light MITSUBISHI DIAMANTE 1900 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 194 of 408

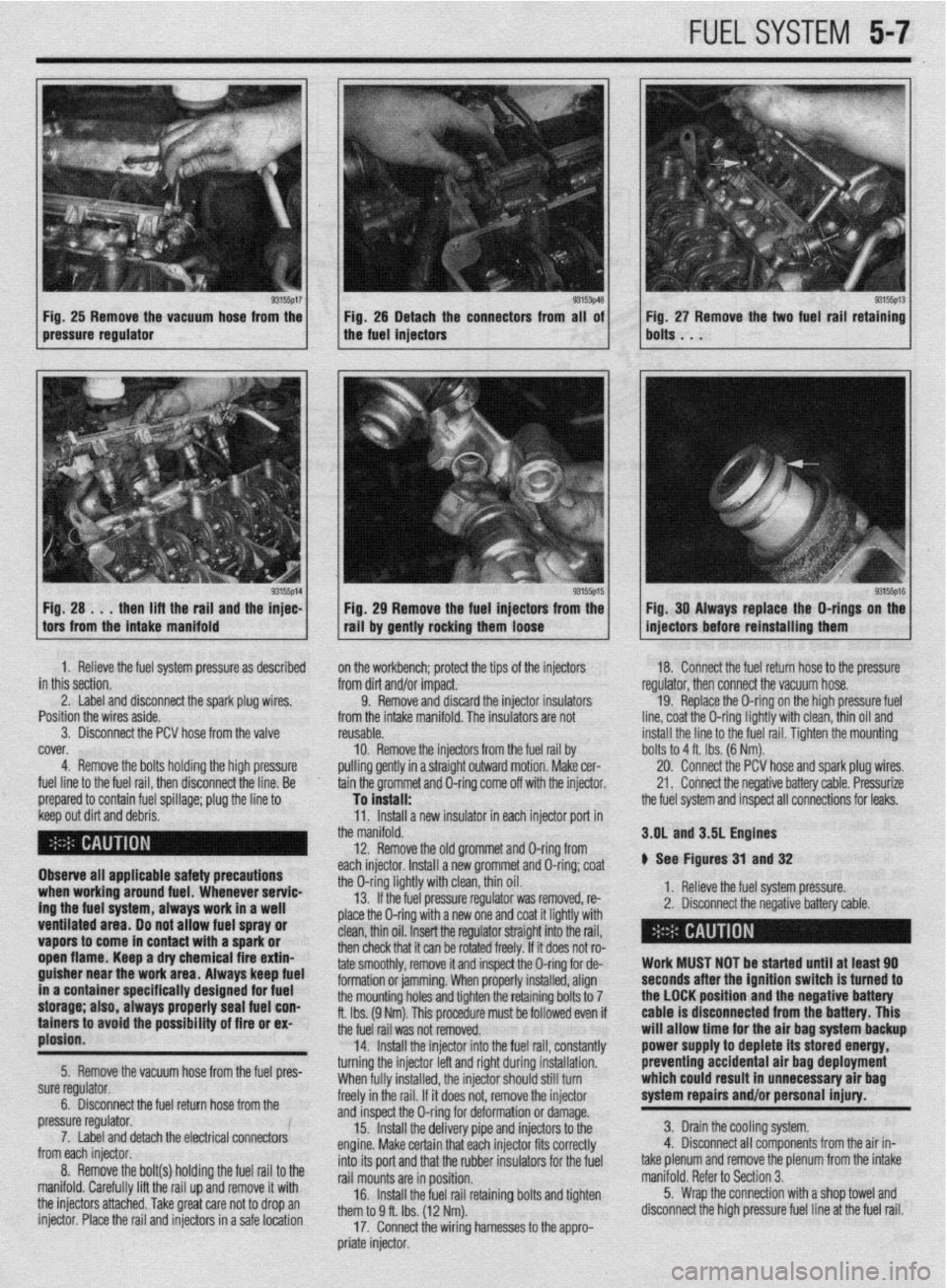

FUELSYSTEM 5-7

Fig, 25 Remove the vacuum hose from the Fig. 25 Detach the connectors from all of

pressure regulator the fuel injectors

1 H; :A ..;lt;;aft~rgi,i~;yl the ;F: 1 / . 93155p15 1 Fig 29 Remove the fuel injectors from the

tall by gently rocking them loose Fig. 27 Remove the two fuel rail retaining

bolts . . .

93155ps Fig. 30 Always replace the O-rings on the

injectors before reinstalling them

1. Relieve the fuel system pressure as described

in this section.

2. Label and disconnect the spark plug wires. ’

Position the wires aside.

3. Disconnect the PCV hose from the valve

cover,

4. Remove the bolts holding the high pressure

fuel line to the fuel rail, then disconnect the line. Be

prepared to contain fuel spillage; plug the line to on the workbench; protect the tips of the injectors

from dirt and/or impact.

9. Remove and discard the injector insulators

from the intake manifold. The insulators are not

reusable.

10. Remove the injectors from

pulling gently in a straight outwarc the fuel rail by

I motion. Make cer-

tain the grommet and O-ring come off with the injector. 18. Connect the fuel return hose to the pressure

regulator, then connect the vacuum hose.

19. Replace the O-ring on the high pressure fuel

line, coat the O-ring lightly with clean, thin oil and

install the line to the fuel rail. Tiahten the mountina

To install: -

the fuel system and inspect all connections for leaks. bolts to 4 ft. Ibs. (6 Nm).

20. Connect the PCV hose and spark plug wires.

21. Connect the negative battery cable. Pressurize

1. neneve me rueI system pressure.

2. Disconnect the negative battery cable. 3.OL and 3.5L Engines

# See Figures 31 and 32

> - ,. .* , ,

I

I

Work MUST NOT be started until at least 90

seconds after the ignition switch is turned to

the LOCK position and the negative battery

cable is disconnected from the battery. This

will allow time for the air bag system backup

power supply to deplete its stored energy,

preventing accidental air bag deployment

which could result in unnecessary air bag

system repairs and/or personal injury.

3. Drain the cooling system.

4. Disconnect all components from the air in-

take plenum and remove the plenum from the intake

manifold. Refer to Section 3.

5. Wrap the connection with a shop towel and

disconnect the high pressure fuel line at the fuel rail. keep out dirt and debris.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possfbility of fire or ex-

plosion.

5. Remove the vacuum hose from the fuel pres-

sure regulator.

6. Disconnect the fuel return hose from the

pressure regulator.

7. Label and detach the electrical connectors

from each injector.

8. Remove the bolt(s) holding the fuel rail to the

manifold. Carefully lift the rail up and remove it with

the injectors attached. Take great care not to drop an

injector. Place the rail and injectors in a safe location 11. Install a new insulator in each injector port in

the manifold.

12. Remove the old grommet and D-ring from

each injector. Install a new grommet and O-ring; coat

the O-ring lightly with clean, thin oil.

13. If the fuel pressure regulator was removed, re-

place the O-ring with a new one and coat it lightly with

clean, thin oil. Insert the regulator straight into the rail,

then check that it can be rotated freely. If it does not ro-

tate smoothly, remove it and inspect the O-ring for de-

formation or jamming. When properly installed, align

the mounting holes and tighten the retaining bolts to 7

ft. Ibs. (9 Nm). This procedure must be followed even if

the fuel rail was not removed.

14. Install the injector into the fuel rail, constantly

turning the injector left and right during installation.

When fully installed, the injector should still turn

freely in the rail. If it does not, remove the injector

and inspect the O-ring for deformation or damage.

15. Install the delivery pipe and injectors to the

engine. Make certain that each injector fits correctly

into its port and that the rubber insulators for the fuel

rail mounts are in position.

16. Install the fuel rail retaining bolts and tighten

them to 9 ff. Ibs. (12 Nm).

17. Connect the wiring harnesses to the appro-

priate injector.

