disc MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 306 of 364

SYSTEM CONSTRUCTION

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)52B-14

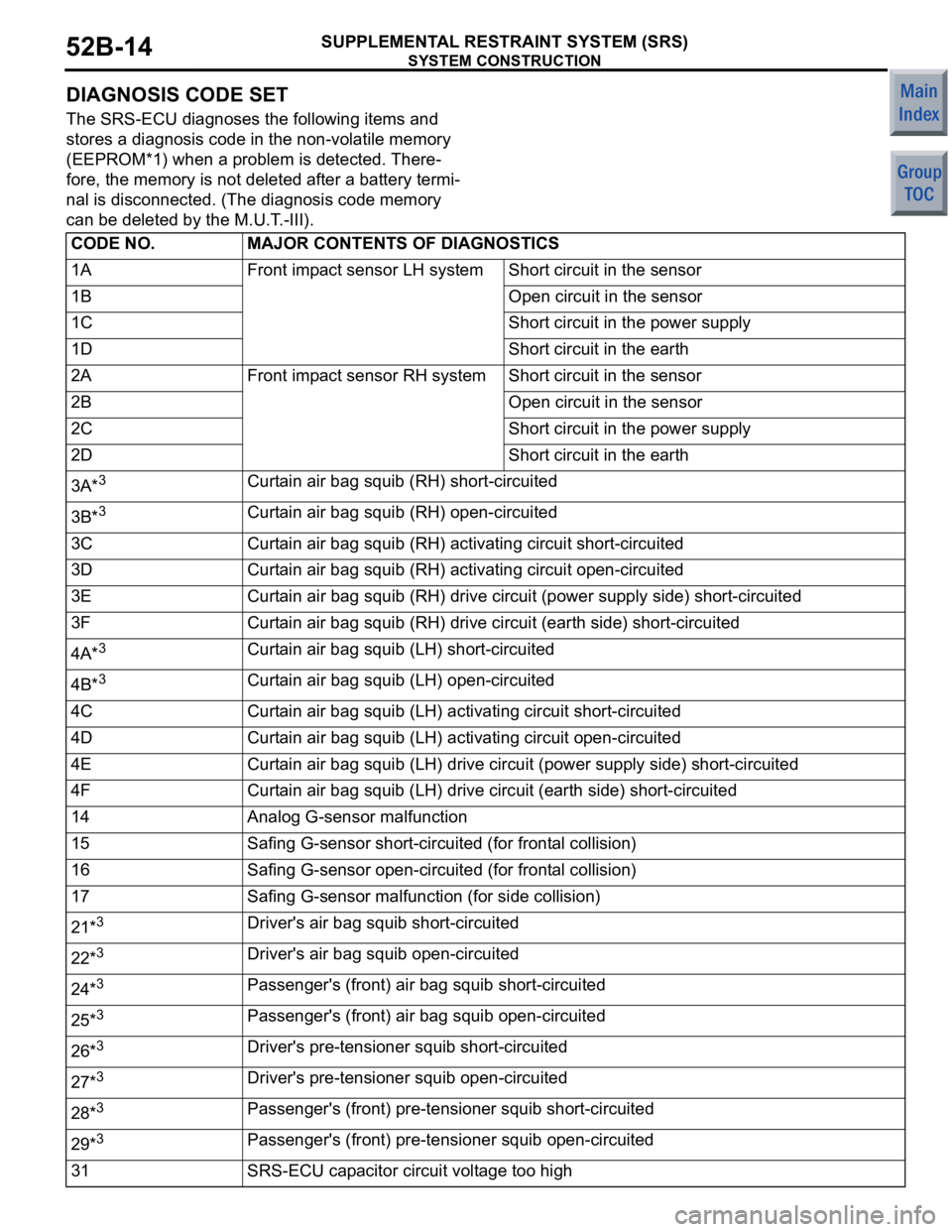

DIAGNOSIS CODE SET

The SRS-ECU diagnoses the following items and

stores a diagnosis code in the non-volatile memory

(EEPROM*1) when a problem is detected. There

-

fore, the memory is not deleted after a battery termi-

nal is disconnected. (The diagnosis code memory

can be deleted by the M.U.T.-III).

CODE NO.MAJOR CONTENTS OF DIAGNOSTICS

1AFront impact sensor LH systemShort circuit in the sensor

1BOpen circuit in the sensor

1CShort circuit in the power supply

1DShort circuit in the earth

2AFront impact sensor RH systemShort circuit in the sensor

2BOpen circuit in the sensor

2CShort circuit in the power supply

2DShort circuit in the earth

3A*3Curtain air bag squib (RH) short-circuited

3B*3Curtain air bag squib (RH) open-circuited

3CCurtain air bag squib (RH) activating circuit short-circuited

3DCurtain air bag squib (RH) activating circuit open-circuited

3ECurtain air bag squib (RH) drive circuit (power supply side) short-circuited

3FCurtain air bag squib (RH) drive circuit (earth side) short-circuited

4A*3Curtain air bag squib (LH) short-circuited

4B*3Curtain air bag squib (LH) open-circuited

4CCurtain air bag squib (LH) activating circuit short-circuited

4DCurtain air bag squib (LH) activating circuit open-circuited

4ECurtain air bag squib (LH) drive circuit (power supply side) short-circuited

4FCurtain air bag squib (LH) drive circuit (earth side) short-circuited

14Analog G-sensor malfunction

15Safing G-sensor short-circuited (for frontal collision)

16Safing G-sensor open-circuited (for frontal collision)

17Safing G-sensor malfunction (for side collision)

