MITSUBISHI COLT 2011 Owner's Manual (in English)

Manufacturer: MITSUBISHI, Model Year: 2011, Model line: COLT, Model: MITSUBISHI COLT 2011Pages: 274, PDF Size: 17.88 MB

Page 191 of 274

4.After the engine coolant temperature has drop-

ped to the normal temperature, stop the engine.

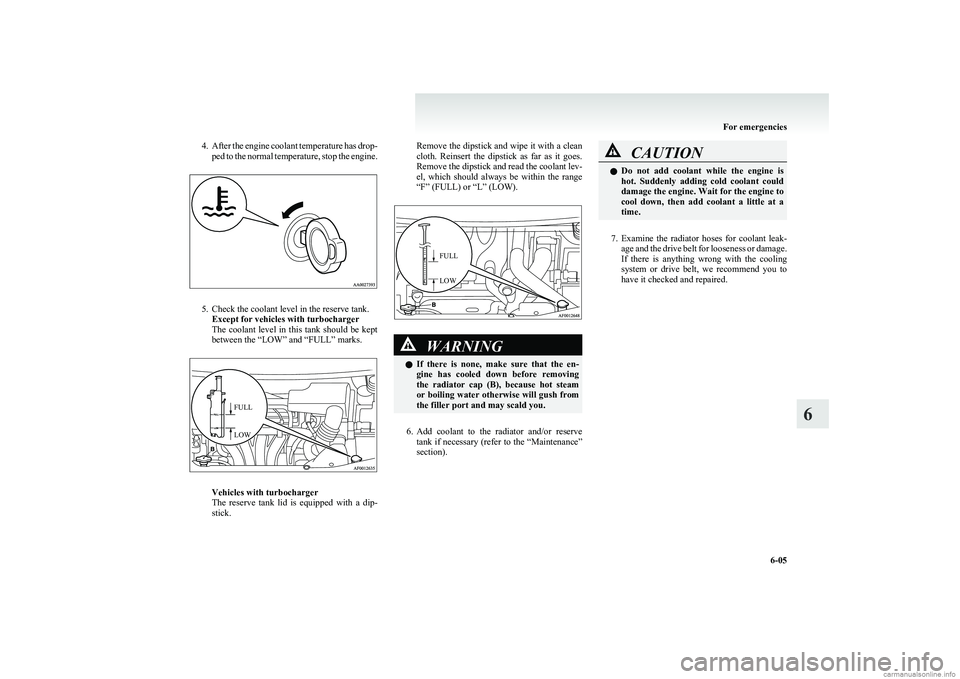

5. Check the coolant level in the reserve tank. Except for vehicles with turbocharger

The coolant level in this tank should be kept

between the “LOW” and “FULL” marks.

FULLLOW

Vehicles with turbocharger

The reserve tank lid is equipped with a dip-

stick.

Remove the dipstick and wipe it with a clean

cloth. Reinsert the dipstick as far as it goes.

Remove the dipstick and read the coolant lev-

el, which should always be within the range

“F” (FULL) or “L” (LOW).FULLLOW

WARNINGl If there is none, make sure that the en-

gine has cooled down before removing

the radiator cap (B), because hot steam

or boiling water otherwise will gush from

the filler port and may scald you.

6. Add coolant to the radiator and/or reserve

tank if necessary (refer to the “Maintenance”

section).

CAUTIONl Do not add coolant while the engine is

hot. Suddenly adding cold coolant could

damage the engine. Wait for the engine to

cool down, then add coolant a little at a

time.

7. Examine the radiator hoses for coolant leak-

age and the drive belt for looseness or damage.

If there is anything wrong with the cooling

system or drive belt, we recommend you to

have it checked and repaired.