Page 195 of 408

5-8 FUELSYSTEM

9 ,npimr w1m.m

1: i”“L,

1: 82”w

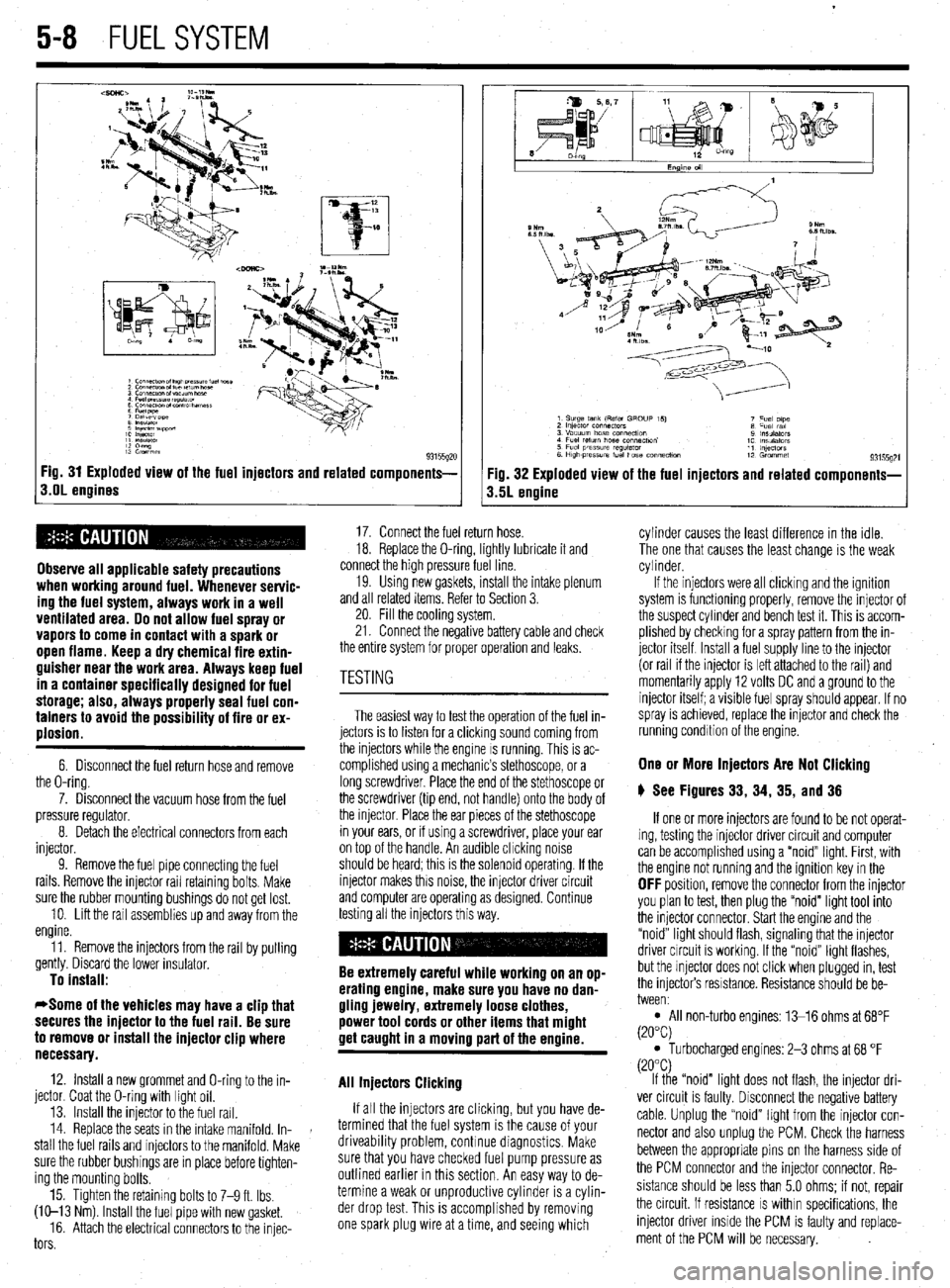

93155gx Fig. 31 Exploded view of the fuel injectors and related components-

s.OL engines

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

6. Disconnect the fuel return hose and remove

the O-ring.

7. Disconnect the vacuum hose from the fuel

pressure regulator.

8. Detach the electrical connectors from each

injector.

9. Remove the fuel pipe connectmg the fuel

rails. Remove the injector rail retaining bolts. Make

sure the rubber mounting bushings do not get lost.

10. Lift the rail assemblies up and away from the

engine.

11. Remove the injectors from the rail by pulling

gently. Discard the lower insulator.

To install:

*Some of the vehicles may have a clip that

secures the injector to the fuel rail. Be sure

to remove or install the injector clip where

necessary.

12. Install a new grommet and O-ring to the in-

jector. Coat the O-ring with light oil.

13. Install the injector to the fuel rail.

14. Replace the seats in the intake manifold. In-

stall the fuel rails and injectors to the manifold. Make

sure the rubber bushings are in place before tighten-

ing the mounting bolts.

15. Tighten the retaining bolts to 7-9 ft. Ibs.

(W-13 Nm) Install the fuel pipe with new gasket.

16. Attach the electrical connectors to the injec-

tors

Fig. 32 Exploded view of the fuel injectors and related components-

3.5L engine

17. Connect the fuel return hose.

18. Replace the O-ring, lightly lubricate it and

connect the high pressure fuel line.

19. Usmg new gaskets, install the intake plenum

and all related items. Refer to Section 3.

20. Fill the cooling system.

21. Connect the negative battery cable and check

the entire system for proper operation and leaks.

The easiest way to test the operation of the fuel in-

jectors is to listen for a clicking sound coming from

the injectors while the engine IS running. This is ac-

complished using a mechanic’s stethoscope, or a

long screwdriver. Place the end of the stethoscope or

the screwdriver (tip end, not handle) onto the body of

the injector. Place the ear pieces of the stethoscope

in your ears, or if using a screwdriver, place your ear

on top of the handle. An audible chcking noise

should be heard; this is the solenoid operating. If the

injector makes this noise, the injector driver circuit

and computer are operating as designed. Continue

testing all the injectors this way.

Be extremely careful while working on an op-

erating engine, make sure you have no dan-

gling jewelry, extremely loose clothes,

power tool cords or other items that might

get caught in a moving part of the ermine.

All Injectors Clicking

If all the injectors are clicking, but you have de-

termined that the fuel system is the cause of your

driveability problem, continue diagnostics. Make

sure that you have checked fuel pump pressure as

outlined earlier in this section. An easy way to de-

termine a weak or unproductive cylinder is a cylin-

der drop test. This is accomplished by removing

one spark plug wire at a time, and seeing which cylinder causes the least difference in the idle.

The one that causes the least change is the weak

cylinder.

If the injectors were all clicking and the ignition

system is functioning properly, remove the injector of

the suspect cylinder and bench test it. This is accom-

plished by checking for a spray pattern from the in-

jector itself Install a fuel supply line to the injector

(or rail if the injector is left attached to the rail) and

momentarily apply 12 volts DC and a ground to the

injector itself; a visible fuel spray should appear. If no

spray is achieved, replace the injector and check the

running condition of the engine.

