wheel MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1320 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-41

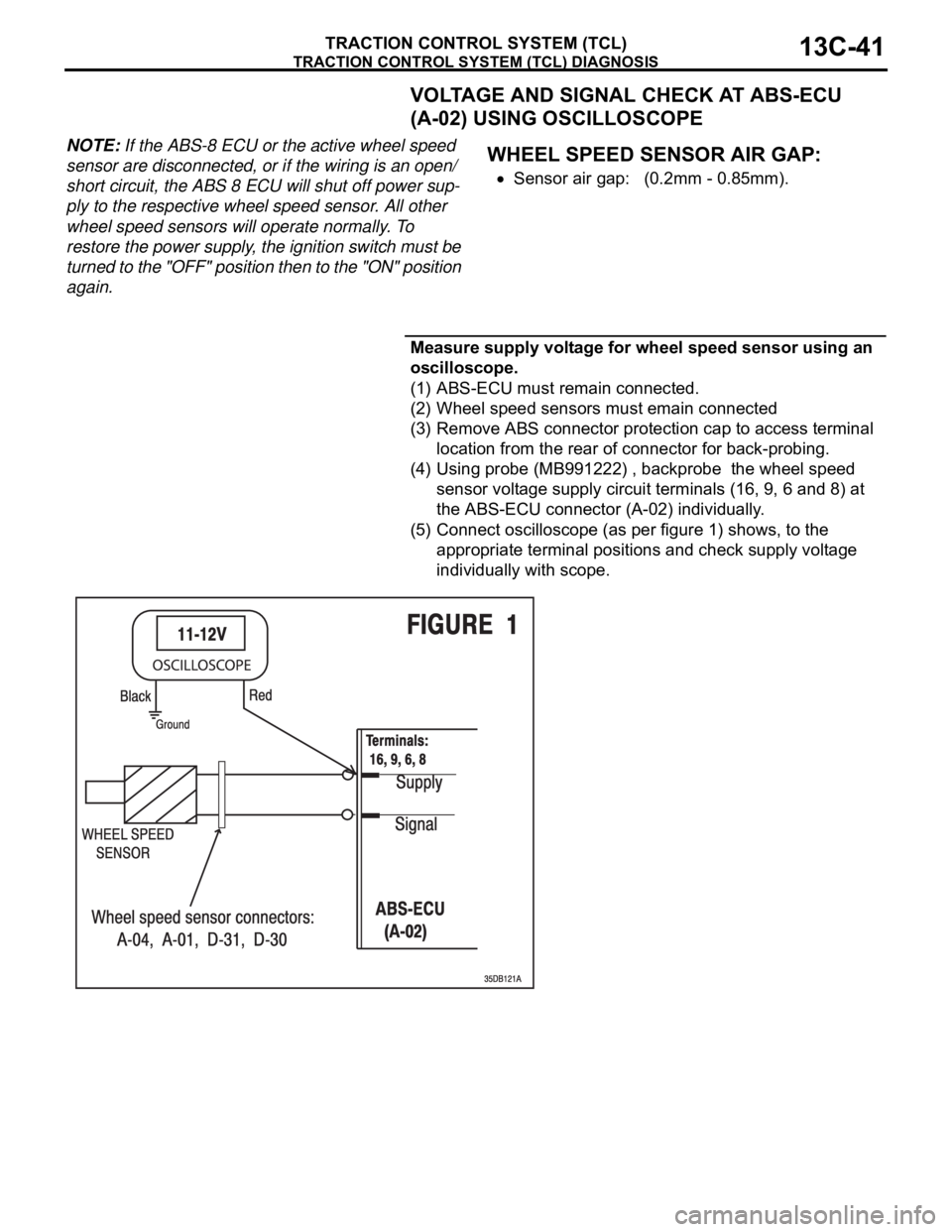

VOLTAGE AND SIGNAL CHECK AT ABS-ECU

(A-02) USING OSCILLOSCOPE

NOTE: If the ABS-8 ECU or the active wheel speed

sensor are disconnected, or if the wiring is an open/

short circuit, the ABS 8 ECU will shut off power sup-

ply to the respective wheel speed sensor. All other

wheel speed sensors will operate normally. To

restore the power supply, the ignition switch must be

turned to the "OFF" position then to the "ON" position

again..

WHEEL SPEED SENSOR AIR GAP:

Sensor air gap: (0.2mm - 0.85mm).

.

Measure supply voltage for wheel speed sensor using an

oscilloscope.

(1) ABS-ECU must remain connected.

(2) Wheel speed sensors must emain connected

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222) , backprobe the wheel speed

sensor voltage supply circuit terminals (16, 9, 6 and 8) at

the ABS-ECU connector (A-02) individually.

(5) Connect oscilloscope (as per figure 1) shows, to the

appropriate terminal positions and check supply voltage

individually with scope.

