battery location MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 822 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-121

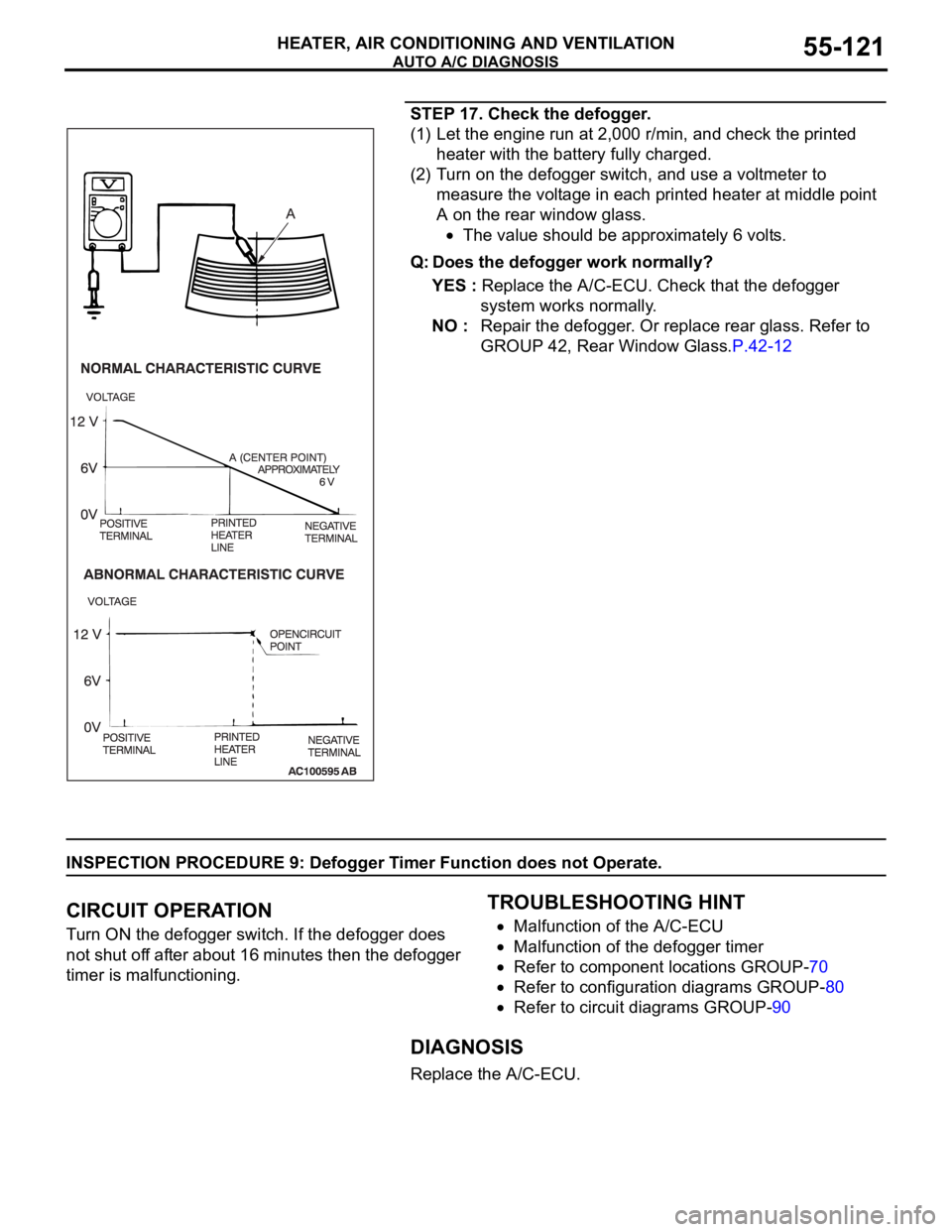

STEP 17. Check the defogger.

(1) Let the engine run at 2,000 r/min, and check the printed

heater with the battery fully charged.

(2) Turn on the defogger switch, and use a voltmeter to

measure the voltage in each printed heater at middle point

A on the rear window glass.

The value should be approximately 6 volts.

Q: Does the defogger work normally?

YES : Replace the A/C-ECU. Check that the defogger

system works normally.

NO : Repair the defogger. Or replace rear glass. Refer to

GROUP 42, Rear Window Glass.P.42-12

INSPECTION PROCEDURE 9: Defogger Timer Function does not Operate.

.

CIRCUIT OPERATION

Turn ON the defogger switch. If the defogger does

not shut off after about 16 minutes then the defogger

timer is malfunctioning.

.

