tow MITSUBISHI ASX 2009 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2009, Model line: ASX, Model: MITSUBISHI ASX 2009 1.GPages: 368, PDF Size: 8.13 MB

Page 201 of 368

NOTE

l The

buzzer may sound lower than the normal

warning sound when the reversing sensor sys-

tem is receiving ultrasonic noise from other

sources, but this is not a malfunction. The buz-

zer will stop sounding and the system will re-

turn to normal operation after the noise is no

longer received.

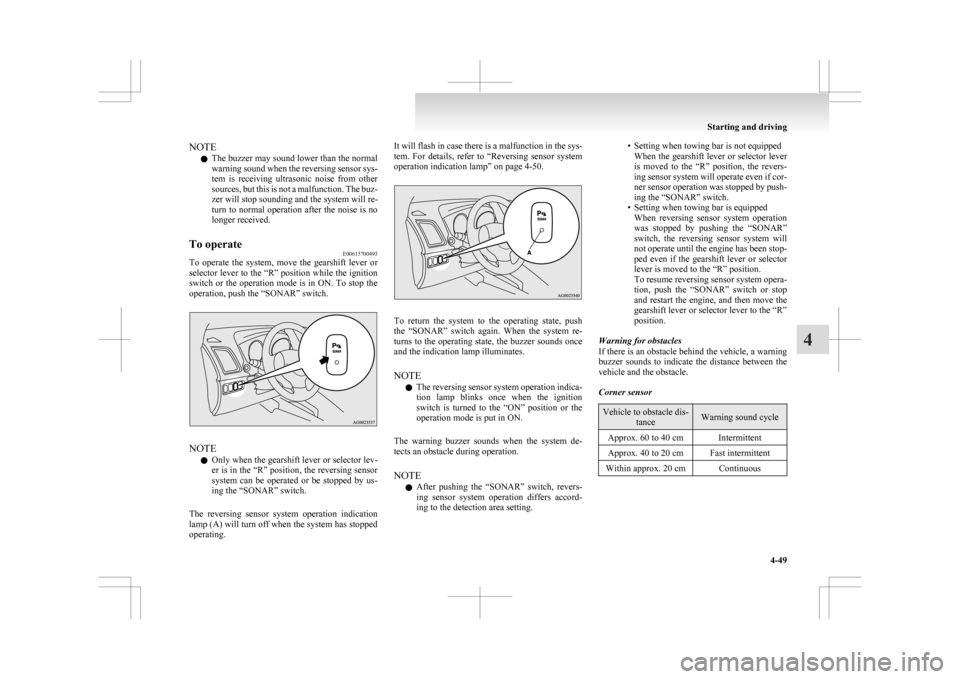

To operate E00615700493

To operate the system, move the gearshift lever or

selector

lever to the “R” position while the ignition

switch or the operation mode is in ON. To stop the

operation, push the “SONAR” switch. NOTE

l Only

when the gearshift lever or selector lev-

er is in the “R” position, the reversing sensor

system can be operated or be stopped by us-

ing the “SONAR” switch.

The reversing sensor system operation indication

lamp (A) will turn off when the system has stopped

operating. It will flash in case there is a malfunction in the sys-

tem.

For details, refer to “Reversing sensor system

operation indication lamp” on page 4-50. To return the system to the operating state, push

the

“SONAR” switch again. When the system re-

turns to the operating state, the buzzer sounds once

and the indication lamp illuminates.

NOTE

l The reversing sensor system operation indica-

tion lamp blinks once when the ignition

switch is turned to the “ON” position or the

operation mode is put in ON.

The warning buzzer sounds when the system de-

tects an obstacle during operation.

NOTE l After pushing the “SONAR” switch, revers-

ing sensor system operation differs accord-

ing to the detection area setting. • Setting when towing bar is not equipped

When

the gearshift lever or selector lever

is moved to the “R” position, the revers-

ing sensor system will operate even if cor-

ner sensor operation was stopped by push-

ing the “SONAR” switch.

• Setting when towing bar is equipped When reversing sensor system operation

was stopped by pushing the “SONAR”

switch, the reversing sensor system will

not operate until the engine has been stop-

ped even if the gearshift lever or selector

lever is moved to the “R” position.