For emergencies

6-05

6

Page 192 of 274

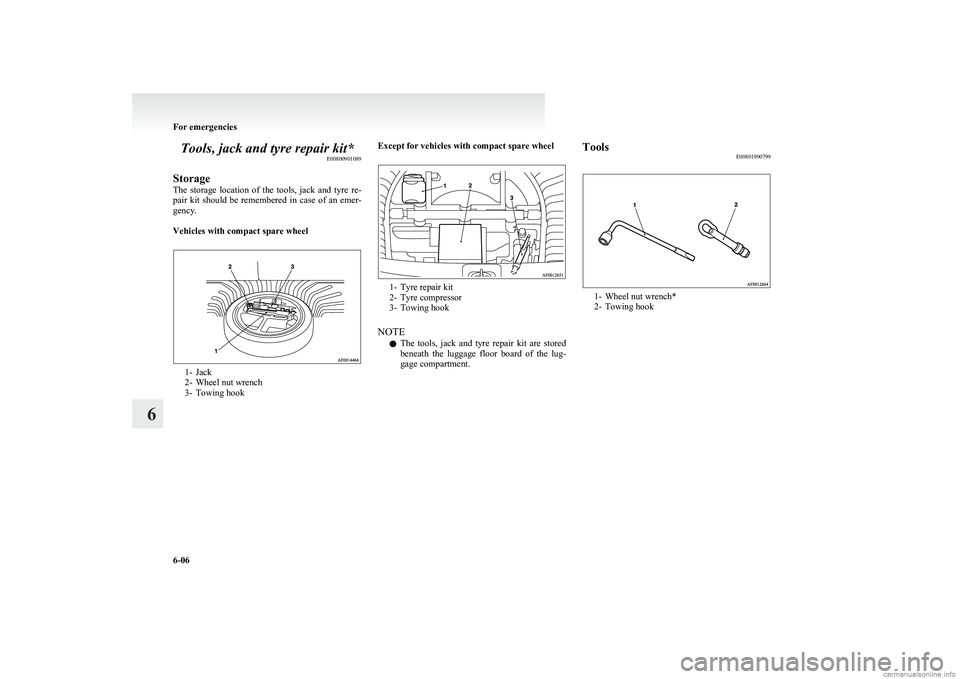

Tools, jack and tyre repair kit*E00800901089

Storage

The storage location of the tools, jack and tyre re-

pair kit should be remembered in case of an emer-

gency.

Vehicles with compact spare wheel

1- Jack

2- Wheel nut wrench

3- Towing hook

Except for vehicles with compact spare wheel

1- Tyre repair kit

2- Tyre compressor

3- Towing hook

NOTE l The tools, jack and tyre repair kit are stored

beneath the luggage floor board of the lug-

gage compartment.

Tools E00801900799

1- Wheel nut wrench*

2- Towing hook

For emergencies

6-06

6

Page 193 of 274

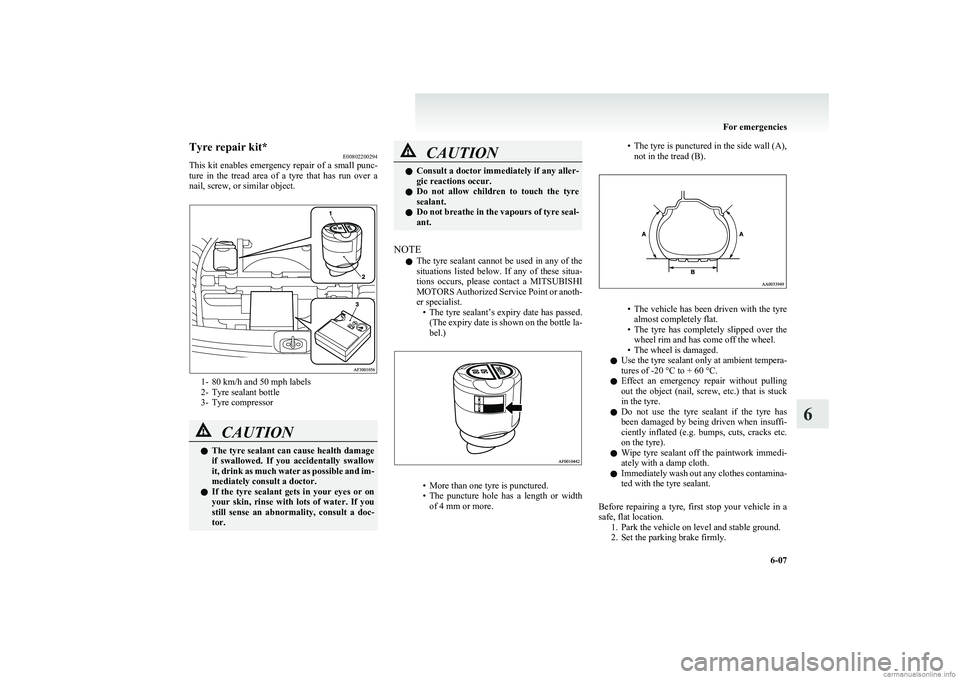

Tyre repair kit*E00802200294

This kit enables emergency repair of a small punc-

ture in the tread area of a tyre that has run over a

nail, screw, or similar object.

1- 80 km/h and 50 mph labels

2- Tyre sealant bottle

3- Tyre compressor

CAUTIONl The tyre sealant can cause health damage

if swallowed. If you accidentally swallow

it, drink as much water as possible and im-

mediately consult a doctor.

l If the tyre sealant gets in your eyes or on

your skin, rinse with lots of water. If you

still sense an abnormality, consult a doc-

tor.CAUTIONl Consult a doctor immediately if any aller-

gic reactions occur.

l Do not allow children to touch the tyre

sealant.

l Do not breathe in the vapours of tyre seal-

ant.