TROUBLESHOOTING HINT

Malfunction of the A/C-ECU

Malfunction of the defogger timer

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Replace the A/C-ECU.

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc

Page 1366 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-35

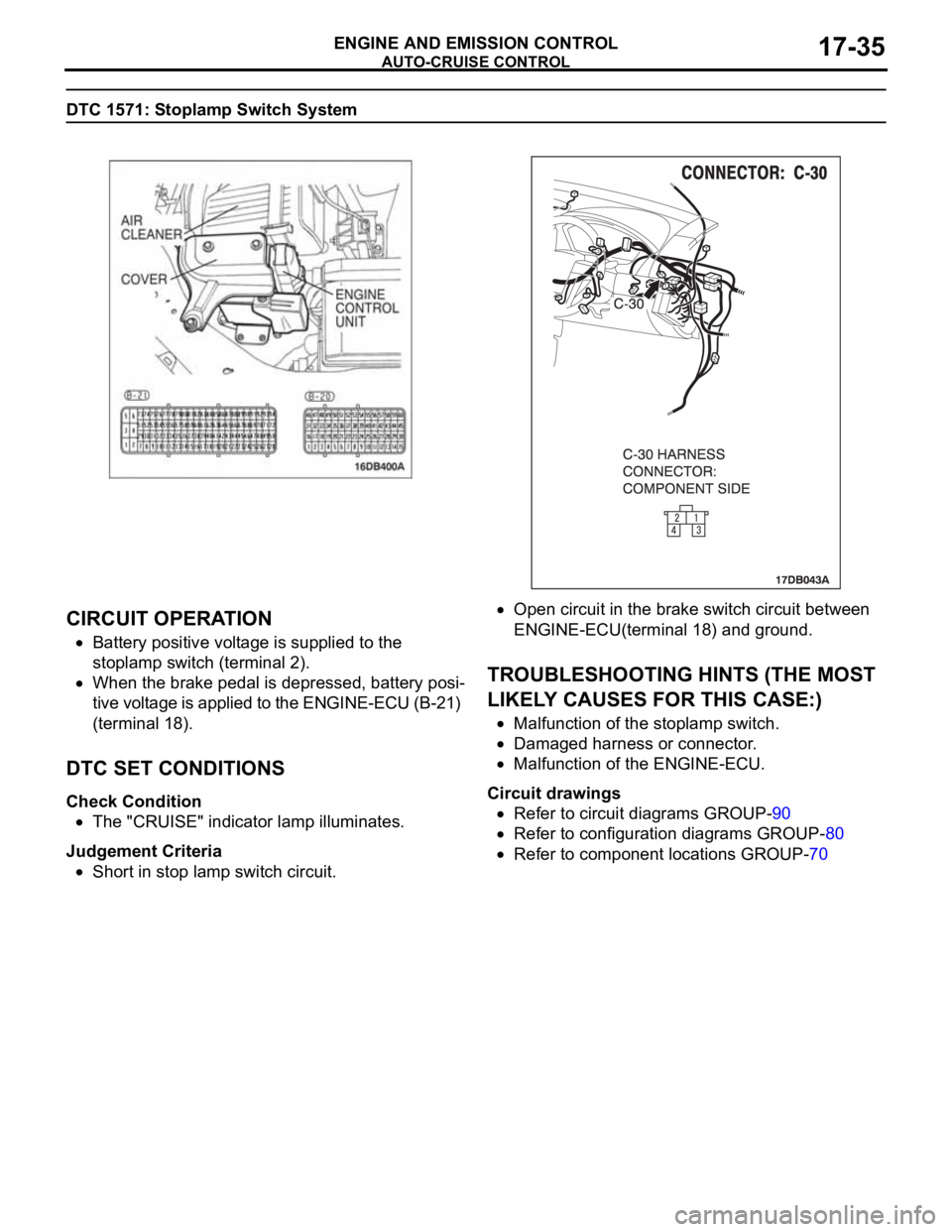

DTC 1571: Stoplamp Switch System

.

CIRCUIT OPERATION

Battery positive voltage is supplied to the

stoplamp switch (terminal 2).

When the brake pedal is depressed, battery posi-

tive voltage is applied to the ENGINE-ECU (B-21)

(terminal 18).

.

DTC SET CONDITIONS

Check Condition

The "CRUISE" indicator lamp illuminates.

Judgement Criteria

Short in stop lamp switch circuit.

Open circuit in the brake switch circuit between

ENGINE-ECU(terminal 18) and ground.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the stoplamp switch.

Damaged harness or connector.

Malfunction of the ENGINE-ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70