coolant temperature MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 20 of 408

GENERALINFORMATIONAND MAINTENANCE l-21

IWSIZXJ FM. 83 A hose clamn that is taa tiaht can

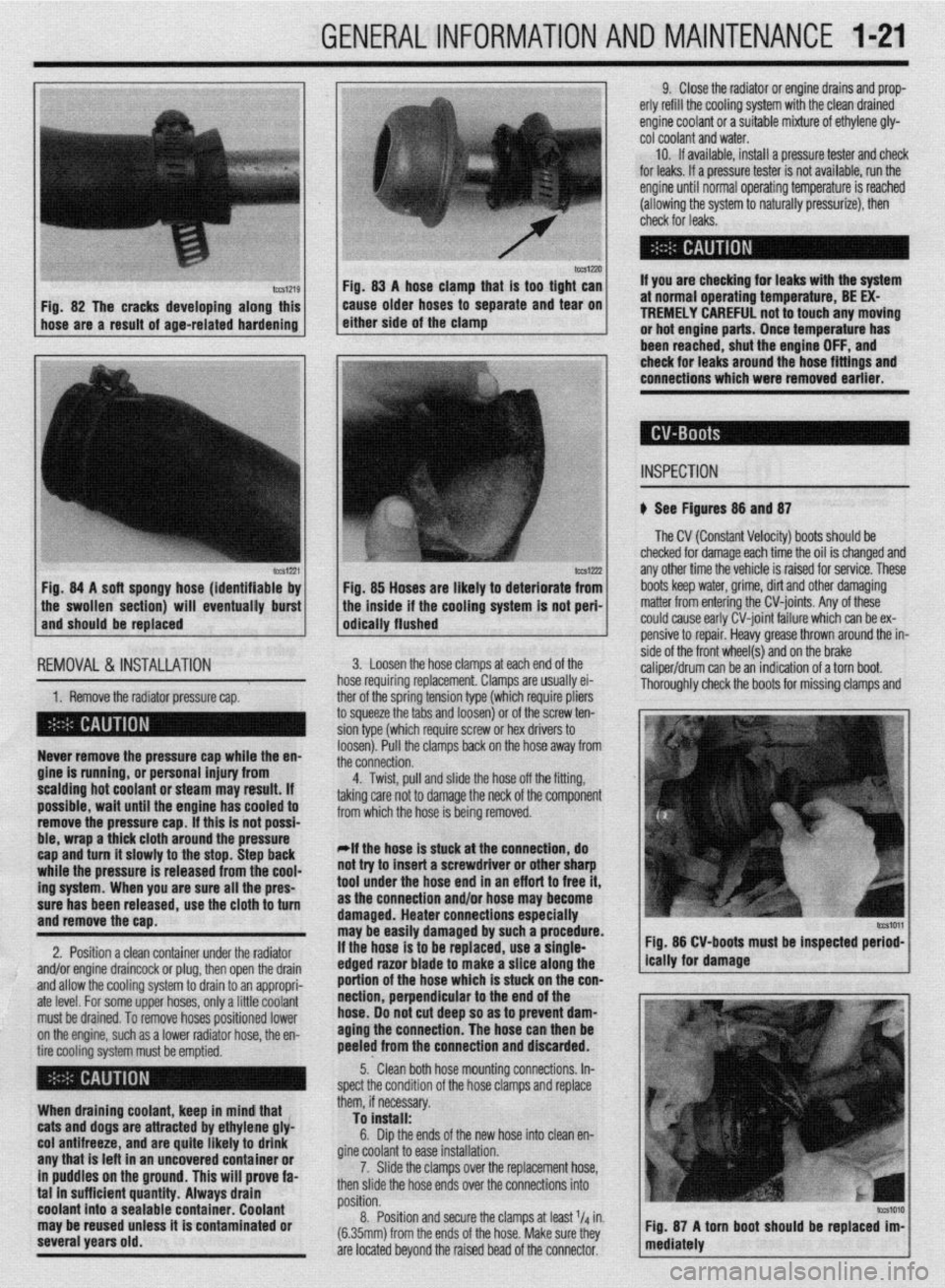

Fig. 82 The cracks developing along this

hose are a result of age-related hardening caise older hoses td separate and ‘iear on

either side of the clamp

lCCS1221 Fig. 84 A soft spongy hose (identifiable by

1 the swollen section) will eventually burst

and should be replaced

IEMOVAL &,INSTALLATION '

1. Remove the radiator pressure cap. her of the sorina tension tvoe (which reouire oliers

3 squeeze the 6bs and loosenj or of the’screw ten-

ion type (which require screw or hex drivers to

oosen). Pull the clamps back on the hose away from

he connection. Never remove the pressure cap while the en-

gine is running, or personal injury from

scalding hot coolant or steam may result. If

possible, wait until the engine has cooled to

remove the pressure cap. If this is not possi-

ble, wrap a thick cloth around the pressure

cap and turn it slowly to the stop. Step back

while the pressure is released from the cool-

ing system. When you are sure all the pres-

sure has been released, use the cloth to turn

and remove the cao.

2. Position a clean container under the radiator

and/or engine draincock or plug, then open the drain

and allow the cooling system to drain to an appropri-

ate level. For some upper hoses, only a little coolant

must be drained. To remove hoses positioned lower

on the engine, such as a lower radiator hose, the en-

tire cooling system must be emptied.

When draining coolant, keep in mind that

cats and dogs are attracted by ethylene gly-

col antifreeze, and are quite likely to drink

any that is left in an uncovered container or

in puddles on the ground. This will prove fa-

tal in sufficient quantity. Always drain

coolant into a sealable container. Coolant

may be reused unless it is contaminated or

several years old. 9. Close the radiator or engine drains and prop-

erly refill the cooling system with the clean drained

engine coolant or a suitable mixture of ethylene gly-

cot coolant and water.

10. If available, install a pressure tester and check

for leaks. If a pressure tester is not available, run the

engine until normal operating temperature is reached

(allowing the system to naturally pressurize), then

check for leaks.

If you are checking for leaks with the system

at normal operating temperature, BE EX-

TREMELY CAREFUL not to touch any moving

or hot engine parts. Once temperature has

been reached. shut the enaine OFF. and

Fig. 85 Hoses are likely to deteriorate from

the inside if the cooling system is not peri-

odically flushed check for leaks around the-hose fittings and

connections which were removed earlier.

INSPECTION

b See Figures 88 and 87

The CV (Constant Velocity) boots should be

checked for damage each time the oil is changed and

any other time the vehicle is raised for service. These

boots keep water, grime, dirt and other damaging

matter from entering the CV-joints. Any of these

could cause early CV-joint failure which can be ex-

pensive to repair. Heavy grease thrown around the in-

side of the front wheel(s) and on the brake

caliper/drum can be an indication of a torn boot.

Thorouahlv check the boots for missina clamos and 3. Loosen the hose clamps at each end of the

rose requiring replacement. Clamps are usually ei-

4. Twist, pull and slide the hose off the fitting,

sking care not to damage the neck of the component

rom which the hose is being removed.

*If the hose is stuck at the connection, do

lot try to insert a screwdriver or other sharp

ool under the hose end in an eff art to free it,

IS the connection and/or hose may become

lamaged. Heater connections especially

nay be easily damaged by such a procedure.

f the hose is to be replaced, use a single-

!dged razor blade to make a slice along the

lortion of the hose which is stuck on the con-

section, perpendicular to the end of the

lose. 00 not cut deep so as to prevent dam-

aging the connection. The hose can then be

keeled from the connection and discarded. Fig. 86 CV-boots must be inspected period-

5.. Clean both hose mounting connections. In-

,pect the condition of the hose clamps and replace

hem, if necessary.

To install:

6. Dip the ends of the new hose into clean en-

fine coolant to ease installation.

7. Slide the clamps over the replacement hose,

hen slide the hose ends over the connections into

rosition.

8. Position and secure the clamps at least l/d in.

6.35mm) from the ends of the hose. Make sure they

Ire located beyond the raised bead of the connector.

