engine MITSUBISHI COLT 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 58 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-10

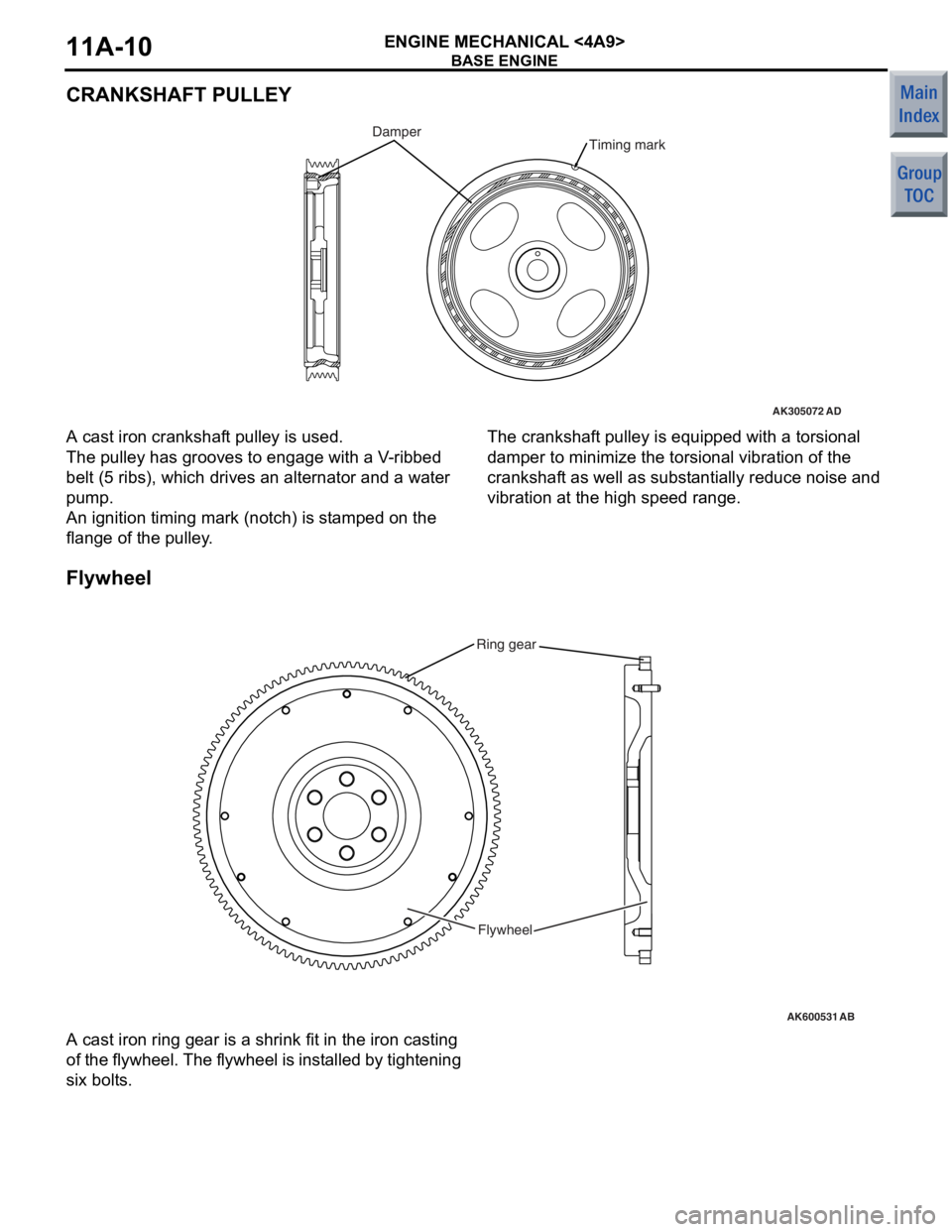

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 59 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-11