To resume reversing sensor system opera-

tion, push the “SONAR” switch or stop

and restart the engine, and then move the

gearshift lever or selector lever to the “R”

position.

Warning for obstacles

If there is an obstacle behind the vehicle, a warning

buzzer sounds to indicate the distance between the

vehicle and the obstacle.

Corner sensor Vehicle to obstacle dis-

tance Warning sound cycle

Approx. 60 to 40 cm Intermittent

Approx. 40 to 20 cm Fast intermittent

Within approx. 20 cm Continuous Starting and driving

4-49 4

Page 202 of 368

Back sensor (vehicles without a towing bar)

Vehicle to obstacle dis-

tance Warning sound cycle

Approx. 150 to 80 cm Intermittent Approx. 80 to 40 cm Fast intermittent

Within approx. 40 cm Continuous Back sensor (vehicles with a towing bar)

Vehicle to obstacle dis-

tance Warning sound cycle

Approx. 150 to 100 cm Intermittent Approx. 100 to 60 cm Fast intermittentWithin approx. 60 cm Continuous CAUTION

l

The distances given are to be used for ref-

erence

only, as errors may be caused by

various factors, such as temperature, hu-

midity, or the shape of the obstacles.

Changing the detection areas E00615800045

The detection areas can be changed as follows:

Vehicles with a towing bar

While

the operation of the system is stopped at the

“SONAR” switch, push the “SONAR” switch ap-

proximately 3 seconds or more, and release it. The

buzzer sounds twice to indicate that the detection

area has been changed. Vehicles without a towing bar

While

the operation of the system is stopped at the

“SONAR” switch, push the “SONAR” switch ap-

proximately 3 seconds or more, and release it. The

buzzer sounds once to indicate that the detection

area has been changed.

NOTE

l The detection area will not change if you

keep the “SONAR” switch pushed for

10 seconds or more.

Reversing sensor system operation in-

dication lamp E00615900222

In case there is a malfunction in the reversing sen-

sor

system, the reversing sensor system operation

indication lamp will blink and the warning buzzer

will sound for approximately 5 seconds. Even after

the buzzer has stopped sounding, the indication

lamp will continue flashing until the system reverts

to the normal state. Have the vehicle inspected at a

MITSUBISHI MOTORS Authorized Service Point. Rear-view camera*

E00618400172

The

rear-view camera is a system that shows the

view behind the vehicle on a screen in the centre

panel. CAUTION

l

The

rear-view camera is an assistance sys-

tem that enables the driver to check for

obstacles behind the vehicle. Its range of

view is limited, so you should not overly

depend on it. Please drive just as careful-

ly as you would if the vehicle did not have

the rear-view camera.

l Be sure to visually confirm safety around

the vehicle with your own eyes. Do not de-

pend entirely on the rear-view camera.

Range of view of rear-view camera

The

range of view of the rear-view camera is limi-

ted to the area shown in the illustrations. It cannot

show both sides and the lower part of the rear bump-

er, etc.

When reversing, be sure to visually confirm safety

around the vehicle. Starting and driving

4-50

4

Page 205 of 368

NOTE

l We

recommend you to use a genuine

MITSUBISHI roof carrier, since the brackets

to be used have a special shape.

For details, we recommend you to consult a

MITSUBISHI MOTORS Authorized Service

Point.

