dead battery MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 5 of 408

1-6 GENERALINFORMATIONAND MAINTENANCE

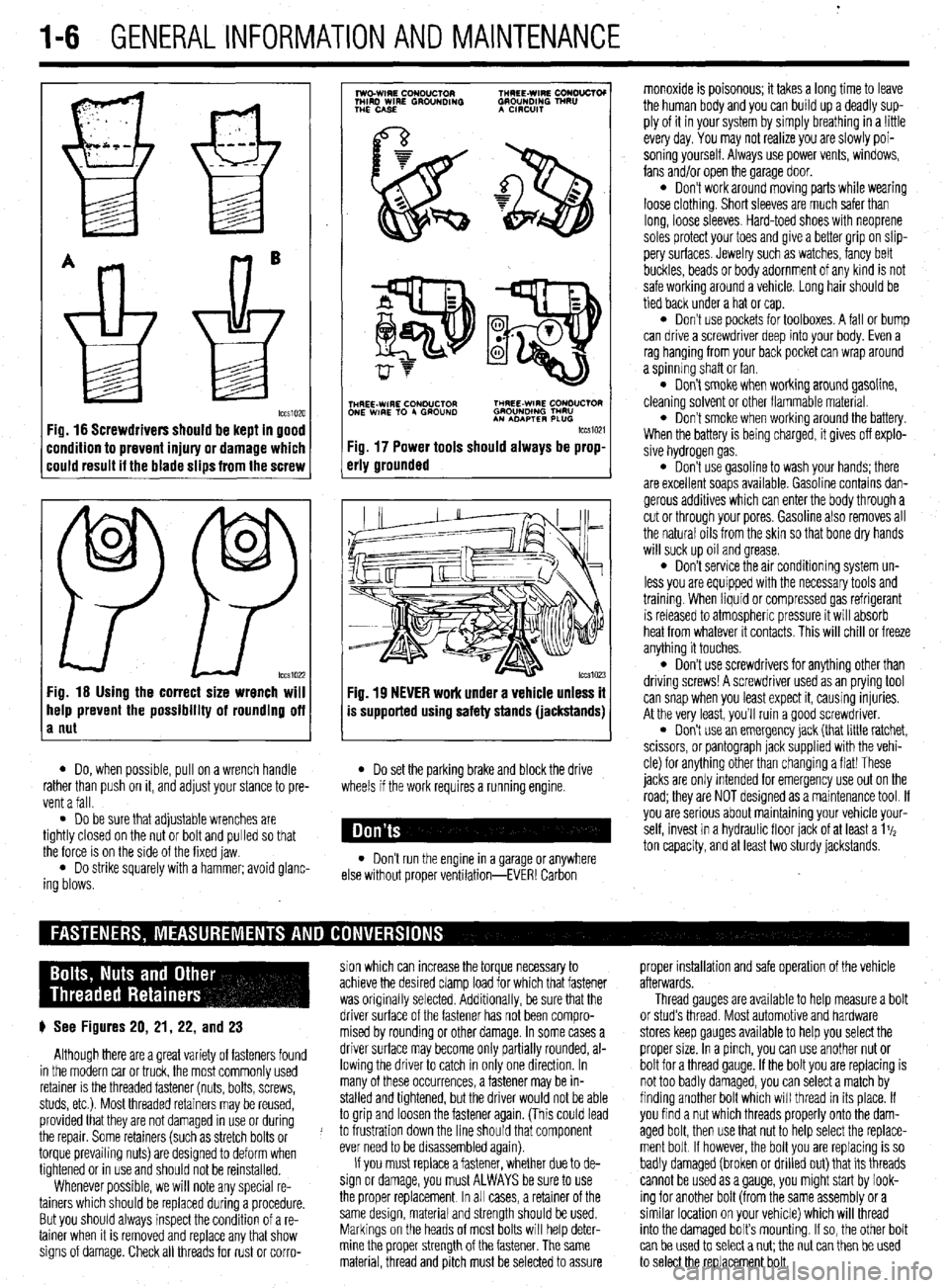

Fig. 16 Screwdrivers should be kept in good

:ondition to prevent injury or damage which

:ould result it the blade slips from the screw

0

0

PP tccs1022 Fig. 16 Using the correct size wrench will

help prevent the possibility of rounding off

a nut

7

lwo.WIRE CouDuClOR TMREE-WIRE CONO”CTOI

MIRD WIRE GROUNDING GROUNDING TNRU

THE CASE A CmxlIT

.

i$Y$$pQ

p-+

TNHREE-WIRE CONDUCTOR THREE-WIRE CONDUCTOR

ONE WIRE TO 4 GROUND GROUNOlNG TMRU

AN ADAPTER PLUG

tccm21

Fig. 17 Power tools should always be prop-

erly grounded

Fig. 19 NEVER work under a vehicle unless it

is supported using safety stands (jackstands)

l Do, when possible, pull on a wrench handle l Do set the parking brake and block the drive

rather than push on it, and adjust your stance to pre-

vent a fall. wheels if the work requires a running engine.

l Do be sure that adjustable wrenches are

tightly closed on the nut or bolt and pulled so that

the force is on the side of the fixed jaw.

l Do strike squarely with a hammer; avoid glanc-

ing blows. l Don’t run the engine in a garage or anywhere

else without proper ventilation-EVER! Carbon monoxide is poisonous; it takes a long time to leave

the human body and you can build up a deadly sup-

ply of it in your system by simply breathing in a !ittle

every day. You may not realize you are slowly poi-

soning yourself. Always use power vents, windows,

fans and/or open the garage door.

l Don’t work around moving parts while wearing

loose clothing. Short sleeves are much safer than

long, loose sleeves. Hard-toed shoes with neoprene

soles protect your toes and give a better grip on slip-

pery surfaces. Jewelry such as watches, fancy belt

buckles, beads or body adornment of any kind is not

safe working around a vehicle. Long hair should be

tied back under a hat or cap.

l Don’t use pockets for toolboxes. A fall or bump

can drive a screwdriver deep into your body. Even a

rag hanging from your back pocket can wrap around

a spinning shaft or fan.

l Don’t smoke when working around gasoline,

cleaning solvent or other flammable material.

l Don’t smoke when workrng around the battery.

When the battery is being charged, it gives off explo-

sive hydrogen gas.

l Don’t use gasoline to wash your hands; there

are excellent soaps available. Gasoline contains dan-

gerous additives which can enter the body through a

cut or through your pores. Gasoline also removes all

the natural oils from the skin so that bone dry hands

will suck up oil and grease.

l Don’t service the air conditioning system un-

less you are equipped with the necessary tools and

trainmg. When liquid or compressed gas refrigerant

is released to atmospheric pressure it will absorb

heat from whatever it contacts. This will chill or freeze

anything it touches.

l Don’t use screwdrivers for anything other than

driving screws! A screwdriver used as an prying tool

can snap when you least expect it, causing injuries.

At the very least, you’ll ruin a good screwdriver.

. Don’t use an emergency jack (that little ratchet,

scissors, or pantograph jack supplied with the vehi-

cle) for anything other than changing a flat! These

jacks are only Intended for emergency use out on the

road; they are NOT designed as a maintenance tool. If

you are serious about mamtaining your vehicle your-

self, invest in a hydraulic floor jack of at least a 1%

ton capacity, and at least two sturdy jackstands.

sion which can increase the torque necessary to proper installation and safe operation of the vehicle

achieve the desired clamp load for which that fastener afterwards.

was originally selected. Additionally, be sure that the Thread gauges are available to help measure a bolt

p See Figures 20, 21, 22, and 23 driver surface of the fastener has not been compro- or stud’s thread. Most automotive and hardware

mised by rounding or other damage. In some cases a stores keep gauges available to help you select the

Although there are a great variety of fasteners found driver surface may become only partially rounded, al- proper size. In a pinch, you can use another nut or

in the modern car or truck, the most commonly used lowing the driver to catch in only one direction. In bolt for a thread gauge. If the bolt you are replacing is

retainer is the threaded fastener (nuts, bolts, screws, many of these occurrences, a fastener may be in- not too badly damaged, you can select a match by

studs, etc.). Most threaded retainers may be reused, stalled and tightened, but the driver would not be able finding another bolt which will thread in its place. If

provided that they are not damaged in use or during to grip and loosen the fastener again. (This could lead you find a nut which threads properly onto the dam-

the repair. Some retainers (such as stretch bolts or J to frustration down the line should that component aged bolt, then use that nut to help select the replace-

torque prevailing nuts) are designed to deform when ever need to be disassembled again). ment bolt If however, the bolt you are replacing is so

tightened or in use and should not be reinstalled. If you must replace a fastener, whether due to de- badly damaged (broken or drilled out) that its threads

Whenever possible, we will note any special re- sign or damage, you must ALWAYS be sure to use cannot be used as a gauge, you might start by look-

tainers which should be replaced during a procedure. the proper replacement In all cases, a retainer of the ing for another bolt (from the same assembly or a

But you should always inspect the condition of a re- same design, material and strength should be used. similar location on your vehicle) which will thread

tainer when It is removed and replace any that show Markings on the heads of most bolts will help deter- into the damaged bolt’s mounting. If so, the other bolt

signs of damage. Check all threads for rust or corro- mine the proper strength of the fastener. The same

can be used to select a nut; the nut can then be used

material, thread and pitch must be selected to assure

to select the replacement bolt.