NOTE

l The tyre sealant cannot be used in any of the

situations listed below. If any of these situa-

tions occurs, please contact a MITSUBISHI

MOTORS Authorized Service Point or anoth-

er specialist. •The tyre sealant’s expiry date has passed.

(The expiry date is shown on the bottle la-

bel.)

• More than one tyre is punctured.

• The puncture hole has a length or width

of 4 mm or more.

• The tyre is punctured in the side wall (A), not in the tread (B).

•The vehicle has been driven with the tyre

almost completely flat.

• The tyre has completely slipped over the

wheel rim and has come off the wheel.

• The wheel is damaged.

l Use the tyre sealant only at ambient tempera-

tures of -20 °C to + 60 °C.

l Effect an emergency repair without pulling

out the object (nail, screw, etc.) that is stuck

in the tyre.

l Do not use the tyre sealant if the tyre has

been damaged by being driven when insuffi-

ciently inflated (e.g. bumps, cuts, cracks etc.

on the tyre).

l Wipe tyre sealant off the paintwork immedi-

ately with a damp cloth.

l Immediately wash out any clothes contamina-

ted with the tyre sealant.

Before repairing a tyre, first stop your vehicle in a

safe, flat location. 1. Park the vehicle on level and stable ground.

2. Set the parking brake firmly.

For emergencies

6-07

6

Page 194 of 274

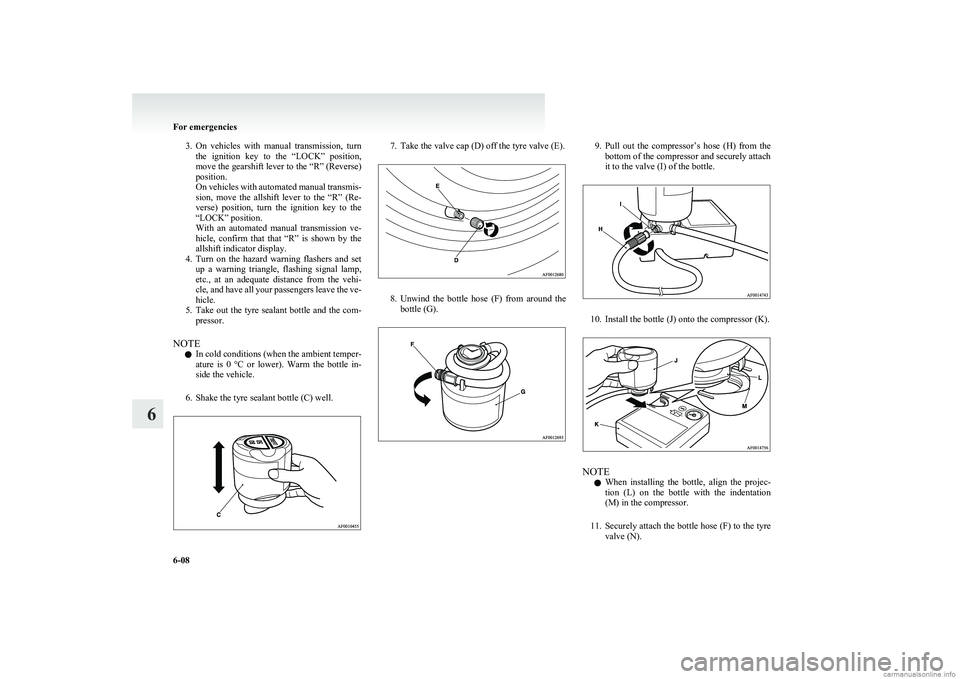

3.On vehicles with manual transmission, turn

the ignition key to the “LOCK” position,

move the gearshift lever to the “R” (Reverse)

position.

On vehicles with automated manual transmis-

sion, move the allshift lever to the “R” (Re-

verse) position, turn the ignition key to the

“LOCK” position.

With an automated manual transmission ve-

hicle, confirm that that “R” is shown by the

allshift indicator display.

4. Turn on the hazard warning flashers and set

up a warning triangle, flashing signal lamp,

etc., at an adequate distance from the vehi-

cle, and have all your passengers leave the ve-

hicle.

5. Take out the tyre sealant bottle and the com-

pressor.

NOTE l In cold conditions (when the ambient temper-

ature is 0 °C or lower). Warm the bottle in-

side the vehicle.

6. Shake the tyre sealant bottle (C) well.7. Take the valve cap (D) off the tyre valve (E).

8. Unwind the bottle hose (F) from around the

bottle (G).

9. Pull out the compressor’s hose (H) from the

bottom of the compressor and securely attach

it to the valve (I) of the bottle.

