engine MITSUBISHI COLT 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 68 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-20

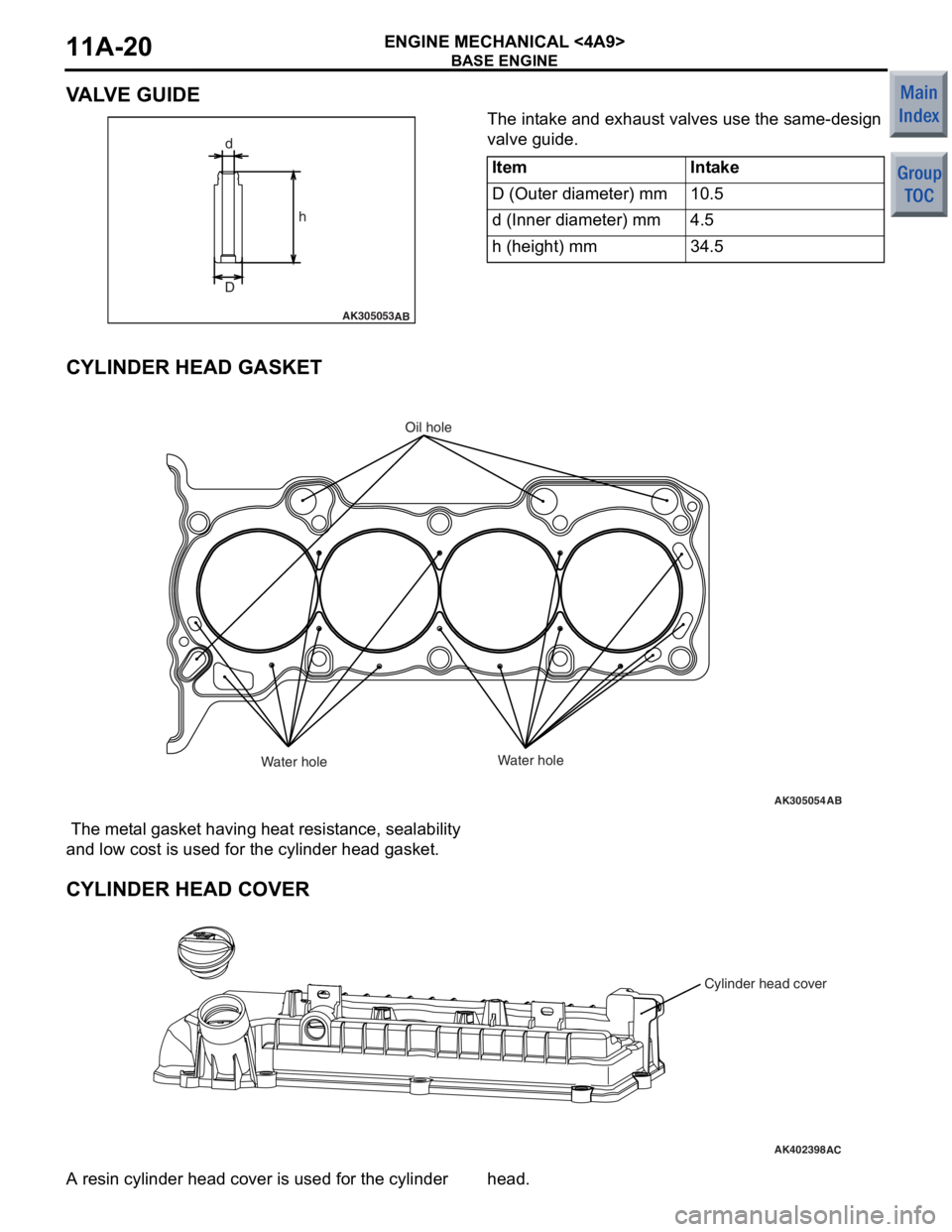

VA LV E G U I D E

AK305053

d

AB

Dh

The in

t a ke an d exhaust valves use the same -design

valve gu

ide.

