engine MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 48 of 364

BASE ENGINE

ENGINE MECHANICAL <4G1>11B-4

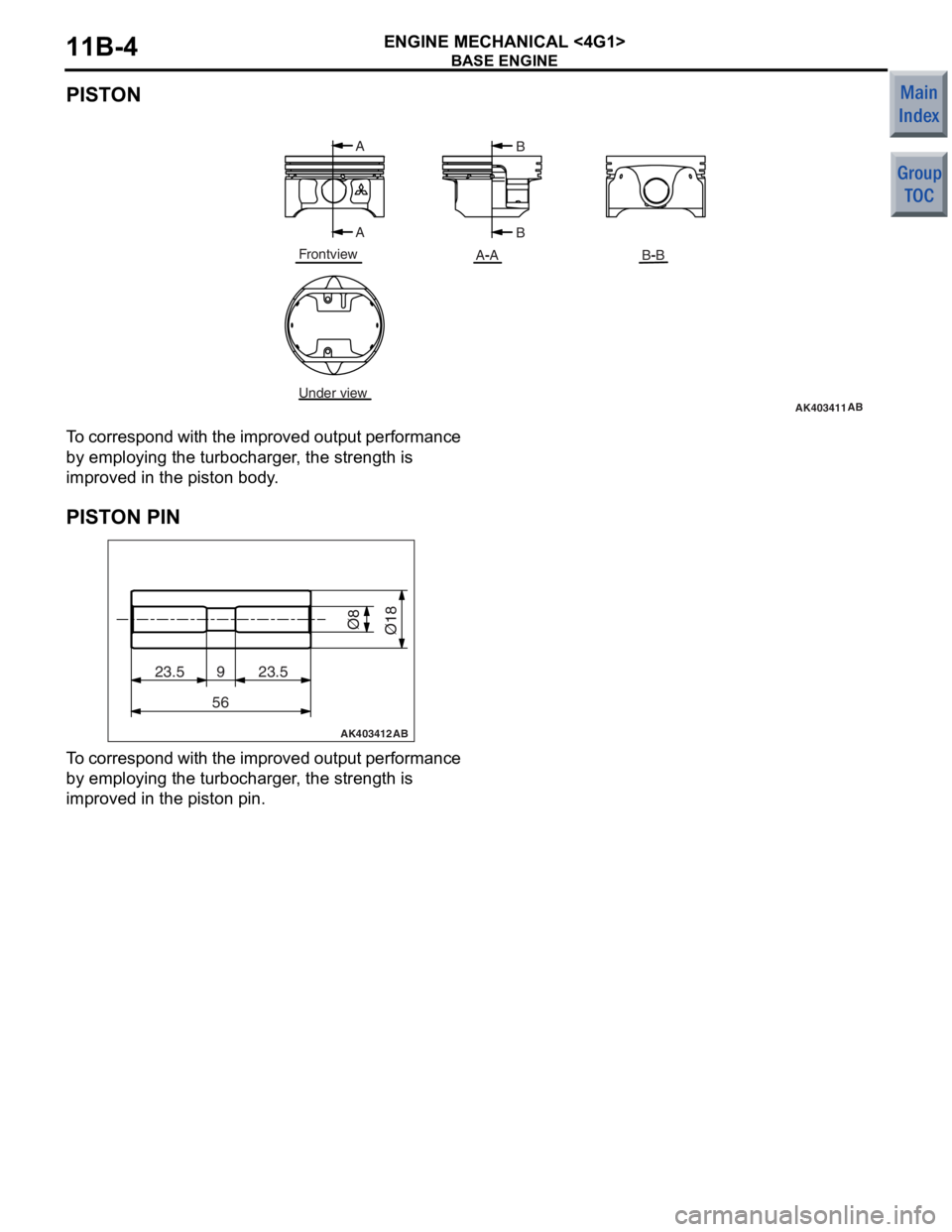

PISTON

AK403411

Frontview

Under view

A-AB -B

A

A B

B

AB

T

o co rrespo nd wi th the imp r ove d o u t put pe rfo r ma nce

by emplo

y in g the t u rbocharger , the strength is

imp

r oved in th e piston b ody .