Page 17 of 408

l

1-18 GENERALINFORMATIONAND MAINTENANCE

the clamps and remove the cables, negative cable

first. On batteries with posts on top, the use of a

puller specially made for this purpose is recom-

mended. These are inexoensive and available in most alternator or turn the adjusting bolt to adjust belt ten-

sion. Once the desired value is reached, secure the

bolt or locknut and recheck tension.

d”t” lJdlL> X”lt;>. 31°C LtXlllllldl lJdllt2)’ MLJIC, dlt’ X- cured with a small bolt. ST& I REMOVAL &INSTALLATION

Clean the cable clamps and the battery terminal I

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shinv. It is esneciallv imnnr-

tant to c

knife is useful nere), since a smart

material or oxidation there will pre Clean the cable clamps and the battery terminal

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shiny. It is especially impor-

tant to clean the inside of the clamp thoroughly (an old

knife is useful here), since a small deposit of foreign

material or oxidation there will prevent a sound electri-

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batteries. It is also a good

idea to apply some dielectric grease to the terminal, as

this will aid in the prevention of corrosion,

After the clamps and terminals are clean, reinstall

the cables, negative cable last; DO NOT hammer the

clamps onto battery posts. Tighten the clamps se-

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and gauge.

CHARGING

the cables, negative cable last; DO NOT hammer the

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and aauae.

CHARGING

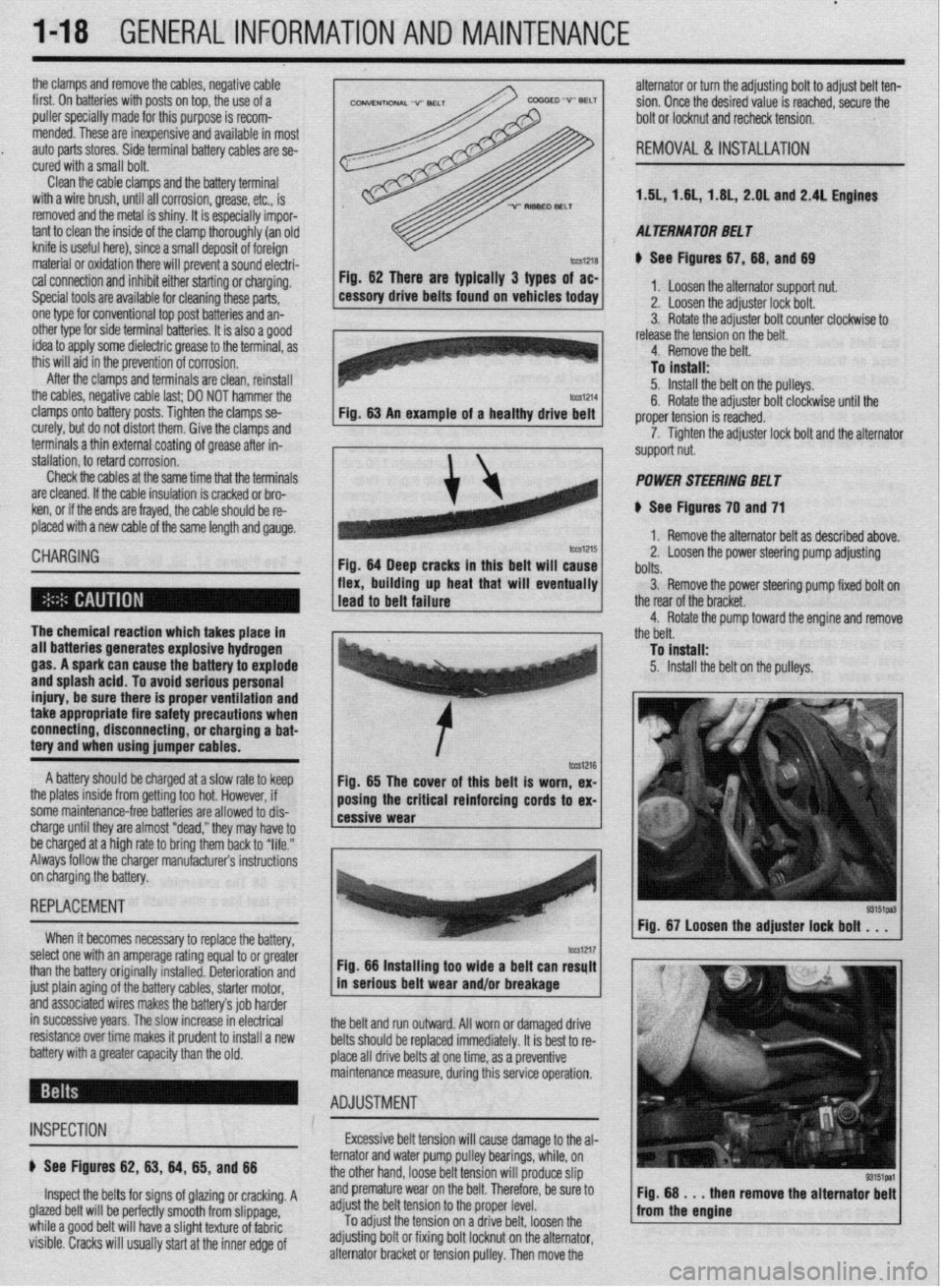

Fig. 62 mere are typically 3 types of ac-

cessory drive belts found on vehicles today 1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

I .I , . . . * . .

I Tn i”et*ll* Fig. 62 There are typically 3 types of ac-

Fig. 64 Deep cracks in this belt will cause

flex, building up heat that will eventually 11, 1.8L, 2.OL and 2.4L Engines

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batterin, I+ if QI@* 3 nnnd

idea to apply some dielectric grr

this will aid in the prevention of ,,vIIuaIUII.

After the clamps and terminals are clean, reinstall 1.5L, 1.6

AL TERNA TOR BE1 T

e See Figures 67,68, and 69

1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

release the tension on the belt.

4. Remove the belt.

To install:

5. Install the belt on the pulleys.

6. Rotate the adjuster bolt clockwise until the

proper tension is reached.

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

8 See Figures 70 and 71

1. Remove the alternator belt as described above.

2. Loosen the power steering pump adjusting

bolts.

3. Remove the power steering oumo fixed bolt on

R Rntatn the cxiillrtm hnit A&+,& until the r -r- .- .- ._.. ._ .______

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

1 ..“‘.I ““..Y...Y up II”“. ..IU. ..m.*

1 lead to belt failure V.

I

I

The chemical reaction which takes place in - 1 the rear of the bracket.

4. Rotate the pump toward the engine and remove

the belt.

all batteries generates explosive hydrogen

gas. A spark can cause the battery to explode

and splash acid. To avoid serious personal

injury, be sure there is proper ventilation and

take appropriate fire safety precautions when

connecting, disconnecting, or charging a bat-

tery and when using jumper cables. To fnstall:

5. Install the belt on the pulleys.

A battery should be charged at a slow rate to keep

the plates inside from getting too hot. However, if

some maintenance-free batteries are allowed to dis-

charge until they are almost “dead,” they may have to

be charged at a high rate to bring them back to “life.”

Always follow the charger manufacturers instructions

on charging the battery. 85 The cover of this belt ex-

Fig. is worn,

REPLACEMENT

When it becomes necessary to reolace thn haeoN

‘” yyL’“‘J’ I or oreMer

select one with an amperage rating equal tc .

a ----

than the battery originally installed. Deterioration and

just plain aging of the battery cables, starter motor,

and associated wires makes the battery’s job harder

in successive years. The slow increase in electrical

resistance over time makes it prudent to install a new

battery with a greater capacity than the old. 1 Fig. 67 Loosen the adjuster lock bolt . . .

I ‘-

I -. -_ tm1217 Fig. 66 Installing too wide a belt can resylt

in serious belt wear and/or breakage

the belt and run outward. All worn or damaged drive

belts should be replaced immediately. It is best to re-

place all drive belts at one time, as a preventive

uring this service operation. maintenance measure, d

- ADJUSTMENT : *

INSPECTION Excessive belt tension will cause damage to the al-

e See Figures 62, 83, 64, 65, and 88

Inspect the belts for signs of glazing or cracking. A

glazed belt will be perfectly smooth from slippage,

while a good belt will have a slight texture of fabric

visible. Cracks will usually start at the inner edge of pulley bearings, while, on

It tension will

Droduce slin ternator and water pump

the other hand, loose be

r ------ r

and premature wear on the belt. Therefore, be sure to

adjust the belt tension to the proper level.