21*3Driver's air bag squib short-circuited

22*3Driver's air bag squib open-circuited

24*3Passenger's (front) air bag squib short-circuited

25*3Passenger's (front) air bag squib open-circuited

26*3Driver's pre-tensioner squib short-circuited

27*3Driver's pre-tensioner squib open-circuited

28*3Passenger's (front) pre-tensioner squib short-circuited

29*3Passenger's (front) pre-tensioner squib open-circuited

31SRS-ECU capacitor circuit voltage too high

Page 310 of 364

SYSTEM CONSTRUCTION

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)52B-18

SQUIB CIRCUIT CONNECTOR LOCK

SWITCH

AC300257

OFFON

OFF ON

Squib

SRS-ECU

A

A

ECU-side connectorB

B

AC

Section B - B

Section A - A

Connector connected

OFF

ON

OFF

ON

Squib

SRS-ECU

Connector disconnected

Terminal

(male)

Partition panelTerminal

(female) Short spring

Wiring harness-side connector

Terminal

(male)

Partition panel Terminal

(female)

Short spring Connector connected

Terminal

(male)

Partition panelTerminal

(female)

Short spring

Diagnosis spring

Diagnosis

spring

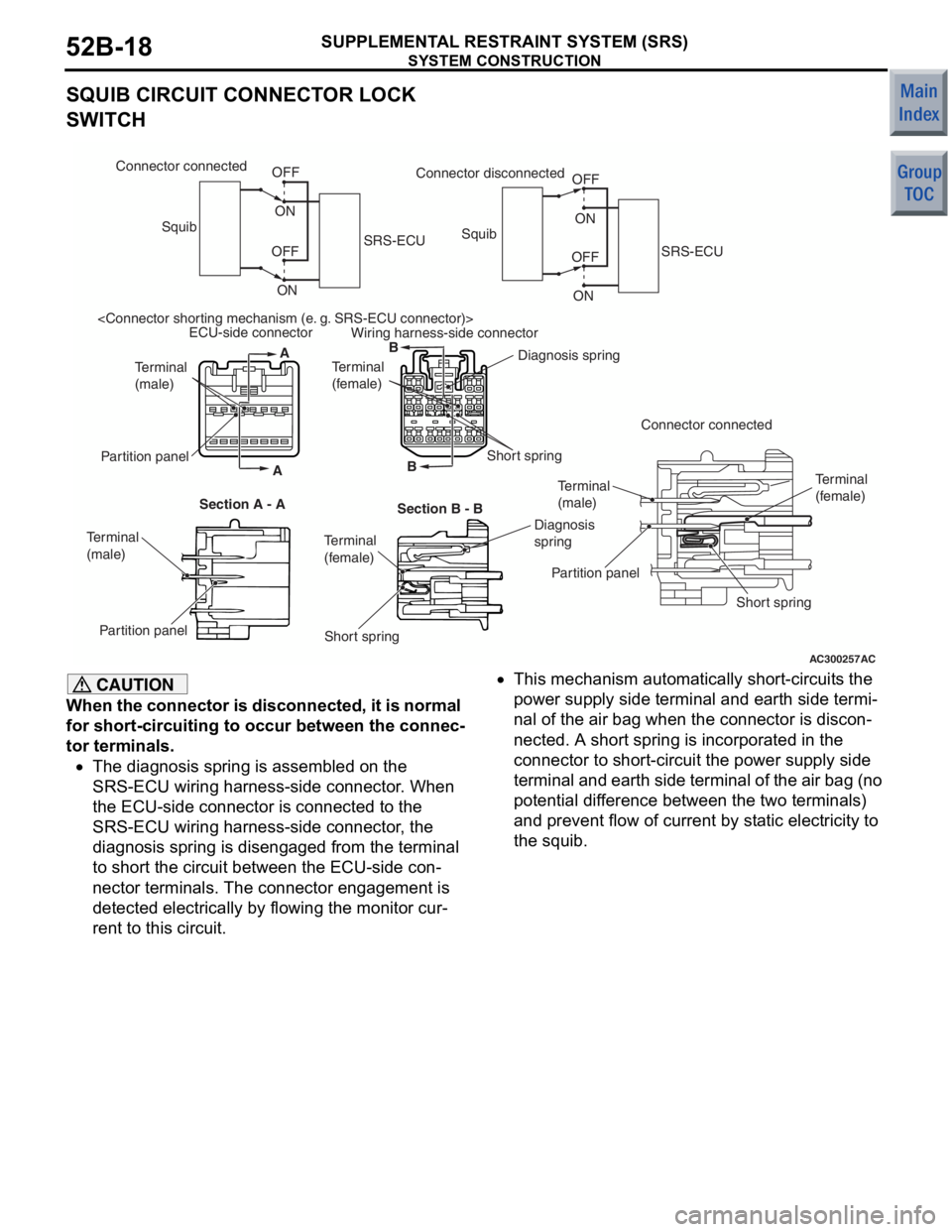

CAUTION

When the connector is disconnected, it is normal

for short-circuiting to occur between the connec

-

tor terminals.

•The diagnosis spring is assembled on the

SRS-ECU wiring harness-side connector. When

the ECU-side connector is connected to the

SRS-ECU wiring harness-side connector, the

diagnosis spring is disengaged from the terminal

to short the circuit between the ECU-side con

-

nector terminals. The connector engagement is

detected electrically by flowing the monitor cur

-

rent to this circuit.

•This mechanism automatically short-circuits the

power supply side terminal and earth side termi

-

nal of the air bag when the connector is discon-

nected. A short spring is incorporated in the

connector to short-circuit the power supply side

terminal and earth side terminal of the air bag (no

potential difference between the two terminals)

and prevent flow of current by static electricity to

the squib.