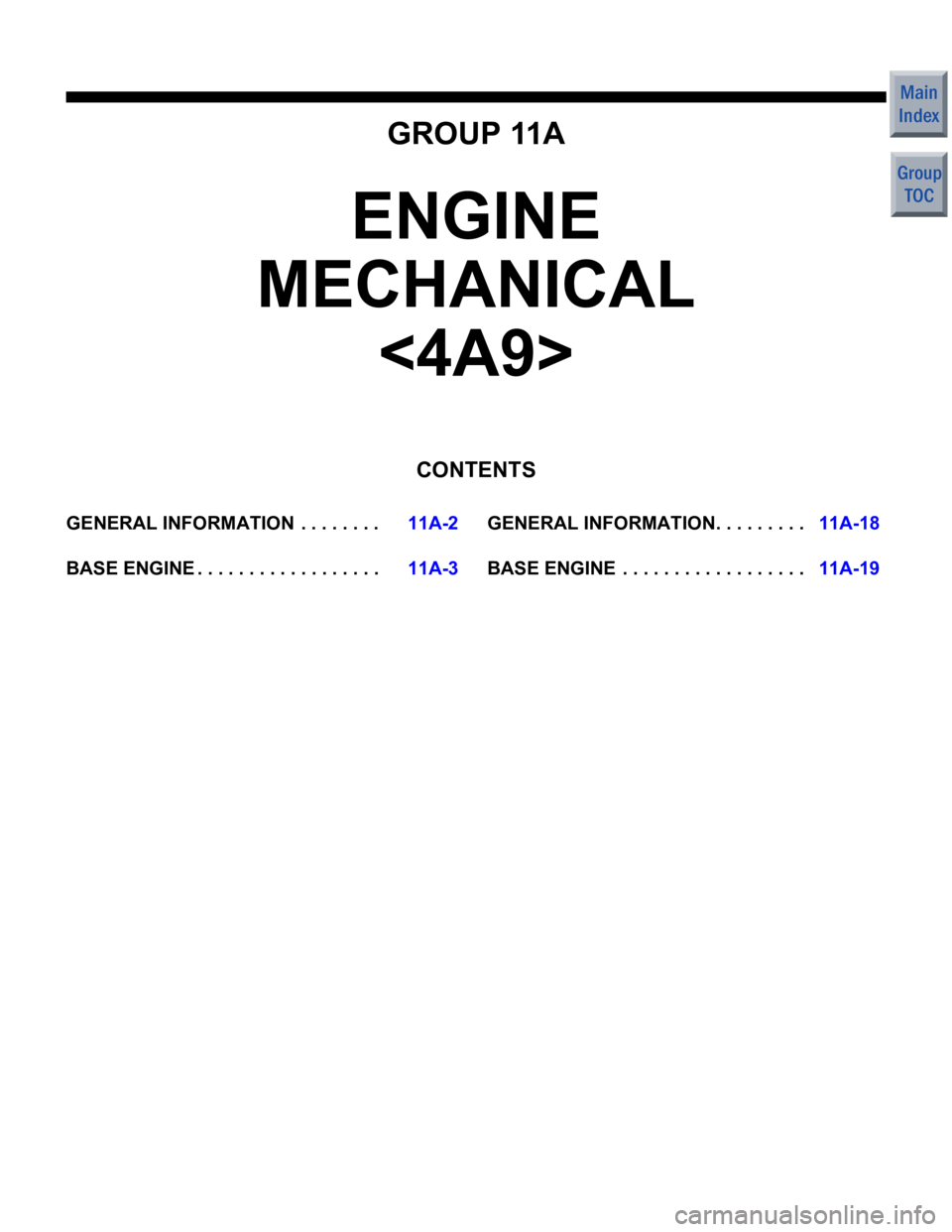

PISTON PIN

AK403412

56

Ø8

Ø18

23.523.5 9

AB

T o co rrespo nd wi th the imp r ove d o u t put pe rfo r ma nce

by emplo

y in g the t u rbocharger , the strength is

imp

r oved in th e piston p i n.

Page 49 of 364

GROUP 11A

ENGINE

MECHANICAL

<4A9>

CONTENTS

GENERAL INFORMATIO N . . . . . . . .11A-2

BASE ENGINE . . . . . . . . . . . . . . . . . .11A-3

GENERAL INFORMATION. . . . . . . . .11A-18

BASE ENGINE . . . . . . . . . . . . . . . . . .11A-19

Page 50 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4A9>11A-2

GENERAL INFORMATION

M2112000100697

The newly developed 1.5L 4A91 engine features

4-cylinder, 16-valve, and double overhead camshafts

(DOHC).

The engine has the following features.