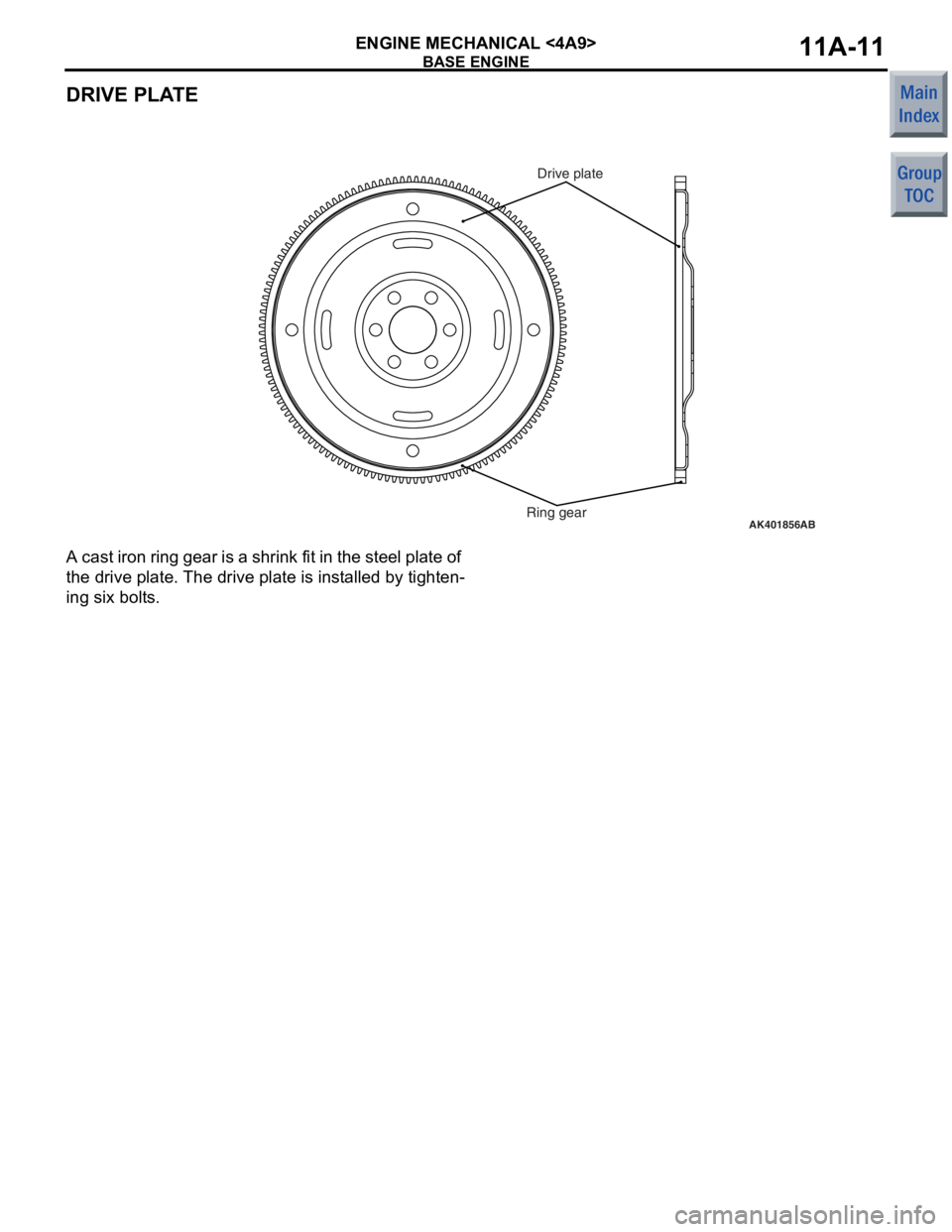

DRIVE PLATE

AK401856Ring gearDrive plateAB

A cast iron

ring g ear is a shrin k fit in th e ste e l plate o f

the drive p

l ate. The drive p l ate is inst alled b y tighten

-

ing six bolts .

Page 60 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-12

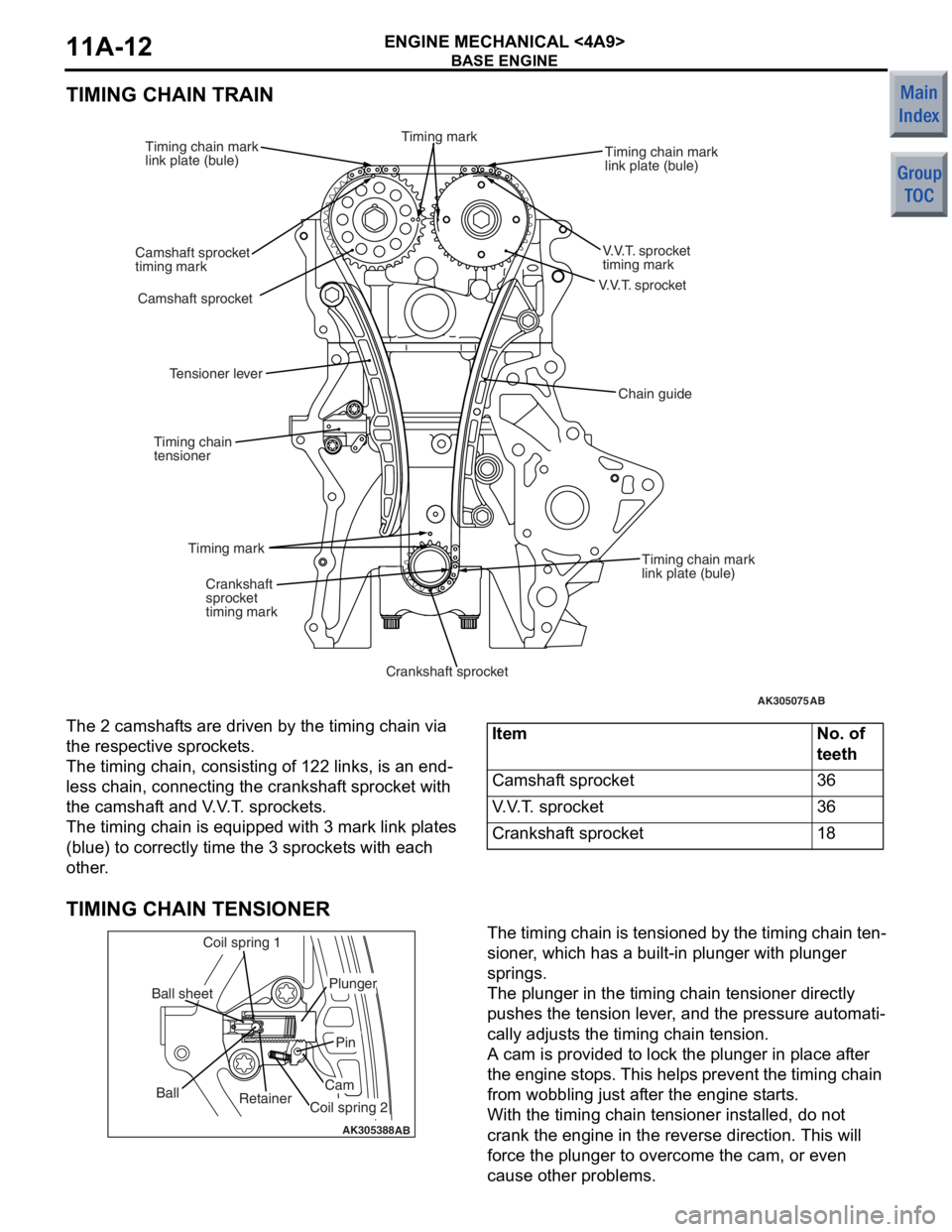

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 61 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-13