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

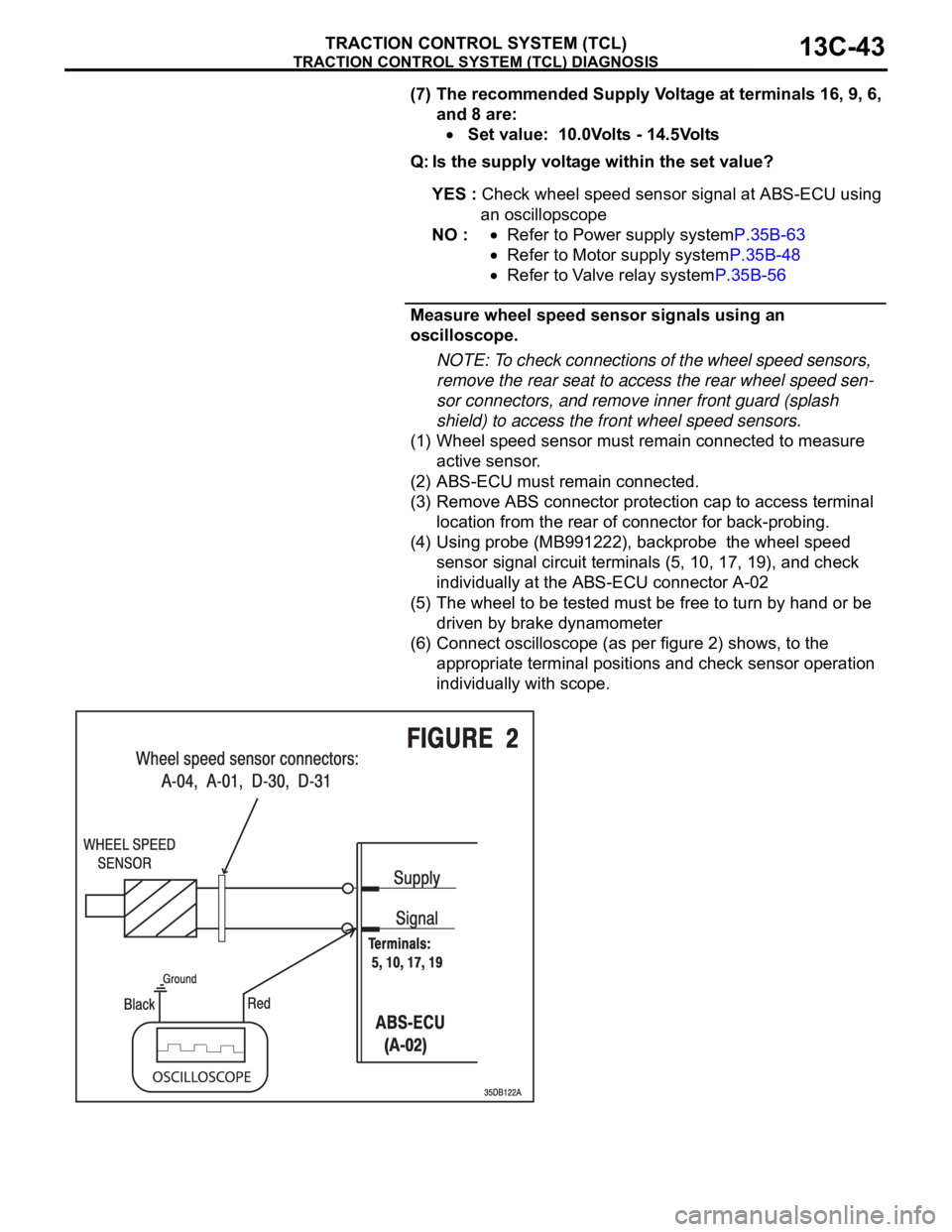

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1323 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-44