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

•Selective valve tappet of direct acting valve sys-

tem for valve clearance adjustment

•Timing chain

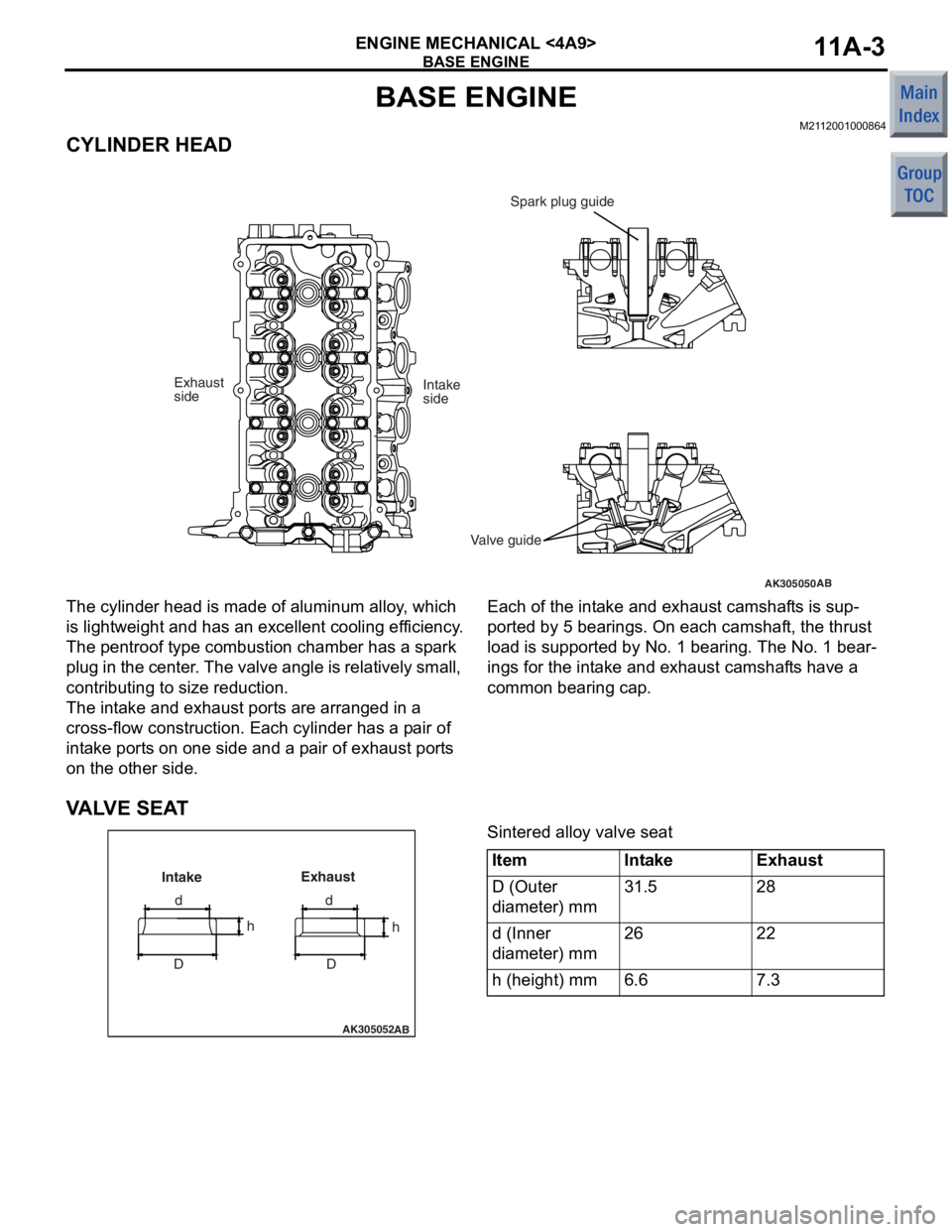

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − AT D C 1 9°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (104)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 51 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-3

BASE ENGINE

M2112001000864

CYLINDER HEAD

AK305050AB

Spark plug guide

Intake

side

Exhaust

side

Valve guide

The cylinder head is made of aluminu m alloy , which

is light

we ight a nd ha s an excelle nt co oling ef ficiency .

The pentroof type comb ustion chamb e r has a sp a r k

plug in the

cent er . The valve an gle is relatively small,

contributing to size redu

ctio n.

The int a ke an d exhaust port s a r e arrang ed in a

cross-flow construction.

Ea ch cylinde r has a p a ir of

int

a ke port s on one side and a p a ir of e x hau st po rt s

on the

other side .

Each o f the int a ke a nd exhaust ca msh a f t s is sup-

ported by 5 bearin gs. On ea ch camshaf t, th e thrust

load

is suppo rted by No. 1 b earin g. The No . 1 bea r

-

ings for the int a ke and exha ust camshaf t s ha ve a

common bearing

ca p.