10. Install the bottle (J) onto the compressor (K).

NOTE

l When installing the bottle, align the projec-

tion (L) on the bottle with the indentation

(M) in the compressor.

11. Securely attach the bottle hose (F) to the tyre

valve (N).

For emergencies

6-08

6

Page 195 of 274

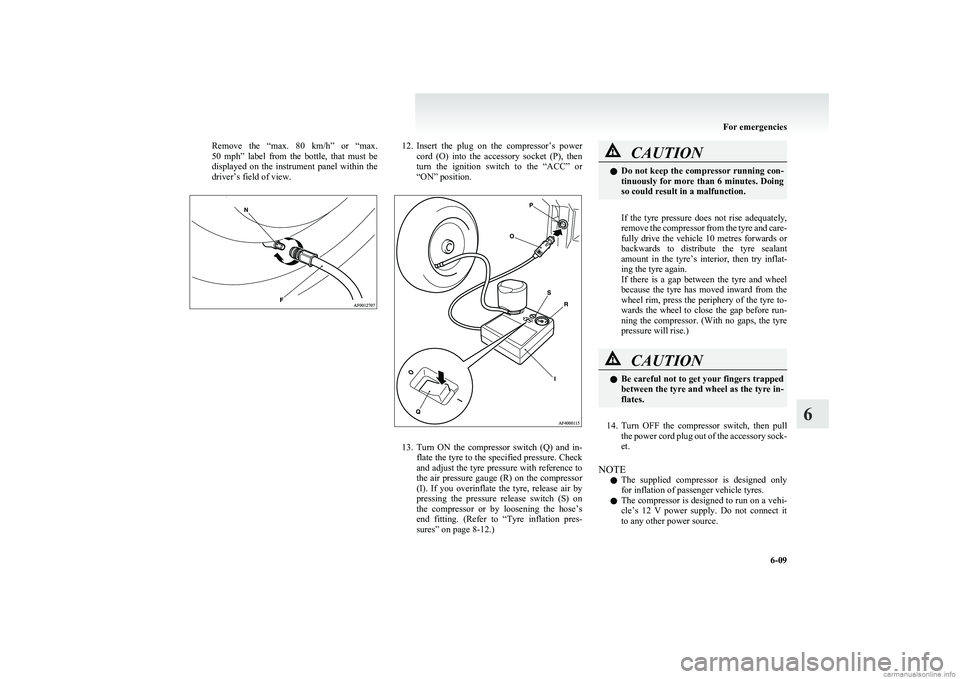

Remove the “max. 80 km/h” or “max.

50 mph ” label from the bottle, that must be

displayed on the instrument panel within the

driver’s field of view.12. Insert the plug on the compressor’s power

cord (O) into the accessory socket (P), then

turn the ignition switch to the “ACC” or

“ON” position.

13. Turn ON the compressor switch (Q) and in-

flate the tyre to the specified pressure. Check

and adjust the tyre pressure with reference to

the air pressure gauge (R) on the compressor

(I). If you overinflate the tyre, release air by

pressing the pressure release switch (S) on

the compressor or by loosening the hose’s

end fitting. (Refer to “Tyre inflation pres-

sures” on page 8-12.)

CAUTIONl Do not keep the compressor running con-

tinuously for more than 6 minutes. Doing

so could result in a malfunction.

If the tyre pressure does not rise adequately,

remove the compressor from the tyre and care-

fully drive the vehicle 10 metres forwards or

backwards to distribute the tyre sealant

amount in the tyre’s interior, then try inflat-

ing the tyre again.

If there is a gap between the tyre and wheel

because the tyre has moved inward from the

wheel rim, press the periphery of the tyre to-

wards the wheel to close the gap before run-

ning the compressor. (With no gaps, the tyre

pressure will rise.)

CAUTIONl Be careful not to get your fingers trapped

between the tyre and wheel as the tyre in-

flates.

14. Turn OFF the compressor switch, then pull

the power cord plug out of the accessory sock-

et.

NOTE l The supplied compressor is designed only

for inflation of passenger vehicle tyres.

l The compressor is designed to run on a vehi-

cle’s 12 V power supply. Do not connect it

to any other power source.

For emergencies

6-09

6

Page 196 of 274

lThe surface of the compressor will get hot

while the compressor is running. Do not

keep the compressor running continuously

for more than 6 minutes. After using the com-

pressor, wait for the compressor to cool be-

fore using it again.

l If the tyre pressure does not rise to the neces-

sary of at least 1.8 bar level within 5 mi-

nutes, the tyre may be so severely damaged

that the tyre sealant cannot be used to effect

an emergency repair. Please contact a

MITSUBISHI MOTORS Authorized Service

Point or another specialist in this event.

l Simply putting sealant and air into the tyre us-

ing the tyre repair kit does not seal the punc-

ture hole. Air will leak through the puncture

hole until the emergency repair procedure is

completed (through step 17 of these instruc-

tions).