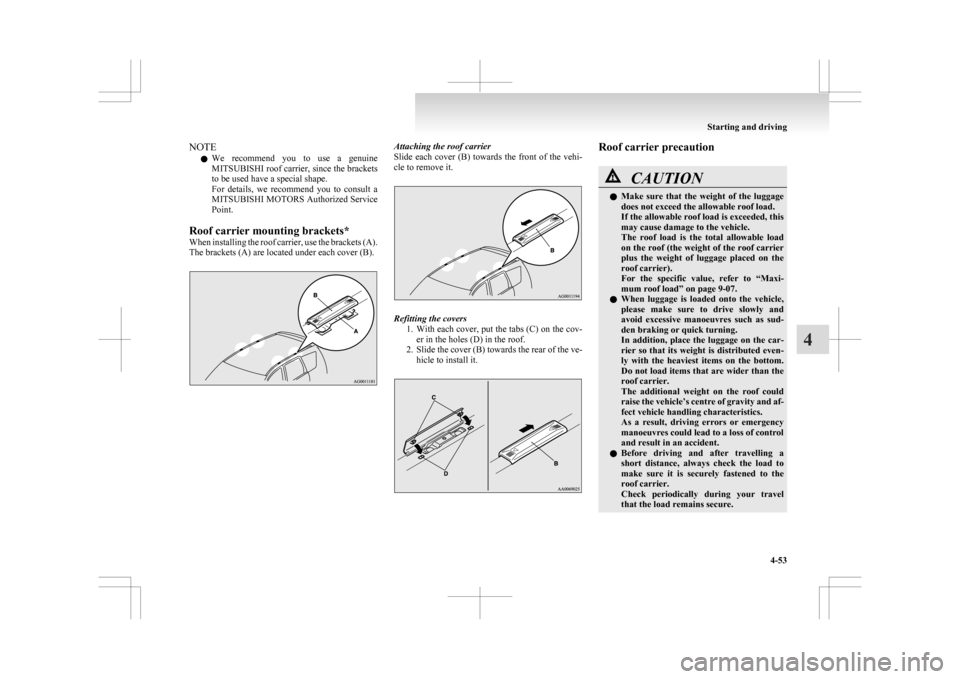

Roof carrier mounting brackets*

When installing the roof carrier, use the brackets (A).

The brackets (A) are located under each cover (B). Attaching the roof carrier

Slide

each cover (B) towards the front of the vehi-

cle to remove it. Refitting the covers

1. With

each cover, put the tabs (C) on the cov-

er in the holes (D) in the roof.

2. Slide the cover (B) towards the rear of the ve- hicle to install it. Roof carrier precaution

CAUTION

l

Make

sure that the weight of the luggage

does not exceed the allowable roof load.

If the allowable roof load is exceeded, this

may cause damage to the vehicle.

The roof load is the total allowable load

on the roof (the weight of the roof carrier

plus the weight of luggage placed on the

roof carrier).

For the specific value, refer to “Maxi-

mum roof load” on page 9-07.

l When luggage is loaded onto the vehicle,

please make sure to drive slowly and

avoid excessive manoeuvres such as sud-

den braking or quick turning.

In addition, place the luggage on the car-

rier so that its weight is distributed even-

ly with the heaviest items on the bottom.

Do not load items that are wider than the

roof carrier.

The additional weight on the roof could

raise the vehicle’s centre of gravity and af-

fect vehicle handling characteristics.

As a result, driving errors or emergency

manoeuvres could lead to a loss of control

and result in an accident.

l Before driving and after travelling a

short distance, always check the load to

make sure it is securely fastened to the

roof carrier.

Check periodically during your travel

that the load remains secure. Starting and driving

4-53 4

Page 206 of 368

NOTE

l To

prevent wind noise or reduction in fuel

economy, remove the roof carrier when not

in use.

l Remove the roof carrier before using an auto-

matic car wash.

l Be sure that adequate clearance is main-

tained for raising the tailgate when installing

a roof carrier. Trailer towing

E00610000459

In

order to tow a trailer with your vehicle, have a

trailer towing device that meets all relevant regula-

tions in your area, mounted consult a

MITSUBISHI MOTORS Authorized Service Point.

The regulations concerning the towing of a trailer

may differ from country to country. You are ad-

vised to obey the regulations in each area. CAUTION

l

Danger of Accident!

A

towing bar should be fitted according

to MITSUBISHI MOTORS guidelines.

Maximum towable weight with brake

and maximum trailer-nose weight

Never

exceed the maximum towable weight with

brake and the maximum trailer-nose weight as lis-

ted in the specifications.

(Refer to page 9-07.)

