEATED OXYGEN SEN-

SOR (FRONT)/RIGHT BANK HEATED OXYGEN

SENSOR (REAR) REMOVAL

Use special tool MD998770 to remove the heated oxygen sen-

sor.

.

<> LEFT BANK HEATED OXYGEN SENSOR

(REAR) REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

INSTALLATION SERVICE POINTS

.

>>A<< RIGHT BANK HEATED OXYGEN SENSOR

(REAR)/RIGHT BANK HEATED OXYGEN SENSOR

(FRONT)/LEFT BANK HEATED OXYGEN SENSOR

(FRONT) INSTALLATION

Use special tool MD998770 to install the heated oxygen sen-

sor.

.

Page 972 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-13

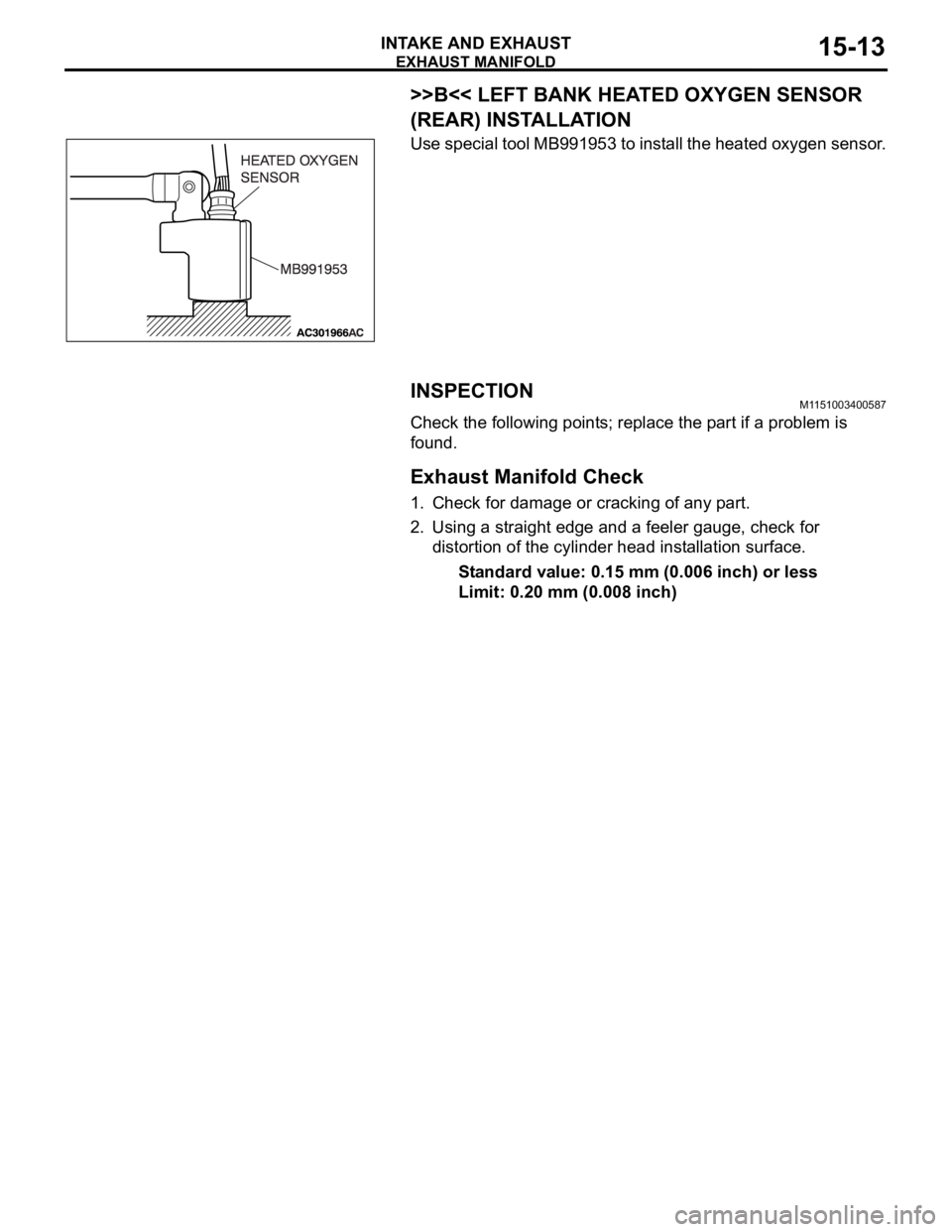

>>B<< LEFT BANK HEATED OXYGEN SENSOR

(REAR) INSTALLATION

Use special tool MB991953 to install the heated oxygen sensor.

INSPECTIONM1151003400587

Check the following points; replace the part if a problem is

found.

.