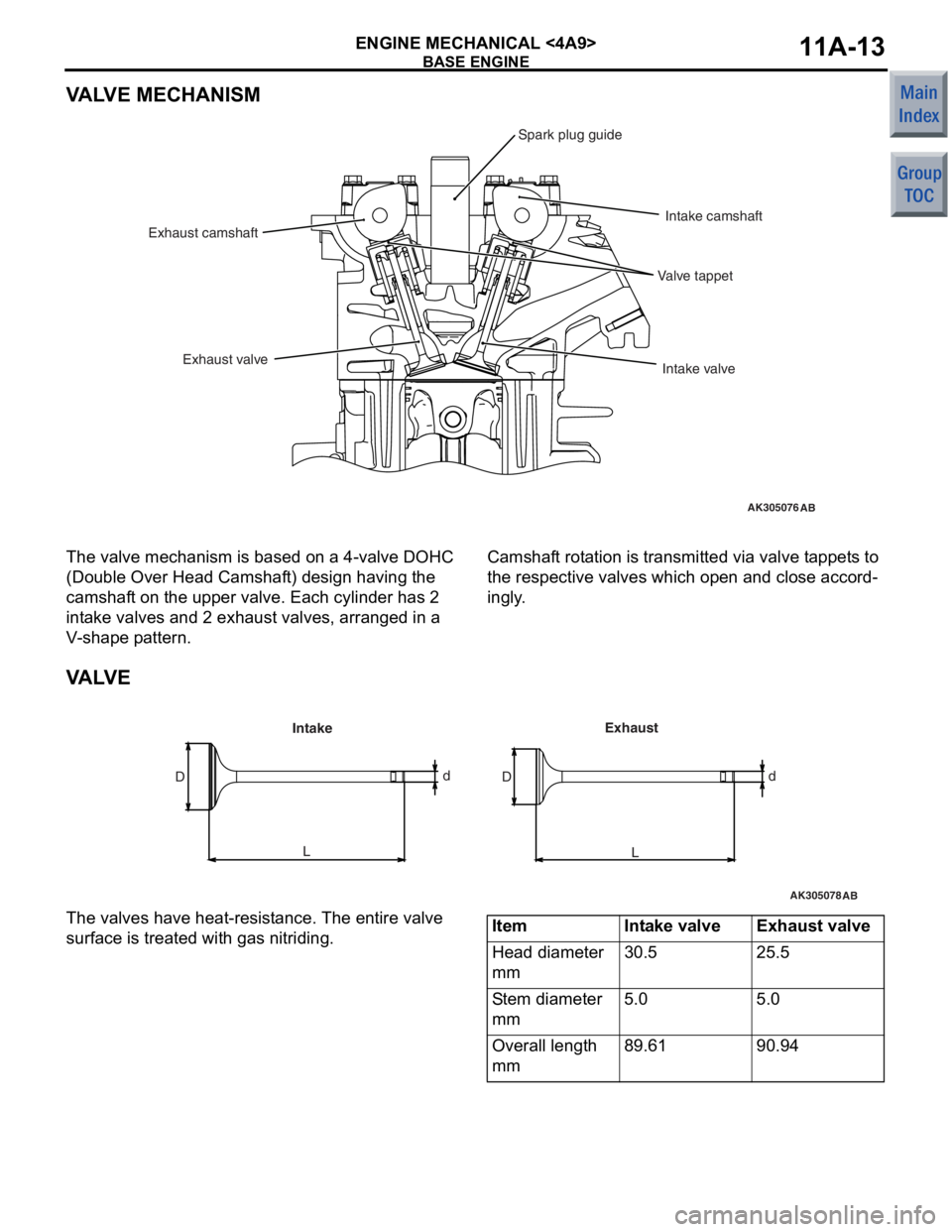

VALVE MECHANISM

AK305076AB

Exhaust valveIntake valve

Exhaust camshaft

Intake camshaft

Spark plug guide

Valve tappet

The valve mechanism is based on a 4-va lve DOHC

(Do

uble Over Head Camsha f t ) d e sign having the

camshaf

t on the u pper valve. Each cylin der has 2

int

a ke valves and 2 exh aust valves, arrang ed in a

V

- shape p a ttern.Camsh a f t rot a tion is transmitte d via va lve t a ppet s to

the respective

valves which ope n and close accord

-

ingly.

