timing MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 89 of 364

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M2120000100175

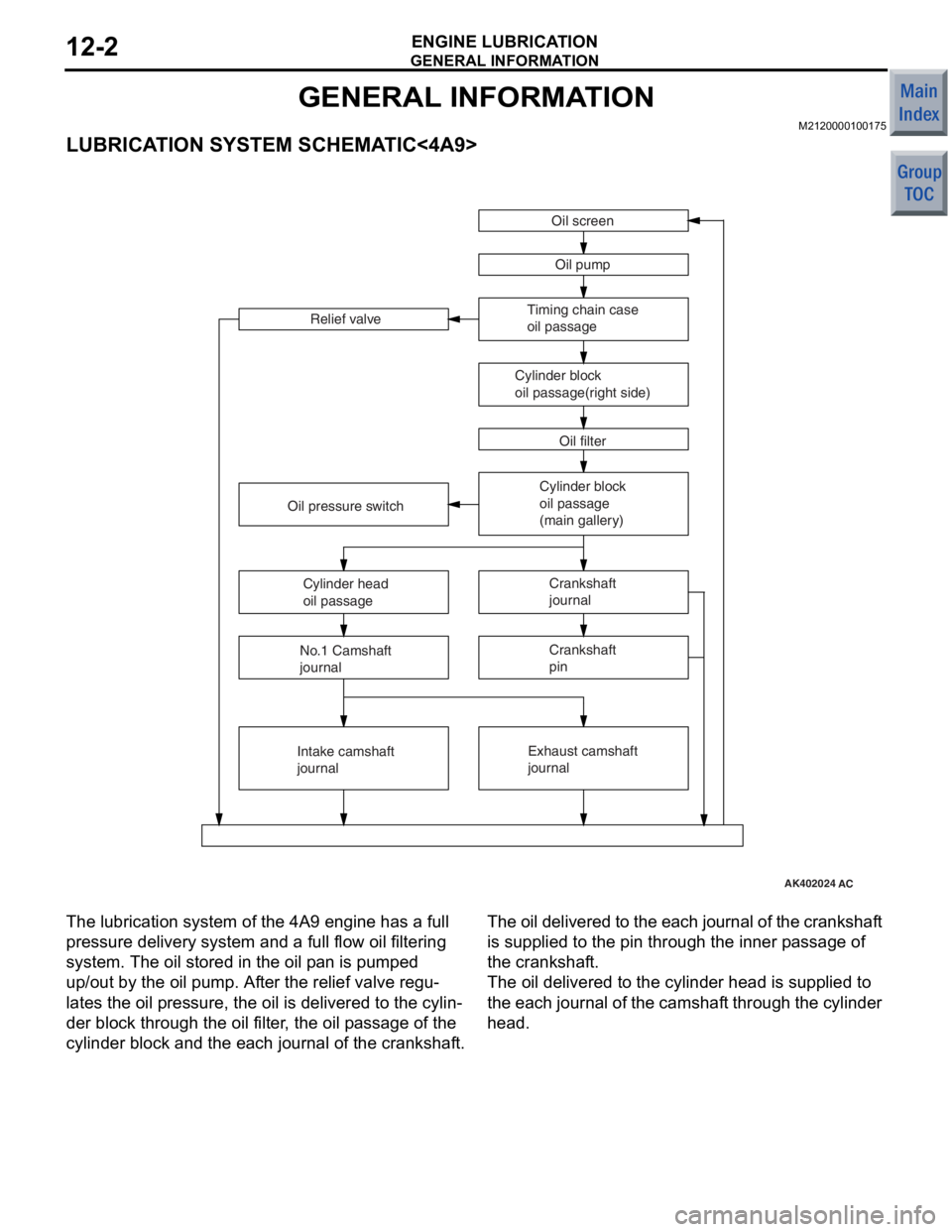

LUBRICATION SYSTEM SCHEMATIC<4A9>

AK402024AC

Oil screenOil pump

Timing chain case

oil passage

Cylinder block

oil passage(right side) Oil filter

Relief valve

Cylinder block

oil passage

(main gallery)Crankshaft

journal

Exhaust camshaft

journal

Oil pressure switch

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal Crankshaft

pin

The lu

brication system of th e 4A9 en gine has a full

pressure de

livery system and a full flow oil filtering

system. The o

il stored in the oil p an is pumped

up/out

by th e oil pump. Af ter the relie f valve regu

-

lates the oil p r essure, th e oil is delivere d to th e cylin-

der block through the o il f ilte r , the o il p a ssag e of the

cylinde

r blo ck a nd the each jou r nal o f the crankshaf t.

The oil del ivered to the ea ch jo urnal of th e cranksh af t

is supplied

to the pin th rough the in ner p a ssage of

the crankshaf

t.

The oil delivered to the cylinder head is supplied t o

the ea

ch journa l of the camshaf t th rough the cylinde r

head.