If you tow a trailer at an altitude of more than

1,000 m above sea-level, reduce your weight by

10 % of the gross combination weight for every in-

crease of 1,000 m above sea-level, as the engine out-

put is lowered owing to decrease in atmospheric

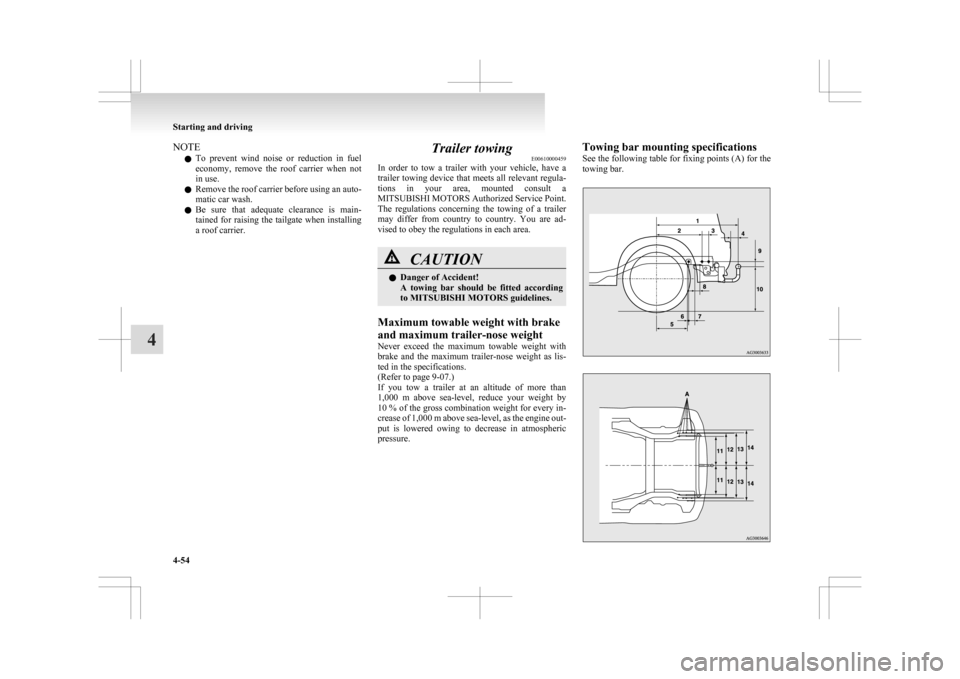

pressure. Towing bar mounting specifications

See

the following table for fixing points (A) for the

towing bar. Starting and driving

4-54

4

Page 216 of 368

Demisting of the windscreen and door windows

E00702100768CAUTION

l

For safety, make sure you have a clear

view through all the windows.

Use the mode selection dial (“ ”

or “ ”) to re-

move frost or mist from the windscreen or door win-

dows. For ordinary demisting

Perform

the following settings to prevent misting

of the windscreen and door windows, and to heat

the leg area.

Heater/Manual air conditioning

Automatic air conditioning 1. Set

the air selection switch (A) to the outside

position.

2. Set the mode selection dial to the “ ”

posi-

tion.

3. Select your desired blower speed by turning the blower speed selection dial.

4. Select your desired temperature by turning the temperature control dial.

5. On vehicles with air conditioning, push the air conditioning switch (B). For quick demisting

Heater/Manual air conditioning

Automatic air conditioning

1.

Set

the mode selection dial to the “ ” posi-

tion.

2.

Set the blower to the maximum speed.

3. Set the temperature to the highest position.

NOTE l When the mode selection dial is in the “ ”

position,

the system operates automatically

and outside air is set automatically.

l To demist effectively, direct the air flow

from the side ventilators towards the door win-

dows.