VALV E

AK305078

d

d

DD

L

Intake

Exhaust

L

AB

The valves ha ve h eat-resist an ce. Th e entire valve

surface is trea

ted with gas nitriding.ItemIntake valveExhaust valve

Head diameter

mm30.525.5

Stem diameter

mm5.05.0

Overall length

mm89.6190.94

Page 62 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-14

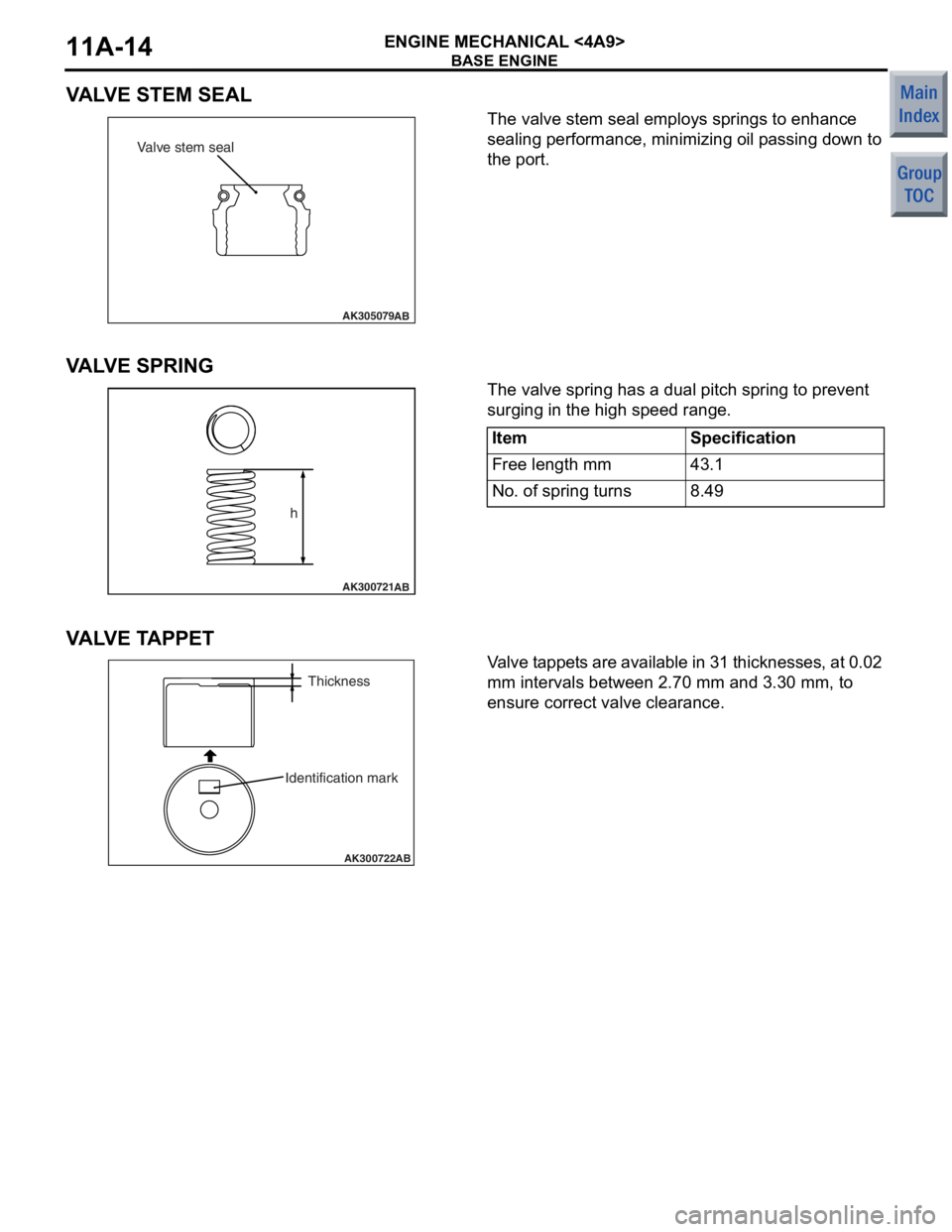

VALVE STEM SEAL

AK305079AB

Valve stem seal

The valve stem seal e m ploys springs to enh ance

sealing p

e rformance , min i mi zing oil p a ssing do wn to

the por

t.

VALV E S P R I N G

AK300721AB

h

The valve spri ng h a s a dual pitch sp ring to prevent

surging in the h

i gh speed range .

ItemSpecification

Free length mm43.1

No. of spring turns8.49

VA L V E T A PPET

AK300722AB

Thickness

Identification mark

Va lve t app et s are avai lable in 31 th ickne sses, at 0. 02

mm

intervals betwee n 2.70 mm and 3 . 30 mm, to

ensu

r e co rrect valve clearan ce.