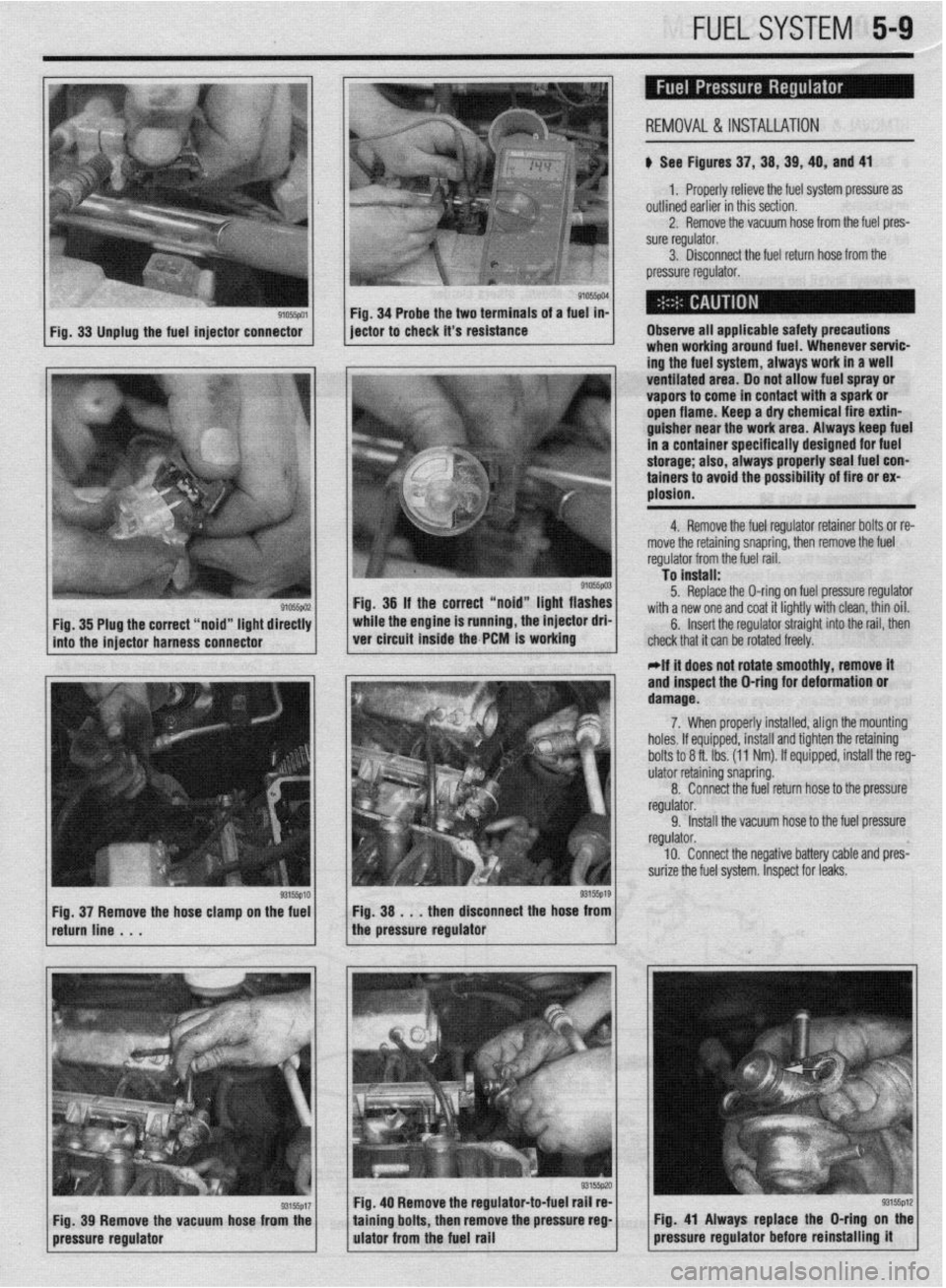

One or More Injectors Are Not Clicking

6 See Figures 33, 34, 35, and 36

If one or more injectors are found to be not operat-

ing, testing the injector driver circuit and computer

can be accomplished using a “noid” light. First, with

the engine not running and the ignition key in the

OFF position, remove the connector from the injector

you plan to test, then plug the “noid” light tool into

the injector connector. Start the engine and the

“noid” light should flash, signaling that the injector

driver circuit is working. If the “noid” light flashes,

but the injector does not click when plugged in, test

the injectors resistance. Resistance should be be-

tween:

l All non-turbo engines: 13-16 ohms at 68°F

(20°C)

l Turbocharged engines: 2-3 ohms at 68 “F

(20°C)

If the “noid” light does not flash, the injector dri-

ver circuit is faulty. Disconnect the negative battery

cable. Unplug the “noid” light from the injector con-

nector and also unplug the PCM. Check the harness

between the appropriate pins on the harness side of

the PCM connector and the injector connector. Re-

sistance should be less than 5.0 ohms; if not, repair

the circuit. If resistance

IS within specifications, the

injector driver inside the PCM is faulty and replace-

ment of the PCM will be necessary.

Page 196 of 408

FUELSYSTEM 5-9

p See Figures 37, 38, 39, 49, and 41

REMOVAL& INSTALLATION

1. Properly relieve the fuel system pressure as

outlined earlier in this section.

2. Remove the vacuum hose from the fuel pres-

sure regulator.

3. Disconnect the fuel return hose from the

pressure regulator.

Fig. 33 Unplug the fuel injector connector

, Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not apow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

I ,“~“*I.“. ..-.. * . ..” ._“. .-... To install:

I

Fig. 36 If the correct “noid” light flashes

while the engine is running, the injector dri-

ver circuit inside the PCM is working 5. Replace the O-ring on fuel pressure regulator

with a new one and coat it lightly with clean, thin oil.

6. Insert the regulator straight into the rail, then

chl . . . . . * * . . , .

xk mat n can oe rorarea rreery. 4. Remove the fuel regulator retainer bolts or re-

move the retaining snapring, then remove the fuel rrwkdnr frnm the fl~el rail

91055pu2 Fig. 35 Plug the correct “noid” light directly

into the iniector harness connector

I I I , r,

If it does not rotate smoothly, remove it

and inspect the O-ring for deformation or

damage.

7. When properly installed, align the mounting

holes. If equipped, install and tighten the retaining

bolts to 8 ft. Ibs. (11 Nm). If equipped, install the reg-

ulator retaining snapring.

8. Connect the fuel return hose to the pressure

regulator.

9. Install the vacuum hose to the fuel pressure

regulator.

10. Connect the negative battery cable and pres-

surize the fuel system. Inspect for leaks.

1 ret;rnline ~ . . g315sp10 1 1 ~~~.~~~s~~~~~u~s,“p”“““’ the hose? 1 Fig 37 Remove the hose clamp on the fuel

Fig. 39 Remove the vacuum hose from the

pressure regulator Fig. 40 Remove the regulator-to-fuel rail re-

taining bolts, then remove the pressure reg-

ulator from the fuel rail

Page 197 of 408

5-10 FUELSYSTEM

1. _

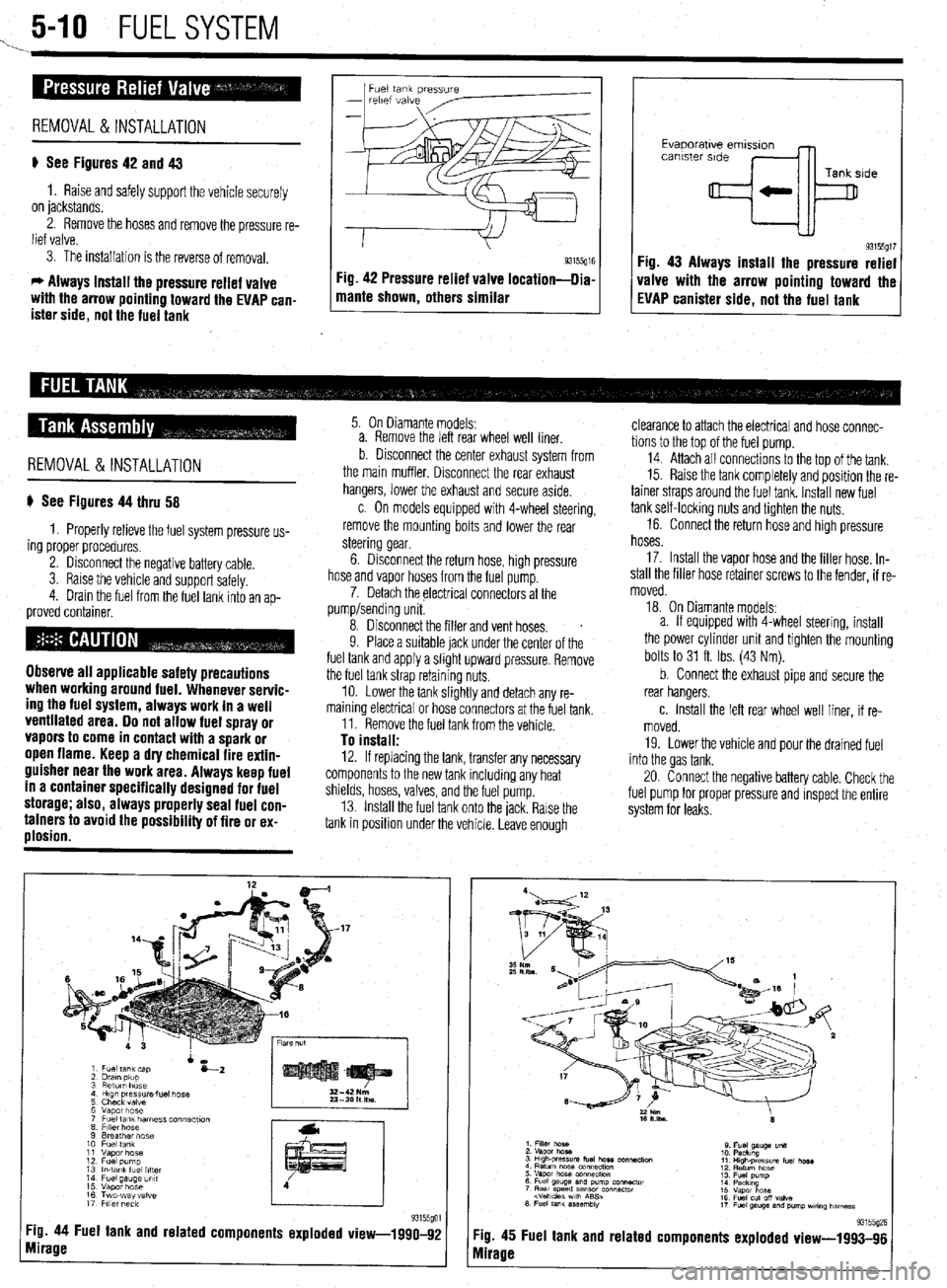

Fuel tank pressure

-

relef vdive

REMOVAL &INSTALLATION

p See Figures 42 and 43

1. Raise and safely support the vehicle securely

on jackstands.

2. Remove the hoses and remove the pressure re-

lief valve.

3. The installation is the reverse of removal.

c, Always install the pressure relief valve

with the arrow pointing toward the EVAP can-

ister side, not the fuel tank 1 mame shown, others similar g3155g” Fig 42 Pressure relief valve location-llia

I I

Evaporatwe emlsslon

canister side

Tank side

+k

93155gt7 Fig. 43 Always install the pressure relief

valve with the arrow pointing toward the

EVAP canister side, not the fuel tank

REMOVAL&INSTALLATION

p See Figures 44 thru 58

1. Properly relieve the fuel system pressure us-

ing proper procedures.