Page 91 of 364

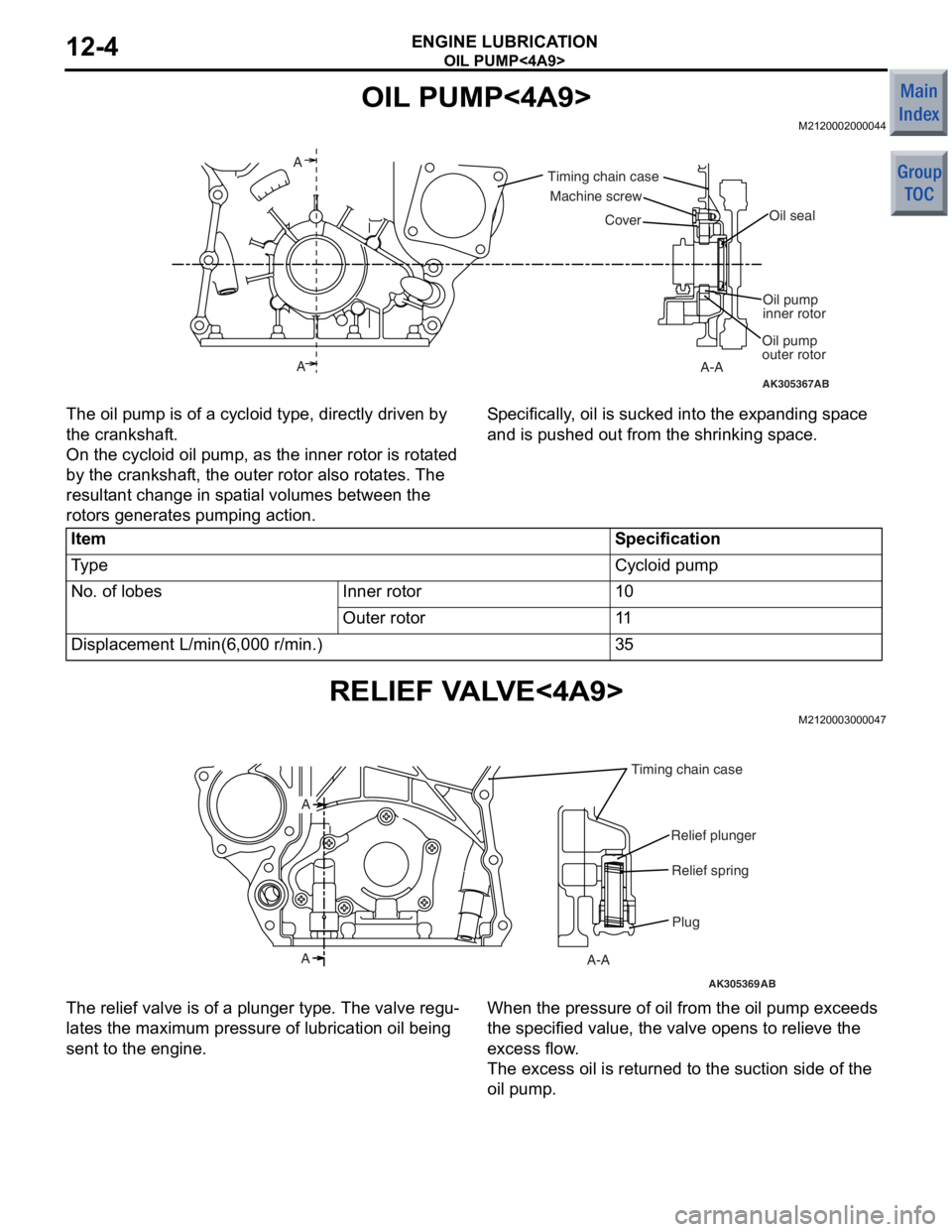

OIL PUMP<4A9>

ENGINE LUBRICATION12-4

OIL PUMP<4A9>

M2120002000044

AK305367AB

Timing chain caseOil pump

inner rotor

Oil pump

outer rotor Oil seal

Cover

Machine screw

A

A-A

A

The oil pump is of a

cyclo i d type, d i rectly driven by

the crankshaf

t.

On the cycloid o il p u mp, as th e inn e r rotor is ro t a ted

by th

e cran kshaf t, the o u ter rot o r also rot a tes. The

result

a n t ch ange in sp at ial volu mes betwee n the

rotors

genera t es p u mping action .

Sp e c ifically , o il is sucked into the exp and ing sp ace

and is pushed

out from the shrinking sp ace.

ItemSpecification

Ty p eCycloid pump

No. of lobesInner rotor10

Outer rotor11

Displacement L/min(6,000 r/min.)35

RELIEF V A L V E<4A9>

M21200030 0004 7

AK305369AB

Plug

A-A

A A

Relief spring

Relief plunger

Timing chain case

The relief valve is of a

plun ger type. The valve re gu-

lates the maximum pre ssu re of lubricatio n oil being

sent

to the e ngin e .

When the pressure of oil from the oil p u mp exceeds

the specified

value, the valve o pens to relieve the

excess flow

.

The excess o il is ret u rned t o the suct ion side of the

oil pump

.

