Speed warning light MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 5 of 1500

GENERAL DESCRIPTION

SIMPLIFIED WIRING SYSTEM (SWS)54B-5

INTERMITTENT CONTROL

ETACS-ECU uses the dial position of the variable

intermittent wiper control switch and the vehicle

speed signal sent by the combination meter to calcu-

late the interval to be sent to the front-ECU. The

front-ECU determines the intermittent time from the

input SWS data signal, and turns ON the windshield

wiper drive signal. When the wiper is at the STOP

position, the windshield wiper auto-stop signal goes

OFF to turn OFF the windshield wiper drive signal.

After the intermittent time from when the windshield

wiper drive signal turned ON, the windshield wiper

drive signal is turned ON again and the above opera-

tion is repeated.

.

MIST WIPER CONTROL

When the ignition switch is in the ACC or ON posi-

tion, and the windshield mist wiper switch of the col-

umn switch is turned ON, the front-ECU turns ON the

windshield wiper drive signal. At the same time, the

wiper speed switching relay is turned ON

(HIGH-SPEED). While the windshield mist wiper

switch is ON, the windshield wiper will operate at

high speed. Then, if the windshield mist wiper switch

is turned off, the wiper operates at low speed until it

stops at the predetermined park position.

When the windshield mist switch is turned on briefly,

the wiper operates once at low speed.

At the point the windshield mist switch is turned ON,

if the windshield wiper has been operating intermit-

tently, the same operations as the above will be per-

formed while the windshield mist wiper switch is ON.

After the windshield mist wiper switch goes OFF, the

intermittent operations will be set again after the

windshield wiper auto-stop signal last is turned ON.

.

WASHER CONTROL

When the ignition switch is in the ACC or ON posi-

tion, and the windshield washer switch of the column

switch is turned ON, the front-ECU turns ON the

windshield washer relay. The windshield wiper drive

signal is turned ON in 0.15 seconds until 2 seconds

after the windshield washer switch goes OFF to

operate the windshield wiper continuously. When the

windshield washer switch is turned ON, if the wind-

shield wiper is operating intermittently, intermittent

operations will be continued after continuous opera-

tions.

HEADLAMP

.

HEADLAMP AUTOMATIC SHUTDOWN

FUNCTION

Even if the lighting switch (tail lamp switch or

headlamp switch) is ON, the headlamps and tail

lamps will automatically go off in the following condi-

tions to prevent the battery from discharging:

When the ignition key is turned from "ON" to "LOCK"

(OFF) or "ACC" position with the lighting switch

turned ON, and this state continues for three min-

utes, the lamp will automatically be turned off. If the

driver's seat door is opened during these three min-

utes, the lamp will go off one second later.

.

HIGH-BEAM INDICATOR

At the same time that the high beams are illumi-

nated, the ETACS-ECU sends a signal to illuminate

the high-beam indicator via the CAN bus line. The

combination meter receives the transmitted signal

and turns the high-beam indicator on and off.

FLASHER TIMER

.

TURN-SIGNAL LAMP

The turn-signal lamp output (flashing signal) is

turned ON when the ignition switch is ON and the

turn-signal lamp switch is ON (LH or RH). If the front

turn-signal lamp or rear turn-signal lamp bulb has

burned out, the flashing speed increases to indicate

that the bulb has burned out.

.

HAZARD WARNING LAMP

Detects the signal where the hazard warning lamp

switch input changes from OFF to ON, and reverse

the flashing state according to this signal. The haz-

ard warning lamps toggle on and off whenever the

hazard warning lamp switch is operated.

.

TURN-SIGNAL INDICATORS

At the same time that the turn-signal lamps are illu-

minated, the ETACS-ECU sends a signal to illumi-

nate the turn-signal lamp indicator via the CAN bus

line. The combination meter receives the transmitted

signal and turns the turn-signal lamp indicator on and

off.

