turn signal MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 7 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-7

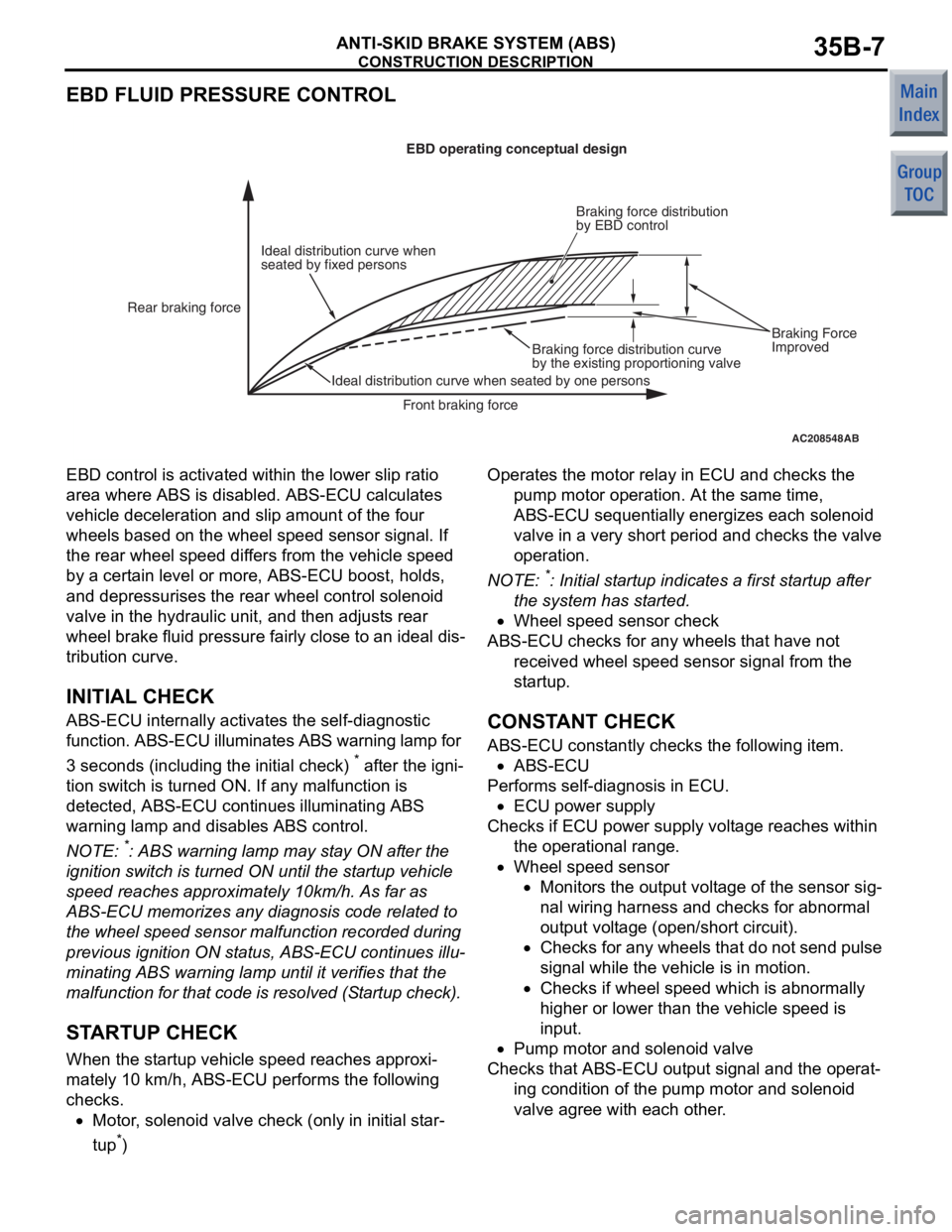

EBD FLUID PRESSURE CONTROL

AC208548AB

Ideal distribution curve when

seated by fixed personsEBD operating conceptual design

Rear braking force

Ideal distribution curve when seated by one persons Braking force distribution curve

by the existing proportioning valveBraking force distribution

by EBD control

Front braking force

Braking Force

Improved

EBD control is

activate d within the lower slip ratio

area where

ABS is disab l ed. ABS-ECU calculates

vehicle

decelera t ion a nd slip amou nt of th e four

whe

e ls based on the wheel sp eed senso r signal. If

the rear

wh eel speed dif f ers f r om th e ve hicle speed

by a

cert ain level or more, ABS-ECU boost, holds,

and de

pressurises the rea r wh eel contro l so leno id

valve in the h

y drau lic unit, and then a d just s rear

whe

e l b r ake fluid pressure fa ir ly close to an ideal dis

-

tribution curve.

INITIAL CHECK

ABS-ECU inter nally activates the self-d iagno stic

function. ABS-ECU illuminates

ABS warning l a mp for

3 seconds (in

c lu ding the in itia l check)

* after th e ign i-

tion switch is turned ON. If a n y malf unction is

detected, ABS-ECU cont

inues illuminating ABS

war

n ing lamp and disables ABS cont rol.