VALV E S E AT

AK305052

d

AB

d

DD h

h

Intake

Exhaust

Sintered

alloy valve seat

ItemIntakeExhaust

D (Outer

diameter) mm31.528

d (Inner

diameter) mm2622

h (height) mm6.67.3

Page 52 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-4

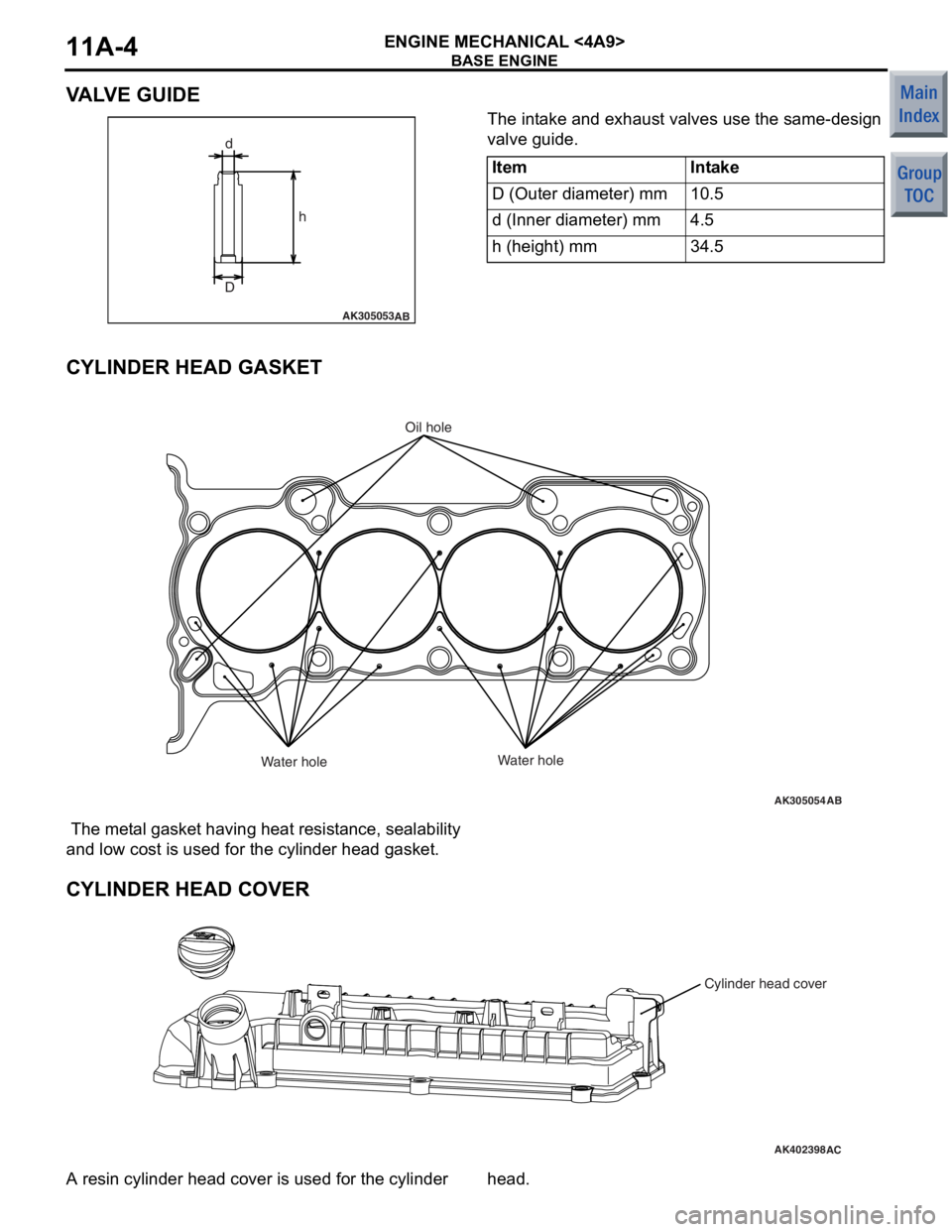

VA LV E G U I D E

AK305053

d

AB

Dh

The in

t a ke an d exhaust valves use the same -design

valve gu

ide.