To

adjust the tension ’ ’ ’ ” ’ ‘* adjusting bolt or fixing b

alternator bracket or tens on a onve Den. loosen me I Fig. 68 . . . then

from the engine remove the alternator

bolt locknut on the alternator,

iion pulley. Then move the

Page 24 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-25

osen the distributor cap retain-

Fig. 106. . . then remove the cap from the

distributor

Fig. 107 Grasp the rotor and pull it straight

off of the distributor shaft

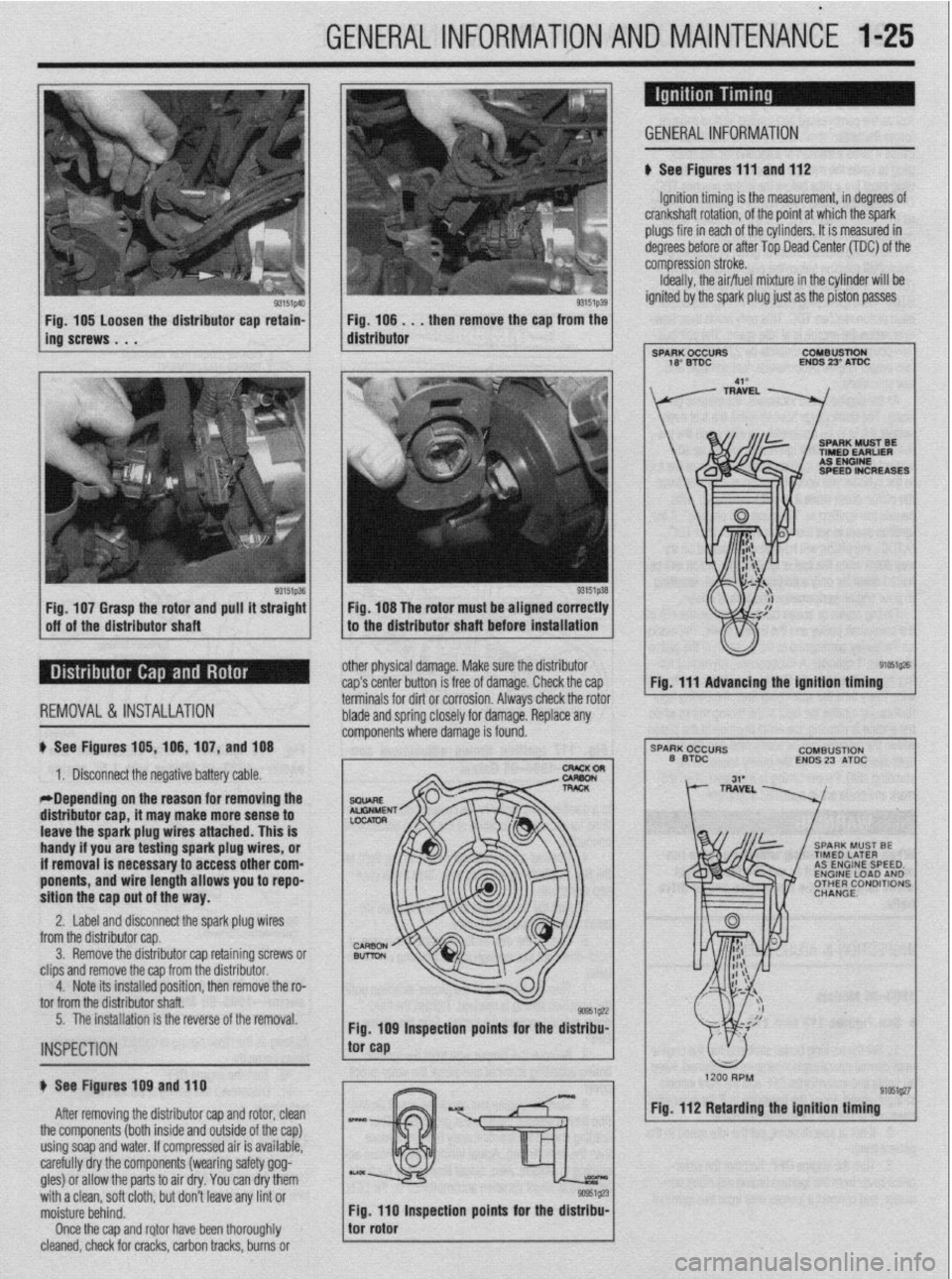

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

*Depending on the reason for removing the

distributor cap, it may make more sense to Fig. 108 The rotor must be aligned correctly

to the distributor shaft before installation

other physical damage. Make sure the distributor

cap’s center button is free of damage. Check the cap

terminals for dirt or corrosion. Always check the rotor

blade and spring closely for damage. Replace any

comoonents where damaae is found.

smmE

ALGNME

LOCATOR

b See Figures 105,106,107, and 108 GENERAL INFORMATION

b See Figures 111 and 112

Ignition timing is the measurement, in degrees of

crankshaft rotation, of the point at which the spark

plugs fire in each of the cylinders. It is measured in

degrees before or after Top Dead Center (TDC) of the

compression stroke.

Ideally, the air/fuel mixture in the cylinder will be

ignited by the spark plug just as the piston passes

I 1 COMBUSTION

ENDS 23’ ATDC

SPEED INCREASES

9ir&1$?6

Fig. 111 Advancing the ignition timing

’

CCURS

COMBUSTION

DC

ENDS 23 ATDC

3. Remove the distributor cap retaining screws or

clips and remove the cap from the distributor.

4. Note its installed position, then remove the ro-

tor from the distributor shaft. leave the spark plug wires attached. This is

handy if you are testing spark plug wires, or

if removal is necessary to access other com-

ponents, and wire length allows you to repo-

sition the cap out of the way.

2. Label and disconnect the spark plug wires

from the distributor cao.

5. The installation is the reverse of the removal.

INSPECTION

u See Figures 109 and 110

9mg27

After removing the distributor cap and rotor, clean

the components (both inside and outside of the cap)

using soap and water. If compressed air is available,

carefully dry the components (wearing safety gog-

gles) or allow the parts to air dry. You can dry them

with a clean, soft cloth, but don’t leave any lint or

moisture behind.

Once the cap and rotor have been thoroughly Inspection points for the dis Fig. 112 Retarding the tgnttion timing

cleaned, check for cracks, carbon tracks, burns or

Page 26 of 408

GENERALINFORMATIONAND MAlNTENANdE I-27

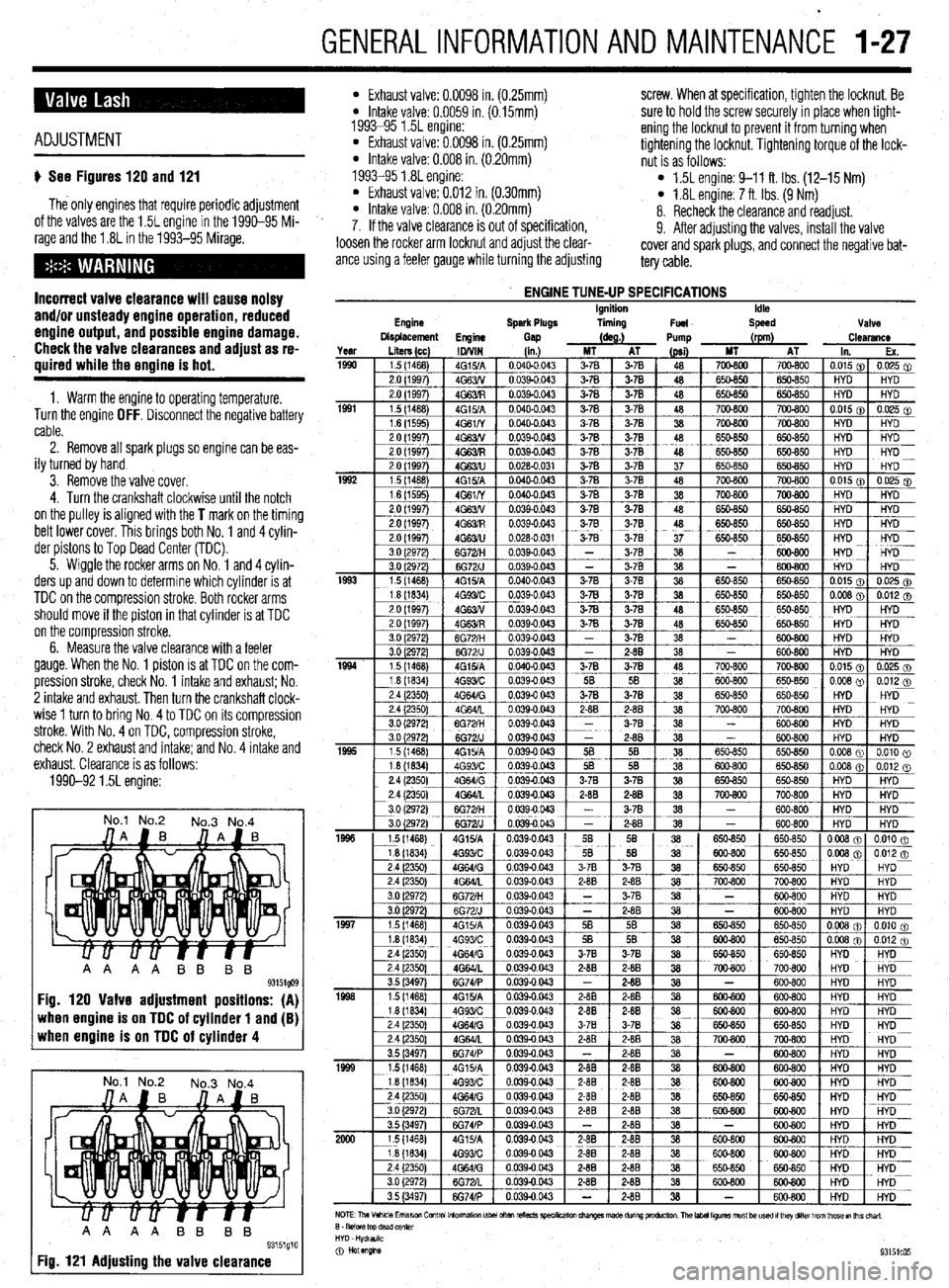

ADJUSTMENT

u See Figures 120 and 121

The only engines that require periodic adjustment

of the valves are the 1.5L engine in the 1990-95 Mi-

rage and the 1.8L in the 1993-95 Mirage.

Incorrect valve clearance will cause noisy

and/or unsteady engine operation, reduced

engine output, and possible engine damage.

Check the valve clearances and adjust as re-

quired while the engine is hot.

1. Warm the engine to operating temperature.

Turn the engine OFF. Disconnect the negative battery

cable.

2. Remove all spark plugs so engine can be eas-

ily turned by hand

3. Remove the valve cover.

4. Turn the crankshaft clockwise until the notch

on the pulley is aligned with the

T mark on the timing

belt lower cover. This brings both No. 1 and 4 cylin-

der pistons to Top Dead Center (TDC).

5. Wiggle the rocker arms on No. 1 and 4 cylin-

ders up and down to determine which cylinder is at

TDC on the compression stroke. Both rocker arms

should move if the piston in that cylinder is at TDC

on the compression stroke.