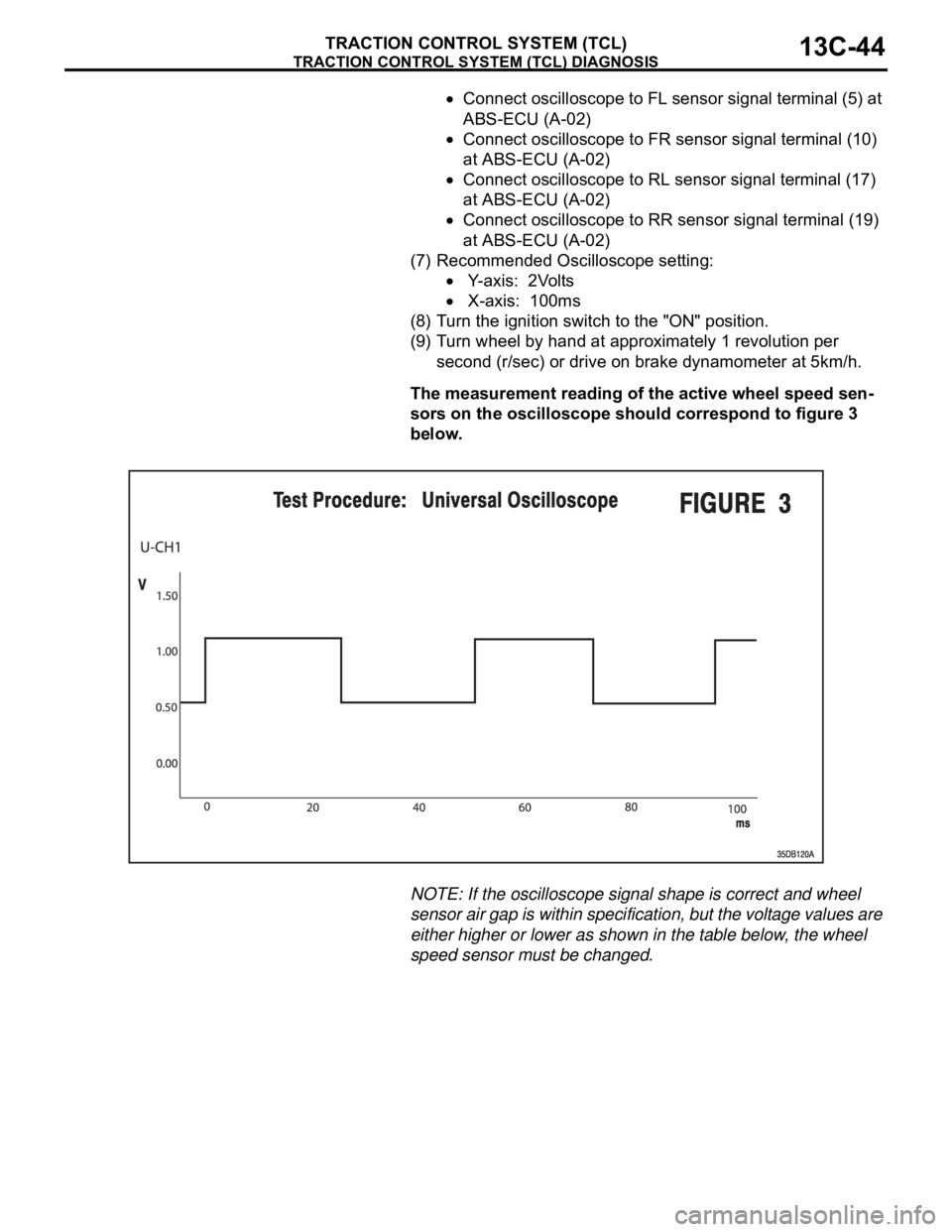

Connect oscilloscope to FL sensor signal terminal (5) at

ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (10)

at ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (17)

at ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (19)

at ABS-ECU (A-02)

(7) Recommended Oscilloscope setting:

Y-axis: 2Volts

X-axis: 100ms

(8) Turn the ignition switch to the "ON" position.

(9) Turn wheel by hand at approximately 1 revolution per

second (r/sec) or drive on brake dynamometer at 5km/h.

The measurement reading of the active wheel speed sen-

sors on the oscilloscope should correspond to figure 3

below.

NOTE: If the oscilloscope signal shape is correct and wheel

sensor air gap is within specification, but the voltage values are

either higher or lower as shown in the table below, the wheel

speed sensor must be changed.