Page 92 of 364

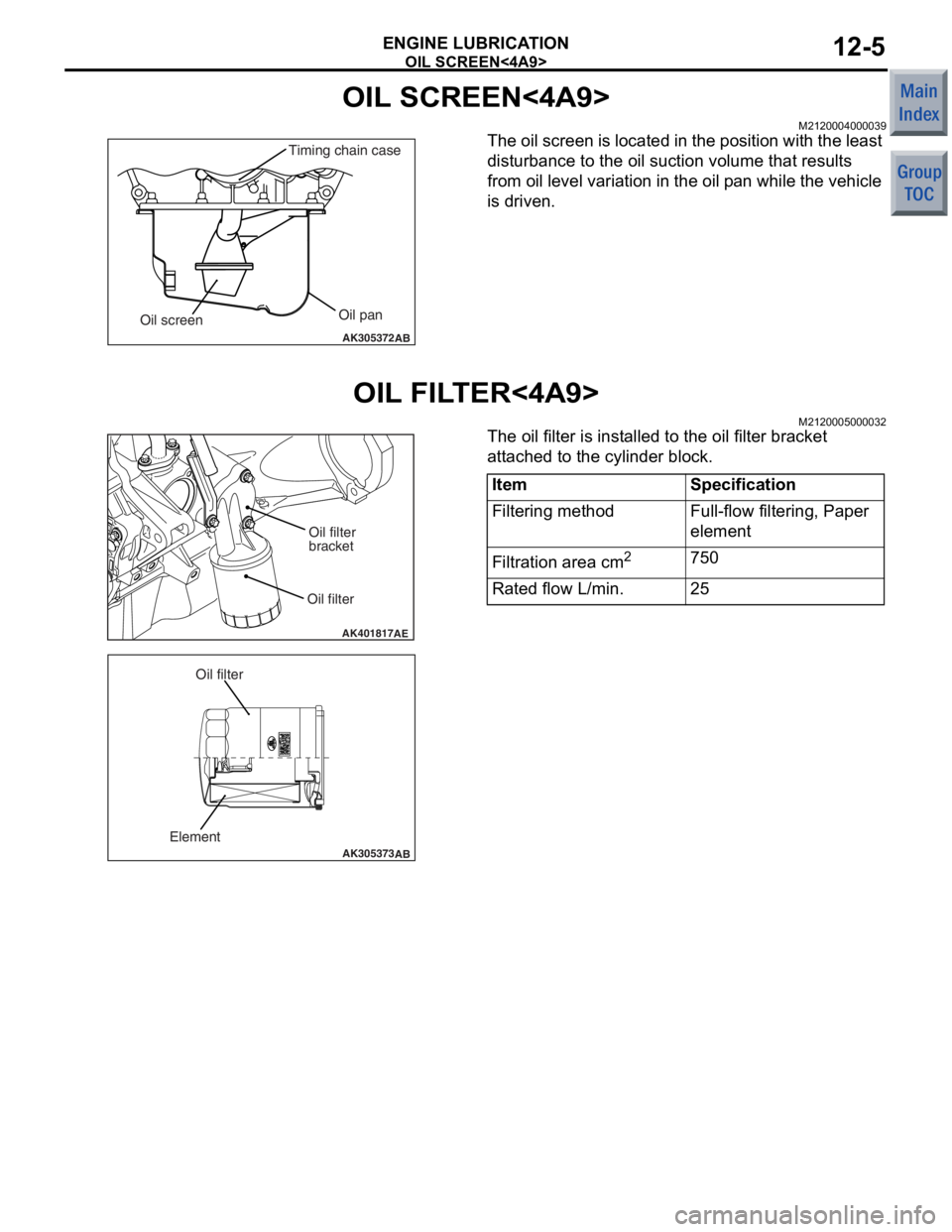

OIL SCREEN<4A9>

ENGINE LUBRICATION12-5

OIL SCREEN<4A9>

M2120004000039

AK305372AB

Timing chain case

Oil pan

Oil screen

The oil screen is located in the po sition with the lea s t

disturbance to

the oil suction vo lume that result s

from oil

level variat ion in the oil p an while the vehicle

is d

r ive n .

OIL FIL T ER<4A9>

M21200050 0003 2

AK401817AE

Oil filterOil filter

bracket

AK305373

AB

Element

Oil filter

The oil filter is inst alled to the oil filter b r acket

att

a che d to the cylin der block.

ItemSpecification

Filtering methodFull-flow filtering, Paper

element

Filtration area cm2750

Rated flow L/min.25

Page 95 of 364

GROUP 13A

MULTIPOINT FUEL INJECTION (MPI)