2. Disconnect the negative battery cable.

3. Raise the vehicle and support safelv.

4. Drain the fuel from the fuel tank into an

ap- proved container.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

5. On Diamante models:

a. Remove the left rear wheel well liner.

b Disconnect the center exhaust system from

the main muffler. Disconnect the rear exhaust

hangers, lower the exhaust and secure aside.

c. On models equipped with 4-wheel steering,

remove the mounting bolts and lower the rear

steering gear.

6. Disconnect the return hose, high pressure

hose and vapor hoses from the fuel pump.

7. Detach the electrical connectors at the

pump/sending unit.

8. Disconnect the filler and vent hoses.

s

9. Place a suitable jack under the center of the

fuel tank and apply a slight upward pressure. Remove

the fuel tank strap retaining nuts.

10. Lower the tank slightly and detach any re-

maining electrical or hose connectors at the fuel tank.

11. Remove the fuel tank from the vehicle.

To install: 12. If replacing the tank, transfer any necessary

components to the new tank including any heat

shields, hoses, valves, and the fuel pump.

13. Install the fuel tank onto the jack. Rarse the

tank in position under the vehicle. Leave enough

Tg. 44 Fuel tank and related components exploded view-1990-92

mirage

clearance to attach the electrical and hose connec-

tions to the top of the fuel pump.

14. Attach all connectrons to the top of the tank.

15. Raise the tank completely and position the re-

tainer straps around the fuel tank. Install new fuel

tank self-locking nuts and tighten the nuts.

16. Connect the return hose and high pressure

hoses.

17. Install the vapor hose and the filler hose. In-

stall the filler hose retainer screws to the fender, if re-

moved.

18. On Diamante models:

a. If equipped with 4-wheel steering, install

the power cylinder unit and tighten the mounting

bolts to 31 ft. Ibs. (43 Nm).

b. Connect the exhaust pipe and secure the

rear hangers.

c. Install the left rear wheel well liner, if re-

moved.

19. Lower the vehicle and pour the drained fuel

into the gas tank.

20. Connect the negative battery cable. Check the

fuel pump for proper pressure and inspect the entire

system for leaks.

:ig. 45

vlirage Fuel tank and related 93155(12E components exploded view-1993-96

Page 198 of 408

FUELSYSTEM 5-11

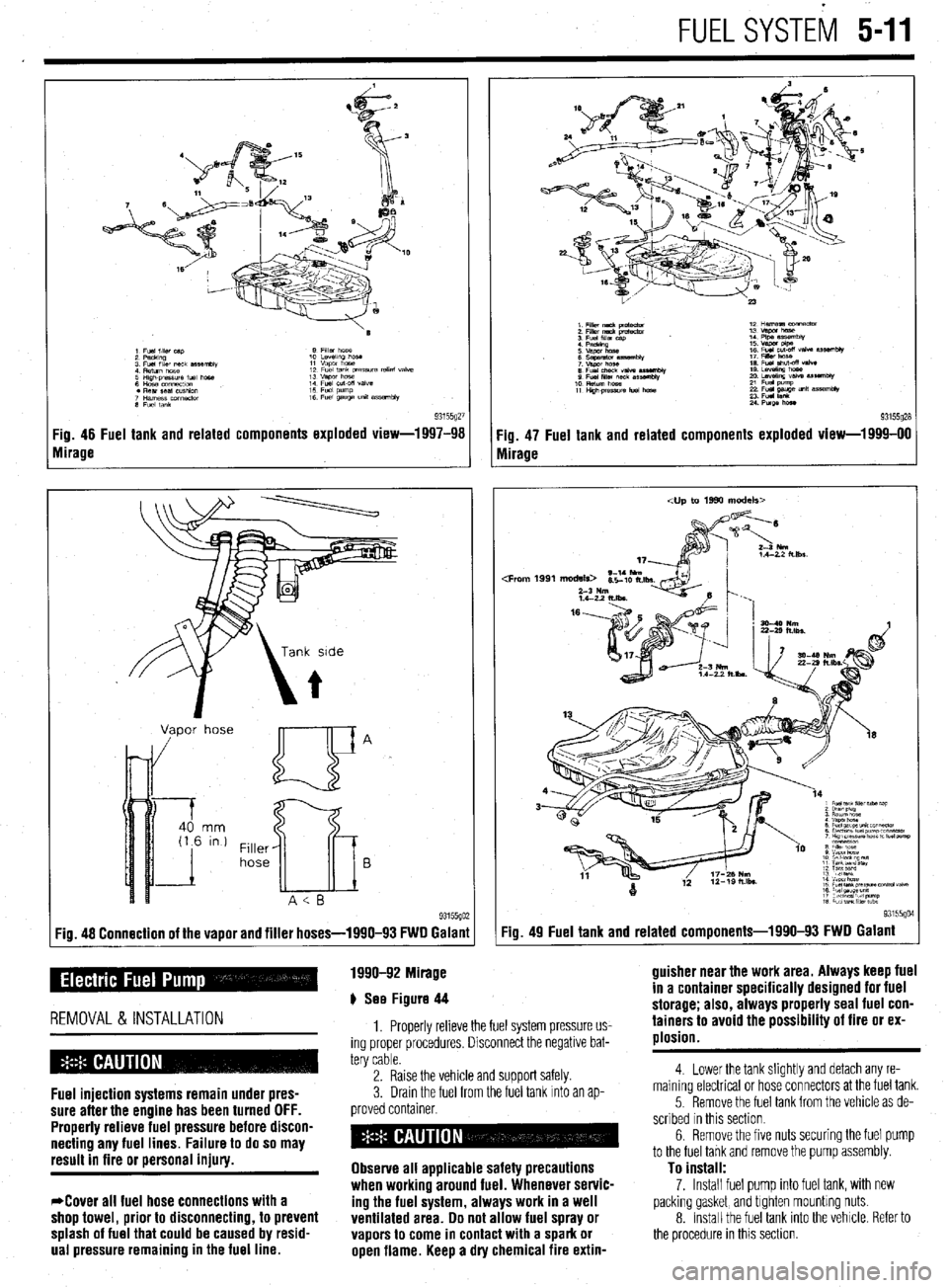

93155gZi Fig. 46 Fuel tank and related components exploded view-1997-98

Mirage

Vapor hose

Filler

hose

Fig. 48 Connection of the vapor and filler hoses-1990-93 FWD Galanl Qt. 49 Fuel tank and related components-1990-93 FWD Galant

1990-92 Mirage

p See Figure 44

REMOVAL &INSTALLATION

Fuel injection systems remain under pres-

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

necting any fuel lines. Failure to do so may

result in fire or personal iniury.

*Cover all fuel hose connections with a

shop towel, prior to disconnecting, to prevent

splash of fuel that could be caused by resid-

ual pressure remaining in the fuel line. Fig. 47 Fuel tank and related components exploded view-1999-00

1. Properly relieve the fuel system pressure us-

ing proper procedures. Disconnect the negative bat-

tery cable

2. Raise the vehicle and support safely.

3.

Dram the fuel from the fuel tank Into an ap-

proved container.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin- guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

4. Lower the tank slightly and detach any re-

maining electrical or hose connectors at the fuel tank.

5. Remove the fuel tank from the vehicle as de-

scribed In this section.

6 Remove the five nuts securing the fuel pump

to the fuel tank and remove the pump assembly.

To install:

7. Install fuel pump into fuel tank, with new

packing gasket, and tighten mounting nuts.

8. Install the fuel tank into the vehrcle. Refer to

the procedure in this section.