Page 1327 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-48

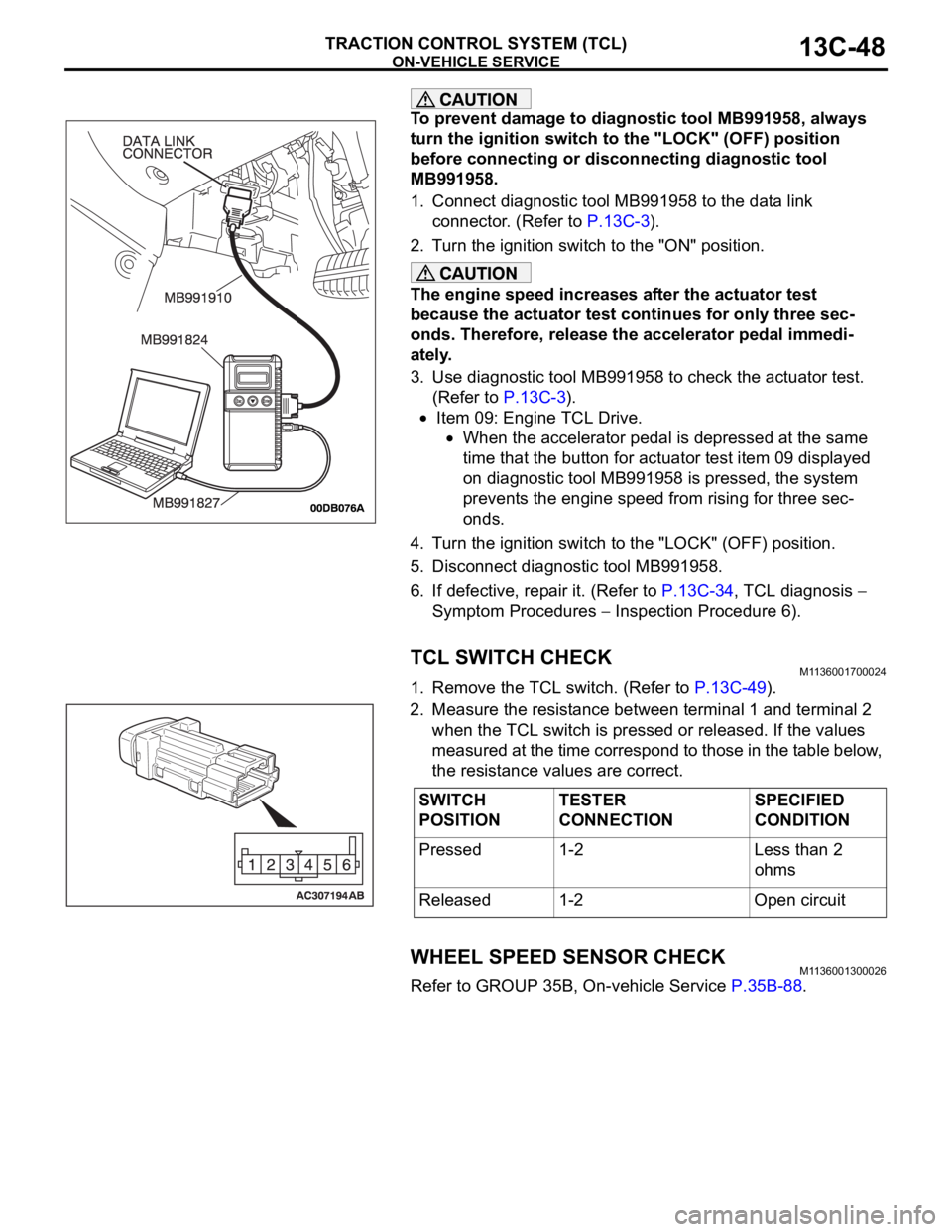

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

2. Turn the ignition switch to the "ON" position.

The engine speed increases after the actuator test

because the actuator test continues for only three sec-

onds. Therefore, release the accelerator pedal immedi-

ately.

3. Use diagnostic tool MB991958 to check the actuator test.

(Refer to P.13C-3).

Item 09: Engine TCL Drive.

When the accelerator pedal is depressed at the same

time that the button for actuator test item 09 displayed

on diagnostic tool MB991958 is pressed, the system

prevents the engine speed from rising for three sec-

onds.

4. Turn the ignition switch to the "LOCK" (OFF) position.

5. Disconnect diagnostic tool MB991958.

6. If defective, repair it. (Refer to P.13C-34, TCL diagnosis

Symptom Procedures

Inspection Procedure 6).

TCL SWITCH CHECKM1136001700024

1. Remove the TCL switch. (Refer to P.13C-49).

2. Measure the resistance between terminal 1 and terminal 2

when the TCL switch is pressed or released. If the values

measured at the time correspond to those in the table below,

the resistance values are correct.

WHEEL SPEED SENSOR CHECKM1136001300026

Refer to GROUP 35B, On-vehicle Service P.35B-88.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