NOTE: *: ABS warning lamp may st ay ON af ter the

ignition

switch is turned ON un til t he st artu p ve hicle

spee

d reaches approximately 10km/h . As far as

ABS-ECU memorizes any d i agn osis code related t o

the

whee l speed sen s or malfunct i on record ed d u ring

previous ignition ON st atus, ABS-ECU continues illu

-

mina ting ABS warn ing lamp until it verif i es that th e

malfunct

i on for tha t co de is resolved (S t a rtup che ck).

STARTUP CHECK

When th e st artup veh i cle sp eed re ache s app roxi-

mately 10 km/h, ABS-ECU performs the following

checks.

•Motor, solen o id valve check (onl y i n ini t ial st ar-

tup*)

Operat es the motor relay in ECU and checks the

pump motor op eratio n. At the same time,

ABS-ECU sequentially e nergizes each solenoid

valve in a ve ry sh ort perio d and ch ecks the valve

ope ration .

NOTE: *: Initia l st artu p ind i ca tes a first st artup af ter

the

system has st arted .

•Whee l speed sensor check

ABS-ECU che cks for a n y whee ls that ha ve no t

received whee l sp eed sens or signal from the

st artu p.

CONSTANT CHECK

ABS-ECU con s t antly ch ecks th e following item.

•ABS-ECU

Performs se lf-diagnosis in ECU.

•ECU power supply

Checks if ECU po we r sup p ly volt ag e reaches within

the operat ional range .

•Whee l speed sensor

•Monitors the ou tput volt age of the sensor sig-

nal wiring ha rness an d che c ks for a bnormal

output

volt ag e (ope n/sho r t circuit).

•Checks fo r any wheels tha t do n o t send pu lse

sig

nal while th e ve hicle is in motion.

•Checks if wheel spee d which is abno rmally

high

er or lo we r than the vehicle speed is

inpu

t.

•Pump mo tor and solenoid valve

Checks tha t ABS-ECU outp u t signal and t he ope rat-

ing co ndition of the pump motor an d so leno id

valve agree

with ea ch ot her .