6. Measure the valve clearance with a feeler

gauge. When the No. 1 piston is at TDC on the com-

pression stroke, check No. 1 intake and

exhaust; No.

2 intake and exhaust. Then turn the crankshaft clock-

wise 1 turn to bring No. 4 to TDC on its compression

stroke. With No. 4 on TDC, compression stroke,

check No. 2 exhaust and intake; and No. 4 intake and

exhaust. Clearance is as follows:

1990-92 1.5L engine:

No.1 No.2

No.3 No.4

when engine is on TDC of cylinder 1 and (B) when engine is on TDC of cylinder 4

No.1 No.2

No.3 No.4

AA AA BB BB

93151g10 Fig. 121 Adjusting the valve clearance

l Exhaust valve: 0.0098 in. (0.25mm) screw. When at specification, tighten the locknut. Be l Intake valve: 0.0059 in. (0.15mm)

1993-95 1.5L engine: sure to hold the screw securely in place when tight-

l Exhaust valve: 0.0098 in. (0.25mm) ening the locknut to prevent it from turning when

* Intake valve: 0.008 in. (0.20mm) tightening the locknut. Tightening torque of the lock-

nut is as follows:

1993-95 1.8L engine:

l Exhaust valve: 0.012 in. (0.30mm) l 1.5L engine: 9-11 ft. Ibs. (12-15 Nm)

l Intake valve: 0.008 in. (0.20mm) l 1.8L engine: 7 ft. Ibs. (9 Nm)

8. Recheck the clearance and readjust.

7. If the valve clearance is out of specification,

9. After adjusting the valves, install the valve

loosen the rocker arm locknut and adjust the clear-

ante using a feeler gauge while turning the adjusting cover and spark plugs, and connect the negative bat-

tery cable.

Engine

ENGINE TUNE-UP SPECIFICATIONS Ignition

Spark Plugs liming

Fuel Idle

Speed Valve

Displacement

Engine

Gap (as.) Pump (rpm)

Clearance

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

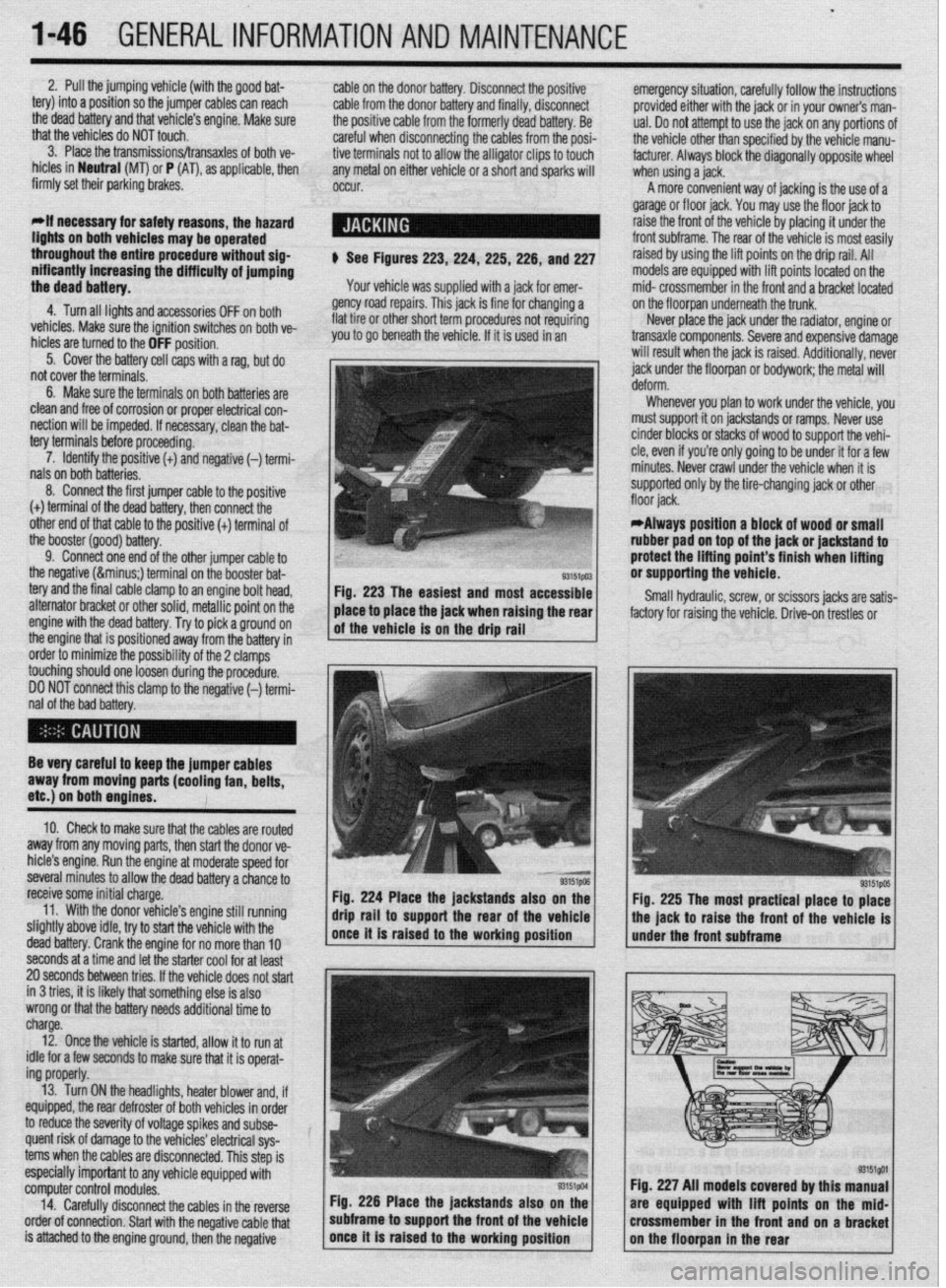

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 51 of 408

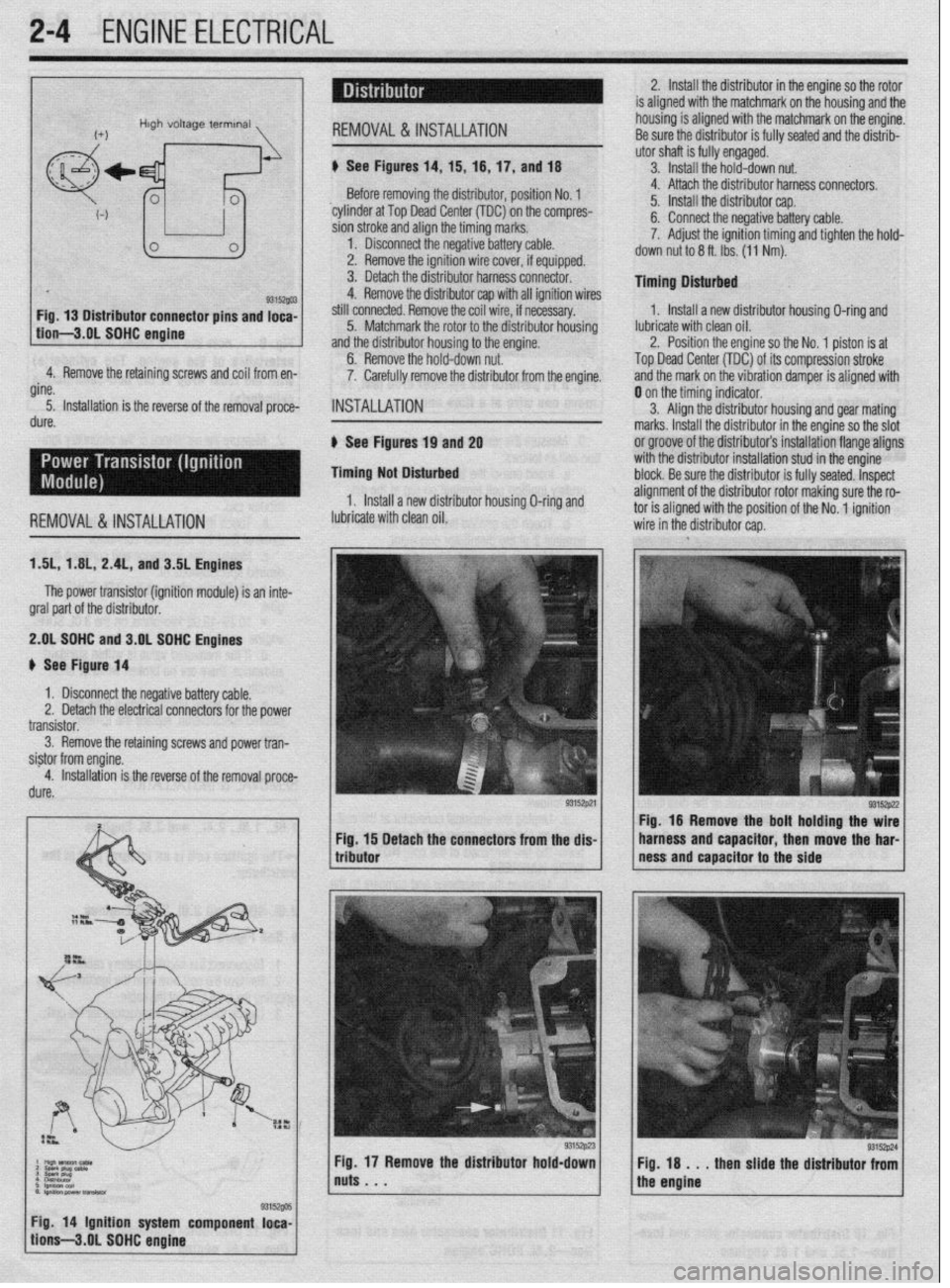

2-4 ENGINEELECTRICAL

2. Install the distributor in the engine so the rotor

is aligned with the matchmark on the housing and the

housing is aligned with the matchmark on the engine.