ItemIntake

D (Outer diameter) mm10.5

d (Inner diameter) mm4.5

h (height) mm34.5

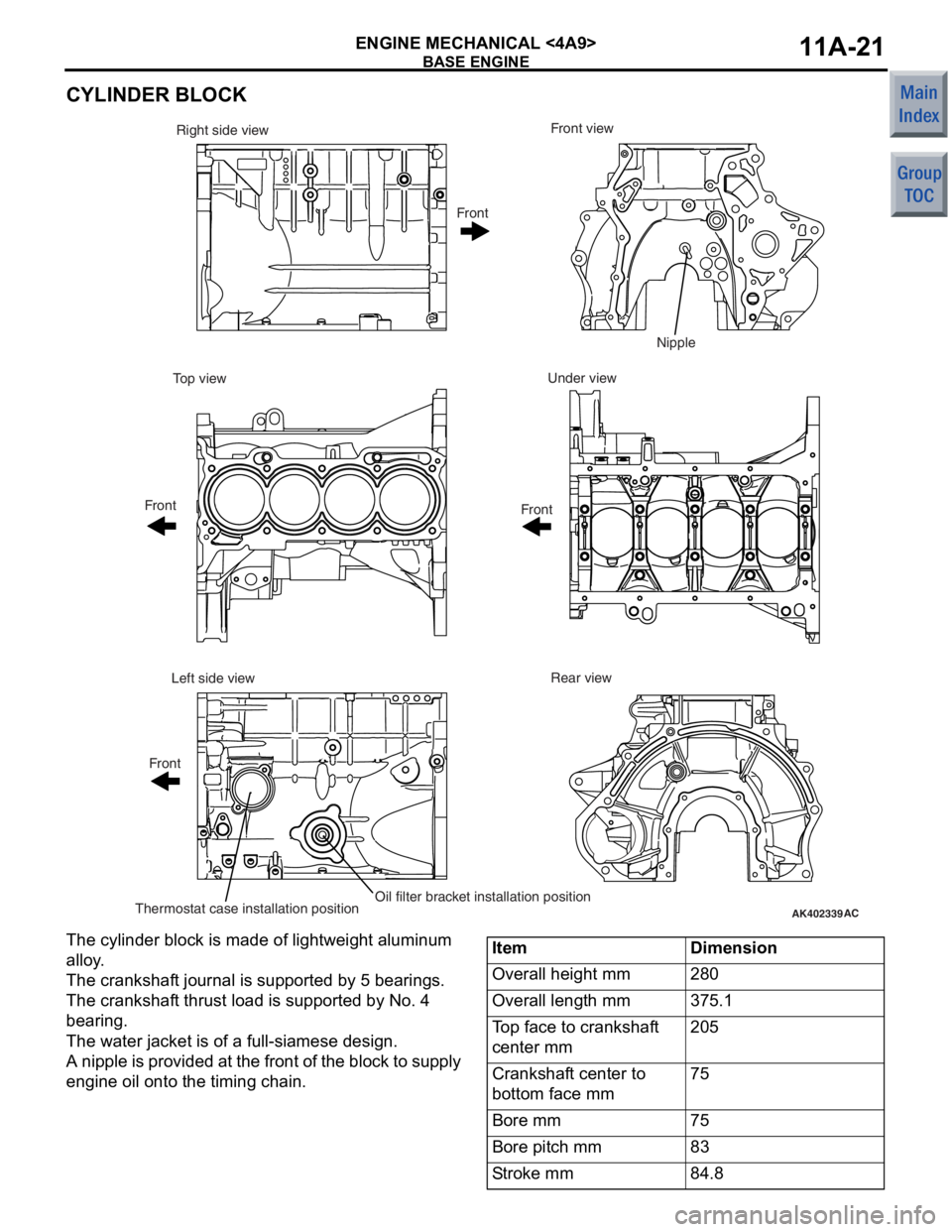

CYLINDER HEAD GASKET

AK305054AB

Water hole

Oil hole

Water hole

Th e met a l g a sket having he at resist ance, sea l ability

and low cost is use

d for th e cylin der hea d gasket .

CYLINDER HEAD COVER

AK402398AC

Cylinder head cover

A resin cylin der hea d co ver is used fo r the cylinder head.