Page 48 of 408

DISTRIBUTOR IGNITION SYSTEM

GENERALINFORMATION 2-2

DIAGNOSISANDTESTING 2-2

SECONDARYSPARKTEST 2-2

CYLINDERDROPTEST 2-2

ADJUSTMENTS 2-3

IGNITION COIL 2-3

TESTING 2-3

REMOVAL&INSTALLATION 2-3

POWERTRANSISTOR

(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

DISTRIBUTOR 2-4

REMOVAL&INSTALLATION 2-4 2-2

INSTALLATION 2-4

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-5

DISTRIBUTORLESS IGNITION

SYSTEM 2-5

GENERALINFORMATION 2-5

DIAGNOSISANDTESTING 2-5

ADJUSTMENTS 2-5

IGNITION COIL(s) 2-5

TESTING 2-5

REMOVAL&INSTALLATION 2-6

POWERTRANSISTOR

(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

CRANKSHAFTANDCAMSHAFTPOSITION

SENSORS 2-7

FIRING ORDERS 2-7

CHARGING SYSTEM 2-8

GENERALINFORMATION 2-8

ALTERNATORPRECAUTIONS 2-8

ALTERNATOR 2-8

TESTING 2-8 I

REMOVAL&INSTALLATION 2-9

REGULATOR 2-10

REMOVAL&INSTALLATION 2-10

STARTING SYSTEM 2-10

GENERALINFORMATION 2-10

STARTER 2-10

TESTING 2-10

REMOVAL&INSTALLATION 2-11

SENDING UNITS 2-11

ENGINECOOLANTTEMPERATURE

SENDING UNIT 2-11

TESTING 2-11

REMOVAL&INSTALLATION 2-11

OIL PRESSURESENDING UNIT 2-12

TESTING 2-12

REMOVAL&INSTALLATION 2-12

Page 59 of 408

.

2-12 ENGINEELECTRICAL

*This section describes the operating prina

ciples of sending units, warning lights and

gauges. Sensors which provide information

to the Enafne Control Unit (ECU) or Electronic

or Power&in Control Module (FCM/PCM) are

covered in Section 4 of this manual.

Instrument panels contain a number of indicating

devices (gauges and warning lights). These devices

are composed of two separate components. One is

the sending unit, mounted on the engine or other re-

mote part of the vehicle, and the other is the actual

gauge or light in the instrument panel.

Several types of sending units exist, however most

can be characterized as being either a pressure type

or a resistance type. Pressure type sending units

convert liquid pressure into an electrical signal which

is sent to the gauge. Resistance type sending units

are most often used to measure temperature and use

variable resistance to control the current flow back to

the indicatinq device. Both types of sendinq units are

connected inseries by a wimto the batteryithiough

the ignition switch). When the ignition is turned ON,

current flows from the battery through the indicating

device and on to the sending unit.

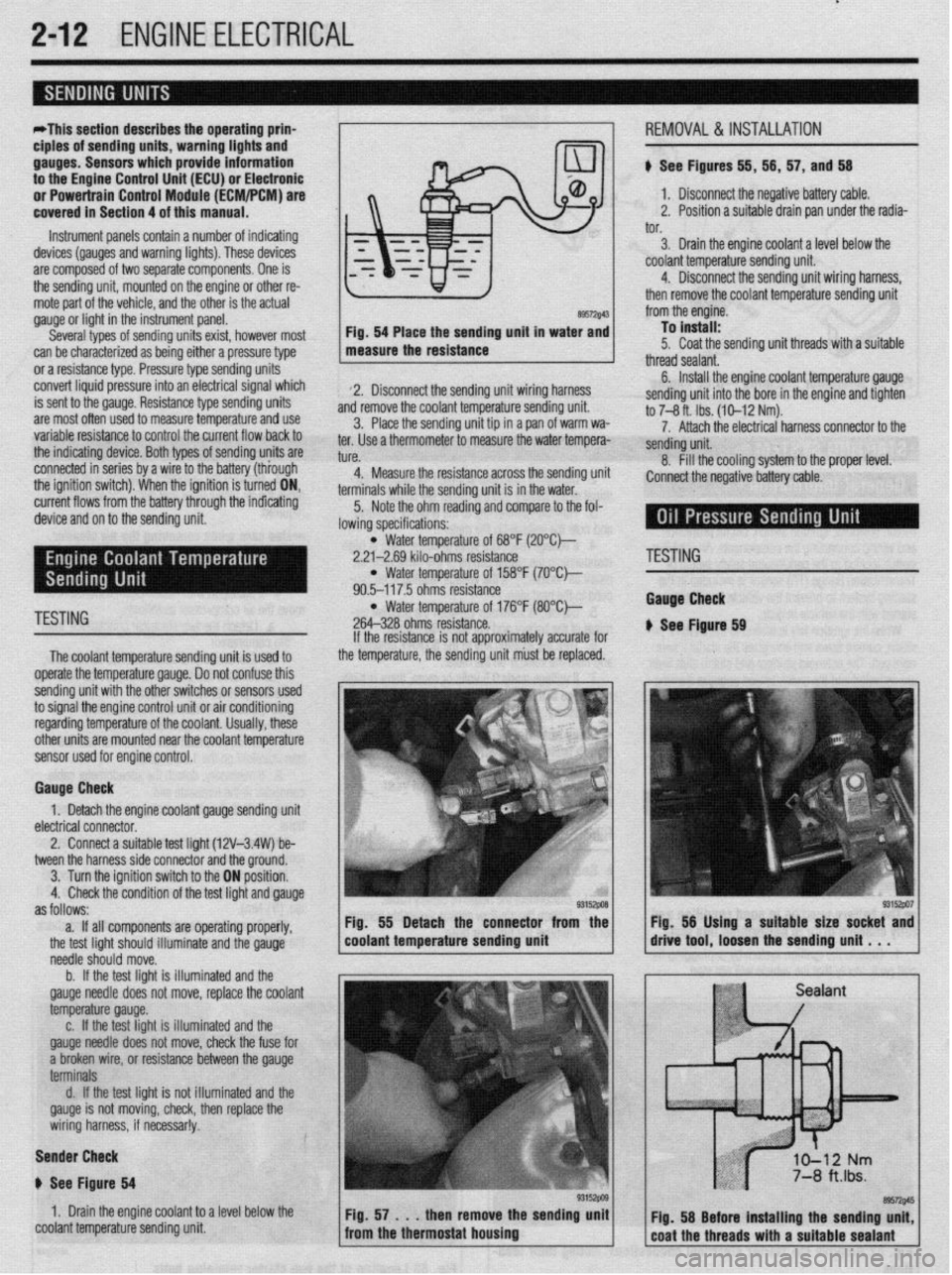

89572$43 Fig. 54 Place the sending unit in water and

measure the resistance

2. Disconnect the sending unit wiring harness

and remove the coolant temperature sending unit.

3. Place the sending unit tip in a pan of warm wa-

ter. Use a thermometer to measure the water tempera-

tl KP

L”,“.

4. Measure the resistance across the sending uni

terminals while the sending unit is in the water.

5. Note the ohm reading and compare to the fol-

lowing specifications: i, 56, 57, and 56

1. Disconnect the negative battery cable.

2. Position a suitable drain pan under the radia-

tor.

3. Drain the engine coolant a level below the

coolant temperature sending unit.

4. Disconnect the sending unit wiring harness,

then remove the coolant temperature sending unit

from the engine.

To install:

5. Coat the sending unit threads with a suitable

thread sealant.

6. Install the engine coolant temperature gauge

sending unit into the bore in the engine and tighten

to 7-8 ft. Ibs. (10-12 Nm).

7. Attach the electrical harness connector to the

sendina unit.

8. fill the cooling system to the proper level.

:onnect the negative battery cable.

l Water temperature of 68°F (2O”C)-

2.21-2.69 kilo-ohms resistance

l Water temperature of 158°F (7O’Ck

90.5-117.5 ohms resistance

TESTING l Water temperature of 176°F (8O”C)-

264-328 ohms resistance.

The coolant temperature sendina unit is used to

operate the temperature gauge. Donot confuse this

sending unit with the other switches or sensors used

to signal the engine control unit or air conditioning

regarding temperature of the coolant. Usually, these

other units are mounted near the coolant temoerature

sensor used for engine control. If the resistance is not approximately accurate for

the temperature, the sending unit must be replaced.

Gauge Check

1. Detach the engine coolant gauge sending unit

electrical connector.

2. Connect a suitable test liaht (12V-3.4W) be-

tween the harness side connector and the around.