15. When you have inflated the tyre to the speci-

fied pressure, stow the compressor and bottle

in the vehicle and promptly start driving the

vehicle so that the tire sealant can spread even-

ly in the tyre. Drive with great care. Do not

exceed a speed of 80 km/h (50 mph). Ob-

serve local speed limits.

Remove the “max. 80 km/h ” or “max.

50 mph ” label from the bottle, that must be

displayed on the instrument panel within the

driver’s field of view.CAUTIONl If you sense any abnormality while driv-

ing, stop the vehicle and contact a

MITSUBISHI MOTORS Authorized

Service Point or another specialist. Other-

wise the tyre pressure may drop before

the emergency repair procedure is com-

pleted, rendering the vehicle unsafe.

NOTE

l Driving faster than 80 km/h

(50 mph) can

make the vehicle vibrate.

16. After driving for 10 minutes, check the tyre

pressure using the air pressure gauge on the

compressor.

If the tyre pressure is not sufficient, inflate

the tyre to the specified pressure again and

drive the vehicle carefully without exceeding

a speed of 80 km/h (50 mph).

CAUTIONl If the tyre pressure is lower than the min-

imum permitted pressure (1.3 bar

{ 130 kPa}), the tyre cannot successfully

be repaired with the tyre sealant. Do not

drive the vehicle any further. Contact a

MITSUBISHI MOTORS Authorized

Service Point or another specialist.

17. After driving for 10 minutes, check the tyre

pressure using the air pressure gauge on the

compressor. (Refer to “Tyre inflation pres-

sures” on page 8-12.) If the tyre pressure

has apparently not dropped, the emergency re-

pair procedure is complete. You must still

not exceed a speed of 80 km/h (50 mph).

Observe local speed limits.

NOTE l If the tyre pressure has dropped below the

specified level when you check it at the end

of the repair procedure, do not drive the vehi-

cle any further. Contact a MITSUBISHI

MOTORS Authorized Service Point or anoth-

er specialist.

l In cold conditions (when the ambient temper-

ature is 0 °C or lower), the time and driving

distance necessary until completion of the re-

pair can be longer than in warmer conditions,

meaning that the tyre pressure can drop be-

low the specified level even when you have

inflated the tyre a second time and subsequent-

ly driven the vehicle. If this happens, inflate

the tyre to the specified pressure once more,

drive for about 10 minutes or 5 km (3 miles),

then check the tyre pressure again. If the tyre

pressure has again dropped below the speci-

fied level, stop driving the vehicle and con-

tact a MITSUBISHI MOTORS Authorized

Service Point or another specialist.

18. Then immediately drive with great care to a

MITSUBISHI MOTORS Authorized Service

Point or another specialist and have tyre re-

pair/replacement performed.

For emergencies

6-10

6

Page 197 of 274

CAUTIONlBe sure to check the tyre pressure for con-

firmation that the emergency repair pro-

cedure is complete.

NOTE

l Please give the empty sealant bottle to your

MITSUBISHI MOTORS Authorized Service

Point when you purchase new sealant or dis-

pose of the sealant bottle according to nation-

al regulations for the disposal of chemical

waste.

l A tyre in which puncture sealant has been

used should ideally be replaced with a new

one. If you wish to have such a tyre properly

repaired for reuse, please contact a

MITSUBISHI MOTORS Authorized Service

Point or another specialist. Note that a proper

repair is impossible following an emergency

repair if the puncture hole cannot be located.

l Wipe away any sealant that gets on the

wheel. Provided the valve is replaced with a

new one, the wheel can be reused.

l The manufacturer is unable to guarantee that

all tyre punctures can be repaired with the

tyre repair kit, in particular cuts or perfora-

tions with a diameter of more than 4 mm or

away from the tyre’s tread. The manufacturer

is not liable for damage sustained through im-

proper use of the tyre repair kit.

l The manufacturer is not liable for damage sus-

tained through re-use of any tyre in which

tyre sealant has been used.