Page 101 of 364

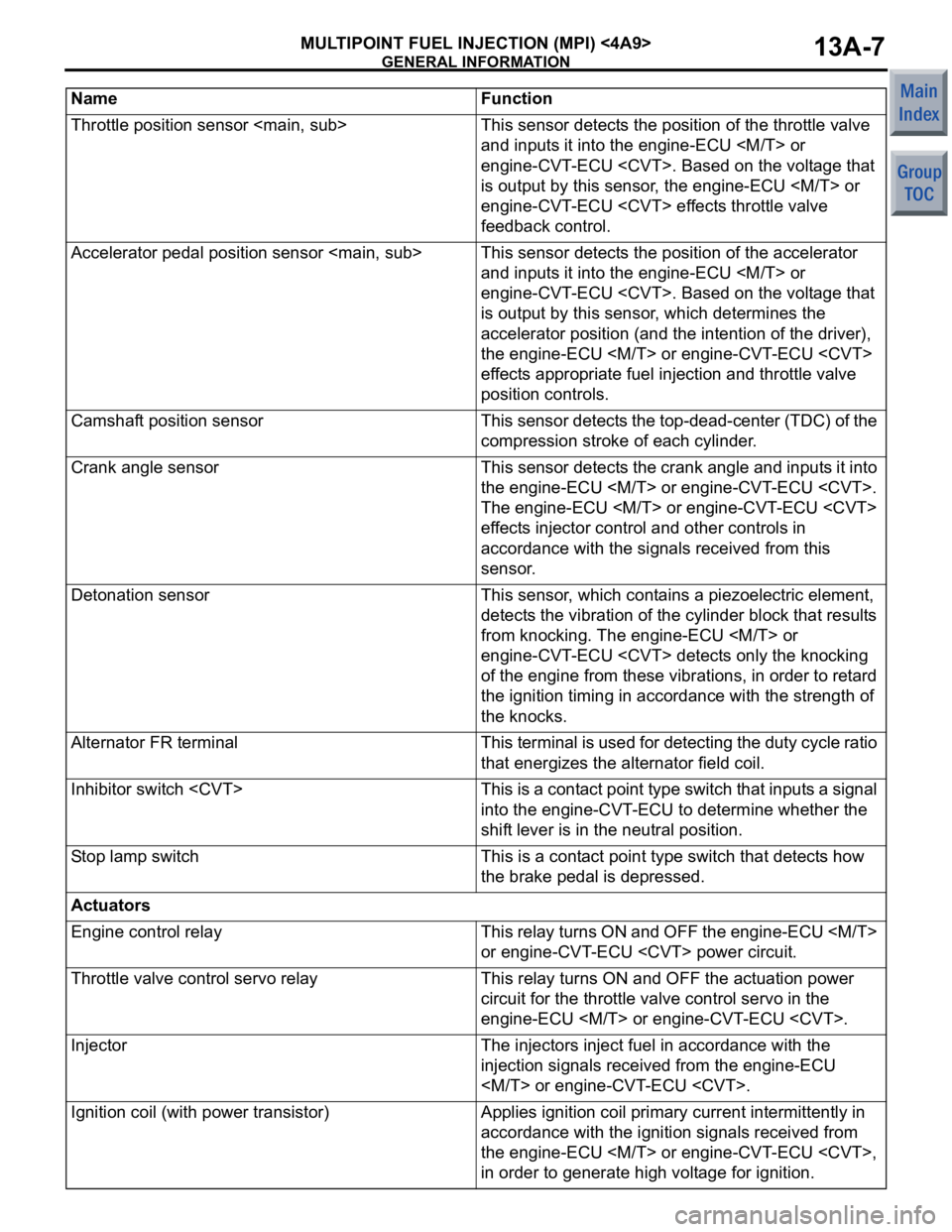

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

Name Function

Page 102 of 364

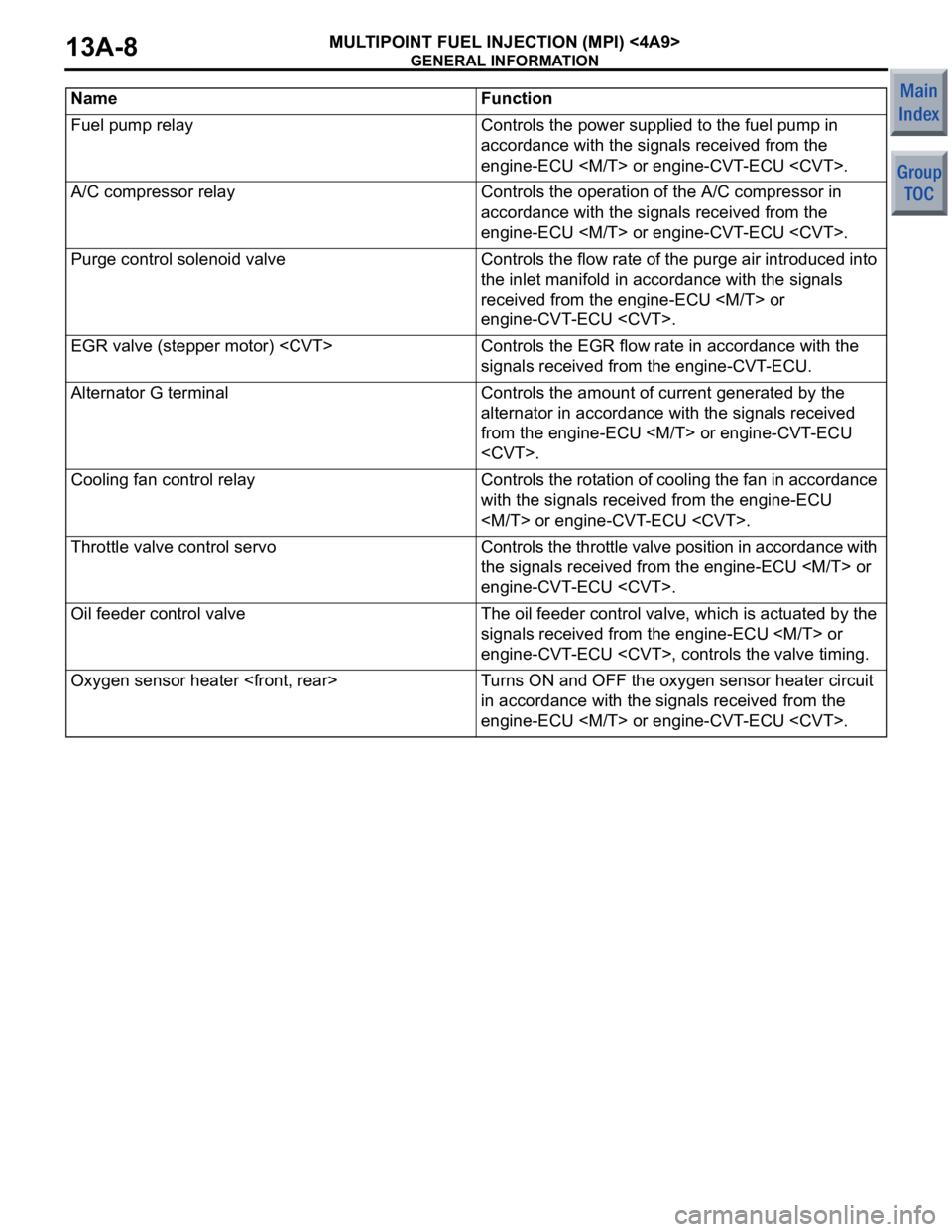

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-8

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU

engine-CVT-ECU

EGR valve (stepper motor)

signals received from the engine-CVT-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU

Cooling fan control relayControls the rotation of cooling the fan in accordance

with the signals received from the engine-ECU

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU

engine-CVT-ECU

Oil feeder control valveThe oil feeder control valve, which is actuated by the

signals received from the engine-ECU

engine-CVT-ECU

Oxygen sensor heater

in accordance with the signals received from the

engine-ECU

Name Function

Page 120 of 364

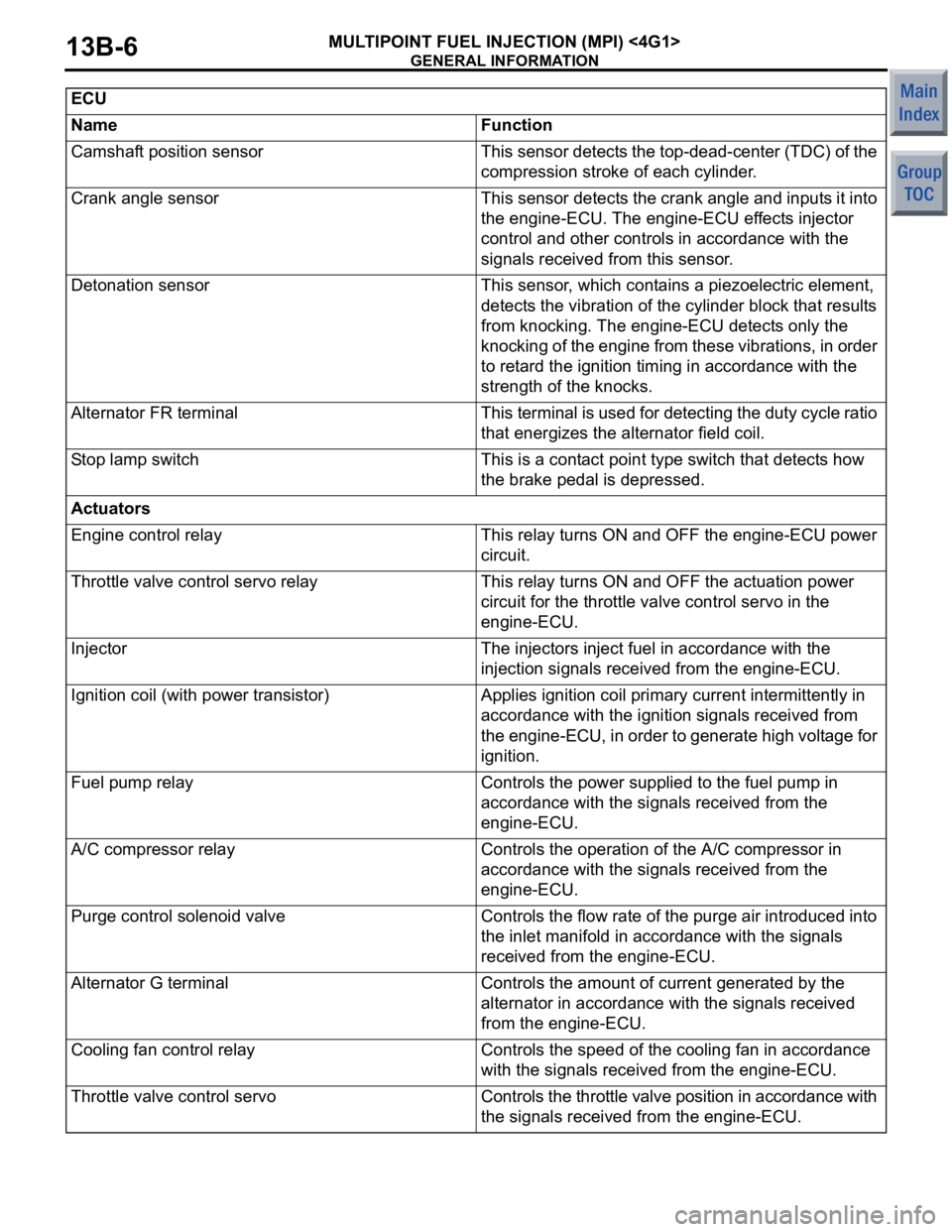

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-6

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU. The engine-ECU effects injector

control and other controls in accordance with the

signals received from this sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU detects only the

knocking of the engine from these vibrations, in order

to retard the ignition timing in accordance with the

strength of the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU power

circuit.

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU.

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU.

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU, in order to generate high voltage for

ignition.

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU.

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU.

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU.

Cooling fan control relayControls the speed of the cooling fan in accordance

with the signals received from the engine-ECU.

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU.

ECU

Name Function

Page 157 of 364

DOOR

BODY42-14

DESCRIPTION OF STRUCTURE AND

OPERATION

TRANSMITTER•

AC309781 AC309891

AC302207AC

Lock button

Unlock button Three-diamond markIndicator lamp

The tran

smitter is integra t ed in to the master key .

•When eit her butt on is pressed , the tra n smitter

emit

s a radio sig nal re prese n ting a sp ecific ID

code.

•There a r e two butto ns o n th e tra n smitte r; th e lo ck

but

ton and the u n lock bu tton.

•An indicator lamp, which illumina tes when signals

are

transmitt ed, is add ed on t he ke y grip. This

in

dicator lamp informs you of the signa l transmis

-

sion sta t us a nd warns you of flat batt e ry .

•A brilliant silver Three -d ia mond mark is st amped

on

the back side of the key grip to improve

app

earance.

•A signal transmissi on circuit (p rinted circuit ) and

a b

a ttery are ho used in on e ca se. T he ca se is

hou

sed in the key grip, thus improving re sist ance

to wat

e r ing r ess.

•A coin type b a ttery , CR1616 is used in th e trans-

mitter.

•The transmit t er butto n ope ration allows the sys-

tem to operate a s follows:

System operationThe transmitter is operated.

All doors (including the tailgate) are locked.Press the lock button once.

All doors (including the tailgate) are unlocked.Press the unlock button once.