4.‘ Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure. Before removing the distributor, position No. 1

‘cylinder at Top Dead Center (TDC) on the compres-

sion stroke and align the timing marks.

1. Disconnect the negative battery cable.

2. Remove the ignition wire cover, if equipped.

3. Detach the distributor harness connector.

4. Remove the distributor cap with all ignition wires

still connected. Remove the coil wire, if necessary.

5. Matchmark the rotor to the distributor housing

and the distributor housing to the engine.

6. Remove the hold-down nut.

7. Carefully remove the distributor from the engine.

INSTALLATION

6 See Figures 19 and 2g

Timing Not Disturbed

1, Install a new distributor housing O-ring and 4. Attach the distributor harness connectors.

5. Install the distributor cap.

6. Connect the negative battery cable.

7. Adjust the ignition timing and tighten the hold-

down nut to 6 ft. Ibs. (11 Nm).

Timing Dlsturbed

1. Install a new distributor housing O-ring and

lubricate with clean oil.

2. Position the engine so the No. 1 piston is at

Top Dead Center (TDC) of its compression stroke

and the mark on the vibration damper is aligned with

REMOVALS& INSTALLATION lubricate with clean oil. 0 on the timing indicator.

3. Align the distributor housing and gear mating

marks. Install the distributor in the engine so the slot

or groove of the distributor’s installation flange aligns

with the distributor installation stud in the engine

block. Be sure the distributor is fully seated. Inspect

alignment of the distributor rotor making sure the ro- tnr ic dinnnd with thn qn,c$nn of the Nn innitinn

ISL, 1 AIL, 2.4L, and 3.5L Engines

The power transistor (ignition module) is an inte-

gral part of the distributor.

2.gL SDHC and 3.OL SOHC Engines

# See Figure 14

1 x Disconnect the negative battery cable.

Remove the retaining screws and power tran-

Detach the connectors from the dis- Fig. 16 Remove the bolt holding the wire

harness and capacitor, then move the har-

ness and capacitor to the side

Fig. 18 . . . then slide the distributor from

the engine

/ tion’s-3.gL SOHC engine g3is~@ 1 Fig 14 Ignition system component loca-

Page 52 of 408

ENGlNEELECTRliAL 2-5

Fig. 19 Adjusting the distributor-1.5L en-

gine shown, others similar

4. Install the hold-down nut.

5. Attach the distributor harness connectors.

6. Install the distributor cap.

7. Connect the negative battery cable.

8. Adjust the ignition timing and tighten the hold-

down nut to 8 ft. Ibs. (11 Nm).

For procedures on the position sensors, please re-

fer to Section 4 in this manual.

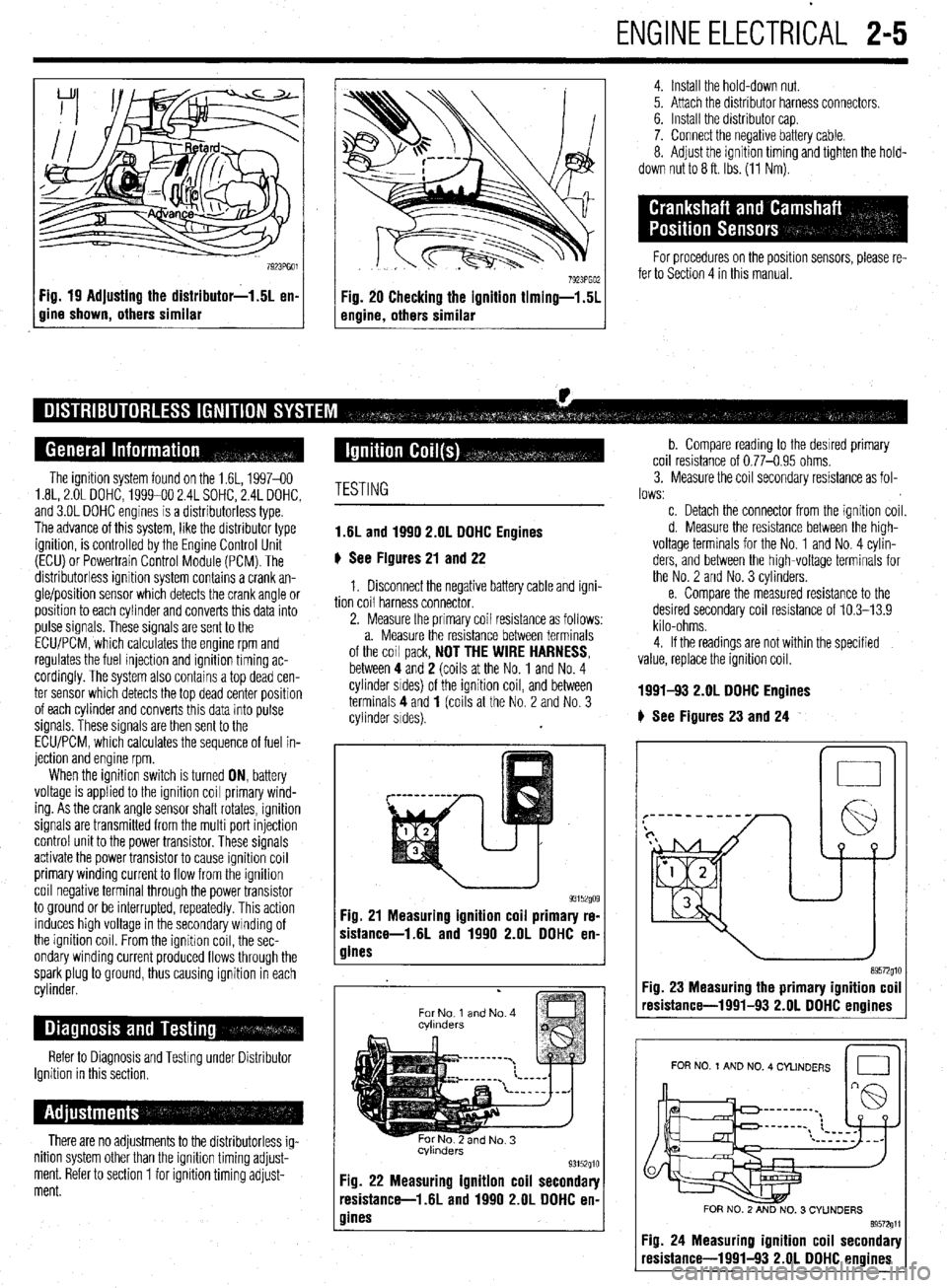

The ignition system found on the 1.6L, 1997-60

1.8L, 2.OL DOHC, 1999-00 2.4L SOHC, 2.4L DOHC,

and 3.OL DOHC engines is a distributorless type.

The advance of this system, like the distributor type

ignition, is controlled by the Engine Control Unit

(ECU) or Powertrain Control Module (PCM). The

distributorless ignition system contains a crank an-

gle/position sensor which detects the crank angle or

position to each cylinder and converts this data into

pulse signals. These signals are sent to the

ECLVPCM, which calculates the engine rpm and

regulates the fuel injection and ignition timing ac-

cordingly. The system also contains a top dead cen-

ter sensor which detects the top dead center position

of each cylinder and converts this data into pulse

signals. These signals are then sent to the

ECU/PCM, which calculates the sequence of fuel in-

jection and engine rpm.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary wind-

ing. As the crank angle sensor shaft rotates, ignition

signals are transmitted from the multi port injection

control unit to the power transistor. These signals

activate the power transistor to cause ignition coil

primary winding current to flow from the ignition

coil negative terminal through the power transistor

to ground or be interrupted, repeatedly. This action

induces high voltage in the secondary winding of

the ignition coil. From the ignitron coil, the sec-

ondary winding current produced flows through the

spark plug to ground, thus causing ignition in each

cylinder.

Refer to Diagnosis and Testing under Distributor

Ignition in this section,

There are no adjustments to the distributorless ig-

nition system other than the ignition timing adjust-

ment. Refer to section 1 for ignition timing adjust-

ment.

TESTING

1.6L and 1990 2.OL DOHC Engines

6 See Figures 21 and 22

1. Disconnect the negative battery cable and igni-

tion coil harness connector.

2. Measure the primary coil resistance as follows:

a. Measure the resistance between terminals

of the coil pack,

NOT THE WIRE HARNESS, between 4 and 2 (coils at the No. 1 and No. 4

cylinder srdes) of the ignition coil, and between

terminals 4 and

1 (coils at the No. 2 and No. 3

cylinder sides).

93152go9 Fig. 21 Measuring ignition coil primary re-

sistance-1.6L and 1990 2.OL DDHC en-

gines

.

For No 1 and No. 4

cvlmders

Fig. 22 Measuring ignition coil secondary

resistance-l .6L and 1990 2.OL DOHC en-

gines

b. Compare reading to the desrred primary

coil resistance of 0.77-0.95 ohms.

3. Measure the coil secondary resistance as fol-

lows:

c. Detach the connector from the ignition coil.

d. Measure the resistance between the high-

voltage terminals for the No. 1 and No. 4 cylin-

ders, and between the high-voltage terminals for

the No. 2 and No. 3 cylinders.

e. Compare the measured resistance to the

desired secondary coil resistance of 10.3-13.9

kilo-ohms.

4. If the readings are not within the specified

value, replace the ignition coil.