<4A9>

CONTENTS

GENERAL INFORMATIO N . . . . . . . .13A-2

FUEL INJECTION CONTROL . . . . . .13A-9

THROTTLE VALVE OPENING

ANGLE CONTROL AND IDLE

SPEED CONTROL . . . . . . . . . . . . . . .13A-10

IGNITION TIMING AND

DISTRIBUTION CONTROL . . . . . . . .13A-11

OTHER CONTROL FUNCTIONS . . . .13A-11

FAN RELAY CONTROL . . . . . . . . . . .13A-12

CONTROLLER AREA NETWORK

(CAN) . . . . . . . . . . . . . . . . . . . . . . . . .13A-13

DIAGNOSIS SYSTEM. . . . . . . . . . . . .13A-14

Page 97 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-3

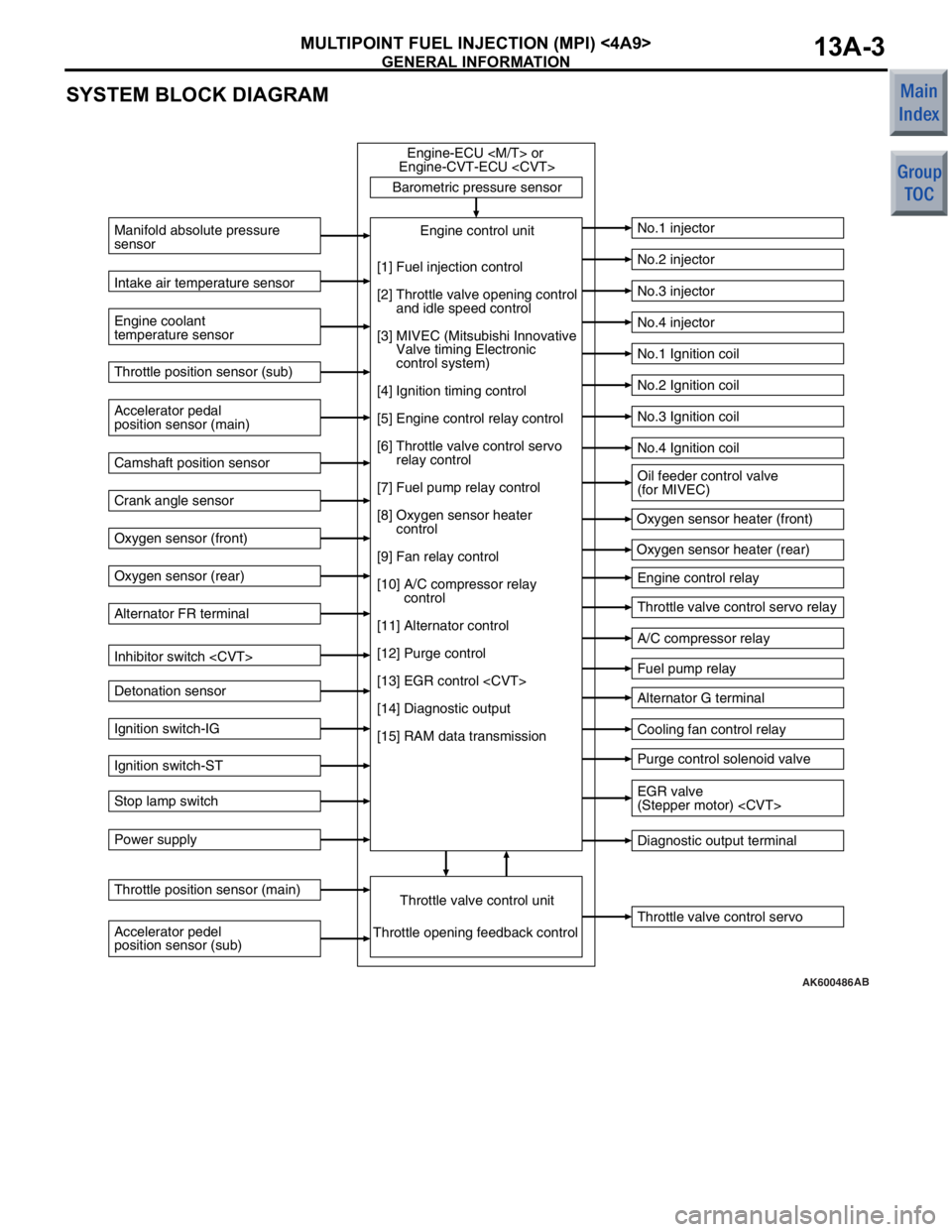

SYSTEM BLOCK DIAGRAM

AK600486

Barometric pressure sensorThrottle valve control servo

Manifold absolute pressure

sensor

Engine coolant

temperature sensor

No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay

Purge control solenoid valve

Diagnostic output terminal

Intake air temperature sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Inhibitor switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Accelerator pedel

position sensor (sub) Throttle position sensor (main)

Throttle valve control unitEngine control unit

Engine-ECU

Engine-CVT-ECU

Throttle opening feedback control Oxygen sensor heater (front)

Oxygen sensor heater (rear)

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor heater

control

[9] Fan relay control

[10] A/C compressor relay

control

[11] Alternator control

[12] Purge control

[13] EGR control

[14] Diagnostic output

[15] RAM data transmission

Oil feeder control valve

(for MIVEC)

EGR valve

(Stepper motor)