The door mirrors are retracted.Press the lock button once to lock all doors (including

the tailgate), and within 30 seconds press the lock

button twice quickly.

The door mirrors return to the unfold position.Press the unlock button once to unlock all doors, and

within 30 seconds press the unlock button twice

quickly.

Page 176 of 364

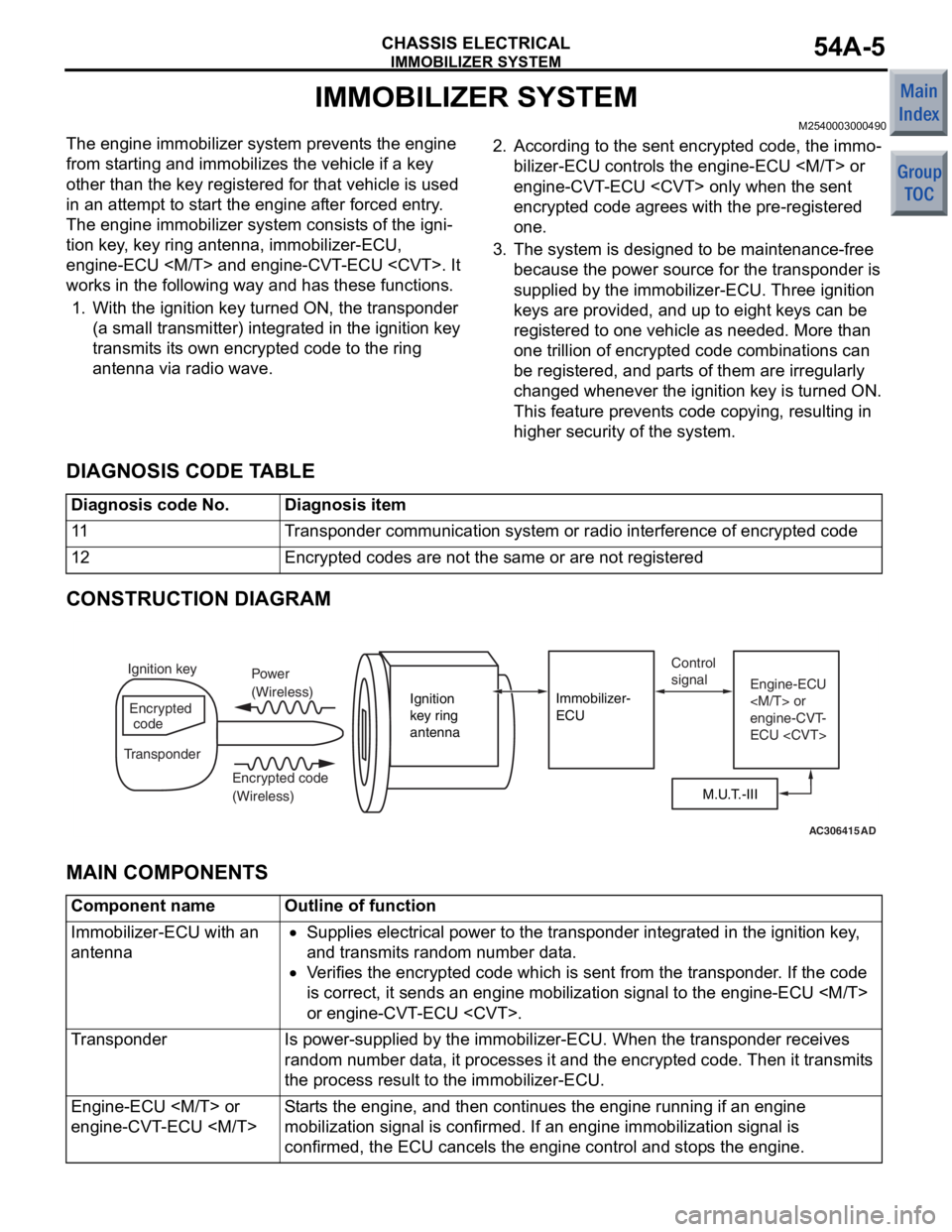

IMMOBILIZER SYSTEM

CHASSIS ELECTRICAL54A-5

IMMOBILIZER SYSTEM

M2540003000490

The engine immobilizer system prevents the engine

from starting and immobilizes the vehicle if a key

other than the key registered for that vehicle is used

in an attempt to start the engine after forced entry.

The engine immobilizer system consists of the igni

-

tion key, key ring antenna, immobilizer-ECU,

engine-ECU

works in the following way and has these functions.

1. With the ignition key turned ON, the transponder

(a small transmitter) integrated in the ignition key

transmits its own encrypted code to the ring

antenna via radio wave.

2. According to the sent encrypted code, the immo-

bilizer-ECU controls the engine-ECU

engine-CVT-ECU

encrypted code agrees with the pre-registered

one.

3. The system is designed to be maintenance-free because the power source for the transponder is

supplied by the immobi lizer-ECU. Three ignition

keys are provided, and up to eight keys can be

registered to one vehicle as needed. More than

one trillion of encrypted code combinations can

be registered, and parts of them are irregularly

changed whenever the ignition key is turned ON.

This feature prevents code copying, resulting in

higher security of the system.