Exhaust Manifold Check

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 973 of 1500

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-14

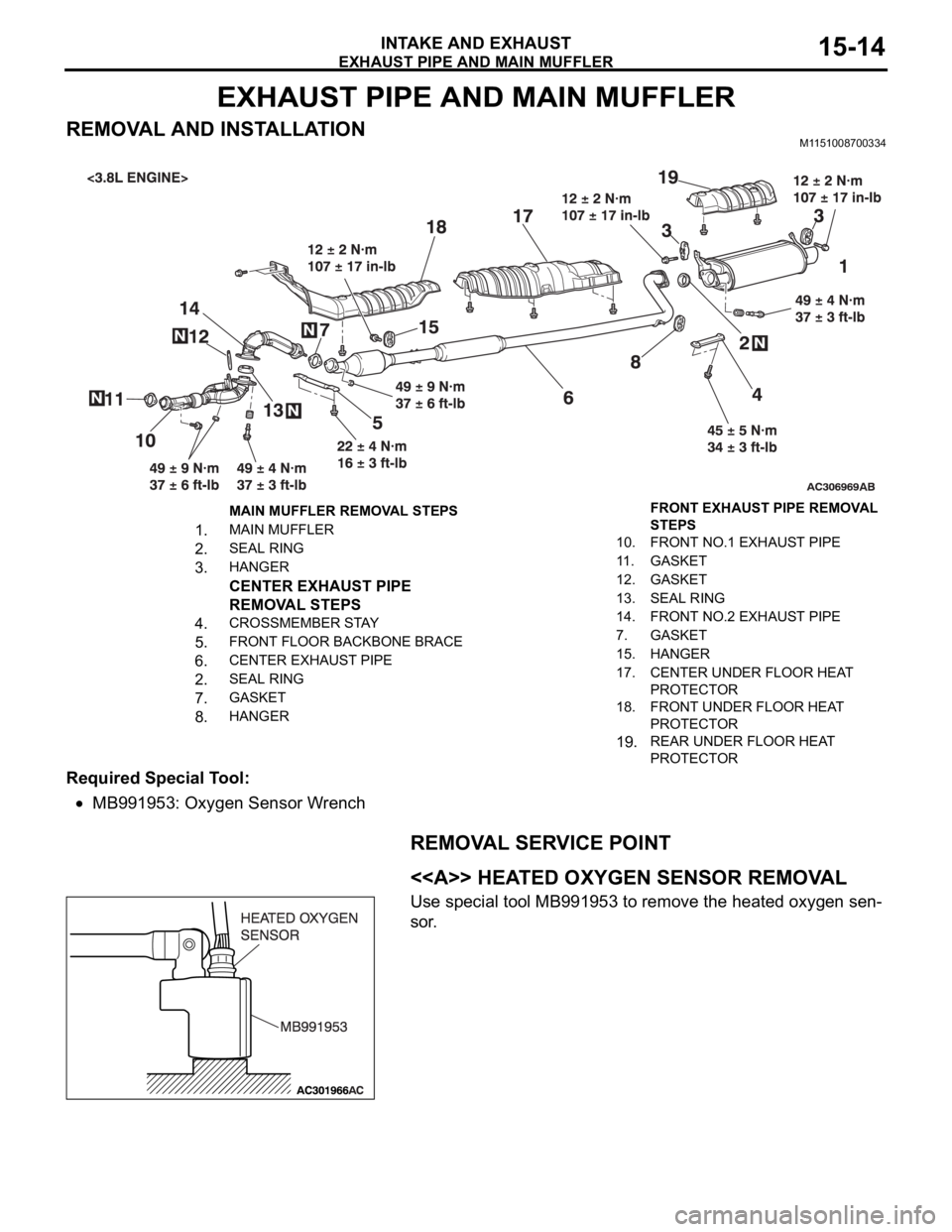

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATIONM1151008700334

Required Special Tool:

MB991953: Oxygen Sensor Wrench

REMOVAL SERVICE POINT

.

<> HEATED OXYGEN SENSOR REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

MAIN MUFFLER REMOVAL STEPS

1.MAIN MUFFLER

2.SEAL RING

3.HANGER

CENTER EXHAUST PIPE

REMOVAL STEPS

4.

CROSSMEMBER STAY

5.FRONT FLOOR BACKBONE BRACE

6.CENTER EXHAUST PIPE

2.SEAL RING

7.GASKET

8.HANGERFRONT EXHAUST PIPE REMOVAL

STEPS

10. FRONT NO.1 EXHAUST PIPE

11. GASKET

12. GASKET

13. SEAL RING

14. FRONT NO.2 EXHAUST PIPE

7. GASKET

15. HANGER

17. CENTER UNDER FLOOR HEAT

PROTECTOR

18. FRONT UNDER FLOOR HEAT

PROTECTOR

19.REAR UNDER FLOOR HEAT

PROTECTOR