Page 69 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-21

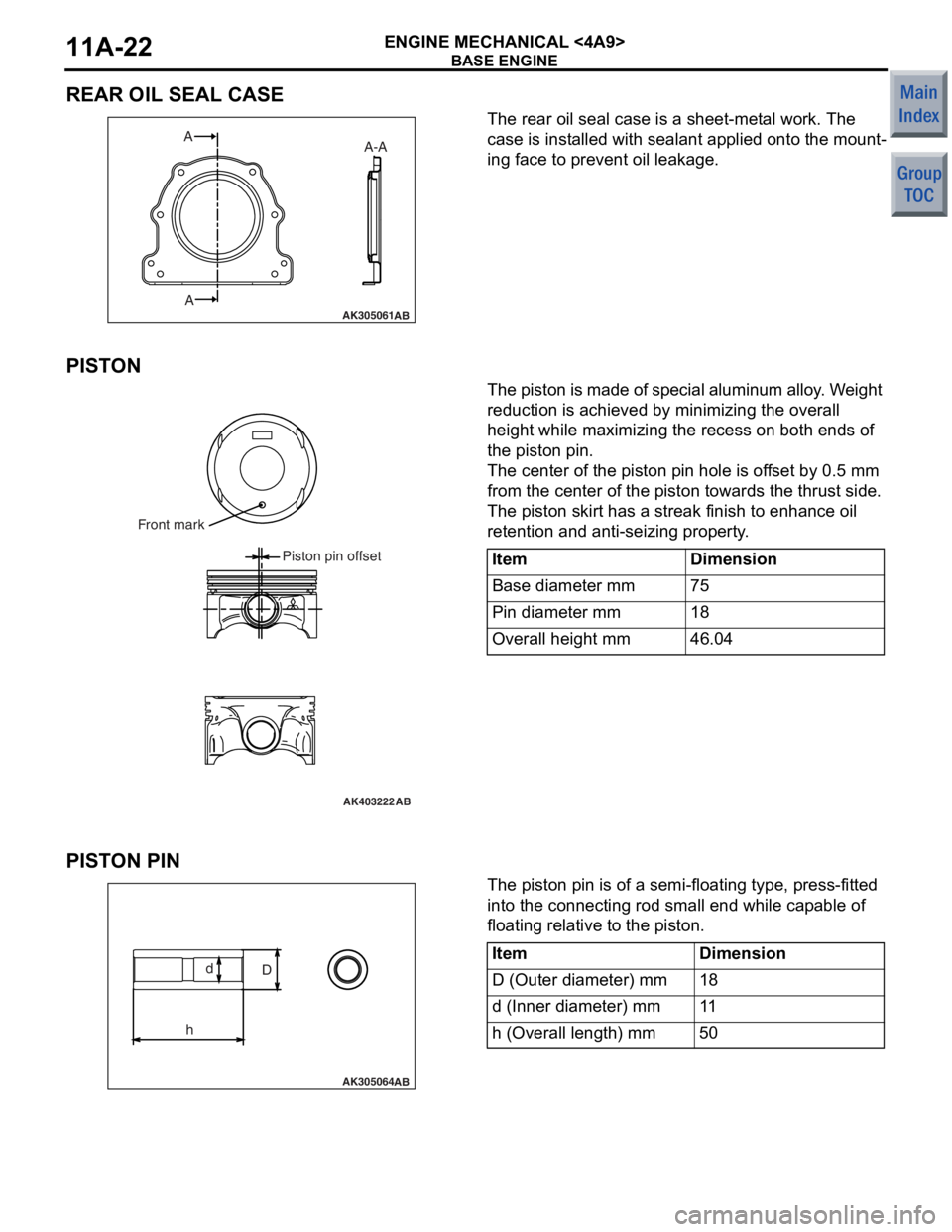

CYLINDER BLOCK

AK402339AC

Front view

Right side view

Under view

Top view

Rear view

Left side view

Thermostat case installation positionOil filter bracket installation position Front

Front Front Front

Nipple

The cylinder b

l ock is ma de of ligh twe i ght aluminum

allo

y .

The crankshaf t jo urnal is supp orted b y 5 b earing s .

The crankshaf

t thru st load is supporte d by No . 4

bearin

g.

The water jacket is of a full-siamese de sig n .

A nipple is p r ovid ed at the fr o n t of the block to su pply

engin

e oil onto the timin g ch ain.

ItemDimension

Overall height mm280

Overall length mm375.1

Top face to crankshaft

center mm205

Crankshaft center to

bottom face mm75

Bore mm75

Bore pitch mm83

Stroke mm84.8

Page 70 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-22

REAR OIL SEAL CASE

AK305061AB

AA A-A

The rea

r oil seal ca se is a sheet -met al wor k . The

case is

inst alled with sealant ap plie d onto th e mou n t

-

ing face to prevent oil leaka ge.

PISTON

AK403222

AB

Front mark

Piston pin offset

The pisto n is made of spec ial a l uminu m all o y . W e ig ht

reduction

is a c hieved by minimizin g the o v erall

heigh

t while maximizing th e recess on bo th end s of

the piston

pin.

The center o f the p i sto n pin hole is of fset by 0.5 mm

from t

he ce nter of the piston towards the th rust side .

The piston skirt ha s a streak finish to enha nce oil

retention an

d anti-seizin g prope rty .

ItemDimension

Base diameter mm75

Pin diameter mm18

Overall height mm46.04

PISTON PIN

AK305064

d

AB

D

h

The piston pin is o f a semi-floating type, p r ess-fitte d

into t

he co nnecting rod small end wh ile cap able of

floating re

lative to the piston .