1991-!I3 2.OL DDHC Engines

# See Figures 23 and 24

n 0

Fig. 23 Measuring the primary ignition coil

resistance-1991-93 2.OL DOHC enoines

I I

FOR NO 1 AND NO. 4 CYLINDERS

Id

FOR NO. 2 AND NO. 3 CYUNDERS

89572611

Fig. 24 Measuring ignition coil secondary

resistance-1991-93 2.OL DOHC engines

Page 95 of 408

3-34 ENGINEANDENGINEOVERHAUL

9. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

10. Remove the front case assembly and oil

pump assembly.

11. Remove the oil pump cover.

12. Remove the inner and outer gears from the

front case.

To install 13. Remove all gasket material from the mating

surfaces and clean all parts.

14. Thoroughly coat both oil pump gears with

clean engine oil and install them in the correct direc-

tion of rotation.

15. Install the pump cover and tighten the bolts to

84 inch Ibs. (10 Nm).

16. Coat the relief valve and spring with clean en-

gine oil. Install them and tighten the plug to 33 ft.

Ibs. (45 Nm).

17. Install a new front crankshaft seal and coat

the lips of the seal with clean engine oil.

18. Install the front case and oil pump assembly

to the engine block using a new gasket. Tighten the

bolts to loft. Ibs. (14 Nm)

19. Install the oil screen with new gasket. Torque

the screen bolts to 14 ft. Ibs. (19 Nm).

20. Install the oil pan.

21. Install the crankshaft sprocket and timing

belt. Refer to the timing belt procedure in this sec-

tion.

22. Fill the crankcase to the proper level.

Operating the engine without the proper

amount and type of engine oil will result in

severe enoine damaae.

23. Connect the negative battery cable.

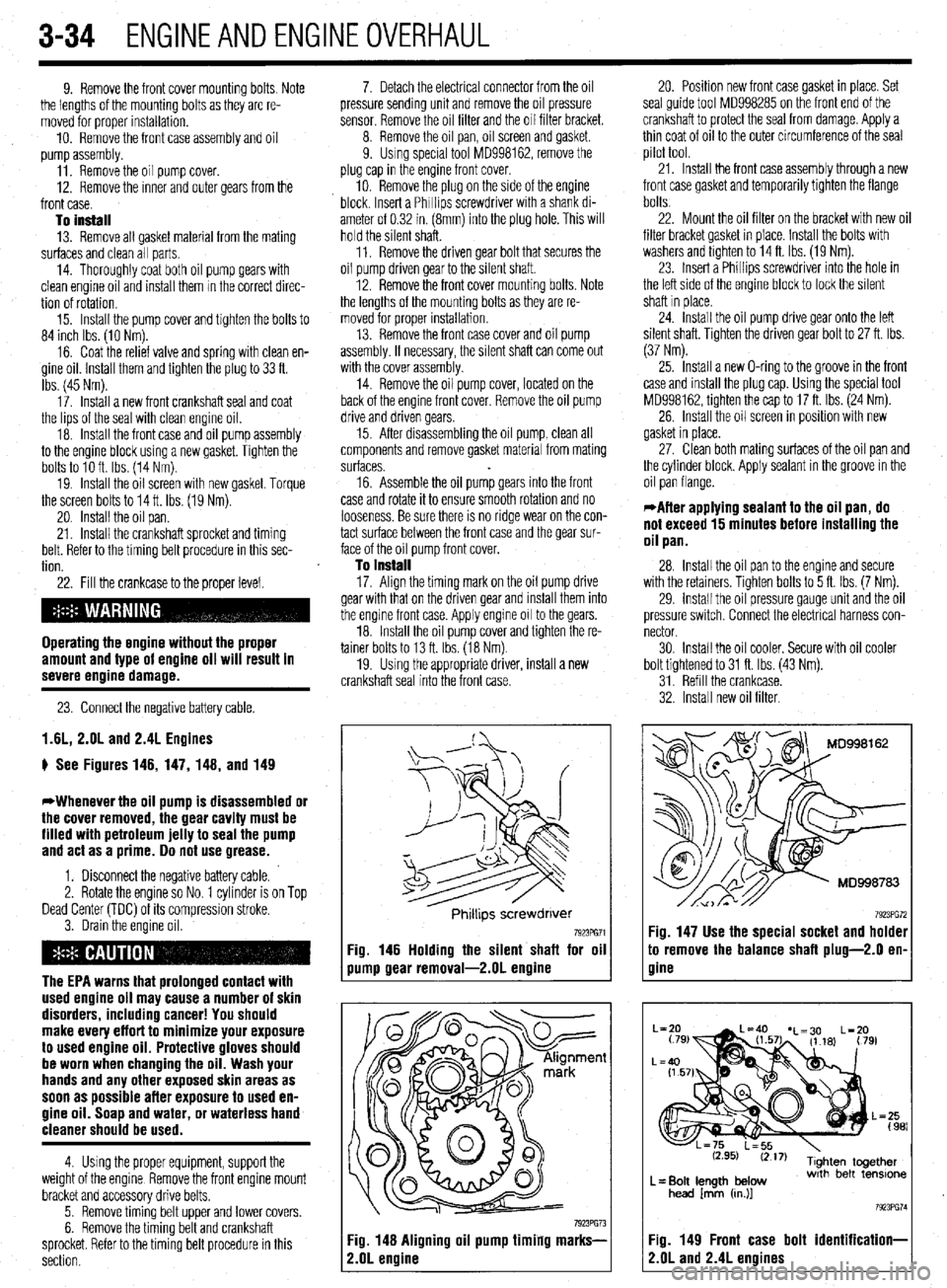

1.6L, 2.OL and 2.4L Engines

p See Figures 146, 147, 148, and 149

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. Do not use grease.

1. Disconnect the negative battery cable.

2. Rotate the engine so No. 1 cylinder is on Top

Dead Center (TDC) of its compression stroke.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible afler exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4 Using the proper equipment, support the

weight of the engine Remove the front engine mount

bracket and accessory drive belts.

5 Remove timing belt upper and lower covers.

6. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section. 7. Detach the electrical connector from the oil

pressure sending unit and remove the oil pressure

sensor. Remove the oil filter and the oil filter bracket.

8. Remove the oil pan, oil screen and gasket.

9. Using special tool MD998162, remove the

plug cap in the engine front cover.

10. Remove the plug on the side of the engine

block. Insert a Phrllips screwdriver with a shank di-

ameter of 0.32 in. (8mm) into the plug hole. This will

hold the silent shaft.

11. Remove the driven gear bolt that secures the

oil pump driven gear to the silent shaft.

12. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

13. Remove the front case cover and oil pump

assembly. If necessary, the silent shaft can come out

with the cover assembly.

14. Remove the oil pump cover, located on the

back of the engine front cover. Remove the oil pump

drive and driven gears.

15. After disassembling the oil pump, clean all

components and remove gasket material from mating

surfaces.

16. Assemble the oil pump gears into the front

case and rotate it to ensure smooth rotation and no

looseness. Be sure there is no ridge wear on the con-

tact surface between the front case and the gear sur-

face of the oil pump front cover.

To install 17. Align the timing mark on the oil pump drive

gear with that on the driven gear and install them into

the engine front case. Apply engine 011 to the gears.

18. Install the oil pump cover and tighten the re-

tainer bolts to 13 ft. Ibs. (18 Nm).

19. Using the appropriate driver, install a new

crankshaft seal into the front case.

Phrllips screwdrrver

7923PG71 Fig. 146 Holding the silent shaft for oil

pump gear removal-2.01 engine

7923PG73 Fig. 148 Aligning oil pump timing marks-

2.OL ermine

20. Position new front case gasket in place. Set

seal guide tool MD998285 on the front end of the

crankshaft to protect the seal from damage. Apply a

thin coat of oil to the outer circumference of the seal

pilot tool.

21. Install the front case assembly through a new

front case gasket and temporarily tighten the flange

bolts.

22. Mount the oil filter on the bracket with new oil

filter bracket gasket in place. Install the bolts with

washers and tighten to 14 ft. Ibs. (19 Nm).

23. Insert a Phillips screwdriver into the hole in

the left side of the engine block to lock the silent

shaft in place.

24. Install the oil pump drive gear onto the left

silent shaft. Tighten the driven gear bolt to 27 ft. Ibs.

(37 Nm).

25. Install a new O-ring to the groove in the front

case and install the plug cap. Using the special tool

MD998162, tighten the cap to 17 ft. Ibs. (24 Nm).

26. Install the oil screen in position with new

gasket in place.

27. Clean both mating surfaces of the oil pan and

the cylinder block. Apply sealant In the groove in the

oil pan flange.

*After applying sealant to the oil pan, do

not exceed 15 minutes before installing the

oil pan.

28. Install the oil pan to the engine and secure

with the retainers. Tighten bolts to 5 ft. Ibs. (7 Nm).

29. install the oil pressure gauge unit and the oil

pressure switch. Connect the electrical harness con-

nector.

30. Install the oil cooler. Secure with oil cooler

bolt tightened to 31 ft. Ibs (43 Nm).

31. Refill the crankcase.

32. Install new oil filter.

7923PG72 Fig. 147 Use the special socket and holder

:o remove the balance shaft plug-2.0 en-

7ine

L= Bolt length below

head /mm (cn.)]

Fig. 149 Front case bolt identification-

?.OL and 2.4L engines

Page 108 of 408

ENGINEANDENGINEOVERHAUL 3-47

DO NOT rotate or turn the camshafts when re-

moving the sprockets or severe engine dam-

age will result from internal component in-

terference.