I

3. Turn the ignition switch to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light should illuminate and the gauge

needle should move.

b. If the test light is illuminated and the

gauge needle does not move, replace the coolant

temperature gauge.

c. If the test light is illuminated and the

gauge needle does not move, check the fuse for

a broken wire, or resistance between the gauge

terminals

d. If the test light is not illuminated and the

gauge is not moving, check, then replace the

wiring harness, if necessar!y.

Sender Check

p See Figure 64

1. Drain the engine coolant to a level below the

coolant temperature sending unit Fig. 55 Detach the connector from the

coolant temperature sending unit

'ESTING

tauga Check

See Ftgure 69

Page 63 of 408

3-2 ENGINEANDENGINEOVERHAUL

REMOVAL &INSTALLATION

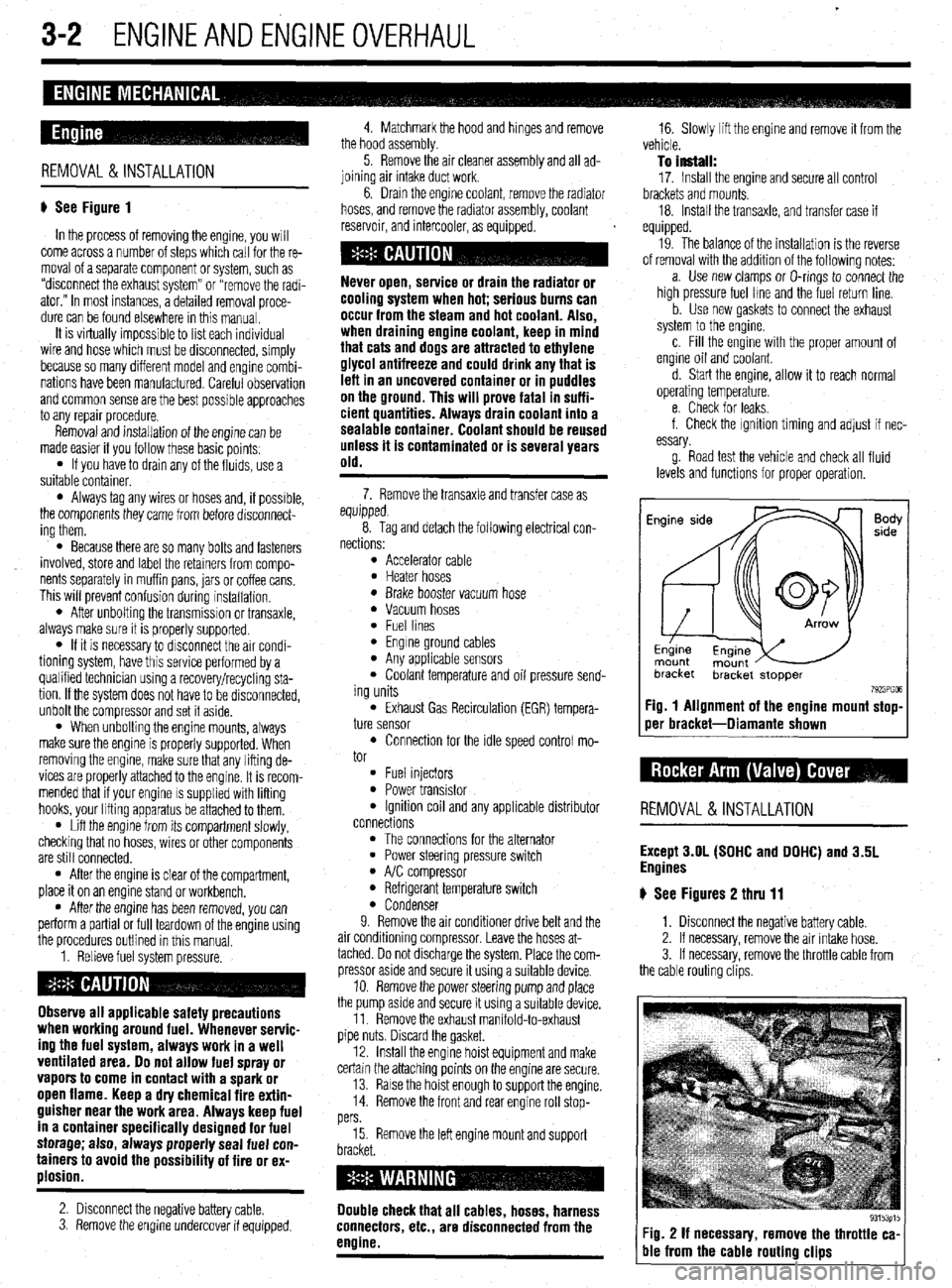

# See Figure 1

In the process of removing the engine, you will

come across a number of steps which call for the re-

moval of a separate component or system, such as

“disconnect the exhaust system” or “remove the radi-

ator.” In most instances, a detailed removal proce-

dure can be found elsewhere in this manual.

It is virtually impossible to list each individual

wire and hose which must be disconnected, simply

because so many different model and engrne combi-

nations have been manufactured Careful observation

and common sense are the best possible approaches

to any repair procedure.

Removal and installation of the engine can be

made easier if you follow these basic points:

l If you have to drain any of the fluids, use a

suitable container.

l Always tag any wires or hoses and, if possrble,

the components they came from before disconnect-

ing them.

l Because there are so many bolts and fasteners

involved, store and label the retainers from compo-

nents separately in muffin pans, jars or coffee cans.

This will prevent confusion during installatron.

l After unbolting the transmisston or transaxle,

always make sure it is properly supported.

l If it is necessary to disconnect the air condi-

tioning system, have this service performed by a

qualified technician using a recovery/recycling sta-

tion If the system does not have to be disconnected,

unbolt the compressor and set it aside.

l When unbolting the engine mounts, always

make sure the engine is properly supported. When

removing the engine, make sure that any lifting de-

vices are properly attached to the engine. It is recom-

mended that if your engine IS supplied with lifting

hooks, your lifting apparatus be attached to them.

l Lift the engine from its compartment slowly,

checking that no hoses, wires or other components

are still connected.

l After the engine is clear of the compartment,

place it on an engine stand or workbench.

l After the engine has been removed, you can

perform a partial or full teardown of the engine using

the procedures outlined in this manual.

1. Relieve fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Remove the engine undercover if equipped. 4. Matchmark the hood and hinges and remove

the hood assembly.

5. Remove the air cleaner assembly and all ad-

joining air intake duct work.

6. Drain the engine coolant, remove the radiator

hoses, and remove the radiator assembly, coolant

reservoir, and intercooler, as equipped.

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

7. Remove the transaxle and transfer case as

equipped.

8. Tag and detach the following electrical con-

nections:

l Accelerator cable l Heater hoses l Brake booster vacuum hose l Vacuum hoses l Fuel lines l Engine ground cables l Any applicable sensors l Coolant temperature and oil pressure send-

ing units

l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Connection for the idle speed control mo-

tor

l Fuel injectors l Power transistor l Ignition coil and any applicable distributor

connections

l The connections for the alternator l Power steering pressure switch l A/C compressor l Refrigerant temperature switch l Condenser

9. Remove the air conditioner drive belt and the

air conditioning compressor. Leave the hoses at-

tached. Do not discharge the system. Place the com-

pressor aside and secure it using a suitable device.

10. Remove the power steering pump and place

the pump asrde and secure it using a surtable device.

11. Remove the exhaust manifold-to-exhaust

pipe nuts. Discard the gasket.

12. Install the engine hoist equipment and make

certain the attaching points on the engine are secure.

13. Raise the hoist enough to support the engine.

14. Remove the front and rear engine roll stop-

pers

15. Remove the left engine mount and support

Double check that all cables, hoses, harness

connectors, etc., are disconnected from the

engine.

16. Slowly lift the engine and remove it from the

vehicle.

To install:

17. Install the engine and secure all control

brackets and mounts.

18. Install the transaxle, and transfer case if

equipped.

19. The balance of the installation is the reverse

of removal with the addition of the following notes:

a. Use new clamps or O-rings to connect the

high pressure fuel lme and the fuel return line.

b. Use new gaskets to connect the exhaust

system to the engine.

c. Fill the engine with the proper amount of

engine oil and coolant.

d. Start the engine, allow it to reach normal

operating temperature.

e. Check for leaks.

f. Check the ignition timing and adjust if nec-

essary.

g. Road test the vehicle and check all fluid

levels and functions for proper operation.