Page 342 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-2

GENERAL INFORMATION

M2350000100848

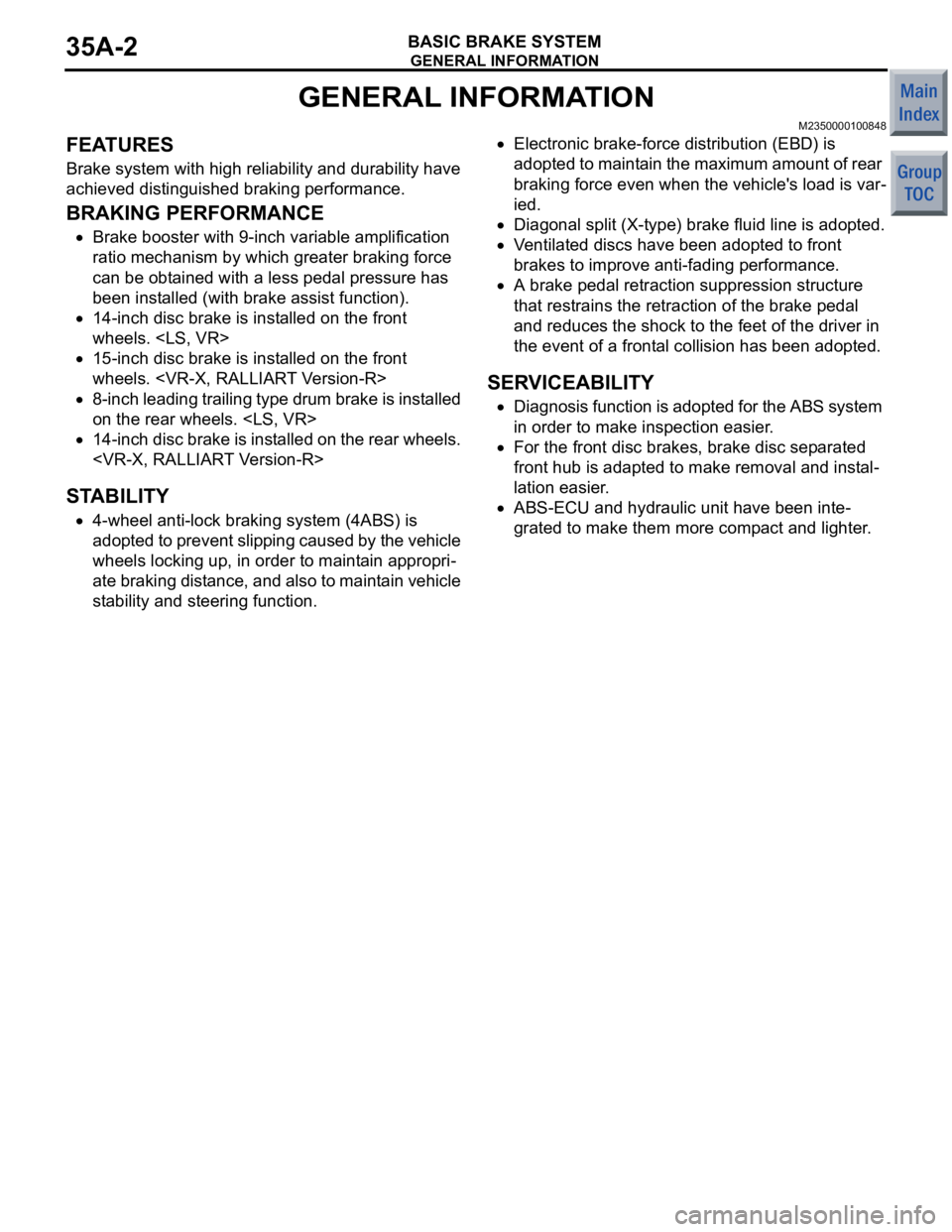

FEATURES

Brake system with high reliability and durability have

achieved distinguished braking performance.

BRAKING PERFORMANCE

•Brake booster with 9-inch variable amplification

ratio mechanism by which greater braking force

can be obtained with a less pedal pressure has

been installed (with brake assist function).

•14-inch disc brake is installed on the front

wheels.

•15-inch disc brake is installed on the front

wheels.

•8-inch leading trailing type drum brake is installed

on the rear wheels.

•14-inch disc brake is installed on the rear wheels.

STABILITY

•4-wheel anti-lock braking system (4ABS) is

adopted to prevent slipping caused by the vehicle

wheels locking up, in order to maintain appropri

-

ate braking distance, and also to maintain vehicle

stability and steering function.

•Electronic brake-force distribution (EBD) is

adopted to maintain the maximum amount of rear

braking force even when the vehicle's load is var

-

ied.

•Diagonal split (X-type) brake fluid line is adopted.

•Ventilated discs have been adopted to front

brakes to improve anti-fading performance.

•A brake pedal retraction suppression structure

that restrains the retraction of the brake pedal

and reduces the shock to the feet of the driver in

the event of a frontal collision has been adopted.

SERVICEABILITY

•Diagnosis function is adopted for the ABS system

in order to make inspection easier.

•For the front disc brakes, brake disc separated

front hub is adapted to make removal and instal

-

lation easier.

•ABS-ECU and hydraulic unit have been inte-

grated to make them more compact and lighter.