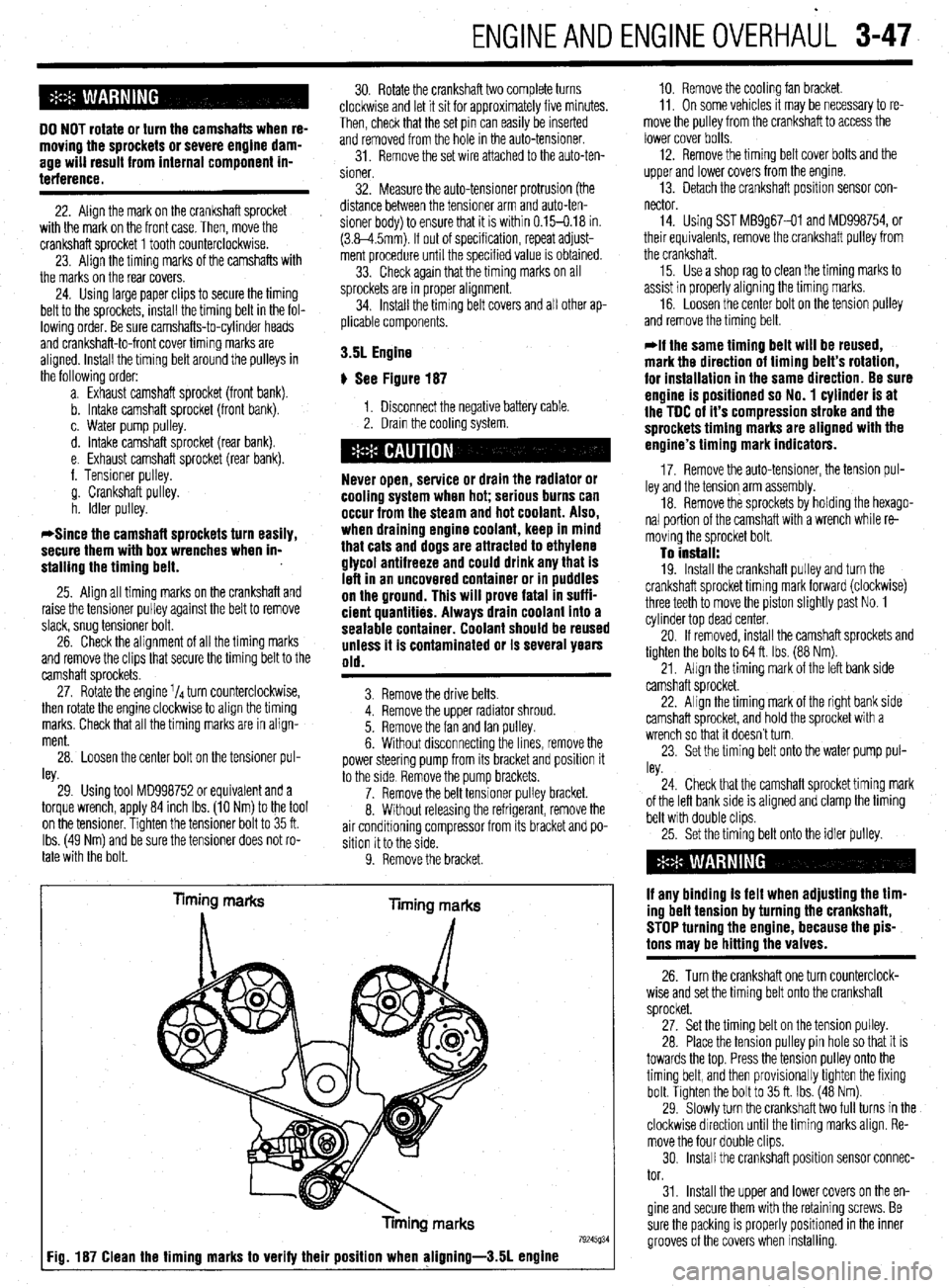

22. Align the mark on the crankshaft sprocket

with the mark on the front case. Then, move the

crankshaft sprocket 1 tooth counterclockwise.

23. Align the timing marks of the camshafts with

the marks on the rear covers.

24. Using large paper clips to secure the timing

belt to the sprockets, install the timing belt in the fol-

lowing order. Be sure camshafts-to-cylinder heads

and crankshaft-to-front cover timing marks are

aligned. Install the timing belt around the pulleys in

the following order:

a. Exhaust camshaft sprocket (front bank).

b. Intake camshaft sprocket (front bank).

c. Water pump pulley.

d. Intake camshaft sprocket (rear bank).

e. Exhaust camshaft sprocket (rear bank).

f. Tensioner pulley.

g. Crankshaft pulley.

h. Idler pulley.

*Since the camshaft sprockets turn easily,

secure them with box wrenches when in-

stalling the timing belt.

25. Align all timing marks on the crankshaft and

raise the tensioner pulley against the belt to remove

slack, snug tensioner bolt.

26. Check the alignment of all the timing marks

and remove the clips that secure the timing belt to the

camshaft sprockets.

27. Rotate the engine 1/4 turn counterclockwise,

then rotate the engine clockwise to align the timing

marks. Check that all the timing marks are in align-

ment.

28. Loosen the center bolt on the tensioner pul-

ley.

29. Using tool MD998752 or equivalent and a

torque wrench, apply 84 inch Ibs. (10 Nm) to the tool

on the tensioner. Tighten the tensioner bolt to 35 ft.

Ibs. (49 Nm) and be sure the tensioner does not ro-

tate with the bolt. 30. Rotate the crankshaft two complete turns

clockwise and let it sit for approximately five minutes.

Then, check that the set pin can easily be inserted

and removed from the hole in the auto-tensioner.

31. Remove the set wire attached to the auto-ten-

sioner

32. Measure the auto-tensioner protrusion (the

distance between the tensioner arm and auto-ten-

sioner body) to ensure that it is within 0.15-0.18 in.

(3.8-4.5mm). If out of specification, repeat adjust-

ment procedure until the specified value is obtained.

33. Check again that the timing marks on all

sprockets are in proper alignment.

34. Install the timing belt covers and all other ap-

plicable components.

3.51 Engine

p See Figure 187

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

giycoi antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the drive belts.

4. Remove the upper radiator shroud.

5. Remove the fan and fan pulley.

6. Without disconnecting the lines, remove the

power steering pump from its bracket and position it

to the side Remove the pump brackets.

7. Remove the belt tensioner pulley bracket.

8. Without releasing the refrigerant, remove the

air conditioning compressor from its bracket and po-

sition it to the side.

9. Remove the bracket.

Timing marks

liming marks

Tinning marks

79245934 Fig. 187 Clean the timing marks to verify their position when aligning-3.51 engine

10. Remove the cooling fan bracket.

11, On some vehicles It may be necessary to re-

move the pulley from the crankshaft to access the

lower cover bolts.

12. Remove the timing belt cover bolts and the

upper and lower covers from the engme.

13. Detach the crankshaft position sensor con-

nector

14. Using SST MB9g67-01 and MD998754, or

their equivalents, remove the crankshaft pulley from

the crankshaft.

15. Use a shop rag to clean the timing marks to

assist in properly aligning the timing marks.

16. Loosen the center bolt on the tension pulley

and remove the timing belt.

@if the same timing belt will be reused,

mark the direction of timing belt’s rotation,

for installation in the same direction. Be sure

engine is positioned so No. 1 cylinder is at

the TDC of it’s compression stroke and the

sprockets timing marks are aligned with the

engine’s timing mark indicators.

17. Remove the auto-tensioner, the tension pul-

ley and the tension arm assembly.

18. Remove the sprockets by holding the hexago-

nal portion of the camshaft with a wrench while re-

moving the sprocket bolt.

To install: 19. Install the crankshaft pulley and turn the

crankshaft sprocket timing mark forward (clockwise)

three teeth to move the piston slightly past No. 1

cylinder top dead center.

20. If removed, install the camshaft sprockets and

tighten the bolts to 64 ft. Ibs. (88 Nm).

21, Align the timing mark of the left bank side

camshaft sprocket.

22. Align the timing mark of the right bank side

camshaft sprocket, and hold the sprocket with a

wrench so that it doesn’t turn.

23. Set the timing belt onto the water pump pul-

ley.

24. Check that the camshaft sprocket timing mark

of the left bank side is aligned and clamp the timing

belt with double clips.

25. Set the timing belt onto the idler pulley.

if any binding is felt when adjusting the tim-

ing belt tension by turning the crankshaft,

STOP turning the engine, because the pis-

tons may be hitting the valves.

26. Turn the crankshaft one turn counterclock-

wise and set the timing belt onto the crankshaft

sprocket.

27. Set the timing belt on the tension pulley.

28. Place the tension pulley pin hole so that it is

towards the top. Press the tension pulley onto the

timing belt, and then provisionally tighten the fixing

bolt. Tighten the bolt to 35 ft. Ibs. (48 Nm).

29. Slowly turn the crankshaft two full turns in the

clockwise direction until the timing marks align. Re-

move the four double clips.

30. Install the crankshaft position sensor connec-

tor.

31. Install the upper and lower covers on the en-

gine and secure them with the retaining screws. Be

sure the packing is properly positioned in the inner

grooves of the covers when installing.

Page 208 of 408

CHASSIS ELECTRiCAL 6-5

them. It is used for voltage and ground tests. To use voltmeter has a positive and a negative lead. To avoid

a 12 volt test light, connect the ground clip to a good damage to the meter, always connect the negative

ground and probe wherever necessary with the pick. lead to the negative (-) side of the circuit (to ground

The test light will illuminate when voltage is detected. or nearest the ground side of the circuit) and connect

This

does not necessarily mean that 12 volts (or any the positive lead to the positive(t) side of the circuit When diagnosing a specific problem, organized

troubleshooting is a must. The complexity of a mod-

particular amount of voltage) is present; it only (to the power source or the nearest power source).

means that some voltage is present. It is advisable Note that the negative voltmeter lead will always be ern automotive vehicle demands that you approach

before using the test light to touch its ground clip black and that the positive voltmeter will always be any problem in a logical, organized manner. There

and probe across the battery posts or terminals to some color other than black (usually red). are certain troubleshooting techniques, however,

which are standard:

make sure the light is operating properly.

l Ohmmeter-the ohmmeter is designed to read l Establish when the problem occurs. Does the

resistance (measured in ohms) in a circuit or compo-

nent. Most ohmmeters will have a selector switch problem appear only under certain conditions? Were

there any noises, odors or other unusual symptoms?