DIAGNOSIS CODE TABLE

Diagnosis code No.Diagnosis item

11Transponder communication system or r adio interference of encrypted code

12Encrypted codes are not the same or are not registered

CONSTRUCTION DIAGRAM

AC306415AD

M.U.T.-III

Ignition

key ring

antenna

Immobilizer-

ECU

Ignition key

Encrypted

code

Transponder Power

(Wireless)

Encrypted code

(Wireless) Control

signal

Engine-ECU

engine-CVT-

ECU

MAIN CO MP O N E N TS

Component name Outline of function

Immobilizer-ECU with an

antenna•Supplies electrical power to the transponder integrated in the ignition key,

and transmits random number data.

•Verifies the encrypted code which is sent from the transponder. If the code

is correct, it sends an engine mobili zation signal to the engine-ECU

or engine-CVT-ECU

TransponderIs power-supplied by the immobilizer-ECU. When the transponder receives

random number data, it processes it an d the encrypted code. Then it transmits

the process result to the immobilizer-ECU.

Engine-ECU

engine-CVT-ECU

mobilization signal is co nfirmed. If an engine immobilization signal is

confirmed, the ECU cancels the engine control and stops the engine.

Page 178 of 364

LIGHTING

CHASSIS ELECTRICAL54A-7

LIGHTING

M2540004000932

EXTERIOR LAMPS

•The headlamp employs a large four-lamp type

integrated with the front turn-signal lamp and

position lamp, creating the integrity appearance

with the hood. The internal lens design looks like

a precision machine, achieving improved appear

-

ance.

•The fog lamp is standard equipped. (VRX, VR

and RALLIART version-R : Standard equipment,

LS : Option)

•The rear combination lamps are a large verti-

cal-type integrated with the tail lamp, stop lamp,

rear turn-signal lamp and back-up lamp.

•The high-mounted stop lamp is equipped as

standard in order to improve safety.

Specifications

ItemSpecification

Headlamp assemblyHeadlamp (halogen bulb)Low-beam W55 (H7)

High-beam W55 (H1)

Position lamp W5 (W5W)

Front turn-signal lamp W21 (W21W)

Fog lamp W55 (H11)

Side turn-signal lamp W5 (WY5W)

Rear combination lamp

assemblyTa i l l a m p W5 (W5W)

Stop lamp W21 (W21W)

Rear turn-signal lamp W21 (W21W)

Back-up lamp W21 (W21W)

High-mounted stop lamp W x units5 × 4 (W5W)

Licence plate lamp W5 (W5W)

NOTE: The brackets ( ) show the bulb type.