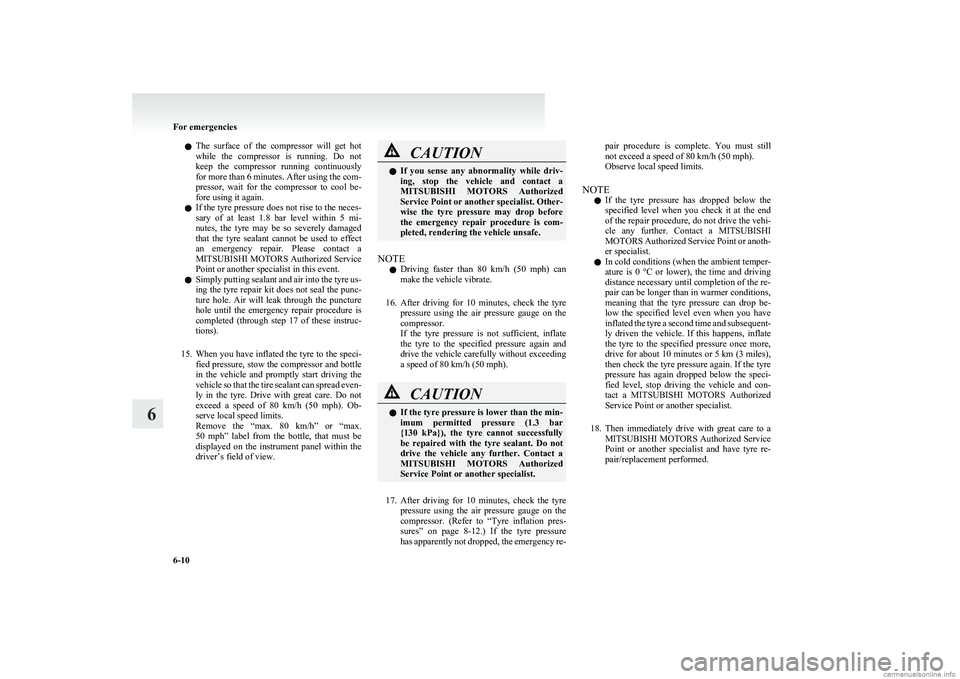

Jack* E00802000423

To remove 1.For vehicles with luggage floor lid, open the

luggage floor lid.

Refer to “Luggage floor lid” on page 5-40.

2. Lift the carpet, then remove the luggage

floor boads (A).

3. Take out the jack from its designated position.

To store

1.Retract the jack, then return it to its original

position.To expandTo retract

2. Return the luggage floor board to its original

position.

For emergencies

6-11

6

Page 198 of 274

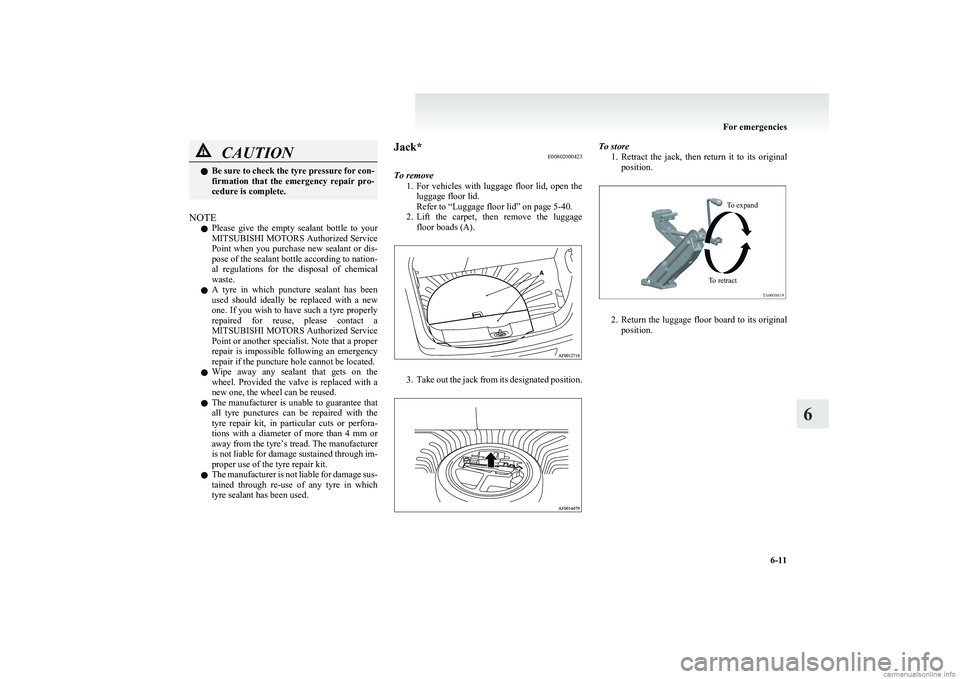

Jacking up the vehicleE00801001218

1. Park the vehicle on level and stable ground.

2. Set the parking brake firmly.

3. On vehicles with manual transmission, turn

the ignition key to the “LOCK” position,

move the gearshift lever to the “R” (Reverse)

position.

On vehicles with automated manual transmis-

sion, move the allshift lever to the “R” (Re-

verse) position, turn the ignition key to the

“LOCK” position.

With an automated manual transmission ve-

hicle, confirm that there is a “A” or “1” in

the allshift indicator display.