Page 200 of 408

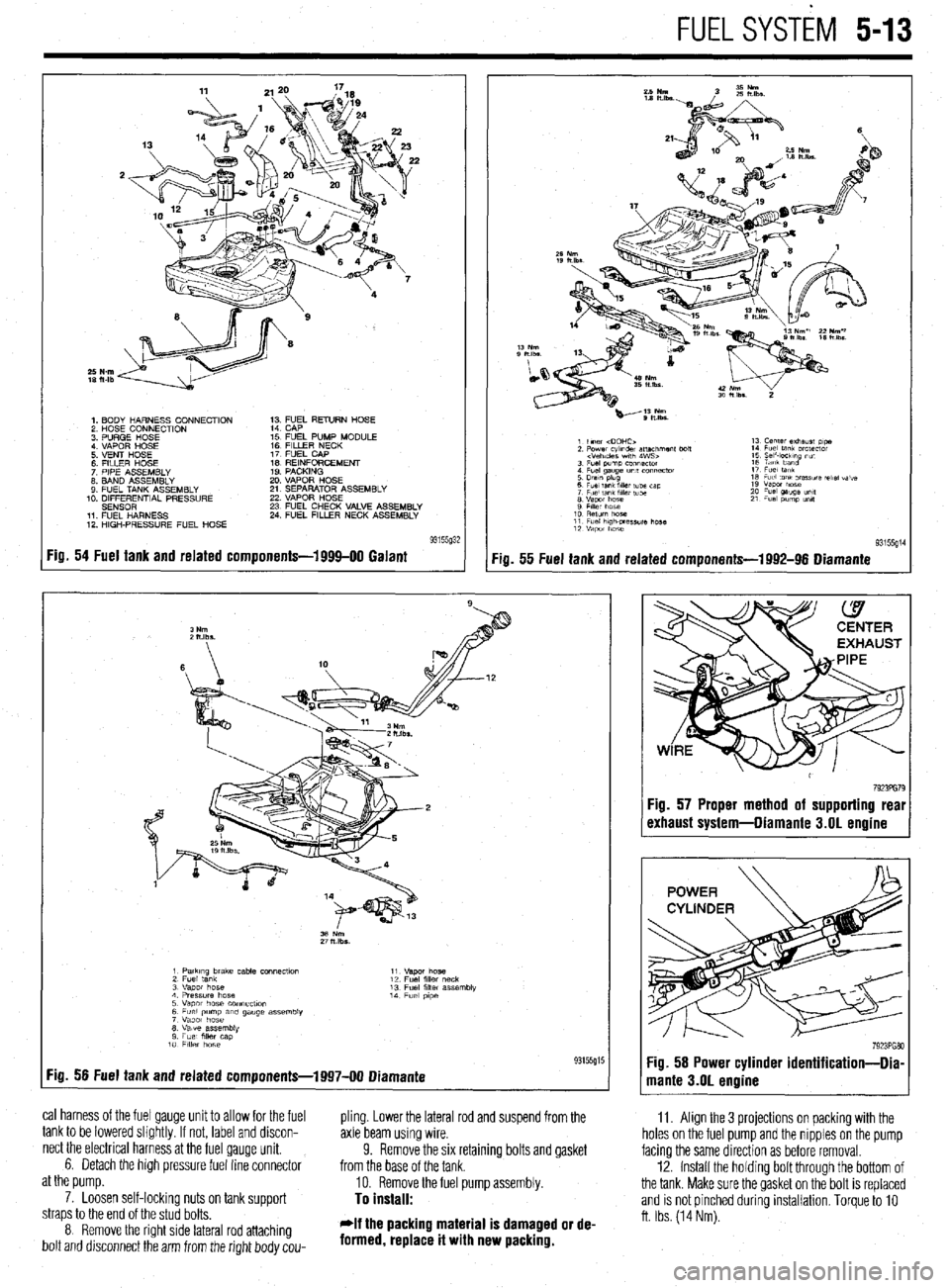

FUELSYSTiM 5-13

1. BODY HARNESS CONNECTION

2 HOSE CONNECTION

3 PURGE HOSE

4 VAPOR HOSE

5 VENT HOSE

6 FllLER HOSE

7 PIPE ASSEMBLY

8. BAND ASSEMBLY

9 FUEL TANK ASSEMBLY

10. DIFFERENTIAL PRESSURE

SENSOR

11 FUEL HARNESS

12 HIGH-PRESSURE FUEL HOSE 1; ;;JL RETURN HOSE

15 FUEL PUMP MODULE

16 FILLER NECK

17 FUEL CAP

IS REINFORCEMENT

19 PACKING

20 VAPOR HOSE

21 SEPARATOR ASSEMBLY

22 VAPOR HOSE

23 FUEL CHECK VALVE ASSEMBLY

24 FUEL FILLER NECK ASSEMBLY

Fig. 54 Fuel tank and related components-1999-00 Galant

:ia. 55 Fuel tank and related components-1992-96 Diamante

11. Align the 3 projections on packing with the

holes on the fuel pump and the nipples on the pump

facing the same direction as before removal.

12. Install the holdrng bolt through the bottom of

the tank. Make sure the gasket on the bolt is replaced

and is not pinched during installation. Torque to 10

ft. Ibs. (14 Nm).

1 PatkIng brake cable COnneCtlo” 11

2 Fuel tank “.qm hose

12 Fuel fllk, neck

3 “apot hose 13 Fuel filler assembly

4 Pressure hose 14

5 Vapor hose COnneCflOn Fuel p,pe

6 Fuel pump am gauge assembly

7 Vapor hose

8 Valve assembly

9 Fuel mer cap

10 FllkY hose

:ig. 56 Fuel tank and related components-1997-00 Diamante 93155g15

cal harness of the fuel gauge unit to allow for the fuel

pling. Lower the lateral rod and suspend from the

tank to be lowered slightly. If not, label and discon-

axle beam using wire.

nect the electrical harness at the fuel gauge unit.

6. Detach the high pressure fuel line connector 9. Remove the six retaining bolts and gasket

from the base of the tank.

at the pump.

10. Remove the fuel pump assembly.

7. Loosen self-lockinq nuts on tank suooort

To install: straps to the end of the stud bolts.

8 Remove the right side lateral rod attaching

bolt and drsconnect the arm from the right body cou- *If the packing material is damaged or de-

formed, replace it with new packing.

7923PG79 :ig. 57 Proper method of supporting real

rxhaust system-Diamante 3.01 engine

Page 204 of 408

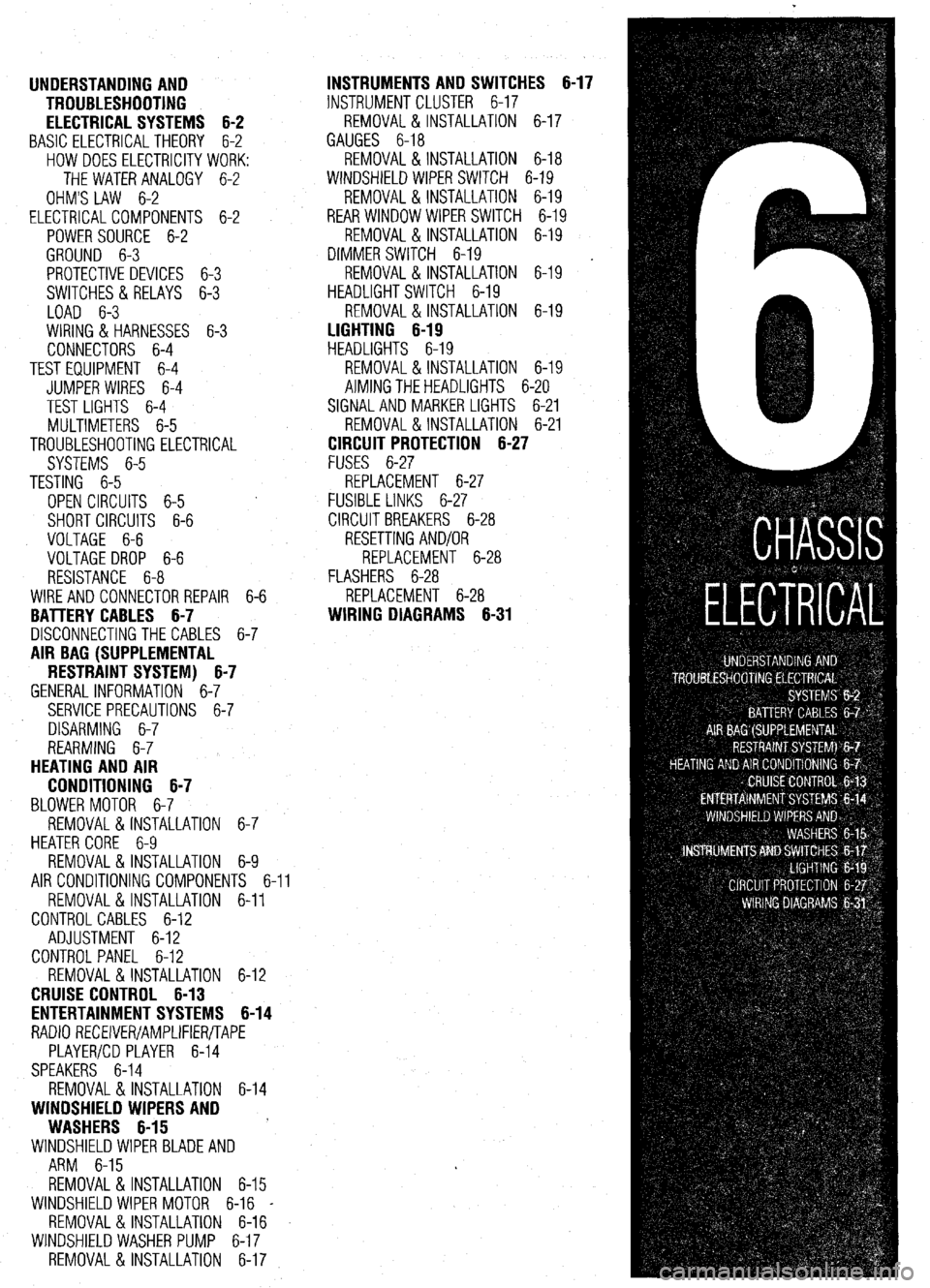

UNDERSTANDING AND

TROUBLESHOOTING

ELECTRICAL SYSTEMS 6-2

BASIC ELECTRICALTHEORY 6-2

HOW DOES ELECTRICITY WORK:

THEWATERANALOGY 6-2

OHM'S LAW 6-2

ELECTRICALCOMPONENTS 6-2

POWERSOURCE 6-2

GROUND 6-3

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

LOAD 6-3

WIRING & HARNESSES 6-3

CONNECTORS 6-4

TEST EQUIPMENT 6-4

JUMPER WIRES 6-4

TEST LIGHTS 6-4

MULTIMETERS 6-5

TROUBLESHOOTING ELECTRICAL

SYSTEMS 6-5

TESTING 6-5

OPEN CIRCUITS 6-5

SHORT CIRCUITS 6-6

VOLTAGE 6-6

VOLTAGE DROP 6-6

RESISTANCE 6-8

WIRE AND CONNECTORREPAIR 6-6

BATTERY CABLES 6-7

DISCONNECTING THE CABLES 6-7

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 6-7

GENERALINFORMATION 6-7

SERVICE PRECAUTIONS 6-7

DISARMING 6-7

REARMING 6-7

HEATING AND AIR

CONDITIONING 6-7

BLOWER MOTOR 6-7

REMOVAL &INSTALLATION 6-7

HEATER CORE 6-9 INSTRUMENTS AND SWITCHES 6-17

INSTRUMENTCLUSTER 6-17

REMOVAL &INSTALLATION 6-17

GAUGES 6-18

REMOVAL&INSTALLATION 6-18

WINDSHIELD WIPER SWITCH 6-19

REMOVAL&INSTALLATION 6-19

REARWINDOWWIPERSWITCH 6-19

REMOVAL &INSTALLATION 6-19

DIMMER SWITCH 6-19

REMOVAL & INSTALLATION 6-19 .

HEADLIGHT SWITCH 6-19

REMOVAL & INSTALLATION 6-19

LIGHTING 6-19

HEADLIGHTS 6-19

REMOVAL &INSTALLATION 6-19

AIMINGTHEHEADLIGHTS 6-20

SIGNAL AND MARKER LIGHTS 6-21

REMOVAL &INSTALLATION 6-21

CIRCUIT PROTECTION 6-27

FUSES 6-27

REPLACEMENT 6-27

FUSIBLE LINKS 6-27

CIRCUIT BREAKERS 6-28

RESETTING AND/OR

REPLACEMENT 6-28

FLASHERS 6-28

REPLACEMENT 6-28

WIRING DIAGRAMS 6-31

REMOVAL & INSTALLATION 6-9

AIR CONDITIONING COMPONENTS 6-11

REMOVAL & INSTALLATION 6-11

CONTROLCABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL & INSTALLATION 6-12

CRUISE CONTROL 6-13

ENTERTAINMENT SYSTEMS 6-14

RADIO RECEIVER/AMPLIFIER/TAPE

PLAYER/CD PLAYER 6-14

SPEAKERS 6-14

REMOVAL & INSTALLATION 6-14

WINDSHIELD WIPERS AND

WASHERS 6-15

WINDSHIELD WIPER BLADE AND

ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16 _

REMOVAL &INSTALLATION 6-16

WINDSHIELD WASHER PUMP 6-17

REMOVAL &INSTALLATION 6-17

Page 205 of 408

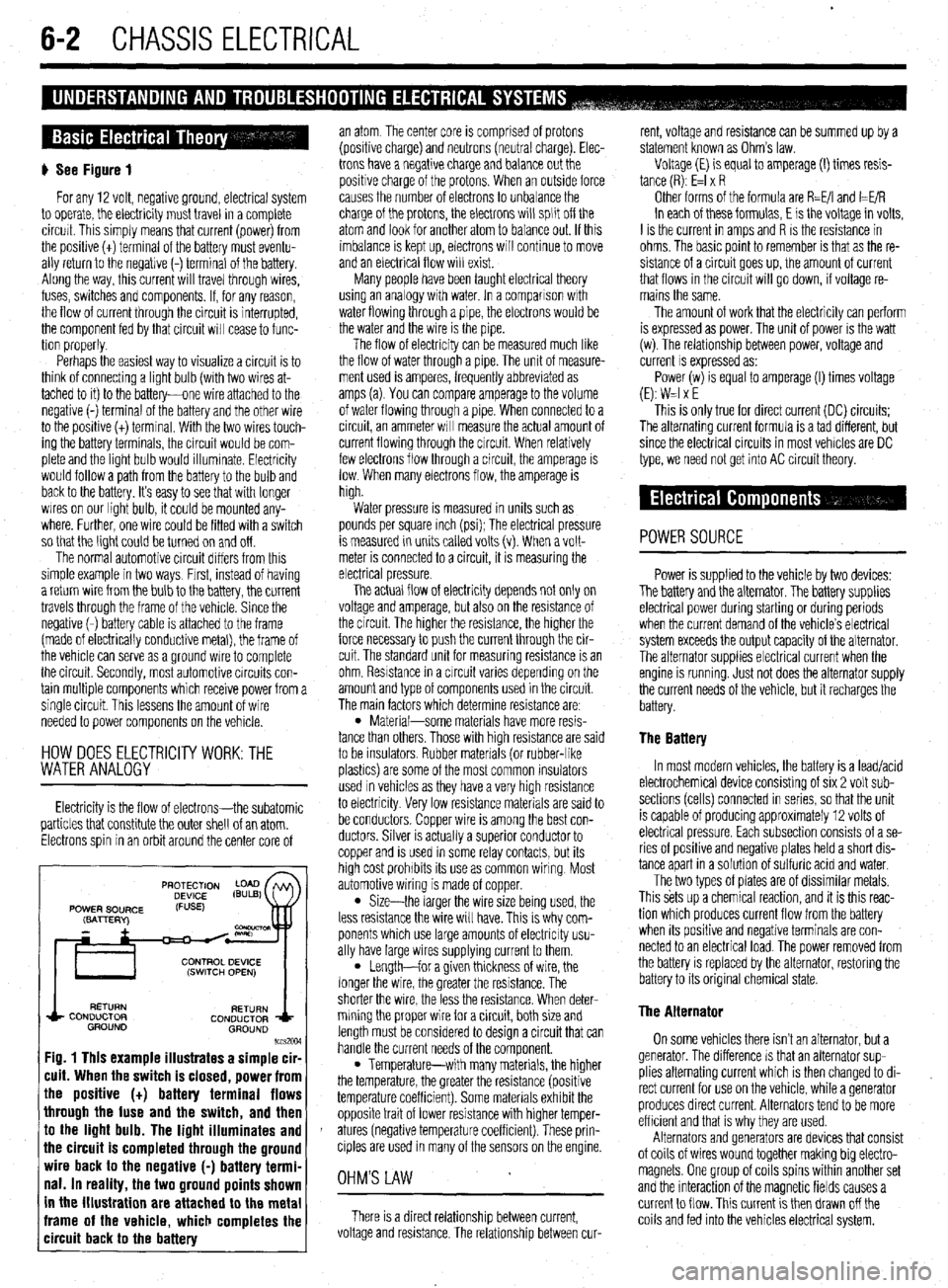

6-2 CHASSIS ELECTRICAL

) See Figure 1

For any 12 volt, negative ground, electrical system

to operate, the electricity must travel in a complete

circurt. This simply means that current (power) from

the posibve (t) terminal of the battery must eventu-

ally return to the negative (-) terminal of the battery.

Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason,

the flow of current through the circuit is interrupted,

the component fed by that circuit will cease to func-

tion properly.

Perhaps the easiest way to visualize a circuit is to

think of connecting a light bulb (with two wires at-

tached to it) to the battery-one wire attached to the

negative (-) terminal of the battery and the other wire

to the positive (t) terminal. With the two wires touch-

ing the battery terminals, the circuit would be com-

plete and the light bulb would illummate. Electricity

would follow a path from the battery to the bulb and

back to the battery. It’s easy to see that wrth longer

wires on our light bulb, it could be mounted any-

where. Further, one wire could be fitted with a switch

so that the light could be turned on and off.

The normal automotive circuit differs from this

simple example in two ways, Frrst, instead of having

a return wire from the bulb to the battery, the current

travels through the frame of the vehicle. Since the

negative (-) battery cable is attached to the frame

(made of electrically conductive metal), the frame of

the vehicle can serve as a ground wire to complete

the circuit. Secondly, most automotive circuits con-

tain multiple components which receive power from a

single circuit. This lessens the amount of wire

needed to power components on the vehicle.

HOW DOES ELECTRlClTYWORK:THE

WATER ANALOGY

Electricity is the flow of electrons-the subatomic

particles that constitute the outer shell of an atom.