ItemDimension

D (Outer diameter) mm18

d (Inner diameter) mm11

h (Overall length) mm50

Page 71 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-23

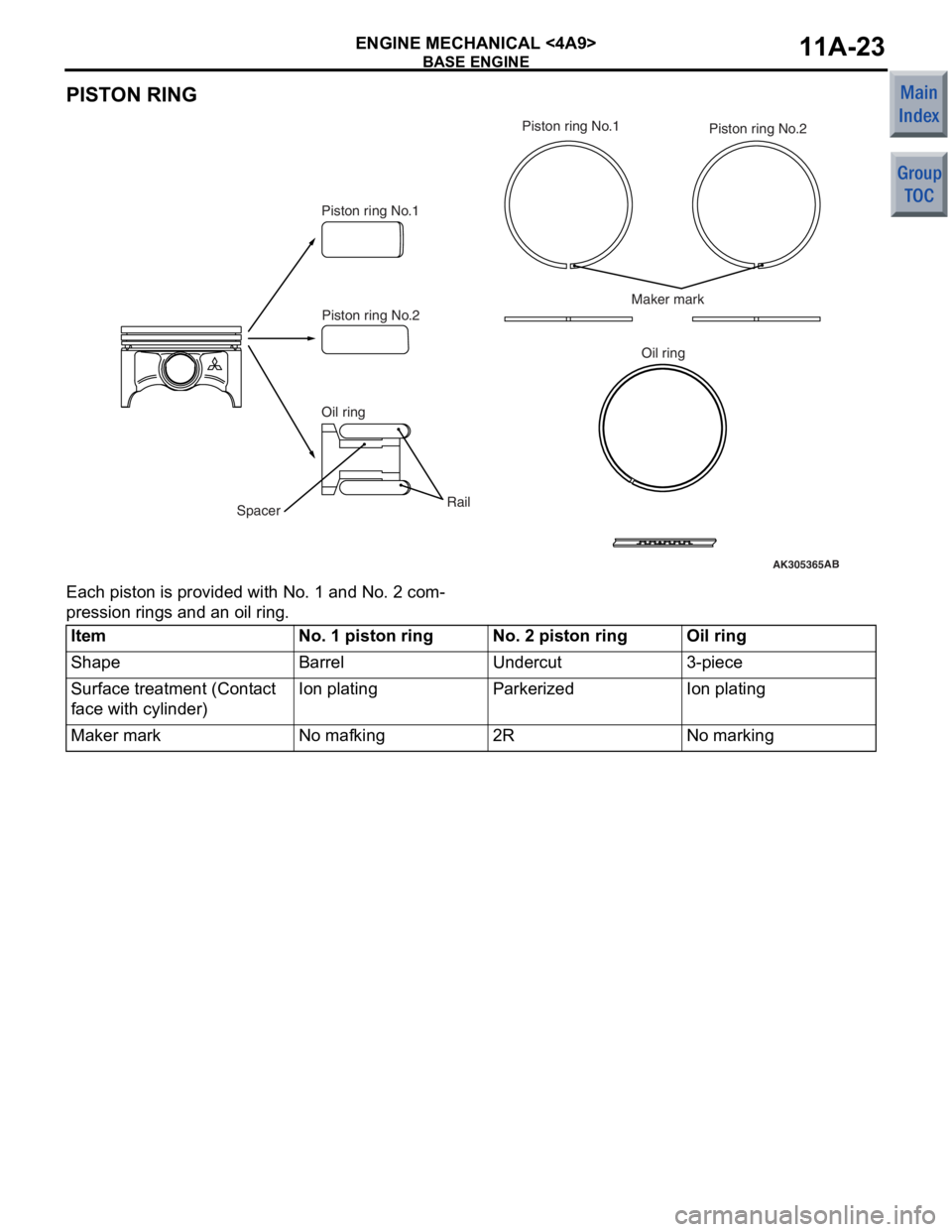

PISTON RING

AK305365AB

Piston ring No.1

Spacer RailMaker mark

Piston ring No.2

Oil ring Piston ring No.1

Piston ring No.2

Oil ring

Ea ch pisto n is provided with No. 1 and No. 2 com-

pression rings and an oil rin g .

ItemNo. 1 piston ringNo. 2 piston ringOil ring

ShapeBarrelUndercut3-piece

Surface treatment (Contact

face with cylinder)Ion platingParkerizedIon plating

Maker markNo mafking2RNo marking

Page 72 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-24

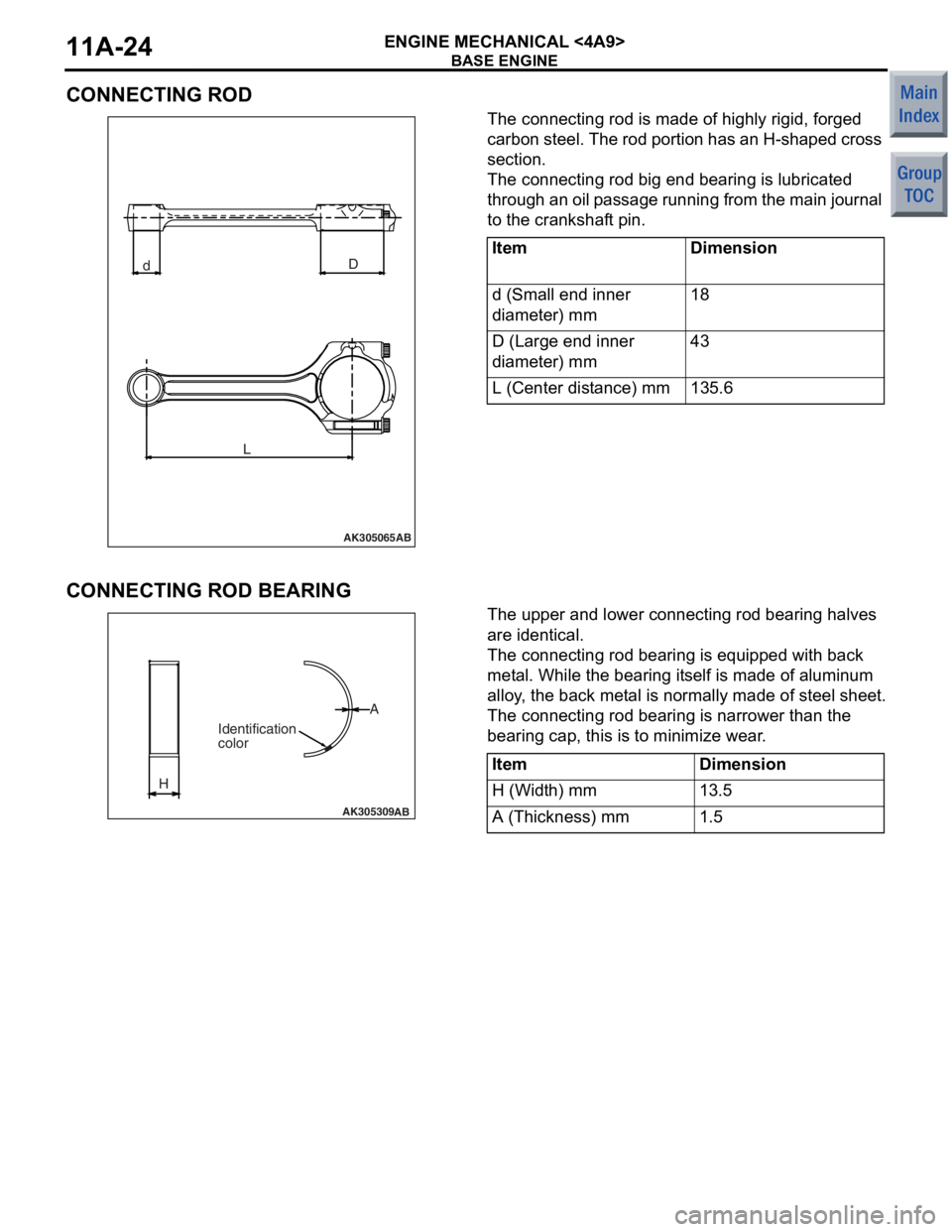

CONNECTING ROD

AK305065AB

dD

L

The connecting rod is made of high ly rigid, forged

carb

on stee l. The rod p o rtion h a s an H- sha ped cro s s

section.