Page 398 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-398

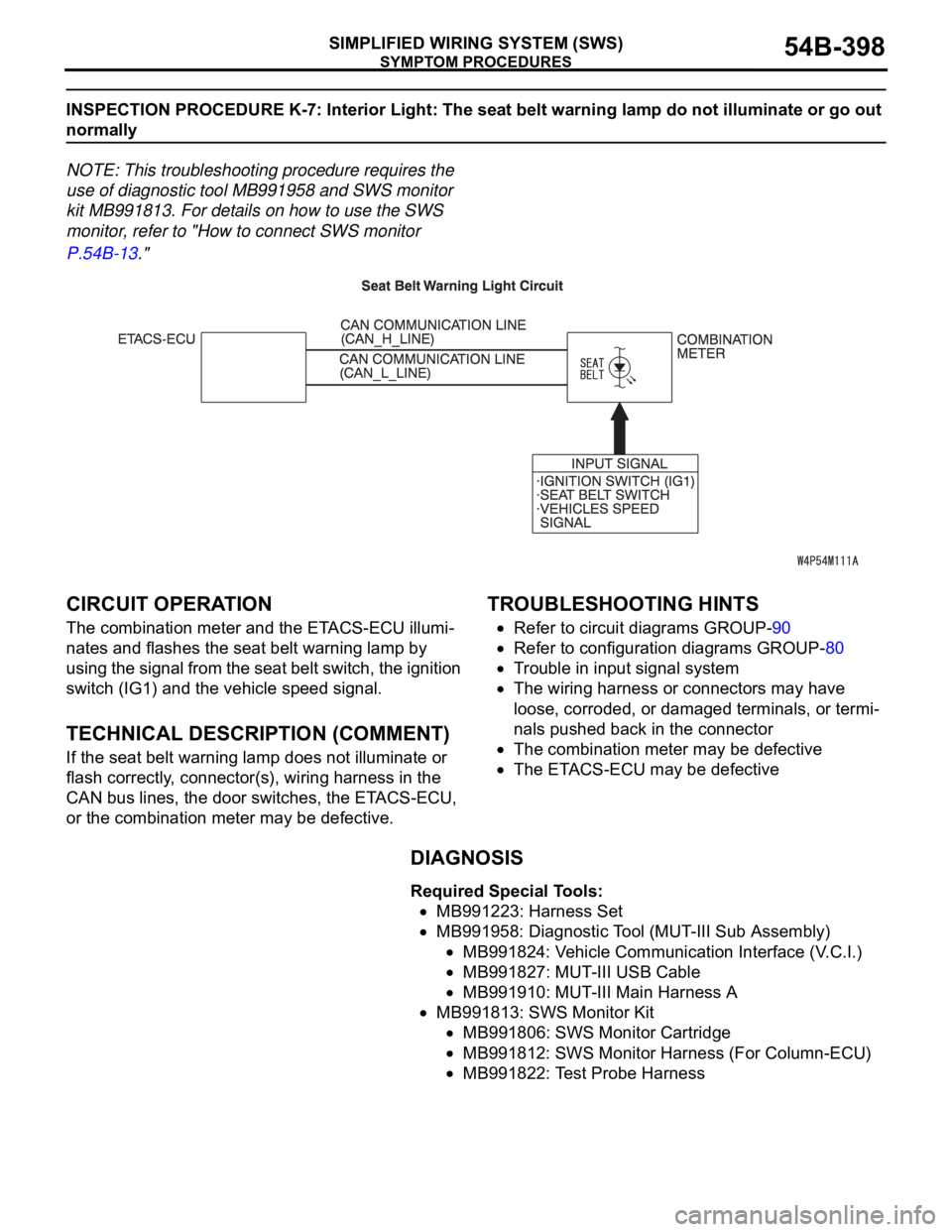

INSPECTION PROCEDURE K-7: Interior Light: The seat belt warning lamp do not illuminate or go out

normally

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The combination meter and the ETACS-ECU illumi-

nates and flashes the seat belt warning lamp by

using the signal from the seat belt switch, the ignition

switch (IG1) and the vehicle speed signal.

.

TECHNICAL DESCRIPTION (COMMENT)

If the seat belt warning lamp does not illuminate or

flash correctly, connector(s), wiring harness in the

CAN bus lines, the door switches, the ETACS-ECU,

or the combination meter may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The combination meter may be defective

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

Page 1472 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-13

A/T DIAGNOSTIC TROUBLESHOOTING STRATEGYM1231007600339

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will find most A/T mal-

functions.

1. Gather as much information as possible about the

complaint from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any A/T Diagnostic Trouble

Codes (DTCs).

4. If you can not verify the condition and there are no

DTCs, the malfunction is intermittent. For

information on how to cope with intermittent

malfunctions, refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunction P.00-14.

5. If you can verify the condition but there are no

DTCs, or the system can not communicate with

diagnostic tool, refer to the Symptom Chart

P.23A-35.6. If there is a DTC, record the number of the code,

then erase the code from memory using

diagnostic tool.

7. Reconfirm the symptom with a Road Test.

8. If a DTC is set again, go to the Inspection Chart

for Diagnostic Trouble Codes.

9. If a DTC is not set again, the malfunction is

intermittent. For information on how to cope with

intermittent malfunctions, refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

How to Cope with Intermittent

Malfunction P.00-14.

10.After repairs are completed, conduct a Road Test

duplicating the complaint conditions to confirm the

malfunction has been eliminated.