ItemIntake

D (Outer diameter) mm10.5

d (Inner diameter) mm4.5

h (height) mm34.5

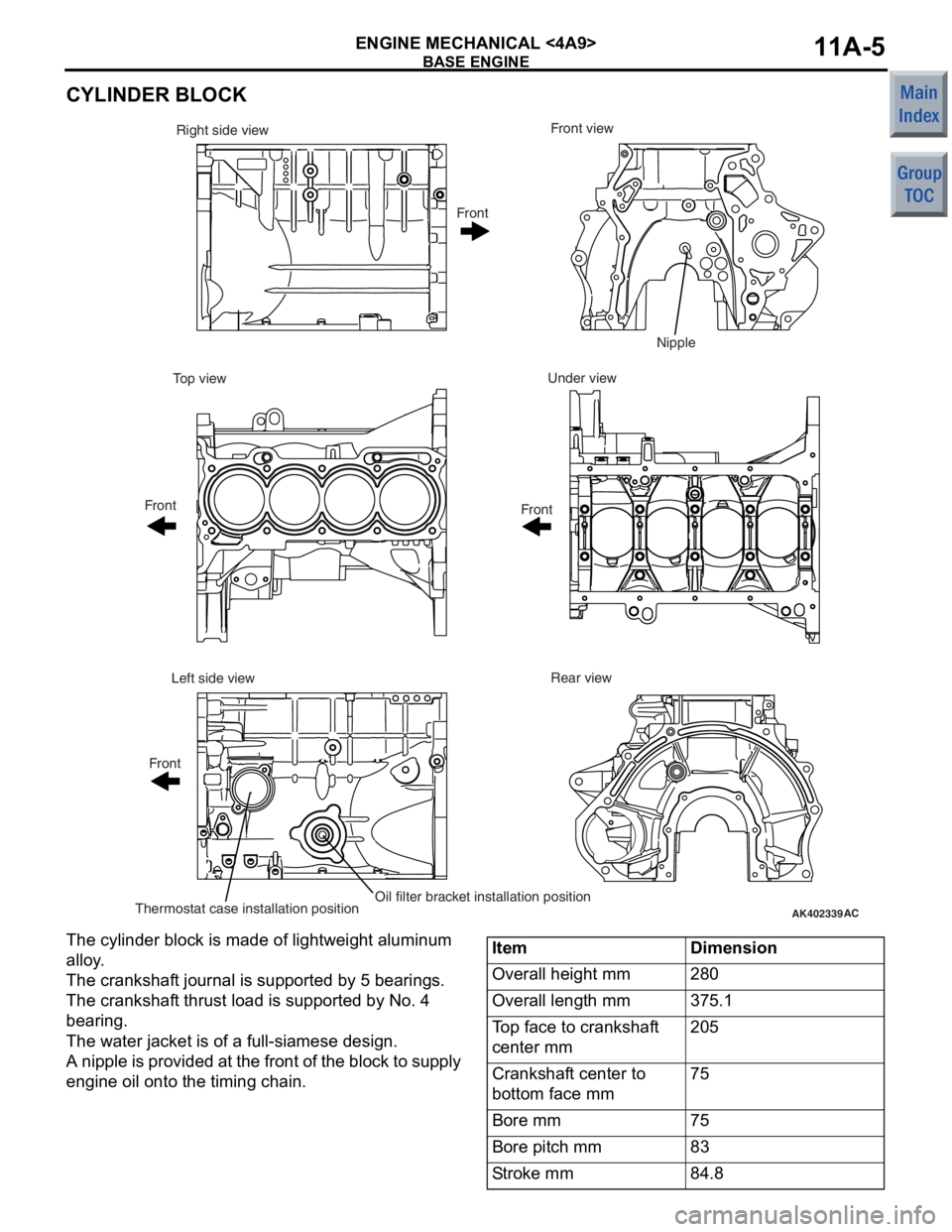

CYLINDER HEAD GASKET

AK305054AB

Water hole

Oil hole

Water hole

Th e met a l g a sket having he at resist ance, sea l ability

and low cost is use

d for th e cylin der hea d gasket .

CYLINDER HEAD COVER

AK402398AC

Cylinder head cover

A resin cylin der hea d co ver is used fo r the cylinder head.

Page 53 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-5

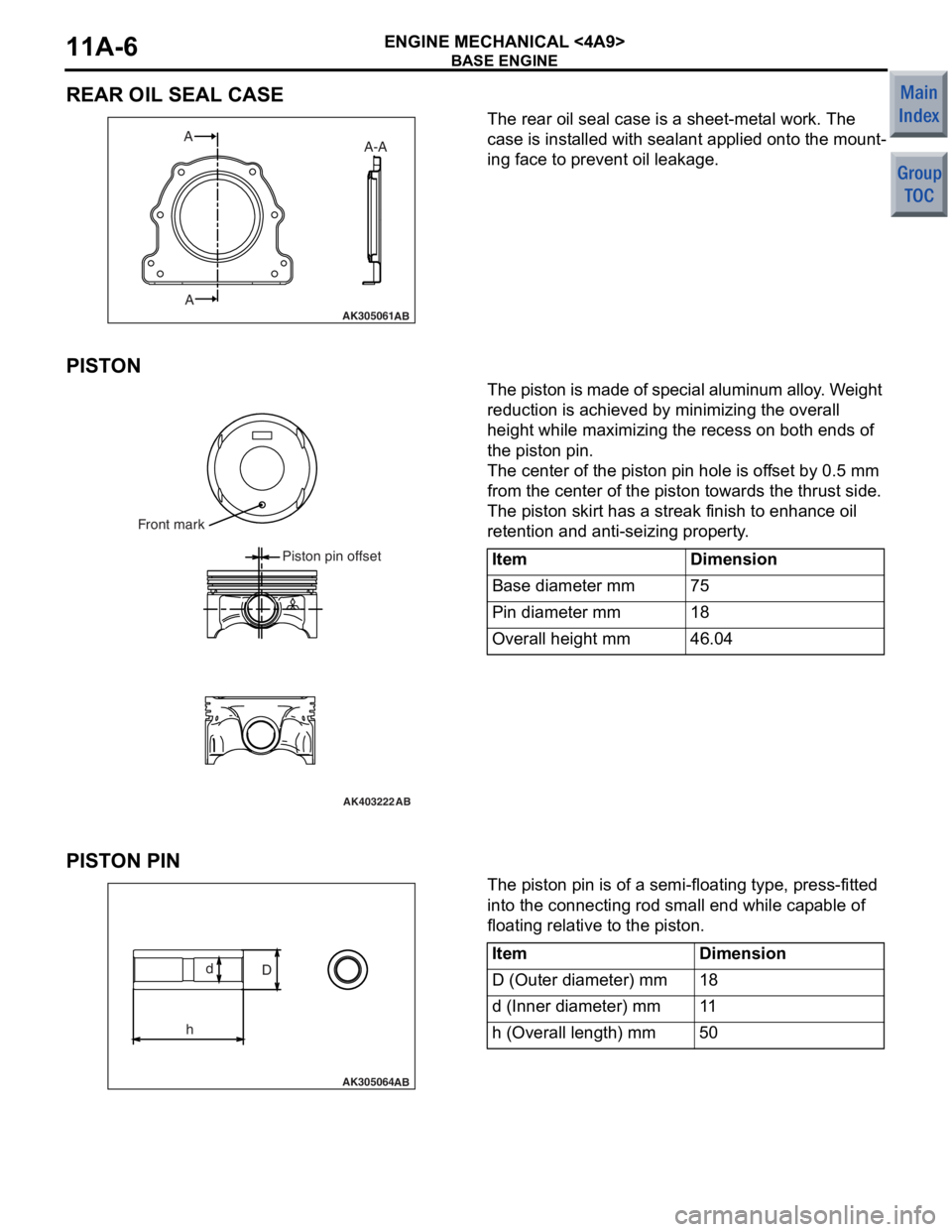

CYLINDER BLOCK

AK402339AC

Front view

Right side view

Under view

Top view

Rear view

Left side view

Thermostat case installation positionOil filter bracket installation position Front

Front Front Front

Nipple

The cylinder b

l ock is ma de of ligh twe i ght aluminum

allo

y .