Page 63 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-15

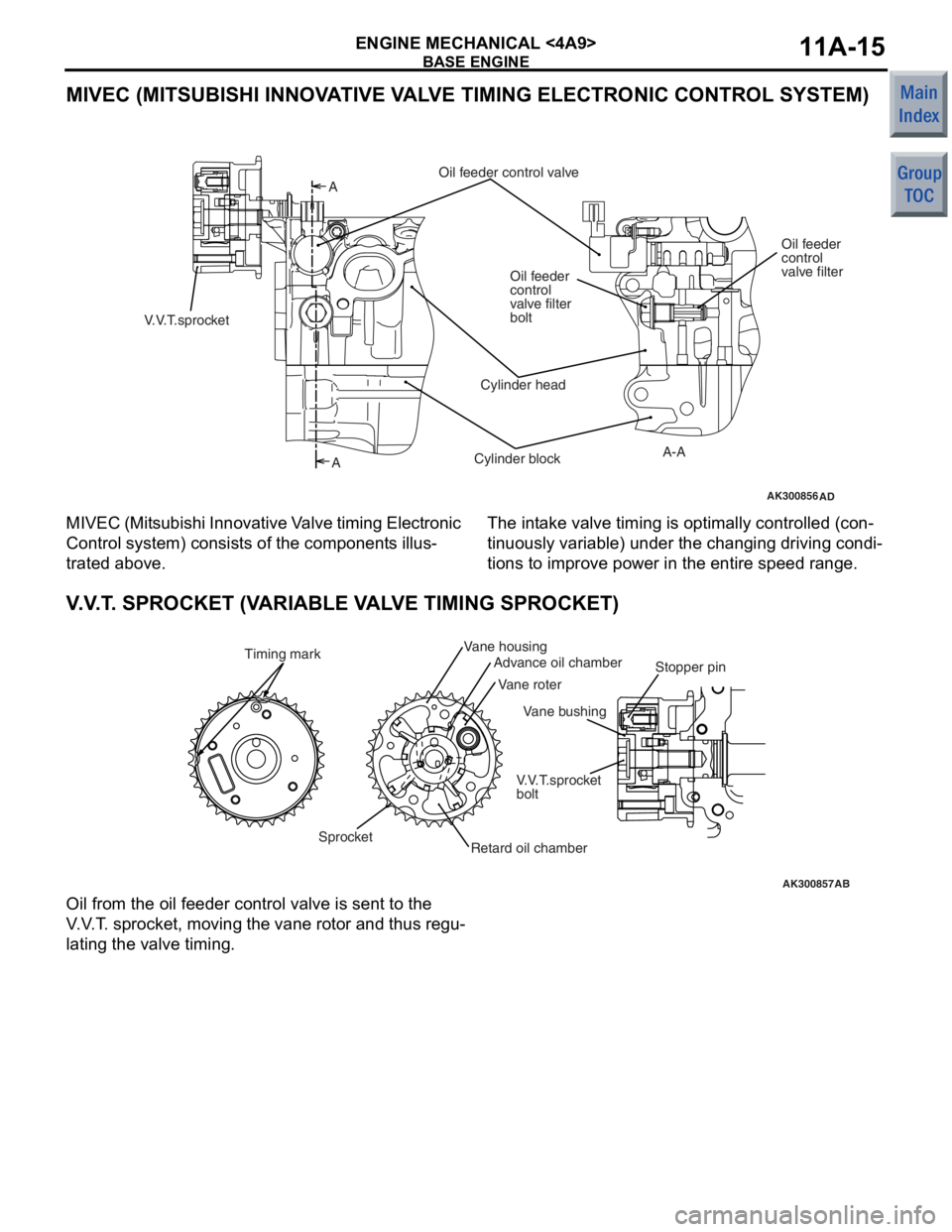

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

AK300856AD

A

A

A-A

Oil feeder control valve

Oil feeder

control

valve filter

Oil feeder

control

valve filter

bolt

Cylinder head

Cylinder block

V.V.T.sprocket

M I VEC (Mit su bis h i Inn o va tive V a lve tim i ng Elect r o n ic

Con

t rol system) consist s of th e compon ent s illus

-

trated above .

The int a ke valve timing is optimally controlled (con-

tinuously variable) un der the chan ging driving condi-

tions to improv e po we r in th e entire sp eed ra nge.

V. V . T . SPROCKET (V ARIABLE V A L V E TIMING SPROCKET)

AK300857

Vane bushing

AB

SprocketVane roter

V.V.T.sprocket

bolt

Timing mark

Vane housing

Advance oil chamber

Retard oil chamber

Stopper pin

Oil from the oil fe

eder control valve is sent t o the

V

. V . T . sp rocket, moving the vane roto r and thus reg u

-

lating the valve timing.