AB

Page 100 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-6

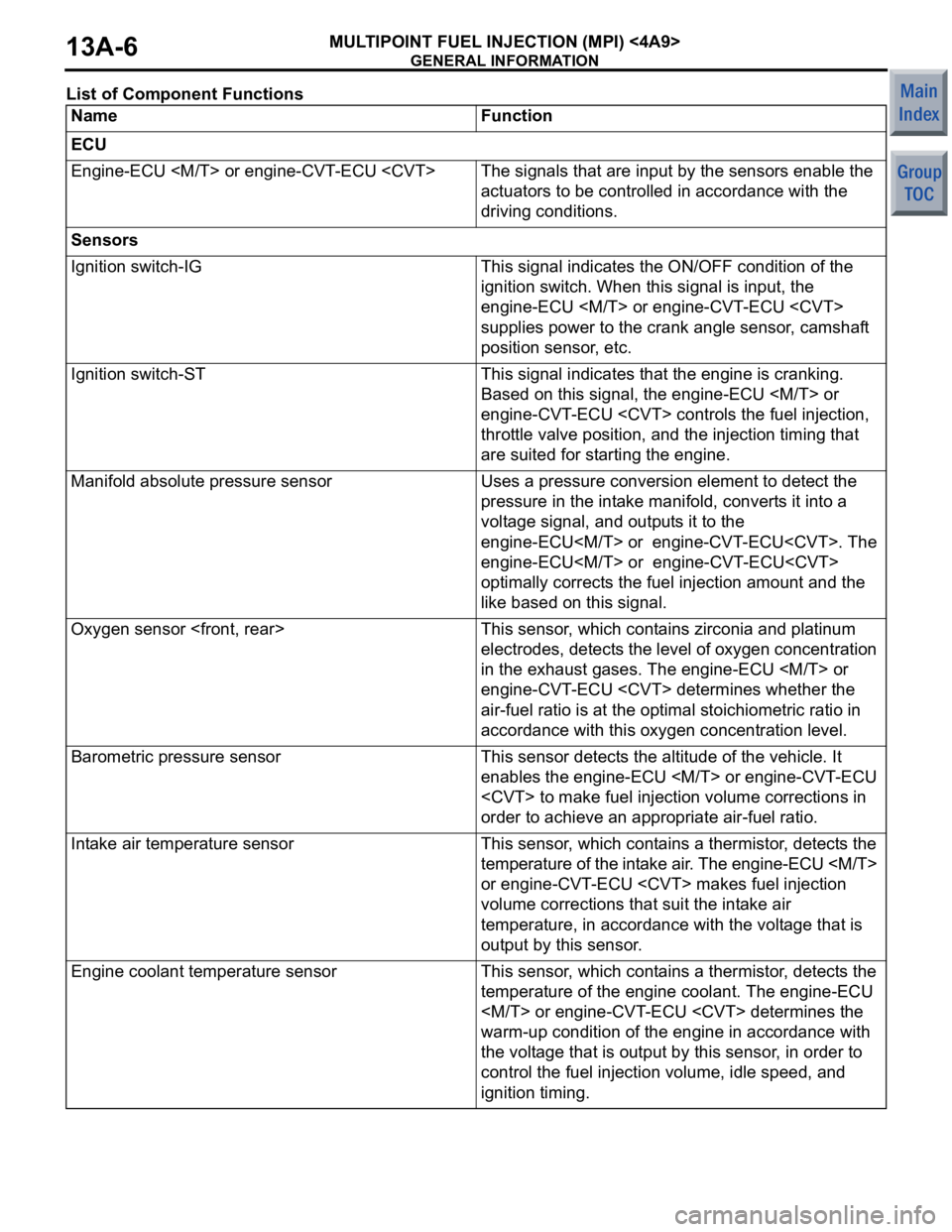

List of Component Functions

NameFunction

ECU

Engine-ECU

actuators to be controlled in accordance with the

driving conditions.

Sensors

Ignition switch-IGThis signal indicates the ON/OFF condition of the

ignition switch. When this signal is input, the

engine-ECU

supplies power to the crank angle sensor, camshaft

position sensor, etc.

Ignition switch-STThis signal indicates that the engine is cranking.

Based on this signal, the engine-ECU

engine-CVT-ECU

throttle valve position, and the injection timing that

are suited for starting the engine.

Manifold absolute pressure sensor Uses a pressure conversion element to detect the

pressure in the intake manifold, converts it into a

voltage signal, and outputs it to the

engine-ECU

engine-ECU

optimally corrects the fuel injection amount and the

like based on this signal.

Oxygen sensor

electrodes, detects the level of oxygen concentration

in the exhaust gases. The engine-ECU

engine-CVT-ECU

air-fuel ratio is at the optimal stoichiometric ratio in

accordance with this oxygen concentration level.

Barometric pressure sensorThis sensor detects the altitude of the vehicle. It

enables the engine-ECU

order to achieve an appropriate air-fuel ratio.

Intake air temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the intake air. The engine-ECU

or engine-CVT-ECU

volume corrections that suit the intake air

temperature, in accordance with the voltage that is

output by this sensor.

Engine coolant temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the engine coolant. The engine-ECU

warm-up condition of the engine in accordance with

the voltage that is output by this sensor, in order to

control the fuel injection volume, idle speed, and

ignition timing.