The crankshaf t jo urnal is supp orted b y 5 b earing s .

The crankshaf

t thru st load is supporte d by No . 4

bearin

g.

The water jacket is of a full-siamese de sig n .

A nipple is p r ovid ed at the fr o n t of the block to su pply

engin

e oil onto the timin g ch ain.

ItemDimension

Overall height mm280

Overall length mm375.1

Top face to crankshaft

center mm205

Crankshaft center to

bottom face mm75

Bore mm75

Bore pitch mm83

Stroke mm84.8

Page 54 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-6

REAR OIL SEAL CASE

AK305061AB

AA A-A

The rea

r oil seal ca se is a sheet -met al wor k . The

case is

inst alled with sealant ap plie d onto th e mou n t

-

ing face to prevent oil leaka ge.

PISTON

AK403222

AB

Front mark

Piston pin offset

The pisto n is made of spec ial a l uminu m all o y . W e ig ht

reduction

is a c hieved by minimizin g the o v erall

heigh

t while maximizing th e recess on bo th end s of

the piston

pin.

The center o f the p i sto n pin hole is of fset by 0.5 mm

from t

he ce nter of the piston towards the th rust side .

The piston skirt ha s a streak finish to enha nce oil

retention an

d anti-seizin g prope rty .

ItemDimension

Base diameter mm75

Pin diameter mm18

Overall height mm46.04

PISTON PIN

AK305064

d

AB

D

h

The piston pin is o f a semi-floating type, p r ess-fitte d

into t

he co nnecting rod small end wh ile cap able of

floating re

lative to the piston .