Page 179 of 364

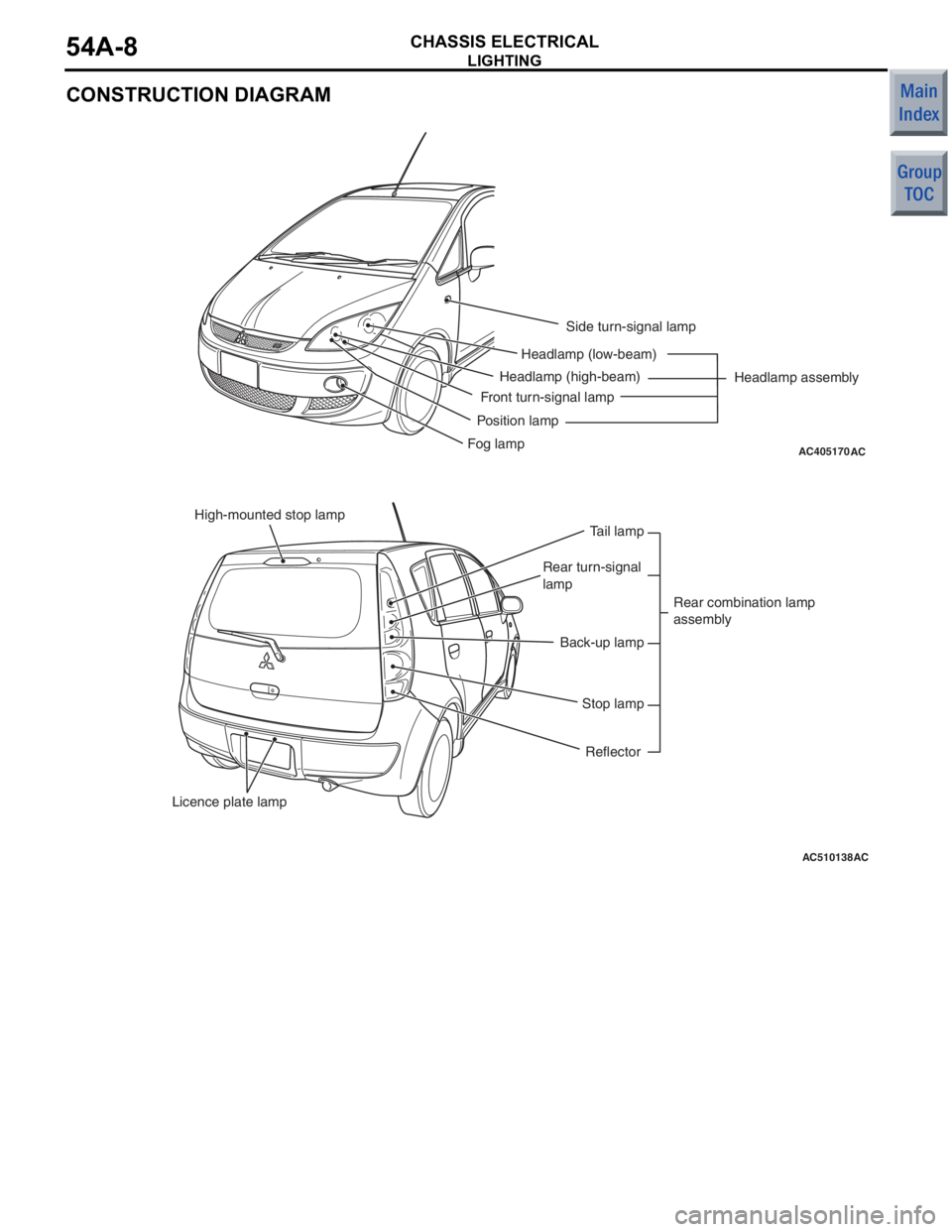

LIGHTING

CHASSIS ELECTRICAL54A-8

CONSTRUCTION DIAGRAM

AC405170

Headlamp (high-beam)

Front turn-signal lamp

Position lamp Side turn-signal lamp

Headlamp assembly

AC

Headlamp (low-beam)

Fog lamp

AC510138AC

High-mounted stop lamp

Licence plate lamp Stop lamp

Reflector

Rear turn-signal

lamp

Back-up lamp Tail lamp

Rear combination lamp

assembly

Page 181 of 364

COMBINATION METER

CHASSIS ELECTRICAL54A-10

COMBINATION METER

M2540005000894

The combination meter features large, clearly visible

analogue indicators. The meter has the speedometer

in the middle, the coolant temperature gauge at

upper right, the fuel gauge at lower right, and the

tachometer at left so that drivers can easily distin

-

guish the information from the meters. The combina-

tion meter offers the following advantages.

•The combination meter is used for air conditioner

and meter drive control to integrate ECU.

•CAN communication is used for more reliable

transmission of all gauge data and indicator lamp

input signals, such as vehicle speed, engine

RPM, and coolant temperature. For further

details on CAN, refer to GROUP 54C, CAN

P.54C-2. The signals that the combination meter

uses are described in the CAN communications

input signals table

.

•Several diagnosis functions such as the diagno-

sis code memory and actuator tests are prepared

in order to improve serviceability.

•For a brighter display at night and for a longer

useful life, all indicator lamps, warning lamps, and

illumination bulbs use LEDs.

•The indicators for the speedometer, fuel gauge,

and other gauges are driven by a stepping motor.

For further details, consult the stepping motor

section

.

•The electronic speedometer operates by receiv-

ing vehicle speed signals sent by the

engine-ECU

via the CAN.

•A large and clear LCD type odo-tripmeter is pro-

vided. The odometer continuously displays val-

ues while the tripmeter adopts a twin-trip (trip A,

trip B) function which is switched by a reset but

-

ton. In addition, clock function is incorporated.

•A fog lamp indicator lamp is provided to let the

driver know that the fog lamp is on.

•A seat belt warning lamp is installed to encourage

the driver to fasten the seat belt.

•The high-contrast meter is adopted. When the

ignition is turned ON, such as the needles and

face display are illuminated with fade-in lighting

by the LED light source.

•To further accentuate the high-contrast lighting,

the light of the high-contrast meter fades in and

fades out when the light is turned on and off

respectively.

•With the auto illumination function incorporated in

the high-contrast meter, a two-stage switching of

daytime (non-dimming) and nighttime (dimming)

is achieved. Also, the brightness can be adjusted

using the illumination control knob.

•A tail lamp indicator lamp is installed which

informs the lighting status of the tail lamps to the

driver.