The connecting rod big end bearing is lu bricated

thr

oug h an oil p a ssage ru nn in g f r om the main jo urn a l

to the cranksha

f t p i n.

ItemDimension

d (Small end inner

diameter) mm18

D (Large end inner

diameter) mm43

L (Center distance) mm135.6

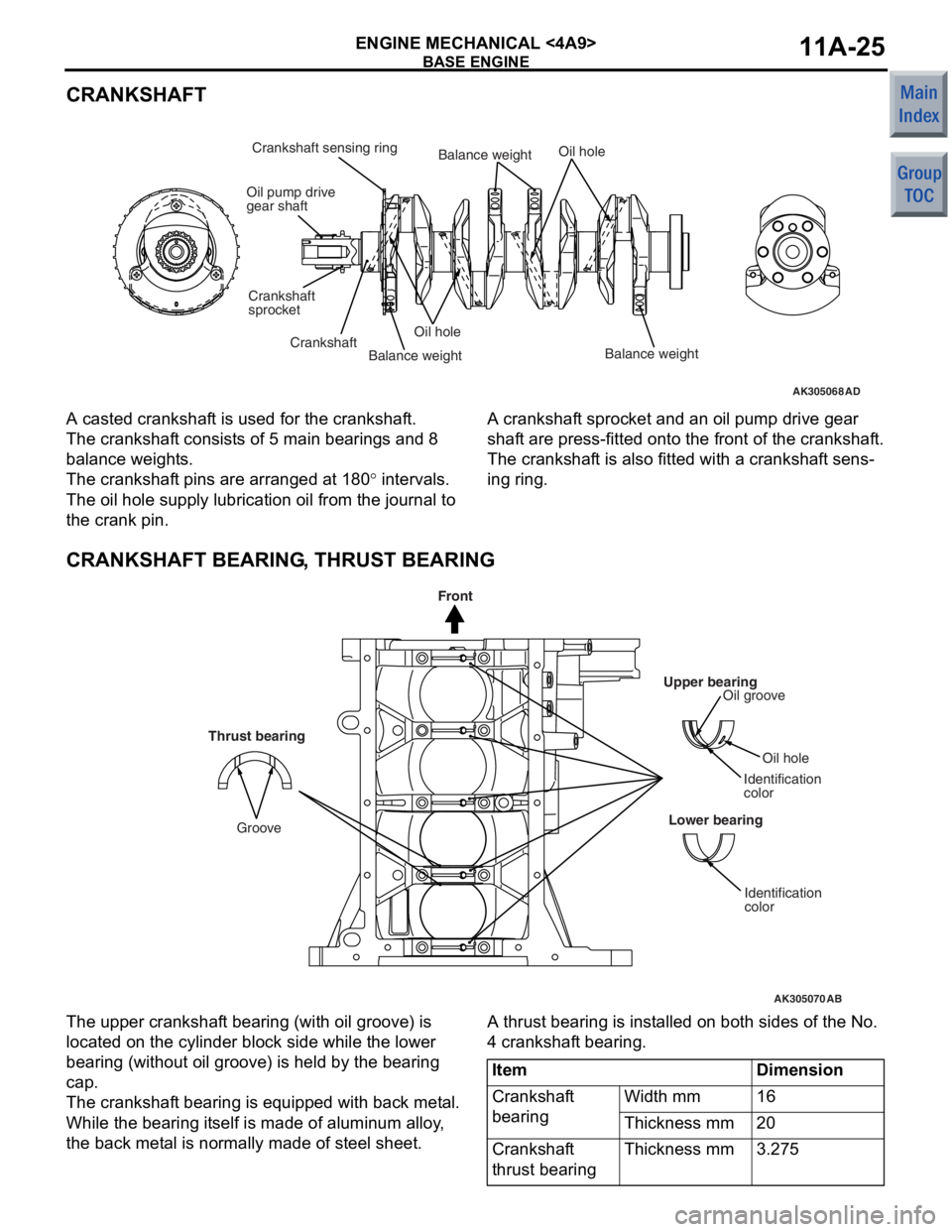

CONNECTING ROD BEARING

AK305309AB

H A

Identification

color

The up

per and lower conne ctin g rod b earin g halves

are id

entical.

The connecting rod be aring is e quip ped wit h back

met

a l. While the b earin g it se lf is ma de of a l uminum

allo

y , the back met a l is no rmally mad e of ste e l shee t.

The connecting rod be aring is n a rrower tha n the

bearin

g ca p, this is to minimize wear .