Pressed 1-2 Less than 2

ohms

Released 1-2 Open circuit

Page 1328 of 1500

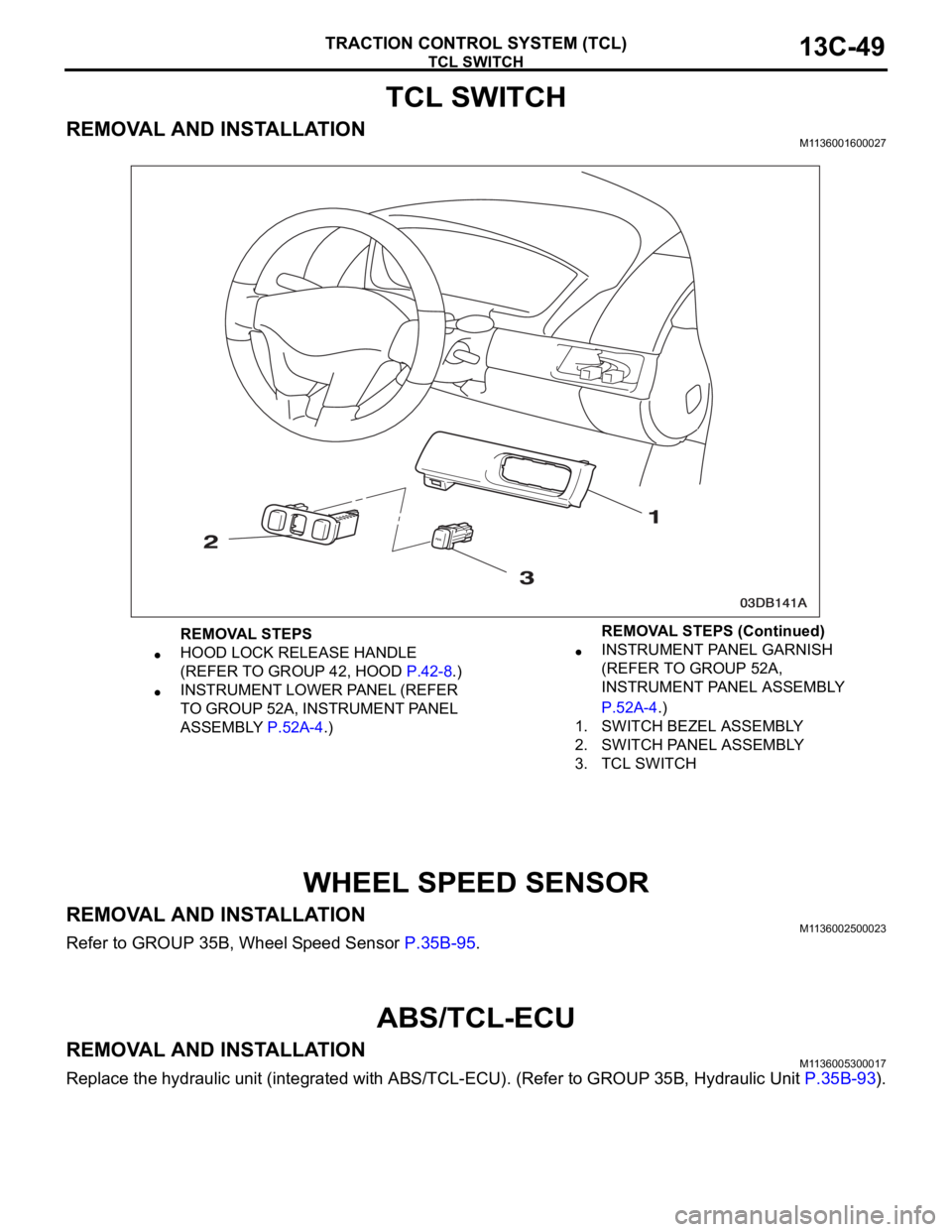

TCL SWITCH

TRACTION CONTROL SYSTEM (TCL)13C-49

TCL SWITCH

REMOVAL AND INSTALLATIONM1136001600027

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATIONM1136002500023

Refer to GROUP 35B, Wheel Speed Sensor P.35B-95.

ABS/TCL-ECU

REMOVAL AND INSTALLATIONM1136005300017

Replace the hydraulic unit (integrated with ABS/TCL-ECU). (Refer to GROUP 35B, Hydraulic Unit P.35B-93).

REMOVAL STEPS

HOOD LOCK RELEASE HANDLE

(REFER TO GROUP 42, HOOD P.42-8.)

INSTRUMENT LOWER PANEL (REFER

TO GROUP 52A, INSTRUMENT PANEL

ASSEMBLY P.52A-4.)

INSTRUMENT PANEL GARNISH

(REFER TO GROUP 52A,

INSTRUMENT PANEL ASSEMBLY

P.52A-4.)