Page 343 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-3

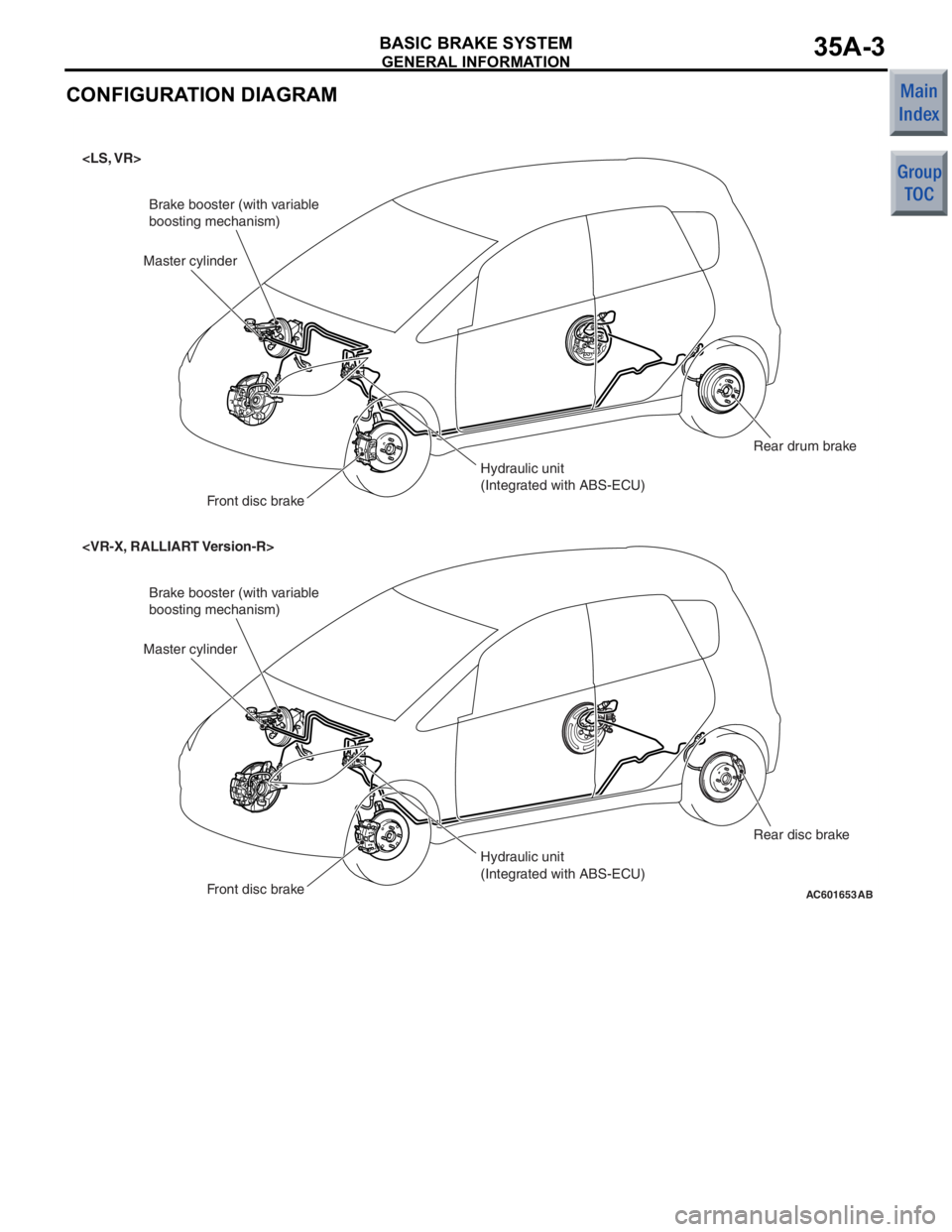

CONFIGURATION DIAGRAM

AC601653

Brake booster (with variable

boosting mechanism)

Hydraulic unit

(Integrated with ABS-ECU)

Master cylinder

Front disc brake Rear drum brake

Brake booster (with variable

boosting mechanism)

Hydraulic unit

(Integrated with ABS-ECU)