Do not use a test light to probe electronic ig- which permits the measurement of different ranges of

Isolate the problem area. To do this, make some sim-

nition, spark plug or coil wires. Never use a resistance (usually the selector switch allows the

multiplication of the meter reading by 10,100,1,000 ple tests and observations, then eliminate the sys-

pick-type test light to probe wiring on com- terns that are working properly. Check for obvious

puter controlled systems unless specifically and 10,000). Some ohmmeters are “auto-ranging”

which means the meter itself will determine which problems, such as broken wires and loose or dirty

instructed to do so. Any wire insulation that

scale to use. Since the meters are powered by an in- connections. Always check the obvious before as-

is pierced by the test light probe should be

ternal battery, the ohmmeter can be used like a self- suming something complicated is the cause.

taped and sealed with silicone after testing.

l Test for problems systematically to determine

powered test light. When the ohmmeter is connected,

the cause once the problem area is isolated. Are all

Like the jumper wire, the 12 volt test light is used current from the ohmmeter flows through the circuit

the components functioning properly? Is there power

to isolate opens in circuits. But, whereas the jumper or component being tested. Since the ohmmeter’s in-

ternal resistance and voltage are known values, the going to electrical switches and motors. Performing

wire is used to bypass the open to operate the load,

amount of current flow through the meter depends on careful, systematic checks will often turn up most

the 12 volt test light is used to locate the presence of

the resistance of the circuit or component being causes on the first inspection, without wasting time

voltage in a circuit. If the test light illuminates, there

tested. The ohmmeter can also be used to perform a checking components that have little or no relation-

is power up to that point in the circuit; if the test light ship to the problem.

does not illuminate, there is an open circuit (no continuity test for suspected open circuits. In using

the meter for making continuity checks, do not be

l Test all repairs after the work is done to make

power). Move the test light in successive steps back

concerned with the

actual resistance readings. Zero sure that the problem is fixed. Some causes can be

toward the power source until the light in the handle traced to more than one component, so a careful veri-

illuminates. The open is between the probe and a resistance, or any ohm reading, indicates continuity

fication of repair work is important in order to pick up

point which was previously probed. in the circuit, Infinite resistance indicates an opening

in the circuit. A high resistance reading where there additional malfunctions that may cause a problem to

The self-powered test light is similar in design to

should be none indicates a problem in the circuit. reappear or a different problem to arise. A blown

the 12 volt test light, but contains a 1.5 volt penlight

Checks for short circuits are made in the same man- fuse, for example, is a simple problem that may re-

battery in the handle. It is most often used in place of

ner as checks for open circuits, except that the circuit quire more than another fuse to repair. If you don’t

a multimeter to check for open or short circuits when look for a problem that caused a fuse to blow, a

power is isolated from the circuit (continuity test). must be isolated from both power and normal

ground. Infinite resistance indicates no continuity, shorted wire (for example) may go undetected.

The battery in a self-powered test light does not Experience has shown that most problems tend

provide much current. A weak battery may not pro- while zero resistance indicates a dead short.

to be the result of a fairly simple and obvious

vide enough power to illuminate the test light even I ’ cause, such as loose or corroded connectors, bad

when a complete circuit is made (especially if there is grounds or damaged wire insulation which causes a

high resistance in the circuit). Always make sure that Never use an ohmmeter to check the resis- short. This makes careful visual inspection of com-

the test battery is strong. To check the battery, briefly tance of a component or wire while there is ponents during testing essential to quick and accu-

touch the ground clip to the probe; if the light glows voltage applied to the circuit. rate troubleshooting.

brightly, the battery is strong enough for testing.

*A self-powered test light should not be

l Ammeter-an ammeter measures the amount

- I

used on any computer controlled system or of current flowing through a circuit in units called

component. The small amount of electricity amperes or amps. At normal operating voltage, most

circuits have a characteristic amount of amperes, OPEN CIRCUITS

transmitted by the test light is enough to

damage many electronic automotive compo- called “current draw” which can be measured using

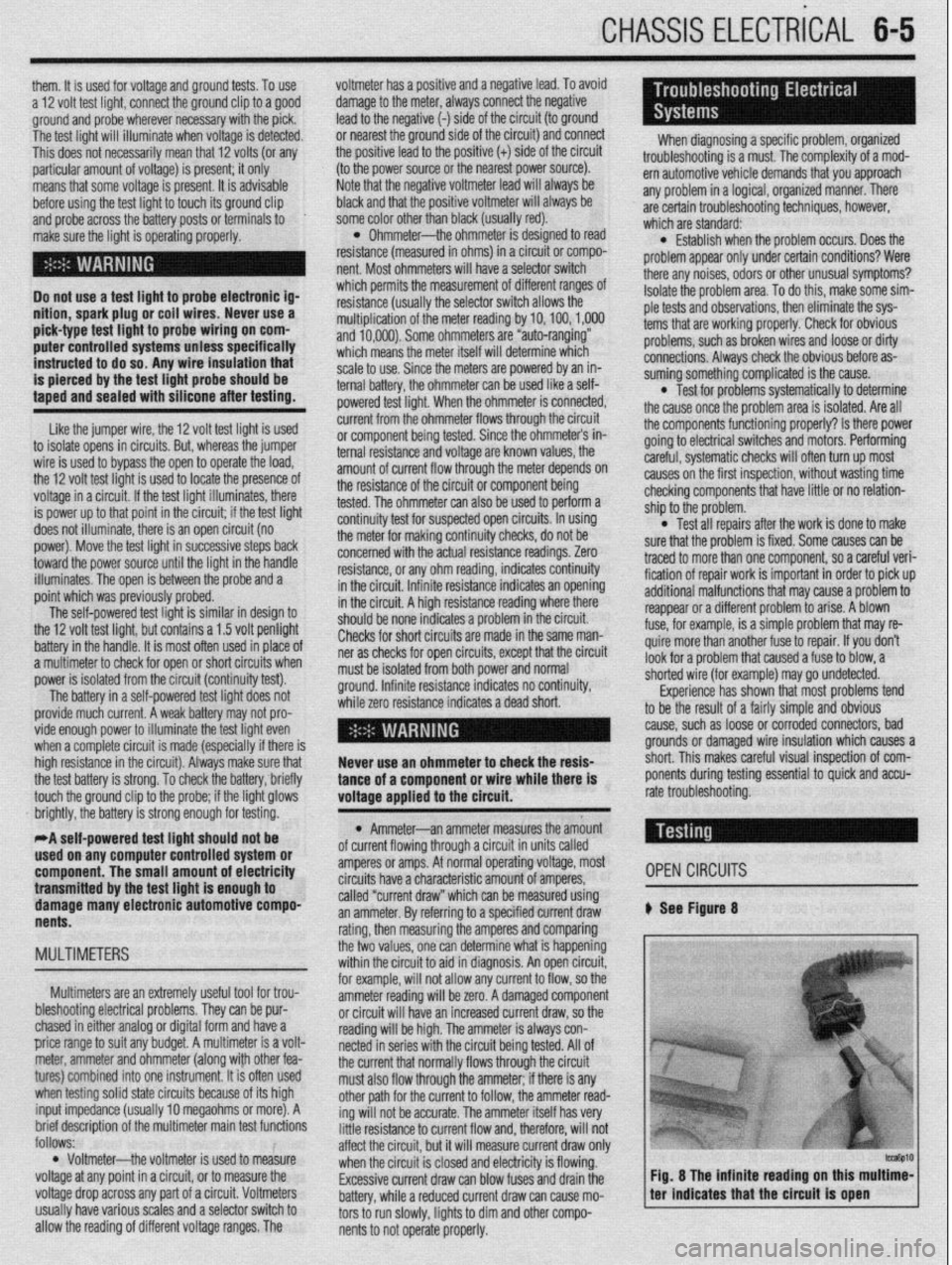

an ammeter. By referring to a specified current draw # See Figure 8

nents.

rating, then measuring the amperes and comparing

MULTIMETERS the two values, one can determine what is happening

within the circuit to aid in diagnosis. An open circuit,

for example, will not allow any current to flow, so the

Multimeters are an extremely useful tool for trou-

bleshooting electrical problems. They can be pur- ammeter reading will be zero. A damaged component

or circuit will have an increased current draw, so the

chased in either analog or digital form and have a

reading will be high. The ammeter is always con-

price range to suit any budget. A multimeter is a volt-

netted in series with the circuit being tested. All of

meter, ammeter and ohmmeter (along with other fea-

the current that normally flows through the circuit

tures) combined into one instrument. It is often used

must also flow through the ammeter; if there is any

when testing solid state circuits because of its high

other path for the current to follow, the ammeter read-

input impedance (usually 10 megaohms or more). A

ing will not be accurate. The ammeter itself has very

brief description of the multiieter main test functions

follows: little resistance to current flow and, therefore, will not

affect the circuit, but it will measure current draw only

l Voltmeter--the voltmeter is used to measure

when the circuit is closed and electricity is flowing.

voltage at any point in a circuit, or to measure the

Excessive current draw can blow fuses and drain the

voltage drop across any part of a circuit. Voltmeters

battery, while a reduced current draw can cause mo-

usually have various scales and a selector switch to

tors to run slowly, lights to dim and other compo-

allow the reading of different voltage ranges. The

nents to not operate properly.