Electrons spin in an orbit around the center core of

RETURN

RETURN

CONDUCTOR

CONDUCTOR

GROUND

GROUND

lccs2w

Fig. 1 This example illustrates a simple cir-

cuit. When the switch is closed, power from

the positive (t) battery terminal flows

through the fuse and the switch, and then

to the light bulb. The light illuminates and

the circuit is completed through the ground

wire back to the negative (-) battery termi-

nal. In reality, the two ground points shown

in the illustration are attached to the metal

frame of the vehicle, which completes the

circuit back to the battery

an atom The center core is comprised of protons

(positive charge) and neutrons (neutral charge). Elec-

trons have a negative charge and balance

out the

positive charge of the protons. When an outside force

causes the number of electrons to unbalance the

charge of the protons, the electrons will split off the

atom and look for another atom to balance out. If this

imbalance is kept up, electrons will continue to move

and an electrical flow will exist.

Many people have been taught electrical theory

using an analogy with water. In a comparison wrth

water flowing through a pipe, the electrons would be

the water and the wire is the pipe.

The flow of electricity can be measured much like

the flow of water through a pipe. The unit of measure-

ment used is amperes, frequently abbreviated as

amps (a). You can compare amperage to the volume

of water flowing through a pipe. When connected to a

circuit, an ammeter WIII measure the actual amount of

current flowing through the circuit. When relatively

few electrons flow through a circuit, the amperage is

low. When many electrons flow, the amperage is

high.

Water pressure is measured in units such as

pounds per square inch (psi); The electrical pressure

is measured in unrts called volts (v). When a volt-

meter is connected to a circuit, it is measuring the

electrical pressure.

The actual flow of electricity depends not only on

voltage and amperage, but also on the resistance of

the circuit The higher the resistance, the higher the

force necessary to push the current through the cir-

cuit. The standard unit for measuring resistance is an

ohm. Resistance in a crrcuit varies dependmg on the

amount and type of components used in the circuit.

The main factors which determine resistance are:

l Material-some materials have more resis-

tance than others Those with high resistance are said

to be insulators Rubber materials (or rubber-like

plashcs) are some of the most common insulators

used in vehicles as they have a very high resistance

to electricity Very low resistance materials are said to

be conductors. Copper wire is among the best con-

ductors. Silver is actually a superior conductor to

copper and is used in some relay contacts, but its

high cost prohibits its use as common wiring Most

automotive wiring is made of copper.

l Size-the larger the wire size being used, the

less resistance the wire will have. This IS why com-

ponents which use large amounts of electricity usu-

ally have large wires supplying current to them.

l Length-for a given thickness of wire, the

longer the wire, the greater the resistance. The

shorter the wire, the less the resistance. When deter-

mining the proper wire for a circuit, both size and

length must be considered to design a circuit that can

handle the current needs of the component.

l Temperature-with many materials, the higher

the temperature, the greater the resistance (positive

temperature coefficient). Some materials exhibit the

opposite trait of lower resistance with higher temper-

atures (negative temperature coefficient). These prin-

ciples are used in many of the sensors on the engine

OHM'S LAW

There is a direct relationship between current,

voltage and resistance. The relationship between cur- rent, voltage and resistance can be summed up by a

statement known as Ohm’s law.

Voltage (E) is equal to amperage (I) times resis-

tance (R): E=l x R

Other forms of the formula are R=E/I and I=E/R

In each of these formulas, E is the voltage in volts,

I is the current in amps and R IS the resistance in

ohms. The basic point to remember is that as the re-

sistance of a circuit goes up, the amount of current

that flows in the circuit will go down, if voltage re-

mains the same.

The amount of work that the electricity can perform

is expressed as power. The unit of power is the watt

(w). The relationship between power, voltage and

current

IS expressed as:

Power(w) is equal to amperage (I) times voltage

(E): W=l x E

This is only true for direct current (DC) circuits:

The alternating current formula is a tad different, but

since the electrical circuits in most vehicles are DC

type, we need not get into AC circuit theory.

POWERSOURCE

Power is supplied to the vehicle by two devices:

The battery and the alternator. The battery supplies

electrical power during starting or during periods

when the current demand of the vehicle’s electrical

system exceeds the output capacity of the alternator.

The alternator supplies electrical current when the

engine is running

Just not does the alternator supply

the current needs of the vehicle, but it recharges the

battery.

The Battery

In most modern vehicles, the battery is a lead/acid

electrochemical device consisting of six 2 volt sub-

sections (cells) connected in series, so that the unit

is capable of producing approximately 12 volts of

electrical pressure. Each subsection consists of a se-

ries of positive and negative plates held a short dis-

tance apart in a solutron of sulfuric acid and water.

The two types of plates are of dissimilar metals,

This sets up a chemrcal reaction, and it is this reac-

tion which produces current flow from the battery

when Its positive and negattve terminals are con-

nected to an electrical load. The power removed from

the battery is replaced by the alternator, restoring the

battery to its original chemical state.

The Alternator

On some vehicles there isn’t an alternator, but a

generator. The difference IS that an alternator sup-

plies alternating current which is then changed to di-

rect current for

use on the vehicle, while a generator

produces direct current. Alternators tend to be more

efficient and that is why they are used.

Alternators and generators are devices that consist

of coils of wires wound together making big electro-

magnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a

current to flow. This current is then drawn off the

coils and fed into the vehicles electrical system.

Page 207 of 408

I

6-4 CHASSIS ELECTRICAL

I

printed circuit is sandwiched between two sheets of

plastic for more protection and flexibility. A complete l Weatherproof-these connectors are most the jumper wire is of too small a gauge, it

printed circuit, consisting of conductors, insulating commonly used where the connector is exposed to

may overheat and possibly melt. Never use

material and connectors for lamps or other compo- the elements. Terminals are protected against mois-

nents is called a printed circuit board. Printed cir- ture and dirt by sealing rings which provide a weath- jumpers to bypass high resistance loads in a

et-tight seal. All repairs require the use of a special circuit. Bypassing resistances, in effect, cre-

cuitry is used in place of individual wires or har- ates a short circuit. This may, in turn, cause

nesses in places where space is limited, such as terminal and the tool required to service it. Unlike

behind instrument panels. standard blade type terminals, these weatherproof damage and fire. Jumper wires should only

be used to bypass lengths of wire or to simu-

Since automotive electrical systems are very sen- terminals cannot be straightened once they are bent. late switches.

sitive to changes in resistance, the selection of prop- ‘Make certain that the connectors are properly seated

erly sized wires is critical when systems are repaired, and all of the sealing rings are in place when con-

netting leads. Jumper wires are simple, yet extremely valuable,

A loose or corroded connection or a replacement wire pieces of test equipment. They are basically test wires

that is too small for the circuit will add extra resis-

l Molded-these connectors require complete which are used to bypass sections of a circuit. Al-

replacement of the connector if found to be defective.

tance and an additional voltage drop to the circuit. though jumper wires can be purchased, they are usu-

The wire gauge number is an expression of the This means splicing a new connector assembly into ally fabricated from lengths of standard automotive

cross-section area of the conductor. Vehicles from the harness. All splices should be soldered to insure

proper contact. Use care when probing the connec- wire and whatever type of connector (alligator clip,

countries that use the metric system will typically de- spade connector or pin connector) that is required for

scribe the wire size as its cross-sectional area in tions or replacing terminals in them, as it is possible

square millimeters. In this method, the larger the to create a short circuit between opposite terminals. If the particular application being tested. In cramped,

hard-to-reach areas, it is advisable to have insulated

wire, the greater the number. Another common sys- this happens to the wrong terminal pair, it is possible

to damage certain components. Always use jumper boots over the jumper wire terminals in order to pre-

tern for expressing wire size is the American Wire vent accidental grounding. It is also advisable to in-

Gauge (AWG) system. As gauge number increases, wires between connectors for circuit checking and

NEVER probe through weatherproof seals. elude a standard automotive fuse in any jumper wire.

area decreases and the wire becomes smaller. An 18

gauge wire is smaller than a 4 gauge wire. A wire

l Hard Shell-unlike molded connectors, the This is commonly referred to as a “fused jumper”. By

inserting an in-line fuse holder between a set of test

terminal contacts in hard-shell connectors can be re-

with a higher gauge number will carry less current

placed. Replacement usually involves the use of a leads, a fused jumper wire can be used for bypassing :

than a wire with a lower gauge number. Gauge wire open circuits. Use a 5 amp fuse to provide protection

size refers to the size of the strands of the conductor, special terminal removal tool that depresses the lock- against voltage spikes.

not the size of the complete wire with insulator. It is ing tangs (barbs) on the connector terminal and al-

lows the connector to be removed from the rear of the Jumper wires are used primarily to locate open

possible, therefore, to have two wires of the same

shell. The connector shell should be replaced if it electrical circuits, on either the ground (-) side of the

gauge with different diameters because one may have

thicker insulation than the other. shows any evidence of burning, melting, cracks, or circuit or on the power (+) side. If an electrical corn-

breaks. Replace individual terminals that are burnt, ponent fails to operate, connect the jumper wire be-

It is essential to understand how a circuit works

corroded, distorted or loose. tween the component and a good ground. If the corn-

before trying to figure out why it doesn’t. An electrical ponent operates only with the jumper installed, the

schematic shows the electrical current paths when a ground circuit is open. If the ground circuit is good,

circuit is operating properly. Schematics break the but the component does not operate, the circuit be-

entire electrical system down into individual circuits. tween the power feed and component may be open. ’

In a schematic, usually no attempt is made to repre- Pinpointing the exact cause of trouble in an elec- By moving the jumper wire successively back from

trical circuit is most times accomplished by the use the component toward the power source, you can

; : sent wiring and components as they physically ap-

pear on the vehicle; switches and other components of special test equipment. The following describes isolate the area of the circuit where the open is lo-

are shown as simply as possible. Face views of har- different types of commonly used test equipment and cated. When the component stops functioning, or the f

j

ness connectors show the cavity or terminal locations briefly explains how to use them in diagnosis. In ad- power is cut off, the open is in the segment of wire j

in all multi-pin connectors to help locate test points. dition to the information covered below, the tool between the jumper and the point previously tested.