l On vehicles with air conditioning, do not set

the temperature control dial to the max. cool

position. Cool air will blow against the win-

dow glasses and prevent demisting. For pleasant driving

5-08

5

Page 246 of 368

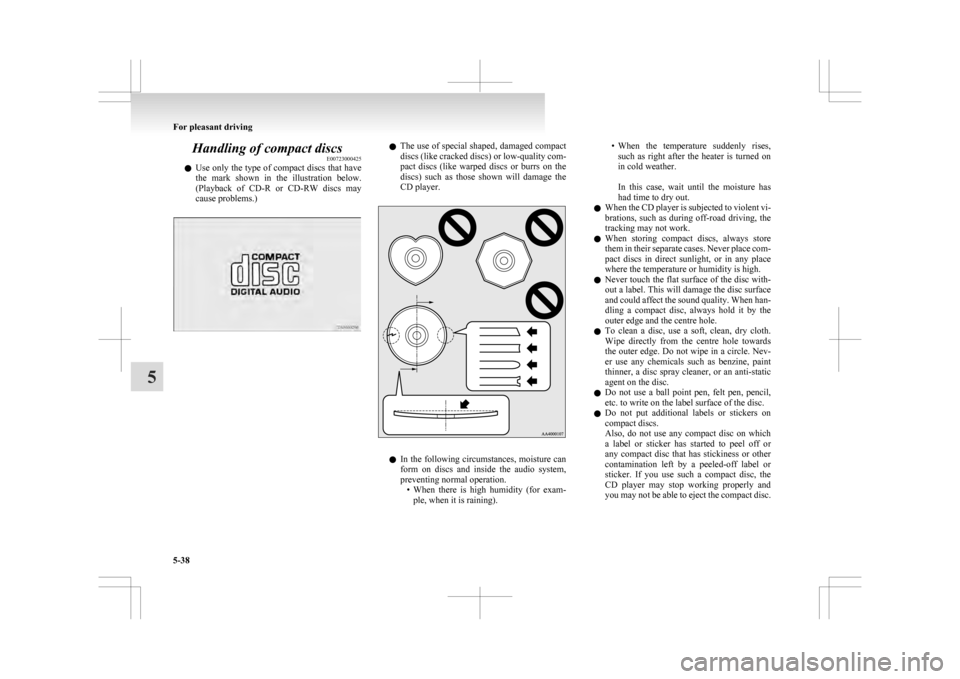

Handling of compact discs

E00723000425

l Use

only the type of compact discs that have

the mark shown in the illustration below.

(Playback of CD-R or CD-RW discs may

cause problems.) l

The use of special shaped, damaged compact

discs (like cracked discs) or low-quality com-

pact discs (like warped discs or burrs on the

discs) such as those shown will damage the

CD player. l

In

the following circumstances, moisture can

form on discs and inside the audio system,

preventing normal operation. • When there is high humidity (for exam-ple, when it is raining). • When

the temperature suddenly rises,

such as right after the heater is turned on

in cold weather.

In this case, wait until the moisture has

had time to dry out.

l When the CD player is subjected to violent vi-

brations, such as during off-road driving, the

tracking may not work.

l When storing compact discs, always store

them in their separate cases. Never place com-

pact discs in direct sunlight, or in any place

where the temperature or humidity is high.

l Never touch the flat surface of the disc with-

out a label. This will damage the disc surface

and could affect the sound quality. When han-

dling a compact disc, always hold it by the

outer edge and the centre hole.

l To clean a disc, use a soft, clean, dry cloth.

Wipe directly from the centre hole towards

the outer edge. Do not wipe in a circle. Nev-

er use any chemicals such as benzine, paint

thinner, a disc spray cleaner, or an anti-static

agent on the disc.

l Do not use a ball point pen, felt pen, pencil,

etc. to write on the label surface of the disc.

l Do not put additional labels or stickers on

compact discs.

Also, do not use any compact disc on which

a label or sticker has started to peel off or

any compact disc that has stickiness or other

contamination left by a peeled-off label or

sticker. If you use such a compact disc, the

CD player may stop working properly and

you may not be able to eject the compact disc. For pleasant driving

5-38

5

Page 279 of 368

If the vehicle breaks down

............................................................ 6-02

Emergency starting ....................................................................... 6-02

Engine overheating ....................................................................... 6-04

Tools, jack and tyre repair kit ....................................................... 6-06

How to change a tyre .................................................................... 6-12

Towing.......................................................................................... 6-19

Operation under adverse driving conditions .................................6-22For emergencies