ItemDimension

H (Width) mm13.5

A (Thickness) mm1.5

Page 73 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-25

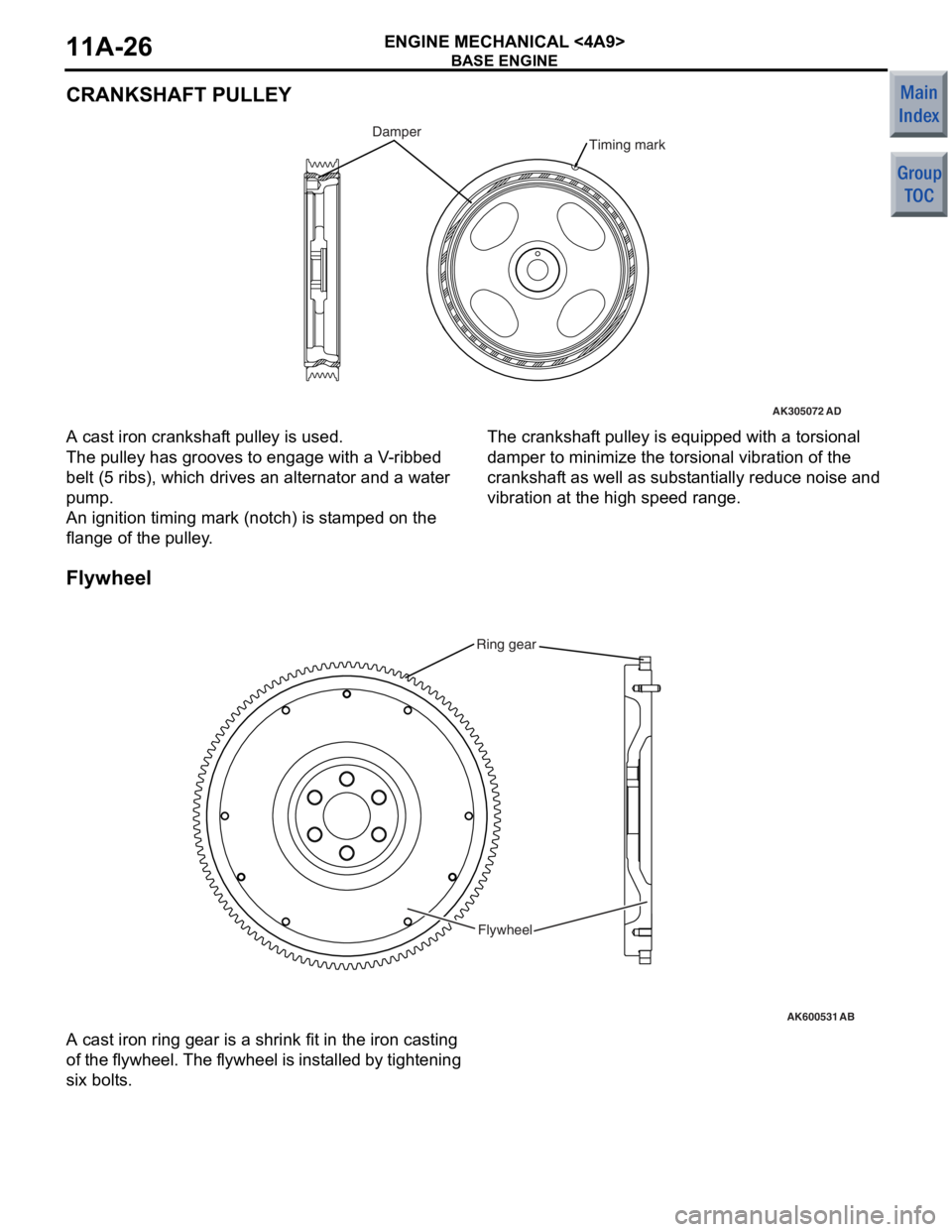

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 74 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-26

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 75 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-27