Fig. 1 Alignment of the engine mount stop-

oer bracket-Diamante shown

REMOVAL &INSTALLATION

Except 3.OL (SOHC and DOHC) and 3.5L

Engines

# See Figures 2 thru 11

1. Disconnect the negative battery cable.

2. If necessary, remove the air intake hose.

3. If necessary, remove the throttle cable from

the cable routing clips.

Fig. 2 If necessary, remove the throttle ca-

ble from the cable routing clips

Page 69 of 408

3-8' ENGINEANDENGINEOVERHAUL

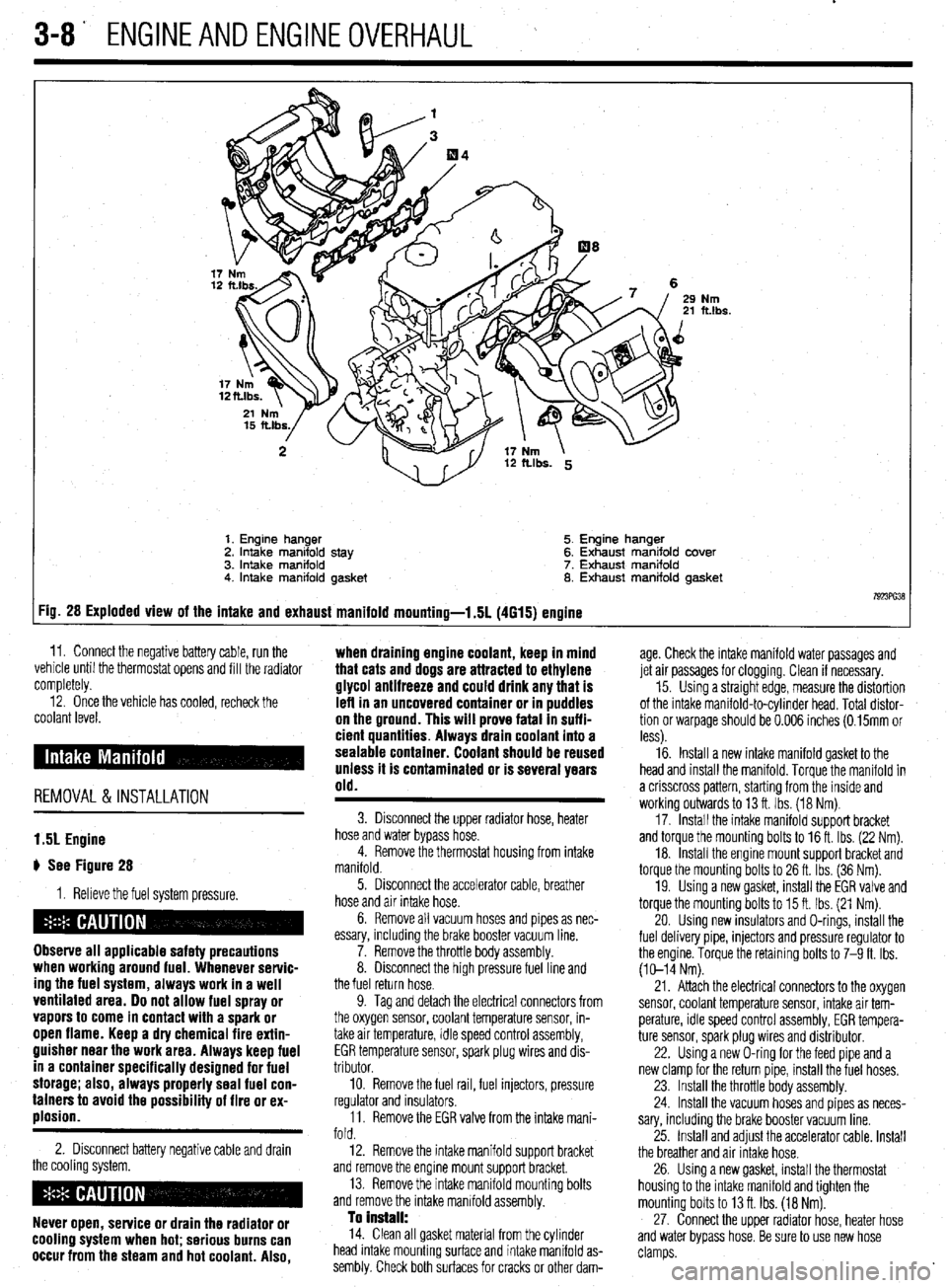

Nm ft.lbs.

1. Engine hanger 5. Engine hanger

2. Intake manifold stay 6. Exhaust manifold cover

3. intake manifold 7. Exhaust manifold

4. Intake manifold gasket 8. Exhaust manifold gasket

7923ffi38 :ig. 28 Exploded view of the intake and exhaust manifold mounting-l .5L (4615) engine

11. Connect the negative battery cable, run the ,. . . .

vemcie unnl me tnermostat opens ano till the radiator

completely. age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

12. Once the vehicle has cooled, recheck the

coolant level.

REMOVAL &INSTALLATION when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal In suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

15. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

16. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 13 ft. Ibs. (18 Nm).

17. Install the intake manifold support bracket

and torque the mounting bolts to 16 ft. Ibs. (22 Nm).

18. Install the engine mount support bracket and

torque the mounting bolts to 26 ft. Ibs. (36 Nm).

19. Using a new gasket, install the EGR valve and

torque the mounting bolts to 15 ft. Ibs. (21 Nm).

20. Using new insulators and O-rings, install the

fuel delivery pipe, injectors and pressure regulator to

the engine. Torque the retaining bolts to 7-9 ft. Ibs.

(10-14 Nm).

1.51 Engine

# See Figure 28

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

3. Disconnect the upper radiator hose, heater

hose and water bypass hose.

4. Remove the thermostat housing from intake

manifold.

5. Disconnect the accelerator cable, breather

hose and air intake hose.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster vacuum line.

7. Remove the throttle body assembly.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, in-

take air temperature, idle speed control assembly,

EGR temperature sensor, spark plug wires and dis-

tributor.

10. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

11. Remove the EGR valve from the intake mani-

fold.

12. Remove the intake manifold support bracket

and remove the engine mount support bracket.

13. Remove the intake manifold mounting bolts

and remove the intake manifold assembly.

To Install: 14. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam- 21. Attach the electrical connectors to the oxygen

sensor, coolant temperature sensor, intake air tem-

perature, idle speed control assembly, EGR tempera-

ture sensor, spark plug wires and distributor.

22. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses.

23. Install the throttle body assembly.

24. Install the vacuum hoses and pipes as neces-

sary, including the brake booster vacuum line.

25. Install and adjust the accelerator cable. Install

the breather and air Intake hose.

26. Using a new gasket, install the thermostat

housing to the intake manifold and tighten the

mounting bolts to 13 ft. Ibs. (18 Nm).

27. Connect the upper radiator hose, heater hose

and water bypass hose. Be sure to use new hose

clamps.

Page 70 of 408

ENGINEANDENGINEOVERHAUL 3-9

28. Fill the system with coolant.

29. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

30. Check and adjust the idle speed and ignition

timing.

31. Once the vehicle has cooled, recheck the

coolant level.