! manufacturer’s instructions booklet (provided with You can sometimes connect the jumper wire di-

the tester) should be read and clearly under.$ood be- rectly from the battery to the “hot” terminal of the I

CONNECTORS 1 fore attempting any test procedures. component, but first make sure the component uses 1

# See Figures 5 and 6 JUMPER WIRES 12 volts in operation. Some electrical components, i

such as fuel injectors or sensors, are designed to op-

Three types of connectors are commonly used in erate on about 4 to 5 volts, and running 12 volts di- j

)

automotive applications-weatherproof, molded and rectly to these components will cause damage.

hard shell.

Never use jumper wires made from a thinner TEST LIGHTS I

gauge wire than the circuit being tested. If

# See Figure 7

The test light is used to check circuits and compo-

I nents while electrical current is flowing through

Fig. 5 Hard shell (left) and weatherproof

(right) connectors have replaceable termi- Fig. 7 A 12 volt test light is used to di%

nals

ements 1 the presence of voltage in a circuit

Page 208 of 408

CHASSIS ELECTRiCAL 6-5

them. It is used for voltage and ground tests. To use voltmeter has a positive and a negative lead. To avoid

a 12 volt test light, connect the ground clip to a good damage to the meter, always connect the negative

ground and probe wherever necessary with the pick. lead to the negative (-) side of the circuit (to ground

The test light will illuminate when voltage is detected. or nearest the ground side of the circuit) and connect

This

does not necessarily mean that 12 volts (or any the positive lead to the positive(t) side of the circuit When diagnosing a specific problem, organized

troubleshooting is a must. The complexity of a mod-

particular amount of voltage) is present; it only (to the power source or the nearest power source).

means that some voltage is present. It is advisable Note that the negative voltmeter lead will always be ern automotive vehicle demands that you approach

before using the test light to touch its ground clip black and that the positive voltmeter will always be any problem in a logical, organized manner. There

and probe across the battery posts or terminals to some color other than black (usually red). are certain troubleshooting techniques, however,

which are standard:

make sure the light is operating properly.

l Ohmmeter-the ohmmeter is designed to read l Establish when the problem occurs. Does the

resistance (measured in ohms) in a circuit or compo-

nent. Most ohmmeters will have a selector switch problem appear only under certain conditions? Were

there any noises, odors or other unusual symptoms?

Do not use a test light to probe electronic ig- which permits the measurement of different ranges of

Isolate the problem area. To do this, make some sim-

nition, spark plug or coil wires. Never use a resistance (usually the selector switch allows the

multiplication of the meter reading by 10,100,1,000 ple tests and observations, then eliminate the sys-

pick-type test light to probe wiring on com- terns that are working properly. Check for obvious

puter controlled systems unless specifically and 10,000). Some ohmmeters are “auto-ranging”

which means the meter itself will determine which problems, such as broken wires and loose or dirty

instructed to do so. Any wire insulation that

scale to use. Since the meters are powered by an in- connections. Always check the obvious before as-

is pierced by the test light probe should be

ternal battery, the ohmmeter can be used like a self- suming something complicated is the cause.

taped and sealed with silicone after testing.

l Test for problems systematically to determine

powered test light. When the ohmmeter is connected,

the cause once the problem area is isolated. Are all

Like the jumper wire, the 12 volt test light is used current from the ohmmeter flows through the circuit

the components functioning properly? Is there power

to isolate opens in circuits. But, whereas the jumper or component being tested. Since the ohmmeter’s in-

ternal resistance and voltage are known values, the going to electrical switches and motors. Performing

wire is used to bypass the open to operate the load,

amount of current flow through the meter depends on careful, systematic checks will often turn up most

the 12 volt test light is used to locate the presence of

the resistance of the circuit or component being causes on the first inspection, without wasting time

voltage in a circuit. If the test light illuminates, there

tested. The ohmmeter can also be used to perform a checking components that have little or no relation-

is power up to that point in the circuit; if the test light ship to the problem.

does not illuminate, there is an open circuit (no continuity test for suspected open circuits. In using

the meter for making continuity checks, do not be

l Test all repairs after the work is done to make

power). Move the test light in successive steps back

concerned with the

actual resistance readings. Zero sure that the problem is fixed. Some causes can be

toward the power source until the light in the handle traced to more than one component, so a careful veri-

illuminates. The open is between the probe and a resistance, or any ohm reading, indicates continuity

fication of repair work is important in order to pick up

point which was previously probed. in the circuit, Infinite resistance indicates an opening

in the circuit. A high resistance reading where there additional malfunctions that may cause a problem to

The self-powered test light is similar in design to

should be none indicates a problem in the circuit. reappear or a different problem to arise. A blown

the 12 volt test light, but contains a 1.5 volt penlight

Checks for short circuits are made in the same man- fuse, for example, is a simple problem that may re-

battery in the handle. It is most often used in place of

ner as checks for open circuits, except that the circuit quire more than another fuse to repair. If you don’t

a multimeter to check for open or short circuits when look for a problem that caused a fuse to blow, a

power is isolated from the circuit (continuity test). must be isolated from both power and normal

ground. Infinite resistance indicates no continuity, shorted wire (for example) may go undetected.

The battery in a self-powered test light does not Experience has shown that most problems tend

provide much current. A weak battery may not pro- while zero resistance indicates a dead short.

to be the result of a fairly simple and obvious

vide enough power to illuminate the test light even I ’ cause, such as loose or corroded connectors, bad

when a complete circuit is made (especially if there is grounds or damaged wire insulation which causes a

high resistance in the circuit). Always make sure that Never use an ohmmeter to check the resis- short. This makes careful visual inspection of com-

the test battery is strong. To check the battery, briefly tance of a component or wire while there is ponents during testing essential to quick and accu-

touch the ground clip to the probe; if the light glows voltage applied to the circuit. rate troubleshooting.

brightly, the battery is strong enough for testing.

*A self-powered test light should not be

l Ammeter-an ammeter measures the amount

- I

used on any computer controlled system or of current flowing through a circuit in units called

component. The small amount of electricity amperes or amps. At normal operating voltage, most

circuits have a characteristic amount of amperes, OPEN CIRCUITS

transmitted by the test light is enough to

damage many electronic automotive compo- called “current draw” which can be measured using

an ammeter. By referring to a specified current draw # See Figure 8

nents.

rating, then measuring the amperes and comparing

MULTIMETERS the two values, one can determine what is happening

within the circuit to aid in diagnosis. An open circuit,

for example, will not allow any current to flow, so the

Multimeters are an extremely useful tool for trou-

bleshooting electrical problems. They can be pur- ammeter reading will be zero. A damaged component

or circuit will have an increased current draw, so the

chased in either analog or digital form and have a

reading will be high. The ammeter is always con-

price range to suit any budget. A multimeter is a volt-

netted in series with the circuit being tested. All of

meter, ammeter and ohmmeter (along with other fea-

the current that normally flows through the circuit

tures) combined into one instrument. It is often used

must also flow through the ammeter; if there is any

when testing solid state circuits because of its high

other path for the current to follow, the ammeter read-

input impedance (usually 10 megaohms or more). A

ing will not be accurate. The ammeter itself has very

brief description of the multiieter main test functions

follows: little resistance to current flow and, therefore, will not

affect the circuit, but it will measure current draw only

l Voltmeter--the voltmeter is used to measure

when the circuit is closed and electricity is flowing.

voltage at any point in a circuit, or to measure the

Excessive current draw can blow fuses and drain the

voltage drop across any part of a circuit. Voltmeters

battery, while a reduced current draw can cause mo-

usually have various scales and a selector switch to

tors to run slowly, lights to dim and other compo-

allow the reading of different voltage ranges. The

nents to not operate properly.