ItemDimension

D (Outer diameter) mm18

d (Inner diameter) mm11

h (Overall length) mm50

Page 55 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-7

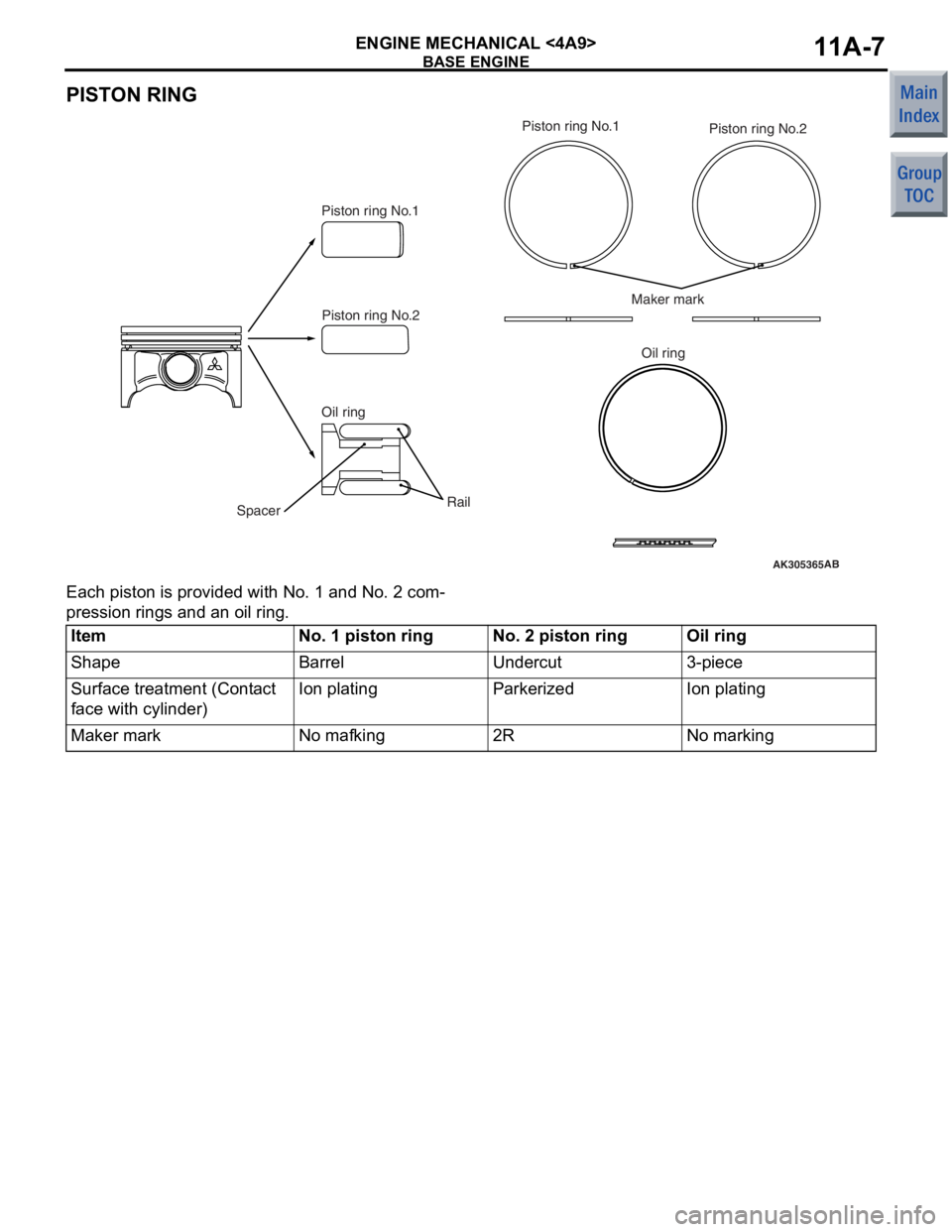

PISTON RING

AK305365AB

Piston ring No.1

Spacer RailMaker mark

Piston ring No.2

Oil ring Piston ring No.1

Piston ring No.2

Oil ring

Ea ch pisto n is provided with No. 1 and No. 2 com-

pression rings and an oil rin g .

ItemNo. 1 piston ringNo. 2 piston ringOil ring

ShapeBarrelUndercut3-piece

Surface treatment (Contact

face with cylinder)Ion platingParkerizedIon plating

Maker markNo mafking2RNo marking

Page 56 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-8

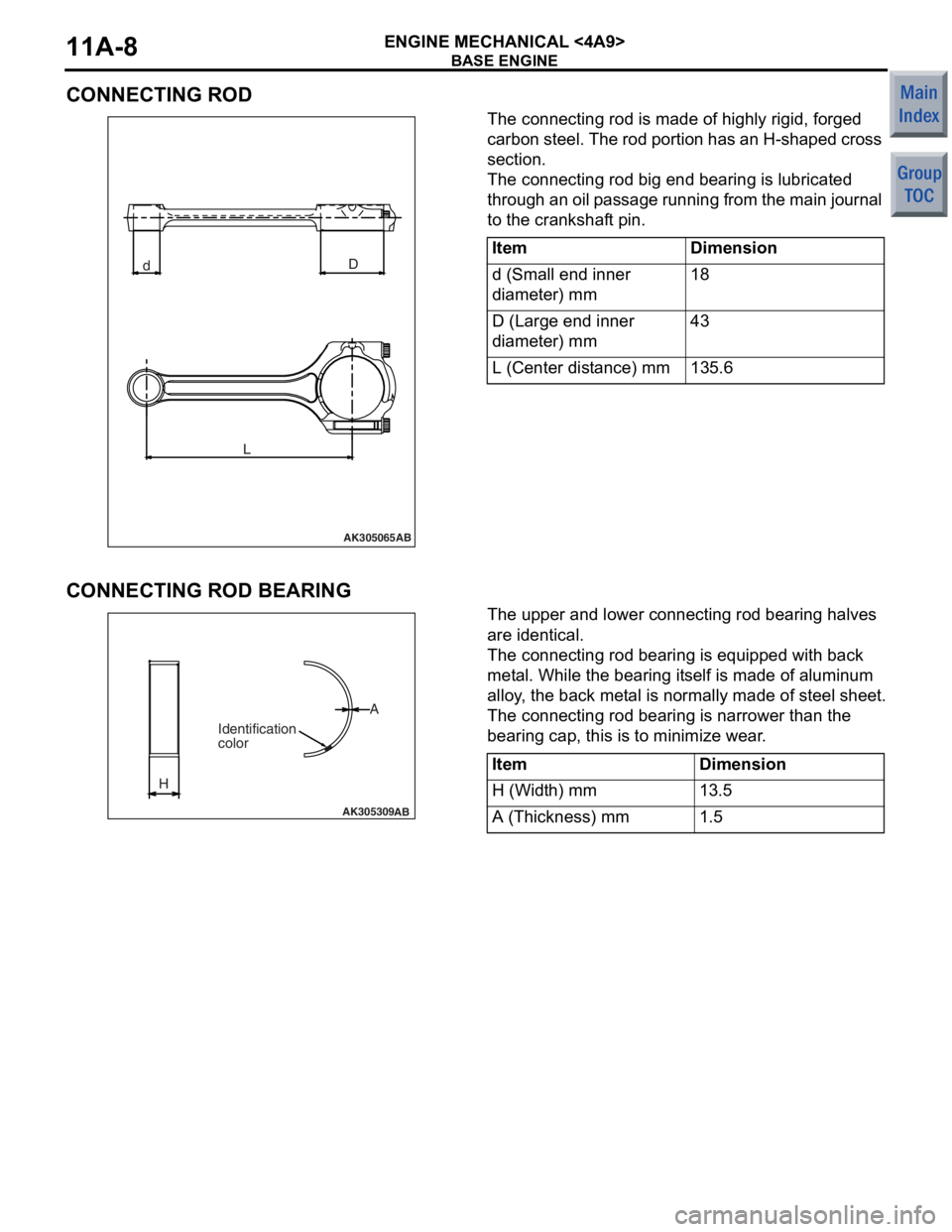

CONNECTING ROD

AK305065AB

dD

L

The connecting rod is made of high ly rigid, forged

carb

on stee l. The rod p o rtion h a s an H- sha ped cro s s

section.