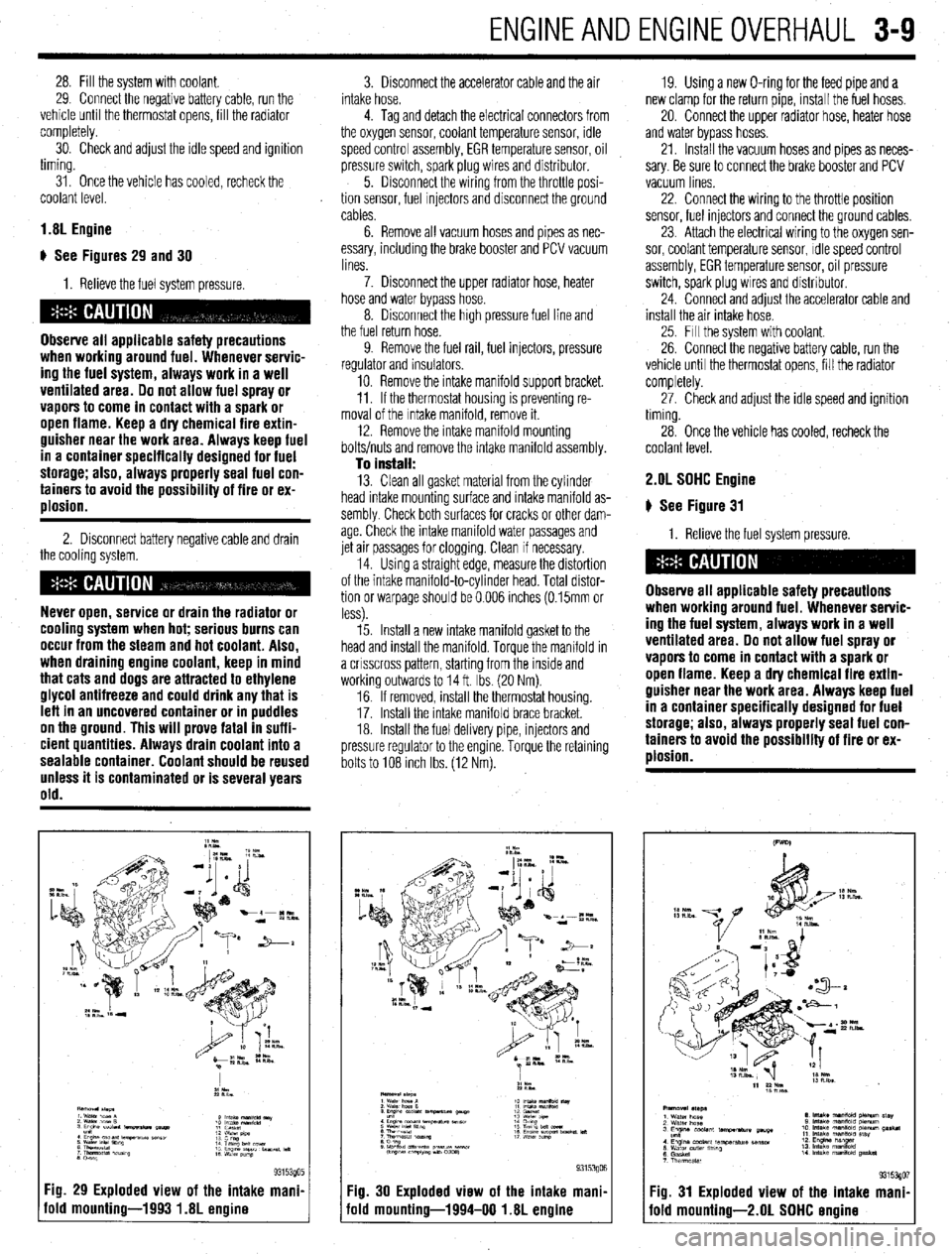

1.8L Engine

) See Figures 29 and 30

I. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

leff in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 29 Exploded view of the intake mani.

old mounting-1993 1.8L engine

3. Disconnect the accelerator cable and the air

intake hose.

4. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, idle

speed control assembly, EGR temperature sensor, oil

pressure switch, spark plug wires and distributor.

5. Disconnect the wiring from the throttle posi-

tion sensor, fuel Injectors and disconnect the ground

cables.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster and PCV vacuum

lines.

7. Disconnect the upper radiator hose, heater

hose and water bypass hose.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

10. Remove the intake manifold support bracket.

11. If the thermostat housing is preventing re-

moval of the Intake manifold, remove it.

12. Remove the intake manifold mounting

bolts/nuts and remove the intake manifold assembly.

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 14 ft. Ibs. (20 Nm).

16. If removed, install the thermostat housing.

17. Install the Intake manifold brace bracket.

18. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 108 Inch Ibs. (12 Nm). 19. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses,

20. Connect the upper radiator hose, heater hose

and water bypass hoses.

21. Install the vacuum hoses and pipes as neces-

sary. Be sure to connect the brake booster and PCV

vacuum lines

22. Connect the wiring to the throttle position

sensor, fuel injectors and connect the ground cables,

23. Attach the electrical wiring to the oxygen sen-

sor, coolant temperature sensor, Idle speed control

assembly, EGR temperature sensor, oil pressure

switch, spark plug wires and distributor.

24. Connect and adjust the accelerator cable and

install the air intake hose.

25. Fill the system with coolant.

26. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

27. Check and adjust the idle speed and ignition

timing.

28. Once the vehicle has cooled, recheck the

coolant level. 2.OL SOHC Engine

# See Figure 31

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

Fig. 30 Exploded view of the intake mani,

iold mounting-1994-00 1.8L engine Fig. 31 Exploded view of the intake mani

fold mounting-2.01 SOHC ermine

Page 71 of 408

3-10 ENGINEANDENGINEOVERHAUL

2. Disconnect the battery negative cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4 Disconnect the accelerator cable and air in-

take hose.

5. Disconnect the upper radiator hose, heater

hose and water bypass hose.

6. Unplug the vacuum connection at the power

brake booster and the PCV valve if still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

7. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

8. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, idle speed control assembly, EGR

temperature sensor, distributor, fuel injectors and

spark plug wires. Position the engine wiring harness

aside.

9. Matchmark the distributor housing to the in-

take manifold, and remove the distributor.

10. Remove the intake manifold bracket and the

engine hanger.

11. If the thermostat housing is preventing re-

moval of the intake manifold, remove it.

12. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Drsassem-

ble manifold from the Intake plenum on a work bench

as required

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14 Assemble the intake manifold assembly using

all new gaskets. Torque air intake plenum bolts to

11-14ff. Ibs. (15-19 Nm).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 11-14 ff. Ibs. (15-19 Nm).

16. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs (6 Nm).

17. install the thermostat housing, intake mani-

fold brace bracket, and engine hanger bracket.

18 Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

19. Align the distributor matchmarks and install

the distributor.

20. Fill the system with coolant,

21. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely. 22. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

23. Once the vehicle has cooled, recheck the

coolant level.