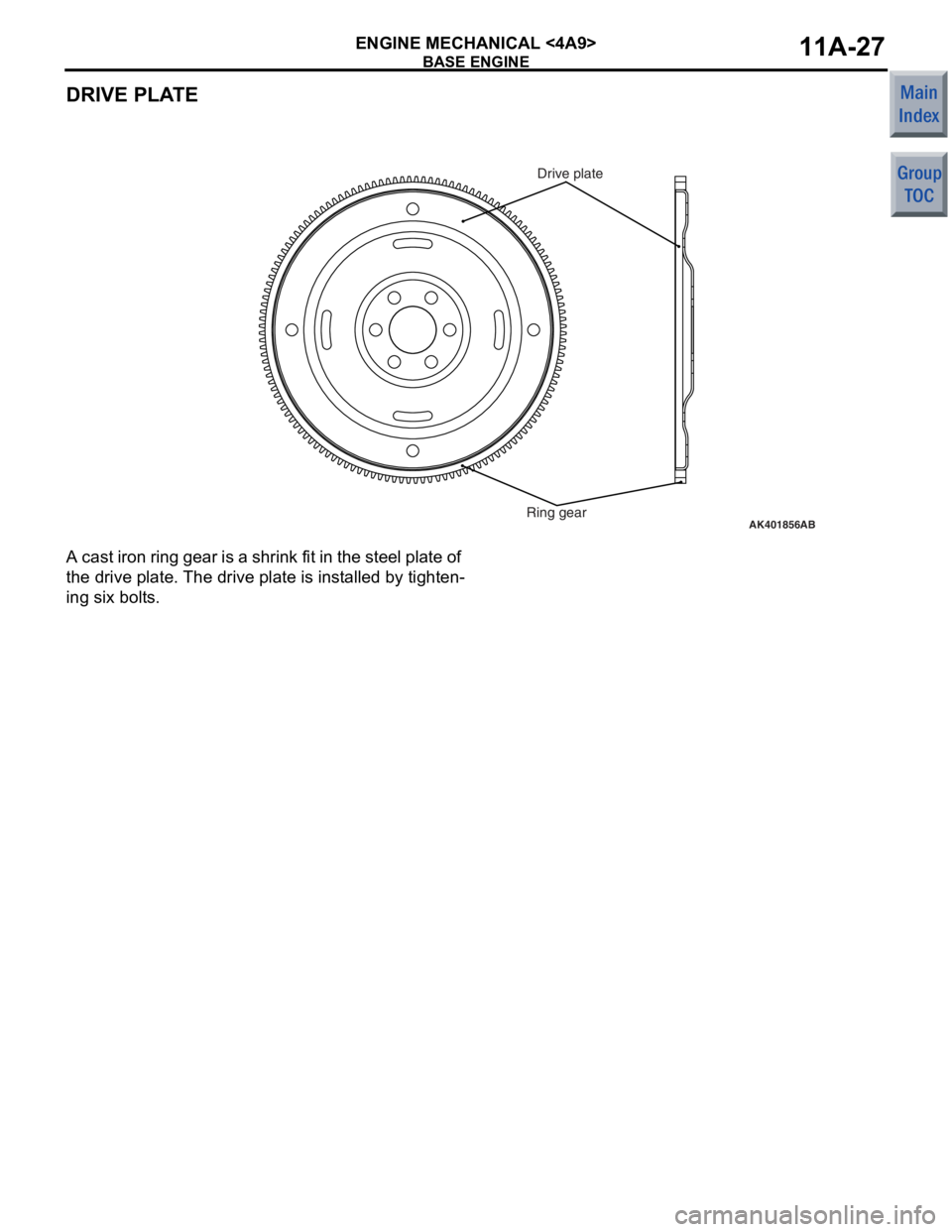

DRIVE PLATE

AK401856Ring gearDrive plateAB

A cast iron

ring g ear is a shrin k fit in th e ste e l plate o f

the drive p

l ate. The drive p l ate is inst alled b y tighten

-

ing six bolts .

Page 76 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-28

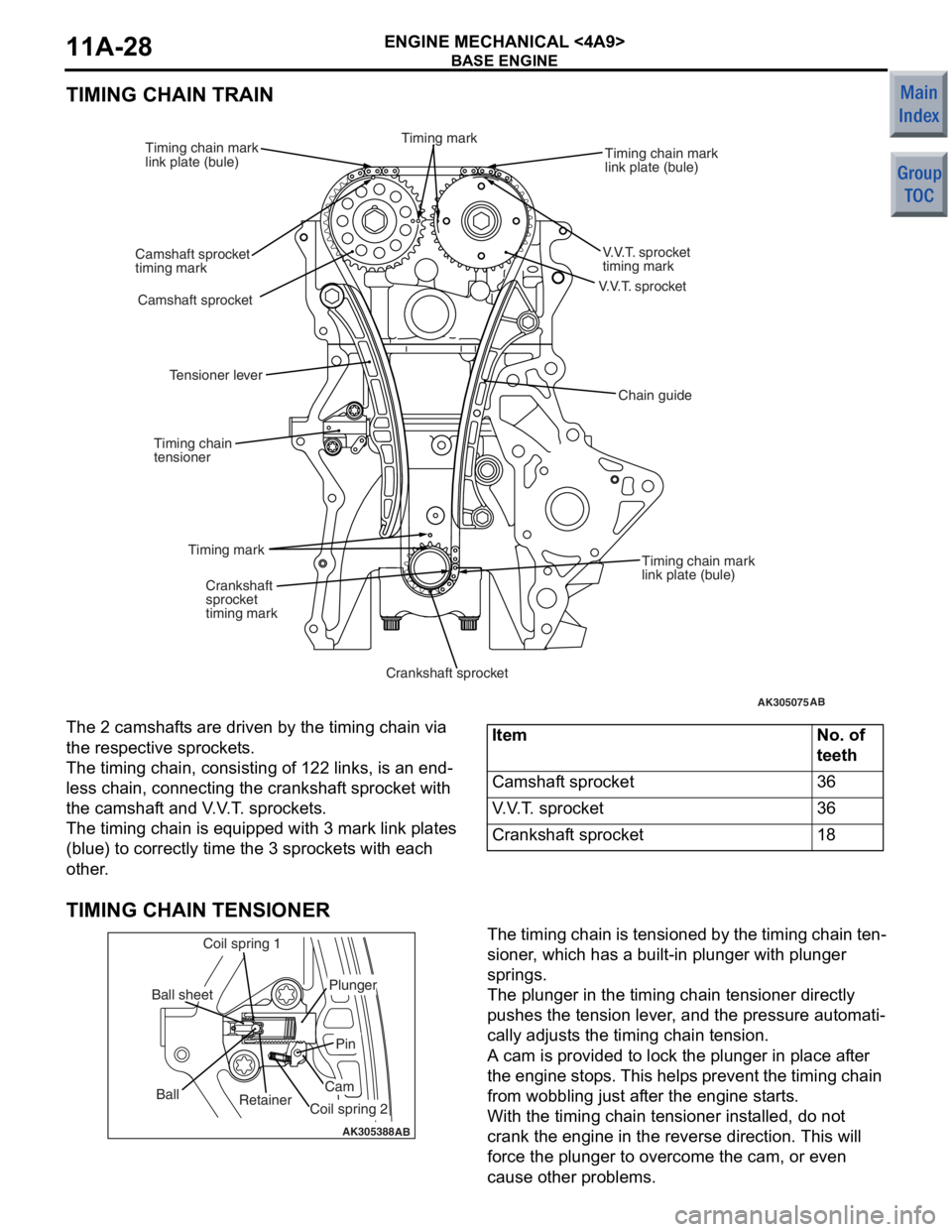

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 77 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-29