Page 64 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-16

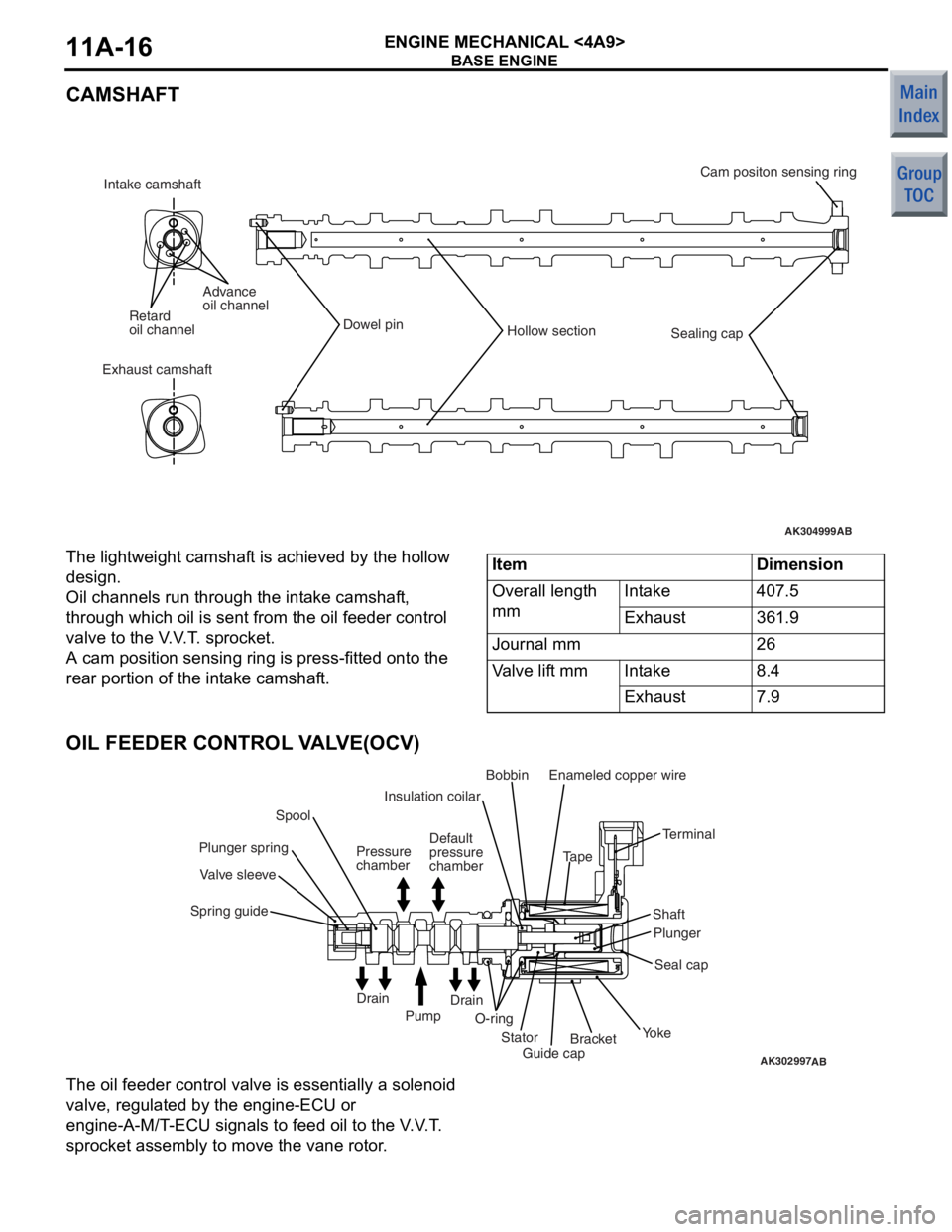

CAMSHAFT

AK304999

Intake camshaft

Exhaust camshaft

AB

Hollow section

Advance

oil channel

Retard

oil channel

Cam positon sensing ring

Dowel pinSealing cap

The lightweight camshaf t is ach i eved by the h o llo w

design.

Oil channels run through the int a ke camshaf t,

through

wh ich oil is sent from t he oil fee der co ntrol

valve to

the V . V . T . sprocket.

A cam position sen s in g ring is press-fitt ed onto the

rear port

i on o f the int a ke camshaf t.

ItemDimension

Overall length

mmIntake407.5

Exhaust361.9

Journal mm26

Valve lift mmIntake8.4

Exhaust7.9

OIL FEEDER CONT ROL V A L V E(OCV)

AK302997AB

Spring guideValve sleeve

Plunger spring Spool

O-ring

Insulation coilar

StatorGuide cap Bracket

Yo k eSeal cap

Plunger

Shaft Terminal

Bobbin

Tape

Enameled copper wire

Drain

Drain

Pump

Pressure

chamber

Default

pressure

chamber

The oil fee

der co ntrol valve is essen t ially a solenoid

valve, re

gulat ed by the en gine -ECU or

engin

e -A-M/T -ECU signals to feed o il to the V . V . T .

sprocket

assemb ly t o move the van e rotor .