1. SWITCH BEZEL ASSEMBLY

2. SWITCH PANEL ASSEMBLY

3. TCL SWITCH REMOVAL STEPS (Continued)

Page 1406 of 1500

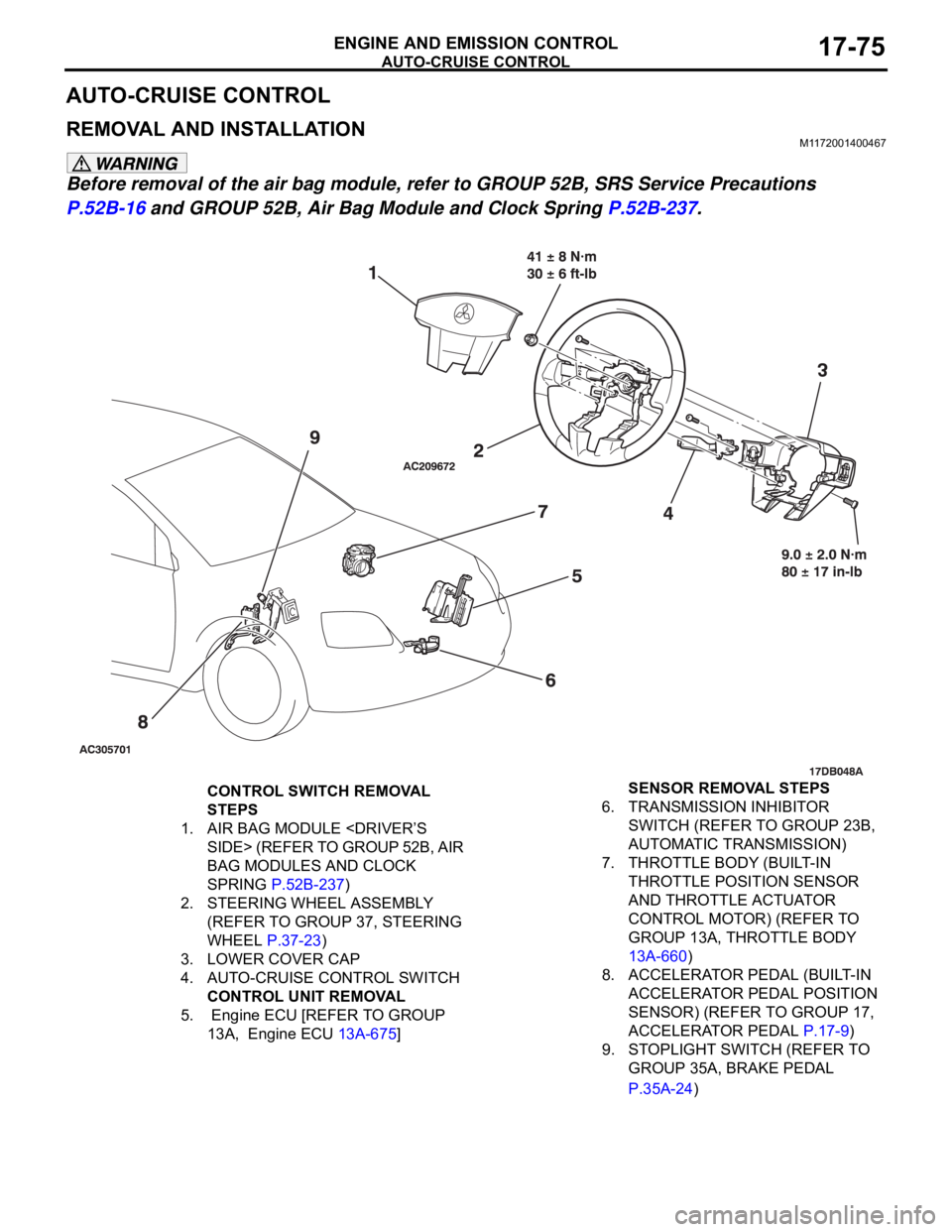

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

Page 1416 of 1500

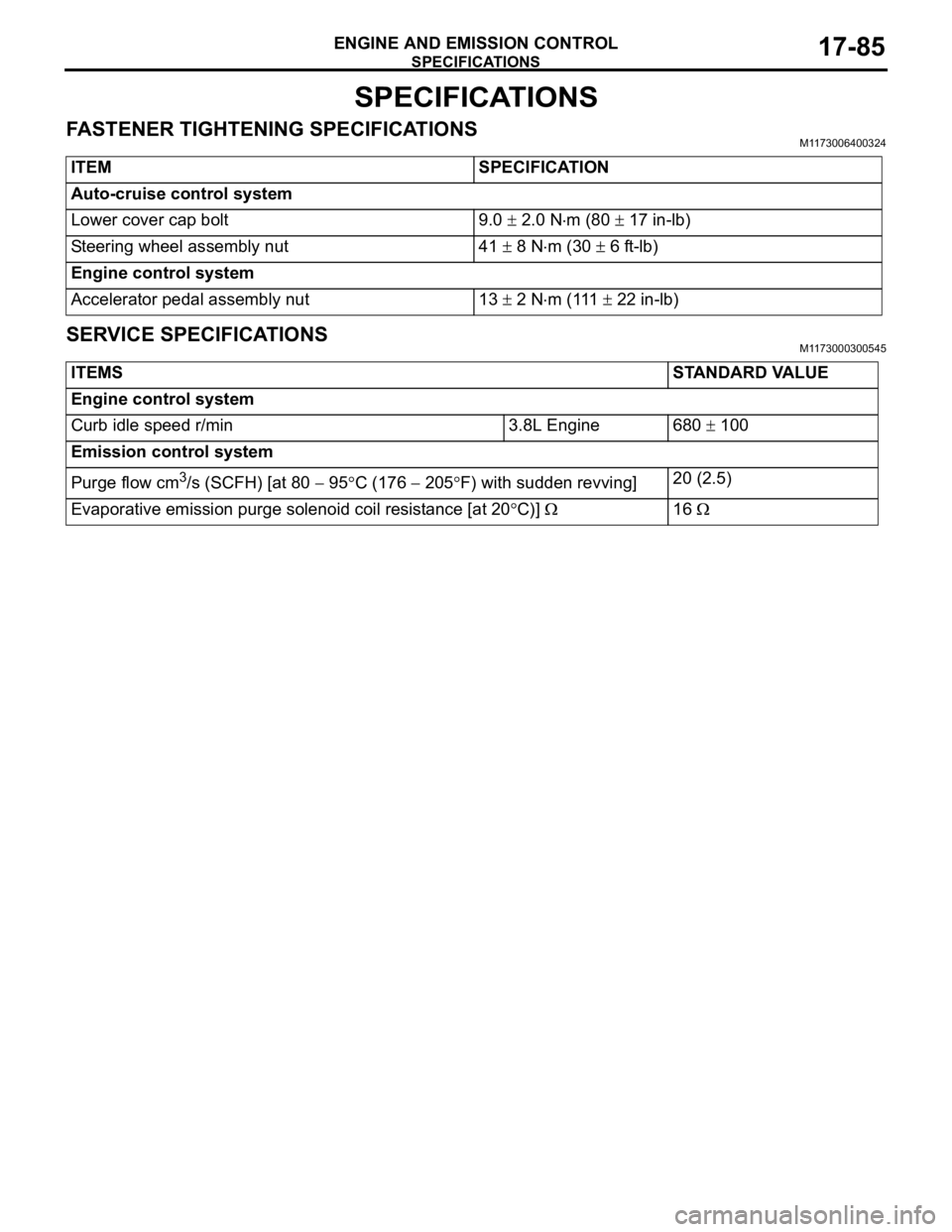

SPECIFICATIONS

ENGINE AND EMISSION CONTROL17-85

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1173006400324

SERVICE SPECIFICATIONSM1173000300545

ITEM SPECIFICATION

Auto-cruise control system

Lower cover cap bolt 9.0

2.0 Nm (80 17 in-lb)

Steering wheel assembly nut 41

8 Nm (30 6 ft-lb)

Engine control system

Accelerator pedal assembly nut 13

2 Nm ( 111 22 in-lb)

ITEMSSTANDARD VALUE

Engine control system

Curb idle speed r/min 3.8L Engine 680

100

Emission control system

Purge flow cm

3/s (SCFH) [at 80 95C (176 205F) with sudden revving]20 (2.5)

Evaporative emission purge solenoid coil resistance [at 20

C)] 16

Page 1418 of 1500

26-1

GROUP 26

FRONT AXLE

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .26-2

FRONT AXLE DIAGNOSIS . . . . . . . .26-2

TROUBLESHOOTING STRATEGY . . . . . . 26-2

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 26-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 26-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .26-4