6

Page 284 of 368

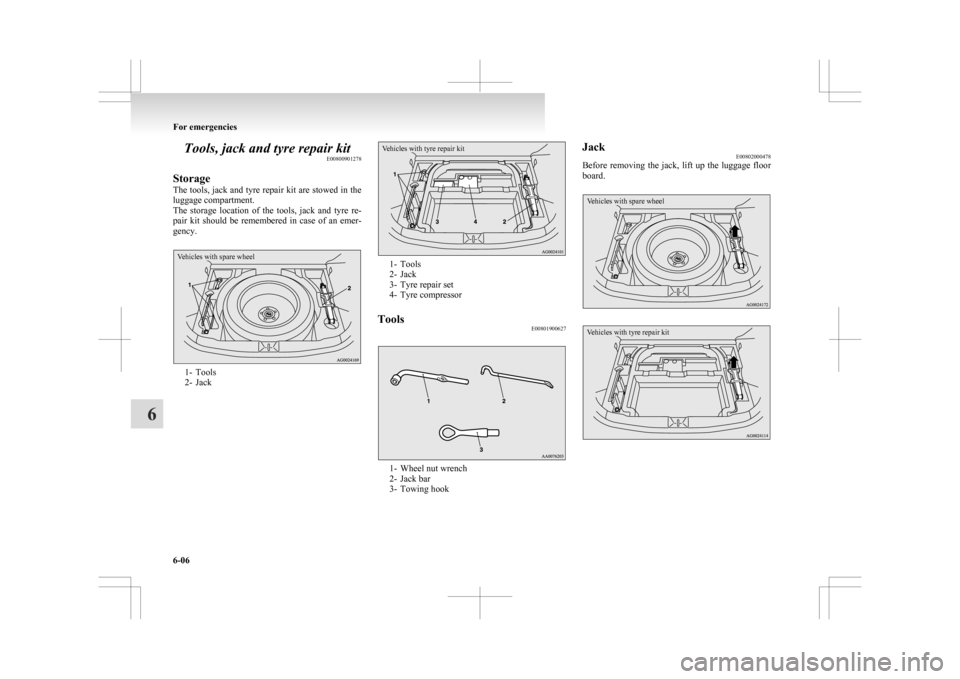

Tools, jack and tyre repair kit

E00800901278

Storage

The

tools, jack and tyre repair kit are stowed in the

luggage compartment.

The storage location of the tools, jack and tyre re-

pair kit should be remembered in case of an emer-

gency.

Vehicles with spare wheel 1- Tools

2-

Jack

Vehicles with tyre repair kit 1- Tools

2-

Jack

3- Tyre repair set

4- Tyre compressor

Tools E00801900627 1- Wheel nut wrench

2-

Jack bar

3- Towing hook Jack

E00802000478

Before

removing the jack, lift up the luggage floor

board.

Vehicles with spare wheel

Vehicles with tyre repair kit For emergencies

6-06

6

Page 288 of 368

14. Place the compressor (M) with its air pres-

sure gauge (N) on top.

Pull out the compressor’s power cord (O), in-

sert the plug on the cord into the accessory

socket or cigarette lighter socket (P), and

then turn the ignition switch to “ACC” posi-

tion or put the operation mode in ACC.

Turn ON the compressor switch (Q) and in-

flate the tyre to the specified pressure. CAUTION

l

The

supplied compressor is designed only

for inflation of passenger vehicle tyres.

l The compressor is designed to run on a ve-

hicle’s 12 V power supply. Do not connect

it to any other power source.

l The compressor is not waterproof. If you

use it in rain, make sure water does not

get on it. CAUTION

l

Any

sand or dust sucked into the compres-

sor could make the compressor break

down. Do not place the compressor direct-

ly on any sandy or dusty surface when us-

ing it.

l Do not disassemble or modify the com-

pressor. Also, do not subject the air pres-

sure gauge to shock. It could malfunction.

15. Check

and adjust the tyre pressure with refer- ence to the air pressure gauge on the compres-

sor. If you overinflate the tyre, release air by

loosening the hose’s end fitting. (Refer to

“Tyre inflation pressures” on page 8-12.)