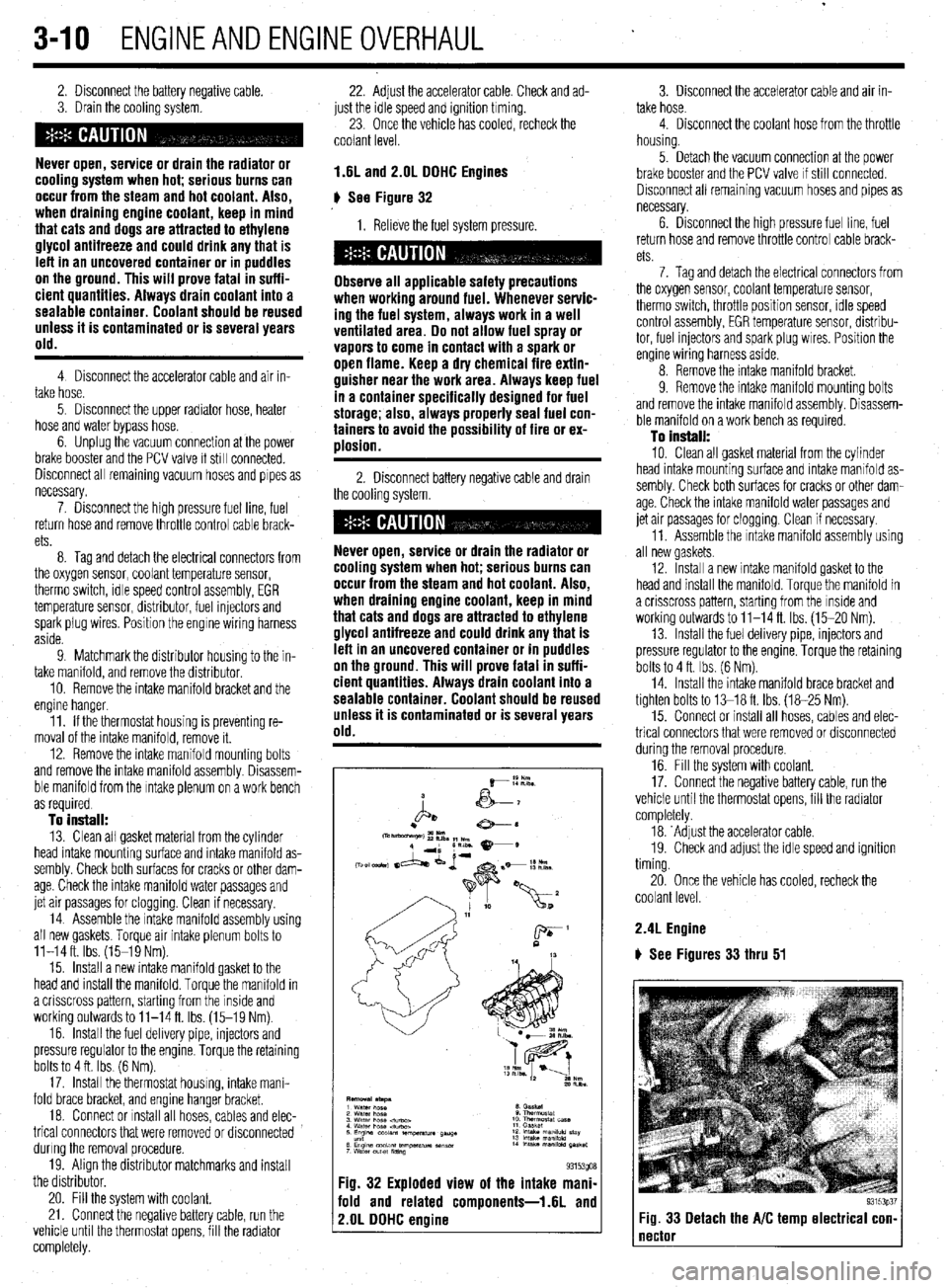

1.6L and 2.OL DDHC Engines

# See Figure 32

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

ulosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 32 Exploded view of the intake mani-

fold and related components-1.6L and

2.OL DDHC engine

3. Disconnect the accelerator cable and air in-

take hose.

4. Disconnect the coolant hose from the throttle

housing.

5. Detach the vacuum connection at the power

brake booster and the PCV valve If still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

6. Drsconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

7. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, throttle position sensor, rdle speed

control assembly, EGR temperature sensor, distribu-

tor, fuel injectors and spark plug wires. Position the

engine wiring harness aside.

8. Remove the intake manifold bracket.

9. Remove the intake mamfold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

To install:

10. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

11. Assemble the Intake manifold assembly using

all new gaskets.

12. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 11-14 ft. Ibs. (15-20 Nm).

13. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs. (6 Nm).

14. Install the intake manifold brace bracket and

tighten bolts to 13-18 ft. Ibs. (18-25 Nm).

15. Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

18. ‘Adjust the accelerator cable.

19. Check and adjust the idle speed and ignition

timing.

20. Once the vehicle has cooled, recheck the

coolant level.

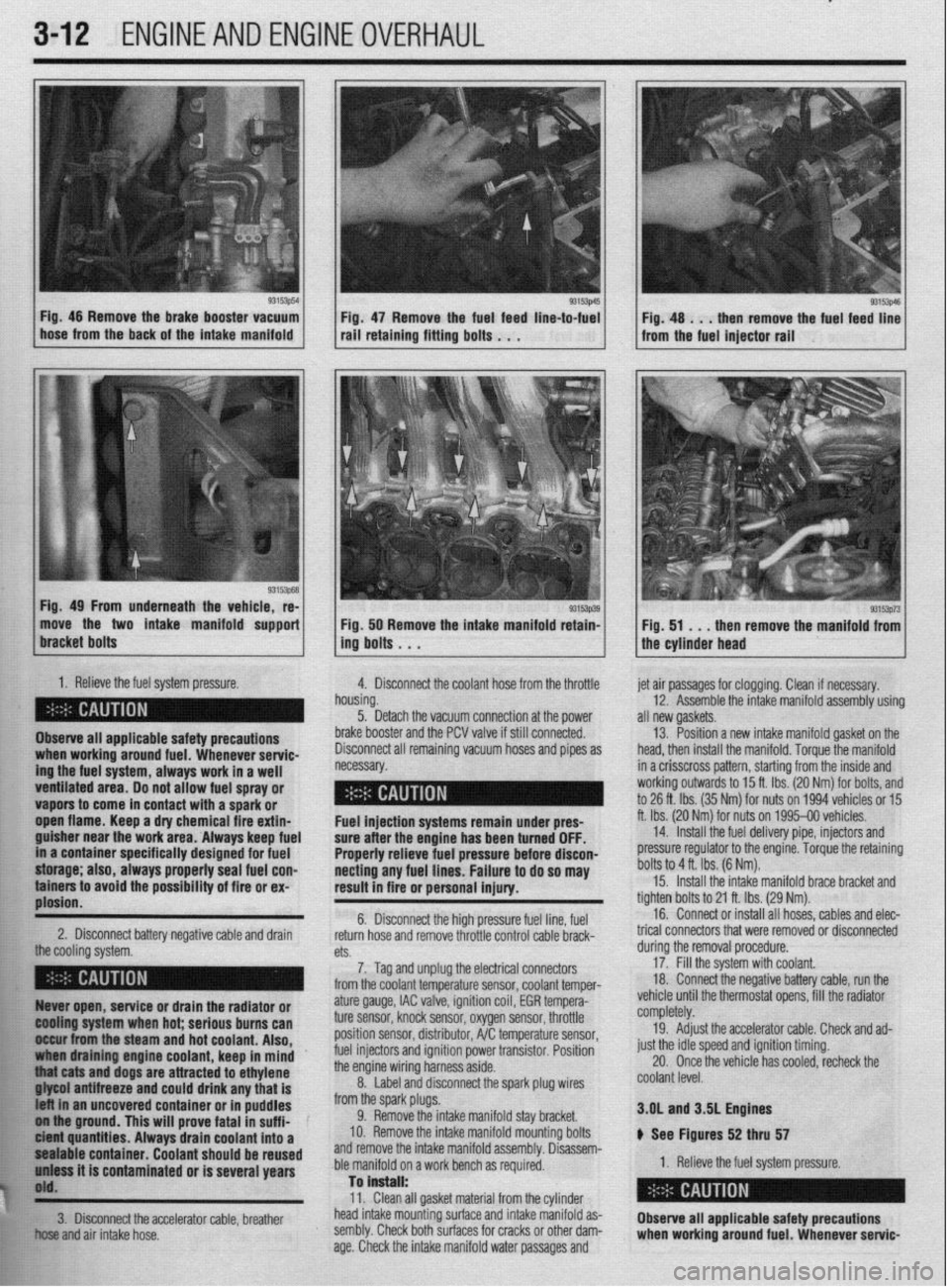

2.4L Engine

) See Figures 33 thru 51

93153p37 Fig. 33 Detach the A/C temp electrical con- 1

Page 73 of 408

.

3-12 ENGINEANDENGINEOVERHAUL

93153p54

1

L Fig. 46 Remove the brake booster vacuum

hose from the back of the intake manifold Fig 47 Remove the fuel feed line-to-fuel rail’retaini”g fitti”g bo,ts . . .

Fig. 49 From underneath the vehicle, re-

move the two intake manifold support

1. Relieve the fuel system pressure.

4. Disconnect the coolant hose from the throttle

Observe all applicable safety precautions

ing the fuel system, always work in a well when working around fuel. Whenever servic-

ventilated area. Do not allow fuel spray or - __.

vapors to come in contact with a spark or

._

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling rtfctnm 93153p39 Fig. 50 Remove the intake manifold retain-

ing bolts . . .

h

n ousing.

5. Detach the vacuum connection at the power

b

rake booster and the PCV valve if still connected.

C lisconnect all remaining vacuum hoses and pipes as

ecessary. et air passages for clogging. Clean if necessary.

12. Assemble the intake manifold assembly using

III new gaskets.

13. Position a new intake manifold gasket on the

lead, then install the manifold. Torque the manifold

n a crisscross pattern, starting from the inside and

vorking outwards to 15 ft. Ibs. (20 Nm) for bolts, and

o 26 ft. Ibs. (35 Nm) for nuts on 1994 vehicles or 15

t. Ibs. (20 Nr$ for nuts on 1995-00 vehicles.

14. Install the fuel delivery pipe, injectors and

xessure regulator to the engine. Torque the retaining

)olts to 4 ft. Ibs. (6 Nm). Fuel injection systems remain under pres- f

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

necting any fuel lines. Failure to do so may [

result in fire or personal injury.

t 6. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack- t

n+C.

cm. durino the removal orocedure. 15. Install the intake manifold brace bracket and

ighten bolts to 21 ft. Ibs. (29 Nm).