Page 101 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

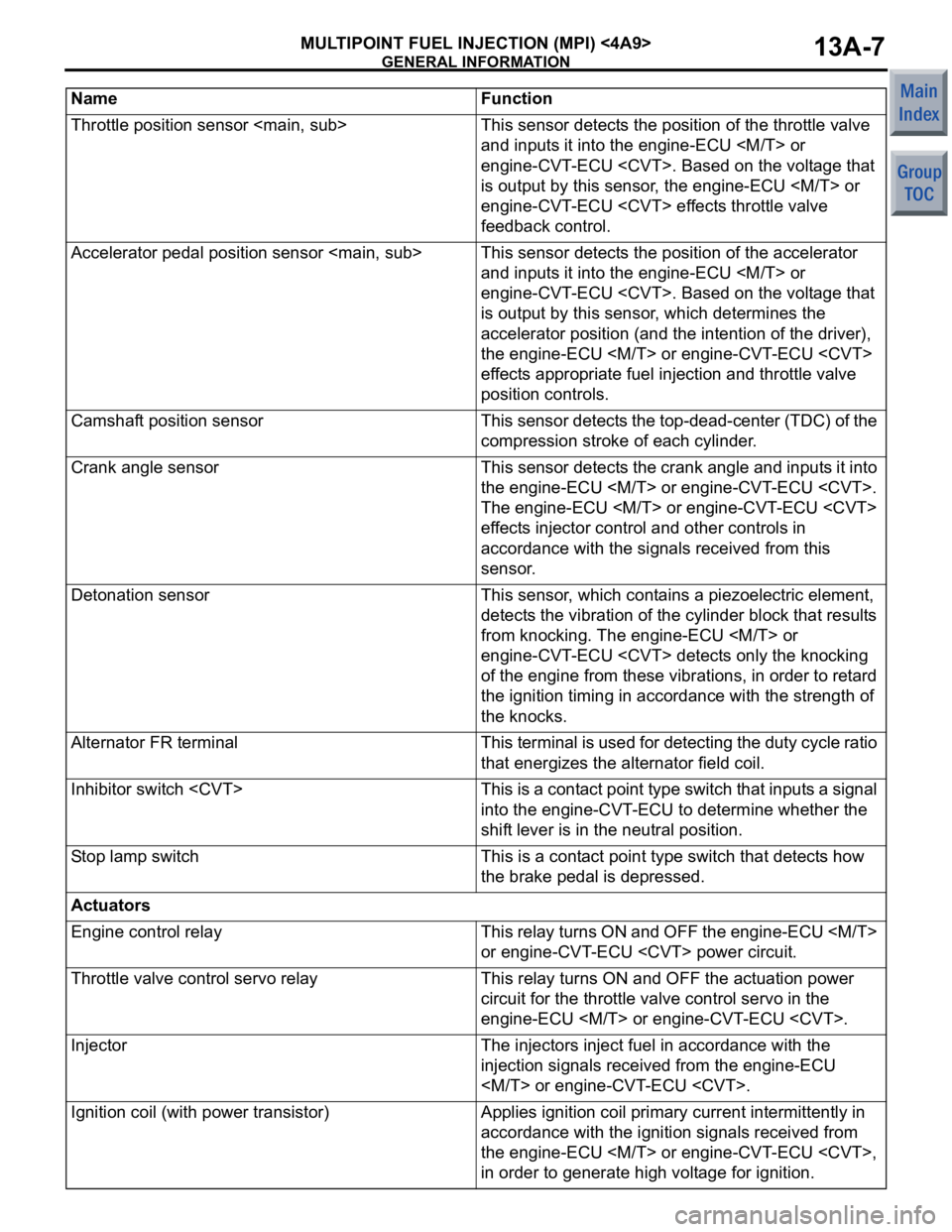

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

Name Function

Page 102 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-8

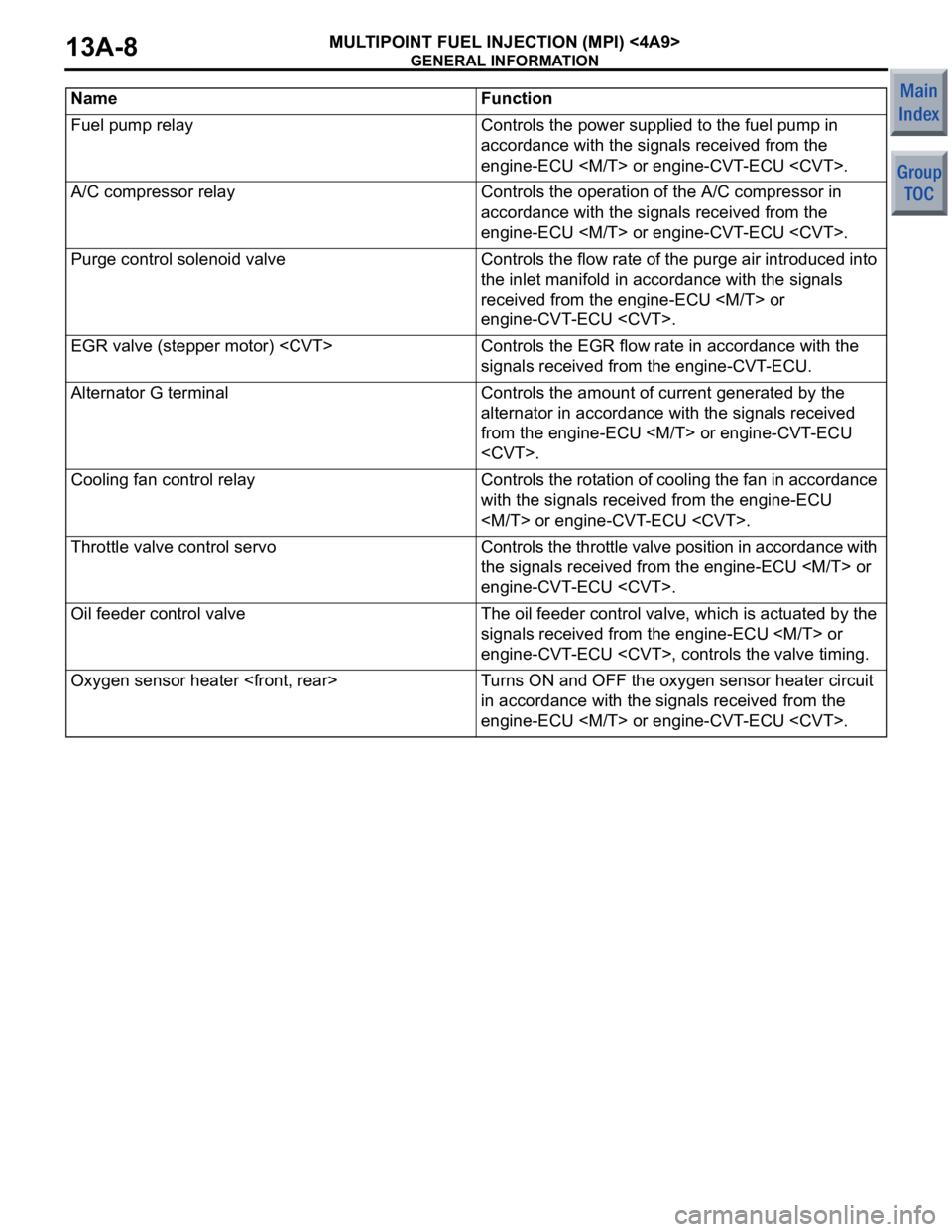

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU

engine-CVT-ECU

EGR valve (stepper motor)

signals received from the engine-CVT-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU

Cooling fan control relayControls the rotation of cooling the fan in accordance

with the signals received from the engine-ECU

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU

engine-CVT-ECU

Oil feeder control valveThe oil feeder control valve, which is actuated by the

signals received from the engine-ECU

engine-CVT-ECU

Oxygen sensor heater

in accordance with the signals received from the

engine-ECU

Name Function

Page 105 of 364

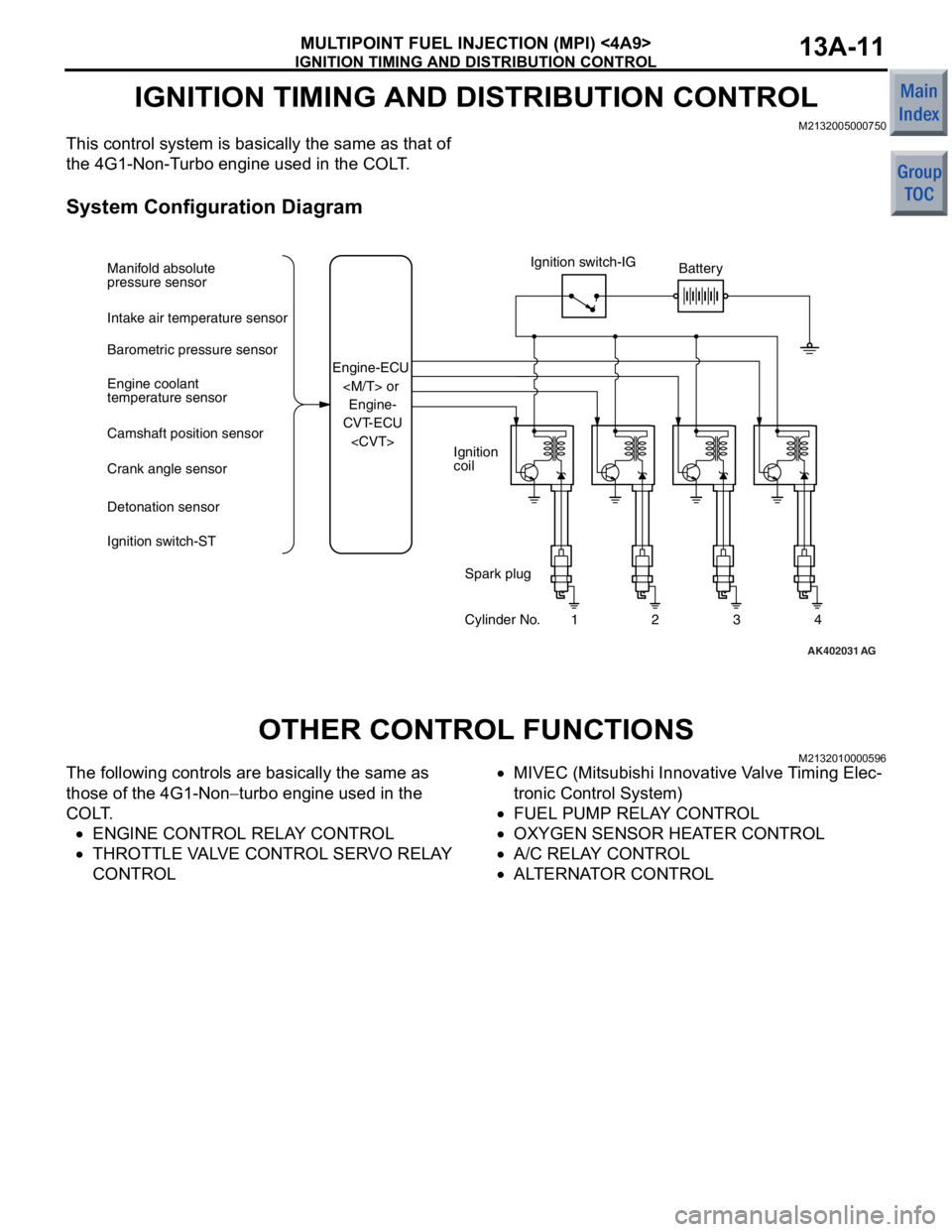

IGNITION TIMING AND DISTRIBUTION CONTROL

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-11

IGNITION TIMING AND DISTRIBUTION CONTROL

M2132005000750

This control system is basically the same as that of

the 4G1-Non-Turbo engine used in the COLT.

System Configuration Diagram

AK402031

Ignition switch-IG

Ignition

coil Battery

Spark plug

Cylinder No. 1 2 3 4

Manifold absolute

pressure sensor

Intake air temperature sensor

Barometric pressure sensor

Engine coolant

temperature sensor

Camshaft position sensor

Crank angle sensor

Detonation sensor

Ignition switch-ST

Engine-ECU

CVT-ECU

AG

OTHER CONTROL FUNCTI O NS

M21320100 0059 6

The following co ntrols are b a sically t he sa me a s

those

of the 4G1 - No n

−turbo eng ine u s ed in the

CO

L

T

.