Master cylinder

Front disc brake Rear disc brake

AB

Page 344 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-4

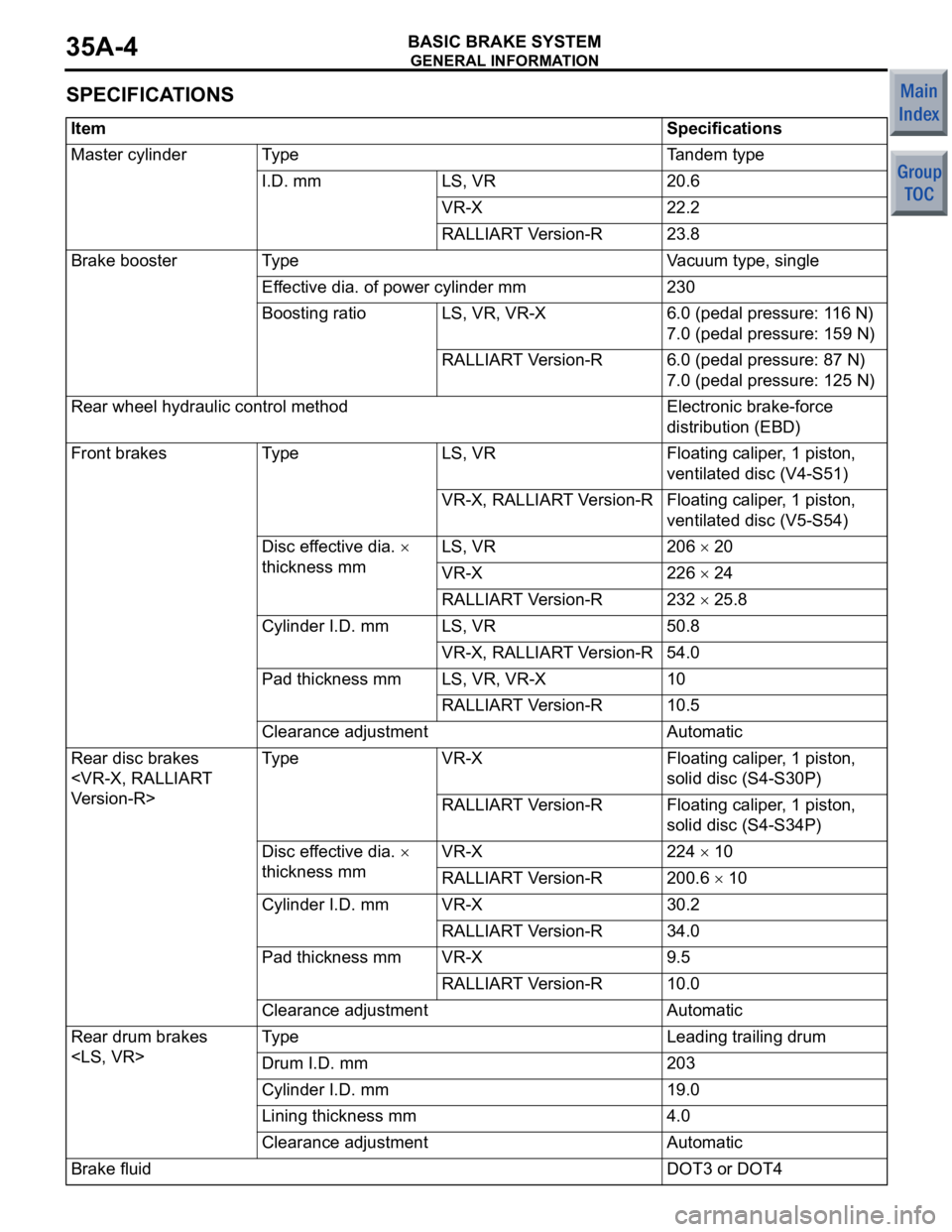

SPECIFICATIONS

ItemSpecifications

Master cylinderTy p eTandem type

I.D. mmLS, VR20.6

VR-X22.2

RALLIART Version-R23.8

Brake boosterTy p eVacuum type, single

Effective dia. of power cylinder mm230

Boosting ratioLS, VR, VR-X6.0 (pedal pressure: 116 N)

7.0 (pedal pressure: 159 N)

RALLIART Version-R6.0 (pedal pressure: 87 N)

7.0 (pedal pressure: 125 N)

Rear wheel hydraulic control methodElectronic brake-force

distribution (EBD)

Front brakesTy p eLS, VRFloating caliper, 1 piston,

ventilated disc (V4-S51)

VR-X, RALLIART Version-RFloating caliper, 1 piston,

ventilated disc (V5-S54)

Disc effective dia. ×

thickness mmLS, VR206 × 20

VR-X226 × 24

RALLIART Version-R232 × 25.8

Cylinder I.D. mmLS, VR50.8

VR-X, RALLIART Version-R54.0

Pad thickness mmLS, VR, VR-X10

RALLIART Version-R10.5

Clearance adjustmentAutomatic

Rear disc brakes

Ty p eVR-XFloating caliper, 1 piston,

solid disc (S4-S30P)

RALLIART Version-RFloating caliper, 1 piston,

solid disc (S4-S34P)