ON-VEHICLE SERVICE . . . . . . . . . . .26-8

WHEEL BEARING END PLAY CHECK . . . 26-8

HUB BOLT REPLACEMENT . . . . . . . . . . . 26-8

FRONT AXLE HUB ASSEMBLY . . . .26-9

REMOVAL AND INSTALLATION . . . . . . . . 26-9

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-12

DRIVE SHAFT ASSEMBLY . . . . . . . .26-13

REMOVAL AND INSTALLATION . . . . . . . . 26-13

DISASSEMBLY AND ASSEMBLY . . . . . . . 26-18

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-25

BJ BOOT REPLACEMENT . . . . . . . . . . . . . 26-26

SPECIFICATIONS . . . . . . . . . . . . . . .26-29

FASTENER TIGHTENING SPECIFICATIONS26-29

GENERAL SPECIFICATIONS . . . . . . . . . . 26-29

SERVICE SPECIFICATIONS . . . . . . . . . . . 26-29

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . 26-30

Page 1419 of 1500

GENERAL DESCRIPTION

FRONT AXLE26-2

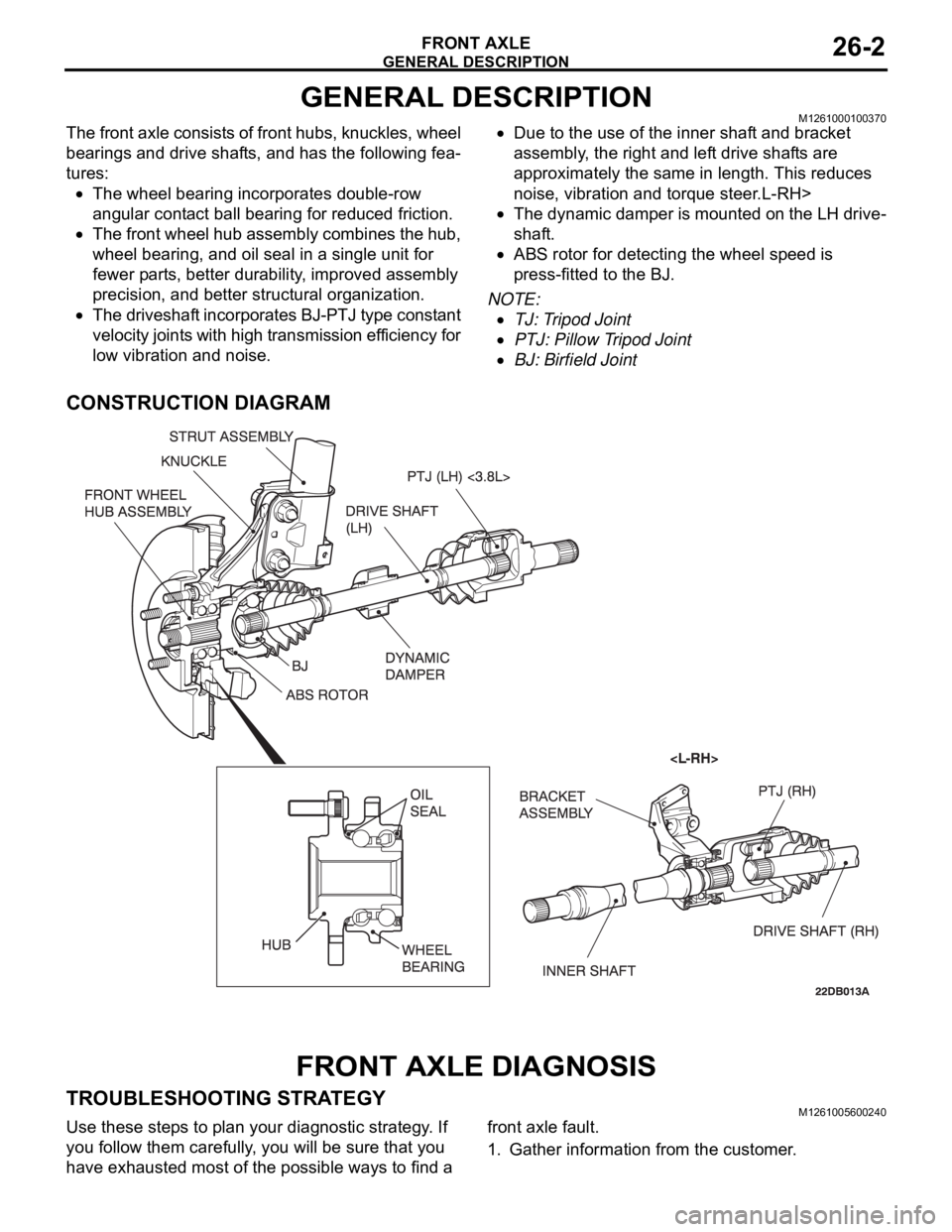

GENERAL DESCRIPTIONM1261000100370

The front axle consists of front hubs, knuckles, wheel

bearings and drive shafts, and has the following fea-

tures:

The wheel bearing incorporates double-row

angular contact ball bearing for reduced friction.

The front wheel hub assembly combines the hub,

wheel bearing, and oil seal in a single unit for

fewer parts, better durability, improved assembly

precision, and better structural organization.

The driveshaft incorporates BJ-PTJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

Due to the use of the inner shaft and bracket

assembly, the right and left drive shafts are

approximately the same in length. This reduces

noise, vibration and torque steer.L-RH>

The dynamic damper is mounted on the LH drive-

shaft.

ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

TJ: Tripod Joint

PTJ: Pillow Tripod Joint

BJ: Birfield Joint

CONSTRUCTION DIAGRAM

FRONT AXLE DIAGNOSIS

TROUBLESHOOTING STRATEGYM1261005600240

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a front axle fault.

1. Gather information from the customer.

Page 1420 of 1500

FRONT AXLE DIAGNOSIS

FRONT AXLE26-3

2. Verify that the condition described by the

customer exists.3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1261005700269

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Noise during Wheel Rotation

DIAGNOSIS

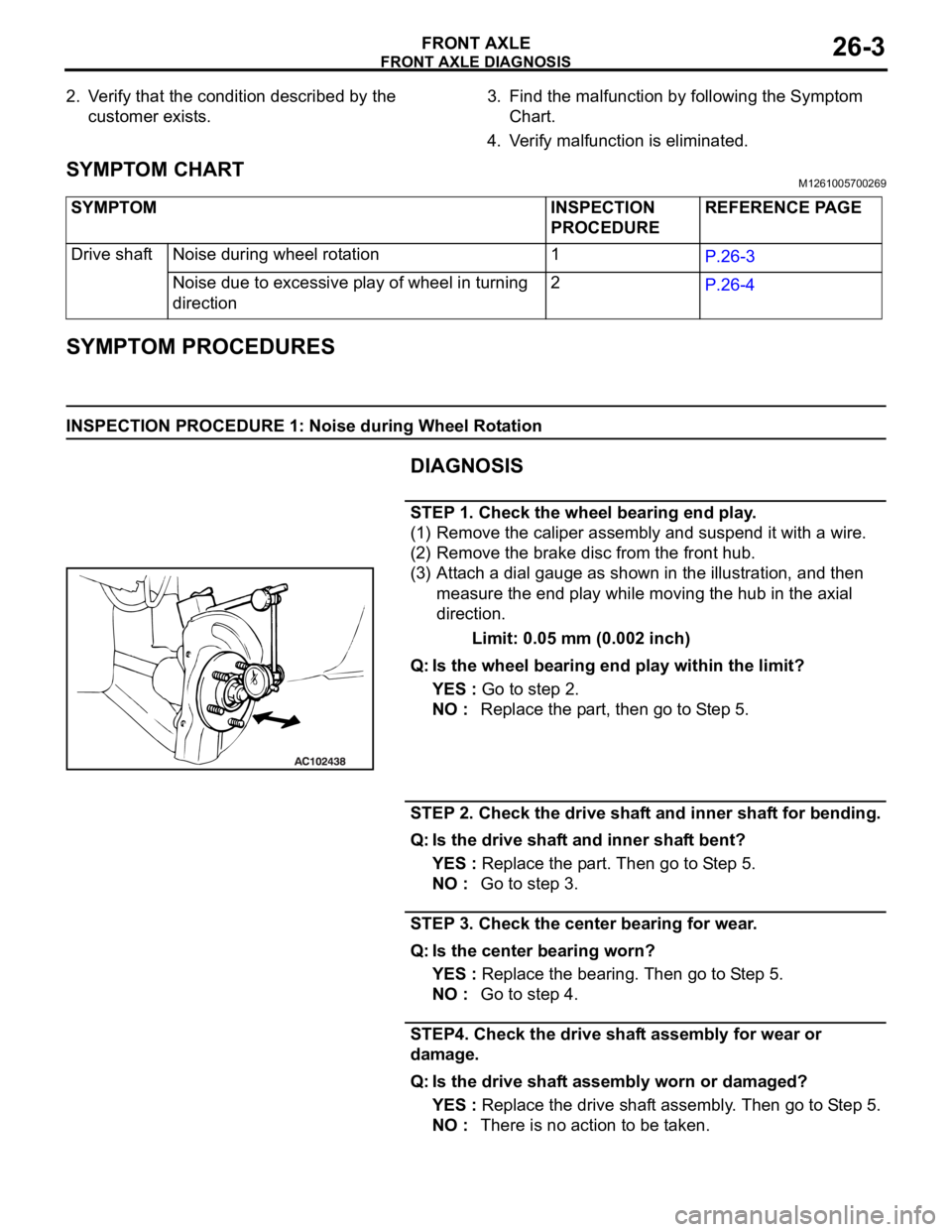

STEP 1. Check the wheel bearing end play.

(1) Remove the caliper assembly and suspend it with a wire.

(2) Remove the brake disc from the front hub.

(3) Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the axial

direction.

Limit: 0.05 mm (0.002 inch)

Q: Is the wheel bearing end play within the limit?

YES : Go to step 2.

NO : Replace the part, then go to Step 5.

STEP 2. Check the drive shaft and inner shaft for bending.

Q: Is the drive shaft and inner shaft bent?

YES : Replace the part. Then go to Step 5.

NO : Go to step 3.

STEP 3. Check the center bearing for wear.

Q: Is the center bearing worn?

YES : Replace the bearing. Then go to Step 5.

NO : Go to step 4.

STEP4. Check the drive shaft assembly for wear or

damage.

Q: Is the drive shaft assembly worn or damaged?

YES : Replace the drive shaft assembly. Then go to Step 5.

NO : There is no action to be taken. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Drive shaft Noise during wheel rotation 1

P.26-3

Noise due to excessive play of wheel in turning

direction2

P.26-4