4. Turn on the hazard warning flashers and set

up a warning triangle, flashing signal lamp,

etc., at an adequate distance from the vehi-

cle, and have all your passengers leave the ve-

hicle.

5. To prevent the vehicle from rolling when it

is raised on the jack, place chocks or blocks

(A) at the tyre that is diagonally opposite

from the tyre (B) you are changing.WARNINGl Be sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.

If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.

NOTE

l The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if nee-

ded.

l If chocks are not available, use stones or any

other objects that are large enough to hold

the wheel in position.

6. Place the jack under one of the jacking

points (C) shown in the illustration. Use the

jacking point closest to the tyre you wish to

change.

WARNINGl Set the jack only at the positions shown

here. If the jack is set at a wrong position,

it could dent your vehicle or the jack

might fall over and cause personal injury.

l Do not use the jack on a tilted or soft sur-

face.

Otherwise, the jack might slip and cause

personal injury. Always use the jack on a

flat, hard surface.

Before setting the jack, make sure there

are no sand or pebbles under the jack base.

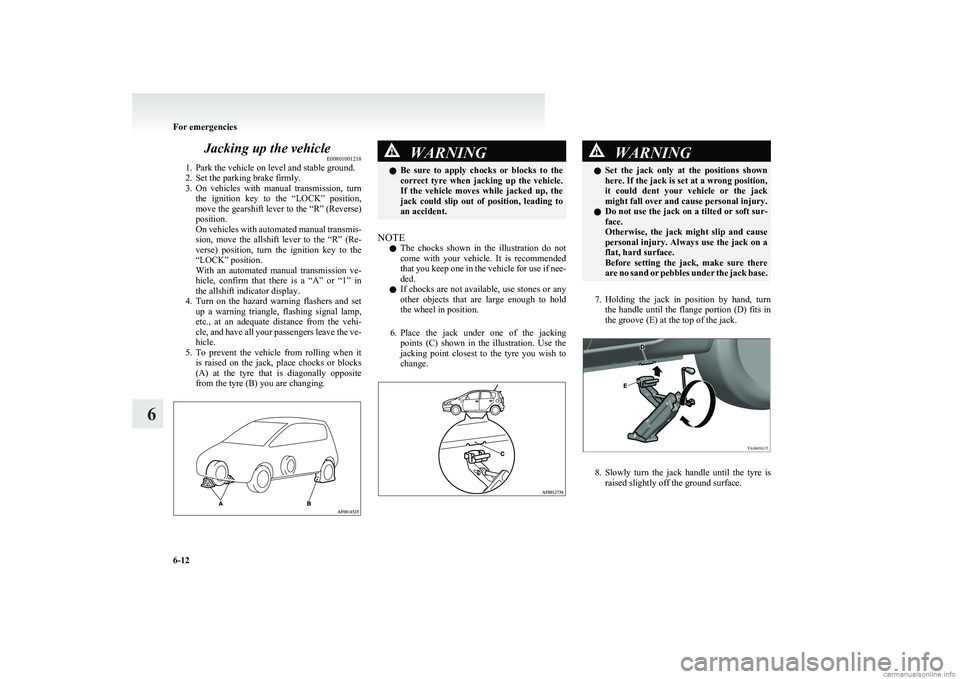

7. Holding the jack in position by hand, turn

the handle until the flange portion (D) fits in

the groove (E) at the top of the jack.

8. Slowly turn the jack handle until the tyre is

raised slightly off the ground surface.

For emergencies

6-12

6

Page 199 of 274

WARNINGlStop jacking up the vehicle as soon as the

tyre is raised off the ground. It is danger-

ous to raise the vehicle any higher.

l Do not get under your vehicle while using

the jack.

l Do not bump the raised vehicle or leave it

sitting on the jack for a long time. Both

are very dangerous.

l Do not use a jack except the one that

came with your vehicle.

l The jack should not be used for any pur-

pose other than to change a tyre.

l No one should be in your vehicle when us-

ing the jack.

l Do not start or run the engine while your

vehicle is on the jack.

l Do not turn the raised wheel. The tyres

still on the ground could turn and make

your vehicle fall off the jack.Spare wheel* E00801101394

Check the air pressure of the spare tyre frequently

and make sure it is ready for emergency use at any

time.

Maintaining the spare wheel at the highest speci-

fied air pressure will ensure that it can always be

used under any conditions (city/high-speed driving,

varying load weight, etc.).

The spare wheel is stored beneath the luggage floor

board of the luggage compartment.