Disc effective dia. ×

thickness mmVR-X224 × 10

RALLIART Version-R200.6 × 10

Cylinder I.D. mmVR-X30.2

RALLIART Version-R34.0

Pad thickness mmVR-X9.5

RALLIART Version-R10.0

Clearance adjustmentAutomatic

Rear drum brakes

Ty p eLeading trailing drum

Drum I.D. mm203

Cylinder I.D. mm19.0

Lining thickness mm4.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

Page 345 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-5

CONSTRUCTION DESCRIPTION

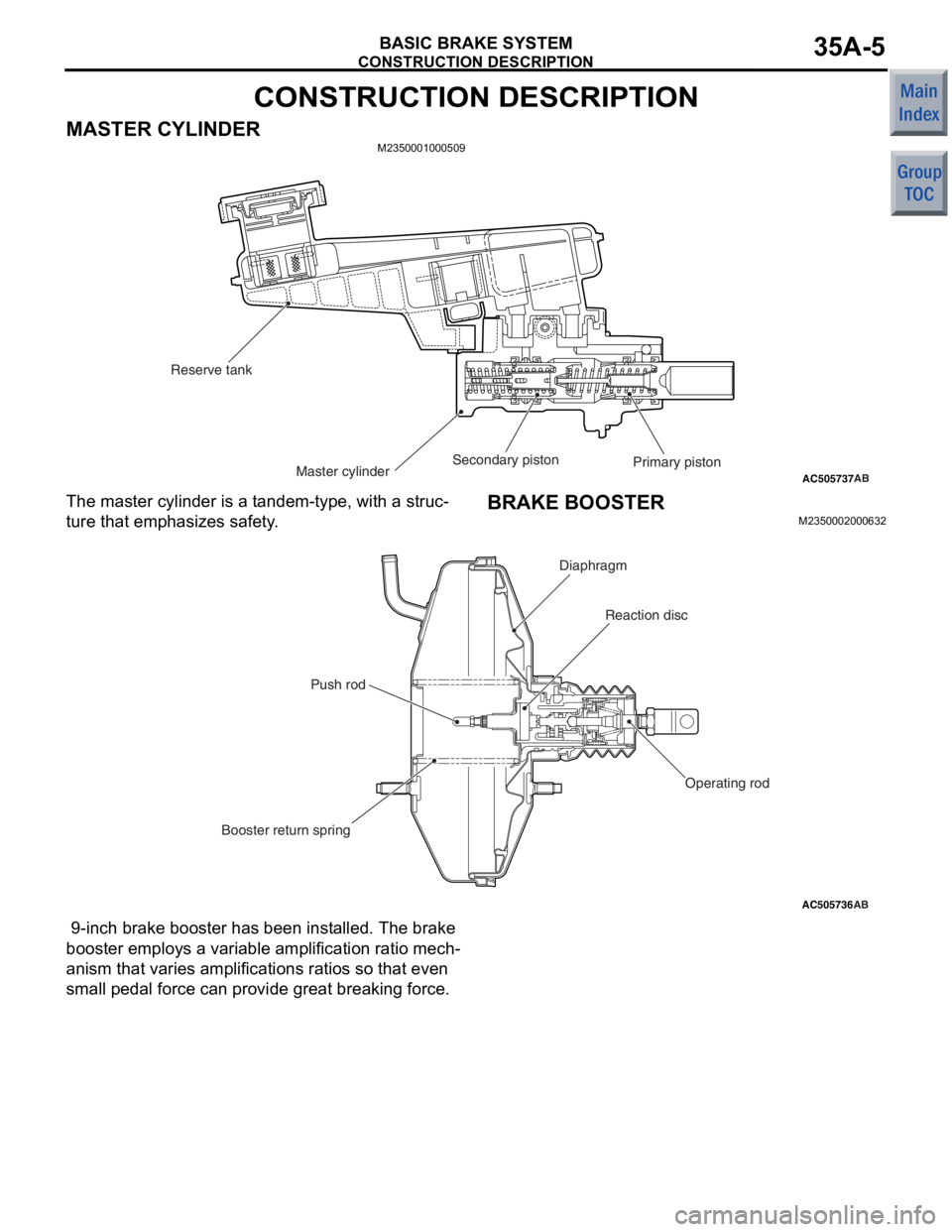

MASTER CYLINDERM2350001000509

AC505737ABMaster cylinder

Reserve tank

Primary piston

Secondary piston

The master

cylind e r is a t andem-typ e, with a stru c-

ture that emp hasizes sa fety .

BRAKE BOOSTER

M23500020 0063 2

AC505736AB

Reaction disc

Booster return spring Push rod

Diaphragm

Operating rod

9-inch brake booste r has been inst alled. T he brake

booster employs a

variable amplification ratio mech

-

anism that va ries amplifications ratios so that e v en

sma

ll p edal force can provide gre a t brea kin g force.