•ENGINE CONTROL RELA Y CONTROL

•THROTTLE VA L V E C O NTROL SER VO R E LA Y

CONTROL

•MIVEC (Mitsub i sh i Inno vative V a lve T i ming Elec-

tronic Con t rol System)

•FUEL PUMP RELA Y CONTROL

•OXYGEN S E NSOR HEA T E R CONTR O L

•A/C RELAY CONTROL

•ALTER N A T OR CONTROL

Page 108 of 364

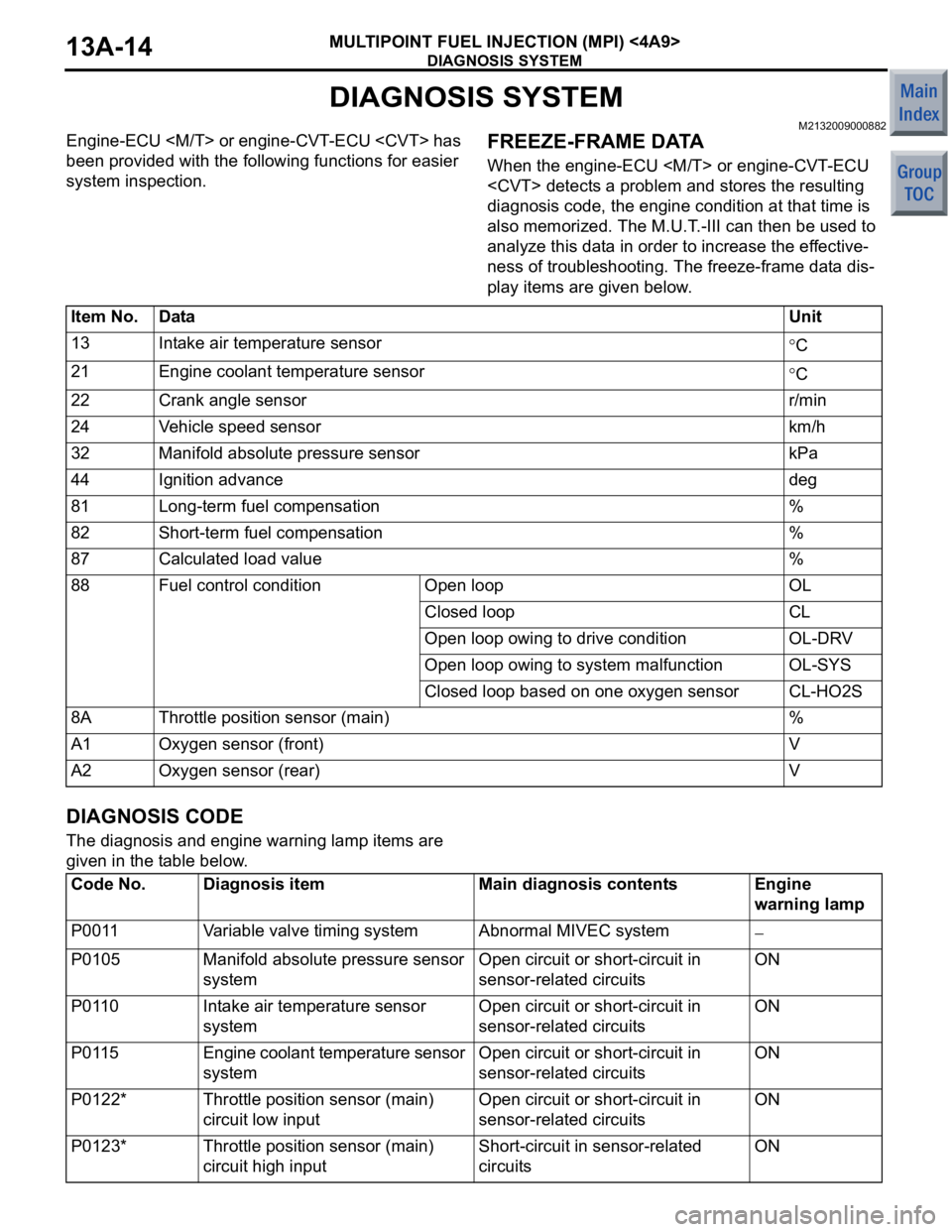

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-14

DIAGNOSIS SYSTEM

M2132009000882

Engine-ECU

been provided with the following functions for easier

system inspection.FREEZE-FRAME DATA

When the engine-ECU

diagnosis code, the engine condition at that time is

also memorized. The M.U.T.-III can then be used to

analyze this data in order to increase the effective

-

ness of troubleshooting. The freeze-frame data dis-

play items are given below.

Item No.DataUnit

13Intake air temperature sensor°C

21Engine coolant temperature sensor°C

22Crank angle sensorr/min

24Vehicle speed sensorkm/h

32Manifold absolute pressure sensorkPa

44Ignition advancedeg

81Long-term fuel compensation%

82Short-term fuel compensation%

87Calculated load value%

88Fuel control conditionOpen loopOL

Closed loopCL

Open loop owing to drive conditionOL-DRV

Open loop owing to system malfunctionOL-SYS

Closed loop based on one oxygen sensorCL-HO2S

8AThrottle position sensor (main)%

A1Oxygen sensor (front)V

A2Oxygen sensor (rear)V

DIAGNOSIS CODE

The diagnosis and engine warning lamp items are

given in the table below.

Code No.Diagnosis itemMain diagnosis contentsEngine

warning lamp

P0011Variable valve timing systemAbnormal MIVEC system−

P0105Manifold absolute pressure sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0110Intake air temperature sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0115Engine coolant temperature sensor

systemOpen circuit or short-circuit in

sensor-related circuitsON

P0122*Throttle position sensor (main)

circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P0123*Throttle position sensor (main)

circuit high inputShort-circuit in sensor-related

circuitsON