Page 183 of 364

COMBINATION METER

CHASSIS ELECTRICAL54A-12

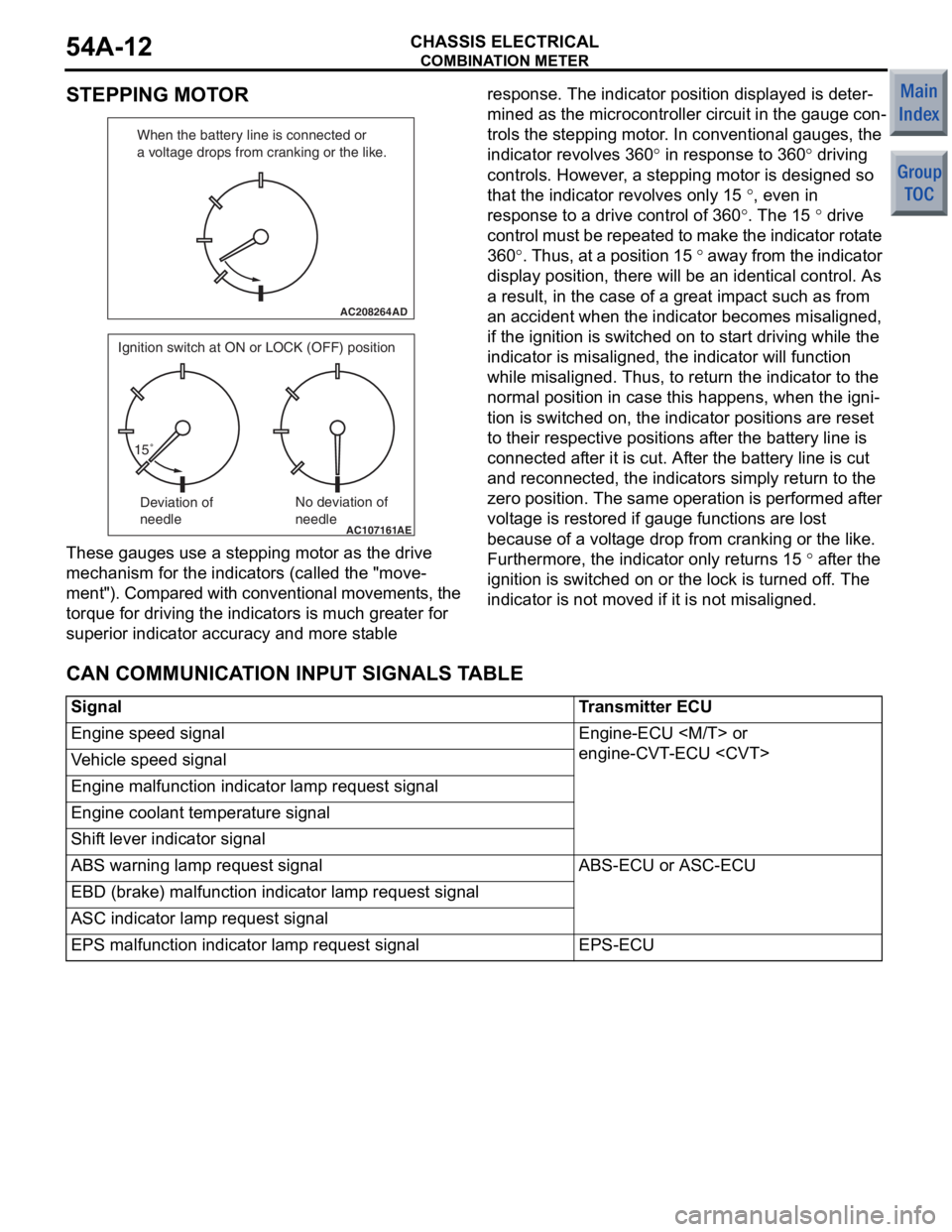

STEPPING MOTOR

AC208264

When the battery line is connected or

a voltage drops from cranking or the like.

AD

AC107161

Deviation of

needleNo deviation of

needle

15˚

AE

Ignition switch at ON or LOCK (OFF) position

These

gauge s use a stepp ing motor a s the drive

mechanism for

the indica tor s (calle d the "move

-

ment"). Compared with conventional movement s, the

torque f

o r driving the indicators is much gre a ter for

supe

rior indicator a ccu racy and more st able respo n se. The indicator po sit i on d i sp layed is dete r

-

min

ed a s t he microcon troller circuit in the gauge co n-

trols the stepping moto r . In conve n tion al gaug es, the

indicato

r revo lves 360

° in response to 3 6 0° driving

contro

ls.

Ho

we

ver

,

a ste

pping

mot

o

r is designed so

that the

ind

i

cat

o

r revolves on

ly

15

°, even in

respo

n

se

to a drive contro

l of 3

6

0

°. The 15 ° drive

c

ont

ro

l m

u

st

be

rep

eat

ed

t

o

ma

ke

th

e

ind

i

cat

o r rot a t e

36

0

°. Th us , at a po sit i o n 15 ° a w a y fr om th e in dicat o r

display positio

n, there

will be an iden tica l control. As

a resu

lt, in the

case of a

great imp a ct such as from

an accide

nt wh

en the indicator becomes misalign ed,

if the

ignition

is

switched o

n

to st art driving while t he

indicato

r is

misaligned,

the indicator will fu nction

wh

ile

misaligned.

Thus, to retu rn the indicator to the

norma

l position in

case this ha ppens, when the ig ni

-

tion is switched on , the indicator p o sitions are re set

to their respective

position s af ter th e batte ry line is

conn

ected af ter it is cut. Af ter th e batte ry line is cut

and reconne

cted , the indicators simply retu rn to th e

zero

positio n. Th e same ope ration is pe rforme d af ter

volt

ag e is resto r ed if gauge functions are lost

beca

u se o f a volt age d r op from cra n king or t he like.

Furthermore, t

he in dicator only re turns 15

° after the

ignition

is switched on

or the

lock is turne

d

of f. The

indicato

r is

not moved

if it is not misa

lig

ned.

CAN COMMUNICA TION INPUT SIGNALS T ABLE

SignalTransmitter ECU

Engine speed signalEngine-ECU

engine-CVT-ECU

Vehicle speed signal

Engine malfunction indicator lamp request signal

Engine coolant temperature signal

Shift lever indicator signal

ABS warning lamp request signalABS-ECU or ASC-ECU

EBD (brake) malfunction indicator lamp request signal

ASC indicator lamp request signal

EPS malfunction indicator lamp request signalEPS-ECU