Page 347 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-7

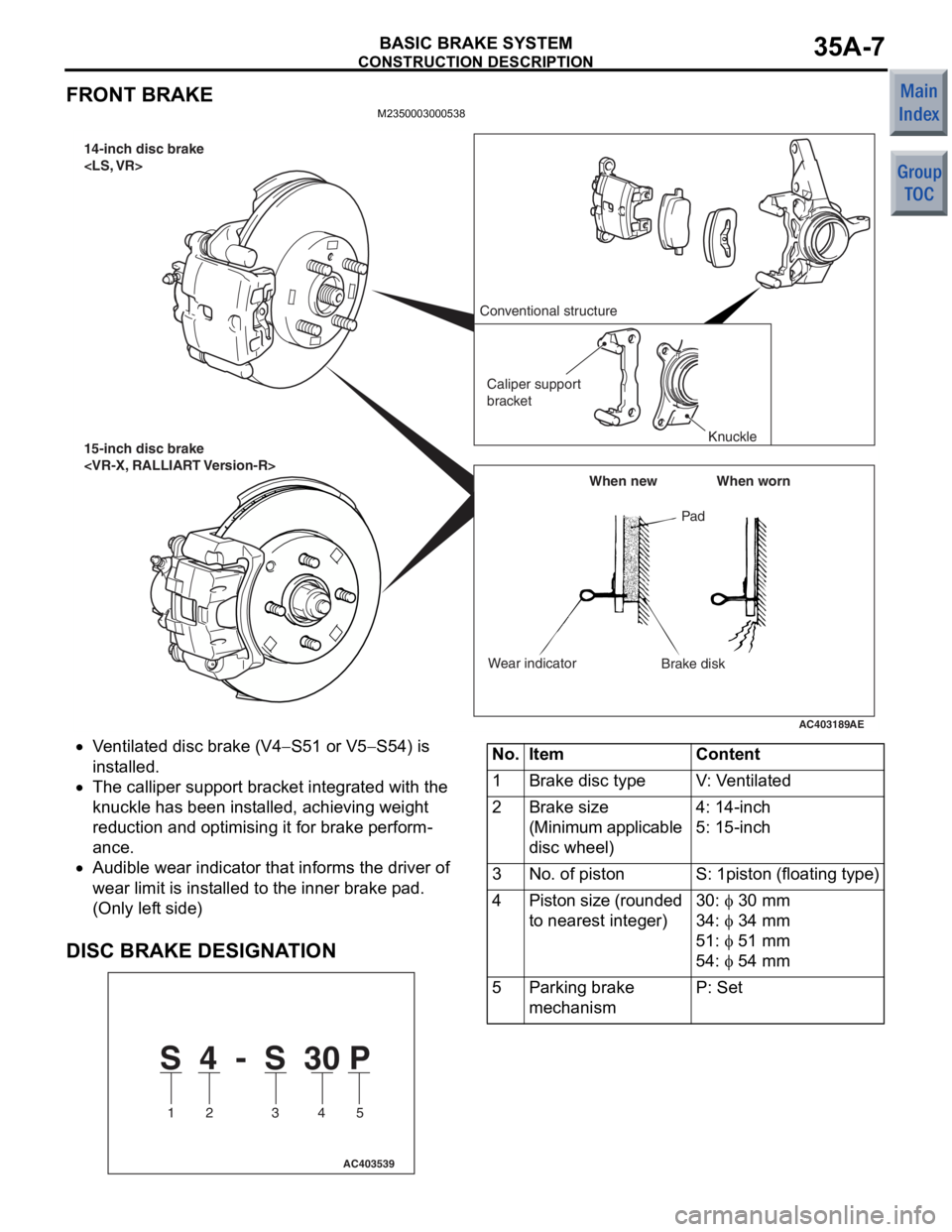

FRONT BRAKE

M2350003000538

AC403189AE

14-inch disc brake

15-inch disc brake

Brake disk

Wear indicator When new When worn

Conventional structure

Caliper support

bracket Knuckle

•Ventilate d disc b r ake (V4−S51 or V5−S54) is

in

st

alled.

•The callipe r sup port bra c ket int egrated with the

kn

uckle h a s be en in st alled, achie v in g weigh t

redu

ction and optimising it for b r ake perform

-

ance.

•Audible wear indicat o r that informs th e driver of

wear limit is inst

alle d to th e inn e r brake p ad.

(Only lef

t side)

DISC BRAKE DESIGNA T ION

S 4 - S 30 P

1 2 3 4 5

AC403539

No.ItemContent

1Brake disc typeV: Ventilated

2Brake size

(Minimum applicable

disc wheel)4: 14-inch

5: 15-inch

3No. of pistonS: 1piston (floating type)

4Piston size (rounded

to nearest integer)30: φ 30 mm

34: φ 34 mm

51: φ 51 mm

54: φ 54 mm

5Parking brake

mechanismP: Set

Page 348 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-8

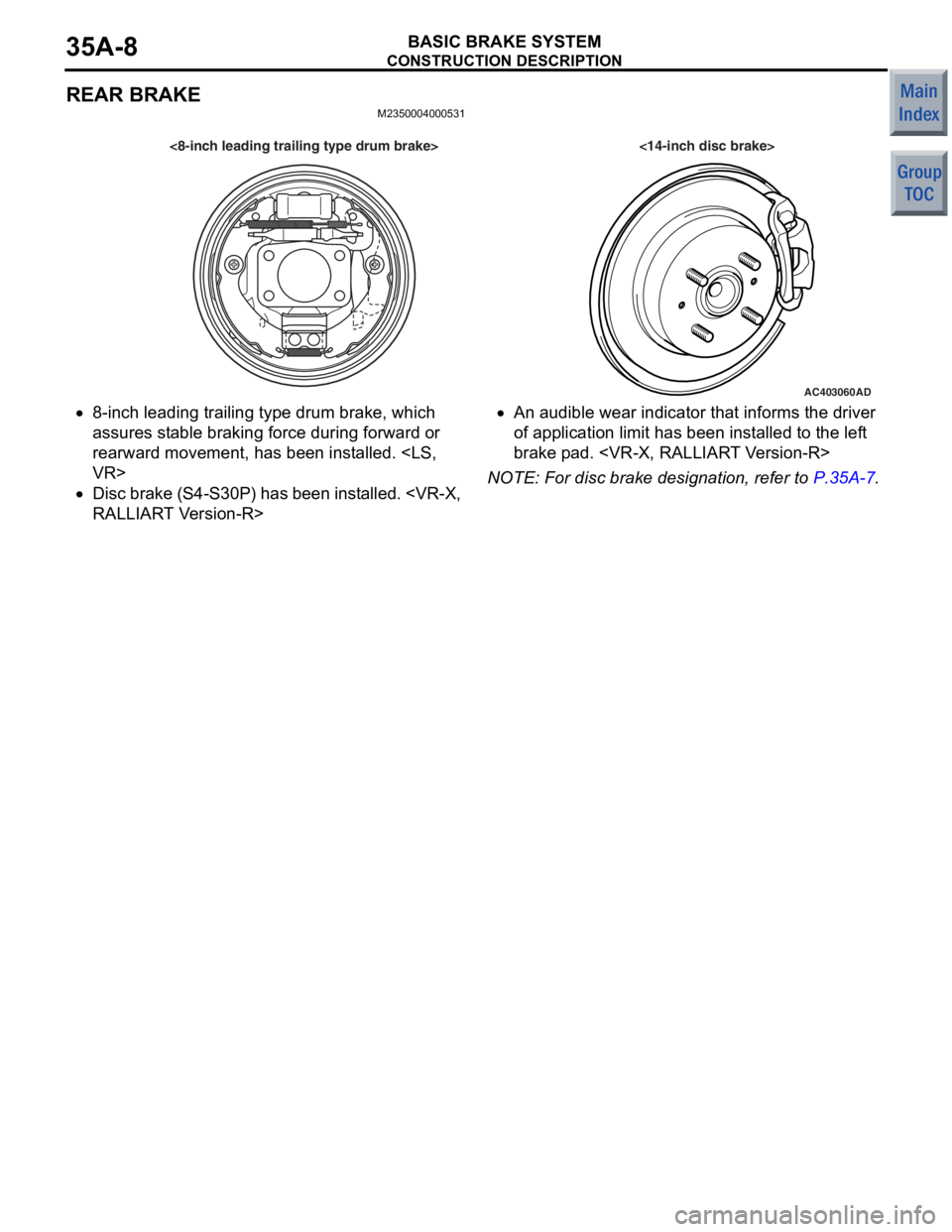

REAR BRAKE

M2350004000531

AC403060AD

<8-inch leading trailing type drum brake> <14-inch disc brake>

•8-inch leading tra iling type drum brake, which

assure

s st ab le bra k in g force during forward or

rearward

movement, ha s bee n inst alle d.