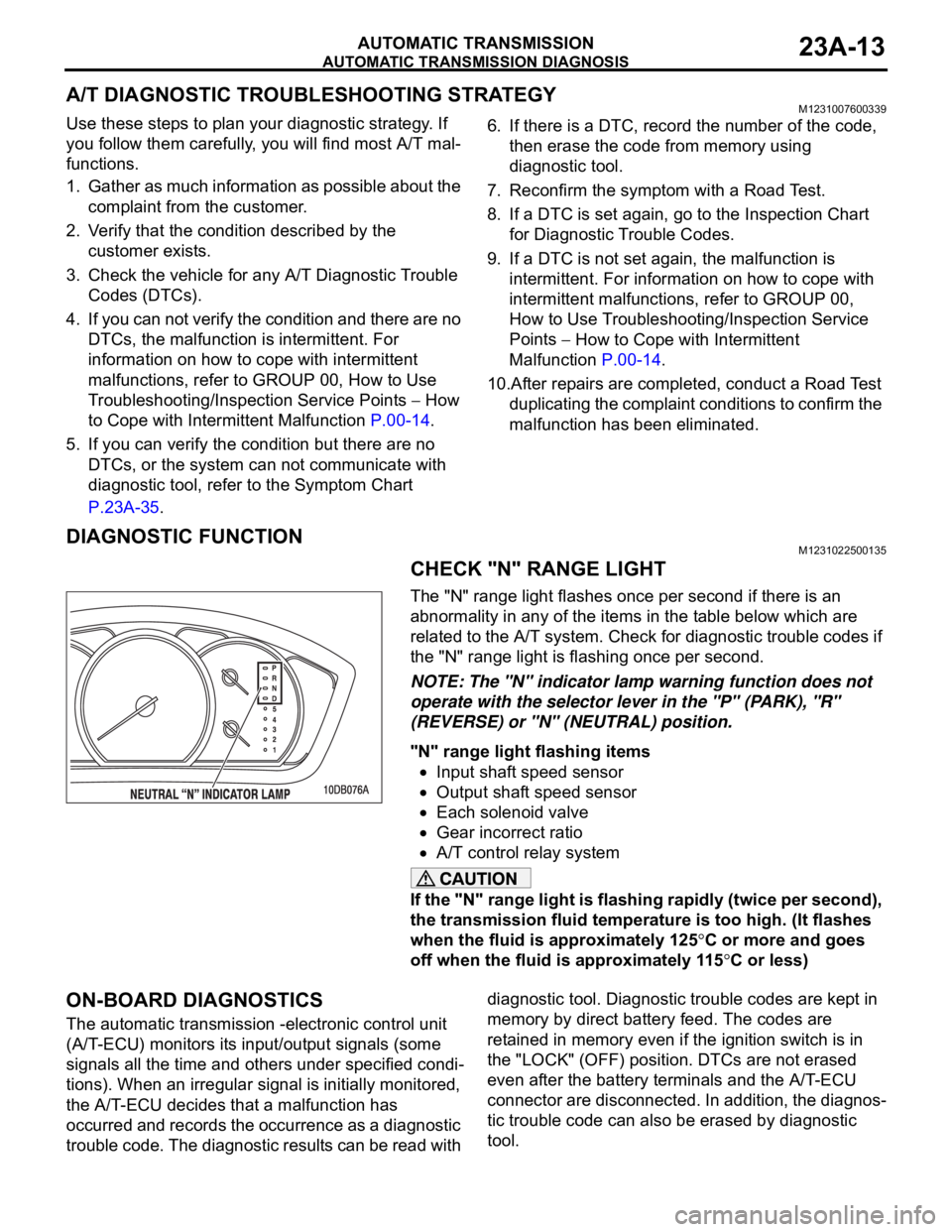

DIAGNOSTIC FUNCTIONM1231022500135

CHECK "N" RANGE LIGHT

The "N" range light flashes once per second if there is an

abnormality in any of the items in the table below which are

related to the A/T system. Check for diagnostic trouble codes if

the "N" range light is flashing once per second.

NOTE: The "N" indicator lamp warning function does not

operate with the selector lever in the "P" (PARK), "R"

(REVERSE) or "N" (NEUTRAL) position.

"N" range light flashing items

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Gear incorrect ratio

A/T control relay system

If the "N" range light is flashing rapidly (twice per second),

the transmission fluid temperature is too high. (It flashes

when the fluid is approximately 125

C or more and goes

off when the fluid is approximately 115

C or less)

ON-BOARD DIAGNOSTICS

The automatic transmission -electronic control unit

(A/T-ECU) monitors its input/output signals (some

signals all the time and others under specified condi-

tions). When an irregular signal is initially monitored,

the A/T-ECU decides that a malfunction has

occurred and records the occurrence as a diagnostic

trouble code. The diagnostic results can be read with diagnostic tool. Diagnostic trouble codes are kept in

memory by direct battery feed. The codes are

retained in memory even if the ignition switch is in

the "LOCK" (OFF) position. DTCs are not erased

even after the battery terminals and the A/T-ECU

connector are disconnected. In addition, the diagnos-

tic trouble code can also be erased by diagnostic

tool.