16. Connect or install all hoses, cables and elec-

rical connectors that were removed or disconnected

7. Tag and unplug the electrical connectors

from the coolant temperature sensor, coolant temper- 17: Fill the system with coolant.

18 Connect the negative battery cable, run the

, . : .., ,, ., , ,

,,,, ,. ,.

93153p73 Fig. 51 . . .

then remove the manifold from

the cylinder head

Ruver open, service or drain the radiator or

@Ming system when hot; serious burns can

II&ur from the steam and hot coolant. Also,

draining engine coolant, keep in mind ’

j “thiat cats and dogs are attracted to ethylene

. . . ..____ “..” 11_,1 -...... any that is

t uncovered container or in puddles

FE ol iha ground. This will prove fatal in suff i-

k ici?M quantities. Always drain coolant into a

$1 pealable container. Coolant should be reused

h’ uniass it is contaminated or is several years

j$O'd.

**w

ature gauge, IAC valve, ignition coil, EGR tempera-

ture sensor, knock sensor, oxygen sensor, throttle

position sensor, distributor, A/C temperature sensor,

fuel injectors and ignition power transistor. Position

the engine wiring harness aside.

8. Label and disconnect the spark plug wires

from the spark plugs.

9. Remove the intake manifold stay bracket.

IO. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

Tan is”.+..ll. vemcle unrn me mermosrar opens, ml tne raalaror

completely.

19. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

20. Once the vehicle has cooled, recheck the

coolant level.

3.OL and 3SL Engines

ti See Figures 52 thru 57

1. Relieve the fuel system pressure.

W.>. Clean all gasket material from the cylinder

!&S head intake mounting surface and intake manifold as-

fir!: 3. Disconnect the accelerator cable, breather

Observe all applicable safety precautions

El .;,

+w..” and air intake hose. sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and when working around fuel. Whenever servic-

Page 74 of 408

ENGINEANDENGINEOVERHAUL 3-13

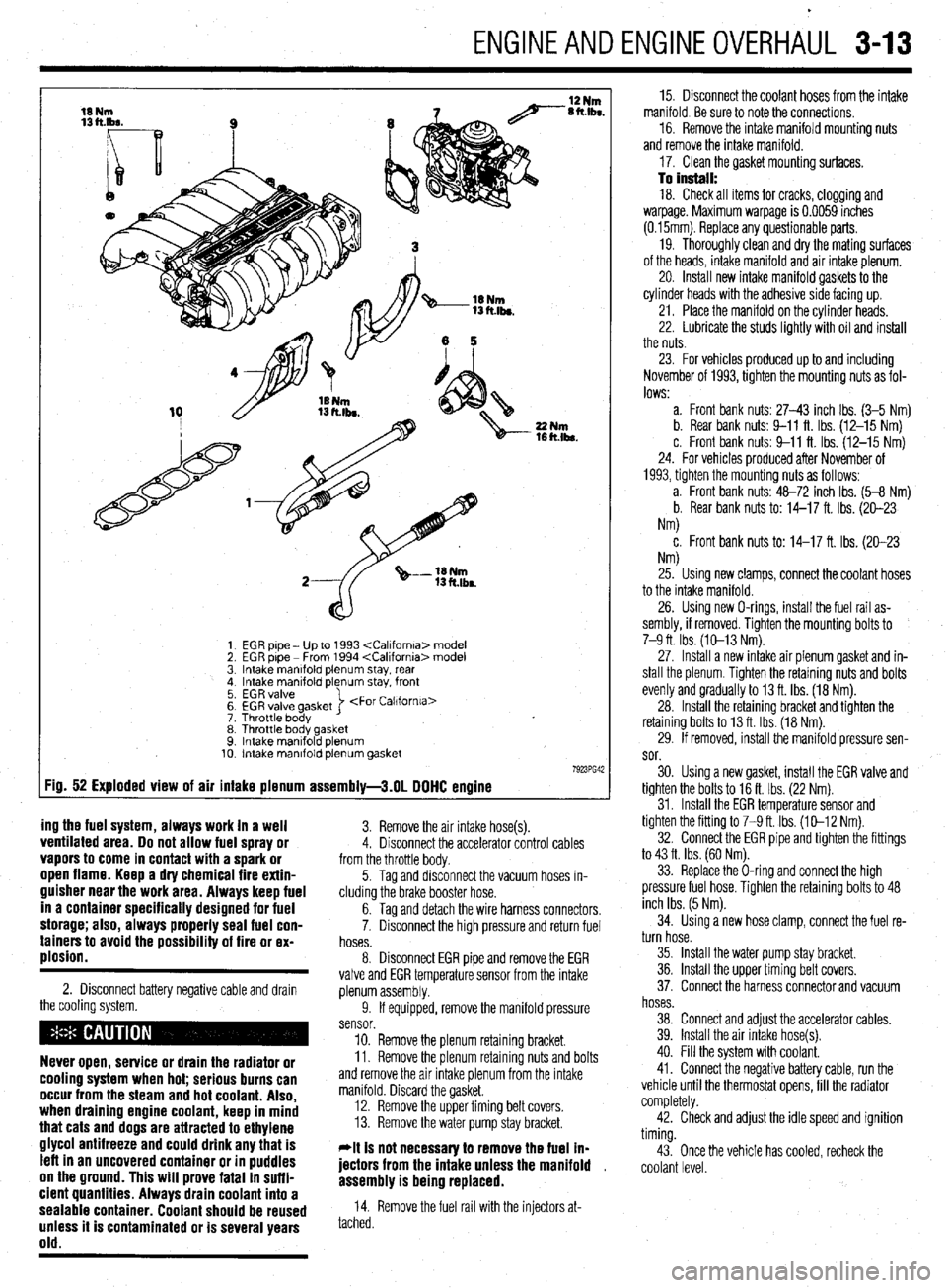

EGR pipe - Up to 1993

EGR pipe - From 1994

Intake manlfold plenum stay, rear

Intake manifold plenum stay. front

EGR valve

EGR valve gasket

Throttle body >

Throttle body gasket

Intake mantfold plenum

Intake manifold plenum gasket

:ig. 52 Exploded view of air intake plenum assembly-3.01 DOHC engine

ing the fuel system, always work in a well

3. Remove the air intake hose(s). ventilated area. Do not allow fuel spray or 4. Disconnect the accelerator control cables vapors to come in contact with a spark or from the throttle body. open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drawn

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

5. Tag and disconnect the vacuum hoses in-

cluding the brake booster hose.

6. Tag and detach the wire harness connectors,

7. Disconnect the high pressure and return fuel

hoses.

8. Disconnect EGR pipe and remove the EGR

valve and EGR temperature sensor from the intake

plenum assembly.

9. If equipped, remove the manifold pressure

sensor.

10. Remove the plenum retaining bracket.

11. Remove the plenum retaining nuts and bolts

and remove the air intake plenum from the intake

manifold. Discard the gasket.

12. Remove the upper timing belt covers.

13. Remove the water pump stay bracket.

*It is not necessav to remove the fuel ln-

jectors from the intake unless the manifold ,

assembly is being replaced.

14. Remove the fuel rail with the injectors at-

tached. 15. Disconnect the coolant hoses from the intake

manifold. Be sure to note the connections.

16. Remove the intake manifold mounting nuts

and remove the intake manifold.

17. Clean the gasket mounting surfaces.

To install: 18. Check all items for cracks, clogging and

warpage. Maximum warpage is 0.0059 inches

(0.15mm). Replace any questionable parts.

19. Thoroughly clean and dry the mating surfaces

of the heads, intake manifold and air intake plenum.

20. Install new intake manifold gaskets to the

cylinder heads with the adhesive side facing up.

21. Place the manifold on the cylinder heads.

22. Lubricate the studs lightly with oil and install

the nuts.

23. For vehicles produced up to and including

November of 1993, tighten the mounting nuts as fol-

lows:

a. Front bank nuts: 27-43 inch Ibs. (3-5 Nm)

b. Rear bank nuts: 9-11 ft. Ibs. (12-15 Nm)

c. Front bank nuts: 9-11 ft. Ibs. (12-15 Nm)

24. For vehicles produced after November of

1993, tighten the mounting nuts as follows:

a. Front bank nuts: 48-72 inch Ibs. (5-8 Nm)

b. Rear bank nuts to: 14-17 ft. Ibs. (20-23

Nm)

c. Front bank nuts to: 14-17 ft. Ibs. (20-23

NM

25. Using new clamps, connect the coolant hoses

to the intake manifold.