•Disc brake (S4 - S3 0 P ) ha s be en in st a l le d.

T V e rsion - R>

•An audible wear indicator th at in forms the d r ive r

of a

pplication limit has been inst a lled to the lef t

brake p

ad.

NOTE: For d i sc brake de sign ation , refer t o P.35A-7.

Page 351 of 364

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)23-3

ELECTRONIC CONTROL SYSTEM

EEPROM

M2231012000024

Because EEPROM has been used, even if the bat-

tery terminals or control unit connectors are discon-

nected, the necessary learned values are stored in

the engine-CVT-ECU to prevent a loss of shift qual

-

ity. (Initialisation is available by M.U.T.-III).

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION

M2231017000018

CAN* communication has been adopted for commu-

nication with other ECUs in order to decrease the

number of wires and ensure information transmis

-

sion. For CVT control, the engine-CVT-ECU receives

the following signals.

CAN COMMUNICATION INPUT SIGNAL TABLE

Input signalTransmitter ECU

Average vehicle speed signal from drive wheelsABS-ECU

Motor current signalEPS-ECU

EPS warning lamp illumination request signal

Compressor signalMeter and A/C-ECU

NOTE: *: For more information about CAN (Control-

ler Area Network), refer to GROUP 54C P.54C-2.

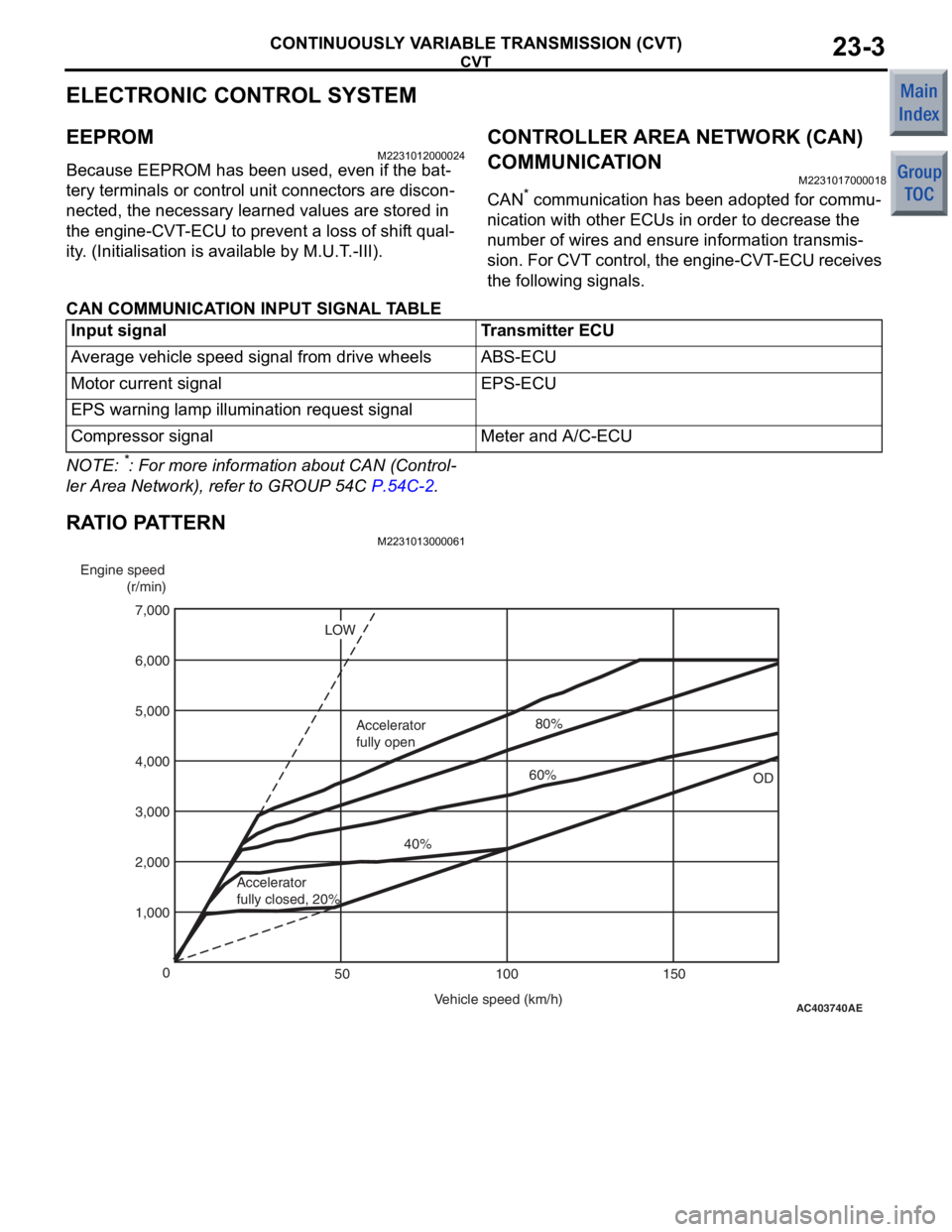

RATIO PATTERN

M2231013000061

AC403740

AE

Engine speed

(r/min)

Vehicle speed (km/h)

0

100 150

50

1,000 2,000 4,000

3,000 5,000

7,000

6,000

OD

LOW

Accelerator

fully closed, 20% 40%

Accelerator

fully open

60%80%