If there is a gap between the tyre and wheel

because the tyre has moved inward from the

wheel rim, press the periphery of the tyre to-

wards the wheel to close the gap before run-

ning the compressor. (With no gaps, the tyre

pressure will rise.) CAUTION

l

Be

careful not to get your fingers trapped

between the tyre and wheel as the tyre in-

flates.

l The surface of the compressor will get

hot while the compressor is running. Do

not keep the compressor running continu-

ously for more than 10 minutes. After us-

ing the compressor, wait for the compres-

sor to cool before using it again. CAUTION

l

If

the compressor becomes sluggish or

hot while operating, it is overheating. Im-

mediately place the switch in the OFF po-

sition and let the compressor cool down

for at least 30 minutes.

NOTE l If

the tyre pressure does not rise to the speci-

fied level within 10 minutes, the tyre may be

so severely damaged that the tyre sealant can-

not be used to effect an emergency repair.

Please contact a MITSUBISHI MOTORS Au-

thorized Service Point or another specialist

in this event.

16. Turn OFF the compressor switch, then pull the power cord plug out of the socket.

NOTE l Simply putting sealant and air into the tyre us-

ing the tyre repair kit does not seal the punc-

ture hole. Air will leak through the puncture

hole until the emergency repair procedure is

completed (through step 19 of these instruc-

tions).

17. When you have inflated the tyre to the speci- fied pressure, stow the compressor, bottle,

and other items in the vehicle and promptly

start driving the vehicle. Drive with great

care. Do not exceed a speed of 80 km/h

(50 mph). Observe local speed limits. For emergencies

6-10

6

Page 291 of 368

Spare wheel information*

E00803600497

Check

the air pressure of the spare tyre frequently

and make sure it is ready for emergency use at any

time.

Maintaining the spare wheel at the highest speci-

fied air pressure will ensure that it can always be

used under any conditions (city/high-speed driving,

varying load weight, etc.).

The spare wheel is stored beneath the luggage floor

board of the luggage compartment. CAUTION

l

The

pressure should be periodically

checked and maintained at the specified

pressure while the tyre is stowed.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no

choice but to drive with an insufficient

tyre pressure, keep your speed down and

inflate the tyre to the correct pressure as

soon as possible. (Refer to “Tyre inflation

pressures” on page 8-12.)

l When the tread wear indicators appear,

the tyre must be replaced.

Refer to “Wheel condition” on page 8-13.

Temporary spare wheel (spare wheel with a speed

limit label)*

The T155/90D16

or T125/90D16 size spare wheel

is stored beneath the luggage floor board of the lug-

gage compartment. It is designed to save space in

the luggage compartment and its light weight

makes it easy to handle in the event of a flat tyre. CAUTION

l

The

temporary spare wheel is for tempo-

rary use only and should be removed as

soon as the original wheel can be re-

paired or replaced.

l The vehicle must not be driven at speeds

in excess of 80 km/h (50 mph) while using

the temporary spare wheel.

l The T155/90D16 or T125/90D16 size

spare wheel is not as good as a standard

wheel in controllability and stability.

When the temporary spare wheel is used,

avoid quick starts, sudden braking and

sharp steering.

Tyre size of the 215/65R16 size tyre is dif-

ferent from that of the standard tyre.

When the temporary spare tyre is used,

avoid quick starts, sudden braking and

sharp steering.

l The temporary spare wheel is specifically

designed for your vehicle and it should

not be used on any other vehicle.

When you purchase a 215/65R16 size

spare wheel, be sure to purchase the type

designed specially for your vehicle from

your MITSUBISHI MOTORS Author-

ized Service Point. CAUTION

l

Do not use tyre chains with your tempora-

ry spare wheel. Because of the smaller

tyre size, a tyre chain will not fit proper-

ly. This could cause damage to the wheel

and result in loss of the chain.

If a front tyre becomes flat when using

tyre chains, first replace a rear wheel

with the temporary spare wheel and then

use the removed rear wheel to replace the

flat front wheel so that you can continue

to use the chains. CAUTION

l

Upon

installation of the T155/90D16 or

T125/90D16 size spare wheel, the ground

clearance is reduced as the tyre is smaller

in diameter than the standard tyre.

When passing over the projections on the

road, take care not to damage the vehi-

cle’s undercarriage. For emergencies

6-13 6