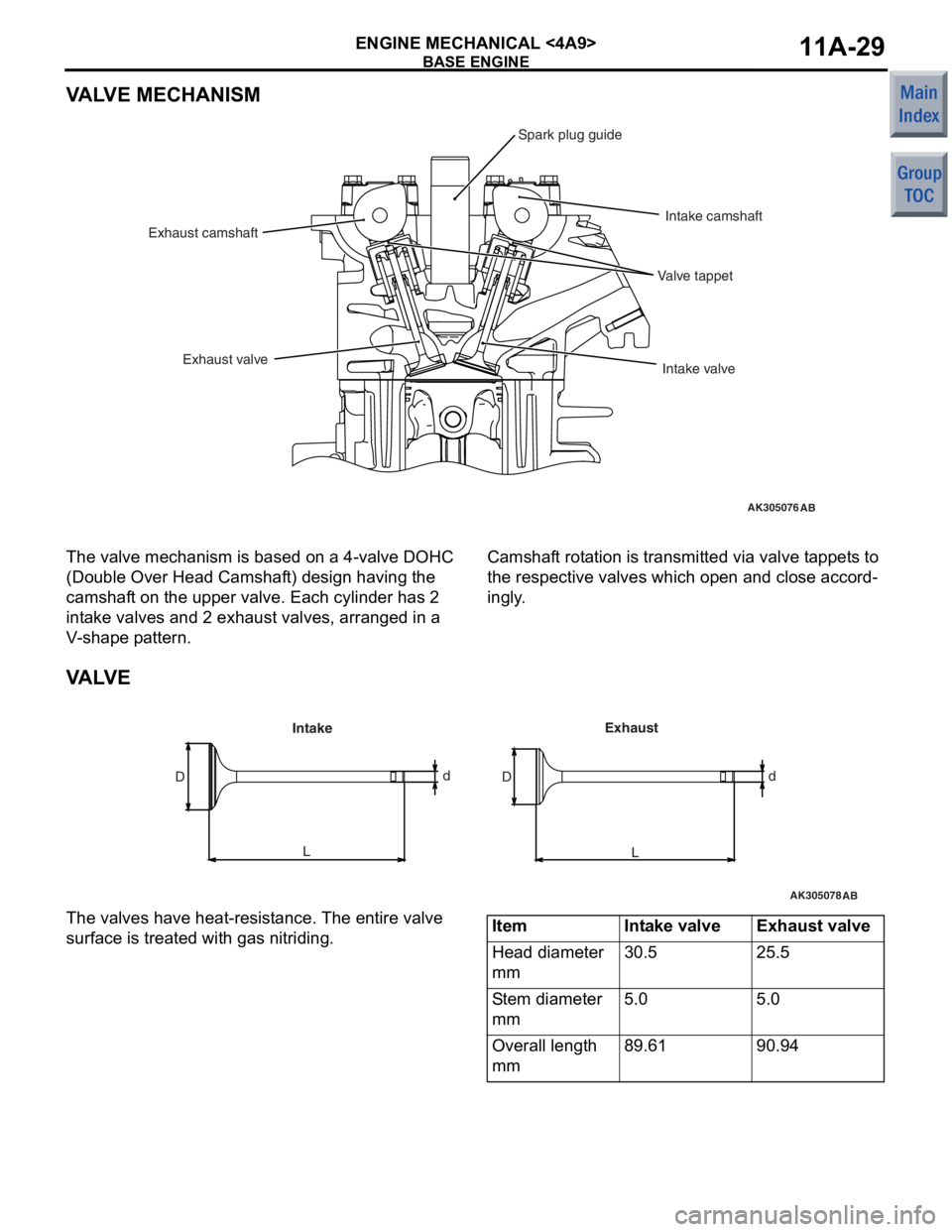

VALVE MECHANISM

AK305076AB

Exhaust valveIntake valve

Exhaust camshaft

Intake camshaft

Spark plug guide

Valve tappet

The valve mechanism is based on a 4-va lve DOHC

(Do

uble Over Head Camsha f t ) d e sign having the

camshaf

t on the u pper valve. Each cylin der has 2

int

a ke valves and 2 exh aust valves, arrang ed in a

V

- shape p a ttern.Camsh a f t rot a tion is transmitte d via va lve t a ppet s to

the respective

valves which ope n and close accord

-

ingly.

VALV E

AK305078

d

d

DD

L

Intake

Exhaust

L

AB

The valves ha ve h eat-resist an ce. Th e entire valve

surface is trea

ted with gas nitriding.ItemIntake valveExhaust valve

Head diameter

mm30.525.5

Stem diameter

mm5.05.0

Overall length

mm89.6190.94