The connecting rod big end bearing is lu bricated

thr

oug h an oil p a ssage ru nn in g f r om the main jo urn a l

to the cranksha

f t p i n.

ItemDimension

d (Small end inner

diameter) mm18

D (Large end inner

diameter) mm43

L (Center distance) mm135.6

CONNECTING ROD BEARING

AK305309AB

H A

Identification

color

The up

per and lower conne ctin g rod b earin g halves

are id

entical.

The connecting rod be aring is e quip ped wit h back

met

a l. While the b earin g it se lf is ma de of a l uminum

allo

y , the back met a l is no rmally mad e of ste e l shee t.

The connecting rod be aring is n a rrower tha n the

bearin

g ca p, this is to minimize wear .

ItemDimension

H (Width) mm13.5

A (Thickness) mm1.5

Page 57 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-9

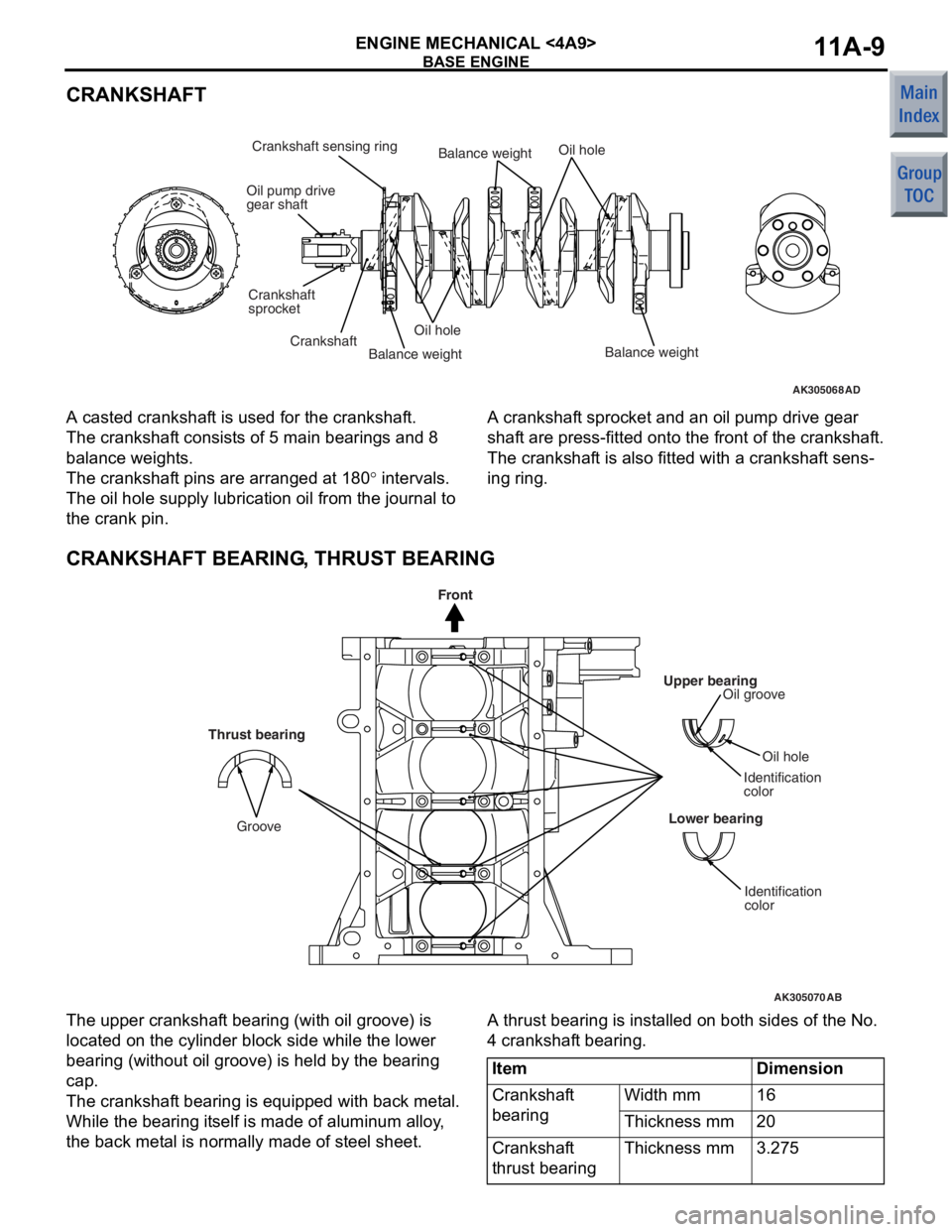

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275