Page 65 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-17

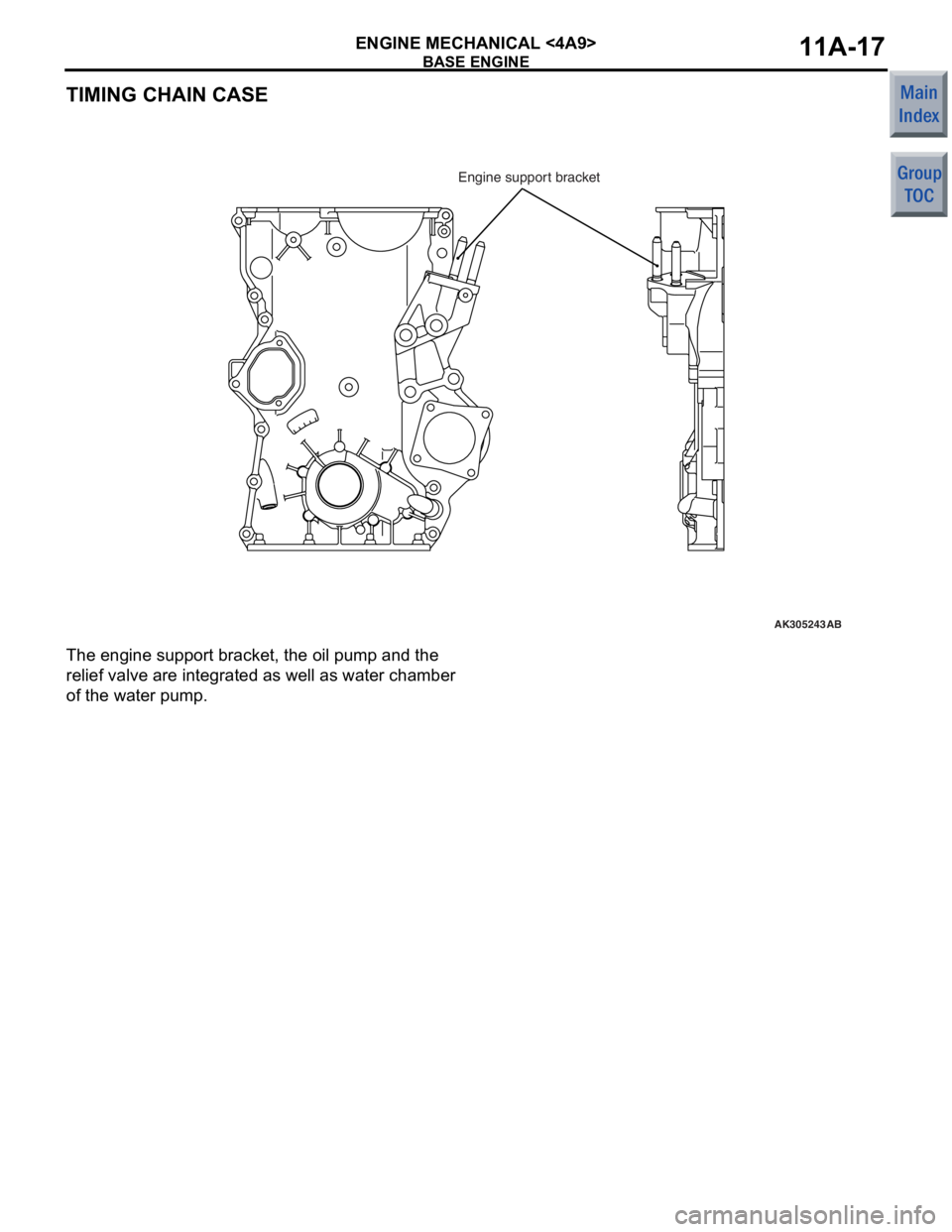

TIMING CHAIN CASE

AK305243

Engine support bracket

AB

The engine supp ort bracket, the oil pu mp a nd the

relie

f valve are in tegrate d as we ll as water chamber

of the wat

e r pump.

Page 66 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4A9>11A-18

GENERAL INFORMATION

M2112000101009

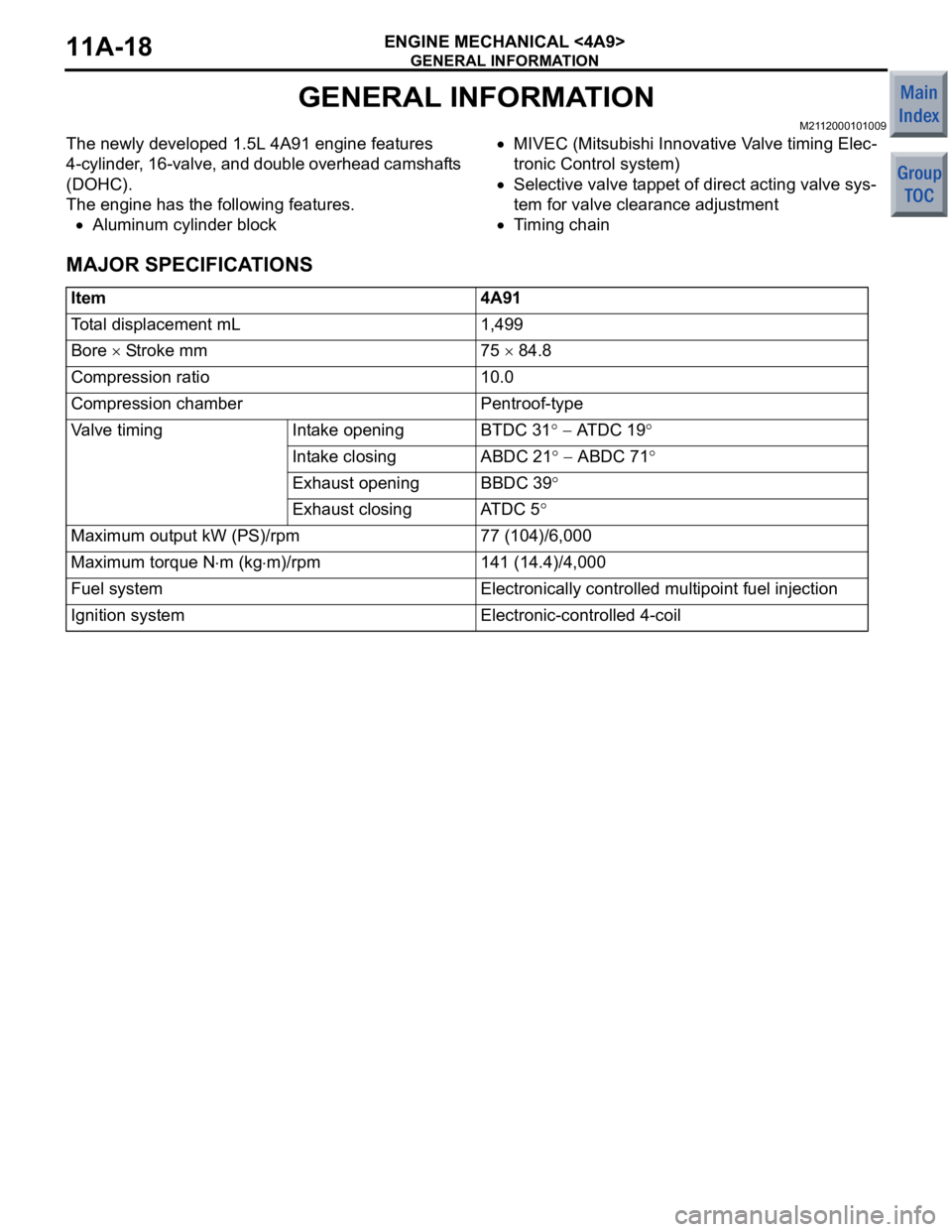

The newly developed 1.5L 4A91 engine features

4-cylinder, 16-valve, and double overhead camshafts

(DOHC).