26. Using new O-rings, install the fuel rail as-

sembly, if removed. Tighten the mounting bolts to

7-9 ft. Ibs. (10-13 Nm).

27. Install a new intake air plenum gasket and in-

stall the plenum. Tighten the retaining nuts and bolts

evenly and gradually to 13 ft. Ibs. (18 Nm).

28. Install the retaining bracket and tighten the

retaining bolts to 13 ft. Ibs. (18 Nm).

29. If removed, install the manifold pressure sen-

sor.

30. Using a new gasket, install the EGR valve and

tighten the bolts to 16 ft. Ibs. (22 Nm).

31. Install the EGR temperature sensor and

tighten the fitting to 7-9 ft. Ibs. (10-12 Nm).

32. Connect the EGR pipe and tighten the fittings

to 43 ft. Ibs. (60 Nm).

33. Replace the O-ring and connect the high

pressure fuel hose. Tighten the retaining bolts to 48

inch Ibs. (5 Nm).

34. Using a new hose clamp, connect the fuel re-

turn hose.

35. Install the water pump stay bracket.

36. Install the upper timing belt covers.

37. Connect the harness connector and vacuum

hoses.

38. Connect and adjust the accelerator cables.

39. Install the air intake hose(s).

40. Fill the system with coolant.

41. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

42. Check and adjust the idle speed and ignition

timing.

43. Once the vehicle has cooled, recheck the

coolant level.

Page 81 of 408

.

3-20 ENGINEANDENGINEOVERHAUL

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the overflow hose and disconnect

the upper radiator hose.

*It is recommended that each clamp be

matchmarked to the hose. Observe the marks

and reinstall the clamps exactly when rein-

stalling the radiator.

4. If equipped with an automatic transaxle, re-

move and plug the fluid cooler hoses.

5. Unplug the electrical connector(s) from the

coolant fan motor.

6. Remove the mounting bolts, then remove the

fan and shroud assembly from the vehicle.

7. Remove the fan blade retainer nut from the

shaft on the fan motor and separate the fan from the

motor.

8. Remove the motor to shroud attaching

screws and the motor from the shroud.

To tnstall: 9. Install the motor to the shroud and secure

with the mounting bolts.

10. Install the remaining components in the re-

verse order of removal.

11. Fill the coohng system. Connect the negative

battery cable and check the cooling fan for proper op-

eration.

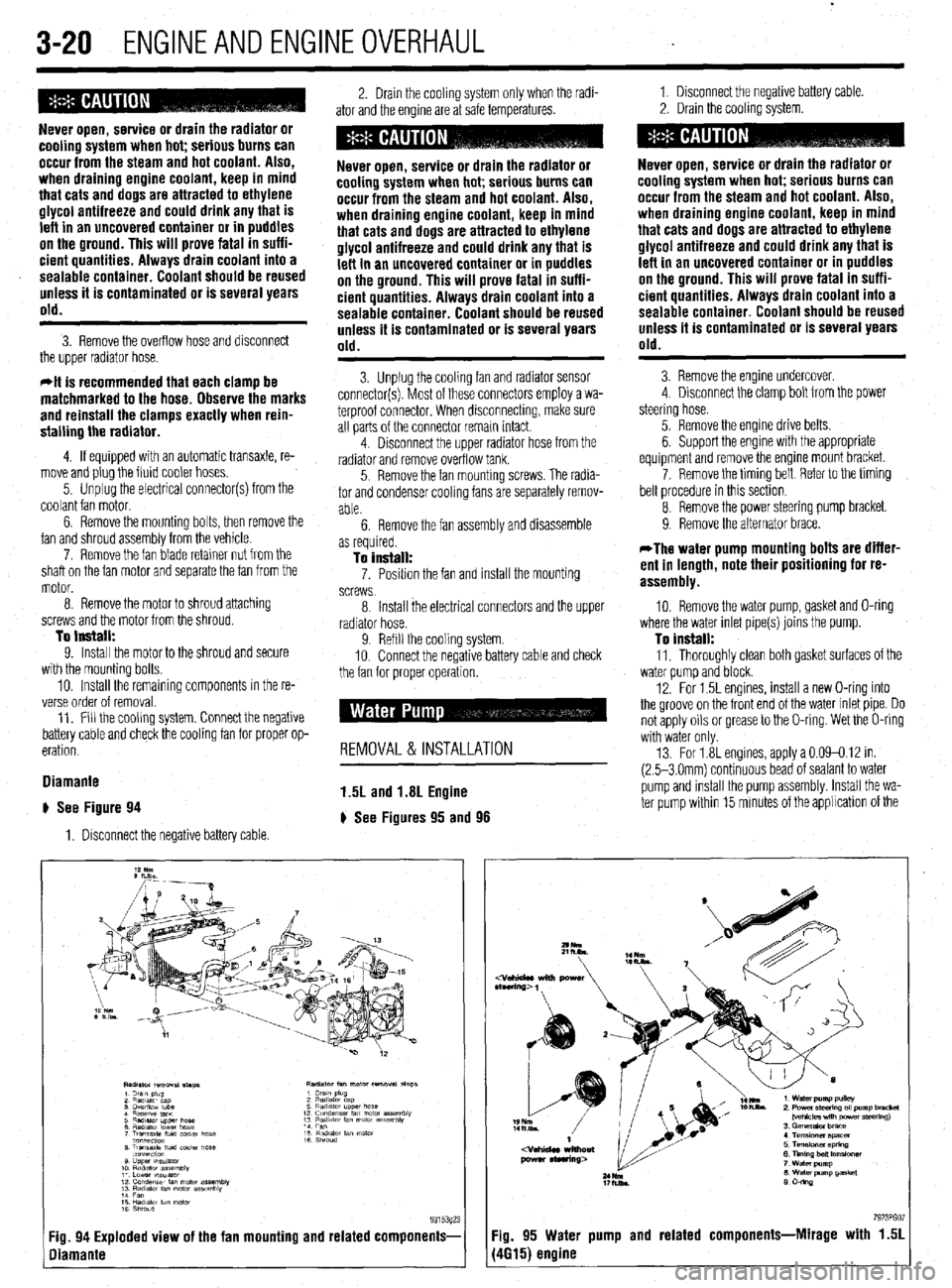

Diamante

# See Figure 94

1. Disconnect the negative battery cable 2. Drain the cooling system only when the radi-

ator and the engine are at safe temperatures. 1. Disconnect the negative battery cable

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Unplug the cooling fan and radiator sensor

connector(s). Most of these connectors employ a wa-

terproof connector. When disconnecting, make sure

all parts of the connector remain intact.

4. Disconnect the upper radiator hose from the

radiator and remove overflow tank.

5. Remove the fan mounting screws. The radia-

tor and condenser cooling fans are separately remov-

able.

6. Remove the fan assembly and disassemble

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4 Disconnect the clamp bolt from the power

steering hose.

5. Remove the engine drive belts.

6. Support the engine with the appropriate

equipment and remove the engine mount bracket.

7. Remove the timing belt Reier to the timing

belt procedure in this section

8 Remove the power steering pump bracket.

9. Remove the alternator brace.

as required.

To install: 7. Posrtion the fan and install the mounting

screws

*The water pump mounting bolts are differ-

ent in length, note their positioning for re-

assembly.

8 Install the electrical connectors and the upper

radiator hose.

9. Refill the cooling system.

IO. Connect the negative battery cable and check

the fan for orooer ooeration. 10. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install: 11, Thoroughly clean both gasket surfaces of the

water oumo and block.

12. For 1.5L engines, install a new O-ring into

the groove on the front end of the water inlet pipe. Do

not apply oils or grease to the O-ring. Wet the O-ring

with water only

13. For 1.8L engines, apply a 0.09-0.12 in.

(2.5-3 Omm) continuous bead of sealant to water

pump and rnstall the pump assembly. Install the wa-

ter pump within 15 minutes of the applrcation of the

REMOVAL & INSTALLATION

1.5L and 1.8L Engine

) See Figures 95 and 98

7923PGO :ig. 94 Exploded view of the fan mounting and related components- Fig. 95 Water pump and related components-Mirage with 1.51

liamante (4615) engine