Compact spare wheel

The compact spare tyre is designed to save space in

the luggage compartment and its lighter weight

makes it easier to use if a flat tyre occurs.CAUTIONl The pressure should be periodically

checked and maintained at the specified

pressure while the tyre is stowed.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no

choice but to drive with an insufficient

tyre pressure, keep your speed down and

inflate the tyre to the correct pressure as

soon as possible. (Refer to “Tyre inflation

pressures” on page 8-12.)

l The compact spare wheel is for tempora-

ry use only and should be removed as

soon as the original wheel can be re-

paired or replaced.

l The vehicle must not be driven at speeds

in excess of 80 km/h (50 mph) while using

the compact spare wheel.CAUTIONl The compact spare tyre is not as good as

a standard tyre in controllability and sta-

bility. When the compact spare tyre is

used, avoid quick starts, sudden braking

and sharp steering.

l Avoid driving through automatic vehicle

washers and over obstacles that could pos-

sibly damage the vehicle’s undercarriage.

Because the compact spare wheel is small-

er than the original wheel, the ground

clearance is slightly reduced.

l The compact spare wheel is specifically de-

signed for your vehicle and it should not

be used on any other vehicle.

l Do not use tyre chains with your compact

spare wheel. Because of the smaller tyre

size, a tyre chain will not fit properly.

This could cause damage to the wheel

and result in loss of the chain.

If a front tyre becomes flat when using

tyre chains, first replace a rear wheel

with the compact spare wheel and then

use the removed rear wheel to replace the

flat front wheel so that you can continue

to use the chains.

For emergencies

6-13

6

Page 200 of 274

CAUTIONlThe compact spare tyre should not be

used on any other wheels, nor should

standard tyres, snow tyres, wheel covers

or trim rings be used with the compact

spare wheel. If such use is attempted, dam-

age to these items or other vehicle compo-

nents may occur.

l Upon installation of the compact spare

tyre, the overall vehicle height is lowered

slightly as the tyre is smaller in diameter

than the standard tyre. When passing

over the projections on the road, take

care not to drive the vehicle with the

same feeling as used in driving with the

standard tyre on.

l Do not install more than one compact

spare wheel at the same time.

l When the tread wear indicators appear,

the tyre must be replaced.

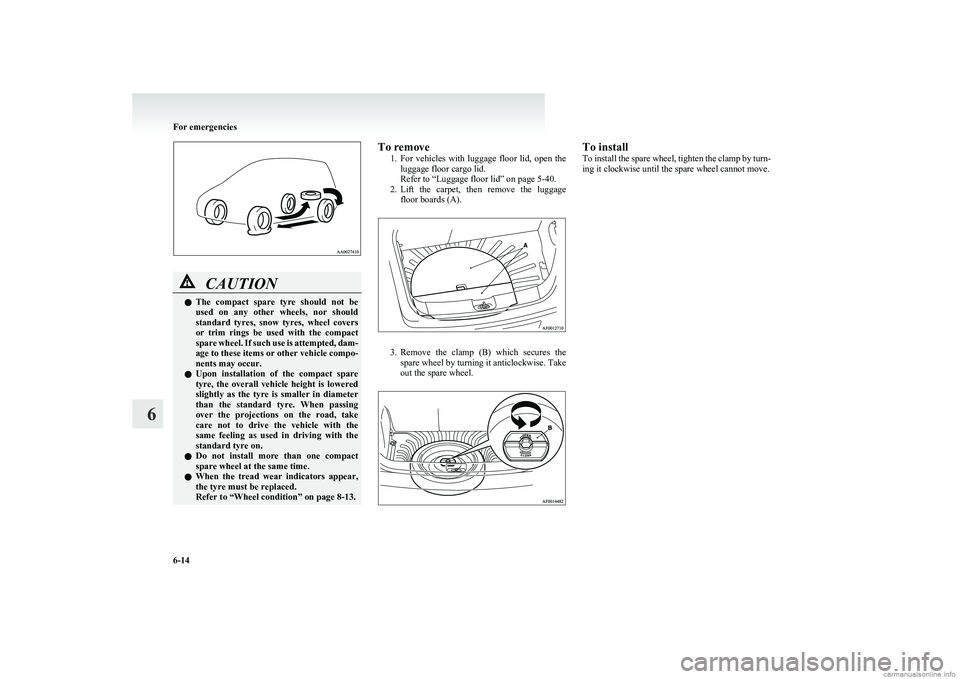

Refer to “Wheel condition” on page 8-13.To remove

1.For vehicles with luggage floor lid, open the

luggage floor cargo lid.

Refer to “Luggage floor lid” on page 5-40.

2. Lift the carpet, then remove the luggage

floor boards (A).

3. Remove the clamp (B) which secures the

spare wheel by turning it anticlockwise. Take

out the spare wheel.

To install

To install the spare wheel, tighten the clamp by turn-

ing it clockwise until the spare wheel cannot move.

For emergencies

6-14

6