The engine has the following features.

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

•Selective valve tappet of direct acting valve sys-

tem for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − AT D C 1 9°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (104)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 67 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-19

BASE ENGINE

M2112001000875

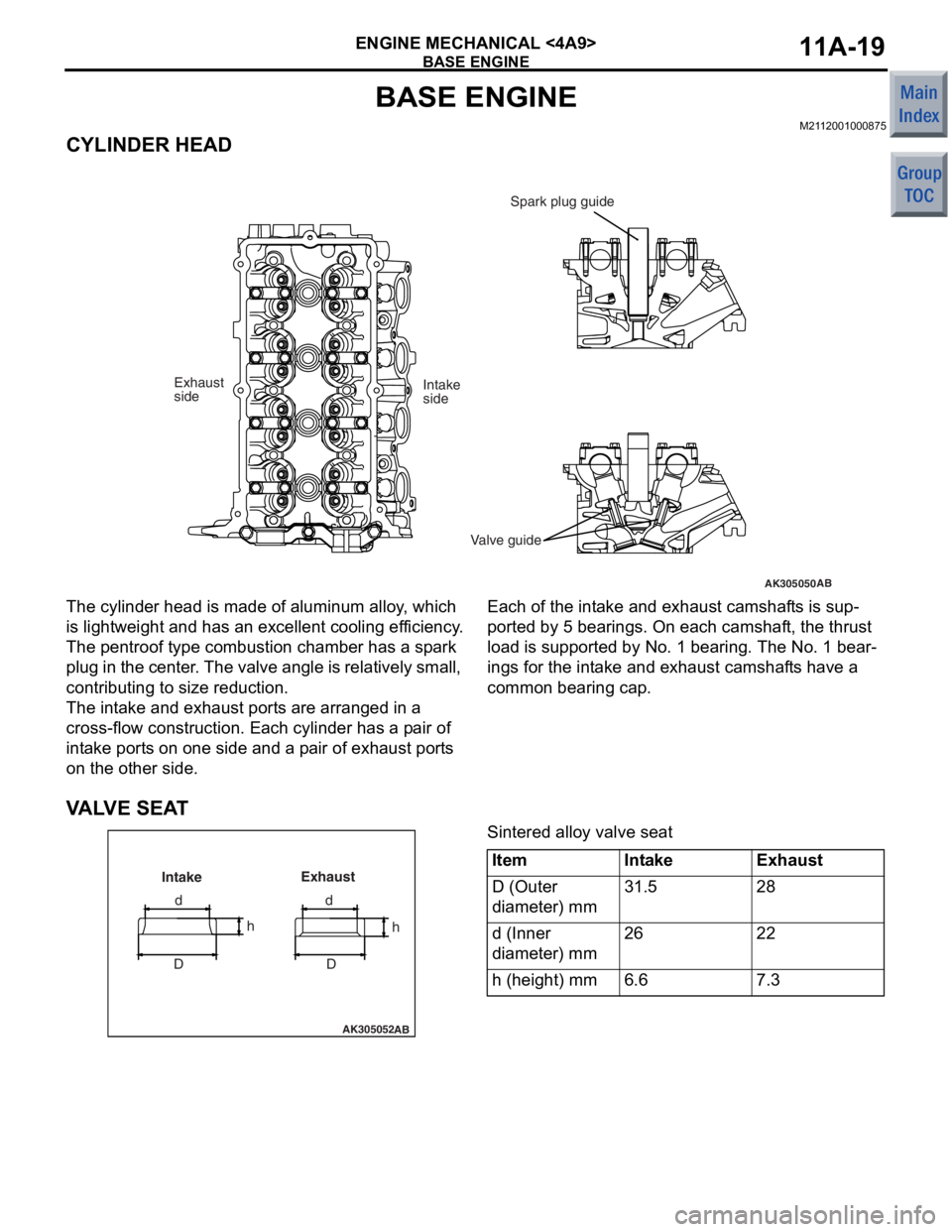

CYLINDER HEAD

AK305050AB

Spark plug guide

Intake

side

Exhaust

side

Valve guide

The cylinder head is made of aluminu m alloy , which

is light

we ight a nd ha s an excelle nt co oling ef ficiency .

The pentroof type comb ustion chamb e r has a sp a r k

plug in the

cent er . The valve an gle is relatively small,

contributing to size redu

ctio n.

The int a ke an d exhaust port s a r e arrang ed in a

cross-flow construction.

Ea ch cylinde r has a p a ir of

int

a ke port s on one side and a p a ir of e x hau st po rt s

on the

other side .

Each o f the int a ke a nd exhaust ca msh a f t s is sup-

ported by 5 bearin gs. On ea ch camshaf t, th e thrust

load

is suppo rted by No. 1 b earin g. The No . 1 bea r

-

ings for the int a ke and exha ust camshaf t s ha ve a

common bearing

ca p.

VALV E S E AT

AK305052

d

AB

d

DD h

h

Intake

Exhaust

Sintered

alloy valve seat

ItemIntakeExhaust

D (Outer

diameter) mm31.528

d (Inner

diameter) mm2622

h (height) mm6.67.3